Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Drying Process

2.3. Mathematical Modelling

3. Quality Analysis

3.1. Measurement of Moisture Content (MC)

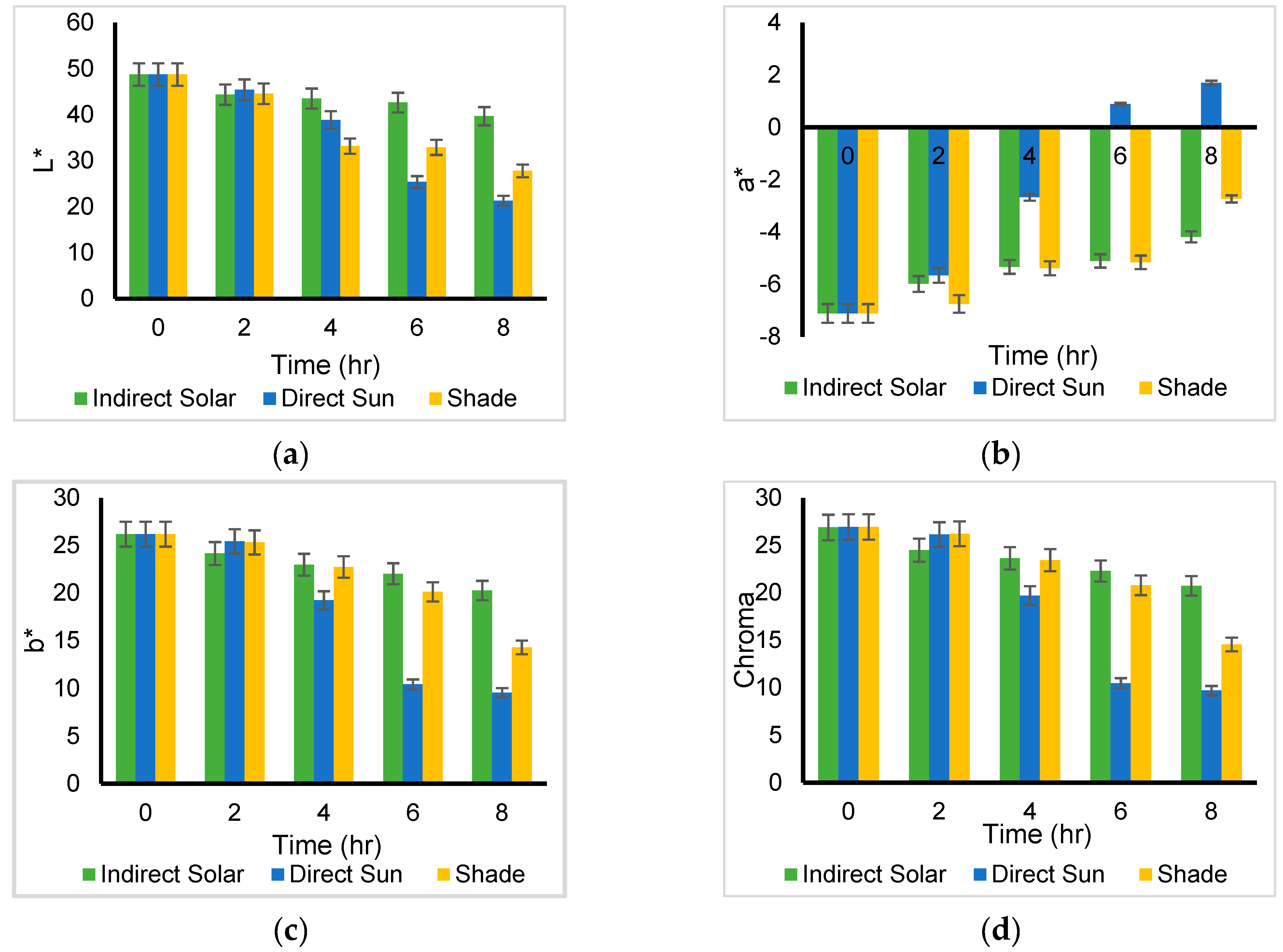

3.2. Color Measurements

3.3. Measurement of Water Activity (Aw)

3.4. Measurement of Total Phenol Content

3.5. Measurement of Antioxidant (AO) Content

3.6. Statistical Analysis

4. Result and Discussion

4.1. Evaluation of Ambient Parameters

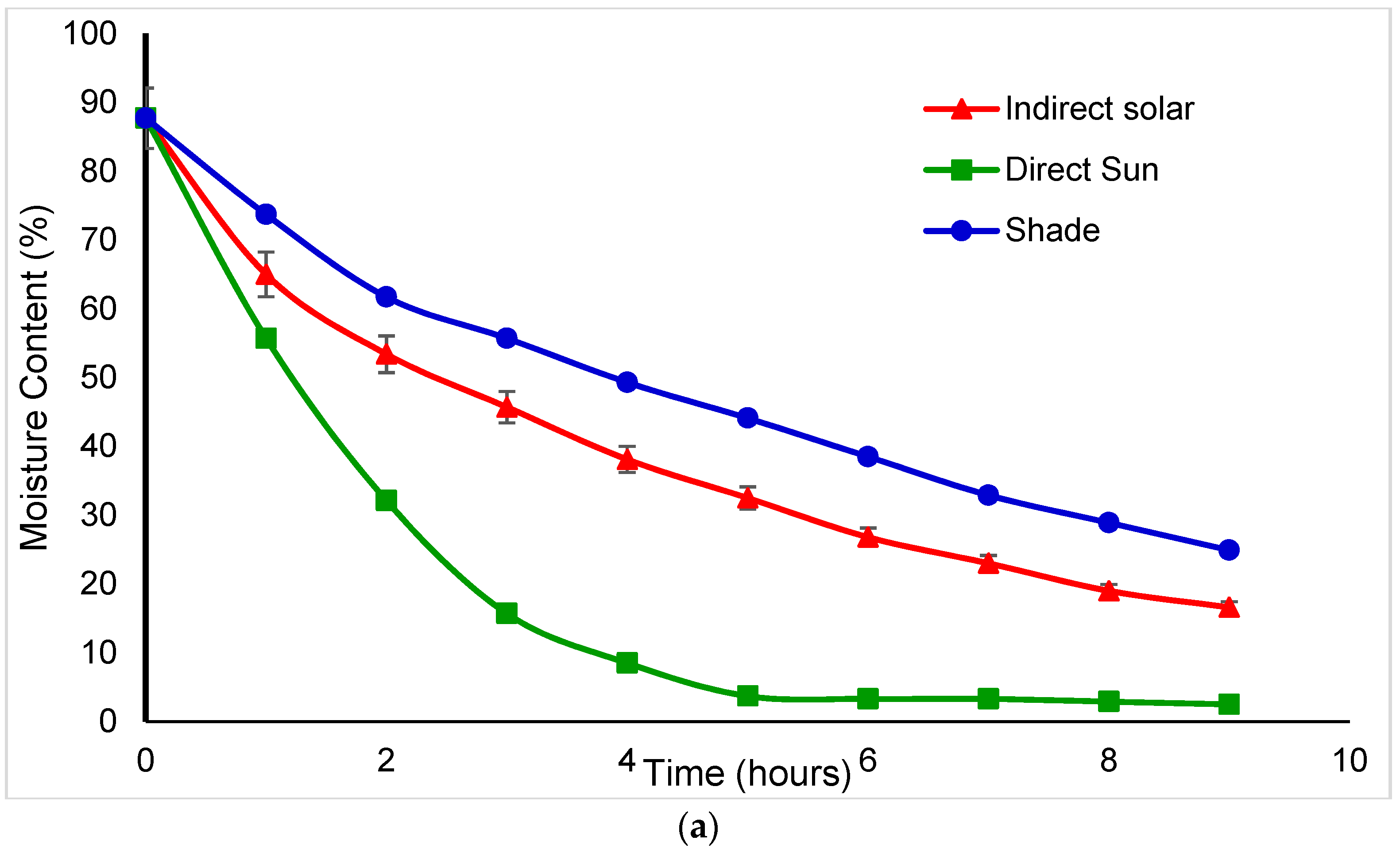

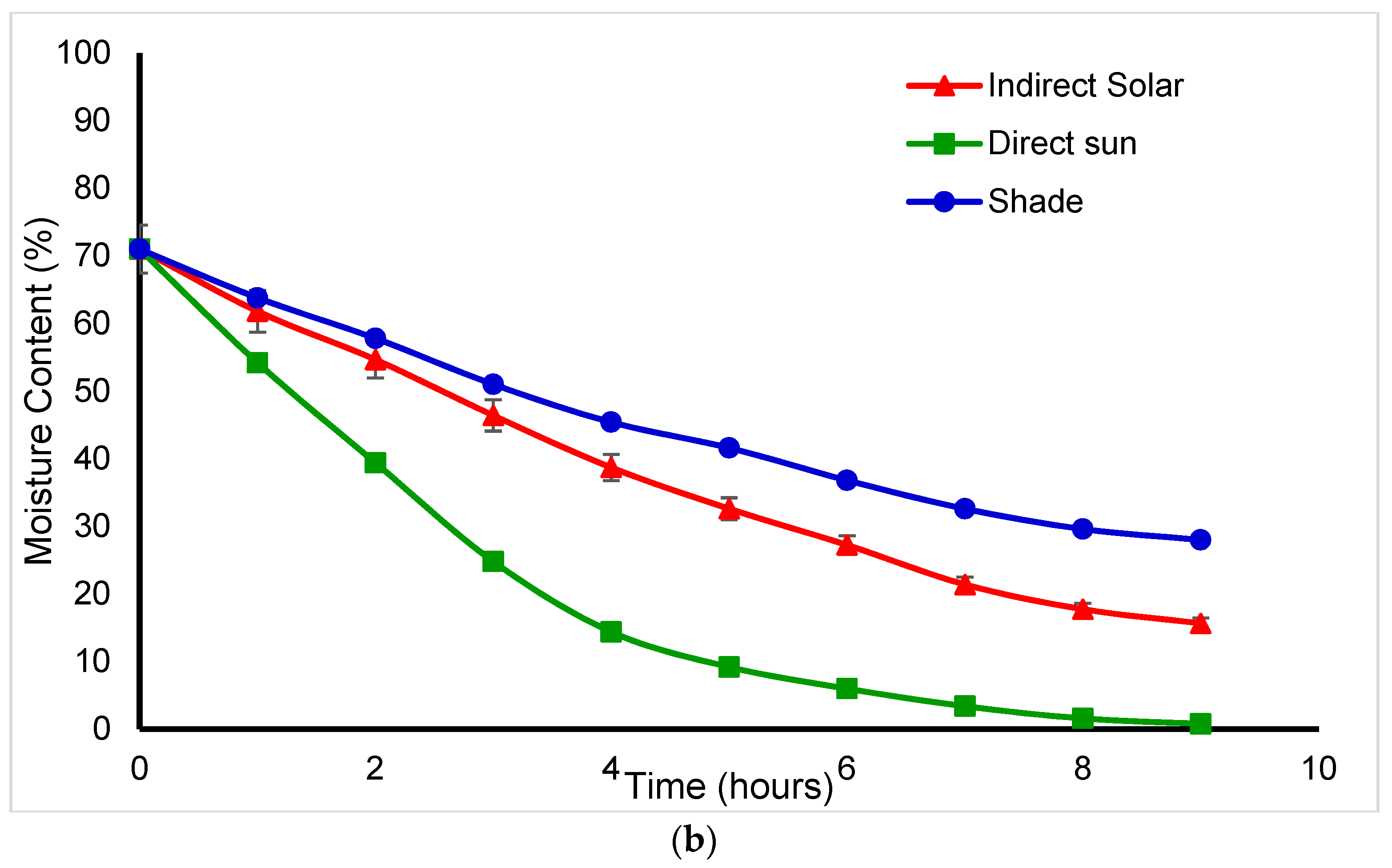

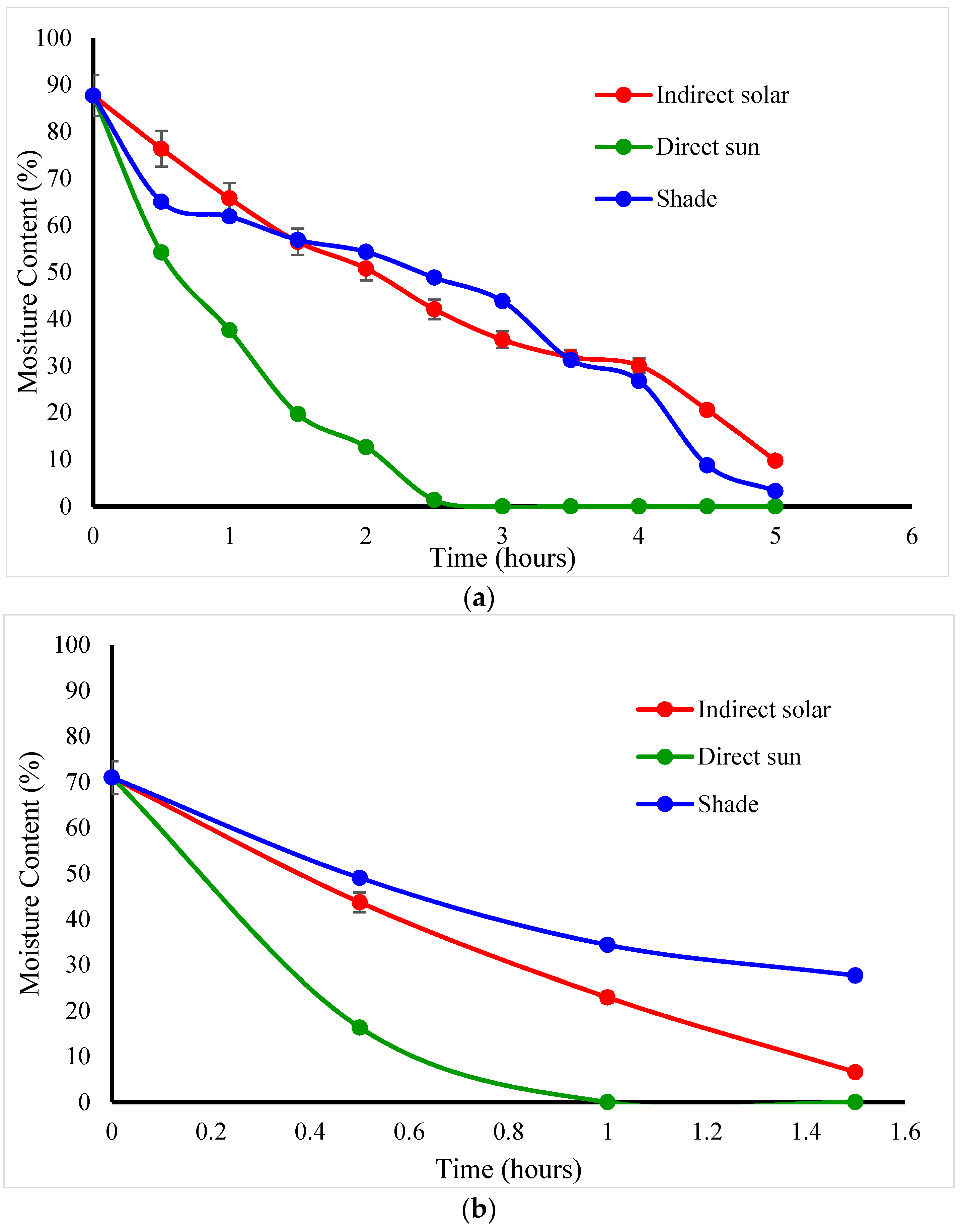

4.2. Medicinal Herbs’ Moisture Content

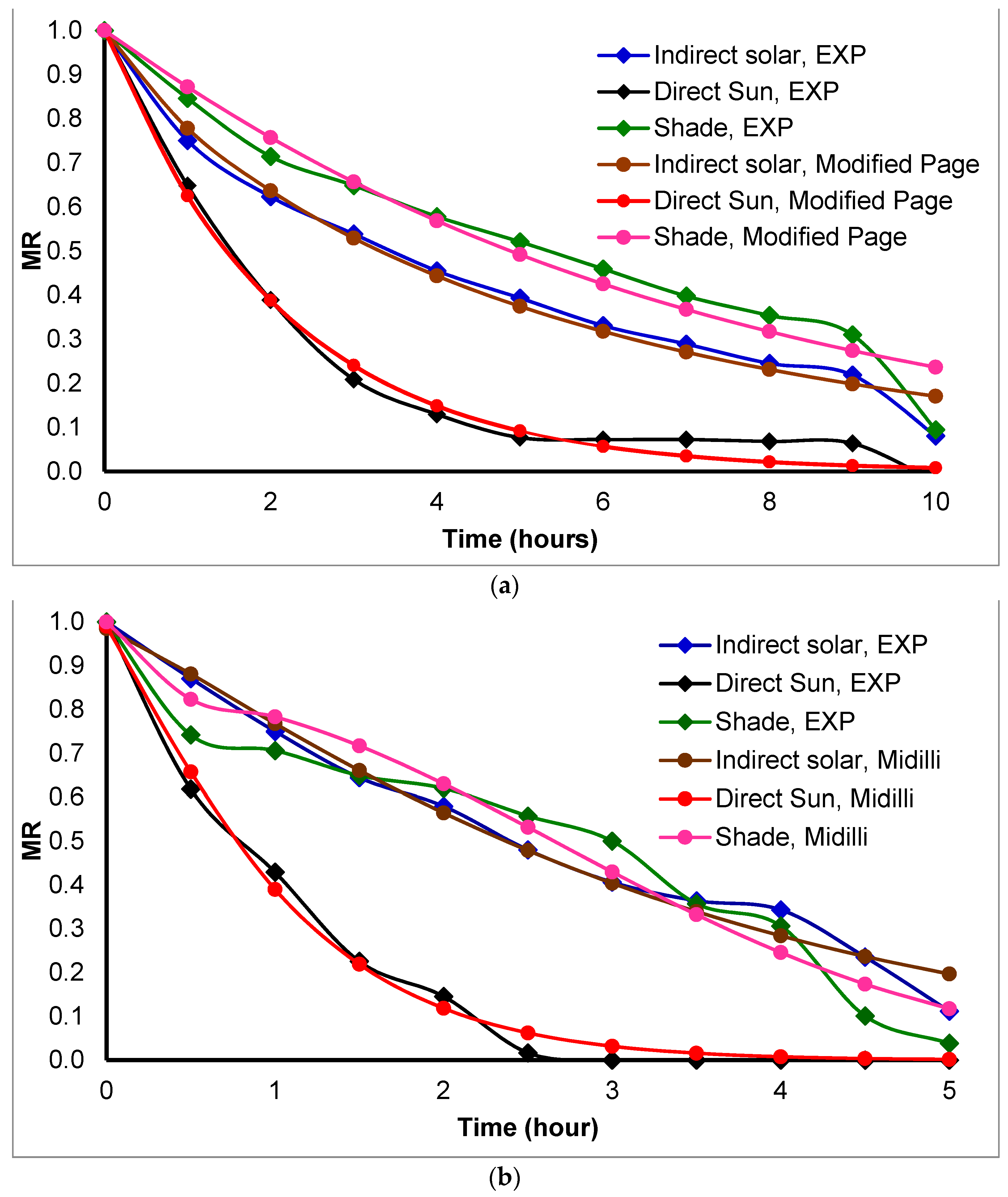

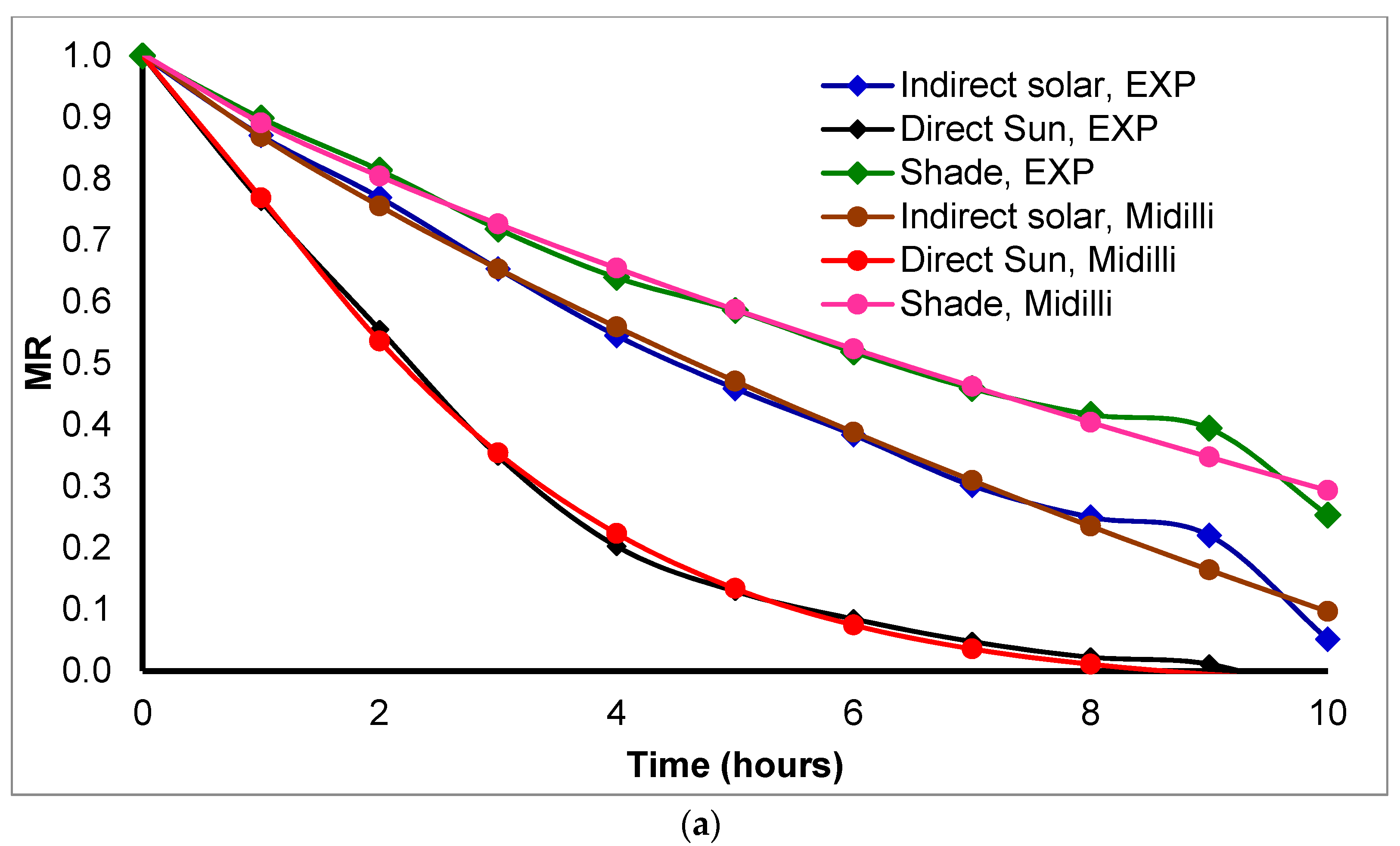

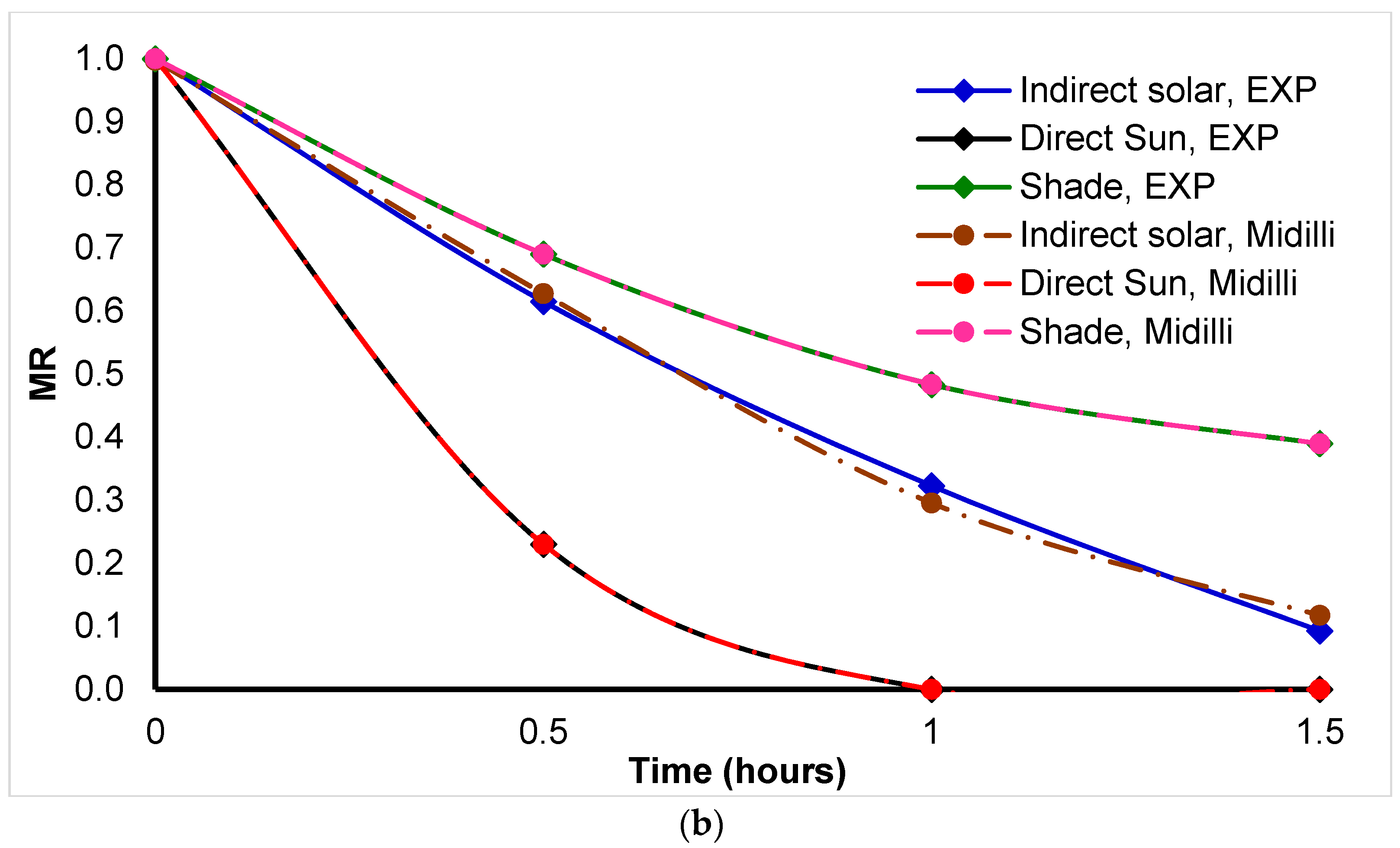

4.3. Drying Kinetic Models of Medicinal Herbs

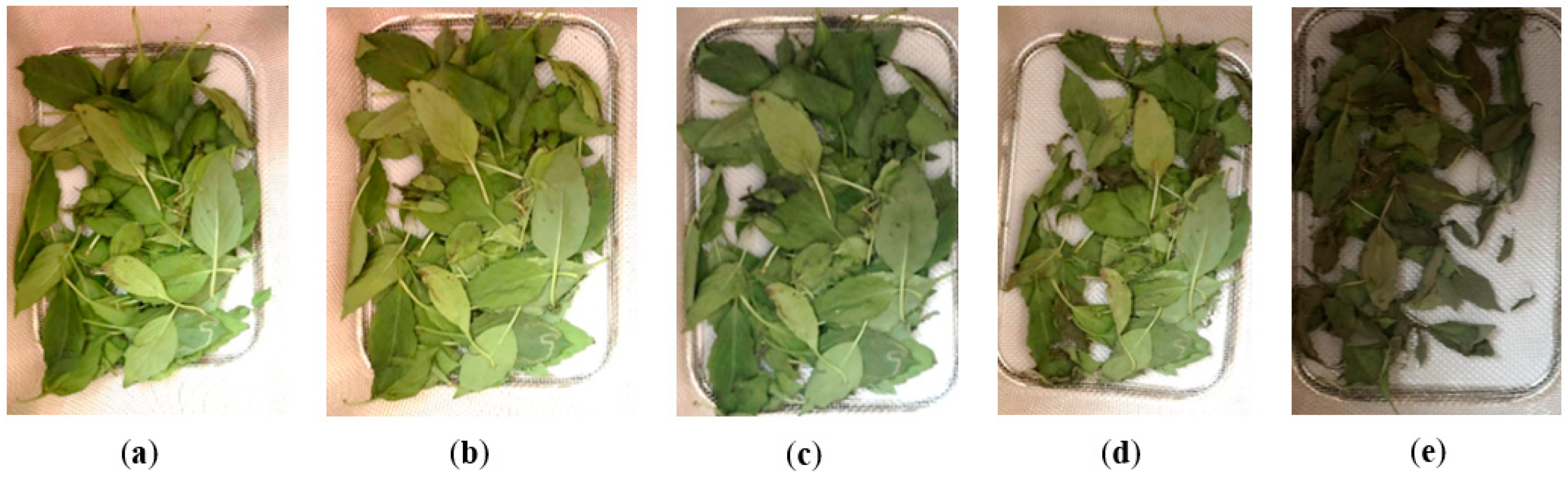

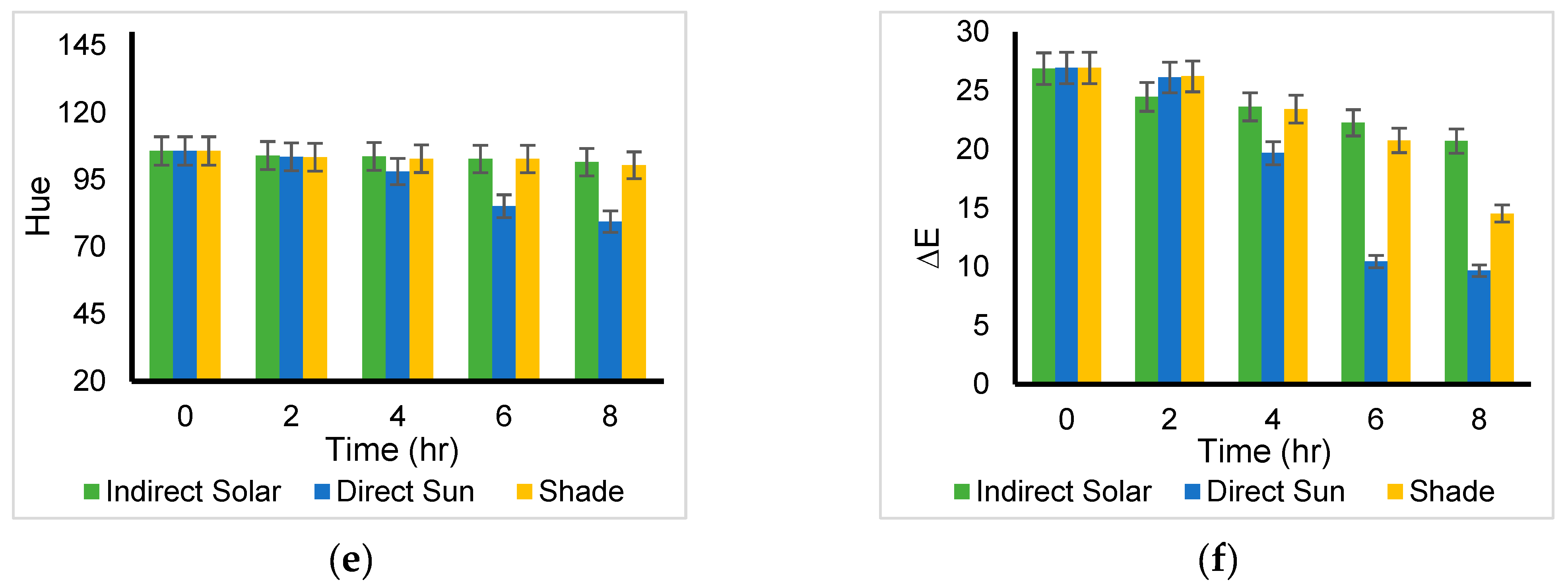

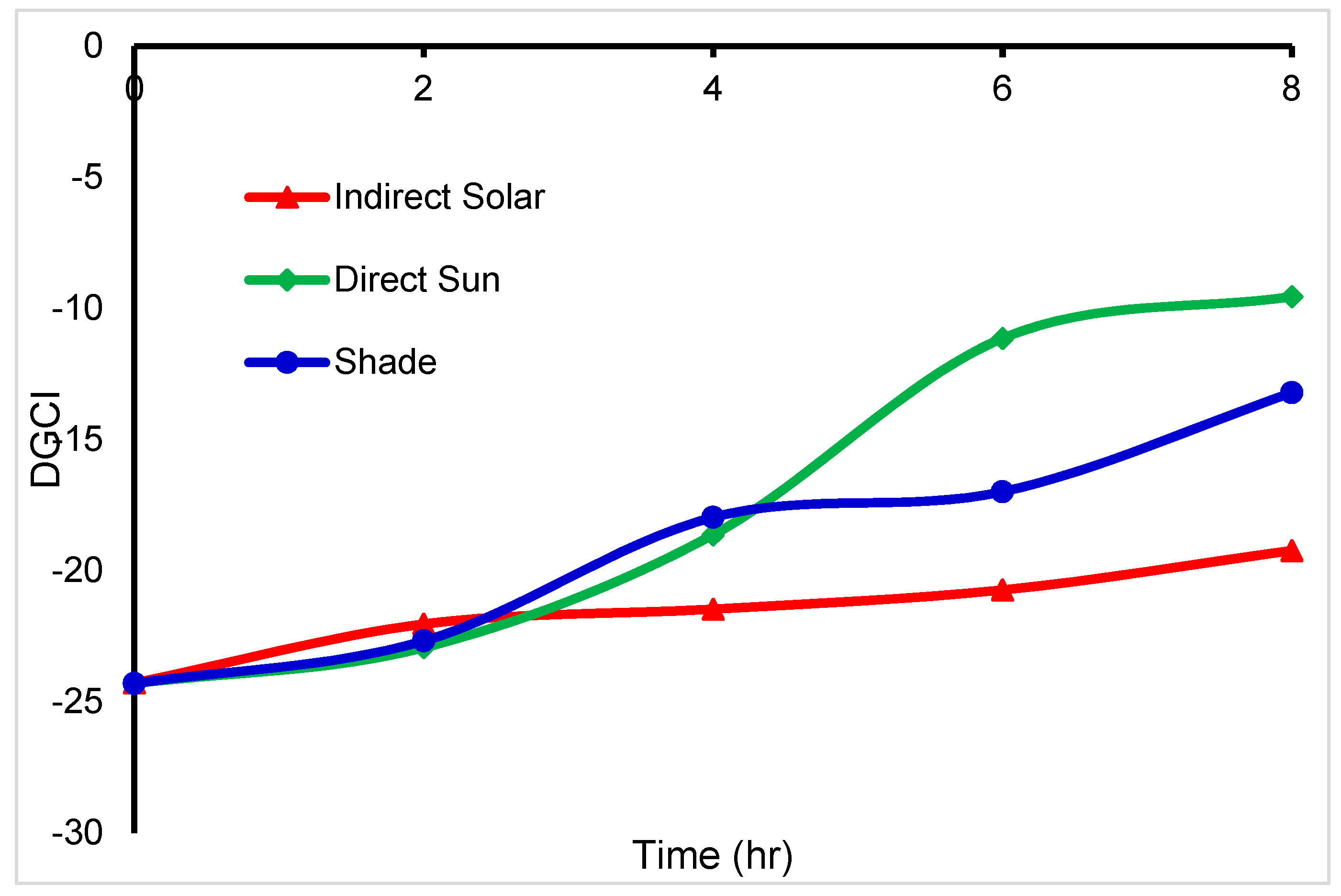

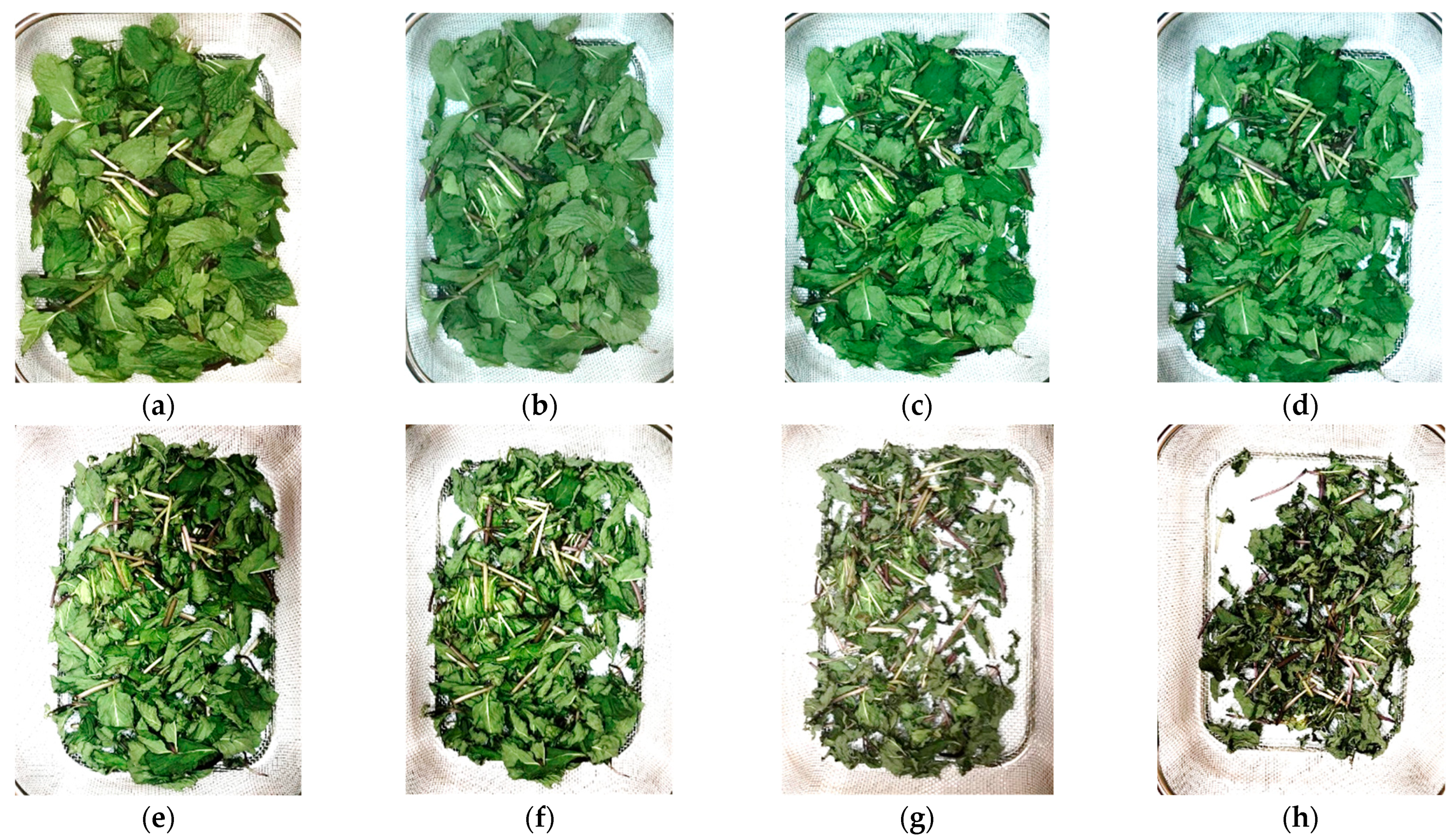

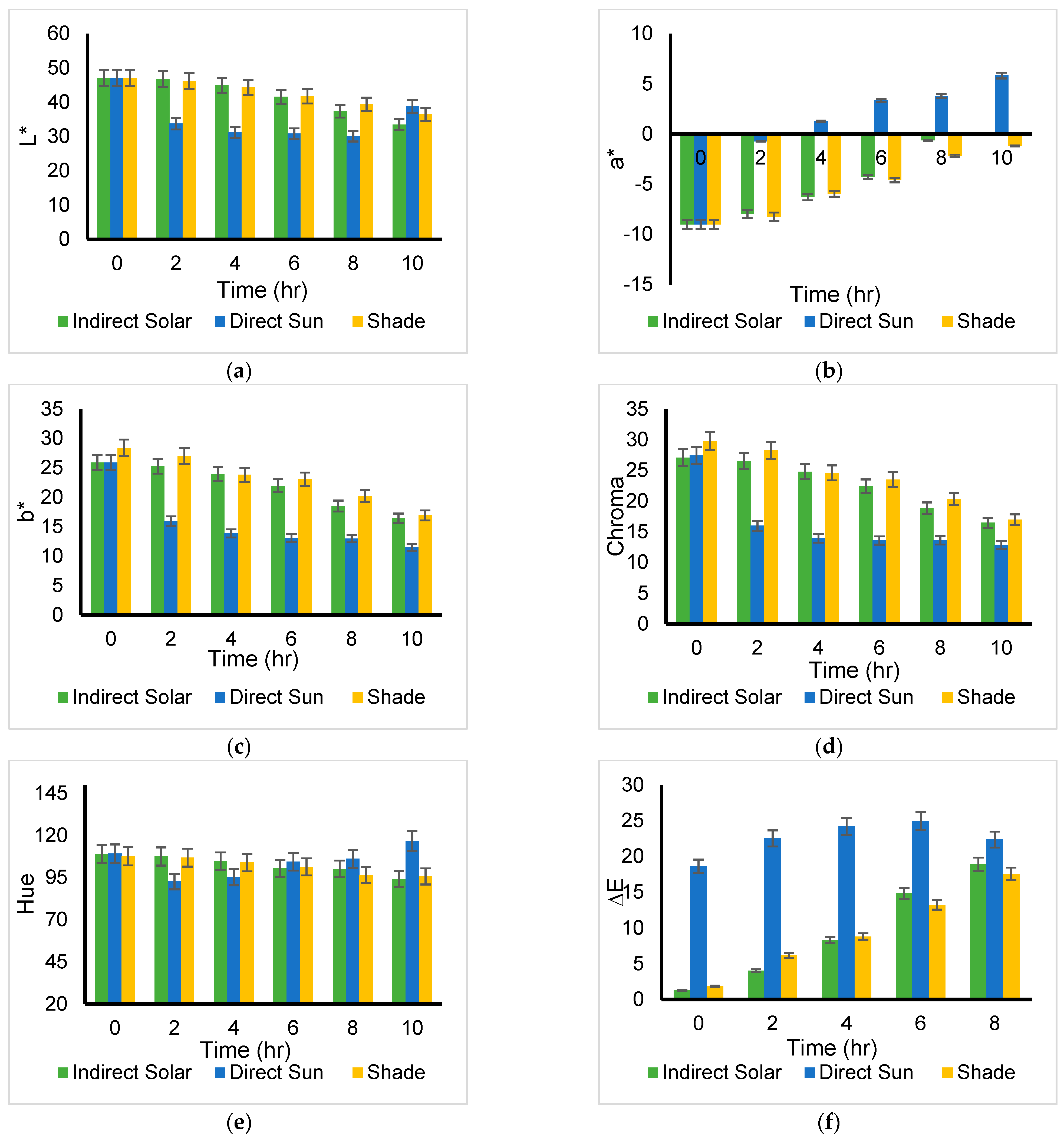

4.4. Color Change of Medicinal Herbs

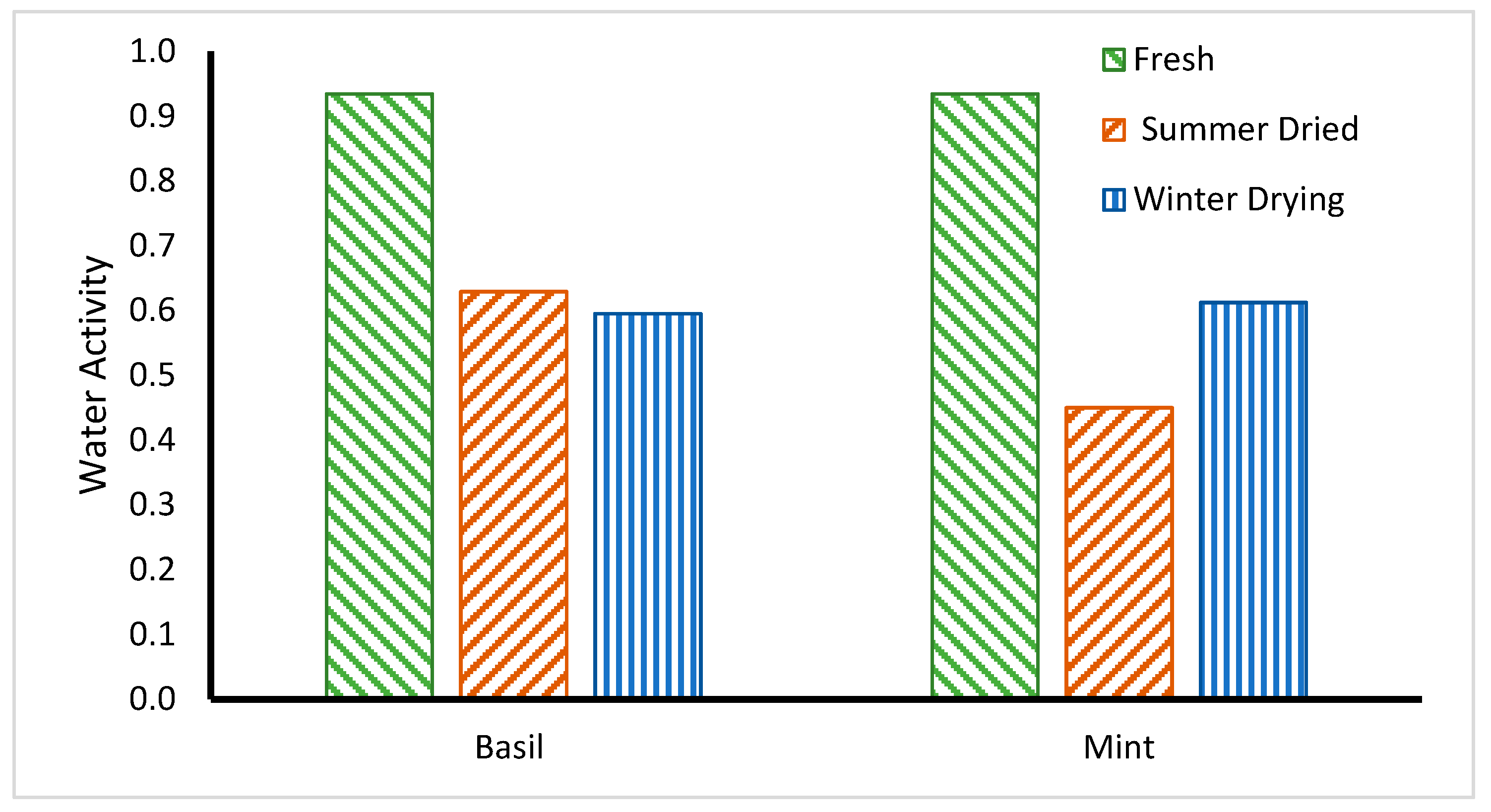

4.5. Water Activity of Dried Medicinal Herbs

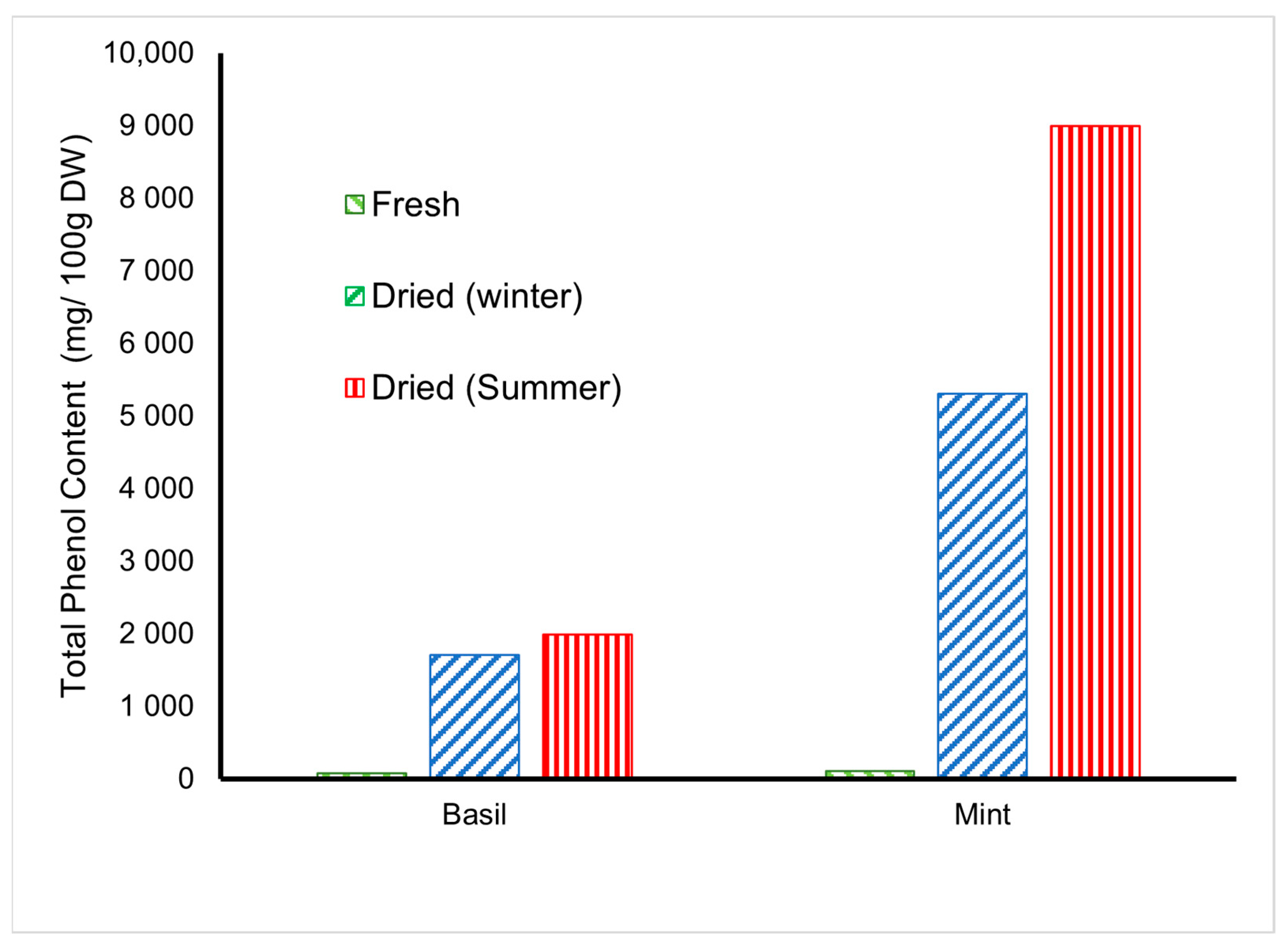

4.6. Total Phenol Content of Medicinal Herbs

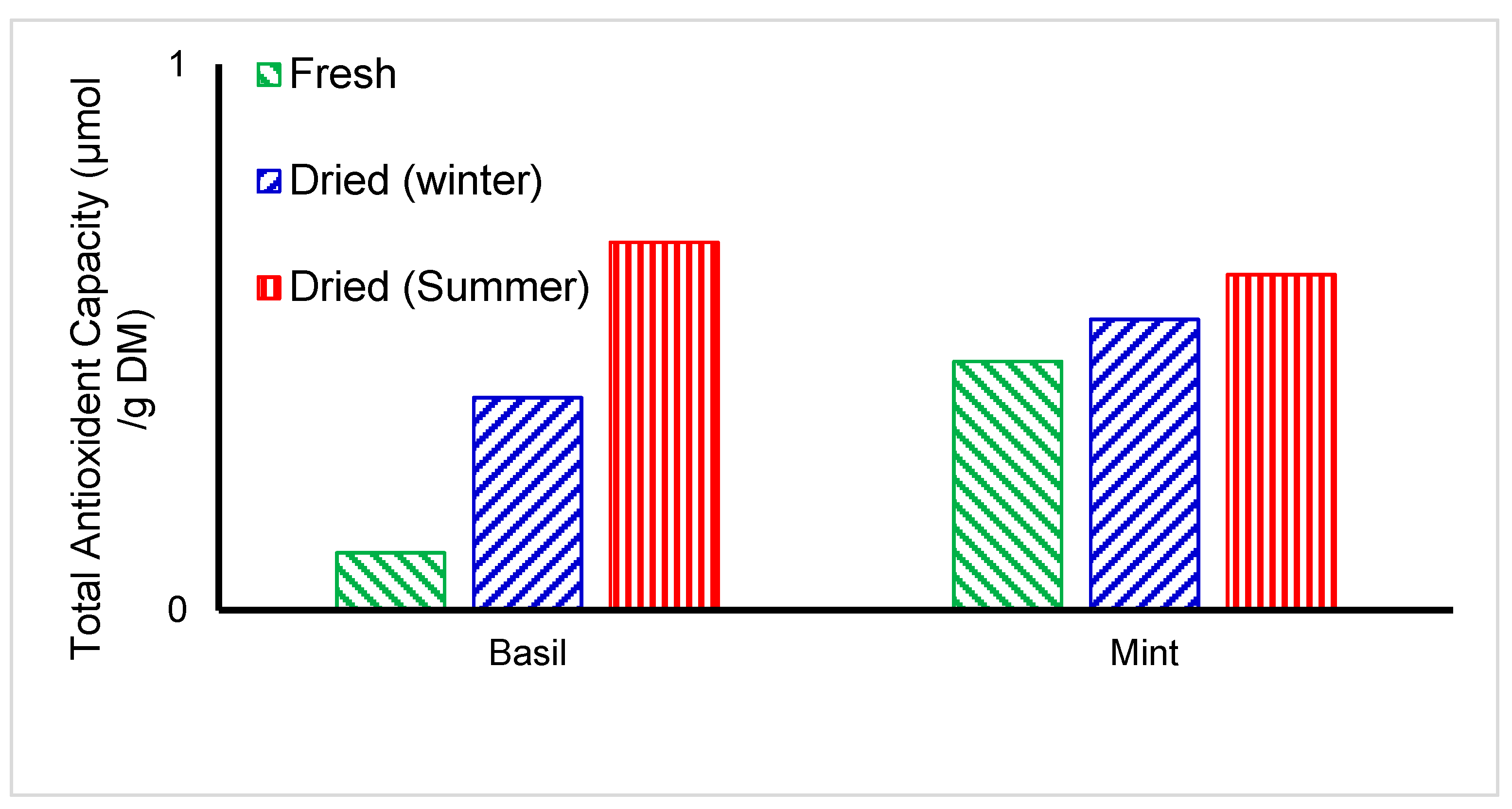

4.7. Antioxidant Capacity of Medicinal Herbs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ambrose, D.C.; Manickavasagan, A.; Naik, R. (Eds.) Leafy Medicinal Herbs: Botany, Chemistry, Postharvest Technology and Uses; CABI: Boston, MA, USA, 2016. [Google Scholar]

- Burton, L. “Food Preservation Methods & Guidance.” The Hub. High Speed Training. 19 December 2018. Available online: www.highspeedtraining.co.uk/hub/food-preservation-methods/ (accessed on 10 April 2022).

- Mouhoubi, K.; Boulekbache-Makhlouf, L.; Madani, K.; Palatzidi, A.; Perez-Jimenez, J.; Mateos-Aparicio, I.; Garcia-Alonso, A. Phenolic compounds and antioxidant activity are differentially affected by drying processes in celery, coriander and parsley leaves. Int. J. Food Sci. Technol. 2022, 57, 3467–3476. [Google Scholar] [CrossRef]

- Rao, T.S.B.; Murugan, S. Solar drying of medicinal herbs: A review. Sol. Energy 2021, 223, 415–436. [Google Scholar]

- Tagnamas, Z.; Kouhila, M.; Bahammou, Y.; Lamsyehe, H.; Moussaoui, H.; Idlimam, A.; Lamharrar, A. Drying kinetics and energy analysis of carob seeds (Ceratonia siliqua L.) convective solar drying. J. Therm. Anal. Calorim. 2022, 147, 2281–2291. [Google Scholar] [CrossRef]

- Singh, S.; Gill, R.; Hans, V.; Singh, M. A novel active-mode indirect solar dryer for agricultural products: Experimental evaluation and economic feasibility. Energy 2021, 222, 119956. [Google Scholar] [CrossRef]

- Bahammou, Y.; Moussaoui, H.; Lamsayeh, H.; Tagnamas, Z.; Kouhila, M.; Ouaabou, R.; Lamharrar, A.; Idlimam, A. Water sorption isotherms and drying characteristics of rupturewort (Herniaria hirsuta) during a convective solar drying for a better conservation. Sol. Energy 2020, 201, 916–926. [Google Scholar] [CrossRef]

- Alharbi, F.R.; Csala, D. Gulf cooperation council countries’ climate change mitigation challenges and exploration of solar and wind energy resource potential. Appl. Sci. 2021, 11, 2648. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.; Roskilly, A. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 233, 367–385. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A.; Sharaf-Eldeen, Y.I. Review on Indian solar drying status. Curr. Sustain. Renew. Energy Rep. 2016, 3, 113–120. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Drying fundamentals. In Industrial Drying of Foods; Baker, G.J., Ed.; Blackie Academic and Professional: London, UK, 1997; pp. 7–29. [Google Scholar]

- White, G.M.; Ross, I.J.; Ponelert, R. Fully exposed drying of popcorn. Trans. ASAE 1981, 24, 466–468. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Yapar, Z. A new model for single-layer drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Mphahlele, R.R.; Pathare, P.B.; Opara, U.L. Drying kinetics of pomegranate fruit peel (cv. Wonderful). Sci. Afr. 2019, 5, e00145. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Rorie, R.L.; Purcell, L.C.; Mozaffari, M.; Karcher, D.E.; King, C.A.; Marsh, M.C.; Longer, D.E. Association of “greenness” in corn with yield and leaf nitrogen concentration. Agron. J. 2011, 103, 529–535. [Google Scholar] [CrossRef]

- Franklyn da Cruz, L.I.M.A.; Simões, A.J.A.; Vieira, I.M.M.; Silva, D.P.; Ruzene, D.S. An overview of applications in pineapple agroindustrial residues. Acta Agric. Slov. 2018, 111, 445–462. [Google Scholar]

- Oboh, G.; Akindahunsi, A.A. Change in the ascorbic acid, total phenol and antioxidant activity of sun-dried commonly consumed green leafy vegetables in Nigeria. Nutr. Health 2004, 18, 29–36. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques—Food Materials. Adv. Chem. Eng. Sci. 2018, 8, 27. [Google Scholar] [CrossRef]

- Kanakidi, L.D.; Tsimogiannis, D.; Kiokias, S.; Oreopoulou, V. Formulation of Rosemary Extracts through Spray-Drying Encapsulation or Emulsification. Nutraceuticals 2022, 2, 1–21. [Google Scholar] [CrossRef]

- Karami, H.; Kaveh, M.; Golpour, I.; Khalife, E.; Rusinek, R.; Dobrzański, B., Jr.; Gancarz, M. Thermodynamic Evaluation of the Forced Convective Hybrid-Solar Dryer during Drying Process of Rosemary (Rosmarinus officinalis L.). Leaves. Energ. 2021, 14, 5835. [Google Scholar] [CrossRef]

- Püntener, A.G.; Schlesinger, U.E. Colorants for Non-Textile Applications; Freeman, H.S., Peters, A.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2000; pp. 382–455. [Google Scholar]

- Imaizumi, T.; Jitareerat, P.; Laohakunjit, N.; Kaisangsri, N. Effect of microwave drying on drying characteristics, volatile compounds and color of holy basil (Ocimum tenuiflorum L.). Agric. Nat. Resour. 2021, 55, 1–6. [Google Scholar]

- Yilmaz, A.; Alibas, I. The impact of drying methods on quality parameters of purple basil leaves. J. Food Processing Preserv. 2021, 45, e15638. [Google Scholar] [CrossRef]

- Therdthai, N.; Zhou, W. Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J. Food Eng. 2009, 91, 482–489. [Google Scholar] [CrossRef]

- Rudra, S.G.; Singh, H.; Basu, S.; Shivhare, U.S. Enthalpy entropy compensation during thermal degradation of chlorophyll in mint and coriander puree. J. Food Eng. 2008, 86, 379–387. [Google Scholar] [CrossRef]

- Vijayan, S.; Thottipalayam, V.A.; Kumar, A. Thin layer drying characteristics of curry leaves (Murraya koenigii) in an indirect solar dryer. Therm. Sci. 2017, 21 (Suppl. 2), 359–367. [Google Scholar] [CrossRef]

- Jimenez-Garcia, S.N.; Vazquez-Cruz, M.A.; Ramirez-Gomez, X.S.; Beltran-Campos, V.; Contreras-Medina, L.M.; Garcia-Trejo, J.F.; Feregrino-Pérez, A.A. Changes in the content of phenolic compounds and biological activity in traditional Mexican herbal infusions with different drying methods. Molecules 2020, 25, 1601. [Google Scholar] [CrossRef]

- Turgay, Ö.; Esen, Y. Antioxidant, total phenolic, ascorbic acid and color changes of Ocimum bacilicum L. by various drying methods. Food Health 2020, 6, 110–116. [Google Scholar] [CrossRef]

- Xylia, P.; Fasko, K.G.; Chrysargyris, A.; Tzortzakis, N. Heat treatment, sodium carbonate, ascorbic acid and rosemary essential oil application for the preservation of fresh Rosmarinus officinalis quality. Postharvest Biol. Technol. 2022, 187, 111868. [Google Scholar] [CrossRef]

- Rababah, T.M.; Alhamad, M.; Al-Mahasneh, M.; Ereifej, K.; Andrade, J.; Altarifi, B.; Al-u’datt, M.; Almajwal, A.; Yang, W. Effects of drying process on total phenolics, antioxidant activity and flavonoid contents of common mediterranean herbs. Int. J. Agric. Biol. Eng. 2015, 8, 145–150. [Google Scholar]

- Katırcı, N.; Işık, N.; Güpür, Ç.; Guler, H.O.; Gursoy, O.; Yilmaz, Y. Differences in antioxidant activity, total phenolic and flavonoid contents of commercial and homemade tomato pastes. J. Saudi Soc. Agric. Sci. 2020, 19, 249–254. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

| Model Name | Model Equation | References |

|---|---|---|

| Lewis | [11] | |

| Modified Page (I) | [12] | |

| Midilli and Kucuk | [13] |

| Midilli and Kucuk | Lewis | Modified Page | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | X2 | RMSE | R2 | X2 | RMSE | R2 | X2 | RMSE | |||

| Basil | Summer | Indirect | 0.98167 | 1.26 × 10−3 | 1.13 × 10−3 | 0.98122 | 1.46 × 10−3 | 1.46 × 10−3 | 0.98538 | 1.29 × 10−3 | 1.15 × 10−3 |

| Direct | 0.97956 | 2.08 × 10−3 | 1.84 × 10−3 | 0.97045 | 2.61 × 10−3 | 2.61 × 10−3 | 0.99302 | 2.09 × 10−3 | 1.14 × 10−3 | ||

| Shade | 0.90394 | 7.39 × 10−3 | 5.97 × 10−3 | 0.88969 | 8.53 × 10−3 | 8.53 × 10−3 | 0.89823 | 8.93 × 10−3 | 7.96 × 10−3 | ||

| Winter | Indirect | 0.96632 | 2.26 × 10−3 | 1.99 × 10−3 | 0.97758 | 1.59 × 10−3 | 1.59 × 10−3 | 0.98578 | 9.68 × 10−4 | 9.00 × 10−4 | |

| Direct | 0.99227 | 7.04 × 10−4 | 6.33 × 10−4 | 0.98972 | 8.70 × 10−4 | 8.70 × 10−4 | 0.98976 | 8.70 × 10−4 | 7.97 × 10−4 | ||

| Shade | 0.96093 | 2.27 × 10−3 | 2.23 × 10−3 | 0.96564 | 2.59 × 10−3 | 2.59 × 10−3 | 0.96586 | 2.59 × 10−3 | 2.37 × 10−3 | ||

| Mint | Summer | Indirect | 0.99536 | 5.81 × 10−4 | 3.79 × 10−4 | 0.96953 | 2.48 × 10−3 | 2.48 × 10−3 | 0.99533 | 5.83 × 10−4 | 3.81 × 10−4 |

| Direct | 0.96712 | 7.75 × 10−3 | 4.28 × 10−3 | 0.95222 | 6.28 × 10−3 | 6.28 × 10−3 | 0.96712 | 7.17 × 10−1 | 4.28 × 10−3 | ||

| Shade | 1.00000 | 3.91 × 10−13 | 2.78 × 10−13 | 0.98853 | 4.56 × 10−4 | 4.56 × 10−4 | 0.99666 | 1.70 × 10−4 | 1.34 × 10−4 | ||

| Winter | Indirect | 0.99248 | 5.97 × 10−4 | 5.48 × 10−4 | 0.97041 | 2.42 × 10−3 | 2.42 × 10−3 | 0.98719 | 1.22 × 10−3 | 1.08 × 10−3 | |

| Direct | 0.99781 | 2.42 × 10−4 | 2.15 × 10−4 | 0.97973 | 1.87 × 10−3 | 1.87 × 10−3 | 0.99674 | 3.58 × 10−4 | 3.15 × 10−4 | ||

| Shade | 0.99221 | 4.36 × 10−4 | 4.04 × 10−4 | 0.99217 | 4.36 × 10−4 | 6.15 × 10−4 | 0.99336 | 5.83 × 10−4 | 5.26 × 10−4 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hamdani, A.; Jayasuriya, H.; Pathare, P.B.; Al-Attabi, Z. Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer. Foods 2022, 11, 4103. https://doi.org/10.3390/foods11244103

Al-Hamdani A, Jayasuriya H, Pathare PB, Al-Attabi Z. Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer. Foods. 2022; 11(24):4103. https://doi.org/10.3390/foods11244103

Chicago/Turabian StyleAl-Hamdani, Anfal, Hemanatha Jayasuriya, Pankaj B. Pathare, and Zahir Al-Attabi. 2022. "Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer" Foods 11, no. 24: 4103. https://doi.org/10.3390/foods11244103

APA StyleAl-Hamdani, A., Jayasuriya, H., Pathare, P. B., & Al-Attabi, Z. (2022). Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer. Foods, 11(24), 4103. https://doi.org/10.3390/foods11244103