Preparation and Characterization of Flavored Sauces from Chinese Mitten Crab Processing By-Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Enzymes

2.2. Raw Material Basic Components

2.3. Optimization of the Enzymatic and Flavor Enhancement Technology

2.3.1. Optimization of the Enzymatic Process Conditions

2.3.2. Optimization of the Flavor Enhancement Technology

2.4. Preparation of the Samples for Flavor Analysis

2.5. E-Tongue

2.6. Free Amino Acid (FAA)

2.7. E-Nose

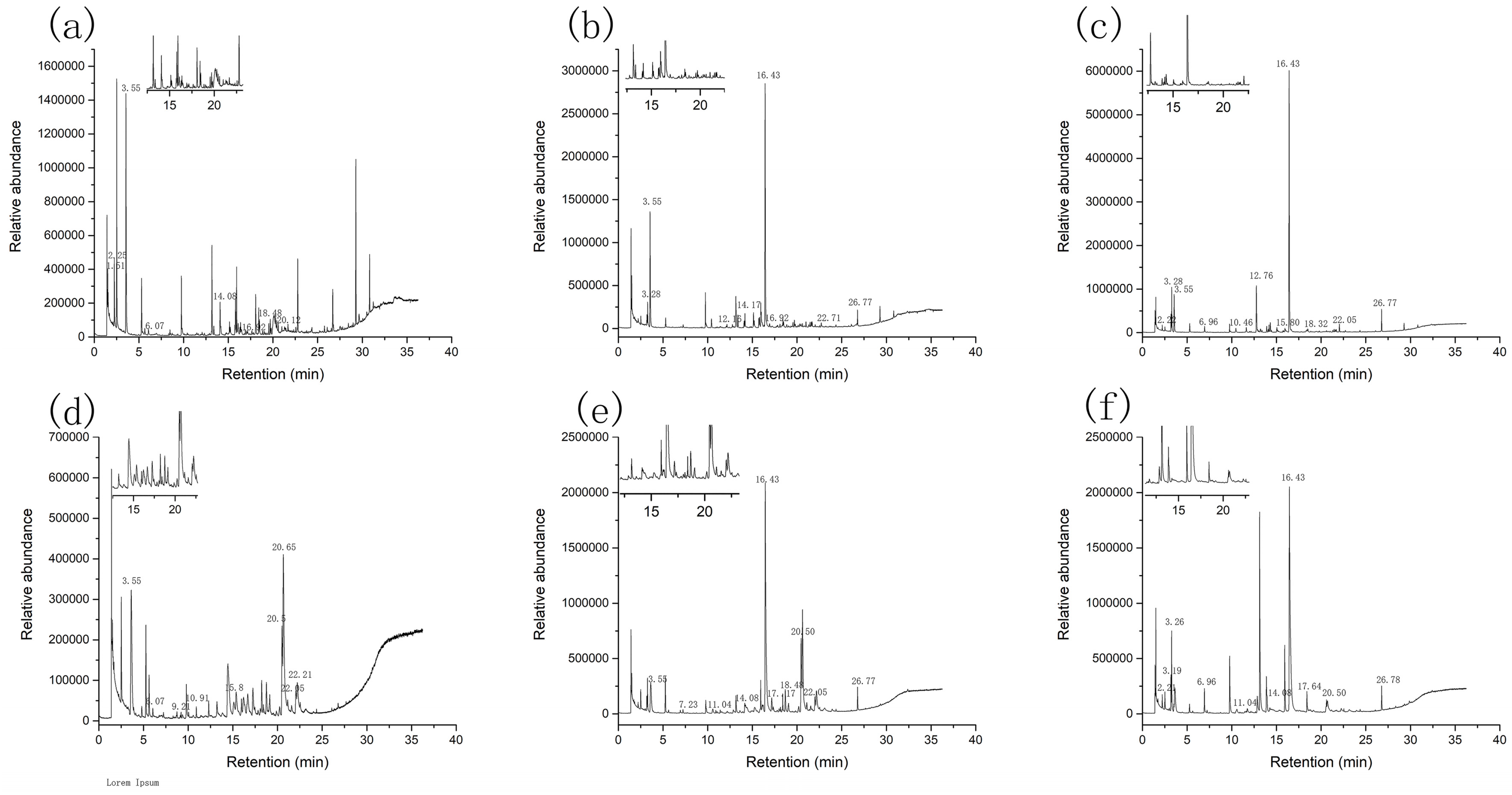

2.8. HS-SPME-GC/MS

2.9. Statistical Analysis

3. Results and Discussion

3.1. Basic Components

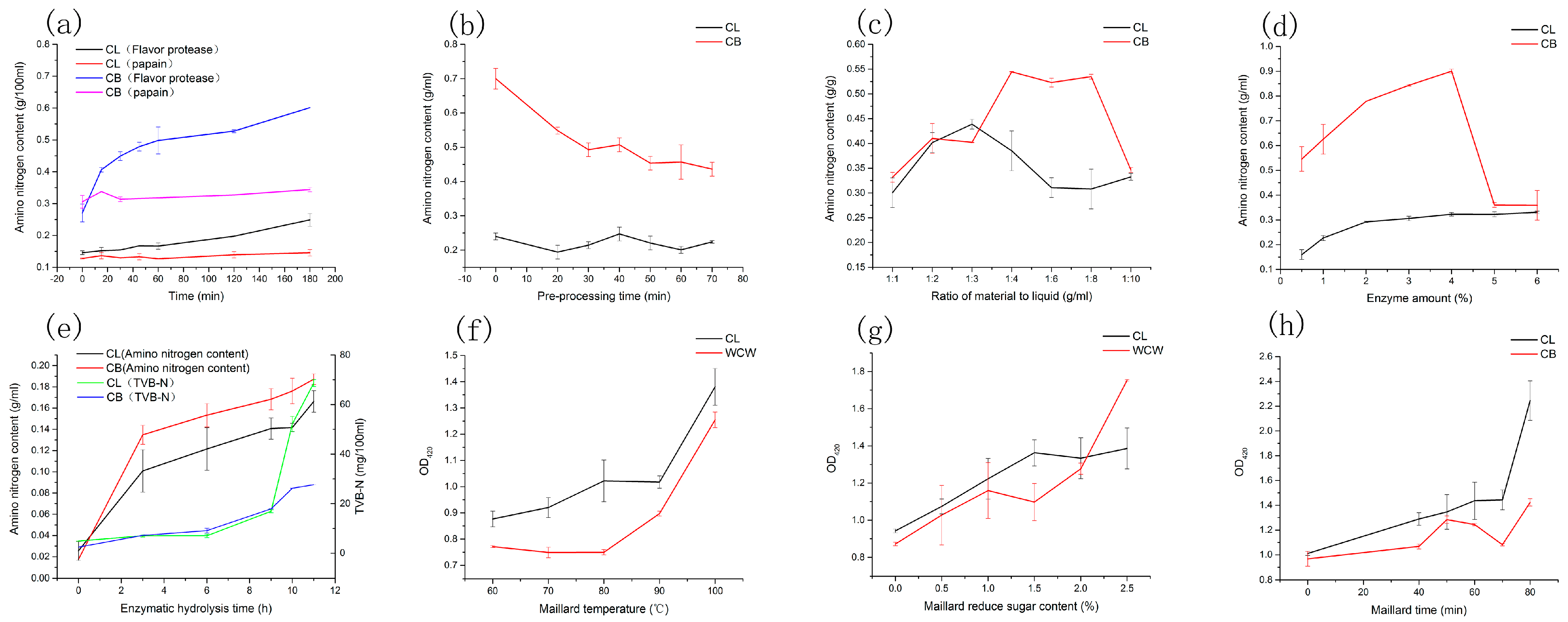

3.2. Optimization of Enzymatic and Flavor Enhancement Technology

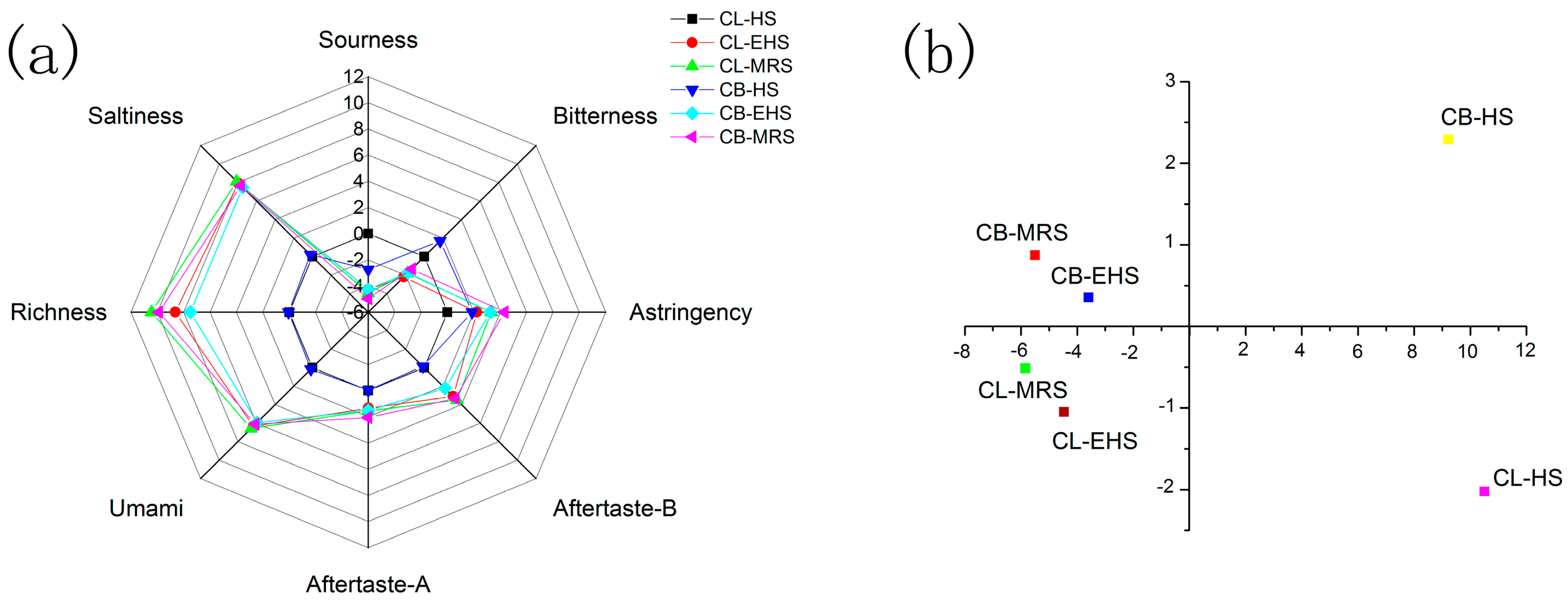

3.3. E-Tongue Analysis

3.4. FAA Evaluation

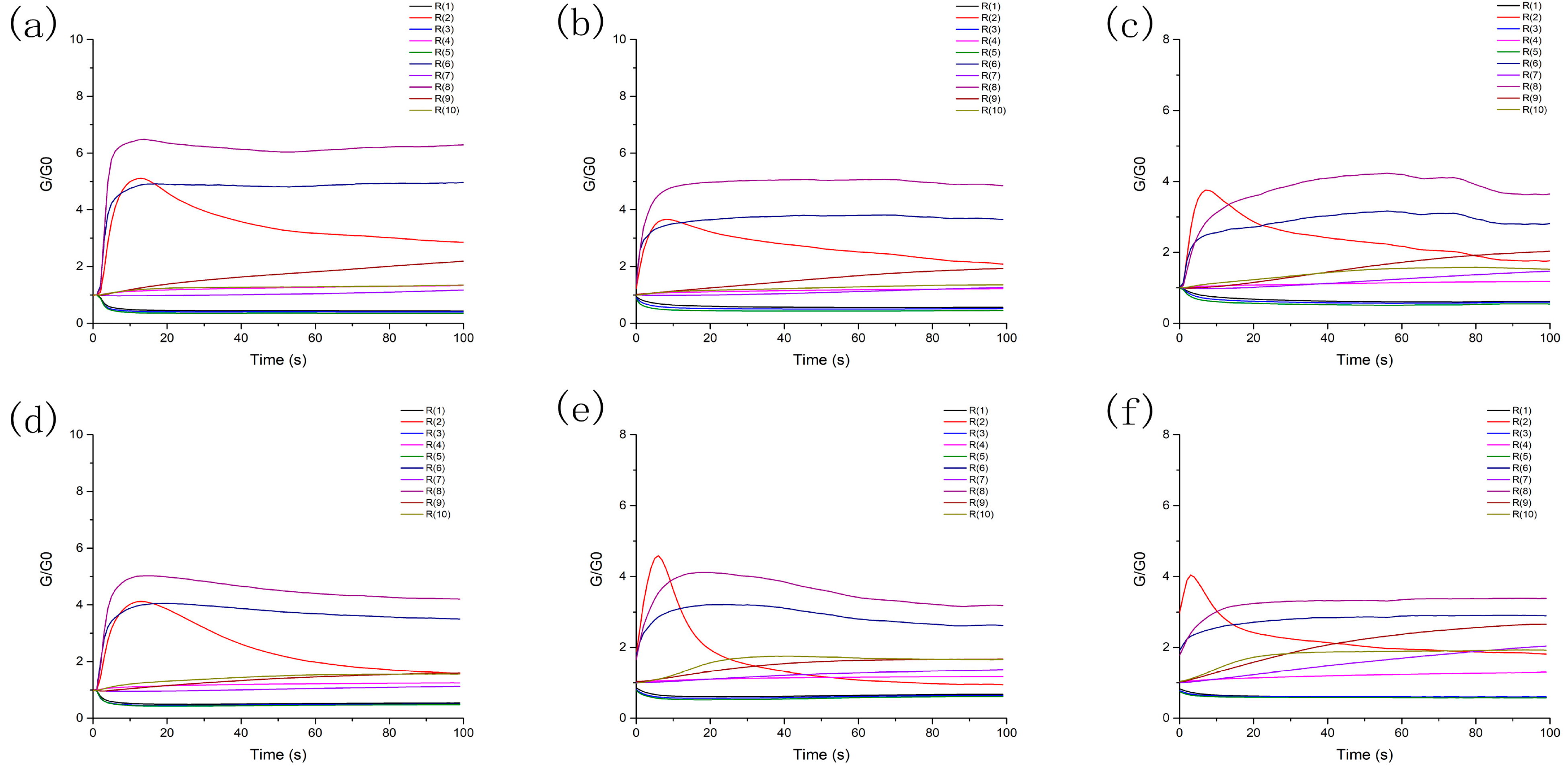

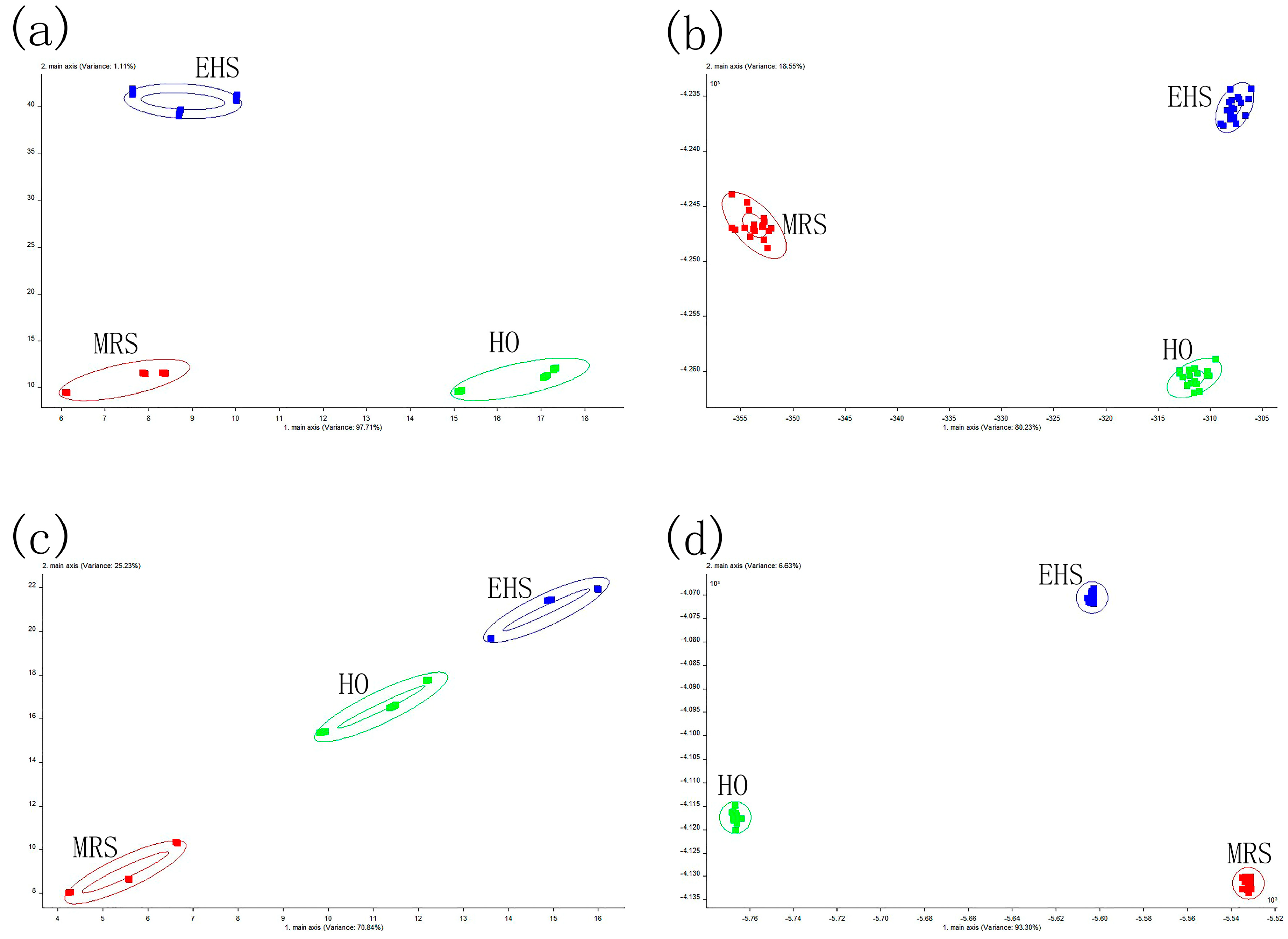

3.5. E-Nose Analysis

3.6. HS-SPME-GC/MS Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dittel, A.I.; Epifanio, C.E. Invasion biology of the Chinese mitten crab eriochier sinensis: A brief review. J. Exp. Mar. Biol. Ecol. 2009, 374, 79–92. [Google Scholar] [CrossRef]

- Luo, R.J.; Jiang, T.; Chen, X.B.; Zheng, C.C.; Liu, H.B.; Yang, J. Determination of geographic origin of Chinese mitten crab (Eriocheir sinensis) using integrated stable isotope and multi-element analyses. Food Chem. 2019, 274, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Fishery Bureau of the Ministry of Agriuclture. China Fishery Statistical Yearbook; China Agriculture Publishing House: Beijing, China, 2021; pp. 89–95. [Google Scholar]

- Nanda, P.K.; Das, A.K.; Dandapat, P.; Dhar, P.; Bandyopadhyay, S.; Dib, A.L.; Lorenzo, J.M.; Gagoua, M. Nutritional aspects, flavour profile and health benefits of crab meat based novel food products and valorisation of processing waste to wealth: A review. Trends Food Sci. Technol. 2021, 112, 252–267. [Google Scholar] [CrossRef]

- Toldra, F.; Reig, M.; Mristory, M.C.; Mora, L. Generation of bioactive peptides during food processing. Food Chem. 2018, 267, 395–404. [Google Scholar] [CrossRef]

- Nooshkam, M.; Varidi, M.; Bashash, M. The Maillard reaction products as food-born antioxidant and antibrowning agents in model and real food systems. Food Chem. 2019, 275, 644–660. [Google Scholar] [CrossRef]

- Yao, F.; Xing, P.; Liu, P. Preparation of flavor-ful sauce from freshwater fish by-products by enzymatic hydrolysis and then fermentation. Food Sci. 2012, 33, 44–49. [Google Scholar]

- Han, J.R.; Du, Y.N.; Tang, Y.; Zhao, J.; Shang, W.H.; Yan, J.N. Structural changes, volatile compounds and antioxidant activities of Maillard reaction products derived from scallop (Eatinopecten yessoensis) female gonad hydrolysates. J. Aquat. Food Prod. T. 2019, 28, 352–364. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 2002. [Google Scholar]

- Sun, J.A.; Yu, X.; Fang, B.; Ma, L.; Xue, C.; Zhang, Z.; Mao, X.Z. Effect of fermentation by Aspergillus oryzae on the biochemical and sensory properties of anchovy (Engraulis japonicus) fish sauce. Int. J. Food Sci. Technol. 2016, 51, 133–141. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Meng, Q.; Li, N.; Ren, L. Evaluation of beef by electronic tongue system ts-5000z: Flavor assessment, recognition and chemical compositions according to its correlation with flavor. PLoS ONE 2015, 10, e013780. [Google Scholar] [CrossRef]

- Pei, J.W.; Ding, L.K.; Li, L.; Zan, L.; Qi, Q.; Liu, H.M.; Zhao, Q. Solubility and amino acids composition of enzymatic oyster hydrolysate after Maillard reaction. Food Ferment. Ind. 2019, 45, 95–99. [Google Scholar]

- Cai, J.S.; Zhu, Y.Y.; Ma, R.H.; Thakur, K.; Wei, Z.J. Effects of roasting level on physicochemical, sensory, and volatile profiles of soybeans using electronic nose and HS-SPME-GC-MS. Food Chem. 2020, 340, 127880. [Google Scholar] [CrossRef]

- Ambigaipalan, P.; Shahidi, F. Bioactive peptides from shrimp shell processing discard: Antioxidant and biological activities. J. Funct. Foods. 2017, 34, 7–17. [Google Scholar] [CrossRef]

- Guo, Y.R.; Gu, S.Q.; Wang, X.C.; Zhuang, K.J.; Wang, S.; Shi, J. Nutrients and non-volatile taste compounds in chinese mitten crab by-products. Fish. Sci. 2015, 81, 193–203. [Google Scholar] [CrossRef]

- Li, P.P.; Liu, Y.W.; Gao, J.H.; Li, J.R.; Zhang, Y.Y.; Li, Y.J.; Lin, H. Flavor improvement of enzymatic hydrolysate of mactra veneriformis by Maillard reaction. Food Sci. 2018, 39, 82–89. [Google Scholar]

- Zhu, Y.W.; Zhou, X.R.; Chen, Y.P.; Liu, Z.Y.; Jiang, S.; Chen, G.L.; Liu, Y. Exploring the relationships between perceived umami intensity, umami components and electronic tongue responses in food matrices. Food Chem. 2022, 30, 130849. [Google Scholar] [CrossRef]

- Wang, Z.C.; Yan, Y.Z.; Tanzeela, Y.N.; Sun, L.J.; Guo, Y.R.; Wang, H.C.; Fang, Z.Y. Multivariate statistical analysis combined with e-nose and E-tongue assays simplifies the tracing of geographical origins of Lycium ruthenicum Murray grown in China. Food Control. 2019, 98, 457–464. [Google Scholar] [CrossRef]

- Je, J.Y.; Park, P.J.; Jung, W.K.; Kim, S.K. Amino acid changes in fermented oyster (Crassostrea gigas) sauce with different fermentation periods. Food Chem. 2005, 91, 15–18. [Google Scholar] [CrossRef]

- Chiang, J.H.; Yeo, M.; Ong, D.; Henry, C.J. Comparison of the molecular properties and volatile compounds of Maillard reaction products derived from animal and cerealbased protein hydrolysates. Food Chem. 2022, 383, 132609. [Google Scholar] [CrossRef]

- Yan, F.; Cui, H.; Zhang, Q.; Hayat, K.; Ho, C.T. Small peptides hydrolyzed from pea protein and their maillard reaction products as taste modifiers: Saltiness, umami, and kokumi enhancement. Food Bioprocess Tech. 2021, 14, 1132–1141. [Google Scholar] [CrossRef]

- Chen, H.; Huo, D.; Zhang, J. Gas recognition in E-nose system: A review. IEEE Trans. Biomed Circuits Syst. 2022, 16, 169–184. [Google Scholar] [CrossRef]

- Bonah, E.; Huang, X.Y.; Yang, H.Y.; Aheto, J.H.; Yi, R.; Yu, S.S.; Tu, H.Y. Nondestructive monitoring, kinetics and antimicrobial properties of ultrasound technology applied for surface decontamination of bacterial foodborne pathogen in pork. Ultrason Sonochem. 2021, 70, 105344. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.S.; Huang, X.Y.; Wang, L.; Ren, Y.; Zhang, X.R.; Wang, Y. Characterization of selected Chinese soybean paste based on flavor profiles using HS-SPME-GC/MS, E-nose and E-tongue combined with chemometrics. Food Chem. 2022, 375, 131840. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.L.; Yang, Y.F.; Wang, W.L.; Fan, Y.X.; Liu, Y.A. A potential flavor seasoning from aquaculture by-products: An example of Takifugu obscurus. LWT Food Sci. Technol. 2021, 151, 112160. [Google Scholar] [CrossRef]

- Josephson, D.B.; Lindsay, R.C.; Stuiber, D.A. Variations in the occurrences of enzymically derived volatile aroma compounds in salt and freshwater fish. J. Agr. Food Chem. 1984, 32, 1344–1347. [Google Scholar] [CrossRef]

- Zhang, N.L.; Yang, Y.F.; Wang, W.L.; Fan, Y.X.; Liu, Y.A. Influence of Maillard reaction in volatile flavor compounds of blue round scad (decapterus maruadsi) enzymatic hydrolysate. J. Aquat. Food Prod. Technol. 2021, 30, 615–629. [Google Scholar] [CrossRef]

- Cai, A.L.; Lin, H.; Cai, L.Y.; Li, D.M.; Dong, Z.J.; Li, J.R. Change regularity of the characteristics of Maillard reaction products derived from xylose and chinese shrimp waste hydrolysates. LWT Food Sci. Technol. 2016, 65, 908–916. [Google Scholar] [CrossRef]

- Scalone, G.L.L.; Lamichhane, P.; Cucu, T.; Dekimpe, N.; Demeulenaer, B. Influence of free amino acids, oligopeptides, and polypeptides on the formation of pyrazines in Maillard model systems. J. Agric. Food Chem. 2015, 63, 5364–5372. [Google Scholar] [CrossRef]

- Liu, J.B.; Liu, M.Y.; He, C.C.; Chen, F. Effect of thermal treatment on the flavor generation from Maillard reaction of xylose and chicken peptide. LWT-Food Sci. Technol. 2015, 64, 316–325. [Google Scholar] [CrossRef]

- Nooshkam, M.; Madadlou, A. Maillard conjugation of lactulose with potentially bioactive peptides. Food Chem. 2016, 192, 831–836. [Google Scholar] [CrossRef]

- Liu, H.M.; An, X.Y.; Chen, J.; Wang, J.; Zhao, Q.; Guo, Q.J.; Che, X.X.; Cui, Y. Optimization of the Maillard reactionconditions of enzymatic hydrolysate of oyster and nutritional evaluation of Maillard reactionproducts. Food Sci. 2017, 38, 178–182. [Google Scholar]

- Negroni, M.; Agostina, A.; Arnoldi, A. Effects of olive, canola, and sunflower oils on the formation of volatiles from the maillard reaction of lysine with xylose and glucose. J. Agric. Food Chem. 2001, 49, 439–445. [Google Scholar] [CrossRef]

- Zamora, R.; Hidalgo, F.J. Coordinate contribution of lipid oxidation and Maillard reaction to the nonenzymatic food browning. Crit. Rev. Food Sci. 2005, 45, 49–59. [Google Scholar] [CrossRef]

- Giri, A.; Osako, K.; Ohshima, T. Identification and characterisation of headspace volatiles of fish miso, a Japanese fish meat based fermented paste, with special emphasis on effect of fish species and meat washing. Food Chem. 2010, 120, 621–631. [Google Scholar] [CrossRef]

| Moisture (%) | Ash * (%) | Crude Protein * (%) | Crude Lipid * (%) | Crude Chitin * (%) | |

|---|---|---|---|---|---|

| CL | 50.60 ± 1.16 | 46.52 ± 0.55 | 42.37 ± 0.18 | 1.26 ± 0.34 | 8.01 ± 0.75 |

| CB | 58.28 ± 0.27 | 41.30 ± 0.21 | 22.43 ± 2.09 | 5.30 ± 0.18 | 19.91 ± 0.92 |

| Taste Attribution | Free Amino Acid | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CL | CB | ||||||||

| HO (mg/mL) | EHS (mg/mL) | MRS (mg/mL) | The Increasing Ratio (%) | HO (mg/mL) | EHS (mg/mL) | MRS (mg/mL) | The Increasing Ratio (%) | ||

| Proline | Sweet/bitter (+) | 0.03 | 0.05 | 0.04 | 25.00 | 0.01 | 0.03 | 0.03 | 66.67 |

| Aspartic acid | Umami (+) | 0.00 | 0.04 | 0.02 | 100.00 | 0.00 | 0.04 | 0.02 | 100.00 |

| Threonine * | Sweet (+) | 0.00 | 0.05 | 0.02 | 100.00 | 0.00 | 0.03 | 0.01 | 100.00 |

| Serine | Sweet (+) | 0.00 | 0.07 | 0.03 | 100.00 | 0.00 | 0.04 | 0.01 | 100.00 |

| Glutamic acid | Umami (+) | 0.00 | 0.09 | 0.04 | 100.00 | 0.01 | 0.09 | 0.04 | 75.00 |

| Glycine | Sweet (+) | 0.04 | 0.10 | 0.05 | 20.00 | 0.05 | 0.08 | 0.03 | −66.67 |

| Alanine | Sweet (+) | 0.05 | 0.18 | 0.11 | 54.55 | 0.05 | 0.09 | 0.05 | 0.00 |

| Cysteine | Bitter/sweet (−) | 0.00 | 0.00 | 0.02 | 100.00 | 0.00 | 0.02 | 0.01 | 100.00 |

| Valine * | Sweet/bitter (−) | 0.00 | 0.09 | 0.07 | 100.00 | 0.00 | 0.05 | 0.03 | 100.00 |

| Methionine * | Bitter/sweet (−) | 0.00 | 0.04 | 0.02 | 100.00 | 0.00 | 0.02 | 0.01 | 100.00 |

| Isoleucine * | Bitter (−) | 0.00 | 0.06 | 0.05 | 100.00 | 0.00 | 0.04 | 0.02 | 100.00 |

| Leucine * | Bitter (−) | 0.00 | 0.13 | 0.09 | 100.00 | 0.00 | 0.07 | 0.04 | 100.00 |

| Tyrosine | Bitter (−) | 0.00 | 0.07 | 0.04 | 100.00 | 0.00 | 0.03 | 0.02 | 100.00 |

| Phenylalanine * | Bitter (−) | 0.00 | 0.09 | 0.05 | 100.00 | 0.00 | 0.04 | 0.02 | 100.00 |

| Histidine * | Bitter (−) | 0.00 | 0.05 | 0.09 | 100.00 | 0.01 | 0.03 | 0.07 | 85.71 |

| Lysine * | Sweet/bitter (−) | 0.00 | 0.12 | 0.06 | 100.00 | 0.01 | 0.08 | 0.04 | 75.00 |

| Arginine | Sweet/bitter (+) | 0.04 | 0.17 | 0.09 | 55.56 | 0.05 | 0.08 | 0.03 | −66.67 |

| EAA/NEAA | -- | 0.00 | 53.85 | 53.45 | -- | 5.56 | 33.72 | 17.44 | -- |

| EAA/TAA | -- | 0.00 | 35.00 | 34.83 | -- | 5.26 | 66.28 | 38.37 | -- |

| Total | -- | 0.16 | 1.40 | 0.89 | -- | 0.19 | 0.86 | 0.48 | -- |

| Umami | -- | 0.00 | 0.13 | 0.06 | -- | 0.01 | 0.13 | 0.06 | -- |

| Sweet | -- | 0.16 | 0.87 | 0.51 | -- | 0.17 | 0.52 | 0.25 | -- |

| Bitter | -- | 0.07 | 0.87 | 0.55 | -- | 0.08 | 0.49 | 0.32 | -- |

| CL | CB | |||||||

|---|---|---|---|---|---|---|---|---|

| HO (%) | EHS (%) | MRS (%) | HO (%) | EHS (%) | MRS (%) | |||

| Aldehydes | Retention Time (min) | Description of Odor | ND | 63.55 | 67.55 | ND | 55.07 | 74.68 |

| 2-methyl butyraldehyde | 3.21 | Chocolate | 1.51 | 2.42 | 1.12 | 2.73 | ||

| 3-methyl butyraldehyde | 3.28 | Chocolate | 4.00 | 7.14 | 3.15 | 7.14 | ||

| Isobutyraldehyde | 2.21 | a pungent odor | 1.31 | |||||

| Decanal | 15.99 | Buckwheat flavor | 3.70 | 0.34 | ||||

| Benzaldehyde | 16.43 | Almond fragrance | 51.31 | 55.15 | 50.41 | 63.50 | ||

| 2-methyl-propanal | 2.22 | Wet grain flavor | 0.68 | |||||

| Benzeneacetaldehyde | 18.32 | Sweet | 0.43 | |||||

| Nonanal | 14.17 | Strong oily smell and sweet orange | 2.31 | 1.39 | ||||

| Hexanal | 7.23 | a pungent odor | 0.39 | |||||

| Octanal | 12.16 | Fruity aroma | 0.72 | |||||

| Ketones | 18.45 | 1.07 | ND | 13.80 | 3.25 | ND | ||

| Acetone | 2.25 | Aromatic smell | 10.32 | |||||

| Methyl hepten | 13.11 | Fresh green, citrus-like | 0.60 | |||||

| 2-Nonanone | 14.08 | Fragrant | 6.66 | 1.07 | 13.80 | 2.69 | ||

| 2-Heptanone, 6-methyl- | 11.04 | Tobacco leaf | 0.16 | |||||

| 3-Octanone | 11.40 | a pungent odor | 0.23 | |||||

| 2-Octanone | 12.17 | Cooked shrimp | 0.17 | |||||

| 2-Undecanone | 17.64 | Cream, cheese favor | 0.87 | |||||

| Alcohols | 56.33 | 30.92 | 9.08 | 68.88 | 28.68 | 7.69 | ||

| Ethanol | 3.55 | Special fragrance | 51.87 | 23.03 | 8.34 | 21.58 | 8.36 | 7.22 |

| 1-Octanol | 16.92 | Metal, medicinal, Mushroom | 0.99 | 0.69 | 3.88 | |||

| 1-Nonanol | 18.48 | Citrus smell | 3.47 | 3.47 | 3.52 | |||

| 1-Hexanol | 13.38 | Green grass | 2.26 | 0.48 | ||||

| 3-Methyl-1-butanol | 10.57 | a mild, choking alcohol odor | 1.10 | |||||

| 1-Octen-3-ol | 15.12 | Mushroom flavor, Earthy taste | 2.25 | |||||

| 2-Ethylhexanol | 15.80 | Sweet and light floral | 2.21 | 0.26 | 3.32 | |||

| (Z)-dodec-4-en-1-ol | 20.50 | nd | 9.37 | 12.60 | 0.47 | |||

| (Z)-4-Decen-1-ol | 20.65 | a food additive | 24.40 | |||||

| 9-Decen-1-ol | 22.05 | Fatty alcohols | 2.86 | 2.62 | ||||

| 1-Undecanol | 22.71 | Citrus scent | 0.48 | |||||

| n-Tridecan-1-ol | 22.72 | Pleasant smell | 0.48 | |||||

| Alkanes | ND | ND | ND | 7.80 | 6.36 | 2.33 | ||

| Bromodicloromethan | 9.21 | By-product of drinking water | 0.35 | |||||

| Cyclohexane, 1,2,3-trimethyl- | 20.24 | nd | 1.12 | |||||

| Cyclooctene, 3-methyl- | 22.21 | nd | 6.34 | 6.36 | ||||

| Bicyclo [4.1.0]heptane, 3-methyl- | 20.71 | nd | 2.33 | |||||

| Aromatics | 2.77 | ND | 1.60 | 0.57 | 0.83 | 2.24 | ||

| Toluene | 6.07 | Aromatic | 1.32 | 0.57 | ||||

| 2,4-Di-tert-butylphenol | 26.78 | Special smell | 2.24 | |||||

| Naphthalene | 19.79 | Mothball smell | 1.45 | 0.26 | ||||

| 1,2-Epoxyoctahydropentalene | 17.33 | Mothball smell | 0.83 | |||||

| Butylated Hydroxytoluene | 22.05 | Odorless and tasteless | 1.35 | |||||

| Pyrazines | ND | 0.78 | 16.23 | ND | 0.45 | 4.33 | ||

| 2,5-Dimethyl pyrazine | 12.76 | A pungent, fry aroma and chocolate, creamy | 0.78 | 9.98 | 0.45 | 3.45 | ||

| Pyrazine | 10.46 | Aromatic | 1.18 | |||||

| 2-Methylpyrazine | 11.62 | Nutty, roasted | 1.19 | 0.88 | ||||

| Ethylpyrazine | 13.00 | Nutty, roasted, meaty, Fishy | 0.36 | |||||

| 2-ethyl-5-methyl-pyrazine | 14.08 | Roast | 0.49 | |||||

| 2,3,5-Trimethylpyrazine | 14.31 | Roast | 2.12 | |||||

| 3-ethyl-2,5-dimethyl-pyrazine | 15.04 | Nuts, roasted scent | 0.92 | |||||

| Phenols | ND | 2.16 | 3.10 | ND | 2.27 | ND | ||

| 2,5-Bis(1,1-dimethylethyl) phenol | 26.77 | Special smell | 2.16 | 3.10 | 2.27 | |||

| Esters | ND | 0.82 | ND | ND | 2.57 | ND | ||

| Formic acid, octyl ester | 17.17 | Barbecue | 2.57 | |||||

| Pentanoic acid, 2,2,4-trimethyl-3-carboxyisopropyl, isobutyl ester | 21.60 | nd | 0.82 | |||||

| Amines | 6.53 | ND | ND | 7.88 | ND | ND | ||

| Trimethylamine | 1.51 | Smelly smell, amine smell | 6.53 | 7.88 | ||||

| Terpenes | ND | 0.69 | ND | ND | ND | ND | ||

| Azulene | 19.81 | Mushroom incense | 0.69 | |||||

| Organosulfur compounds | ND | ND | 2.43 | ND | 0.25 | 8.58 | ||

| Dimethyl disulfide | 6.96 | a cabbage-like odor | 1.20 | 0.25 | 2.54 | |||

| Dimethyl trisulfide | 13.91 | Sulfur, leek, cooked onion | 1.23 | 6.04 | ||||

| Oxime s | 15.91 | ND | ND | ND | ND | ND | ||

| Oxime-, methoxy-phenyl- | 20.12 | nd | 15.91 | |||||

| Pyrroles | ND | ND | ND | 0.45 | ND | ND | ||

| N-Methyl pyrrole | 8.75 | Roast | 0.45 | |||||

| Furans | ND | ND | ND | 0.61 | 0.26 | ND | ||

| 2-Pentylfuran | 10.91 | Bean, fruit, earth, green | 0.61 | 0.26 | ||||

| Pyrimidines | ND | ND | ND | ND | ND | 0.15 | ||

| Pyrimidine | 10.46 | Aroma | 0.15 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhou, Y.; Ren, Y.; Sun, J. Preparation and Characterization of Flavored Sauces from Chinese Mitten Crab Processing By-Products. Foods 2023, 12, 51. https://doi.org/10.3390/foods12010051

Sun Y, Zhou Y, Ren Y, Sun J. Preparation and Characterization of Flavored Sauces from Chinese Mitten Crab Processing By-Products. Foods. 2023; 12(1):51. https://doi.org/10.3390/foods12010051

Chicago/Turabian StyleSun, Ying, Yan Zhou, Yanmei Ren, and Jianan Sun. 2023. "Preparation and Characterization of Flavored Sauces from Chinese Mitten Crab Processing By-Products" Foods 12, no. 1: 51. https://doi.org/10.3390/foods12010051

APA StyleSun, Y., Zhou, Y., Ren, Y., & Sun, J. (2023). Preparation and Characterization of Flavored Sauces from Chinese Mitten Crab Processing By-Products. Foods, 12(1), 51. https://doi.org/10.3390/foods12010051