Flour on Gluten-Free Muffins from Different Edible Cassava Varieties in Thailand

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Cassava Flour Preparation

2.3. The Chemical Properties of Flours from Cassava Varieties

2.3.1. Proximate Analysis

2.3.2. Total Cyanide Content, Acrylamide, Amylose, Gluten Content, and Viscosity

2.3.3. Color of Cassava Flour

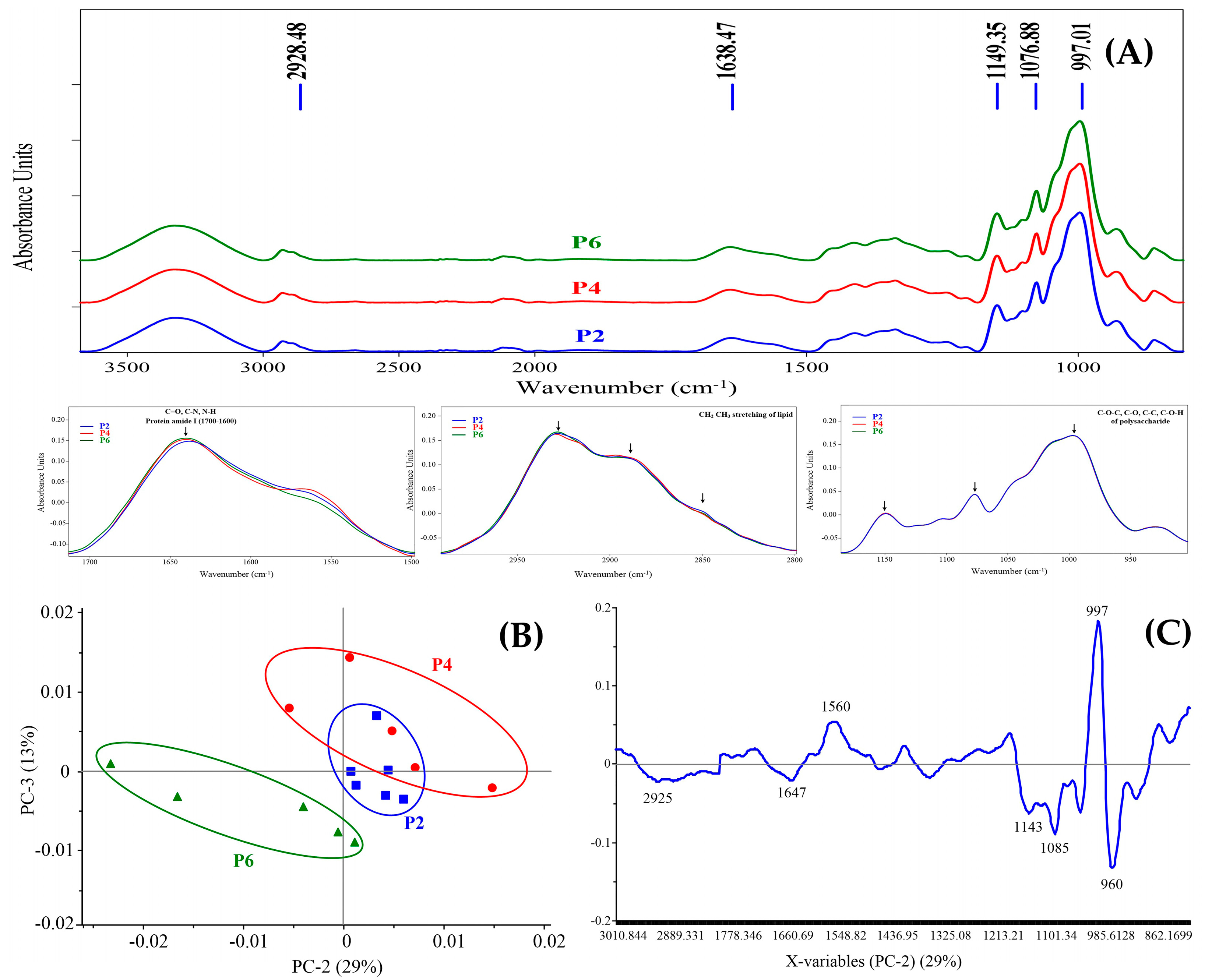

2.3.4. FTIR Spectrometric Analysis

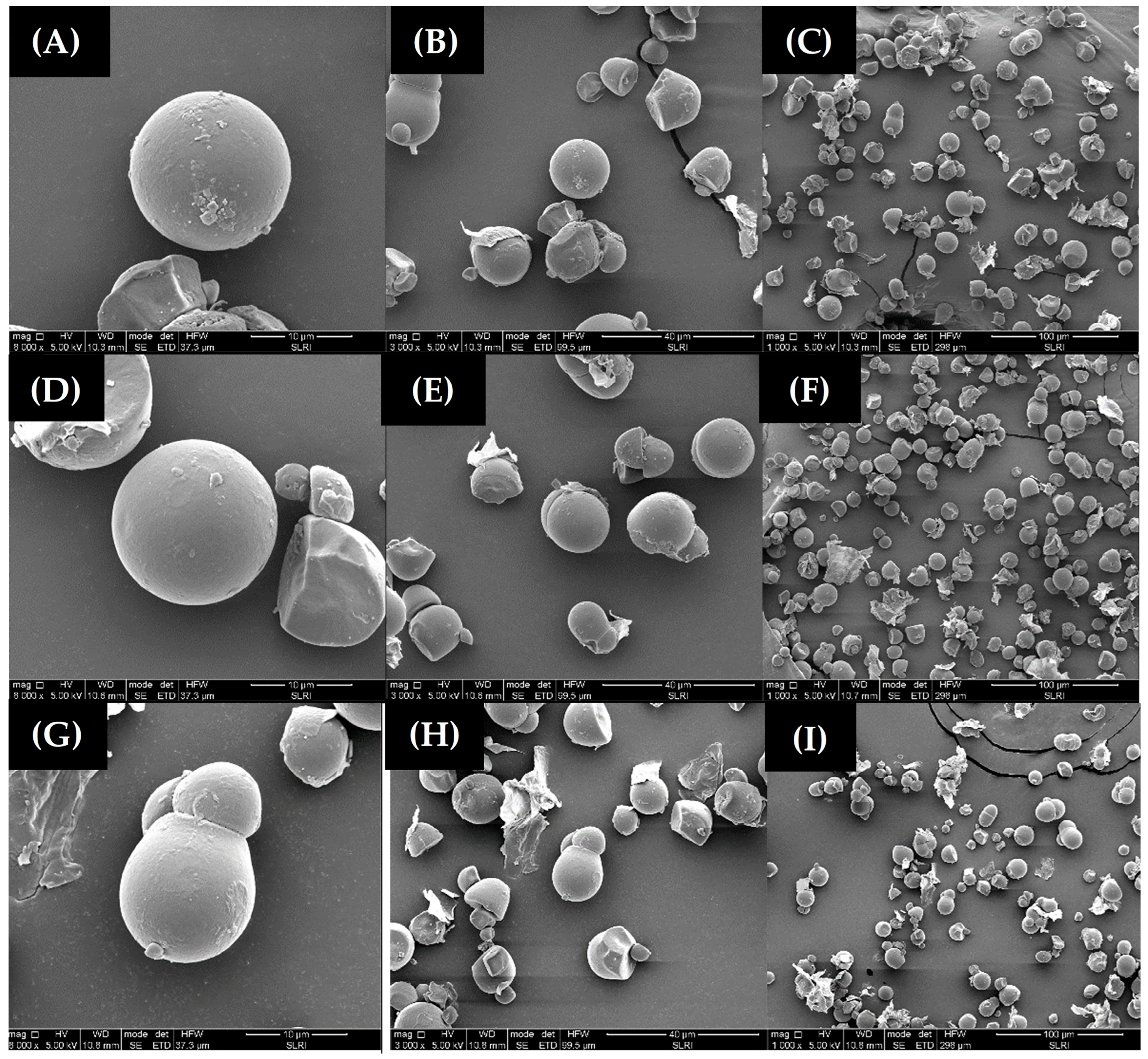

2.3.5. Microstructure of Cassava Flour

2.4. Effects on the Quality and Sensory Characteristics of the Gluten-Free Muffin

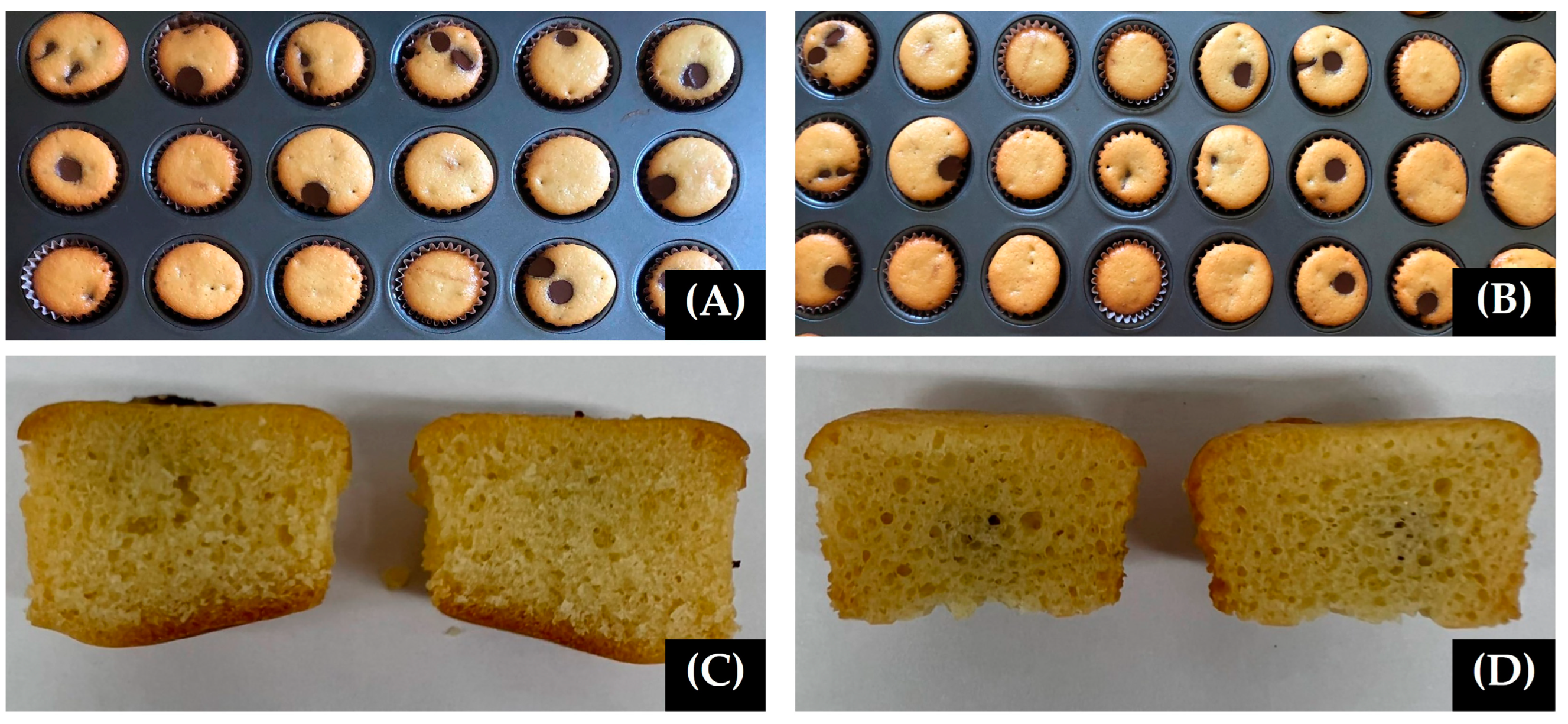

2.4.1. Gluten-Free Muffin and All-Purpose Flour Muffin Preparation

2.4.2. Bake Loss of the Gluten-Free Muffin and the All-Purpose Flour Muffin

2.4.3. Color of Gluten-Free Muffin and All-Purpose Flour Muffin

2.4.4. Firmness of the Gluten-Free Muffin and the All-Purpose Flour Muffin

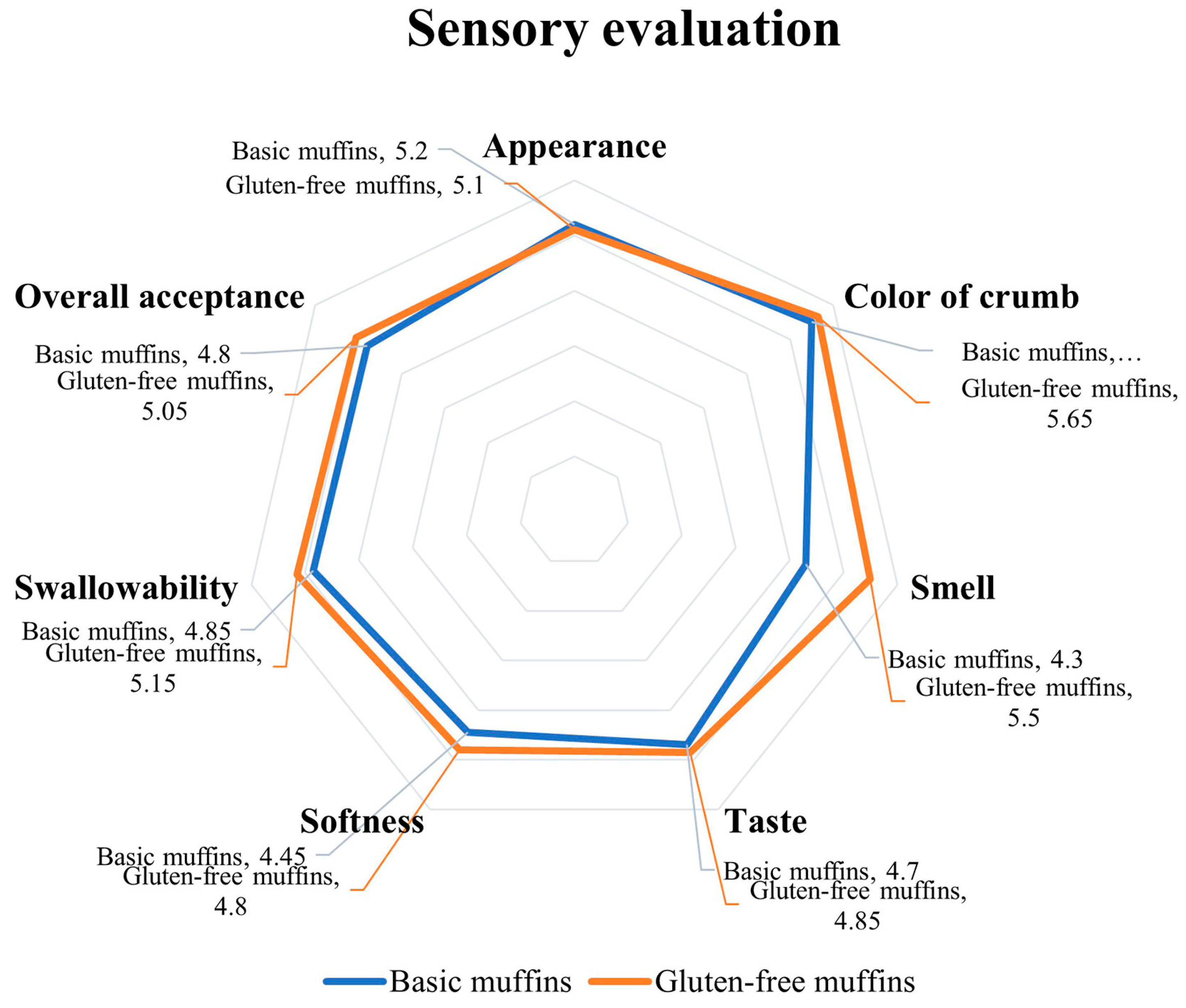

2.4.5. Sensory Evaluation of the Gluten-Free Muffin and the All-Purpose Flour Muffin

2.5. Statistical Analysis

3. Results

3.1. Proximate Analysis

3.2. Total Cyanide Content, Acrylamide, Amylose, Gluten Content, and Viscosity

3.3. Color of Cassava Flour

3.4. FTIR Analysis

3.5. Microstructure of Cassava Flour

3.6. Effects on the Quality and Sensory Characteristics of the Gluten-Free Muffin

3.6.1. The Physical Characteristics of the Gluten-Free Muffin

3.6.2. Sensory Evaluation of the Gluten-Free Muffin

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nanbol, K.K.; Namo, O. The contribution of root and tuber crops to food security: A review. J. Agric. Sci. Technol. B 2019, 9, 221–233. [Google Scholar]

- Fathima, A.A.; Sanitha, M.; Tripathi, L.; Muiruri, S. Cassava (Manihot esculenta) dual use for food and bioenergy: A review. Food Energy Secur. 2022, e380. [Google Scholar] [CrossRef]

- Adigwe, O.P.; Egharevba, H.O.; Emeje, M.O. Starch: A Veritable Natural Polymer for Economic Revolution. In Starch—Evolution and Recent Advances, 1st ed.; Emeje, M.O., Ed.; IntechOpen: London, UK, 2022; Chapter 3; pp. 23–42. [Google Scholar]

- Wang, Z.; Mhaske, P.; Farahnaky, A.; Kasapis, S.; Majzoobi, M. Cassava starch: Chemical modification and its impact on functional properties and digestibility, a review. Food Hydrocoll. 2022, 129, 107542. [Google Scholar] [CrossRef]

- Ayetigbo, O.; Latif, S.; Abass, A.; Müller, J. Comparing characteristics of root, flour and starch of biofortified yellow-flesh and white-flesh cassava variants, and sustainability considerations: A review. Sustainability 2018, 10, 3089. [Google Scholar] [CrossRef]

- Zhang, Y.; Nie, L.; Sun, J.; Hong, Y.; Yan, H.; Li, M.; You, X.; Zhu, L.; Fang, F. Impacts of environmental factors on pasting properties of cassava flour mediated by its macronutrients. Front. Nutr. 2020, 7, 598960. [Google Scholar] [CrossRef] [PubMed]

- Udoro, E.O.; Anyasi, T.A.; Jideani, A.I.O. Process-induced modifications on quality attributes of cassava (Manihot esculenta Crantz) flour. Processes 2021, 9, 1891. [Google Scholar] [CrossRef]

- Chisenga, S.M.; Workneh, T.S.; Bultosa, G.; Laing, M. Proximate composition, cyanide contents, and particle size distribution of cassava flour from cassava varieties in Zambia. AIMS Agric. Food 2019, 4, 869–891. [Google Scholar] [CrossRef]

- Kumari, J.; Morya, S. Celiac disease: An epidemiological condition: Insight on gluten free diet, significance and regulatory recommendations. Pharma Innov. J. 2021, 10, 641–654. [Google Scholar] [CrossRef]

- Demirkesen, I.; Ozkaya, B. Recent strategies for tackling the problems in gluten-free diet and products. Crit. Rev. Food Sci. Nutr. 2022, 62, 571–597. [Google Scholar] [CrossRef]

- Roman, L.; Belorio, M.; Gomez, M. Gluten-free breads: The gap between research and commercial reality. Compr. Rev. Food Sci. Food Saf. 2019, 18, 690–702. [Google Scholar] [CrossRef]

- Lu, H.; Guo, L.; Zhang, L.; Xie, C.; Li, W.; Gu, B.; Li, K. Study on quality characteristics of cassava flour and cassava flour short biscuits. Food Sci. Nutr. 2020, 8, 521–533. [Google Scholar] [CrossRef]

- Issara, U.; Rawdkuen, S. Instant organic rice bran milk: A nutritional quality aspect. Int. Food Res. J. 2018, 25, 1600–1605. [Google Scholar]

- Qin, Y.; Duan, B.; Shin, J.A.; So, H.J.; Hong, E.S.; Jeong, H.G.; Lee, J.H.; Lee, K.T. Effect of fermentation on cyanide and ethyl carbamate contents in cassava flour and evaluation of their mass balance during lab-scale continuous distillation. Foods 2021, 10, 1089. [Google Scholar] [CrossRef] [PubMed]

- Desmarchelier, A.; Bebius, A.; Reding, F.; Griffin, A.; Ahijado Fernandez, M.; Beasley, J.; Clauzier, E.; Delatour, T. Towards a consensus LC-MS/MS method for the determination of acrylamide in food that prevents overestimation due to interferences. Food Addit. Contam. Part A 2022, 39, 653–665. [Google Scholar] [CrossRef] [PubMed]

- Avaro, M.R.A.; Pan, Z.; Yoshida, T.; Wada, Y. Two alternative methods to predict amylose content of rice grain by using tristimulus CIE lab values and developing a specific color board of starch-iodine complex solution. Plant Prod. Sci. 2011, 14, 164–168. [Google Scholar] [CrossRef]

- Željka, M.B.; Gojković, C.V.; Radoslav, G. Gliadin proteins from wheat flour: The optimal determination conditions by ELISA. Foods Raw Mater. 2021, 9, 364–370. [Google Scholar]

- Gamel, T.H.; Abdel-Aal, E.S.M.; Wood, P.J.; Ames, N.P.; Tosh, S.M. Application of the Rapid Visco Analyzer (RVA) as an effective rheological tool for measurement of β-glucan viscosity. Food Chem. 2012, 89, 52–58. [Google Scholar] [CrossRef]

- Tiwari, A.; Mishra, S. Sensory evaluation of wheat bran biscuits mixed with flaxseed. Asian J. Adv. Res. Rep. 2019, 6, 1–5. [Google Scholar] [CrossRef]

- Radünz, M.; Camargo, T.M.; Nunes, C.F.P.; Pereira, E.D.S.; Ribeiro, J.A.; Hackbart, H.C.D.S.; Radünz, A.F.O.; Radünz, A.L.; Gularte, M.A.; Barbosa, F.D.F. Gluten-free green banana flour muffins: Chemical, physical, antioxidant, digestibility and sensory analysis. J. Food Sci. Technol. 2021, 58, 1295–1301. [Google Scholar] [CrossRef]

- Hasmadi, M.; Harlina, L.; Jau-Shya, L.; Mansoor, A.H.; Jahurul, M.H.A.; Zainol, M.K. Physicochemical and functional properties of cassava flour grown in different locations in Sabah, Malaysia. Food Res. 2020, 4, 991–999. [Google Scholar]

- Peprah, B.B.; Parkes, E.Y.; Harrison, O.A.; van Biljon, A.; Steiner-Asiedu, M.; Labuschagne, M.T. Proximate composition, cyanide content, and carotenoid retention after boiling of provitamin A-rich cassava grown in Ghana. Foods 2020, 9, 1800. [Google Scholar] [CrossRef] [PubMed]

- Ojo, M.O.; Ariahu, C.C.; Chinma, E.C. Proximate, functional and pasting properties of cassava starch and mushroom (Pleurotus pulmonarius) flour blends. Am. J. Food Sci. Technol. 2017, 5, 11–18. [Google Scholar]

- Oyeyinka, S.A.; Adeloye, A.A.; Smith, S.A.; Adesina, B.O.; Akinwande, F.F. Physicochemical properties of flour and starch from two cassava varieties. Agrosearch 2019, 19, 28–45. [Google Scholar] [CrossRef]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a tool for measuring starch-related physiochemical properties in cereals: A review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

- Charoenkul, N.; Uttapap, D.; Pathipanawat, W.; Takeda, Y. Physicochemical characteristics of starches and flours from cassava varieties having different cooked root textures. Food Sci. Technol. 2011, 44, 1774–1781. [Google Scholar] [CrossRef]

- Herawati, H.; Kamsiati, E. The Effects of Some Additives on Characteristics RVA Profile of Cassava Flour. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Online, 22 September 2022. [Google Scholar]

- Wang, C.; Wang, Y.; Liu, X.; Cao, P.; Hu, X.; Chen, Y.; Li, S.; Xiao, Y.; Min, Y. Commercial potato starch standards cannot be used in place of cassava starch standards when measuring the starch content of cassava samples. Starch-Stärke 2019, 71, 1800339. [Google Scholar] [CrossRef]

- Jeong, D.; Chung, H.J. Physical, textural and sensory characteristics of legume-based gluten-free muffin enriched with waxy rice flour. Food Sci. Biotechnol. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Dewi, P.S.; Ulandari, D.; Susanto, N.S. Effect of Glucomannan Addition on Physical and Sensory Characteristic of Gluten-Free Muffin from Modified Cassava Flour and Maize Flour. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Malang, Indonesia, 25 August 2020. [Google Scholar]

| Cassava Flour Varieties | Proximate 1/, 2/ | ||||

|---|---|---|---|---|---|

| Ash (%) | Carbohydrate (%) | Fat (%) | Moisture (%) | Protein (%) | |

| Flour from Pirun 2 | 1.53 ± 0.07 c | 84.32 ± 0.11 | 0.95 ± 0.01 a | 10.65 ± 0.01 | 2.15 ± 0.01 a |

| Flour from Pirun 4 | 1.69 ± 0.02 b | 84.91 ± 0.46 | 0.87 ± 0.00 b | 10.56 ± 0.01 | 1.97 ± 0.00 b |

| Flour from Pirun 6 | 1.91 ± 0.00 a | 84.27 ± 0.04 | 0.79 ± 0.02 c | 10.85 ± 0.45 | 2.18 ± 0.01 a |

| F-Test | ** | ns | ** | ns | ** |

| Cassava Flour Varieties | Amylose Content 1/ (%) | Acrylamide 2/ (µg/kg) | Total Cyanide 1/, 3/ (mg/kg Dry Basis) | Gluten Content 2/ (mg/kg Dry Basis) | Peak Viscosity 1/, 3/ (mPa.s) |

|---|---|---|---|---|---|

| Flour from Pirun 2 | 19.10 ± 0.63 | N | 3.17 ± 0.44 b | N | 3390.00 ± 0.57 c |

| Flour from Pirun 4 | 20.30 ± 0.74 | N | 5.68 ± 0.51 a | N | 4640.00 ± 0.58 b |

| Flour from Pirun 6 | 19.93 ± 0.47 | N | 2.93 ± 0.16 b | N | 6286.00 ± 1.52 a |

| F-Test 3/ | ns | - | ** | - | ** |

| Cassava Flour Varieties | Color Parameter1/ | ||

|---|---|---|---|

| L* | a* | b* | |

| Flour from Pirun 2 | 98.30 ± 2.77 | 1.15 ± 0.37 | 15.76 ± 1.20 |

| Flour from Pirun 4 | 97.65 ± 0.65 | 1.75 ± 0.12 | 15.51 ± 0.31 |

| Flour from Pirun 6 | 99.46 ± 0.40 | 1.01 ± 0.34 | 14.73 ± 0.04 |

| F-Test 2/ | ns | ns | ns |

| Treatments 1/ | Bake loss (%) | Firmness (N) | Color 2/ | ||

|---|---|---|---|---|---|

| L* | a* | b* | |||

| Basic muffins | 10.27 ± 1.29 | 07.72 ± 0.53 | 67.46 ± 2.06 | 11.18 ± 1.33 b | 42.17 ± 0.43 |

| Gluten-free muffins | 13.13 ± 0.56 | 07.22 ± 0.65 | 57.99 ± 2.88 | 20.79 ± 2.39 a | 42.99 ± 1.56 |

| F-Test | ns | ns | ns | * | ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sangpueak, R.; Saengchan, C.; Laemchiab, K.; Kiddeejing, D.; Siriwong, S.; Thumanu, K.; Hoang, N.H.; Phansak, P.; Buensanteai, K. Flour on Gluten-Free Muffins from Different Edible Cassava Varieties in Thailand. Foods 2022, 11, 4053. https://doi.org/10.3390/foods11244053

Sangpueak R, Saengchan C, Laemchiab K, Kiddeejing D, Siriwong S, Thumanu K, Hoang NH, Phansak P, Buensanteai K. Flour on Gluten-Free Muffins from Different Edible Cassava Varieties in Thailand. Foods. 2022; 11(24):4053. https://doi.org/10.3390/foods11244053

Chicago/Turabian StyleSangpueak, Rungthip, Chanon Saengchan, Kansinee Laemchiab, Dusadee Kiddeejing, Supatcharee Siriwong, Kanjana Thumanu, Nguyen Huy Hoang, Piyaporn Phansak, and Kumrai Buensanteai. 2022. "Flour on Gluten-Free Muffins from Different Edible Cassava Varieties in Thailand" Foods 11, no. 24: 4053. https://doi.org/10.3390/foods11244053

APA StyleSangpueak, R., Saengchan, C., Laemchiab, K., Kiddeejing, D., Siriwong, S., Thumanu, K., Hoang, N. H., Phansak, P., & Buensanteai, K. (2022). Flour on Gluten-Free Muffins from Different Edible Cassava Varieties in Thailand. Foods, 11(24), 4053. https://doi.org/10.3390/foods11244053