Effects of Wheat Tempering with Slightly Acidic Electrolyzed Water on the Microbiota and Flour Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. SAEW Preparation

2.3. Wheat Tempering

2.4. Grains Grinding

2.5. Analysis of Microbial Concentrations

2.6. Amplicon-Based Metagenomic Analysis

2.7. Effects of Optimal SAEW Tempering on Flour Characteristics

2.7.1. Compositional and Physicochemical Analysis

2.7.2. Pasting Properties

2.7.3. Thermal Properties

2.8. Statistical Analysis

3. Results

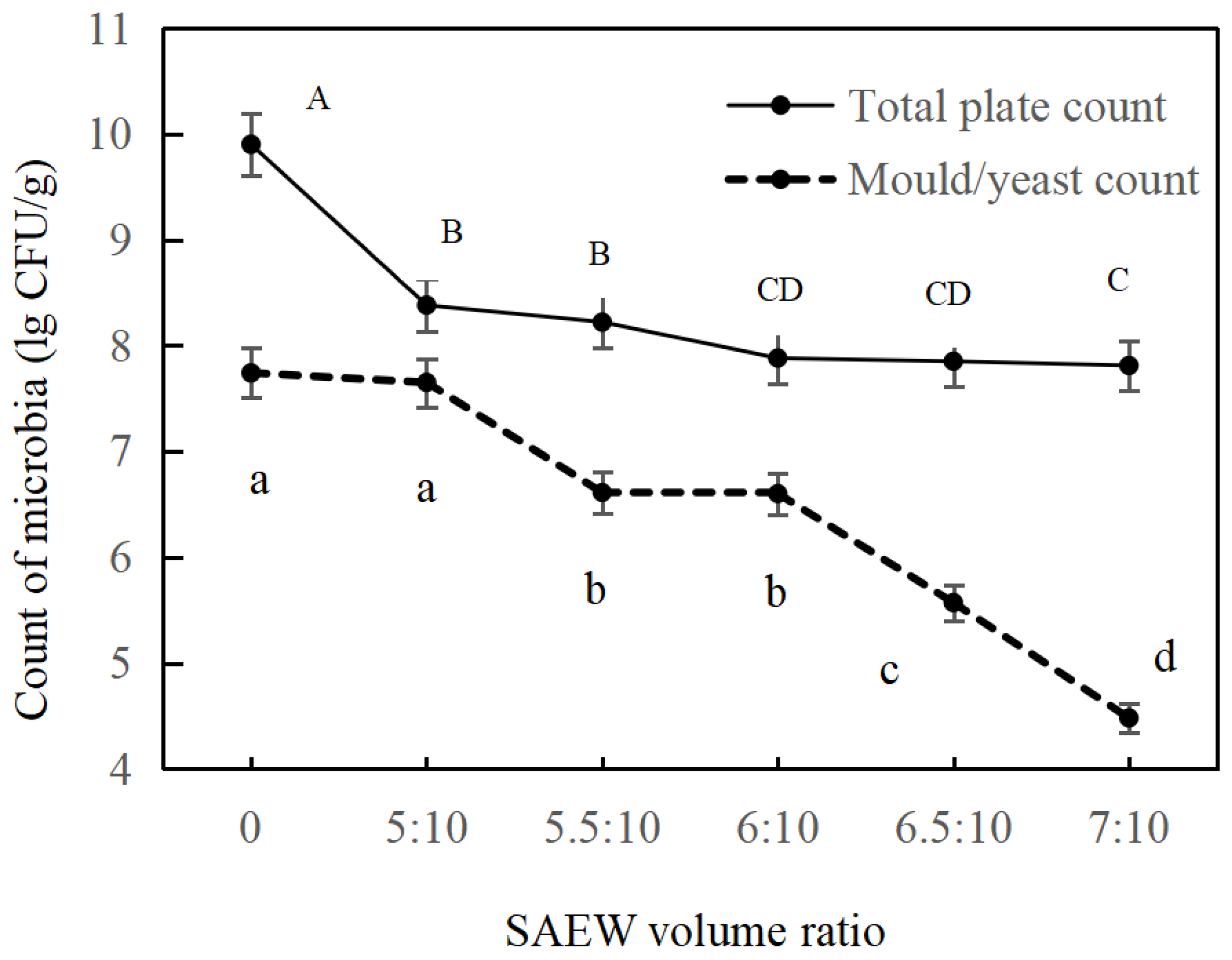

3.1. Microbial Counts in Tempered Wheat Kernels

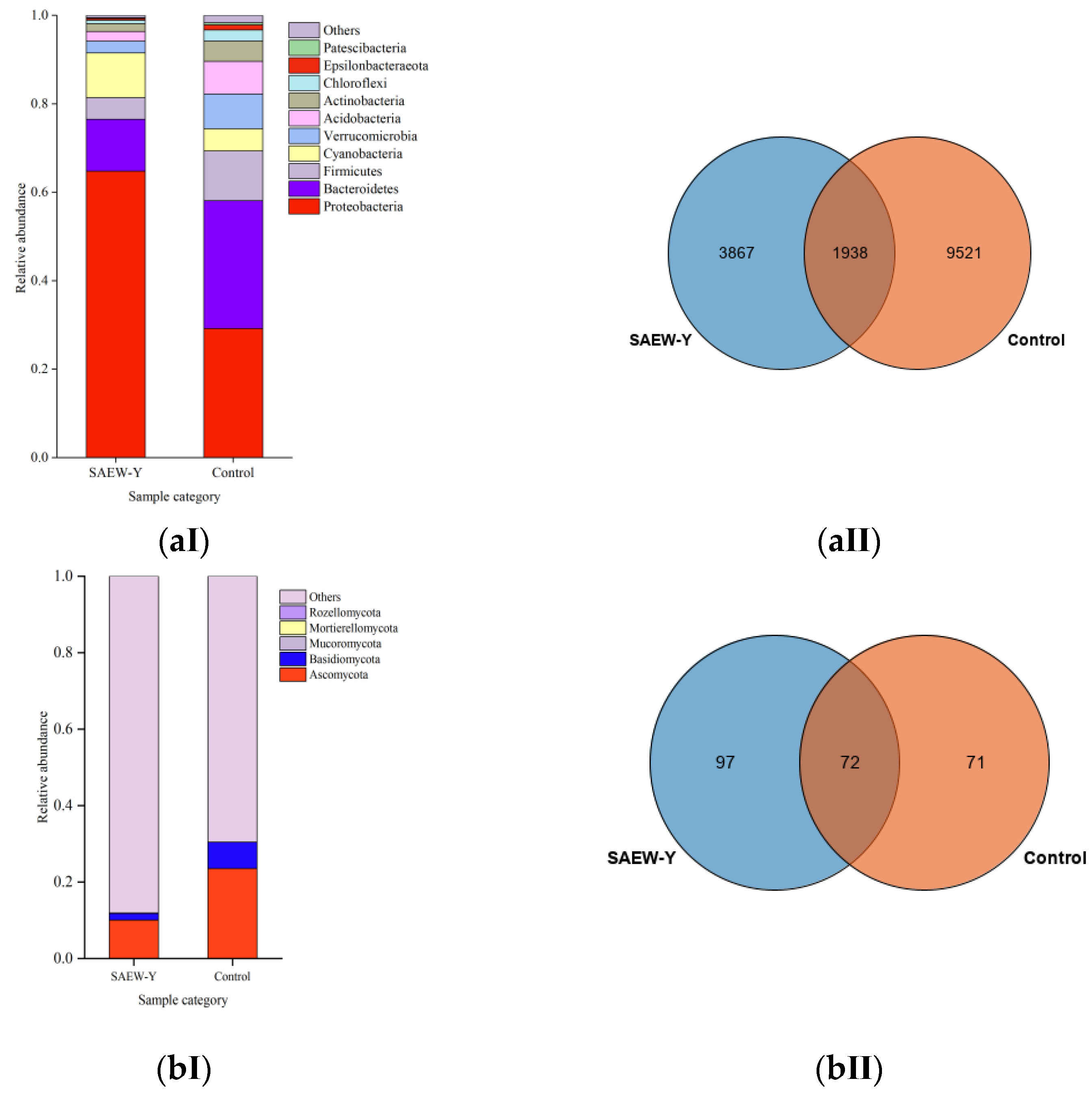

3.2. Effects of Optimal Volume Ratio SAEW Tempering on Microbial Community Composition

3.2.1. Relative Abundance

3.2.2. Taxonomic Abundance Cluster Heatmap

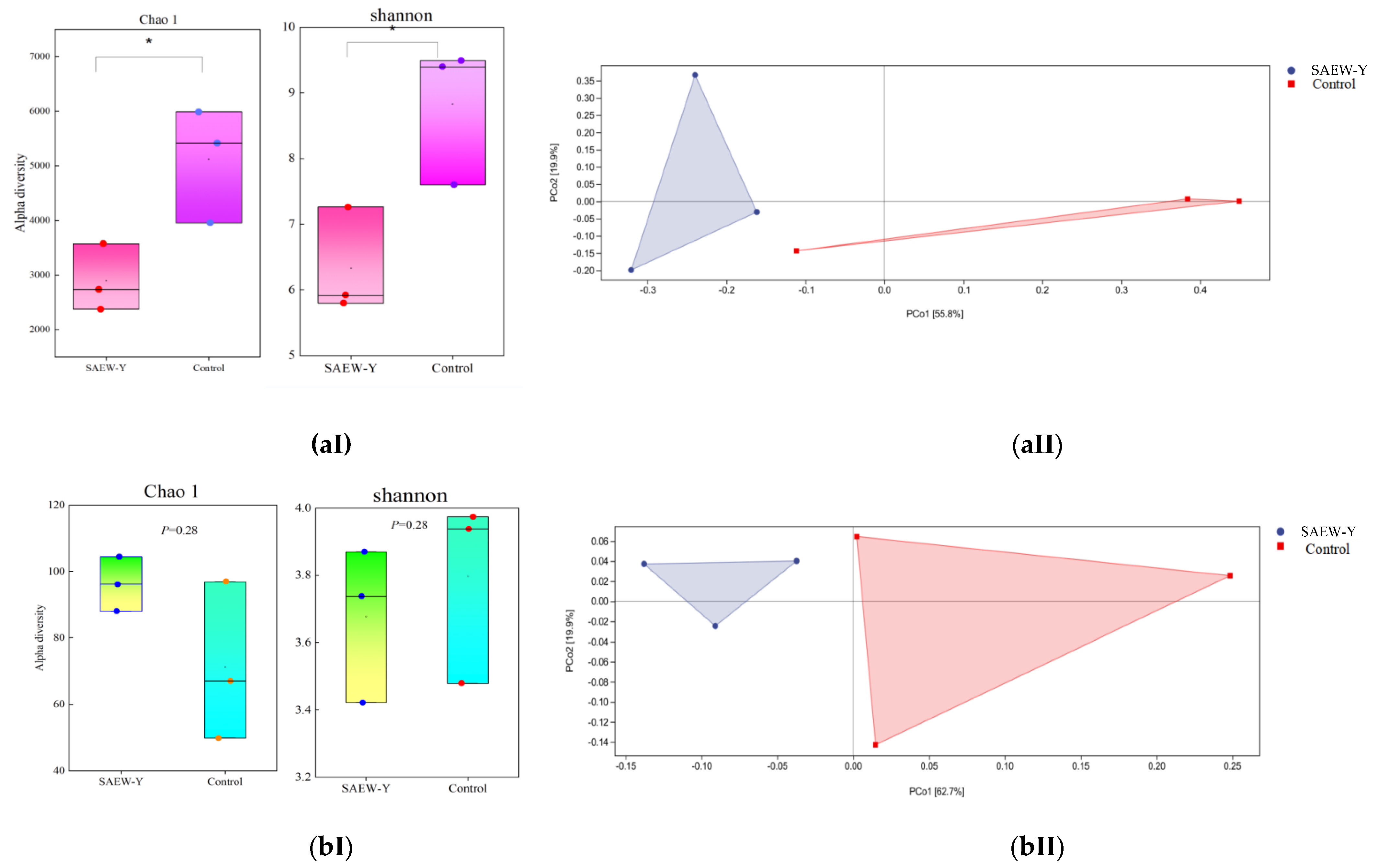

3.2.3. The Alpha and Beta Diversity Indices of the Microbial Community

3.3. Physical and Chemical Properties of Flour

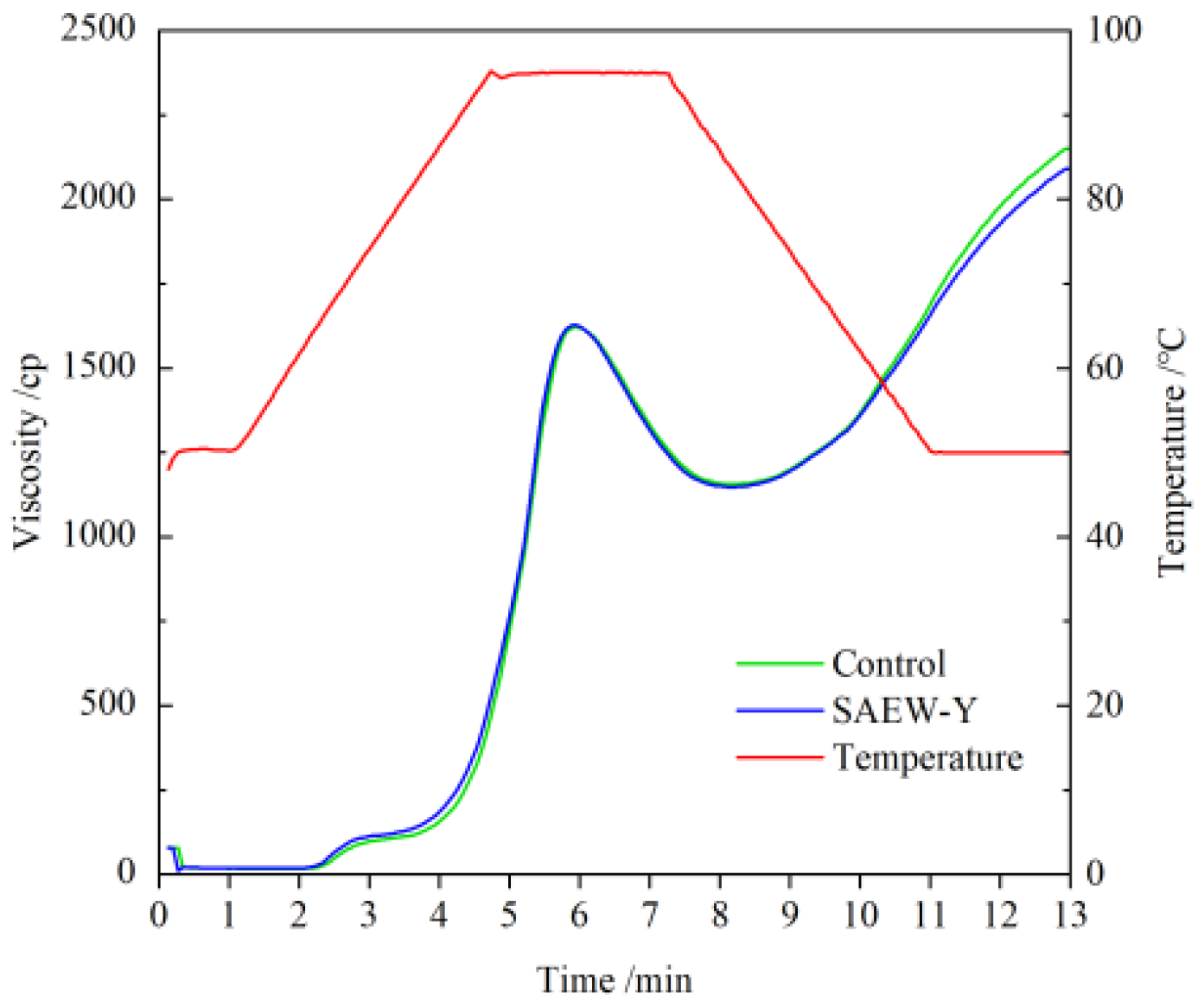

3.4. Pasting Properties

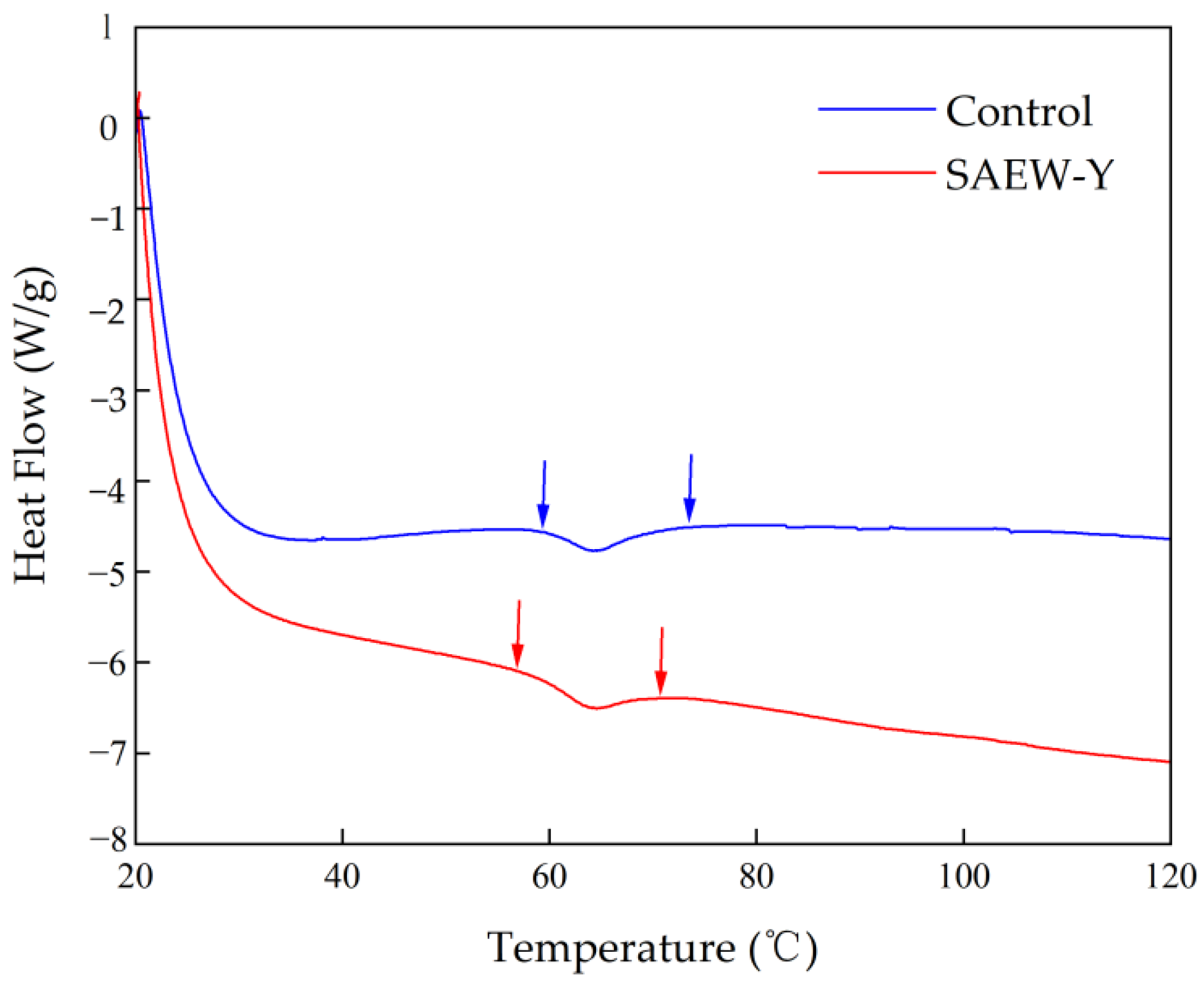

3.5. Thermal Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joseph, M.A. Cereal volatiles, a review. J. Agric. Food Chem. 1978, 26, 175–178. [Google Scholar]

- Kenechukwu, A.O.; Ndidi, O.C.L. Public health significance of food borne pathogens in edible flours. Afr. J. Microbiol. Res. 2015, 9, 509–514. [Google Scholar]

- Berghofer, L.K.; Hocking, A.D.; Miskelly, D.; Jansso, E. Microbiology of wheat and flour milling in Australia. Int. J. Food Microbiol. 2003, 85, 137–149. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Q. Grain and Oil Food Microbiology Test, 3rd ed.; China Light Industry Press: Beijing, China, 2000; pp. 205–211. [Google Scholar]

- Schnürer, J.; Olsson, J.; Börjesson, T. Fungal volatiles as indicators of food and feeds spoilage. Fungal Genet. Biol. 1999, 27, 209–217. [Google Scholar] [CrossRef]

- Hu, Y.M.; Nie, W.; Hu, X.Z.; Li, Z.G. Microbial decontamination of wheat grain with superheated steam. Food Control 2016, 62, 264–269. [Google Scholar] [CrossRef]

- Forghani, F.; Bakker, M.D.; Futral, A.N.; Gonzalez, F.D. Long-Term Survival and Thermal Death Kinetics of Enterohemorrhagic Escherichia coli Serogroups O26, O103, O111, and O157 in Wheat Flour. Appl. Environ. Microbiol. 2018, 84, e00283-18. [Google Scholar] [CrossRef]

- Huang, X.L.; Zhu, S.M.; Zhou, X.M.; He, J.S.; Yu, Y.; Ye, Z.Y. Preservative effects of the combined treatment of slightly acidic electrolyzed water and ice on pomfret. Int. J. Agric. Biol. Eng. 2021, 14, 230–236. [Google Scholar] [CrossRef]

- Morita, C.; Sano, K.; Morimatsu, S.; Kiura, H.; Goto, T.; Kohno, T.; Hong, W.; Miyoshi, H.; Iwasawa, A.; Nakamura, Y.; et al. Disinfection potential of electrolyzed solutions containing sodium chloride at low concentrations. J. Virol. Methods 2000, 85, 163–174. [Google Scholar] [CrossRef]

- Wang, H.H.; Duan, D.B.; Wu, Z.Y.; Xue, S.W.; Xu, X.L.; Zhou, G.H. Primary concerns regarding the application of electrolyzed water in the meat industry. Food Control 2019, 95, 50–56. [Google Scholar] [CrossRef]

- Xuan, X.T.; Fan, Y.F.; Ling, J.G.; Hu, Y.Q.; Liu, D.H.; Chen, S.G.; Ye, X.Q.; Ding, T. Preservation of squid by slightly acidic electrolyzed water ice. Food Control 2017, 73, 1483–1489. [Google Scholar] [CrossRef]

- Hara, Y.S.; Watanuki, A.; Arai, E. Effects of Weakly Electrolyzed Water on Properties of Japanese Wheat Noodles (Udon). Food Sci. Technol. Res. 2003, 9, 320–326. [Google Scholar] [CrossRef][Green Version]

- Suzuki, K.; Nakamura, T.; Doi, T.; Kokubo, S.; Tomita, M. The disinfectant effect of slightly acidic electrolyzed water prepared with hydrochloric acid as a raw material for lettuce. J. Antibact. Antifung. Agents 2005, 33, 589–597. [Google Scholar]

- Li, H.Y.; Liang, D.; Huang, J.; Cui, C.J.; Rao, H.; Zhao, D.D.; Hao, J.X. The Bactericidal Efficacy and the Mechanism of Action of Slightly Acidic Electrolyzed Water on Listeria monocytogenes’ Survival. Foods 2021, 10, 2671. [Google Scholar] [CrossRef] [PubMed]

- Laca, A.; Mousia, Z.; Diaz, M.; Webb, C.; Pandiella, S.S. Distribution of microbial contamination within cereal grains. J. Food Eng. 2006, 72, 332–338. [Google Scholar] [CrossRef]

- Sabillon, L.; Stratton, J.; Rose, D.J.; Flores, R.A.; Bianchini, A. Reduction in microbial load of wheat by tempering with organic acid and saline solutions. Cereal Chem. 2016, 93, 638–646. [Google Scholar] [CrossRef]

- Marcel, M. Cutadapt removes adapter sequences from high-throughput sequencing reads. EMBnet.journal 2011, 17, 10. [Google Scholar]

- Liu, D.Q.; Tong, C. Bacterial community diversity of traditional fermented vegetables in China. LWT 2017, 86, 40–48. [Google Scholar] [CrossRef]

- Mirani, A.; Goli, M. Optimization of cupcake formulation by replacement of wheat flour with different levels of eggplant fiber using response surface methodology. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis: Methods 14.004 (Moisture), 14.006 (Ash), 7062 (Crude Fat) and 2.057 (Crude Protein); AOAC: Washington, DC, USA, 1984. [Google Scholar]

- AACC. Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2016; Available online: http://methods.aaccnet.org/toc.aspx (accessed on 30 November 2016).

- Mirani, A.; Goli, M. Production of the eggplant-fiber incorporated cupcake and evaluating its chemical, textural and colorimetric properties over a ten-day storage time. J. Food Process. Preserv. 2021, 45, e15311. [Google Scholar] [CrossRef]

- GB/T 5506.1-2008; Wheat and Wheat Flour—Gluten Content—Part 1: Determination of Wet Gluten by Manual Method. Standardization Administration of the Peoples Republic of China: Beijing, China, 2008.

- GB/T 5506.3-2008; Wheat and Wheat Flour—Gluten Content—Part 3: Determination of Dry Gluten from Wet Gluten by an Oven Drying Method. Standardization Administration of China: Beijing, China, 2008.

- Xiao, Y.H.; Liu, S.C.; Shen, M.Y.; Jiang, L.; Ren, Y.M.; Luo, Y.; Xie, J.H. Effect of different Mesona chinensis polysaccharides on pasting, gelation, structural properties and in vitro digestibility of tapioca starch-Mesona chinensis polysaccharides gels. Food Hydrocolloids 2020, 99, 105327. [Google Scholar] [CrossRef]

- Shen, H.S.; Ge, X.Z.; Zhang, Q.; Zhang, X.Y.; Lu, Y.F.; Jiang, H.; Zhang, G.Q.; Li, W.H. Dielectric barrier discharge plasma improved the fine structure, physicochemical properties and digestibility of α-amylase enzymatic wheat starch. Innov. Food Sci. Emerg. Technol. 2022, 78, 102991. [Google Scholar] [CrossRef]

- Benam, N.S.; Goli, M.; Ardebili, S.M.S.; Vaezshoushtari, N. The quality characteristics of dough and toast bread prepared with wheat flour containing different levels of Portulaca oleracea leaf powder. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Cardoso, R.V.C.; Fernandes, Â.; Heleno, S.A.; Rodrigues, P.; Gonzaléz-Paramás, A.M.; Barros, L.; Ferreira, I.C.F.R. Physicochemical characterization and microbiology of wheat and rye flours. Food Chem. 2018, 280, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.L.; Cao, W.; Hung, Y.C.; Li, B.M. Disinfection effect of slightly acidic electrolyzed water on celery and cilantro. Food Control 2016, 69, 147–152. [Google Scholar] [CrossRef]

- Rule, K.L.; Ebbett, V.R.; Vikesland, P.J. Formation of chloroform and chlorinated organics by free-chlorine-mediated oxidation of triclosan. Environ. Sci. Technol. 2005, 39, 3176–3185. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.X.; Guo, X.N.; Xing, J.J.; Sun, X.H.; Zhu, K.X. Effects of wheat tempering with slightly acidic electrolyzed water on the microbial, biological, and chemical characteristics of different flour streams. LWT 2020, 118, 108790. [Google Scholar] [CrossRef]

- Magallanes, L.A.M.; Simsek, S. Pathogens control on wheat and wheat flour: A review. Cereal Chem. 2020, 98, 17–30. [Google Scholar] [CrossRef]

- Yuan, Q.S.; Yang, P.; Wu, A.B.; Zuo, D.Y.; He, W.J.; Guo, M.W.; Huang, T.; Li, H.P.; Liao, Y.C. Variation in the Microbiome, Trichothecenes, and Aflatoxins in Stored Wheat Grains in Wuhan, China. Toxins 2018, 10, 171. [Google Scholar] [CrossRef]

- Neupane, A.; Sharma, R.; Duveiller, E.; Shrestha, S. Sources of Cochliobolus sativus Inoculum Causing Spot Blotch under Warm Wheat Growing Conditions in South Asia. Cereal Res. Commun. 2010, 38, 541–549. [Google Scholar] [CrossRef]

- Aregbe, A.Y.; Mu, T.H.; Sun, H.N. Effect of different pretreatment on the microbial diversity of fermented potato revealed by high-throughput sequencing. Food Chem. 2019, 290, 125–134. [Google Scholar] [CrossRef]

- Ke, L.Q.; Wang, L.L.; Li, H.B.; Lin, H.P.; Zhao, L. Molecular identification of lacticacid bacteria in Chinese rice wine using species-specific multiplex PCR. Eur. Food Res. Technol. 2014, 239, 59–65. [Google Scholar] [CrossRef]

- Los, A.; Ziuzina, D.; Boehm, D.; Bourke, P. Effects of cold plasma on wheat grain microbiome and antimicrobial efficacy against challenge pathogens and their resistance. Int. J. Food Microbiol. 2020, 335, 108889. [Google Scholar] [CrossRef] [PubMed]

- İbanoǧlu, Ş. Influence of tempering with ozonated water on the selected properties of wheat flour. J. Food Eng. 2001, 48, 345–350. [Google Scholar] [CrossRef]

- Lunn, G.D.; Kettlewell, P.S.; Major, B.J.; Scott, R.K. Effects of pericarp alpha-amylase activity on wheat (Triticum aestivum) Hagberg falling number. Ann. Appl. Biol. 2001, 138, 207–214. [Google Scholar] [CrossRef]

- Song, X.; Zhao, H.; Fang, K.E.; Lou, Y.S.; Liu, Z.K.; Liu, C.F.; Ren, Z.D.; Zhou, X.R.; Fang, H.; Zhu, Y.C. Effect of platinum electrode materials and electrolysis processes on the preparation of acidic electrolyzed oxidizing water and slightly acidic electrolyzed water. RSC Adv. 2019, 9, 3113–3119. [Google Scholar] [CrossRef]

- Ai, Y.F.; Jane, J.L. Gelatinization and rheological properties of starch. Starch/Stärke 2015, 67, 213–224. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, R.; Chen, Z.X.; Zhong, Q.X. Enzymatically modified starch with low digestibility produced from amylopectin by sequential amylosucrase and pullulanase treatments. Food Hydrocoll. 2019, 95, 195–202. [Google Scholar] [CrossRef]

- Gao, S.S.; Liu, H.; Sun, L.J.; Liu, N.; Wang, J.; Huang, Y.F.; Wang, F.Y.; Cao, J.W.; Fan, R.; Zhang, X.N.; et al. The effects of dielectric barrier discharge plasma on physicochemical and digestion properties of starch. Int. J. Biol. Macromol. 2019, 138, 819–830. [Google Scholar] [CrossRef]

- Bao, J.S.; Corke, H. Pasting Properties of γ-Irradiated Rice Starches as Affected by pH. J. Agric. Food Chem. 2001, 50, 336–341. [Google Scholar] [CrossRef]

| SAEW Volume Ratio (v/v) | pH Value | ORP/mv | ACC/mg/L |

|---|---|---|---|

| 5:10 | 6.06 ± 0.02 a | 890 ± 5 a | 9 ± 2 e |

| 5.5:10 | 6.02 ± 0.01 ab | 886 ± 2 a | 15 ± 2 d |

| 6:10 | 5.98 ± 0.02 bc | 872 ± 4 b | 20 ± 2 c |

| 6.5:10 | 5.88 ± 0.01 cd | 861± 3 c | 25 ± 2 b |

| 7:10 | 5.83 ± 0.02 d | 860 ± 3 c | 32 ± 1 a |

| Sample | Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ash Content (%) | Flour Yield (%) | Gluten Content (%) | Protein (%) | Falling Number (s) | Chromaticity | ||||

| Wet Gluten | Dry Gluten | L* | a* | b* | |||||

| Control | 0.59 ± 0.03 a | 72.6 ± 0.1 a | 36.48 ± 0.44 a | 11.49 ± 0.12 a | 11.79 ± 0.41 a | 337 ± 20 b | 89.88 ± 0.01 a | 0.57 ± 0.02 a | 7.82 ± 0.01 b |

| SAEW-Y | 0.53 ± 0.01 a | 73.3 ± 0.1 a | 35.11 ± 0.34 a | 12.31 ± 0.10 a | 11.78 ± 0.29 b | 379 ± 6 a | 89.63 ± 0.44 a | 0.52 ± 0.06 a | 8.76 ± 0.32 a |

| Sample | Pasting Properties | Thermal Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PV/cP | TV/cP | BD/cP | FV/cP | SB/cP | PET/min | PT/°C | Gelatinization Temperature | ||||

| To/°C | Tp/°C | Tc/°C | ΔH/J/g | ||||||||

| Control | 1623 ± 23 a | 1157 ± 11 a | 466 ± 12 a | 2152 ± 25 a | 995 ± 14 a | 5.97 ± 0.02 a | 89.65 ± 0.06 a | 60.19 ± 0.05 a | 64.20 ± 0 a | 73.77 ± 0.45 a | 4.95 ± 0.06 a |

| SAEW-Y | 1628 ± 12 a | 1149 ± 0 a | 479 ± 12 a | 2092 ± 13 a | 943 ± 13 a | 6.00 ± 0.05 a | 88.45 ± 0.01 a | 58.98 ± 0.07 b | 63.11 ± 0 b | 69.27 ± 0.16 b | 5.44 ± 0.16 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, M.; Fu, Y.; Li, N.; Zhao, Y.; Yang, B.; Wang, L.; Ouyang, S. Effects of Wheat Tempering with Slightly Acidic Electrolyzed Water on the Microbiota and Flour Characteristics. Foods 2022, 11, 3990. https://doi.org/10.3390/foods11243990

Qin M, Fu Y, Li N, Zhao Y, Yang B, Wang L, Ouyang S. Effects of Wheat Tempering with Slightly Acidic Electrolyzed Water on the Microbiota and Flour Characteristics. Foods. 2022; 11(24):3990. https://doi.org/10.3390/foods11243990

Chicago/Turabian StyleQin, Mingqian, Yingwu Fu, Ning Li, Yinyin Zhao, Baowei Yang, Li Wang, and Shaohui Ouyang. 2022. "Effects of Wheat Tempering with Slightly Acidic Electrolyzed Water on the Microbiota and Flour Characteristics" Foods 11, no. 24: 3990. https://doi.org/10.3390/foods11243990

APA StyleQin, M., Fu, Y., Li, N., Zhao, Y., Yang, B., Wang, L., & Ouyang, S. (2022). Effects of Wheat Tempering with Slightly Acidic Electrolyzed Water on the Microbiota and Flour Characteristics. Foods, 11(24), 3990. https://doi.org/10.3390/foods11243990