Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.)

Abstract

:1. Introduction

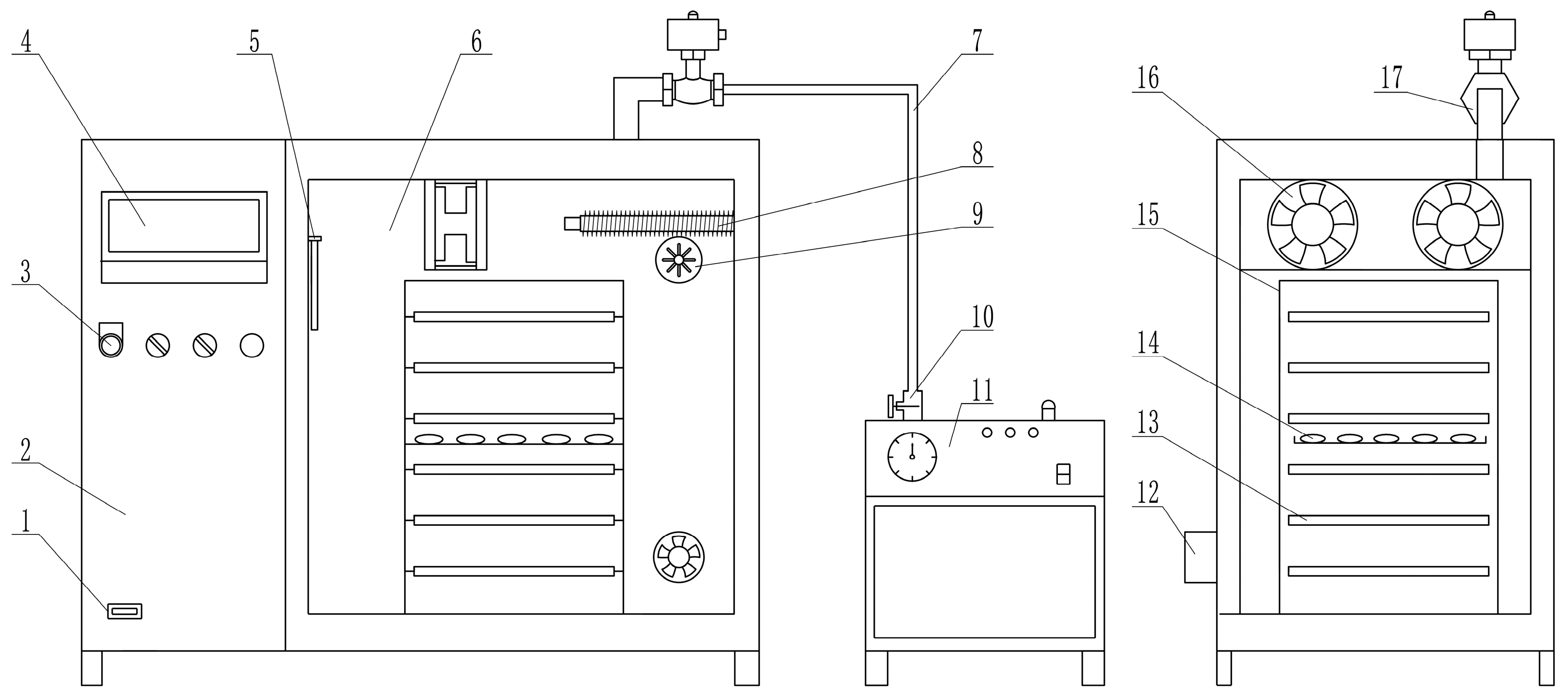

2. General Plan Design

2.1. Analysis of Design Requirements

2.2. Working Principle

2.3. Dryer Design

2.3.1. Infrared Heating Plate Selection

2.3.2. Heating Tube Selection

2.3.3. Supply Fan Selection

2.3.4. Rack and Tray Design

2.3.5. Humidification and Dehumidification Device Selection

2.4. Control System Design

2.4.1. Human–Computer Interaction Platform Interface Design

2.4.2. Medium Temperature Monitoring and Control

2.4.3. Medium Humidity Monitoring and Control

2.4.4. Material Temperature Monitoring and Control

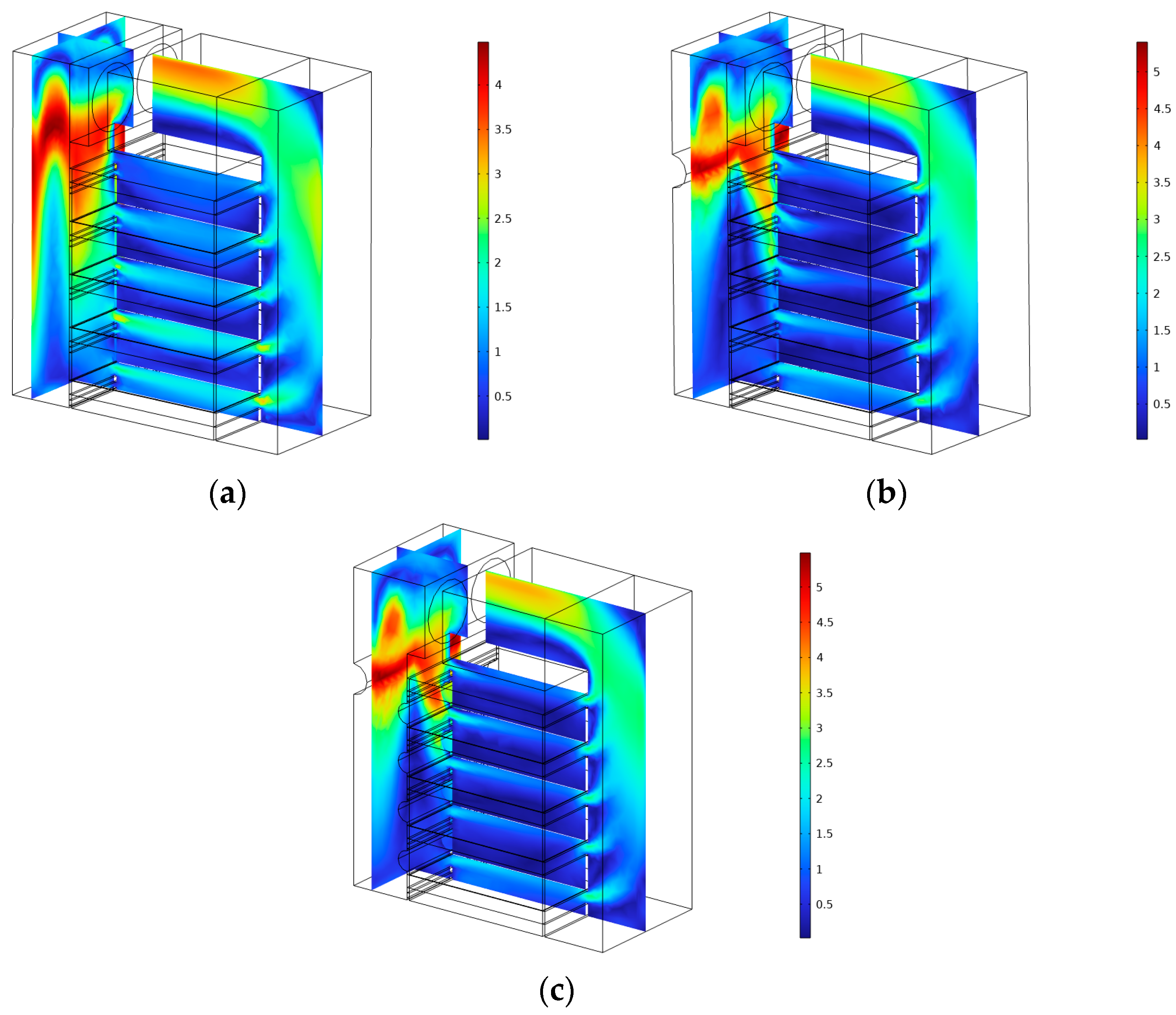

3. Analysis and Optimization of Flow Field in Air Distribution Chamber

3.1. Numerical Modeling and Meshing

3.2. Control Equations and Simplifying Assumptions

3.3. Boundary Conditions and Evaluation Indexes

3.4. Model Validation

3.5. Flow Field Analysis and Optimization

4. Experimental Research and Analysis

4.1. Test Materials

4.2. Test Method

4.2.1. Drying

4.2.2. Specific Energy Consumption (SEC)

4.2.3. Color Difference Degree

4.2.4. Browning Degree

4.2.5. Determination of Rehydration Ratio

4.2.6. Ascorbic Acid Retention Rate

4.2.7. Data Processing

4.3. Test Results and Analysis

4.3.1. Drying Kinetics

4.3.2. Drying Quality

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, N.X.; Wang, Q.Y.; Huang, H.L.; Chen, J.; Wu, G.; Zhu, M.N.; Shao, F.; Yan, Z.H.; Sang, Z.P.; Cao, L.; et al. A Comprehensive Review on Extraction, Structure, Detection, Bioactivity, and Metabolism of Flavonoids from Sea Buckthorn (Hippophae rhamnoides L.). J. Food Biochem. 2023, 2023, 4839124. [Google Scholar] [CrossRef]

- Ma, Q.G.; He, N.X.; Huang, H.L.; Fu, X.M.; Zhang, Z.L.; Shu, J.C.; Wang, Q.Y.; Chen, J.; Wu, G.; Zhu, M.N.; et al. Hippophae rhamnoides L.: A Comprehensive Review on the Botany, Traditional Uses, Phytonutrients, Health Benefits, Quality Markers, and Applications. J. Agric. Food Chem. 2023, 71, 4769–4788. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhao, F.L.; Wei, P.P.; Chai, X.Y.; Hou, G.G.; Meng, Q.G. Phytochemistry, Health Benefits, and Food Applications of Sea Buckthorn (Hippophae rhamnoides L.): A Comprehensive Review. Front. Nutr. 2022, 9, 1036295. [Google Scholar] [CrossRef] [PubMed]

- Zuchowski, J. Phytochemistry and Pharmacology of Sea Buckthorn (Elaeagnus rhamnoides; Syn. Hippophae rhamnoides): Progress from 2010 to 2021. Phytochem. Rev. 2022, 22, 3–33. [Google Scholar] [CrossRef]

- Geng, Z.H.; Wang, J.; Zhu, L.C.; Yu, X.L.; Zhang, Q.; Li, M.Q.; Hu, B.; Yang, X.H. Metabolomics Provide a Novel Interpretation of the Changes in Flavonoids during Sea buckthorn (Hippophae rhamnoides L.) Drying. Food Chem. 2023, 413, 135598. [Google Scholar] [CrossRef]

- Geng, Z.H.; Zhu, L.C.; Wang, J.; Yu, X.L.; Li, M.Q.; Yang, W.X.; Hu, B.; Zhang, Q.; Yang, X.H. Drying Sea Buckthorn Berries (Hippophae rhamnoides L.): Effects of Different Drying Methods on Drying Kinetics, Physicochemical Properties, and Microstructure. Front. Nutr. 2023, 10, 1106009. [Google Scholar] [CrossRef]

- Xu, Y.; Kou, J.M.; Zhang, Q.; Tan, S.D.; Zhu, L.C.; Geng, Z.H.; Yang, X.H. Visual Detection of Water Content Range of Seabuckthorn Fruit Based on Transfer Deep Learning. Foods 2023, 12, 550. [Google Scholar] [CrossRef]

- Tan, S.D.; Xu, Y.; Zhu, L.C.; Geng, Z.H.; Zhang, Q.; Yang, X.H. Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes. Foods 2022, 11, 3675. [Google Scholar] [CrossRef]

- Geng, Z.H.; Torki, M.; Kaveh, M.; Beigi, M.; Yang, X.H. Characteristics and Multi-Objective Optimization of Carrot Dehydration in a Hybrid Infrared/hot Air Dryer. LWT-Food Sci. Technol. 2022, 172, 114229. [Google Scholar] [CrossRef]

- Geng, Z.H.; Wang, H.; Torki, M.; Beigi, M.; Zhu, L.C.; Huang, X.; Yang, X.H.; Hu, B. Thermodynamically Analysis and Optimization of Potato Drying in a Combined Infrared/convective Dryer. Case Stud. Therm. Eng. 2023, 42, 10267. [Google Scholar] [CrossRef]

- Jiang, C.Y.; Shang, S.; Zheng, J.; Fu, B.S.; Guo, M.Q.; Shen, P.B.; Jiang, P.F. Application of an Artificial Neural Network Model to Predict the Change of Moisture during Drying of Sturgeon Bone Marrow. Qual. Assur. Saf. Crop. 2023, 15, 84–91. [Google Scholar] [CrossRef]

- Jiang, D.L.; Li, C.C.; Lin, Z.F.; Wu, Y.T.; Pei, H.J.; Zielinska, M.; Xiao, H.W. Experimental and Numerical Study on the Shrinkage-Deformation of Carrot Slices during Hot Air Drying. Int. J. Agric. Biol. Eng. 2023, 16, 260–272. [Google Scholar] [CrossRef]

- Bantle, M.; Kolsaker, K.; Eikevik, T.M. Modification of the Weibull Distribution for Modeling Atmospheric Freeze-Drying of Food. Dry. Technol. 2011, 29, 1161–1169. [Google Scholar] [CrossRef]

- Ju, H.Y.; Zhao, S.H.; Mujumdar, A.S.; Fang, X.M.; Gao, Z.J.; Zheng, Z.A.; Xiao, H.W. Energy Efficient Improvements in Hot Air Drying by Controlling Relative Humidity Based on Weibull and Bi-Di Models. Food Bioprod. Process. 2018, 111, 20–29. [Google Scholar] [CrossRef]

- Xu, L.; Fang, X.; Wu, W.; Chen, H.; Mu, H.; Gao, H. Effects of High-Temperature Pre-Drying on the Quality of Air-Dried Shiitake Mushrooms (Lentinula edodes). Food Chem. 2019, 285, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Sileshi, S.T.; Hassen, A.A.; Adem, K.D. Simulation of Mixed-Mode Solar Dryer with Vertical Air Distribution Channel. Heliyon 2022, 8, e11898. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Dutta, S.; Pande, P.; Naik-Nimbalkar, V. Intensify Staple Fibre Drying by Optimizing Air Distribution in Multistage Convective Dryer Using CFD. Chem. Eng. Process. 2022, 173, 108807. [Google Scholar] [CrossRef]

- Daza-Gomez, M.A.M.; Velasco, C.A.G.; Daza, J.C.G.; Ratkovich, N. 3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber. Processes 2022, 10, 2721. [Google Scholar] [CrossRef]

- Shi, M.Y.; Zhang, Y.; Wang, Y.F.; Gao, M.; Li, J.; Deng, Z.H.; Liu, R.; Li, M. Flow Field Analysis and Design Optimisation of Tibetan Medicine Double Heat Pump Drying Room. Comput. Electron. Agric. 2022, 199, 107141. [Google Scholar] [CrossRef]

- Cheng, H.; Zhang, Z.P.; Ren, F.; Wu, Z.Q.; Hou, C.T. Experimental Study of Modal Characteristics for Heated Composite Structures. J. Aerosp. Eng. 2022, 35, 04022038. [Google Scholar] [CrossRef]

- Joudi-Sarighayeh, F.; Abbaspour-Gilandeh, Y.; Kaveh, M.; Szymanek, M.; Kulig, R. Response Surface Methodology Approach for Predicting Convective/Infrared Drying, Quality, Bioactive and Vitamin C Characteristics of Pumpkin Slices. Foods 2023, 12, 1114. [Google Scholar] [CrossRef] [PubMed]

- Goyal, V.; Asati, A.K.; Arora, A. An Experimental and Modeling Study for a Novel Bank-Type Earth Air Heat Exchanger for the Summer Season Using Full Factorial Design. J. Therm. Sci. Eng. Appl. 2023, 15, 021006. [Google Scholar] [CrossRef]

- Kumar, T.A.; Pareek, S.; Kaur, R.; Sagar, N.A.; Singh, L.; Sami, R.; Aljuraide, N.I.; Elhakem, A.; Alsharari, Z.D.; Alruwais, R.S.; et al. Optimization of Ultrasonic-Assisted Enzymatic Extraction of Freeze-Dried Sea Buckthorn (Hippophae rhamnoides L.) Berry Oil Using Response Surface Methodology. Sustainability 2022, 14, 10849. [Google Scholar] [CrossRef]

- Eshetu, G.; Mulugeta, A.; Delele, N.G. Importance of Integrated CFD and Product Quality Modeling of Solar Dryers for Fruits and Vegetables: A Review. Sol. Energy 2021, 220, 88–110. [Google Scholar] [CrossRef]

- Hasan, J.; Sepideh, A.; Jie, X. On the Effect of Turbulence Models on CFD Simulations of a Counter-Current Spray Drying Process. Chem. Eng. Res. Des. 2019, 141, 592–607. [Google Scholar] [CrossRef]

- Gong, Z.; Wang, P.K.; Li, D.P. Analysis and Structure Optimization of the Temperature and Flow Fields of the Belt Dryer with Multi-Temperature Zones. Trans. CSAE 2021, 37, 40–47. [Google Scholar] [CrossRef]

- Dai, J.W.; Xiao, H.W.; Bai, J.W. Numerical Simulation and Optimum Design on Airflow Distribution Chamber of Air-impingement Jet Dryer. Trans. CSAE 2013, 29, 69–76. [Google Scholar] [CrossRef]

- Xing, T.Y.; Luo, X.; Li, M.; Wang, Y.F.; Deng, Z.H.; Yao, M.C.; Zhang, W.X.; Zhang, Z.D.; Gao, M. Study on Drying Characteristics of Gentiana Macrophylla under the Interaction of Temperature and Relative Humidity. Energy 2023, 273, 127261. [Google Scholar] [CrossRef]

- Yue, Y.M.; Zhang, Q.; Wan, F.X.; Ma, G.J.; Zang, Z.P.; Xu, Y.R.; Jiang, C.H.; Huang, X.P. Effects of Different Drying Methods on the Drying Characteristics and Quality of Codonopsis pilosulae Slices. Foods 2023, 12, 1323. [Google Scholar] [CrossRef]

- Adnouni, M.; Jiang, L.; Zhang, X.; Zhang, L.; Pathare, P.B.; Roskilly, A.P. Computational Modelling for Decarbonised Drying of Agricultural Products: Sustainable Processes, Energy Efficiency, and Quality Improvement. J. Food Eng. 2023, 338, 111247. [Google Scholar] [CrossRef]

- Li, W.F.; Zhang, Y.X.; Deng, H.L.; Yuan, H.; Fan, X.; Yang, H.Y.; Tan, S. In Vitro and in Vivo Bioaccessibility, Antioxidant Activity, and Color of Red Radish Anthocyanins as Influenced by Different Drying Methods. Food Chem. X 2023, 18, 100633. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.Z.; Yang, X.H.; Mujumdar, A.S.; Zhao, J.H.; Wang, D.; Zhang, Q.; Wang, J.; Gao, Z.J.; Xiao, H.W. Red Pepper (Capsicum annuum L.) Drying: Effects of Different Drying Methods on Drying Kinetics, Physicochemical Properties, Antioxidant Capacity, and Microstructure. Dry. Technol. 2018, 36, 893–907. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.L.; Vidyarthi, S.K.; Wang, Q.H.; Gao, L.; Li, B.R.; Wei, Q.; Liu, Y.H.; Xiao, H.W. Effects of Different Drying Methods on Drying Kinetics, Physicochemical Properties, Microstructure, and Energy Consumption of Potato (Solanum tuberosum L.) Cubes. Dry. Technol. 2020, 39, 418–431. [Google Scholar] [CrossRef]

- Wang, J.; Yang, X.H.; Mujumdar, A.S.; Wang, D.; Zhao, J.H.; Fang, X.M.; Zhang, Q.; Xie, L.; Gao, Z.J.; Xiao, H.W. Effects of Various Vlanching Methods on Weight Loss, Enzymes Inactivation, Phytochemical Contents, Antioxidant Capacity, Ultrastructure and Drying Kinetics of Red Bell Pepper (Capsicum annuum L.). LWT-Food Sci. Technol. 2017, 77, 337–347. [Google Scholar] [CrossRef]

- Ju, H.Y.; Vidyarthi, S.K.; Karim, M.A.; Yu, X.L.; Zhang, W.P.; Xiao, H.W. Drying Quality and Energy Consumption Efficient Improvements in Hot Air Drying of Papaya Slices by Step-Down Relative Humidity Based on Heat and Mass Transfer Characteristics and 3D Simulation. Dry. Technol. 2022, 41, 460–476. [Google Scholar] [CrossRef]

- Zhang, W.P.; Yang, X.H.; Mujumdar, A.S.; Ju, H.Y.; Xiao, H.W. The Influence Mechanism and Control Strategy of Relative Humidity on Hot Air Drying of Fruits and Vegetables: A Review. Dry. Technol. 2021, 40, 2217–2234. [Google Scholar] [CrossRef]

- Xie, Y.K.; Li, X.Y.; Zhang, Y.; Zheng, Z.A.; Huang, L.Q.; Liu, D.H.; Xiao, H.W.; Liu, Y.H. Effects of High-Humidity Hot Air Impingement Steaming on Gastrodia Elata: Steaming Degree, Weight loss, Texture, Drying Kinetics, Microstructure and Active Components. Food Bioprod. Process. 2021, 127, 255–265. [Google Scholar] [CrossRef]

- Yu, X.L.; Zielinska, M.; Ju, H.Y.; Mujumdar, A.S.; Duan, X.; Gao, Z.J.; Xiao, H.W. Multistage Relative Humidity Control Strategy Enhances Energy and Exergy Efficiency of Convective Drying of Carrot Cubes. Int. J. Heat Mass Tranf. 2020, 149, 119231. [Google Scholar] [CrossRef]

- Zhu, L.C.; Li, M.Q.; Yang, W.X.; Zhang, J.Y.; Yang, X.H.; Zhang, Q.; Wang, H.T. Effects of Different Drying Methods on Drying Characteristics and Quality of Glycyrrhiza uralensis (Licorice). Foods 2023, 12, 1652. [Google Scholar] [CrossRef]

- Geng, Z.H.; Huang, X.; Wang, J.; Xiao, H.W.; Yang, X.H.; Zhu, L.C.; Qi, X.C.; Zhang, Q.; Hu, B. Pulsed Vacuum Drying of Pepper (Capsicum annuum L.): Effect of High Humidity hot air impingement blanching pretreatment on drying kinetics and quality attributes. Foods 2022, 11, 318. [Google Scholar] [CrossRef]

- Shang, J.Y.; Zhao, B.; Li, L.M.; Liu, M.; Hong, J.; Fan, X.Q.; Wu, T.F.; Liu, C.; Zheng, X.L. Impact of A/B-Type Wheat Starch Granule Ratio on Rehydration Behavior and Cooking Quality of Noodles and the Underlying Mechanisms. Food Chem. 2023, 405, 134896. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, B.M.; Hong, S.Y.; Yeo, H.H.; Jeong, S.H.; Lee, D.U. A Pulsed Electric Field Accelerates the Mass Transfer during the Convective Drying of Carrots: Drying and Rehydration Kinetics, Texture, and Carotenoid Content. Foods 2023, 12, 589. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.Y.; Huang, D.; Qin, Y.T.; Zhang, Y.X.; Lu, Y.J.; Huang, S.; Gong, G.L. Ultrasound-Assisted Hot Air Drying Characteristics of Phyllanthus emblica. J. Food Process Eng. 2023, 46, 14286. [Google Scholar] [CrossRef]

| Prioritization Scheme | Maximum Velocity (m/s) | Minimum Velocity (m/s) | Maximum Velocity Deviation Ratio |

|---|---|---|---|

| z = 38, r = 1 | 1.7124 | 1.3025 | 18.33% |

| z = 38, r = 2 | 1.7848 | 1.4591 | 14.13% |

| z = 38, r = 3 | 1.7737 | 1.3843 | 13.38% |

| z = 38, r = 4 | 2.0215 | 1.3417 | 27.43% |

| z = 39, r = 1 | 1.7126 | 1.2967 | 19.01% |

| z = 39, r = 2 | 1.7685 | 1.5148 | 11.02% |

| z = 39, r = 3 | 1.8009 | 1.4477 | 13.32% |

| z = 39, r = 4 | 2.0164 | 1.4304 | 24.54% |

| z = 40, r = 1 | 1.7045 | 1.3177 | 18.05% |

| z = 40, r = 2 | 1.5471 | 1.4226 | 5.02% |

| z = 40, r = 3 | 1.5905 | 1.3468 | 8.41% |

| z = 40, r = 4 | 1.7702 | 1.3231 | 18.28% |

| z = 41, r = 1 | 1.6966 | 1.2992 | 19.41% |

| z = 41, r = 2 | 1.7305 | 1.524 | 6.81% |

| z = 41, r = 3 | 1.7551 | 1.5864 | 7.24% |

| z = 41, r = 4 | 1.9825 | 1.5842 | 17.77% |

| z = 42, r = 1 | 1.7043 | 1.2841 | 20.21% |

| z = 42, r = 2 | 1.707 | 1.4702 | 9.30% |

| z = 42, r = 3 | 1.7205 | 1.6063 | 4.45% |

| z = 42, r = 4 | 1.8499 | 1.599 | 10.73% |

| z = 43, r = 1 | 1.7236 | 1.2799 | 20.55% |

| z = 43, r = 2 | 1.6845 | 1.461 | 9.87% |

| z = 43, r = 3 | 1.6539 | 1.6294 | 0.88% |

| z = 43, r = 4 | 1.6815 | 1.6125 | 5.39% |

| z = 44, r = 1 | 1.7334 | 1.3054 | 19.18% |

| z = 44, r = 2 | 1.7057 | 1.4264 | 12.17% |

| z = 44, r = 3 | 1.6856 | 1.543 | 5.90% |

| z = 44, r = 4 | 1.6939 | 1.5521 | 5.87% |

| Parameter | Fresh | Drying Methods | |

|---|---|---|---|

| 75 °C-N | 75 °C-10% | ||

|  |  | |

| L* | 57.14 ± 0.11 a | 38.47 ± 0.26 c | 39.28 ± 0.04 b |

| a* | 33.34 ± 0.22 a | 23.14 ± 0.03 b | 22.89 ± 0.06 c |

| b* | 54.83 ± 0.23 a | 35.59 ± 0.21 c | 39.76 ± 0.04 b |

| ΔE | / | 28.69 ± 0.31 | 25.60 ± 0.05 |

| Browning index | 0.09 ± 0.00 c | 0.34 ± 0.01 a | 0.26 ± 0.02 b |

| (Abs/g d.m.) | |||

| Vc retention rate | 1.00 + 0.00 a | 0.24 + 0.07 c | 0.32 + 0.01 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, Z.; Li, M.; Zhu, L.; Zhang, X.; Zhu, H.; Yang, X.; Yu, X.; Zhang, Q.; Hu, B. Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.). Foods 2023, 12, 2299. https://doi.org/10.3390/foods12122299

Geng Z, Li M, Zhu L, Zhang X, Zhu H, Yang X, Yu X, Zhang Q, Hu B. Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.). Foods. 2023; 12(12):2299. https://doi.org/10.3390/foods12122299

Chicago/Turabian StyleGeng, Zhihua, Mengqing Li, Lichun Zhu, Xiaoqiang Zhang, Hongbo Zhu, Xuhai Yang, Xianlong Yu, Qian Zhang, and Bin Hu. 2023. "Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.)" Foods 12, no. 12: 2299. https://doi.org/10.3390/foods12122299

APA StyleGeng, Z., Li, M., Zhu, L., Zhang, X., Zhu, H., Yang, X., Yu, X., Zhang, Q., & Hu, B. (2023). Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.). Foods, 12(12), 2299. https://doi.org/10.3390/foods12122299