Abstract

The development and scope of using various food preservation methods depends on the level of consumers’ acceptance. Despite their advantages, in the case of negative attitudes, producers may limit their use if it determines the level of sales. The aim of this study was to evaluate the perception of seven different food processing methods and to identify influencing factors, such as education as well as living area and, at the same time, to consider whether consumers verify this type of information on the labels. Additionally, the study included the possibility of influencing consumer attitudes by using alternative names for preservation methods, on the example of microwave treatment. The results showed that conventional heat treatments were the most preferred preservation methods, whereas preservatives, irradiation, radio waves and microwaves were the least favored, suggesting that consumers dislike methods connected with “waves” to a similar extent as their dislike for preservatives. The control factors proved to significantly modify the evaluation of the methods. The analysis of alternative names for microwave treatment showed that “dielectric heating” was significantly better perceived. These research findings are important as the basis for understanding consumer attitudes. Implications for business and directions of future research are also indicated.

1. Introduction

According to European Union law, producers are obliged not only to provide information regarding nutritional value on food and beverage packaging, but also of the specific treatment that has been used on the food product [1]. As consumer awareness increases, so does their attention to what food products they purchase by reading the labels, which often influences purchasing decision [2]. Products which are supposed to be beneficial for people’s health are more likely to be chosen. The most frequently checked consumer information on the packaging is the expiration date, ingredients list and the nutritional value [2,3,4,5,6], whereas the processing method is the least searched [7]. Consumers nowadays seek for products that are fresh, tasty, do not contain preservatives or other chemical additives but, at the same time, are safe and have a long shelf-life. Many people prefer natural foods with “green labels” [8,9,10]. The food producer must adapt to the preferences of consumers and earn their trust, to gain their acceptability [6,11]. The answer to the needs of consumers regarding the high nutritional values and clean label trend is the use of novel technologies in the food industry. The lack of consumer acceptance analysis may determine the high failure rate of novel product implementation, which is why it is crucial to appropriately communicate the use of innovative technologies to consumers [12].

Despite their growing awareness, many consumers exhibit fear of innovative technologies and may show resentment towards novel food products produced with the use of such technologies. This phenomenon is called food technology neophobia and is connected with the cult of natural or traditional food [13,14,15]. Additionally, this is a personality trait that affects consumer willingness to accept new food technologies [16]. There is a belief that traditional, simple food, without preservatives, has the highest nutritional value and is of best quality, which is why such products are highly desirable [11,17]. Moreover, consumers are often deterred by the complicated names of technologies that are unknown and incomprehensible to them [16,18]. Other reasons for the emergence of food technology neophobia are disgust, reluctance towards sensory feature, and fear of danger after consuming this product. Many factors have impact on this phenomenon, including psychological barriers, knowledge, functional barriers connected to ease of use, benefits and risks as well as socio-demographic factors [13]. Furthermore, education level and appropriate dissemination of information are important factors for facilitating the widespread adoption of new food technologies and avoiding failure in innovative marketing strategies [19].

Therefore, production processes and marketing activities should be combined in such a way that consumers perceive it as a product that is as natural and familiar to them as possible [10]. Recent years have shown significant technological progress in the food sector, thereby increasing the quantity of new products on the market [20,21]. Despite the reluctance of consumers to accept new technologies, food products created using such methods may have a positive effect on the product choice. The advantages of using new technologies are: increased production efficiency, increased safety and nutritional value with less demand for energy, water and chemicals, which is also important for sustainability [16,22].

The goal of food preservation is to provide microbiological safety and extend the shelf-life of products. Due to its effectiveness, despite the development of novel technologies, conventional thermal preservation methods are still the most commonly used approaches in the industry [23]. Pasteurisation consists of heating the product up to the temperature of 100 °C, while during sterilisation, the temperature exceeds 100 °C. In conventional thermal preservation methods, heat is generated outside of the material and occurs via convection throughout its entire volume [24]. Despite guaranteeing microbiological safety, these traditional methods result in reduction of some thermally sensitive food ingredients, especially vitamins and polyphenols, which are related to food quality [25].

Microwave heating is a valid alternative to conventional heating. Microwaves are radio waves in the spectrum of electromagnetic radiation with wavelengths ranging from one millimetre to even one metre. In literature on the subject, microwave heating is often referred to as dielectric heating because waves are absorbed by materials having dielectric properties [26,27]. Such materials, also called dielectrics, have a relatively high specific resistance and low electrical conductivity. Moreover, the molecules or atoms comprising the dielectric (such as agri-food products) exhibit dipole movement. Microwave technology is a widely used technology within the food industry. It is applied for cooking, drying, thawing, pasteurisation or sterilisation of food products and most households contain a small microwave [28,29,30,31].

There are also non-thermal technologies that extend the shelf-life of food products without the use of high temperatures. One of such is the use natural bioactive compounds such as using plant materials. Some plant extracts show antioxidant and/or antimicrobial properties and can be used as an alternative to chemical preservatives [32]. Another example are chitosan-based apple peel polyphenols [33] furcellaran-chitosan [34] or furcellaran-gelatin with green and pu-erh tea edible coatings [35]. Physical non-thermal preservation methods allow reduce treatment time.

Different non-thermal preservation technologies include ionising radiation, which is also in the range of electromagnetic waves [25]. Irradiation of food uses low-energy radiation and 3 types of radiation are authorised for use in the food industry, which include high-energy gamma rays, X-rays and accelerated electrons in accordance with the Codex General standard for Irradiated Food [25,36]. Irradiation works directly through damage of cell components such as carbohydrates, DNA and lipids, and indirectly via free radicals and reactive species (e.g., hydro-electrons, hydrogen atoms, or hydroxyl radicals). It is a consequence of radiolysis of water reaction with cells or food components, and has proven effective in the reduction of insects and microorganisms [37,38].

High hydrostatic pressure (HHP) is a technique in which pressures of 100–1000 MPa are applied to the product, resulting in the inactivation of the majority of pathogenic microorganisms. HPP-treated food must be packed and contain water, then closed in a chamber where the pressure is gradually increased. It is closed in a chamber where the pressure is increased. Depending on the type of food, the process lasts from several seconds to 20 min [39,40]. Consumer demand for freshness and the longest possible shelf-life can be provided by packaging in modified atmospheres (MAP). This technology is based on packaging in vapour- or gas-barrier materials of fresh and minimally processed food products in a packaging system where the air composition is changed, ensuring an optimal gas composition around the product. Due to reduced O2 and CO2, the metabolic processes and microbial activity significantly slow down, thus extending the shelf-life of the food product [41,42].

The abovementioned techniques are only several examples of the modern methods already in use within the food industry and producers apply them to preserve their products. The applicability of the methods may depend on many factors and also have their pros and cons. The advantages and disadvantages of the described technologies are presented in Table 1. Despite growing awareness, many consumers do not read labels for various reasons, such as lack of time, too much information on the label or trust in the brand name [5,43]. From the producer’s point of view, consumers who declare reading labels are credible in assessing the product, and it can also be assumed that they understand the declarations on the label better. The results of the study carried out by Szymkowiak et al. [7] allowed to show a specific attitude-behaviour dissonance in which consumers declared that the most important attribute of the product choice is the processing method, even though it was the least searched for on the label.

Table 1.

Advantages and disadvantages of selected food preservation methods.

Despite the many advantages and electromagnetic heating being widespread, especially the microwave spectrum, some consumers still negatively perceive this kind of preservation. Negative associations are related to radiation and it being harmful for human health [3,57,58,59]. One of the potential ways to improve microwave perception among consumers is changing the method name to another “safe sounding” synonym. Associations of the preservation method with a product influence purchasing decision [60,61]. Therefore, the aim of this research study was to evaluate the perception of different food processing methods and to identify factors influencing them. In the study, the possibility of influencing the attitudes of consumers by modifying the processing name was also included.

2. Materials and Methods

2.1. Respondents

In order to assess the preferences of various food preservation methods, a questionnaire study was conducted among 438 respondents who declared that they were responsible for making food purchases in their households. The survey was conducted both in electronic and paper version to reach respondents from rural areas, who do not actively use the Internet. In both cases, the participants did not receive any remuneration. Participants who failed the validation questions (e.g., “If you read the question carefully, select the answer I strongly disagree”, n = 33) were excluded from the analyses. Therefore, the answers of 405 respondents were taken for analysis. The mean age in the analysed sample was 34.71 (SD = 1.85, minimum = 19, maximum = 85). The majority were women (74%). The group differed in terms of household and place of residence size. The detailed characteristics of the sample are presented in Table 2.

Table 2.

Description of the study group.

2.2. Study Design

The questionnaire was divided into 3 parts. In the first one, the respondents were to indicate their attitude towards the analysed methods (Table 3) on a 7-grade scale where 1—means a very negative attitude and 7—a very positive attitude. In the second part of the study, a photo of the product (ham) was presented 4 times together with an annotation that the product was preserved by 1 of 4 methods: electromagnetic wave with a length of 32.76 cm (wavelength of microwave at 915 MHz frequency), dielectric wave, electromagnetic wave or microwave. These terms are synonymous with each other from a technological perspective; however, linguistic modifications were assumed to be associated with different reactions and thus, different perception of the product. The order of displaying the methods was random, which allowed to eliminate bias. Participants were not provided with additional definitions or explanations of the methods. This allowed their overall relationship with the methods to be assessed, which is consistent with the level of detail shown on product labels. On this basis, consumers were to state how much they would be interested in purchasing a product on a seven-point scale (1—“definitely not”, 7—“definitely yes”). Finally, the respondents answered the identification questions, including those regarding their purchasing behaviour.

Table 3.

Designation of the analysed methods.

2.3. Data Analysis

At the stage of data analysis, ANOVA with repeated measurements was used. This type of analysis of variance, to a greater extent, allows to take the variability for a particular respondent into account. Thus, it is possible to identify differences, also in a situation where some respondents generally expressed higher preferences for all methods, or vice versa. Subsequently, additional analyses were conducted between groups due to additional moderators important from the perspective of the subject under study: education and declared paying attention to processing methods when selecting food products at a store. In the case of education, the division was made into 3 groups: people with secondary and lower education (n = 129), bachelor level (138), and master’s degree level and higher (138). The χ2 analysis showed that the differences in group sizes were statistically insignificant: chi2 (2) = 0.04, p = 0.98. In the case of the second variable, two groups were created: people who verified (155 respondents) and did not verify the type of preservation method (250).

3. Results and Discussion

3.1. Consumer Preference for the Food Product Preservation Method

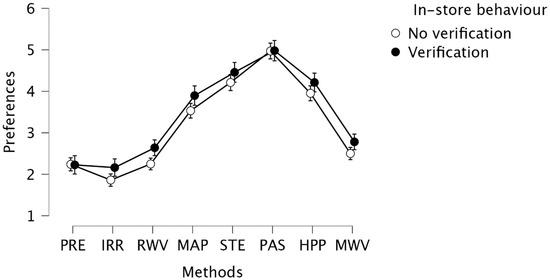

In the first part, ANOVA analysis was performed in 3 iterations. The first analysis allowed to confirm that the method strongly determined preferences F (2828, 7) = 271.159, p < 0.001, η2 = 0.402. Post-hoc analysis, applied to compare the obtained values for all pairs, showed significant statistical differences between them, apart from the relationship between MWV and RWV (t(404) = 2.192, p = 0.057) and between in RWV and PRE (t(404) = 1.702, p = 0.089). Detailed values for all comparisons are presented in tabular form in Supplementary material (Table S1). The most negative ratio (average below 3 on the 1–7 scale) was indicated by the respondents in relation to IRR (M = 1.975, SD = 1.379), PRE (M = 2.235, SD = 1.348), RWV (M = 2.398, SD = 1.462) and MWV (M = 2.607, SD = 1.501). The respondents expressed a more positive attitude towards MAP (M = 3.672, SD = 1.868), HPP (M = 4.052, SD = 1.790) and STE (M = 4.306, SD = 1.763). The PAS method was rated the highest (M = 4.975, SD = 1.613). Next, an analysis was conducted with the use of a moderator, which was the declared behaviour in the store. A table with results of post-hoc analysis, depending on in the store behaviour, is provided in Supplementary material (Table S2). This analysis revealed that the factor significantly influences the general level of preferences in relation to all methods (F (403.1) = 5.423, p = 0.02, η2 = 0.003). People who check food preservation methods on products when shopping at a store express a more positive attitude towards all of the methods (Figure 1).

Figure 1.

Consumer’ preference for food product preservation methods (PRE—addition of preservatives; IRR—irradiation preservation; RWV—radio wave preservation; MAP—packaging in modified atmosphere preservation; STE—sterilisation; PAS—pasteurisation; HPP—high pressure processing; MWV—microwave preservation).

The results of the study indicate differences between various methods of food preservation and consumer preferences. Consumers’ nutritional literacy affects their ability to process food labels [62]. Therefore, it can be assumed that consumers who declared verifying the preservation method on the label of food products have a better understanding of the method itself. In our study, consumers who verified the preservation method gave higher ratings for preservation method preferences, but the trend was the same for non-verifying consumers.

In this study, PAS and STE were conventional types of preservation methods and both of them received the highest score. Consumers are accustomed to the above-mentioned techniques because they associate them with traditional production to which they are accustomed [63,64]. Moreover, they were programmed from early childhood to prefer familiar foods [65]. Conventionally processed products are mainly associated with health and natural products, while those including references to industrial processing technology are perceived as processed and, therefore, unhealthy [66,67]. MAP and HHP were also rated relatively high, which may mean a positive reception of these technologies. In previous research conducted by Deliza and Ares [12], it was also confirmed that consumers have a positive attitude towards HHP and are willing to buy products treated via this technology, after being informed about how this method works. Nonetheless, it should be noted that many people have never heard of this technology. In a study by Lee et al. [68], the respondents evaluated juices treated with HHP and pulsed electric fields. In their opinion, conventional thermal treatment decreased the pleasant notes such as natural and fresh, whereas undesirable notes like cooked flavour or sourness increased. Similar to the case of MAP, Guerrero [11] demonstrated that this technology was negatively perceived by consumers. Participants were suspicious and immediately rejected the MAP packed product. Moreover, it was noted that they are not willing to pay more for products packed in MAP, despite the fact that those products maintained freshness and high quality for a longer period of time. Ortiz et al. [69] indicated that consumers can pay more for vacuum packaging as opposed to MAP.

The significance of naturalness has crucial meaning for consumers nowadays. They prefer food free from preservatives, additives or artificial ingredients for perceived naturalness of foods. The result is that now, more than ever, manufacturers often try to produce products with “green labels” [10]. A perceived lack of naturalness also hinders the acceptance of new food preservation methods and technologies [65]. This phenomenon would explain the negative perception of preservatives in our research. In a study by Perito et al. [67], the majority of the respondents declared willingness to consume biopreservatives, only if they replaced synthetic ones. According to Dominick et al. [70], 83% of respondents agreed that a product with an “all natural” label meant no preservatives. They perceived “all natural” foods without preservatives and additives as products with better taste, nutritional value and increased food safety. IRR, RWV and MWV were similarly perceived, relatively negative, as the preservatives. These, technologies have a common denominator, since all 3 methods are based on “waves”. In a survey by Szymkowiak et al. [7], respondents showed dislike towards the microwave preservation method, whereas conventional thermal preservation was considered the most positive. Microwave technology is known to consumers through the widespread domestic use of microwave ovens. However, there is a common belief among such consumers that microwaved foods are unhealthy and often associated with radiation [58]. The negative perception of microwaves can be a result of disinformation and fake news in social media, such as “using microwaves to heat food can cause carcinogenesis” [71,72]. In their study, Wolfson et al. [73] noted that consumers perceived microwave heating negatively due to radiation or “zapping” nutrients out of the food. Especially among the older generation of consumers, their statement was also that microwave heating is “lazy” or “cheating” one’s way out of cooking. Consumer aversion to radiation-related technologies of food preservation may be associated with the risk of making food radioactive or the formation of harmful compounds, but also with the wrong image that food irradiation is a nuclear technology. Moreover, for some consumers, products labelled as irradiated may be read as a health warning [12,61,74,75]. The lack of proper knowledge affects consumer acceptance of food irradiation technologies and can be a main reason for the limited application this method [74].

3.2. Consumer Preference for Food Product Preservation Methods According to Education Level and Main Area of Residence

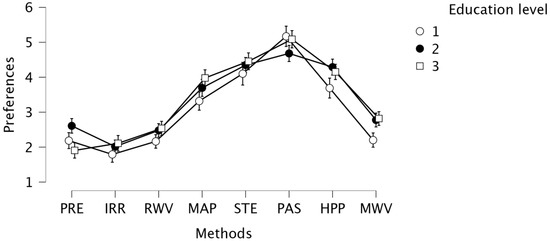

For the education variable, the study revealed between- (F (402.2) = 4.090, p = 0.017, η2 = 0.005) and within-subject effects (F (2814.14) = 4.122, p = 0.001, η2 = 0.009). This indicates that the level of education determined the overall level of method preference as well as the interaction effect. People with lower educational levels, compared to other groups, showed lower preferences for most methods, except pasteurisation (Figure 2). A table with the post-hoc analysis values for all 276 pairs of comparisons can be found in Supplementary material (Table S3). Moreover, we observed that the main place of the respondents’ residence determines the level of acceptance of various methods (F (3.401) = 4.874, p = 0.002). Residents of rural areas, on average, assessed the methods of food preservation by 0.4 lower on a 7-level scale than residents of cities with 100,000–500,000 inhabitants ((t(404) = 2.662, p = 0.04), and compared to residents of cities with above 500,000 inhabitants ((t(404) = 3.444, p = 0.004). This means that people living in rural areas have a lower acceptance of various food preservation methods.

Figure 2.

Consumer preference for food product preservation methods depending on education level; 1—lowest; 2—average; 3—highest (PRE—addition of preservatives; IRR—irradiation preservation; RWV—radio wave preservation; MAP—packaging in modified atmosphere preservation; STE—sterilisation; PAS—pasteurisation; HPP—high-pressure processing; MWV—microwave preservation).

The results of our research allowed to show that respondents with the lowest (1 in Figure 2) education level caused polarisation between the options for declaring preferences for preserving methods. It can be interpreted that they definitely prefer the familiar, conventional technologies, and most definitely, do not prefer those which are unknown to them. The group of consumers with the highest education level (3 on the graph) perceived novel methods better compared to those least educated. This may result from the fact that more educated people show greater knowledge and awareness related to novel methods of food preservation. Popek and Halagarda [76] also confirmed correlations between education level, place of residence and greater knowledge of consumers. Similarly, Moreb et al. [77] indicated that people living in the city were more knowledgeable about food safety and food handling practices than those who lived in the countryside.

The survey, in which consumers were asked about their knowledge of microwave radiation and its effect on food, revealed that consumers know very little about it. The reason may be that it is difficult to obtain such knowledge from reliable sources [3,78]. Most consumers who do not know the process or who have little knowledge of it, show greater uncertainty regarding the safety of processed food products and often believe that they are dangerous and may pose a health risk [74]. Verbeke et al. [79] demonstrated that providing additional information about novel technologies positively increased their perception. Nonetheless, preservatives, although known to most people, are nor accepted. Increasingly, manufacturers are resigning from their addition, despite the fact that they are mostly considered safe. However, due to the fact of their potentially negative effects and low level of acceptance among consumers, other solutions or natural substitutes are being sought [80,81,82].

3.3. Consumer Preference for Alternative Names of Microwave Treatment

In the last part of the analysis, in accordance with the second goal adopted in the paper, the impact of the alternative name of the method for microwaves on product perception, was analysed. The study revealed that different names cause different perceptions of the product (F (1212.3) = 17.874, p < 0.001, η2 = 0.042). Post-hoc analysis revealed that while interchangeably using MWV, EMV, LWV does not cause statistically significant differences, the DIE version of labelling (M = 2.986, SD = 1.510) results in more desirable reactions (Table 4). Additional analyses carried out with controlling the inter-group factor revealed the importance of both the interest in the processing methods expressed by the declaration of method verification while shopping ((F (403.1) = 8.533, p < 0.004, η2 = 0.015) and education ((F (402.2) = 4.571, p < 0.011, η2 = 0.016) on the use of alternative names for general product preferences. Detailed analysis confirmed that consumers, verifying methods while shopping, better perceived the product described as DIE (M = 3.316, SD = 1.445), and this was a statistically significant difference (t(404) = 3.769, p = 0.004) compared to the preferences for this version of the product declared by persons who did not verify the method (M = 2.752, SD = 1.511). In the case of education, the mean value of the group with the lowest education was lower (M = 2.767, SD = 1.598) than in the group with undergraduate (M = 3.116, SD = 1.324) and graduate education (M = 3.007, SD = 1.587).

Table 4.

Post-hoc Comparisons—Alternative names for microwaves (PRE—addition of preservatives; IRR—irradiation preservation; RWV—radio wave preservation; MAP—packaging in modified atmosphere preservation; STE—sterilisation; PAS—pasteurisation; HPP—high-pressure processing; MWV—microwave preservation).

Microwaves are non-ionising electromagnetic waves having a frequency within the range of 30–300 MHz, and wavelength ranging from 1 m to 1 mm. Microwaves are recognised as radio waves and are absorbed at the molecular level. They react with dipoles and ions and have the ability to heat a material with dielectric properties. This explains why various names of the microwave technology (such as “electromagnetic radiation” or “radio-frequency waves preservation”) could be used. The thermal effect of microwaves is obtained through the molecular movement of dipoles and ions, which generates friction among the rotating molecules and, subsequently, in the dissipation of the energy as heat [29,83,84]. Due to the negative perception of microwave treatment [7], in this study, 4 alternative names were compared (microwave preservation—MWV; preservation using am electromagnetic wave with a length of 32.76 cm—LWV; electromagnetic wave preservation—EMV; and dielectric heating preservation—DIE). MWV, LWV and EMV showed no significant differences in consumer perception. Only dielectric heating preservation was significantly better perceived among alternative names. This might be because only in this name was there no reference to “waves”. In addition, the prefix “di” refers to multiplication, which can be seen as an enhancing element increasing and improving the attributes of the product. Moreover, consumers might associate them more with the traditional methods of meal preparation using an electric stove or magnetic induction (dielectric and electric). This, however, is just a hypothesis which should be confirmed in future research. Familiar associations of technology name with technologies that can be applied at individual households increase acceptance [18], whereas the term “radiation” in microwave radiation can raise concerns [85]. It should be also mentioned that although dielectric heating preservation was perceived much better than alternative names of microwave treatment, the preference value was still 3.316, which is relatively low compared to the other methods under study, as it was below the lower half of the rating scale (Supplementary material). Such a different attitude can also be explained on the basis of feelings-as-information theory [86,87,88]. The ease of processing individual names influences judgment [89]. Subjective experiences such as emotions and metacognitive feelings serve as a source of information for consumers and influence decisions made [87,90,91].

In this study, the importance is shown of terminology used in food technology in relation to consumer perception. Names that evoke positive associations are more preferred by consumers [60,61]. Even without knowing the details of the new technologies, the name itself may affect the perception by consumers and their willingness to buy. On an example of cultured meat, Verbeke et al. [79] explained that possible cognitive association or attitude activation matter, such as “in vitro” may activate attitudes linked with laboratory practices or growth processes in bioreactors. “Technical” names may evoke thoughts or strengthen perceptions of unnaturalness, being too scientific for the consumers. In a study by Martins et al. [66], respondents positively associated the cold-pressed juice concept, although the processing method was unknown to them. They had associations with a natural and unprocessed product, probably due to the words “pressed” and “cold” in the name of the technology.

There are various advantages and benefits that many novel food processing technologies provide for food processors and consumers alike. Despite this, however, many consumers negatively regard these novel food technologies. Changing the name of the preservation method, especially to one which is not associated with “waves”, seems to be a valid alternative for food processors. Additionally, the research results indicate that for producers, the application of the methods may also be conditioned by the target group and market. This can increase consumer trust and willingness to buy, while maintaining safety and often higher nutritional value of the product.

4. Conclusions

The implementation of new technologies is an indispensable element of food engineering and the production of new food products. Novel food processing and preservation technologies offer many advantages in terms of nutrient retention, good quality and food safety. However, the implementation of new technologies is strongly related to acceptance by consumers. The results of this study allowed to indicate that conventional methods of food preservation were best perceived and accepted by respondents as they are well-known to them. Packaging in a modified atmosphere and with high hydrostatic pressure were also relatively well-perceived, whereas every method related with radiation (microwaves, radiowaves, irradiation) were perceived negatively, comparably to preservatives. Higher-educated respondents perceived new technologies more positively, which may result from their greater awareness and knowledge of food preservation. In the evaluation of the preferences for alternative methods to microwave treatment, the respondents rated “dielectric heating” as the best compared to the alternative “waves” methods. Consumers, despite their interest in new methods of food processing and preservation, are still distrustful of new technologies and worry about food safety. Increasing efforts regarding education about these technologies should result in their acceptance. Moreover, future research could be conducted to investigate, what, apart from the name of the preservation technology, would convince the consumers to increase their preferences for novel food preservation technologies. The authors, despite their best efforts, have not managed to eliminate all the factors that limit the generalization of the obtained conclusions. The study was done both online and on paper, which made it possible to reach people who do not use the Inter-net less or at all, in addition, the data was also collected in rural areas, however, it does not allow to indicate that the sample is representative. The study focuses on the general assessment of individual methods and the identification of indirect factors, such as education or the main area of residence, without referring to the immediate reasons that may determine individual preferences. Understanding the motives is an important next step in understanding consumer behaviour and how to form their attitudes.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/foods11091349/s1, Table S1: Post hoc comparisons—methods; Table S2: Post hoc comparisons—in-store behaviour ∗ methods; Table S3: Post hoc comparisons—education level ∗ Methods.

Author Contributions

P.G.: Investigation, Resources, Writing—original draft. A.S.; Methodology, Supervision, Formal analysis, Writing—review and editing. P.K.; Project administration, Supervision, Writing—original draft, Writing—review and editing; M.Z.: Supervision, Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by of the National Centre for Research and Development in Poland under the “Szybka Ścieżka” program No. POIR.01.01.01–00–1438/15, “Innovative Technology for Pasteurization of Food Products Using Microwaves also in a Modified Atmosphere”, in cooperation with the Weindich Sp. J. company.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Committee of Ethical Science Research conducted with participation of humans at Poznań University of Economics and Business (Decision no. 5/2022 24 March 2022).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data is contained within the article or supplementary material.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- European Parliament and Council. EC, No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Eur. Commision 2011, 20, 168–213. [Google Scholar]

- Mulders, M.D.; Corneille, O.; Klein, O. Label reading, numeracy and food & nutrition involvement. Appetite 2018, 128, 214–222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- New, C.; Thung, T.; Premarathne, J.; Russly, A.; Abdulkarim, S.; Son, R. Microwave oven safety: A food safety consumer survey in Malaysia. Food Control 2017, 80, 420–427. [Google Scholar] [CrossRef]

- Hieke, S.; Newman, C.L. The Effects of Nutrition Label Comparison Baselines on Consumers’ Food Choices. J. Consum. Aff. 2015, 49, 613–626. [Google Scholar] [CrossRef]

- Masoodi, N.; Mubarak, H. Nutritional knowledge and consumers use and understanding of food labels. Int. J. Physiol. Nutr. Phys. Educ. 2019, 4, 1371–1376. [Google Scholar]

- Nuttavuthisit, K.; Thøgersen, J. The Importance of Consumer Trust for the Emergence of a Market for Green Products: The Case of Organic Food. J. Bus. Ethics 2017, 140, 323–337. [Google Scholar] [CrossRef]

- Szymkowiak, A.; Guzik, P.; Kulawik, P.; Zając, M. Attitude-behaviour dissonance regarding the importance of food preservation for customers. Food Qual. Pref. 2020, 84, 103935. [Google Scholar] [CrossRef]

- Ricci, E.C.; Banterle, A.; Stranieri, S. Trust to Go Green: An Exploration of Consumer Intentions for Eco-friendly Con-venience Food. Ecol. Econ. 2018, 148, 54–65. [Google Scholar] [CrossRef] [Green Version]

- Kulshreshtha, K.; Bajpai, N.; Tripathi, V.; Sharma, G. Consumer preference for eco-friendly appliances in trade-off: A conjoint analysis approach. Interna-tional. J. Prod. Dev. 2019, 23, 212–243. [Google Scholar] [CrossRef]

- Román, S.; Sánchez-Siles, L.M.; Siegrist, M. The importance of food naturalness for consumers: Results of a systematic review. Trends Food Sci. Technol. 2017, 67, 44–57. [Google Scholar] [CrossRef]

- Guerrero, L.; Claret, A.; Verbeke, W.; Sulmont-Rossé, C.; Hersleth, M. Innovation in Traditional Food Products: Does It Make Sense? In Innovation Strategies in the Food Industry: Tools for Implementation; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 77–89. [Google Scholar]

- Deliza, R.; Ares, G. Consumer Perception of Novel Technologies. In Fruit Preservation; Springer: New York, NY, USA, 2018; pp. 1–20. [Google Scholar]

- Giordano, S.; Clodoveo, M.L.; De Gennaro, B.; Corbo, F. Factors determining neophobia and neophilia with regard to new technologies applied to the food sector: A systematic review. Int. J. Gastron. Food Sci. 2018, 11, 1–19. [Google Scholar] [CrossRef]

- Schnettler, B.; Miranda-Zapata, E.; Miranda, H.; Velásquez, C.; Orellana, L.; Sepúlveda, J.; Lobos, G.; Sánchez, M.; Grunert, K.G. Psychometric analysis of the Food Technology Neophobia Scale in a Chilean sample. Food Qual. Prefer. 2016, 49, 176–182. [Google Scholar] [CrossRef]

- McKenzie, K.; Metcalf, D.A.; Saliba, A. Validation of the Food Technology Neophobia Scale in a Chinese sample using exploratory and confirmatory factor analysis. Food Qual. Prefer. 2021, 89, 104148. [Google Scholar] [CrossRef]

- Siegrist, M.; Hartmann, C. Consumer acceptance of novel food technologies. Nat. Food 2020, 1, 343–350. [Google Scholar] [CrossRef]

- Dickson-Spillmann, M.; Siegrist, M.; Keller, C. Attitudes toward chemicals are associated with preference for natural food. Food Qual. Prefer. 2011, 22, 149–156. [Google Scholar] [CrossRef]

- Meijer, G.W.; Lähteenmäki, L.; Stadler, R.H.; Weiss, J. Issues surrounding consumer trust and acceptance of existing and emerging food processing technologies. Crit. Rev. Food Sci. Nutr. 2021, 61, 97–115. [Google Scholar] [CrossRef]

- Cattaneo, C.; Lavelli, V.; Proserpio, C.; Laureati, M.; Pagliarini, E. Consumers’ attitude towards food by-products: The influence of food technology neophobia, education and information. Int. J. Food Sci. Technol. 2018, 54, 679–687. [Google Scholar] [CrossRef]

- Khouryieh, H.A. Novel and emerging technologies used by the U.S. food processing industry. Innov. Food Sci. Emerg. Technol. 2020, 67, 102559. [Google Scholar] [CrossRef]

- Zhang, L.; Lan, R.; Zhang, B.; Erdogdu, F.; Wang, S. A comprehensive review on recent developments of radio frequency treatment for pasteurizing agricultural products. Crit. Rev. Food Sci. Nutr. 2021, 61, 380–394. [Google Scholar] [CrossRef]

- Vidigal, M.C.; Minim, V.P.; Simiqueli, A.A.; Souza, P.H.; Balbino, D.F.; Minim, L.A. Food technology neophobia and consumer attitudes toward foods produced by new and conventional technologies: A case study in Brazil. LWT 2015, 60, 832–840. [Google Scholar] [CrossRef] [Green Version]

- Roobab, U.; Aadil, R.M.; Madni, G.M.; Bekhit, A.E.-D. The Impact of Nonthermal Technologies on the Microbiological Quality of Juices: A Review. Compr. Rev. Food Sci. Food Saf. 2018, 17, 437–457. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.; Vicente, A. Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res. Int. 2010, 43, 1936–1943. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.-H.; Wang, L.-H.; Zeng, X.-A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zia, S.; Khan, M.R.; Zeng, X.; Sehrish; Shabbir, M.A.; Aadil, R.M. Combined effect of microwave and ultrasonication treatments on the quality and stability of sugarcane juice during cold storage. Int. J. Food Sci. Technol. 2019, 54, 2563–2569. [Google Scholar] [CrossRef]

- Gulzar, N.; Sameen, A.; Aadill, R.M.; Sahar, A.; Rafiq, S.; Huma, N.; Nadeem, M.; Arshad, R.; Saleem, I.M. Descriptive Sensory Analysis of Pizza Cheese Made from Mozzarella and Semi-Ripened Cheddar Cheese Under Microwave and Conventional Cooking. Foods 2020, 9, 214. [Google Scholar] [CrossRef] [Green Version]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Guzik, P.; Kulawik, P.; Zając, M.; Migdał, W. Microwave applications in the food industry: An overview of recent developments. Crit. Rev. Food Sci. Nutr. 2021, 1–20. [Google Scholar] [CrossRef]

- Meda, V.; Orsat, V.; Raghavan, V. Microwave heating and the dielectric properties of foods. In The Microwave Processing of Foods; Elsevier: New York, NY, USA, 2017; pp. 23–43. [Google Scholar] [CrossRef]

- Kim, J.; Mun, S.C.; Ko, H.-U.; Kim, K.-B.; Khondoker, M.A.H.; Zhai, L. Review of microwave assisted manufacturing technologies. Int. J. Precis. Eng. Manuf. 2012, 13, 2263–2272. [Google Scholar] [CrossRef]

- Khan, M.R.; Syed, A.; Zia, S.; Ahmed, W.; Aadil, R.M.; Manzoor, M.F.; Inam-Ur-Raheem, M.; Abid, M.; Shabbir, M.A.; Qureshi, S.; et al. Stabilization and attributive amelioration of sugarcane juice by naturally derived preservatives using aonla and moringa extract. Food Sci. Nutr. 2021, 9, 3048–3058. [Google Scholar] [CrossRef]

- Riaz, A.; Aadil, R.M.; Amoussa, A.M.O.; Bashari, M.; Abid, M.; Hashim, M.M. Application of chitosan-based apple peel polyphenols edible coating on the preservation of.strawberry (Fragaria ananassa cv Hongyan) fruit. J. Food Process. Preserv. 2021, 45, e15018. [Google Scholar] [CrossRef]

- Kulawik, P.; Jamróz, E.; Janik, M.; Tkaczewska, J.; Krzyściak, P.; Skóra, M.; Guzik, P.; Milosavljević, V.; Tadele, W. Biological activity of biopolymer edible furcellaran-chitosan coatings enhanced with bioactive peptides. Food Control 2022, 137, 108933. [Google Scholar] [CrossRef]

- Kulawik, P.; Jamróz, E.; Zając, M.; Guzik, P.; Tkaczewska, J. The effect of furcellaran-gelatin edible coatings with green and pu-erh tea extracts on the microbiological, physicochemical and sensory changes of salmon sushi stored at 4 °C. Food Control 2019, 100, 83–91. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. Wholesomeness and safety aspects of irradiated foods. Food Chem. 2019, 285, 363–368. [Google Scholar] [CrossRef] [PubMed]

- Bisht, B.; Bhatnagar, P.; Gururani, P.; Kumar, V.; Tomar, M.S.; Sinhmar, R.; Rathi, N.; Kumar, S. Food irradiation: Effect of ionizing and non-ionizing radiations on preservation of fruits and vegetables– A review. Trends Food Sci. Technol. 2021, 114, 372–385. [Google Scholar] [CrossRef]

- Bevelacqua, J.J.; Mortazavi, S.J. Can irradiated food have an influence on people’s health? In Genetically Modified and Irradiated Food–Controversial Issues: Facts Versus Perceptions, 1st ed.; Andersen, V., Ed.; Elsevier: New York, NY, USA, 2020; pp. 243–257. [Google Scholar]

- Fellows, P.J. Food Processing Technology: Principles and Practice, 3rd ed.; Woodhead: Cambridge, UK, 2009. [Google Scholar]

- Huang, H.-W.; Hsu, C.-P.; Wang, C.-Y. Healthy expectations of high hydrostatic pressure treatment in food processing industry. J. Food Drug Anal. 2020, 28, 1–13. [Google Scholar] [CrossRef]

- Opara, U.L.; Caleb, O.J.; Belay, Z.A. Modified atmosphere packaging for food preservation. In Food Quality and Shelf Life; Elsevier: Amsterdam, The Netherlands, 2019; pp. 235–259. [Google Scholar]

- Zhang, M.; Meng, X.; Bhandari, B.; Fang, Z.; Chen, H. Recent Application of Modified Atmosphere Packaging (MAP) in Fresh and Fresh-Cut Foods. Food Rev. Int. 2015, 31, 172–193. [Google Scholar] [CrossRef]

- Moreira, M.J.; García-Díez, J.; De Almeida, J.M.M.M.; Saraiva, C. Evaluation of food labelling usefulness for consumers. Int. J. Consum. Stud. 2019, 43, 327–334. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Medina-Meza, I.; Candoğan, K.; Bermúdez-Aguirre, D. Advanced retorting, microwave assisted thermal sterilization (MATS), and pressure assisted thermal sterilization (PATS) to process meat products. Meat Sci. 2014, 98, 420–434. [Google Scholar] [CrossRef]

- Zhu, M.-M.; Peng, Z.-Y.; Lu, S.; He, H.-J.; Kang, Z.-L.; Ma, H.-J.; Zhao, S.-M.; Wang, Z.-R. Physicochemical Properties and Protein Denaturation of Pork Longissimus Dorsi Muscle Subjected to Six Microwave-Based Thawing Methods. Foods 2019, 9, 26. [Google Scholar] [CrossRef] [Green Version]

- Heinz, V.; Buckow, R. Food preservation by high pressure. J. Consum. Prot. Food Saf. 2010, 5, 73–81. [Google Scholar] [CrossRef]

- Syed, Q.A.; Buffa, M.; Guamis, B.; Saldo, J. Factors Affecting Bacterial Inactivation during High Hydrostatic Pressure Processing of Foods: A Review. Crit. Rev. Food Sci. Nutr. 2015, 56, 474–483. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-Y.; Huang, H.-W.; Hsu, C.-P.; Yang, B.B. Recent Advances in Food Processing Using High Hydrostatic Pressure Technology. Crit. Rev. Food Sci. Nutr. 2016, 56, 527–540. [Google Scholar] [CrossRef] [PubMed]

- Belay, Z.; Caleb, O.J.; Opara, U.L. Modelling approaches for designing and evaluating the performance of modified atmosphere packaging (MAP) systems for fresh produce: A review. Food Packag. Shelf Life 2016, 10, 1–15. [Google Scholar] [CrossRef]

- Oliveira, M.; Abadias, M.; Usall, J.; Torres, R.; Teixidó, N.; Viñas, I. Application of modified atmosphere packaging as a safety approach to fresh-cut fruits and vegetables—A review. Trends Food Sci. Technol. 2015, 46, 13–26. [Google Scholar] [CrossRef]

- Bornhorst, E.R.; Tang, J.; Sablani, S.S.; Barbosa-Cánovas, G.V. Thermal pasteurization process evaluation using mashed potato model food with Maillard reaction products. LWT 2017, 82, 454–463. [Google Scholar] [CrossRef]

- Wang, H.; Tan, S.; Xu, X.; Zhao, L.; Zhang, J.; Yao, B.; Gao, Y.; Zhou, H.; Peng, R. Long term impairment of cognitive functions and alterations of NMDAR subunits after continuous microwave exposure. Physiol. Behav. 2017, 181, 1–9. [Google Scholar] [CrossRef]

- Ekezie, F.-G.C.; Sun, D.-W.; Han, Z.; Cheng, J.-H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Technol. 2017, 67, 58–69. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, M.; Bhandari, B. Recent development in the application of alternative sterilization technologies to prepared dishes: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1188–1196. [Google Scholar] [CrossRef]

- Roberts, P.B. Food irradiation: Standards, regulations and world-wide trade. Radiat. Phys. Chem. 2016, 129, 30–34. [Google Scholar] [CrossRef]

- Feng, X.; Jo, C.; Nam, K.C.; Ahn, D.U. Effect of irradiation on the parameters that influence quality characteristics of raw beef round eye. Innov. Food Sci. Emerg. Technol. 2018, 45, 115–121. [Google Scholar] [CrossRef]

- Asioli, D.; Rocha, C.; Wongprawmas, R.; Popa, M.; Gogus, F.; Almli, V. Microwave-dried or air-dried? Consumers’ stated preferences and attitudes for organic dried strawberries. A multi-country investigation in Europe. Food Res. Int. 2018, 120, 763–775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pérez, M.; López-Yerena, A.; Lozano-Castellón, J.; Olmo-Cunillera, A.; Lamuela-Raventós, R.M.; Martin-Belloso, O.; Vallverdú-Queralt, A. Impact of Novel Technologies on Virgin Olive Oil Processing, Consumer Acceptance, and the Valorization of Olive Mill Wastes. Antioxidants 2021, 10, 417. [Google Scholar] [CrossRef] [PubMed]

- Kilic, B.; Dudinskaya, E.C.; Proi, M.; Naspetti, S.; Zanoli, R. Are They Careful Enough? Testing Consumers’ Perception of Alternative Processing Technologies on the Quality of Organic Food. Nutrients 2021, 13, 2922. [Google Scholar] [CrossRef]

- Bryant, C.J.; Barnett, J.C. What’s in a name? Consumer perceptions of in vitro meat under different names. Appetite 2019, 137, 104–113. [Google Scholar] [CrossRef] [PubMed]

- Bearth, A.; Siegrist, M. “As long as it is not irradiated”–Influencing factors of US consumers’ acceptance of food irradiation. Food Qual. Prefer. 2019, 71, 141–148. [Google Scholar] [CrossRef]

- Bryła, P. Who Reads Food Labels? Selected Predictors of Consumer Interest in Front-of-Package and Back-of-Package Labels during and after the Purchase. Nutrients 2020, 12, 2605. [Google Scholar] [CrossRef]

- Frewer, L.J.; van der Lans, I.A.; Fischer, A.R.; Reinders, M.J.; Menozzi, D.; Zhang, X.; Berg, I.V.D.; Zimmermann, K.L. Public perceptions of agri-food applications of genetic modification–A systematic review and meta-analysis. Trends Food Sci. Technol. 2013, 30, 142–152. [Google Scholar] [CrossRef]

- Olsen, N.V.; Grunert, K.G.; Sonne, A.-M. Consumer acceptance of high-pressure processing and pulsed-electric field: A review. Trends Food Sci. Technol. 2010, 21, 464–472. [Google Scholar] [CrossRef]

- Tuorila, H.; Hartmann, C. Consumer responses to novel and unfamiliar foods. Curr. Opin. Food Sci. 2020, 33, 1–8. [Google Scholar] [CrossRef]

- Martins, I.B.A.; Oliveira, D.; Rosenthal, A.; Ares, G.; Deliza, R. Brazilian consumer’s perception of food processing technologies: A case study with fruit juice. Food Res. Int. 2019, 125, 108555. [Google Scholar] [CrossRef]

- Perito, M.; Chiodo, E.; Serio, A.; Paparella, A.; Fantini, A. Factors Influencing Consumers’ Attitude Towards Biopreservatives. Sustainability 2020, 12, 10338. [Google Scholar] [CrossRef]

- Lee, P.Y.; Kebede, B.T.; Lusk, K.; Mirosa, M.; Oey, I. Investigating consumers’ perception of apple juice as affected by novel and conventional processing technologies. Int. J. Food Sci. Technol. 2017, 52, 2564–2571. [Google Scholar] [CrossRef]

- Ortiz, A.; Tejerina, D.; Díaz-Caro, C.; Elghannam, A.; García-Torres, S.; Mesías, F.J.; Trujillo, J.; Crespo-Cebada, E. Is packaging affecting consumers’ preferences for meat products? A study of modified atmosphere packaging and vacuum packaging in Iberian dry-cured ham. J. Sens. Stud. 2020, 35, 1–11. [Google Scholar] [CrossRef]

- Dominick, S.R.; Fullerton, C.; Widmar, N.J.O.; Wang, H. Consumer Associations with the “All Natural” Food Label. J. Food Prod. Mark. 2017, 24, 249–262. [Google Scholar] [CrossRef]

- Pan, W.; Liu, D.; Fang, J. An Examination of Factors Contributing to the Acceptance of Online Health Misinformation. Front. Psychol. 2021, 12, 630268. [Google Scholar] [CrossRef] [PubMed]

- Guzik, P.; Szymkowiak, A.; Kulawik, P.; Zając, M.; Migdał, W. The confrontation of consumer beliefs about the impact of microwave-processing on food and human health with existing research. Trends Food Sci. Technol. 2021, 119, 110–121. [Google Scholar] [CrossRef]

- Wolfson, J.A.; Bleich, S.N.; Smith, K.C.; Frattaroli, S. What does cooking mean to you?: Perceptions of cooking and factors related to cooking behavior. Appetite 2016, 97, 146–154. [Google Scholar] [CrossRef]

- Galati, A.; Moavero, P.; Crescimanno, M. Consumer awareness and acceptance of irradiated foods: The case of Italian consumers. Br. Food J. 2019, 121, 1398–1412. [Google Scholar] [CrossRef]

- Pedreschi, F.; Mariotti-Celis, M.S. Irradiation kills microbes. In Genetically Modified and Irradiated Food; Elsevier: Amsterdam, The Netherlands, 2020; pp. 233–242. ISBN 978-0-12-817240-7. [Google Scholar]

- Popek, S.; Halagarda, M. Genetically modified foods: Consumer awareness, opinions and attitudes in selected EU countries. Int. J. Consum. Stud. 2017, 41, 325–332. [Google Scholar] [CrossRef]

- Moreb, N.A.; Priyadarshini, A.; Jaiswal, A.K. Knowledge of food safety and food handling practices amongst food handlers in the Republic of Ireland. Food Control. 2017, 80, 341–349. [Google Scholar] [CrossRef] [Green Version]

- Diplock, K.J.; Jones-Bitton, A.; Leatherdale, S.T.; Rebellato, S.; Hammond, D.; Majowicz, S.E. Food Safety Education Needs of High-School Students: Leftovers, Lunches, and Microwaves. J. Sch. Health 2019, 89, 578–586. [Google Scholar] [CrossRef] [PubMed]

- Verbeke, W.; Sans, P.; Van Loo, E.J. Challenges and prospects for consumer acceptance of cultured meat. J. Integr. Agric. 2015, 14, 285–294. [Google Scholar] [CrossRef]

- Kumari, P.K.; Akhila, S.; Rao, Y.S.; Devi, B.R. Alternative to Artificial Preservatives. Syst. Rev. Pharm. 2019, 10, 99–102. [Google Scholar]

- Hussain, M.A.; Sumon, T.A.; Mazumder, S.K.; Ali, M.M.; Jang, W.J.; Abualreesh, M.H.; Sharifuzzaman, S.M.; Brown, C.L.; Lee, H.T.; Lee, E.W.; et al. Essential oils and chitosan as alternatives to chemical preservatives for fish and fisheries products: A review. Food Control. 2021, 129, 108244. [Google Scholar] [CrossRef]

- Dwivedi, S.; Prajapati, P.; Vyas, N.; Malviya, S.; Kharia, A. A Review on Food Preservation: Methods, harmful effects and better alternatives. Asian J. Pharm. Pharmacol. 2017, 3, 193–199. [Google Scholar]

- Appleton, T.; Colder, R.; Kingman, S.; Lowndes, I.; Read, A. Microwave technology for energy-efficient processing of waste. Appl. Energy 2005, 81, 85–113. [Google Scholar] [CrossRef]

- Hao, Y.-H.; Zhao, L.; Peng, R.-Y. Effects of microwave radiation on brain energy metabolism and related mechanisms. Mil. Med Res. 2015, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Junqueira-Gonçalves, M.P.; Galotto, M.J.; Valenzuela, X.; Dinten, C.M.; Aguirre, P.; Miltz, J. Perception and view of consumers on food irradiation and the Radura symbol. Radiat. Phys. Chem. 2011, 80, 119–122. [Google Scholar] [CrossRef]

- Schwarz, N. Feelings as information: Informational and motivational functions of affective states. In Handbook of Motivation and Cognition: Foundations of Social Behavior; Hig-gins, E.T., Sorrentino, R.M., Eds.; The Guilford Press: New York, NY, USA, 1990; Volume 2. [Google Scholar]

- Schwarz, N. Feelings-as-Information Theory. In Handbook of Theories of Social Psychology Van Lange PAM; Kruglanski, A.W., Higgins, E.T., Eds.; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2012; pp. 289–308. [Google Scholar]

- Winkielman, P.; Schwarz, N.; Fazendeiro, T.; Reber, R. The Hedonic Marking of Processing Fluency: Implications for Evaluative Judgment. The Psychology of Evaluation: Affective Processes in Cognition and Emotion; Lawrence Erlbaum: Mahwah, NJ, USA, 2003; pp. 189–217. [Google Scholar]

- Schwarz, N.; Bless, H.; Strack, F.; Klumpp, G.; Rittenauer-Schatka, H.; Simons, A. Ease of retrieval as information: Another look at the availability heuristic. J. Personal. Soc. Psychol. 1991, 61, 95. [Google Scholar] [CrossRef]

- Schwarz, N. Metacognitive Experiences in Consumer Judgment and Decision Making. J. Consum. Psychol. 2004, 14, 332–348. [Google Scholar] [CrossRef] [Green Version]

- Schwarz, N.; Sanna, L.J.; Skurnik, I.; Yoon, C. Metacognitive Experiences and the Intricacies of Setting People Straight: Implications for Debiasing and Public Information Campaigns. Adv. Exp. Soc. Psychol. 2007, 39, 127–161. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).