Scale-Up of Alfalfa (Medicago sativa) Protein Recovery Using Screw Presses

Abstract

:1. Introduction

2. Materials and Methods

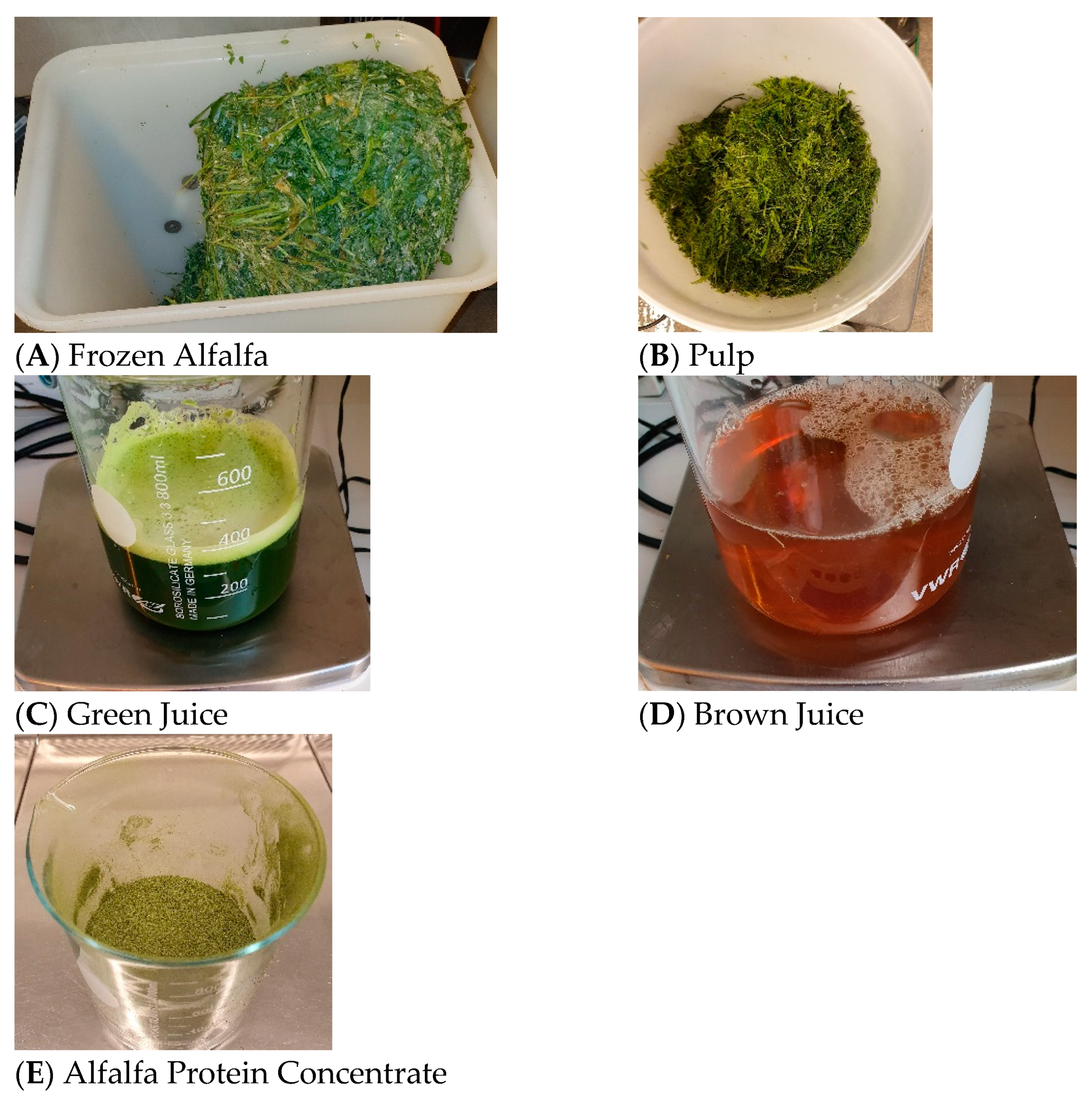

2.1. Production of Alfalfa Protein Concentrate

2.2. Dry Matter and Ash Content

2.3. Protein, Insoluble and Soluble Fiber and Available Carbohydrates

- Available carbohydrate determination through α-amylase, protease and amyloglucosidase incubation.

- Filtration with 96% ethanol to determinate the soluble fiber fraction.

- Protein and ash determination.

- Calculation of the insoluble fiber fraction from the equation below:

2.4. Preparation of Protein for SDS-PAGE and Bradford Soluble Protein Analyses

2.5. SDS-PAGE

2.6. Soluble Protein by Bradford

2.7. Protein Digestibility

2.8. Amino Acid Analysis

2.9. Total Fat Analyses

2.10. L-a-b Color Measurement

2.11. Statistical Analysis

3. Results and Discussion

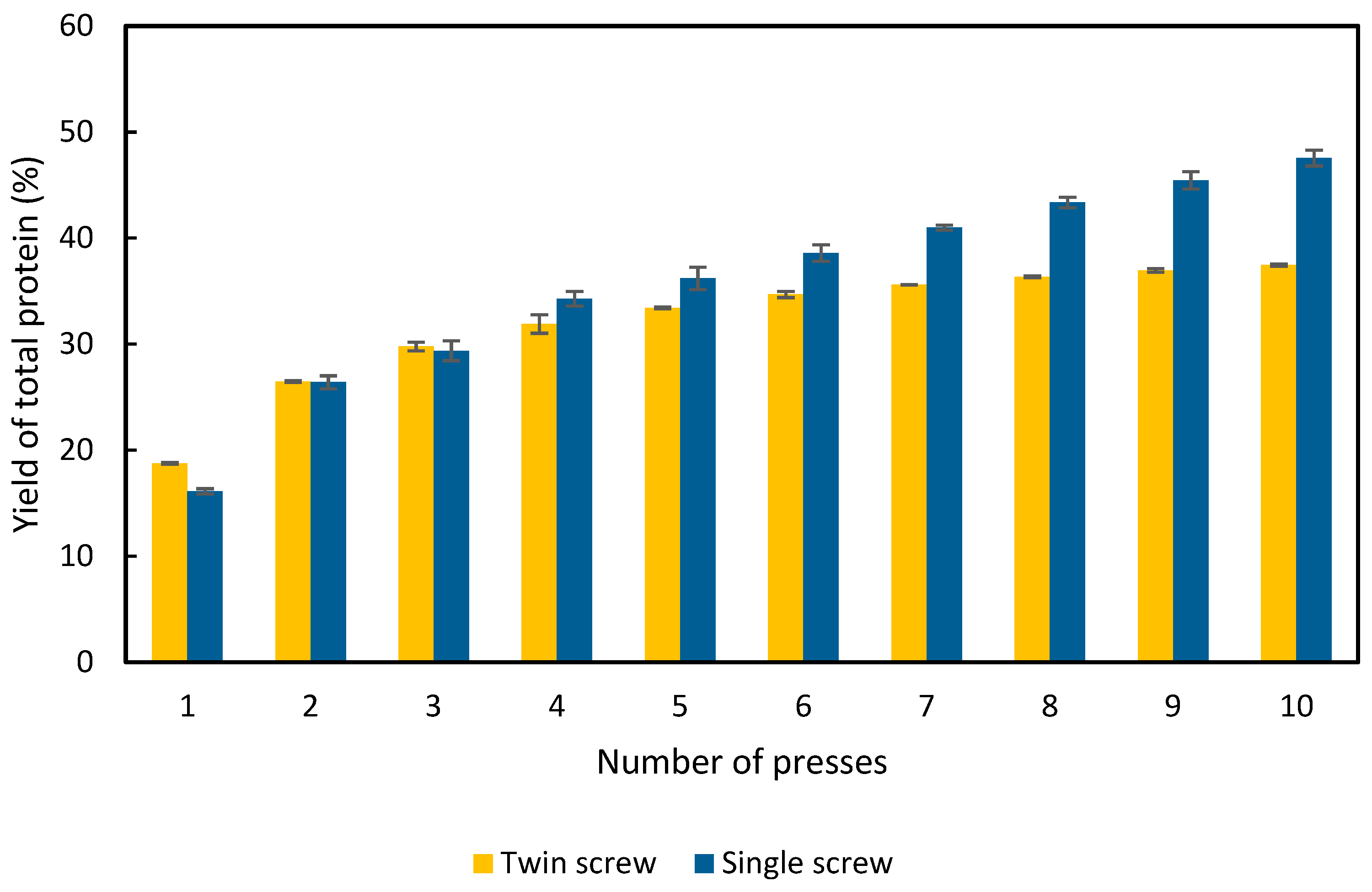

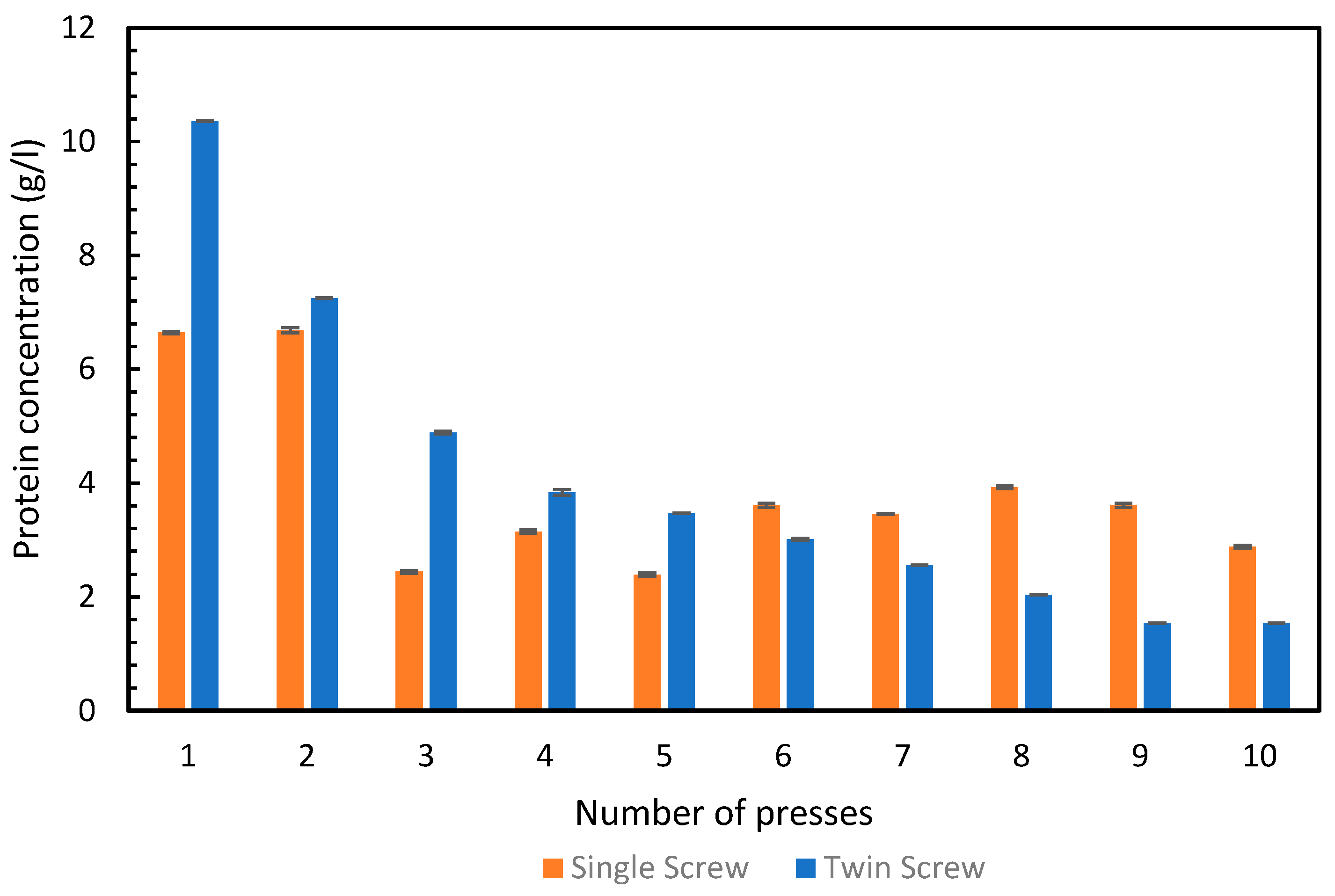

3.1. Comparison of Single- and Twin-Screw Presses for Extraction of APC

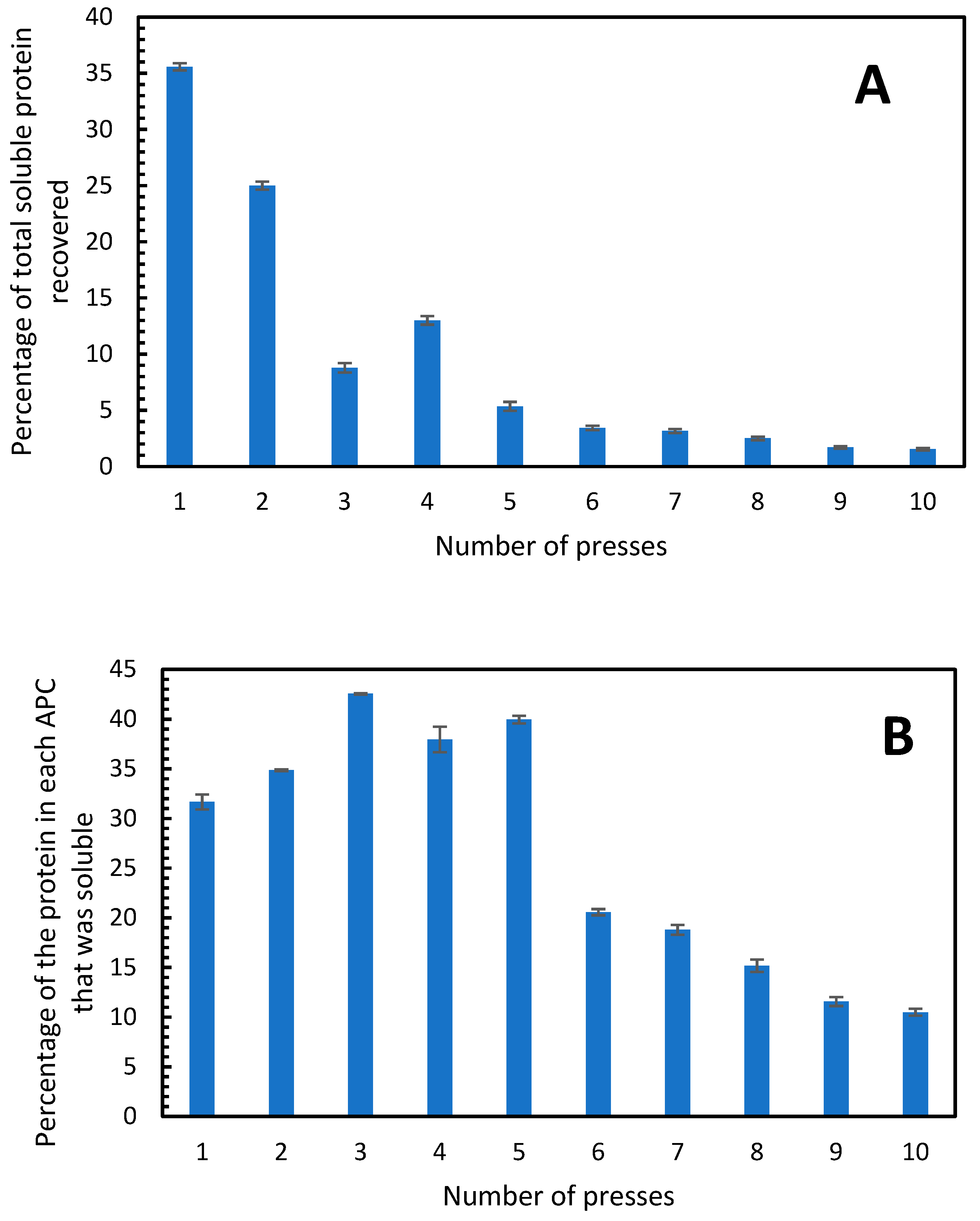

3.2. Soluble Protein and Protein Profile by SDS-PAGE

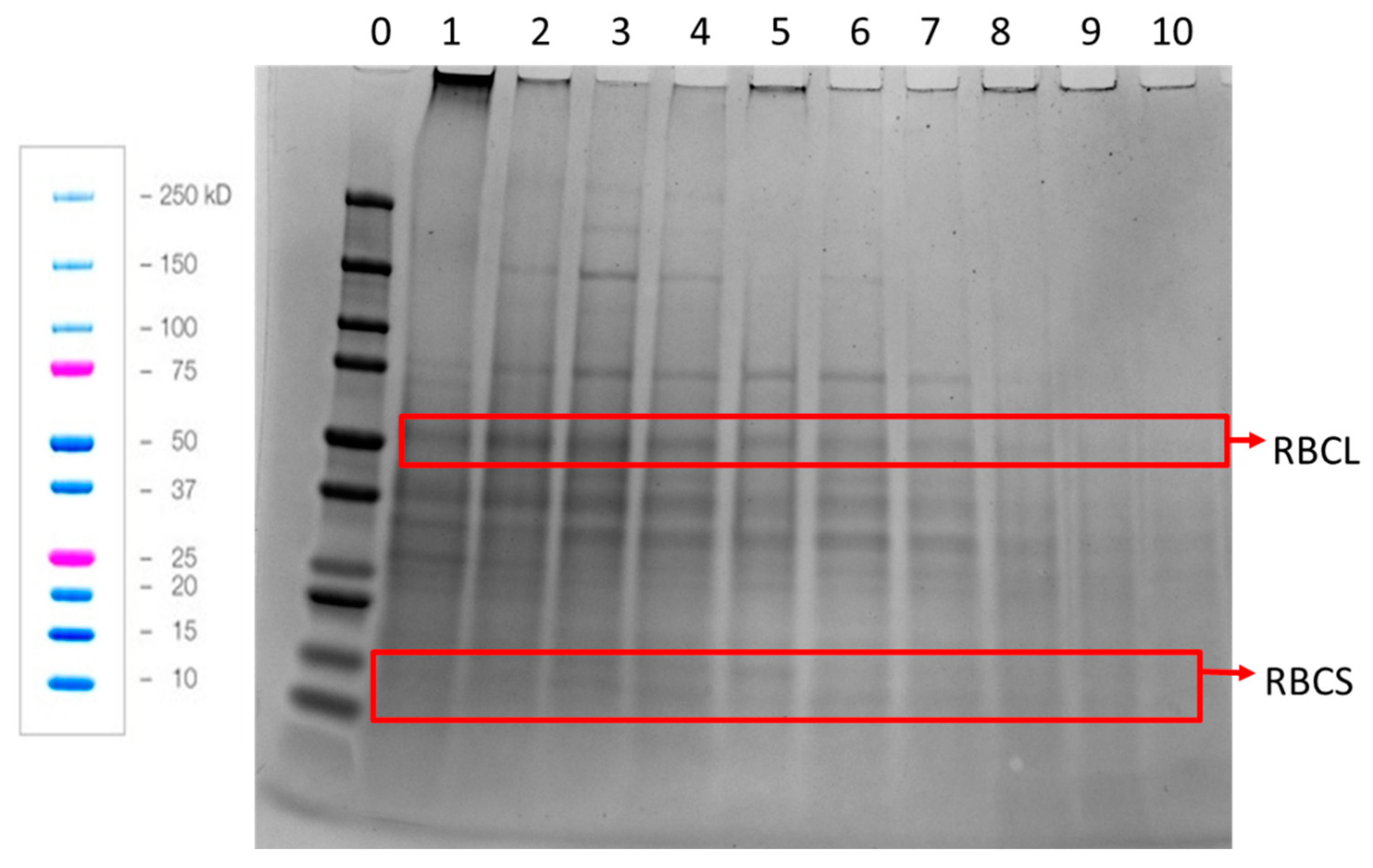

3.3. Amino Acid Profile of APC

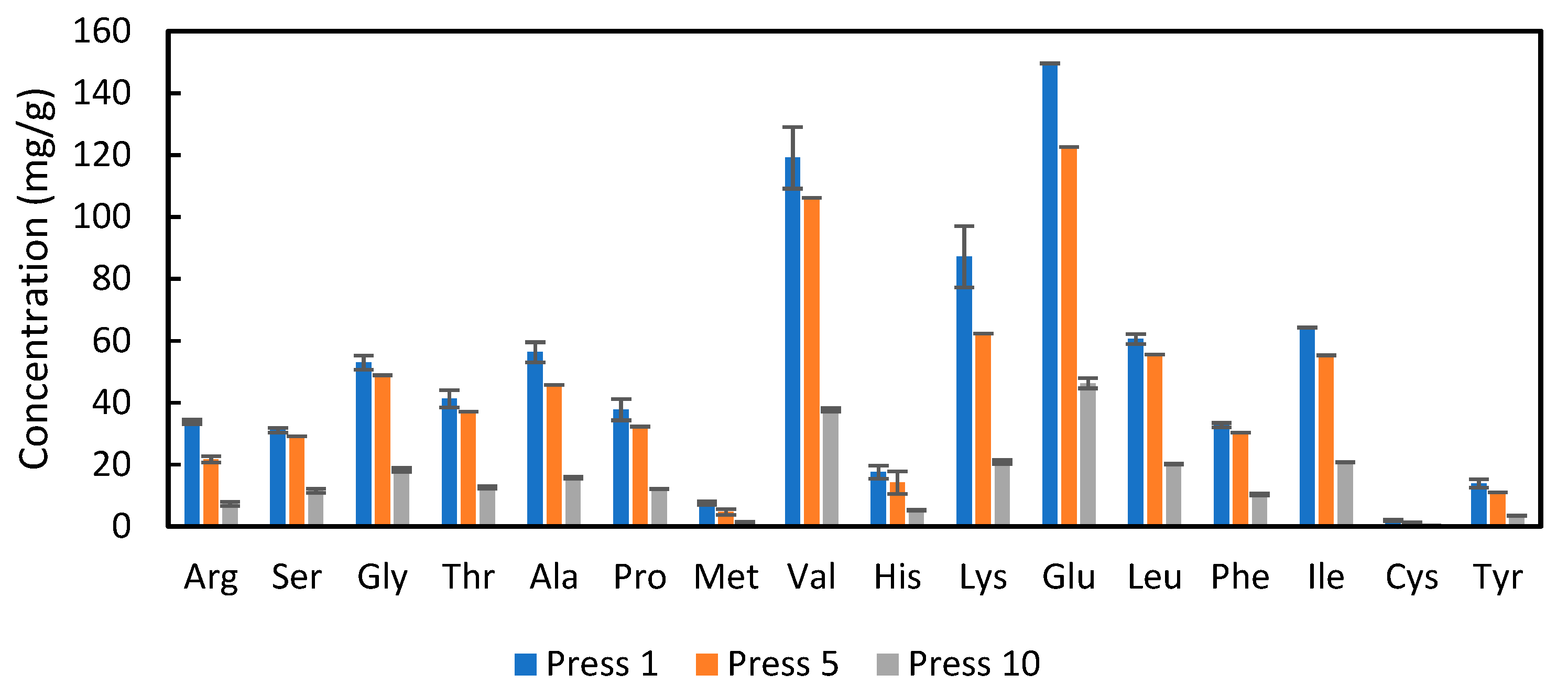

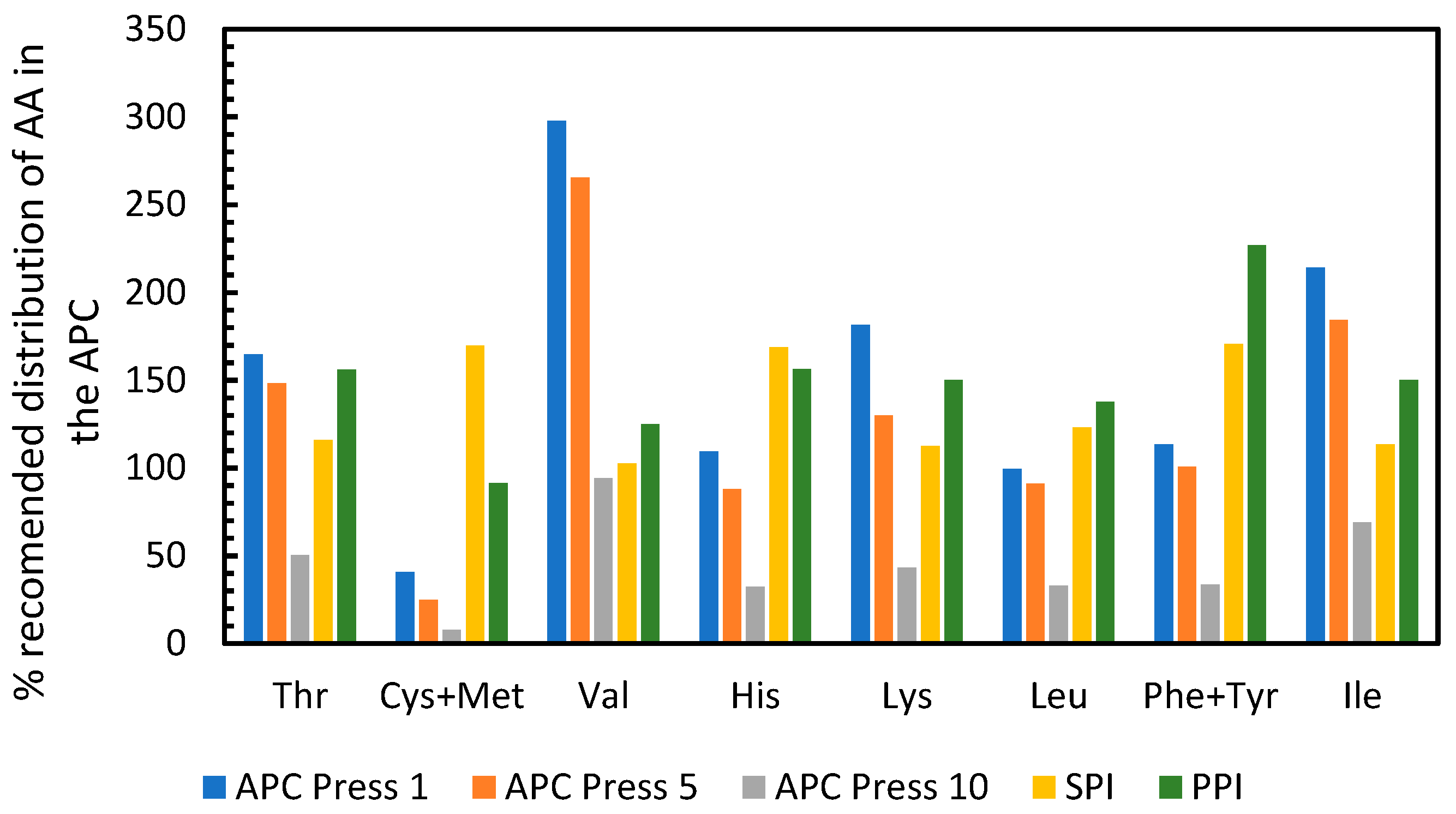

3.4. Color of the APC

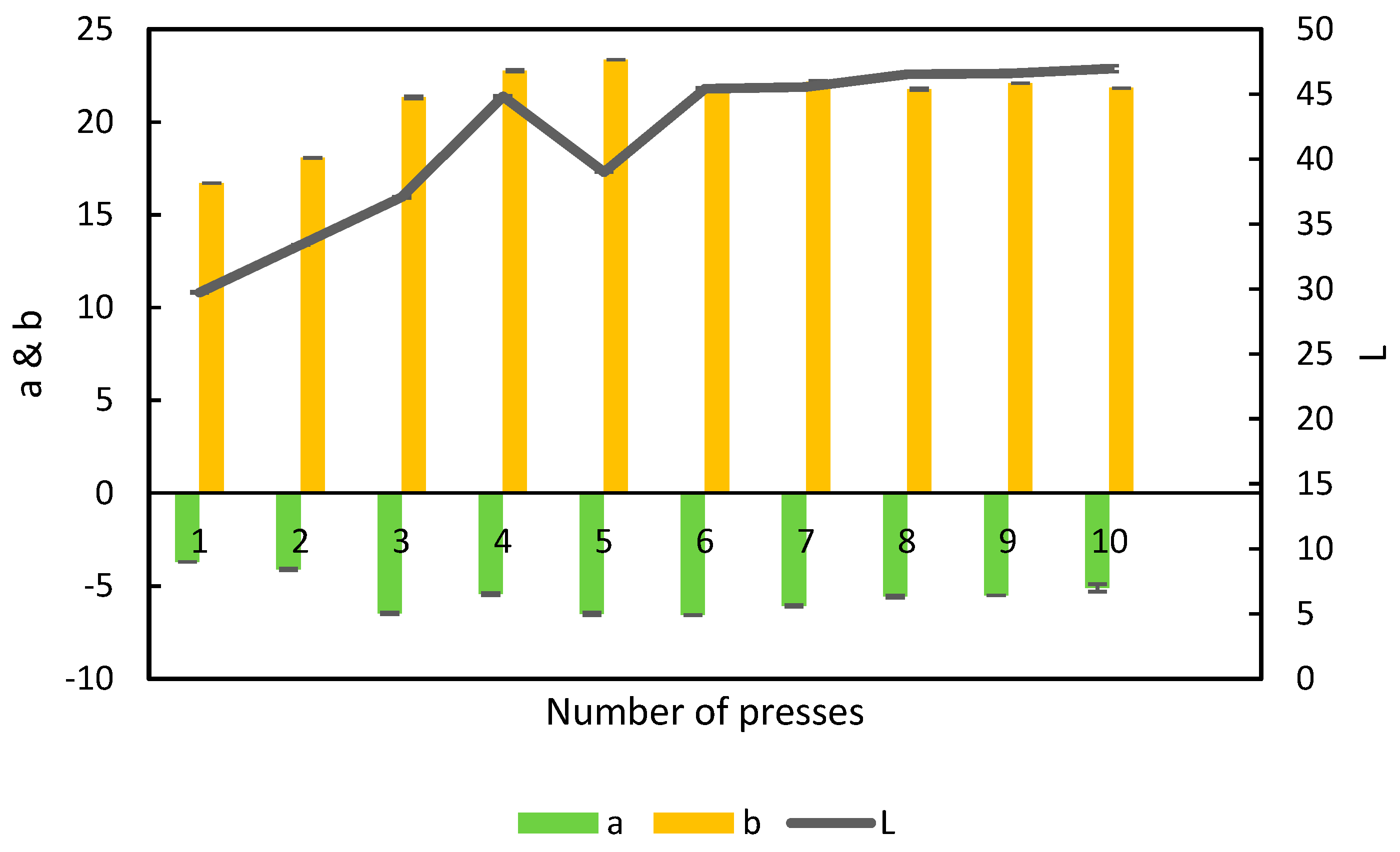

3.5. Properties of APC Produced with Single-Screw Press

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Twin-Screw Press | ||||

|---|---|---|---|---|

| Press Number | Pulp | Green Juice | Brown Juice | Green Pellet |

| 1 | 932 | 3589 | 3474 | 321 |

| 2 | 681 | 2059 | 1897 | 182 |

| 3 | 555 | 1415 | 1303 | 118 |

| 4 | 485 | 1138 | 1023 | 108 |

| 5 | 469 | 963 | 855 | 101 |

| 6 | 432 | 942 | 836 | 98 |

| 7 | 413 | 861 | 797 | 62 |

| 8 | 391 | 815 | 754 | 56 |

| 9 | 378 | 775 | 718 | 54 |

| 10 | 358 | 746 | 693 | 48 |

| Single-Screw Press | ||||

| Press Number | Pulp | Green Juice | Brown Juice | Green Pellet |

| 1 | 16221 | 53131 | 47938 | 4834 |

| 2 | 12449 | 33703 | 42101 | 3959 |

| 3 | 9549 | 26566 | 25020 | 969 |

| 4 | 8769 | 34220 | 32297 | 1809.7 |

| 5 | 7494 | 17578 | 16814 | 693 |

| 6 | 7108 | 14514 | 13572 | 874 |

| 7 | 6587 | 15244 | 13696 | 1003 |

| 8 | 6183 | 13175 | 12091 | 1027 |

| 9 | 5849 | 12749 | 11789 | 974 |

| 10 | 5827 | 15900 | 14653 | 1113 |

Appendix B

| Press | Arg | Ser | Gly | Thr | Ala | Pro |

|---|---|---|---|---|---|---|

| 1 | 4.18 | 3.85 | 6.56 | 5.10 | 6.98 | 4.67 |

| 5 | 3.19 | 4.30 | 7.21 | 5.47 | 6.74 | 4.76 |

| 10 | 2.99 | 4.72 | 7.53 | 5.18 | 6.45 | 4.94 |

| Press | Met | Val | His | Lys | Glu | Leu |

| 1 | 0.92 | 14.76 | 2.17 | 10.79 | 18.54 | 7.51 |

| 5 | 0.68 | 15.67 | 2.08 | 9.19 | 18.09 | 8.19 |

| 10 | 0.59 | 15.46 | 2.13 | 8.54 | 18.99 | 8.23 |

| Press | Phe | Ile | Cys | Tyr | ||

| 1 | 4.05 | 7.97 | 0.23 | 1.72 | ||

| 5 | 4.47 | 8.16 | 0.16 | 1.63 | ||

| 10 | 4.23 | 8.49 | 0.14 | 1.41 |

| Press Number | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Protein (% DM) | 51.35 ± 0.08 | 49.16 ± 0.07 | 39.45 ± 0.41 | 36.75 ± 087 | 33.80 ± 0.09 |

| Press number | 6 | 7 | 8 | 9 | 10 |

| Protein (% DM) | 31.21 ± 0.29 | 28.07 ± 0.03 | 28.43 ± 0.09 | 26.69 ± 0.17 | 24.53 ± 0.12 |

References

- Flachowsky, G.; Meyer, U.; Südekum, K.H. Land use for edible protein of animal origin—A review. Animals 2017, 7, 25. [Google Scholar] [CrossRef] [PubMed]

- Kavut, Y.T.; Avicioglu, R. Yield and Quality Performances of Various Alfalfa (Medicago Sativa L.) Cultivars in Different Soil Textures in a Mediterranean Enviroment. Turk. J. F. Crop. 2015, 20, 65–71. [Google Scholar]

- Kaldy, M.S. Protein yield of various crops as related to protein value. Econ. Bot. 1972, 26, 142–144. [Google Scholar] [CrossRef]

- El-Ramady, H.; Abdalla, N.; Kovacs, S.; Domokos-Szabolcsy, É.; Bákonyi, N.; Fari, M.; Geilfus, C.M. Sustainable biorefinery of alfalfa (Medicago sativa L.): A review. Egypt. J. Bot. 2020, 60, 621–639. [Google Scholar] [CrossRef]

- Mielmann, A. The utilisation of lucerne: A review. Br. Food J. 2013, 115, 590–600. [Google Scholar] [CrossRef]

- EFSA. Commission Decision of 13 October 2009 Authorising the Placing on the Market of a Leaf Extract from Lucerne (Medicago sativa) as Novel Food or Novel Food Ingredient under Regulation (EC) No 258/97 of the European Parliament and of the Council; EFSA: Parma, Italy, 2009. [Google Scholar]

- Knuckles, B.E.; Bickoff, E.M.; Kohler, G.O. Pro-Xan Process: Methods for Increasing Protein Recovery from Alfalfa. J. Agric. Food Chem. 1972, 20, 1055–1057. [Google Scholar] [CrossRef]

- Griffiths, F.P. Production and utilization of alfalfa. Econ. Bot. 1949, 3, 170–183. [Google Scholar] [CrossRef]

- Knuckles, B.E.; DeFremery, D.; Kohler, G.O. Coumestrol Content of Fractions Obtained during Wet Processing of Alfalfa. J. Agric. Food Chem. 1976, 24, 1177–1180. [Google Scholar] [CrossRef] [PubMed]

- BioRefine. Available online: https://www.biorefine.dk/ (accessed on 24 May 2021).

- Lamsal, B.P.; Koegel, R.G.; Gunasekaran, S. Some physicochemical and functional properties of alfalfa soluble leaf proteins. LWT Food Sci. Technol. 2007, 40, 1520–1526. [Google Scholar] [CrossRef]

- Tanambell, H.; Møller, A.H.; Corredig, M.; Dalsgaard, T.K. RuBisCO from alfalfa—native subunits preservation through sodium sulfite addition and reduced solubility after acid precipitation followed by freeze-drying. LWT 2022, 154, 112682. [Google Scholar] [CrossRef]

- Vincent Corp. Specifications on Vincent CP-4. Available online: https://vincentcorp.com/wp-content/uploads/CP_VP_Screw_Press_1M-08_13_0.pdf (accessed on 19 September 2022).

- Sheen, S.J. Comparison of Chemical and Functional Properties of Soluble Leaf Proteins from Four Plant Species. J. Agric. Food Chem. 1991, 39, 681–685. [Google Scholar] [CrossRef]

- Megazyme. Available Carbohydrates and Dietary Fiber Assay Procedure. Available online: https://www.megazyme.com/available-carbohydrates-dietary-fiber-assay-kit (accessed on 14 October 2022).

- Applied biosystems Pierce Coomasie Plus Bradford protocal. Available online: https://www.thermofisher.com/document-connect/document-connect.html?url=https://assets.thermofisher.com/TFS-Assets%2FLSG%2Fmanuals%2FMAN0011344_CoomassiePlus_Bradford_Asy_Reag_UG.pdf (accessed on 28 August 2022).

- Saunders, R.M.; Connor, M.A.; Booth, A.N.; Bickoff, E.M.; Kohler, G.O. Measurement of digestibility of alfalfa protein concentrates by in vivo and in vitro methods. J. Nutr. 1973, 103, 530–535. [Google Scholar] [CrossRef] [PubMed]

- Phenomenex. User Guide for EZ:Faast Amino Kit; Phenomenex: Torrance, CA, USA, 2003. [Google Scholar]

- Edwards, R.H.; Miller, R.E.; de Fremery, D.; Knuckles, B.E.; Bickoff, E.M.; Kohler, G.O. Pilot Plant Production of an Edible White Fraction Leaf Protein Concentrate from Alfalfa. J. Agric. Food Chem. 1975, 23, 620–626. [Google Scholar] [CrossRef]

- Hojilla-Evangelista, M.P.; Selling, G.W.; Hatfield, R.; Digman, M. Extraction, composition, and functional properties of dried alfalfa (Medicago sativa L.) leaf protein. J. Sci. Food Agric. 2017, 97, 882–888. [Google Scholar] [CrossRef] [PubMed]

- Yakhlef, M.; Giangrieco, I.; Ciardiello, M.A.; Fiume, I.; Mari, A.; Souiki, L.; Pocsfalvi, G. Potential allergenicity of Medicago sativa investigated by a combined IgE-binding inhibition, proteomics and in silico approach. J. Sci. Food Agric. 2021, 101, 1182–1192. [Google Scholar] [CrossRef]

- Corgneau, M.; Gaiani, C.; Petit, J.; Nikolova, Y.; Banon, S.; Ritié-Pertusa, L.; Le, D.T.L.; Scher, J. Nutritional quality evaluation of commercial protein supplements. Int. J. Food Sci. Technol. 2019, 54, 2586–2594. [Google Scholar] [CrossRef]

- Ly, B.C.K.; Dyer, E.B.; Feig, J.L.; Chien, A.L.; Del Bino, S. Research Techniques Made Simple: Cutaneous Colorimetry: A Reliable Technique for Objective Skin Color Measurement. J. Investig. Dermatol. 2020, 140, 3–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palmer, L.S. Xanthophyll, the principal natural yellow pigment of the egg yolk, body fat, and blood serum of the hen. The physiological relation of the pigment to the xanthophyll of plants. J. Biol. Chem. 1915, 23, 261–279. [Google Scholar] [CrossRef]

- NIH PubChem. Available online: https://pubchem.ncbi.nlm.nih.gov/ (accessed on 31 August 2022).

- Kahyani, A.; Ghorbani, G.R.; Alikhani, M.; Ghasemi, E.; Sadeghi-Sefidmazgi, A.; Beauchemin, K.A.; Nasrollahi, S.M. Performance of dairy cows fed diets with similar proportions of undigested neutral detergent fiber with wheat straw substituted for alfalfa hay, corn silage, or both. J. Dairy Sci. 2019, 102, 10903–10915. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Hansen, M.; Hobley, T.J.; Jensen, P.R. Valorization of Green Biomass: Alfalfa Pulp as a Substrate for Oyster Mushroom Cultivation. Foods 2022, 11, 2519. [Google Scholar] [CrossRef] [PubMed]

| Component | Protein (%) | Water (%) | Ash (%) | Fat (%) | Total (%) |

|---|---|---|---|---|---|

| Raw Alfalfa | 4.3 ± 0.5 | 79.38 | 1.78 ± 0.21 | 0.25 ± 0.00 | 85.7 |

| Component\Press | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| APC obtained (g) | 818.4 | 511 | 136.9 | 268.5 | 99.7 |

| Protein (%) | 43.12 ± 0.26 | 44.08 ± 0.83 | 47.40± 0.93 | 40.07± 0.68 | 42.14 ±1.06 |

| Protein Digestibility (%) | 87.36 ± 0.86 | 82.42 ± 1.30 | 76.20 ± 1.39 | 69.16 ± 0.49 | 70.43 ± 1.69 |

| Insoluble fiber (%) | 21.13 | 24.83 | 29.34 | 35.03 | 34.6 |

| Soluble fiber (%) | 1.67 | 1.21 | 2.17 | 2.22 | 2.41 |

| Glucose (%) | 3.15 ± 0.63 | 2.27 ± 0.48 | 1.79 ± 0.76 | 1.20 ± 0.65 | 2.14 ±0.00 |

| Fructose (%) | 2.29 ± 0.47 | 0.30 ± 0.30 | 0.04 ± 0.06 | 0.38 ± 0.53 | 0.00 ±0.00 |

| Ash (%) | 8.24 ± 0.28 | 3.15 ± 0.55 | 3.07 ± 0.37 | 2.72 ± 0.28 | 2.40 ±0.18 |

| Fat (%) | 1.25 ± 0.15 | 3.77 ± 0.86 | 2.46 ± 0.25 | 2.41 ± 0.12 | 2.76 ± 0.09 |

| Component\Press | 6 | 7 | 8 | 9 | 10 |

| APC obtained (g) | 126.8 | 134.8 | 133.6 | 120.3 | 120.8 |

| Protein (%) | 41.29 ± 0.77 | 39.08 ± 0.13 | 38.69 ± 0.59 | 38.24 ± 0.82 | 37.84 ±0.80 |

| Protein Digestibility (%) | 62.28 ± 1.39 | 61.84 ± 0.82 | 64.07 ± 0.35 | 63.72 ± 0.43 | 65.02 ± 1.16 |

| Insoluble fiber (%) | 39.36 | 41.56 | 42.16 | 44.94 | 45.6 |

| Soluble fiber (%) | 1.51 | 1.71 | 1.82 | 1.77 | 1.86 |

| Glucose (%) | 1.61 ± 0.12 | 1.00 ± 0.12 | 1.06 ± 0.07 | 0.77 ± 0.12 | 0.55 ±0.18 |

| Fructose (%) | 0.34± 0.36 | 0.38 ± 0.30 | 0.04 ± 0.06 | 0.17 ± 0.00 | 0.55 ±0.78 |

| Ash (%) | 3.16 ± 0.61 | 2.95 ± 0.50 | 2.95 ± 0.57 | 2.52 ± 0.25 | 2.70 ± 0.29 |

| Fat (%) | 2.56 ± 0.04 | 2.71 ± 0.16 | 2.31 ± 0.04 | 2.13 ± 0.16 | 2.25 ± 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hansen, M.; Andersen, C.A.; Jensen, P.R.; Hobley, T.J. Scale-Up of Alfalfa (Medicago sativa) Protein Recovery Using Screw Presses. Foods 2022, 11, 3229. https://doi.org/10.3390/foods11203229

Hansen M, Andersen CA, Jensen PR, Hobley TJ. Scale-Up of Alfalfa (Medicago sativa) Protein Recovery Using Screw Presses. Foods. 2022; 11(20):3229. https://doi.org/10.3390/foods11203229

Chicago/Turabian StyleHansen, Mikkel, Christina Albers Andersen, Peter Ruhdal Jensen, and Timothy John Hobley. 2022. "Scale-Up of Alfalfa (Medicago sativa) Protein Recovery Using Screw Presses" Foods 11, no. 20: 3229. https://doi.org/10.3390/foods11203229

APA StyleHansen, M., Andersen, C. A., Jensen, P. R., & Hobley, T. J. (2022). Scale-Up of Alfalfa (Medicago sativa) Protein Recovery Using Screw Presses. Foods, 11(20), 3229. https://doi.org/10.3390/foods11203229