Effect of Resistant Starch Sources on the Physical Properties of Dough and on the Eating Quality and Glycemic Index of Salted Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Flour Formulation

2.1.1. Green Banana Flour (GBF)

2.1.2. Heat Moisture Treatment Corn Starch (HMT-CS)

2.1.3. High-Amylose Corn Starch (Hylon VII)

2.2. Proximate Analyses

2.3. Preparation of Salted Noodles

2.4. Dough Characteristics

2.5. Salted Noodles Evaluation

2.5.1. Physical Properties

2.5.2. Texture Profile Analysis

2.5.3. Sensory Evaluation

2.6. Total Starch and Resistant Starch

2.7. In Vitro Starch Digestibility and Estimated Glycemic Index

2.8. Statistical Analysis

3. Results and Discussion

3.1. Farinograph Characteristics

3.2. Extensograph Measurements

3.3. Proximate Compositions, Total Starch Content, and Resistant Starch Content of Cooked Salted Noodles

3.4. Texture Profile Analyses

3.5. Cooking Quality of Salted Noodles

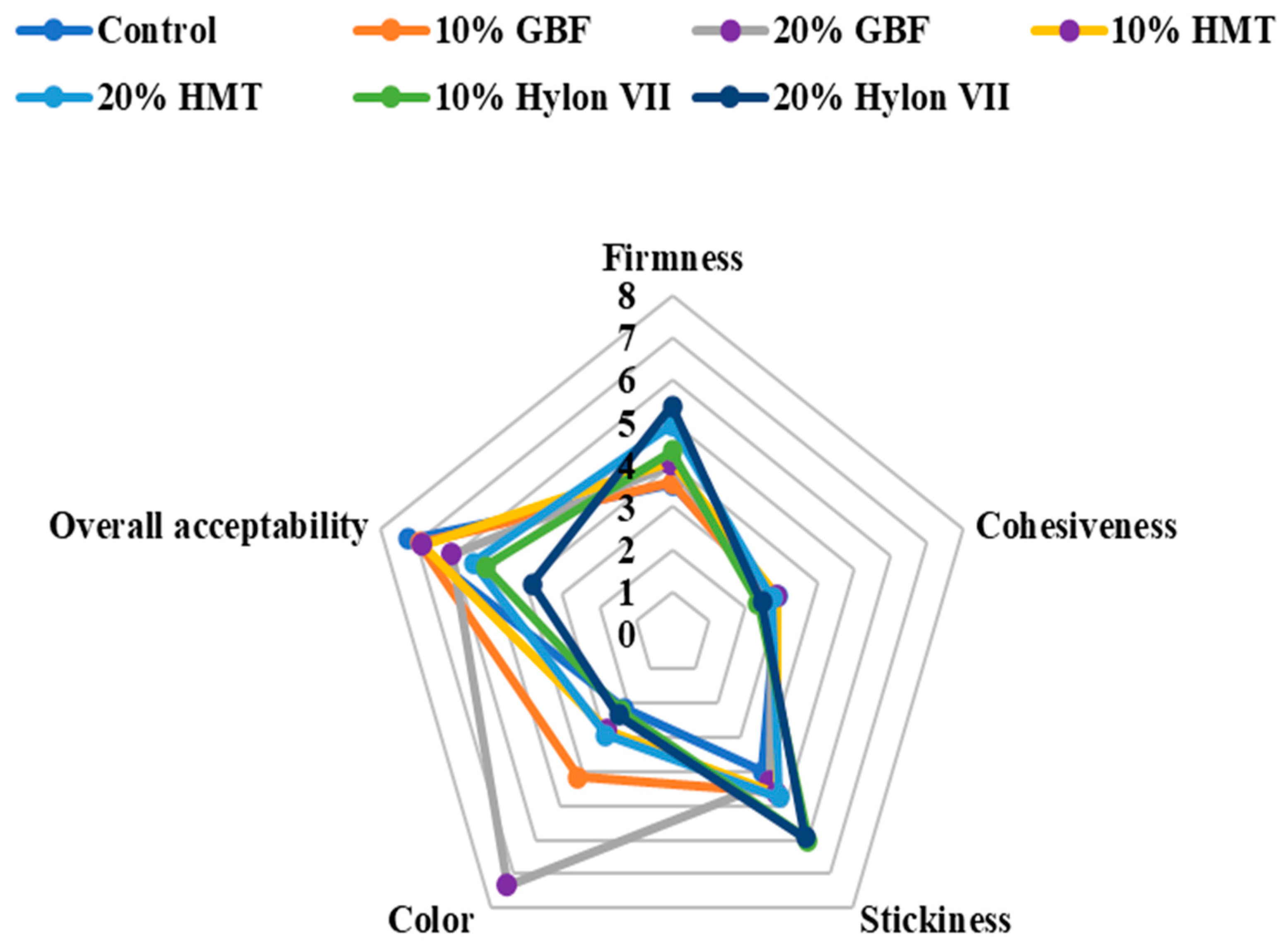

3.6. Sensory Evaluation

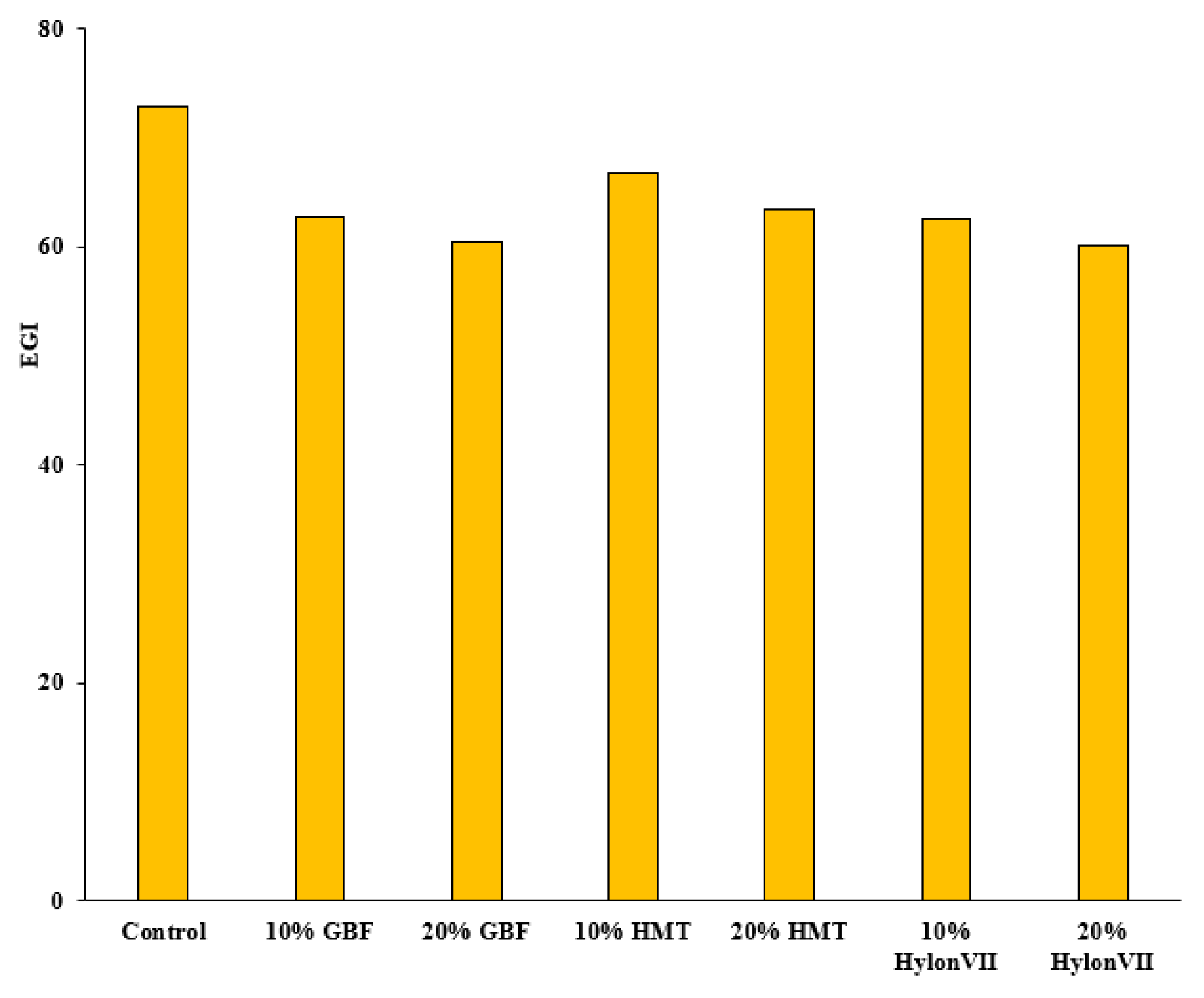

3.7. In Vitro Starch Digestibility and Estimated Glycemic Index

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Meng, S.; Chen, D.; Zhu, X.; Yuan, H. Structure characterization and hypoglycemic effects of dual modified resistant starch from indica rice starch. Carbohydr. Polym. 2014, 103, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Sivaprakasam, S.; Bhutia, Y.D.; Yang, S.; Ganapathy, V. Short-Chain Fatty Acid Transporters: Role in Colonic Homeostasis. Compr. Physiol. 2017, 8, 299–314. [Google Scholar] [PubMed]

- Raigond, P.; Ezekiel, R.; Raigond, B. Resistant starch in food: A review. J. Sci. Food Agric. 2015, 95, 1968–1978. [Google Scholar] [CrossRef] [PubMed]

- Birt, D.F.; Boylston, T.; Hendrich, S.; Jane, J.-L.; Hollis, J.; Li, L.; McClelland, J.; Moore, S.; Phillips, G.J.; Rowling, M. Resistant starch: Promise for improving human health. Adv. Nutr. 2013, 4, 587–601. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Beta, T.; Corke, H. Effects of salt and alkaline reagents on dynamic rheological properties of raw oriental wheat noodles. Cereal Chem. 2006, 83, 211–217. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B. Effect of compositional variation of gluten proteins and rheological characteristics of wheat flour on the textural quality of white salted noodles. Int. J. Food Prop. 2014, 17, 731–740. [Google Scholar] [CrossRef]

- Raungrusmee, S.; Shrestha, S.; Sadiq, M.B.; Anal, A.K. Influence of resistant starch, xanthan gum, inulin and defatted rice bran on the physicochemical, functional and sensory properties of low glycemic gluten-free noodles. LWT 2020, 126, 109279. [Google Scholar] [CrossRef]

- Yang, J.; Bi, Y.; Liang, S.; Gu, Z.; Cheng, L.; Li, C.; Li, Z.; Zhang, Y.; Hong, Y. The in vivo digestibility study of banana flour with high content of resistant starch at different ripening stages. Food Funct. 2020, 11, 10945–10953. [Google Scholar] [CrossRef]

- Tribess, T.; Hernández-Uribe, J.; Méndez-Montealvo, M.; Menezes, E.; Bello-Perez, L.A.; Tadini, C. Thermal properties and resistant starch content of green banana flour (Musa cavendishii) produced at different drying conditions. LWT-Food Sci. Technol. 2009, 42, 1022–1025. [Google Scholar] [CrossRef]

- da Mota, R.V.; Lajolo, F.M.; Cordenunsi, B.R.; Ciacco, C. Composition and functional properties of banana flour from different varieties. Starch-Stärke 2000, 52, 63–68. [Google Scholar] [CrossRef]

- Aurore, G.; Parfait, B.; Fahrasmane, L. Bananas, raw materials for making processed food products. Trends Food Sci. Technol. 2009, 20, 78–91. [Google Scholar] [CrossRef]

- Le Leu, R.K.; Hu, Y.; Brown, I.L.; Woodman, R.J.; Young, G.P. Synbiotic intervention of Bifidobacterium lactis and resistant starch protects against colorectal cancer development in rats. Carcinogenesis 2010, 31, 246–251. [Google Scholar] [CrossRef] [PubMed]

- Chatpapamon, C.; Wandee, Y.; Uttapap, D.; Puttanlek, C.; Rungsardthong, V. Pasting properties of cassava starch modified by heat-moisture treatment under acidic and alkaline pH environments. Carbohydr. Polym. 2019, 215, 338–347. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Effect of heat-moisture treatment on the in vitro digestibility and physicochemical properties of starch-hydrocolloid complexes. Food Hydrocoll. 2020, 104, 105736. [Google Scholar] [CrossRef]

- Yan, X.; Wu, Z.-Z.; Li, M.-Y.; Yin, F.; Ren, K.-X.; Tao, H. The combined effects of extrusion and heat-moisture treatment on the physicochemical properties and digestibility of corn starch. Int. J. Biol. Macromol. 2019, 134, 1108–1112. [Google Scholar] [CrossRef]

- Ji, Y.; Yu, J. In vitro digestion and physicochemical characteristics of corn starch mixed with amino acid modified by heat-moisture treatment. Food Hydrocoll. 2018, 77, 720–725. [Google Scholar] [CrossRef]

- Li, P.-H.; Huang, C.-C.; Yang, M.-Y.; Wang, C.-C.R. Textural and sensory properties of salted noodles containing purple yam flour. Food Res. Int. 2012, 47, 223–228. [Google Scholar] [CrossRef]

- Huang, D.-W.; Chan, Y.-J.; Huang, Y.-C.; Chang, Y.-J.; Tsai, J.-C.; Mulio, A.T.; Wu, Z.-R.; Hou, Y.-W.; Lu, W.-C.; Li, P.-H. Quality Evaluation, Storage Stability, and Sensory Characteristics of Wheat Noodles Incorporated with Isomaltodextrin. Plants 2021, 10, 578. [Google Scholar] [CrossRef]

- Reshmi, S.; Sudha, M.; Shashirekha, M. Noodles fortified with Citrus maxima (pomelo) fruit segments suiting the diabetic population. Bioact. Carbohydr. Diet. Fibre 2020, 22, 100213. [Google Scholar] [CrossRef]

- Miś, A.; Nawrocka, A.; Dziki, D. Behaviour of dietary fibre supplements during bread dough development evaluated using novel farinograph curve analysis. Food Bioprocess Technol. 2017, 10, 1031–1041. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Xia, M.; Li, Z.; Wang, M.; Wang, P.; Yang, P.; Gao, X.; Gao, J. Common buckwheat-resistant starch as a suitable raw material for food production: A structural and physicochemical investigation. Int. J. Biol. Macromol. 2020, 145, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.; Gani, A.; Jhan, F.; Jenno, J.L.H.; Arif Dar, M. Resistant starch type 2 from lotus stem: Ultrasonic effect on physical and nutraceutical properties. Ultrason. Sonochem. 2021, 76, 105655. [Google Scholar] [CrossRef] [PubMed]

- Sui, W.; Xie, X.; Liu, R.; Wu, T.; Zhang, M. Effect of wheat bran modification by steam explosion on structural characteristics and rheological properties of wheat flour dough. Food Hydrocoll. 2018, 84, 571–580. [Google Scholar] [CrossRef]

- Pu, H.; Wei, J.; Wang, L.; Huang, J.; Chen, X.; Luo, C.; Liu, S.; Zhang, H. Effects of potato/wheat flours ratio on mixing properties of dough and quality of noodles. J. Cereal Sci. 2017, 76, 236–242. [Google Scholar] [CrossRef]

- Senthil, A.; Ravi, R.; Bhat, K.K.; Seethalakshmi, M.K. Studies on the quality of fried snacks based on blends of wheat flour and soy flour. Food Qual. Prefer. 2002, 13, 267–273. [Google Scholar] [CrossRef]

- Sudha, M.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Sudha, M.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Sabanis, D.; Makri, E.; Doxastakis, G. Effect of durum flour enrichment with chickpea flour on the characteristics of dough and lasagne. J. Sci. Food Agric. 2006, 86, 1938–1944. [Google Scholar] [CrossRef]

- Li, S.; Ward, R.; Gao, Q. Effect of heat-moisture treatment on the formation and physicochemical properties of resistant starch from mung bean (Phaseolus radiatus) starch. Food Hydrocoll. 2011, 25, 1702–1709. [Google Scholar] [CrossRef]

- Chang, H.; Wu, L.C. Texture and quality properties of Chinese fresh egg noodles formulated with green seaweed (Monostroma nitidum) powder. J. Food Sci. 2008, 73, S398–S404. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The impact of resistant starch on gluten-free dough and bread. Food Hydrocoll. 2009, 23, 988–995. [Google Scholar] [CrossRef]

- Saifullah, R.; Abbas, F.; Yeoh, S.; Azhar, M. Utilization of green banana flour as a functional ingredient in yellow noodle. Int. Food Res. J. 2009, 16, 373–379. [Google Scholar]

- Kumar, P.S.; Saravanan, A.; Sheeba, N.; Uma, S. Structural, functional characterization and physicochemical properties of green banana flour from dessert and plantain bananas (Musa spp.). LWT 2019, 116, 108524. [Google Scholar] [CrossRef]

- Kumar, S.; Nambi, E.; Shiva, K.N.; Vaganan, M.; Ravi, I.; Jeyabaskaran, K.J.; Uma, S. Thin layer drying kinetics of Banana var. Monthan (ABB): Influence of convective drying on nutritional quality, microstructure, thermal properties, color, and sensory characteristics. J. Food Process Eng. 2019, 42, e13020. [Google Scholar] [CrossRef]

| Composite Flour (%) | Farinographic Dough Characteristics | |||||

|---|---|---|---|---|---|---|

| Water Absorption (%) | Dough Development Time (min) | Breakdown Time (min) | Stability (min) | Peak Time (min) | Mixing Tolerance Index (B.U.) | |

| Control | 65.6 d ± 0.1 | 1.8 c ± 0.3 | 23.2 a ± 0.2 | 21.0 a | 11.2 a | 20.0 g |

| 10% GBF | 66.2 c ± 0.1 | 1.6 b ± 0.1 | 16.4 b ± 0.2 | 16.0 b | 11.5 b | 25.0 f |

| 20% GBF | 66.4 c ± 0.1 | 1.5 b ± 0.2 | 13.6 c ± 0.5 | 6.5 d | 7.7 c | 45.5 c |

| 10% HMT | 67.8 b ± 0.1 | 1.6 a ± 0.1 | 12.1 d ± 0.0 | 15.0 b | 8.1 c | 32.0 e |

| 20% HMT | 67.6 b ± 0.1 | 1.6 ab ± 0.1 | 11.4 e ± 0.4 | 6.0 d | 4.3 d | 56.5 b |

| 10% Hylon | 68.5 a ± 0.1 | 1.6 ab ± 0.1 | 10.3 e ± 0.4 | 12.5 c | 3.1 d | 38.0 d |

| 20% Hylon | 69.2 a ± 0.1 | 1.5 ab ± 0.1 | 8.5 e ± 0.4 | 5.5 d | 1.6 e | 63.5 a |

| Composite Flour (%) | Extensographic Properties | |||||

|---|---|---|---|---|---|---|

| Maximum Resistance to Extension (BU) | Extensibility (cm) | |||||

| 45 (min) | 90 (min) | 135 (min) | 45 (min) | 90 (min) | 135 (min) | |

| Control | 58 e | 743 c | 733 e | 16.8 a | 13.4 a | 13.6 a |

| 10% GBF | 668 d | 808 c | 798 d | 14.1 b | 13.9 a | 12.8 b |

| 20% GBF | 696 d | 895 b | 847 c | 13.4 c | 12.1 b | 10.6 c |

| 10% HMT | 780 bc | 933 b | 959 b | 12.7 d | 10.8 c | 10.7 c |

| 20% HMT | 850 b | 960 b | >1000 a | 11.5 e | 10.1 c | 9.6 d |

| 10% Hylon | 830 b | >1000 a | 980 b | 11.8 e | 10.6 c | 9.5 d |

| 20% Hylon | 960 a | >1000 a | >1000 a | 9.2 f | 8.1 d | 7.9 e |

| Proximate Compositions | ||||||

|---|---|---|---|---|---|---|

| Types of Noodles | Protein | Fat | Ash | Crude Fiber | Total Starch | Resistant Starch |

| Control | 10.25 ab | 1.26 a | 1.98 b | 1.85 b | 65.8 c | 3.25 e |

| 10% GBF | 10.96 a | 1.21 a | 2.15 ab | 2.15 a | 65.3 c | 7.16 c |

| 20% GBF | 11.28 a | 1.13 bc | 2.31 a | 2.12 a | 63.5 d | 10.92 b |

| 10% HMT | 9.53 b | 1.18 ab | 2.05 b | 1.47 d | 67.0 b | 5.89 d |

| 20% HMT | 8.67 c | 1.06 c | 1.97 b | 1.42 d | 69.1 a | 7.27 c |

| 10% Hylon | 9.32 bc | 1.15 b | 1.93 b | 1.84 b | 67.2 b | 9.83 b |

| 20% Hylon | 8.76 c | 1.24 a | 2.01 b | 1.70 c | 68.5 a | 14.12 a |

| Texture Profile Analysis | ||||||

|---|---|---|---|---|---|---|

| Hardness (g × force) | Cohesiveness | Springiness | Gumminess (g × force) | Chewiness | Shearing Force (g × force) | |

| Control | 525 f | 0.62 a | 0.92 a | 325.5 f | 299.5 d | 170.2 f |

| 10% GBF | 627 e | 0.56 b | 0.93 a | 351.1 e | 326.5 c | 201.6 e |

| 20% GBF | 683 d | 0.58 b | 0.89 b | 396.1 d | 352.6 b | 239.7 d |

| 10% HMT | 612 e | 0.62 a | 0.87 b | 379.4 e | 330.1 c | 226.3 d |

| 20% HMT | 758 c | 0.56 b | 0.81 c | 424.5 c | 343.8 b | 269.5 c |

| 10% Hylon VII | 821 b | 0.57 b | 0.82 c | 468.0 b | 383.7 a | 287.2 b |

| 20% Hylon VII | 947 a | 0.57 b | 0.72 d | 539.8 a | 388.6 a | 374.5 a |

| Resistant Starch Source Flour (%) | Cooking Weight Gain (%) | Cooking Weight Loss (%) |

|---|---|---|

| 0% | 95.87 a | 1.77 b |

| 10% GBF | 92.51 a | 2.32 a |

| 20% GBF | 90.38 b | 2.51 a |

| 10% HMT | 95.14 a | 2.23 a |

| 20% HMT | 92.33 a | 2.57 a |

| 10% Hylon VII | 85.92 c | 2.21 a |

| 20% Hylon VII | 81.05 c | 2.38 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.-H.; Wang, C.-W.; Lu, W.-C.; Chan, Y.-J.; Wang, C.-C.R. Effect of Resistant Starch Sources on the Physical Properties of Dough and on the Eating Quality and Glycemic Index of Salted Noodles. Foods 2022, 11, 814. https://doi.org/10.3390/foods11060814

Li P-H, Wang C-W, Lu W-C, Chan Y-J, Wang C-CR. Effect of Resistant Starch Sources on the Physical Properties of Dough and on the Eating Quality and Glycemic Index of Salted Noodles. Foods. 2022; 11(6):814. https://doi.org/10.3390/foods11060814

Chicago/Turabian StyleLi, Po-Hsien, Chien-Wen Wang, Wen-Chien Lu, Yung-Jia Chan, and Chiun-Chuan Roger Wang. 2022. "Effect of Resistant Starch Sources on the Physical Properties of Dough and on the Eating Quality and Glycemic Index of Salted Noodles" Foods 11, no. 6: 814. https://doi.org/10.3390/foods11060814

APA StyleLi, P.-H., Wang, C.-W., Lu, W.-C., Chan, Y.-J., & Wang, C.-C. R. (2022). Effect of Resistant Starch Sources on the Physical Properties of Dough and on the Eating Quality and Glycemic Index of Salted Noodles. Foods, 11(6), 814. https://doi.org/10.3390/foods11060814