Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review

Abstract

1. Introduction

- RQ1.

- To what extent has research been conducted on the development of meat analogues derived from plant protein-based materials?

- RQ2.

- What are the key research themes in the literature on plant-based meat analogues?

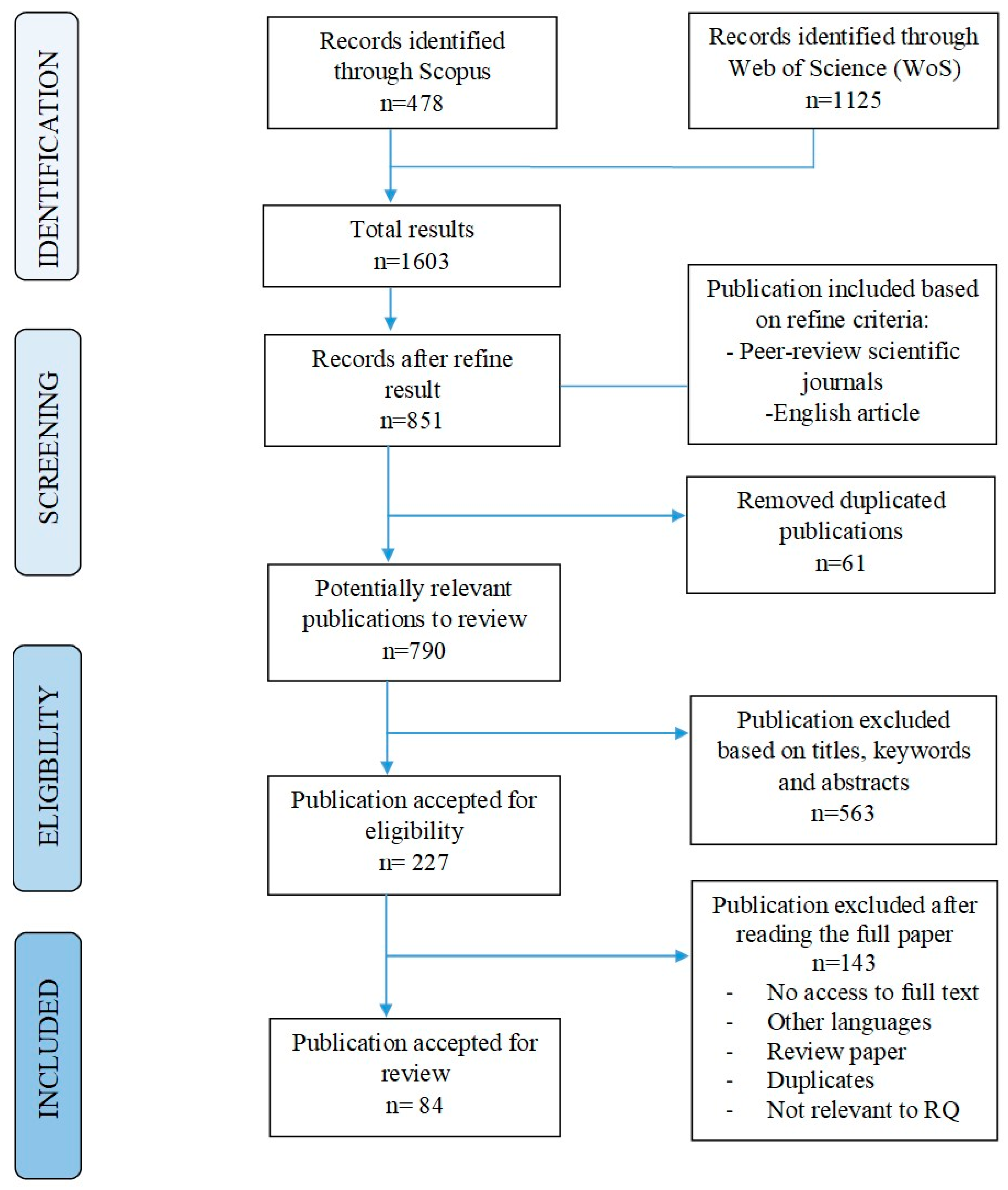

2. Methodology

2.1. Overview of Review Protocol

2.2. Literature Retrieval and Selection

2.3. Bibliometric Analysis

3. Results and Discussion

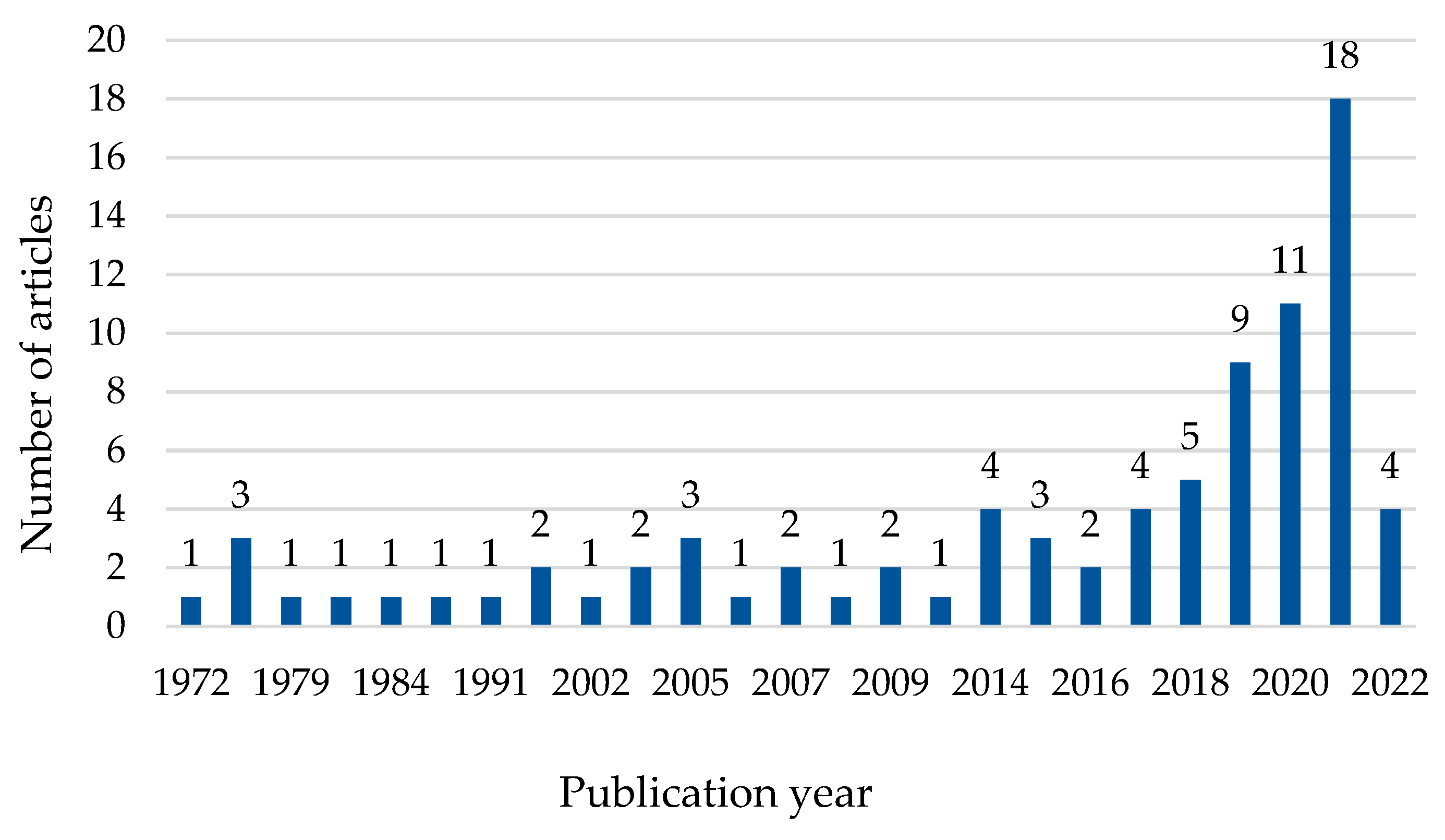

3.1. Publication Trends

3.2. Journal-Based Publications

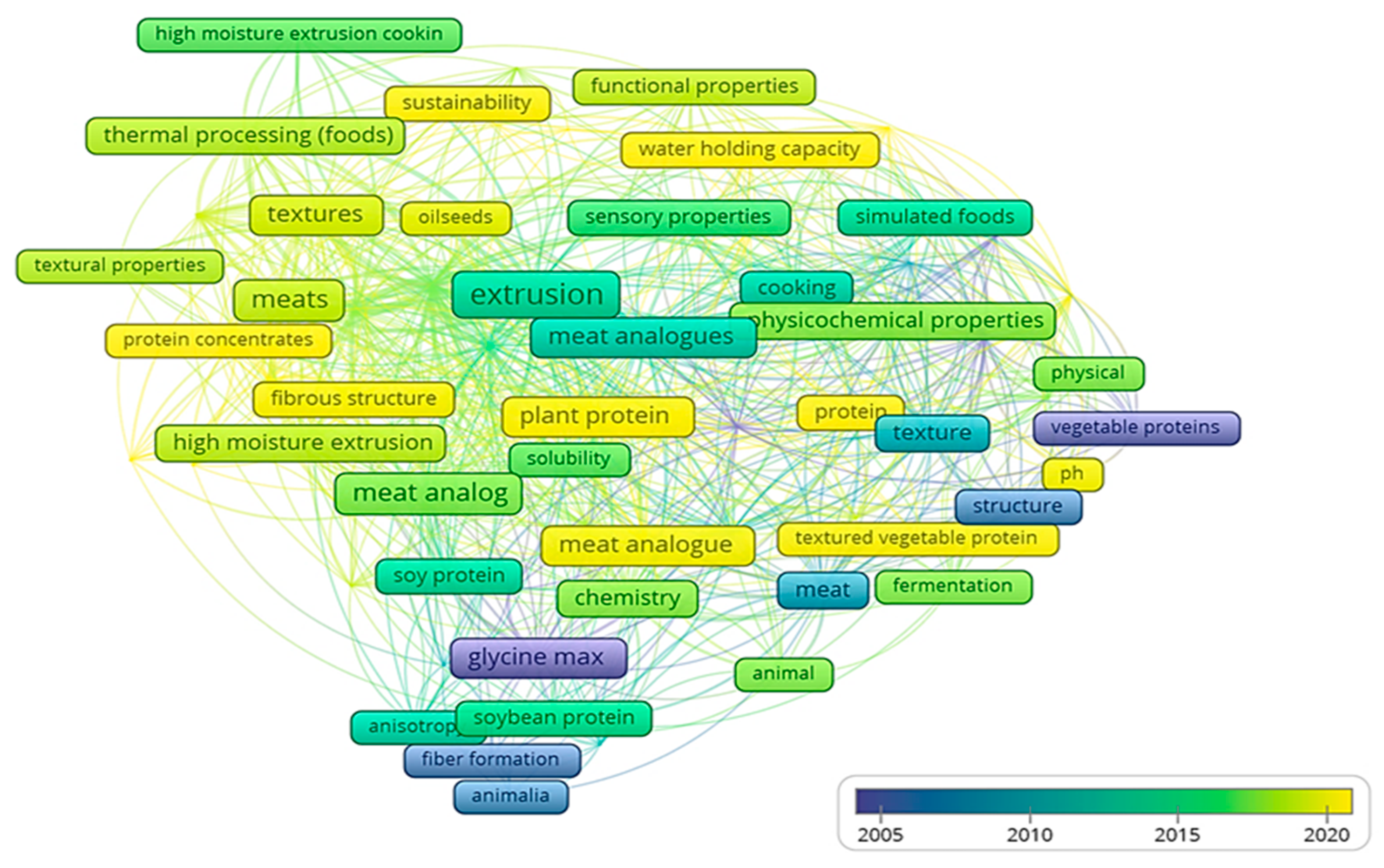

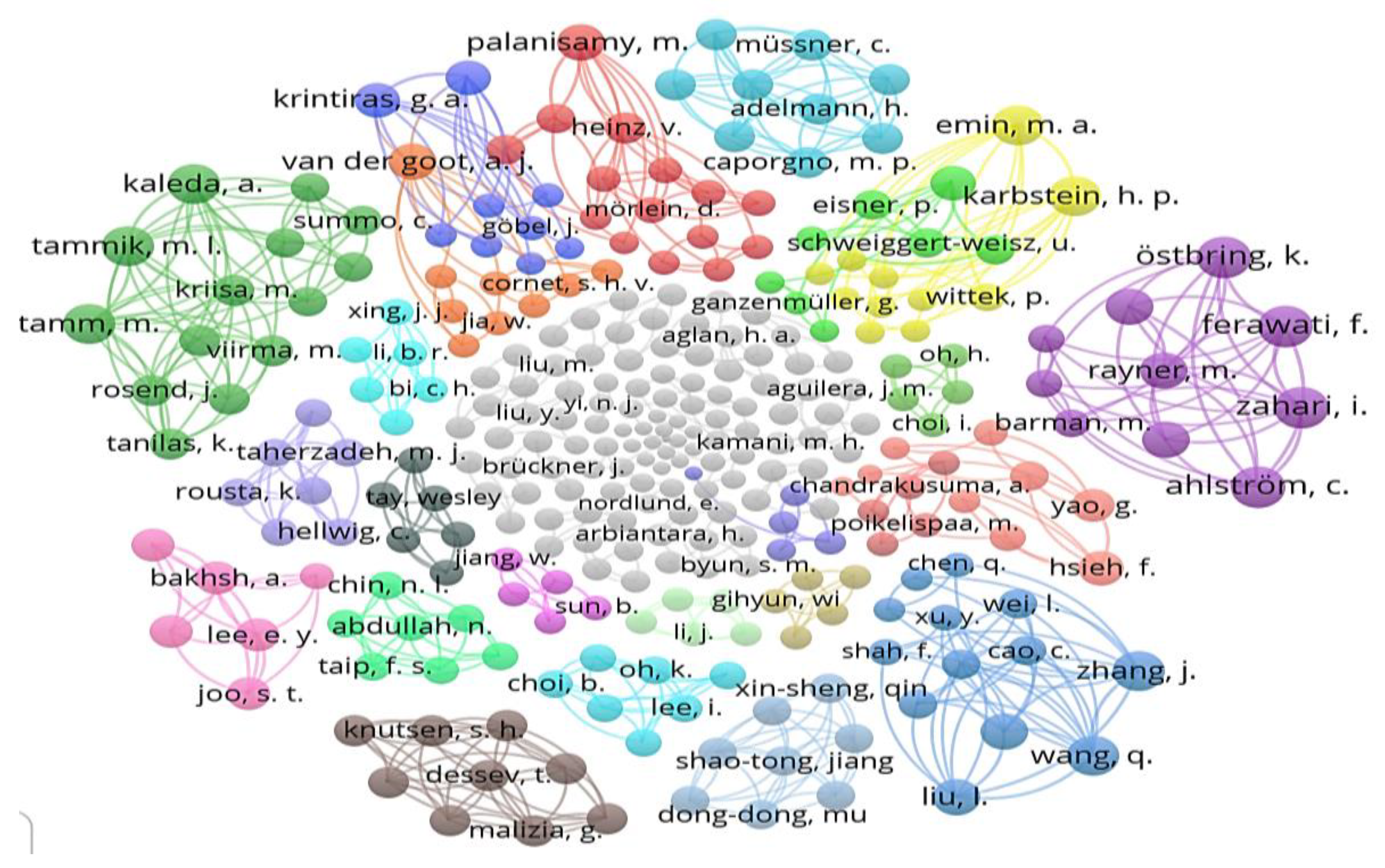

3.3. Meat Analogue Bibliometric Networks

3.3.1. Network Visualization for Author Keywords

3.3.2. Network Visualization by Author

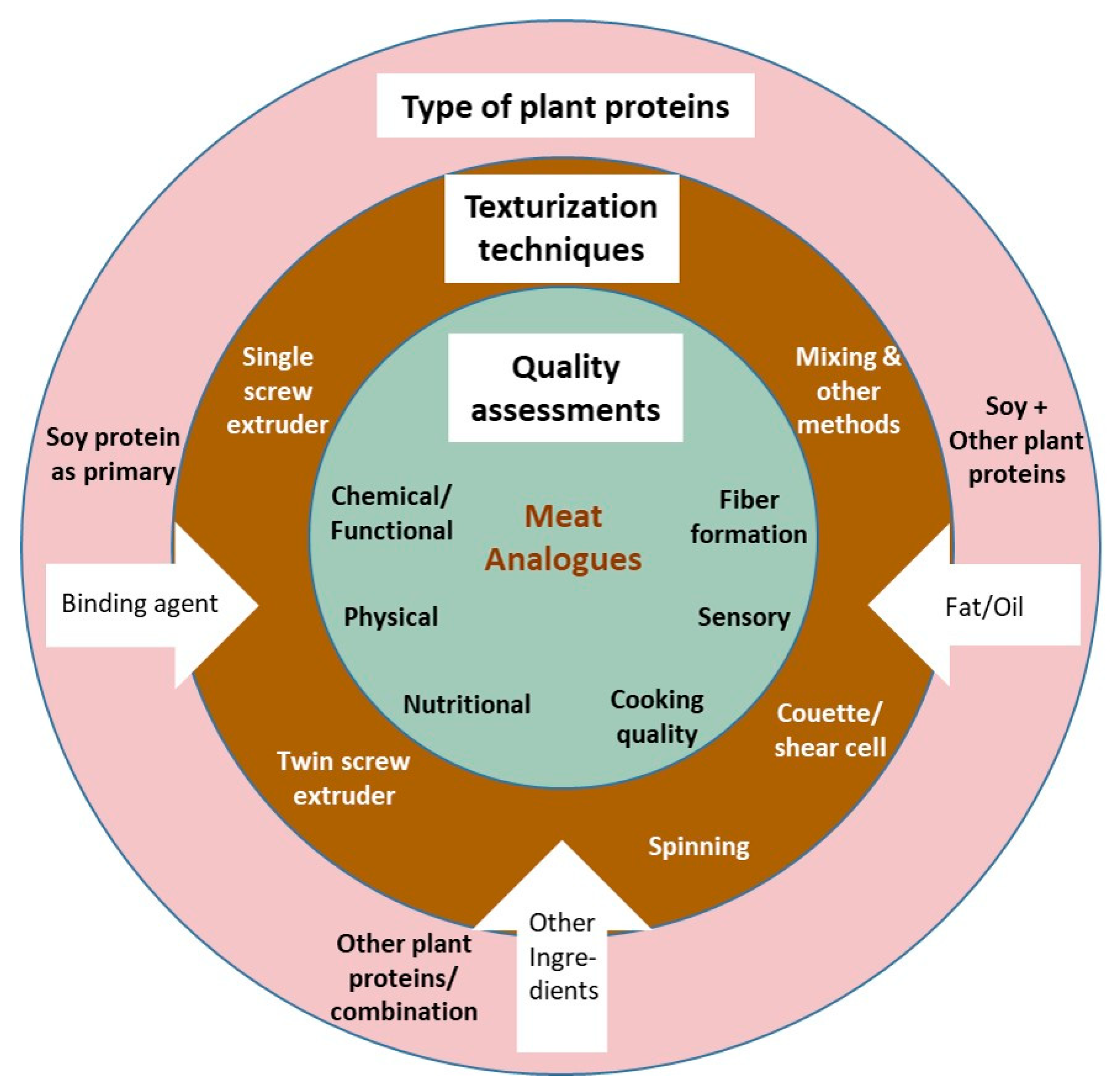

3.4. Classifications

3.4.1. Objectives of the Reviewed Studies

3.4.2. Type of Plant Proteins Used

Soy Protein as Primary Component

Soy Protein Combined with Other Plant Proteins

Alternative Proteins without Soy Protein

3.4.3. Product Type

Texturized Vegetable Protein (TVP)

Meat Analogues

3.4.4. Added Ingredient Used to Improve Texturized Products

Binding Agents

Fat/Oil

Other Ingredients

3.4.5. Type of Texturization Technique

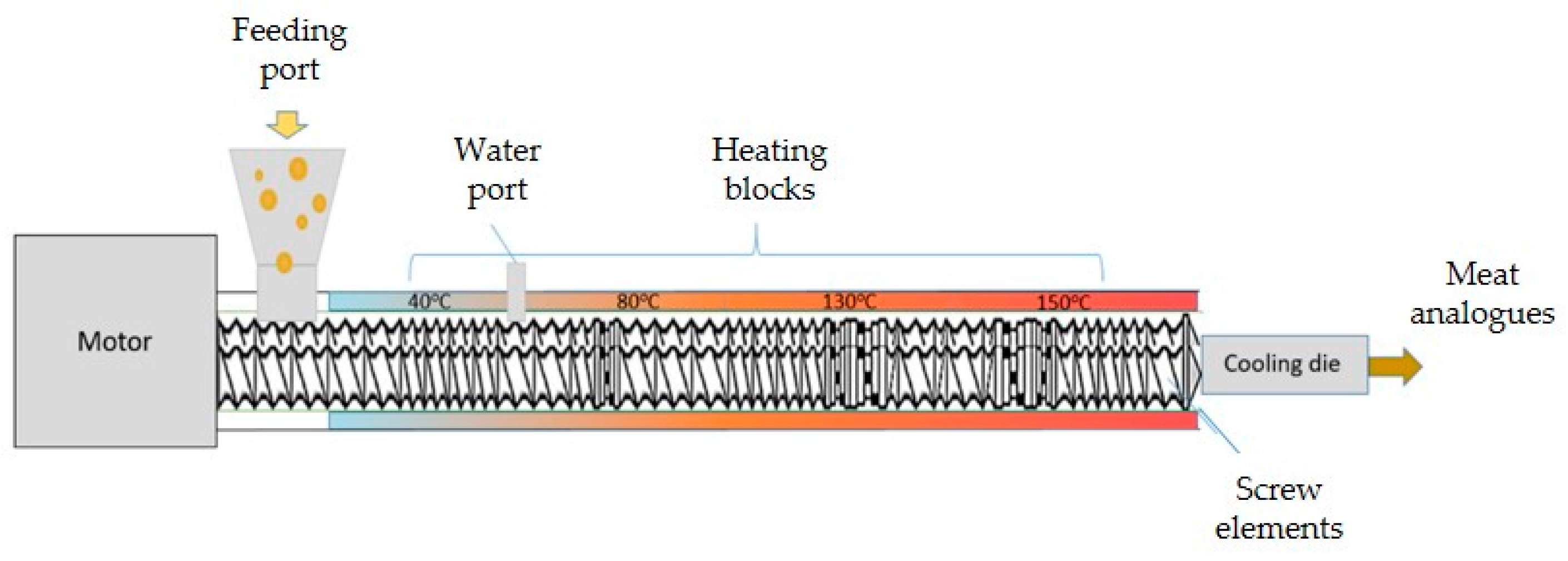

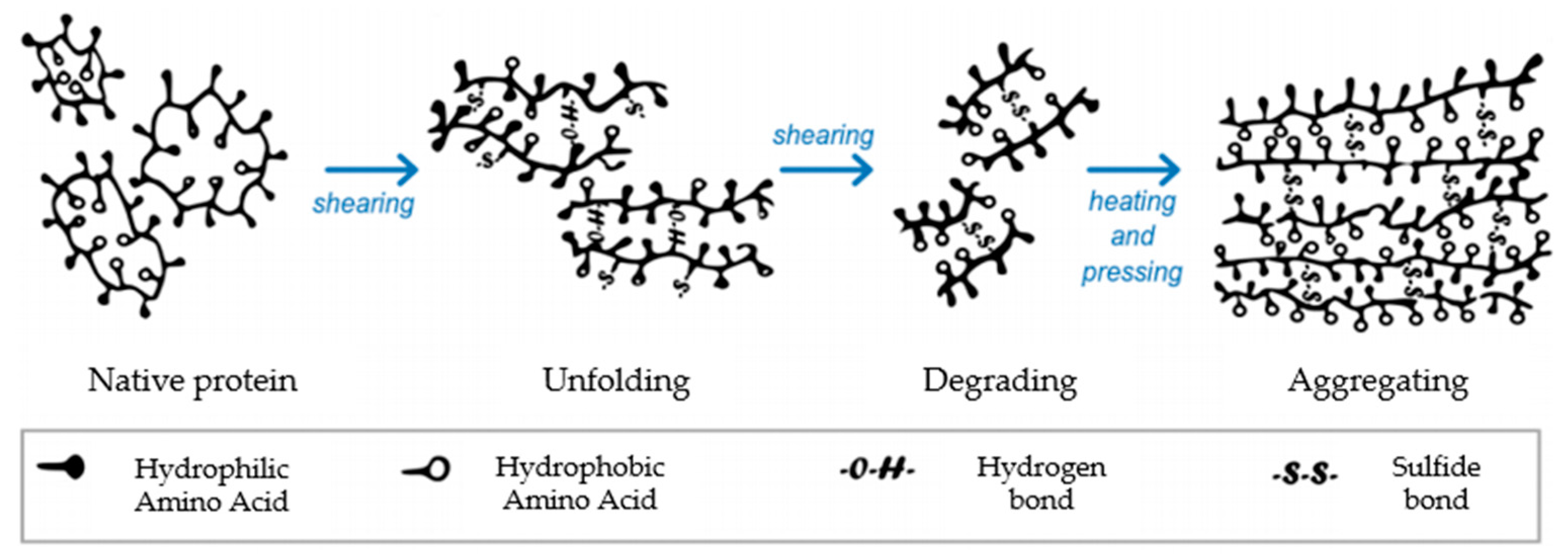

Extrusion

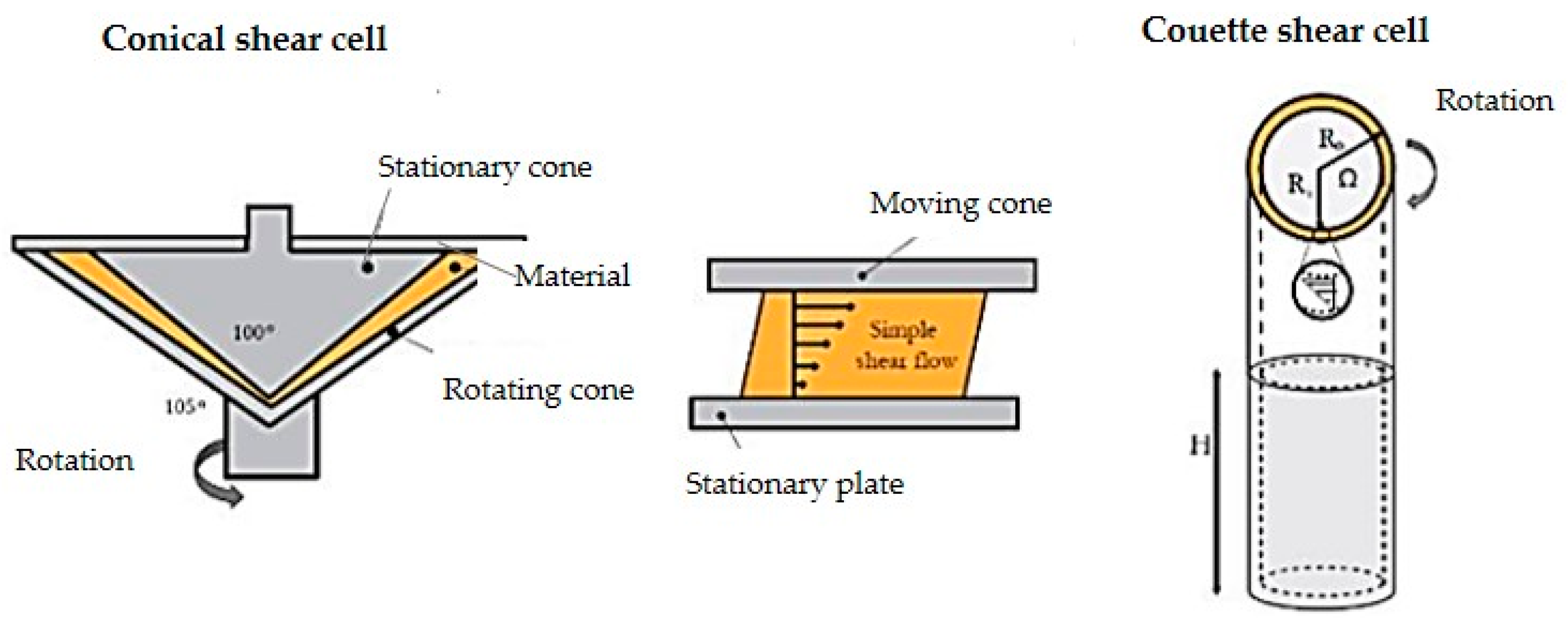

Shear/Couette Cell

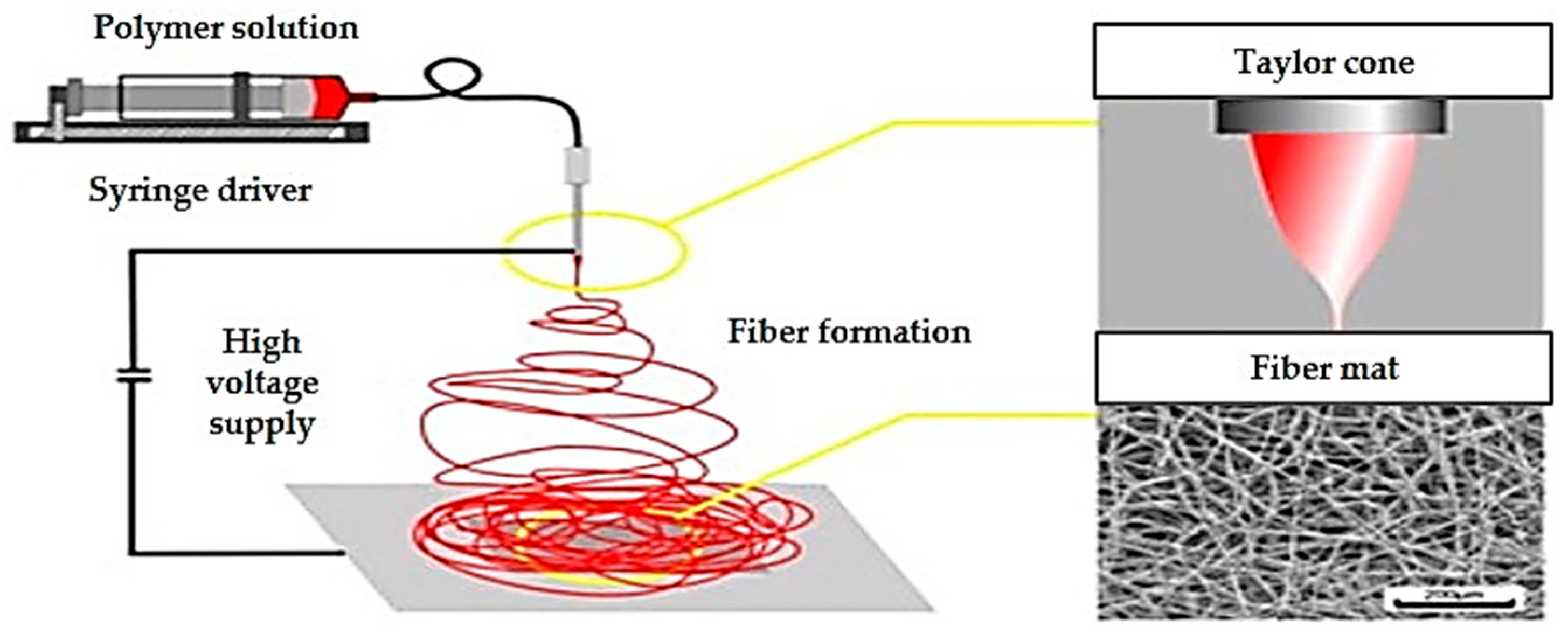

Spinning

Other Texturization Methods

3.4.6. Quality Assessment Considered

Chemical/Functional Properties

Physical Properties

Fiber Formation

Nutritional Analysis

Cooking Quality

Sensory Evaluation

Other Assessments

4. Recommendation for Future Studies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Population Division, Department of Economic and Social Affairs, United Nations. World Population Prospects Highlights; Revision Highlights, 2019 Revision; UN: New York, NY, USA, 2019; ISBN 978-92-1-148316-1. [Google Scholar]

- Machovina, B.; Feeley, K.J.; Ripple, W.J. Biodiversity Conservation: The Key Is Reducing Meat Consumption. Sci. Total Environ. 2015, 536, 419–431. [Google Scholar] [CrossRef]

- Derbyshire, E.J. Flexitarian Diets and Health: A Review of the Evidence-Based Literature. Front. Nutr. 2017, 3, 55. [Google Scholar] [CrossRef]

- Götze, F.; Brunner, T.A. A Consumer Segmentation Study for Meat and Meat Alternatives in Switzerland. Foods 2021, 10, 1273. [Google Scholar] [CrossRef]

- Toribio-Mateas, M.A.; Bester, A.; Klimenko, N. Impact of Plant-Based Meat Alternatives on the Gut Microbiota of Consumers: A Real-World Study. Foods 2021, 10, 2040. [Google Scholar] [CrossRef]

- Watson, J. Plant-Based Meat Market to Reach USD 30.92 Billion by 2026—Reports and Data. GlobeNewswire News Room 2019. [Google Scholar]

- Ramachandraiah, K. Potential Development of Sustainable 3D-Printed Meat Analogues: A Review. Sustainability 2021, 13, 938. [Google Scholar] [CrossRef]

- Sanchez-Sabate, R.; Sabaté, J. Consumer Attitudes Towards Environmental Concerns of Meat Consumption: A Systematic Review. Int. J. Environ. Res. Public Health 2019, 16, 1220. [Google Scholar] [CrossRef]

- Gibson, D.L.; Dwivedi, B.K. Production of Meat Substitutes from Spent Brewers’ Yeast and Soy Protein. Can. Inst. Food Technol. J. 1970, 3, 113–115. [Google Scholar] [CrossRef]

- Sun, C.; Fu, J.; Chang, Y.; Li, S.; Fang, Y. Structure Design for Improving the Characteristic Attributes of Extruded Plant-Based Meat Analogues. Food Biophys. 2022, 17, 137–149. [Google Scholar] [CrossRef]

- Taranto, M.V.; Cegla, G.F.; Rhee, K.C. Morphological, Ultrastructural and Rheological Evaluation of Soy and Cottonseed Flours Texturized by Extrusion and Nonextrusion Processing. J. Food Sci. 1978, 43, 973–979. [Google Scholar] [CrossRef]

- Byun, S.M.; Kwon, J.H.; Kim, C.J.; Lee, Y.H. Soyprotein Fiber Formation. Korean J. Food Sci. Technol. 1978, 10, 143–150. [Google Scholar]

- Kyriakopoulou, K.; Dekkers, B.; Van Der Goot, A.J. Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar]

- Zahari, I.; Ferawati, F.; Purhagen, J.K.; Rayner, M.; Ahlström, C.; Helstad, A.; Östbring, K. Development and Characterization of Extrudates Based on Rapeseed and Pea Protein Blends Using High-Moisture Extrusion Cooking. Foods 2021, 10, 2397. [Google Scholar] [CrossRef] [PubMed]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- Dekkers, B.L. Creation of Fibrous Plant Protein Foods; Wageningen University: Wageningen, The Netherlands, 2018. [Google Scholar]

- Krintiras, G.A.; Diaz, J.G.; van der Goot, A.J.; Stankiewicz, A.I.; Stefanidis, G.D. On the Use of the Couette Cell Technology for Large Scale Production of Textured Soy-Based Meat Replacers. J. Food Eng. 2016, 169, 205–213. [Google Scholar] [CrossRef]

- Nieuwland, M.; Geerdink, P.; Brier, P.; van den Eijnden, P.; Henket, J.T.M.M.; Langelaan, M.L.P.; Stroeks, N.; Deventer, H.C.; van Martin, A.H. Food-Grade Electrospinning of Proteins. Innov. Food Sci. Emerg. Technol. 2013, 20, 269–275. [Google Scholar] [CrossRef]

- Hashizume, K. Preparation of a New Protein Food Material by Freezing. JARQ Jpn. Agric. Res. Q. 1978, 12, 104–108. [Google Scholar]

- Aguilera, J.M.; Rossi, F.; Hiche, E.; Chichester, C.O. Development and Evaluation of an Extrusion-Texturized Peanut Protein. J. Food Sci. 1980, 45, 246–250. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Zhang, Y.; Meng, S.; Wang, Q. Rheological Properties of Pea Protein Isolate-Amylose/Amylopectin Mixtures and the Application in the High-Moisture Extruded Meat Substitutes. Food Hydrocoll. 2021, 117, 106732. [Google Scholar] [CrossRef]

- Chiang, J.H.; Tay, W.; Ong, D.S.M.; Liebl, D.; Ng, C.P.; Henry, C.J. Physicochemical, Textural and Structural Characteristics of Wheat Gluten-Soy Protein Composited Meat Analogues Prepared with the Mechanical Elongation Method. Food Struct. 2021, 28, 100183. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Snel, S.J.E.; Lesschen, J.; van der Goot, A.J.; van der Sman, R.G.M. Enhancing the Water Holding Capacity of Model Meat Analogues through Marinade Composition. J. Food Eng. 2021, 290, 110283. [Google Scholar] [CrossRef]

- Ferawati, F.; Zahari, I.; Barman, M.; Hefni, M.; Ahlström, C.; Witthöft, C.; Östbring, K. High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties. Foods 2021, 10, 843. [Google Scholar] [CrossRef] [PubMed]

- Ranasinghesagara, J.; Hsieh, F.H.; Huff, H.; Yao, G. Laser Scanning System for Real-Time Mapping of Fiber Formations in Meat Analogues. J. Food Sci. 2009, 74, E39–E45. [Google Scholar] [CrossRef] [PubMed]

- Sakai, K.; Sato, Y.; Okada, M.; Yamaguchi, S. Improved Functional Properties of Meat Analogs by Laccase Catalyzed Protein and Pectin Crosslinks. Sci. Rep. 2021, 11, 16631. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.H. A Comparison of Physicochemical Characteristics, Texture, and Structure of Meat Analogue and Meats. J. Sci. Food Agric. 2019, 99, 2708–2715. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi, S.S.H.; Wang, Q. Changes in Conformation and Quality of Vegetable Protein during Texturization Process by Extrusion. Crit. Rev. Food Sci. Nutr. 2019, 59, 3267–3280. [Google Scholar] [CrossRef] [PubMed]

- Mosibo, O.K.; Ferrentino, G.; Alam, M.R.; Morozova, K.; Scampicchio, M. Extrusion Cooking of Protein-Based Products: Potentials and Challenges. Crit. Rev. Food Sci. Nutr. 2022, 62, 2526–2547. [Google Scholar] [CrossRef]

- Navale, S.A.; Swami, S.B.; Thakor, N.J. Extrusion cooking technology for foods: A review. J. Ready Eat Food 2015, 2, 66–80. [Google Scholar]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High Moisture Extrusion Cooking of Pea Protein Isolates: Raw Material Characteristics, Extruder Responses, and Texture Properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Eisner, P.; Schweiggert-Weisz, U. Effect of High Moisture Extrusion Cooking on Protein-Protein Interactions of Pea (Pisum sativum L.) Protein Isolates. Int. J. Food Sci. Technol. 2015, 50, 1390–1396. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Boom, R.M.; van der Goot, A.J. Structuring Processes for Meat Analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Asgar, M.A.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A.A. Nonmeat Protein Alternatives as Meat Extenders and Meat Analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of Extrusion Technology in Plant Food Processing Byproducts: An Overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef] [PubMed]

- Bohrer, B.M. An Investigation of the Formulation and Nutritional Composition of Modern Meat Analogue Products. Food Sci. Hum. Wellness 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Owens, S.F.; Levary, R.R. Evaluating Design Alternatives of an Extruded Food Production Line Using Simulation. Simulation 2002, 78, 626–632. [Google Scholar] [CrossRef]

- Banovic, M.; Sveinsdóttir, K. Importance of Being Analogue: Female Attitudes towards Meat Analogue Containing Rapeseed Protein. Food Control 2021, 123, 107833. [Google Scholar] [CrossRef]

- Lei, S.; Youling, L.X. Plant Protein-Based Alternatives of Reconstructed Meat: Science, Technology, and Challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef]

- McClements, D.J.; Weiss, J.; Kinchla, A.J.; Nolden, A.A.; Grossmann, L. Methods for Testing the Quality Attributes of Plant-Based Foods: Meat- and Processed-Meat Analogs. Foods 2021, 10, 260. [Google Scholar] [CrossRef]

- Higgins, J.P.T.; Altman, D.G.; Gøtzsche, P.C.; Jüni, P.; Moher, D.; Oxman, A.D.; Savović, J.; Schulz, K.F.; Weeks, L.; Sterne, J.A.C. The Cochrane Collaboration’s Tool for Assessing Risk of Bias in Randomised Trials. BMJ 2011, 343, d5928. [Google Scholar] [CrossRef]

- Mohamed Shaffril, H.A.; Samsuddin, S.F.; Abu Samah, A. The ABC of Systematic Literature Review: The Basic Methodological Guidance for Beginners. Qual. Quant. 2021, 55, 1319–1346. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wu, K.; Wu, J. A Bibliometric Analysis of Research on Haze during 2000–2016. Environ. Sci. Pollut. Res. 2017, 24, 24733–24742. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Tran, B.X.; McIntyre, R.S.; Latkin, C.A.; Phan, H.T.; Vu, G.T.; Nguyen, H.L.T.; Gwee, K.K.; Ho, C.S.H.; Ho, R.C.M. The Current Research Landscape on the Artificial Intelligence Application in the Management of Depressive Disorders: A Bibliometric Analysis. Int. J. Environ. Res. Public Health 2019, 16, 2150. [Google Scholar] [CrossRef]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef]

- Gihyun, W.; Junhwan, B.; Honggyun, K.; Youngjae, C.; Mi-Jung, C. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Immonen, M.; Chandrakusuma, A.; Sibakov, J.; Poikelispää, M.; Sontag-Strohm, T. Texturization of a Blend of Pea and Destarched Oat Protein Using High-Moisture Extrusion. Foods 2021, 10, 1517. [Google Scholar] [CrossRef]

- Kaleda, A.; Talvistu, K.; Tamm, M.; Viirma, M.; Rosend, J.; Tanilas, K.; Kriisa, M.; Part, N.; Tammik, M.-L. Impact of Fermentation and Phytase Treatment of Pea-Oat Protein Blend on Physicochemical, Sensory, and Nutritional Properties of Extruded Meat Analogs. Foods 2020, 9, 1059. [Google Scholar] [CrossRef]

- Kendler, C.; Duchardt, A.; Karbstein, H.P.; Emin, M.A. Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues. Foods 2021, 10, 697. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.; Huang, S.; Zhang, Z. Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour. Foods 2021, 10, 437. [Google Scholar] [CrossRef] [PubMed]

- Mazlan, M.M.; Talib, R.A.; Chin, N.L.; Shukri, R.; Taip, F.S.; Nor, M.Z.M.; Abdullah, N. Physical and Microstructure Properties of Oyster Mushroom-Soy Protein Meat Analog via Single-Screw Extrusion. Foods 2020, 9, 1023. [Google Scholar] [CrossRef]

- Rousta, N.; Hellwig, C.; Wainaina, S.; Lukitawesa, L.; Agnihotri, S.; Rousta, K.; Taherzadeh, M.J. Filamentous Fungus Aspergillus Oryzae for Food: From Submerged Cultivation to Fungal Burgers and Their Sensory Evaluation—A Pilot Study. Foods 2021, 10, 2774. [Google Scholar] [CrossRef]

- Yuan, X.; Jiang, W.; Zhang, D.; Liu, H.; Sun, B. Textural, Sensory and Volatile Compounds Analyses in Formulations of Sausages Analogue Elaborated with Edible Mushrooms and Soy Protein Isolate as Meat Substitute. Foods 2022, 11, 52. [Google Scholar] [CrossRef] [PubMed]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef] [PubMed]

- Wittek, P.; Ellwanger, F.; Karbstein, H.P.; Emin, M.A. Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue. Foods 2021, 10, 1753. [Google Scholar] [CrossRef]

- Dahl, S.R.; Villota, R. Twin-Screw Extrusion Texturization of Acid and Alkali Denatured Soy Proteins. J. Food Sci. 1991, 56, 1002–1007. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion Process Parameters, Sensory Characteristics, and Structural Properties of a High Moisture Soy Protein Meat Analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Ranasinghesagara, J.; Fu-Hung, H.; Gang, Y. An Image Processing Method for Quantifying Fiber Formation in Meat Analogs under High Moisture Extrusion. J. Food Sci. 2005, 70, E450–E454. [Google Scholar] [CrossRef]

- Ranasinghesagara, J.; Hsieh, F.; Yao, G. A Photon Migration Method for Characterizing Fiber Formation in Meat Analogs. J. Food Sci. 2006, 71, E227–E231. [Google Scholar] [CrossRef]

- Yao, G.; Liu, K.S.; Hsieh, F. A New Method for Characterizing Fiber Formation in Meat Analogs during High Moisture Extrusion. J. Food Sci. 2004, 69, E303–E307. [Google Scholar] [CrossRef]

- Arora, B.; Kamal, S.; Sharma, V.P. Effect of Binding Agents on Quality Characteristics of Mushroom Based Sausage Analogue. J. Food Process. Preserv. 2017, 41, e13134. [Google Scholar] [CrossRef]

- Arueya, G.L.; Owosen, B.S.; Olatoye, K.K. Development of Texturized Vegetable Protein from Lima Bean (Phaseolus lunatus) and African Oil Bean Seed Pentaclethra macrophylla (Benth): Optimization Approach. Acta Univ. Cibiniensis Ser. E Food Technol. 2017, 21, 61–68. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Joo, S.-T. Evaluation of Rheological and Sensory Characteristics of Plant-Based Meat Analog with Comparison to Beef and Pork. Food Sci. Anim. Resour. 2021, 41, 983–996. [Google Scholar] [CrossRef]

- Bayram, M.; Bozkurt, H. The Use of Bulgur as a Meat Replacement: Bulgur-Sucuk (a Vegetarian Dry-Fermented Sausage). J. Sci. Food Agric. 2007, 87, 411–419. [Google Scholar] [CrossRef]

- Brückner, J.; Mieth, G.; Zdziennicki, A.K.; Gwiazda, S. Influence of Sunflower Flour on the Extrusion Behaviour of Soya Grits and the Functional Properties of the Extrudates (Short Communication). Food Nahr. 1987, 31, 1037–1039. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Bocker, L.; Mussner, C.; Stirnemann, E.; Haberkorn, I.; Adelmann, H.; Handschin, S.; Windhab, E.J.; Mathys, A. Extruded Meat Analogues Based on Yellow, Heterotrophically Cultivated Auxenochlorella Protothecoides Microalgae. Innov. Food Sci. Emerg. Technol. 2020, 59, 102275. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of Soy Protein to Wheat Gluten Ratio on the Physico-Chemical Properties of Extruded Meat Analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- Emin, M.A.; Quevedo, M.; Wilhelm, M.; Karbstein, H.P. Analysis of the Reaction Behavior of Highly Concentrated Plant Proteins in Extrusion-like Conditions. Innov. Food Sci. Emerg. Technol. 2017, 44, 15–20. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y. Effects of the Specific Mechanical Energy on the Physicochemical Properties of Texturized Soy Protein during High-Moisture Extrusion Cooking. J. Food Eng. 2014, 121, 32–38. [Google Scholar] [CrossRef]

- Filho, G.C.S.; Vessoni Penna, T.C.; Schaffner, D.W. Microbiological Quality of Vegetable Proteins during the Preparation of a Meat Analog. Ital. J. Food Sci. 2005, 17, 269–283. [Google Scholar]

- Grahl, S.; Palanisamy, M.; Strack, M.; Meier-Dinkel, L.; Toepfl, S.; Mörlein, D. Towards More Sustainable Meat Alternatives: How Technical Parameters Affect the Sensory Properties of Extrusion Products Derived from Soy and Algae. J. Clean. Prod. 2018, 198, 962–971. [Google Scholar] [CrossRef]

- Husain, H.; Huda-Faujan, N. Potential Application of Grey Oyster Mushroom Stems as Halal Meat Replacer in Imitation Chicken Nuggets. Food Res. 2020, 4, 179–186. [Google Scholar] [CrossRef]

- Jia, W.; Curubeto, N.; Rodríguez-Alonso, E.; Keppler, J.K.; van der Goot, A.J. Rapeseed Protein Concentrate as a Potential Ingredient for Meat Analogues. Innov. Food Sci. Emerg. Technol. 2021, 72, 102758. [Google Scholar] [CrossRef]

- Kamani, M.H.; Meera, M.S.; Bhaskar, N.; Modi, V.K. Partial and Total Replacement of Meat by Plant-Based Proteins in Chicken Sausage: Evaluation of Mechanical, Physico-Chemical and Sensory Characteristics. J. Food Sci. Technol. 2019, 56, 2660–2669. [Google Scholar] [CrossRef]

- Kim, K.; Choi, B.; Lee, I.; Lee, H.; Kwon, S.; Oh, K.; Kim, A.Y. Bioproduction of Mushroom Mycelium of Agaricus Bisporus by Commercial Submerged Fermentation for the Production of Meat Analogue. J. Sci. Food Agric. 2011, 91, 1561–1568. [Google Scholar] [CrossRef]

- Kozlowska, H.; Elkowicz, K.; Lossow, B.; Smith, O.B. The Structural Modification of Vegetable Protein Preparations by High and Low Pressure Extrusion-Cooking Processes. Acta Aliment. Pol. 1979, 5, 81–85. [Google Scholar]

- Krintiras, G.A.; Gobel, J.; Bouwman, W.G.; van der Goot, A.J.; Stefanidis, G.D. On Characterization of Anisotropic Plant Protein Structures. Food Funct. 2014, 5, 3233–3240. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Gobel, J.; van der Goot, A.J.; Stefanidis, G.D. Production of Structured Soy-Based Meat Analogues Using Simple Shear and Heat in a Couette Cell. J. Food Eng. 2015, 160, 34–41. [Google Scholar] [CrossRef]

- Lee, G.; Huff, H.E.; Hsieh, F. Overall Heat Transfer Coefficient between Cooling Die and Extruded Product. Trans. Am. Soc. Agric. Eng. 2005, 48, 1461–1469. [Google Scholar] [CrossRef]

- Lee, J.-S.; Oh, H.; Choi, I.; Yoon, C.S.; Han, J. Physico-Chemical Characteristics of Rice Protein-Based Novel Textured Vegetable Proteins as Meat Analogues Produced by Low-Moisture Extrusion Cooking Technology. LWT 2022, 157, 113056. [Google Scholar] [CrossRef]

- Lee, E.J.; Hong, G.P. Effects of Microbial Transglutaminase and Alginate on the Water-Binding, Textural and Oil Absorption Properties of Soy Patties. Food Sci. Biotechnol. 2020, 29, 777–782. [Google Scholar] [CrossRef]

- Lindriati, T.; Herlina, H.; Arbiantara, H.; Asrofi, M. Optimization of Meat Analog Production from Concentrated Soy Protein and Yam (Xanthosoma sagittifolium) Powder Using Pasta Machine. Food Res. 2020, 4, 887–895. [Google Scholar] [CrossRef]

- Liu, K.S.; Hsieh, F.-H. Protein-Protein Interactions in High Moisture-Extruded Meat Analogs and Heat-Induced Soy Protein Gels. J. Am. Oil Chem. Soc. 2007, 84, 741–748. [Google Scholar] [CrossRef]

- Liu, K.S.; Hsieh, F.-H. Protein-Protein Interactions during High-Moisture Extrusion for Fibrous Meat Analogues and Comparison of Protein Solubility Methods Using Different Solvent Systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Ryu, G. Effects of Green Tea Contents on the Quality and Antioxidant Properties of Textured Vegetable Protein by Extrusion-Cooking. Food Sci. Biotechnol. 2019, 28, 67–74. [Google Scholar] [CrossRef]

- Mattice, K.D.; Marangoni, A.G. Comparing Methods to Produce Fibrous Material from Zein. Food Res. Int. 2020, 128, 108804. [Google Scholar] [CrossRef]

- Maung, T.T.; Gu, B.Y.; Kim, M.H.; Ryu, G.H. Fermentation of Texturized Vegetable Proteins Extruded at Different Moisture Contents: Effect on Physicochemical, Structural, and Microbial Properties. Food Sci. Biotechnol. 2020, 29, 897–907. [Google Scholar] [CrossRef]

- Murillo, J.L.S.; Osen, R.; Hiermaier, S.; Ganzenmueller, G. Towards Understanding the Mechanism of Fibrous Texture Formation during High-Moisture Extrusion of Meat Substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Nayak, B.; Panda, B.P. Modelling and Optimization of Texture Profile of Fermented Soybean Using Response Surface Methodology. AIMS Agric. Food 2016, 1, 409–418. [Google Scholar] [CrossRef]

- Neumann, P.E.; Jasberg, B.K.; Wall, J.S.; Walker, C.E. Uniquely Textured Products Obtained by Coextrusion of Corn Gluten Meal and Soy Flour. Cereal Chem. 1984, 61, 439–445. [Google Scholar]

- Omohimi, C.I.; Sobukola, O.P.; Sarafadeen, K.O.; Sanni, L.O. Effect of Thermo-Extrusion Process Parameters on Selected Quality Attributes of Meat Analogue from Mucuna Bean Seed Flour. Niger. Food J. 2014, 32, 21–30. [Google Scholar] [CrossRef]

- Palanisamy, M.; Franke, K.; Berger, R.G.; Heinz, V.; Topfl, S. High Moisture Extrusion of Lupin Protein: Influence of Extrusion Parameters on Extruder Responses and Product Properties. J. Sci. Food Agric. 2019, 99, 2175–2185. [Google Scholar] [CrossRef]

- Palanisamy, M.; Topfl, S.; Aganovic, K.; Berger, R.G. Influence of Iota Carrageenan Addition on the Properties of Soya Protein Meat Analogues. LWT—Food Sci. Technol. 2018, 87, 546–552. [Google Scholar] [CrossRef]

- Parmer, E.L., Jr.; Wang, B.; Aglan, H.A.; Mortley, D. Physicochemical Properties of Texturized Meat Analog Made from Peanut Flour and Soy Protein Isolate with a Single-Screw Extruder. J. Texture Stud. 2004, 35, 371–382. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Bühler, J.M.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein Concentrate: Influence of Thermomechanical Treatment on Protein-Protein Interactions and Rheological Properties. J. Food Eng. 2019, 251, 11–18. [Google Scholar] [CrossRef]

- Pöri, P.; Nisov, A.; Nordlund, E. Enzymatic Modification of Oat Protein Concentrate with Trans- and Protein-Glutaminase for Increased Fibrous Structure Formation during High-Moisture Extrusion Processing. LWT 2022, 156, 113035. [Google Scholar] [CrossRef]

- Alonso, R.; Orúe, E.; Zabalza, M.J.; Grant, G.; Marzo, F. Effect of Extrusion Cooking on Structure and Functional Properties of Pea and Kidney. J. Sci. Food Agric. 2000, 80, 397–403. [Google Scholar] [CrossRef]

- Rehrah, D.; Ahmedna, M.; Goktepe, I.; Jianmei, Y. Extrusion Parameters and Consumer Acceptability of a Peanut-Based Meat Analogue. Int. J. Food Sci. Technol. 2009, 44, 2075–2084. [Google Scholar] [CrossRef]

- Saerens, W.; Smetana, S.; Van Campenhout, L.; Lammers, V.; Heinz, V. Life Cycle Assessment of Burger Patties Produced with Extruded Meat Substitutes. J. Clean. Prod. 2021, 306, 127177. [Google Scholar] [CrossRef]

- Saldanha do Carmo, C.; Knutsen, S.H.; Malizia, G.; Dessev, T.; Geny, A.; Zobel, H.; Myhrer, K.S.; Varela, P.; Sahlstrøm, S. Meat Analogues from a Faba Bean Concentrate Can Be Generated by High Moisture Extrusion. Future Foods 2021, 3, 100014. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.Y.; Ryu, G.H. Effects of Extrusion Types, Screw Speed and Addition of Wheat Gluten on Physicochemical Characteristics and Cooking Stability of Meat Analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Sharima Abdullah, N.; Hassan, C.Z.; Arifin, N.; Huda Faujan, N. Physicochemical Properties and Consumer Preference of Imitation Chicken Nuggets Produced from Chickpea Flour and Textured Vegetable Protein. Int. Food Res. J. 2018, 25, 1016–1025. [Google Scholar]

- Stanley, D.W.; Cumming, D.B.; deMan, J.M. Texture-Structure Relationships in Texturized Soy Protein. I. Textural Properties and Ultrastructure of Rehydrated Spun Soy Fibers. Can. Inst. Food Technol. J. 1972, 5, 118–123. [Google Scholar] [CrossRef]

- Stephan, A.; Ahlborn, J.; Zajul, M.; Zorn, H. Edible Mushroom Mycelia of Pleurotus Sapidus as Novel Protein Sources in a Vegan Boiled Sausage Analog System: Functionality and Sensory Tests in Comparison to Commercial Proteins and Meat Sausages. Eur. Food Res. Technol. 2018, 244, 913–924. [Google Scholar] [CrossRef]

- Wen, Y.; Xin-Sheng, Q.; Shui-Zhong, L.; Yan-Yan, Z.; Xi-Yang, Z.; Dong-Dong, M.; Shao-Tong, J.; Zhi, Z. Effect of Calcium Stearyl Lactylate on Physicochemical Properties of Texturized Wheat Gluten. Food Sci. Technol. Res. 2017, 23, 203–211. [Google Scholar] [CrossRef][Green Version]

- Wu, M.; Sun, Y.; Bi, C.H.; Ji, F.; Li, B.R.; Xing, J.J. Effects of Extrusion Conditions on the Physicochemical Properties of Soy Protein/Gluten Composite. Int. J. Agric. Biol. Eng. 2018, 11, 230–237. [Google Scholar] [CrossRef]

- Xia, S.; Xue, Y.; Xue, C.; Jiang, X.; Li, J. Structural and Rheological Properties of Meat Analogues from Haematococcus Pluvialis Residue-Pea Protein by High Moisture Extrusion. LWT 2022, 154, 112756. [Google Scholar] [CrossRef]

- Yuliarti, O.; Kovis, T.J.K.; Yi, N.J. Structuring the Meat Analogue by Using Plant-Based Derived Composites. J. Food Eng. 2021, 288, 110138. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wei, L.; Cao, C.; Yan, W.; Wang, Q. Converting Peanut Protein Biomass Waste into a “Double Green” Meat Substitutes Using a High-Moisture Extrusion Process: A Multiscale Method to Explore a Process for Forming a Meat-like Fibrous Structure. J. Agric. Food Chem. 2019, 67, 10713–10725. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, L.; Jian, Y.; Shah, F.; Xu, Y.; Wang, Q. High-Moisture Extrusion of Peanut Protein-/Carrageenan/Sodium Alginate/Wheat Starch Mixtures: Effect of Different Exogenous Polysaccharides on the Process Forming a Fibrous Structure. Food Hydrocoll. 2020, 99, 105311. [Google Scholar] [CrossRef]

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting Nitrogen into Protein—Beyond 6.25 and Jones’ Factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef] [PubMed]

| Database | Search String |

|---|---|

| SCOPUS | TITLE-ABS-KEY (((“meat analog*” OR “meat substitute*” OR “meat replace*” OR “meat alternat*” OR “mock meat” OR “imitat* meat” OR “faux meat” OR “HMMA” OR “TVP” OR “vegan meat” OR “plant based meat” OR “textur* protein” OR “extrud* protein” OR “extrud* food”) AND (“extru*” OR “textur*”)) AND NOT (“drug” OR “polymer*” OR “packaging” OR “DNA” OR “gene*” OR “pet food” OR “animal feed”)) AND (LIMIT-TO(LANGUAGE, “English”)) AND (LIMIT-TO (SRCTYPE, “j”)) |

| Web of Science (WoS) | TS=(((“meat analog*” OR “meat substitute*” OR “meat replace*” OR “meat alternat*” OR “mock meat” OR “imitat* meat” OR “faux meat” OR “HMMA” OR “TVP” OR “vegan meat” OR “plant based meat” OR “textur* protein” OR “extrud* protein” OR “extrud* food”) AND (“extru*” OR “textur*”)) NOT (“drug” OR “polymer*” OR “packaging” OR “DNA” OR “gene*” OR “pet food” OR “animal feed”)) AND (LIMIT-TO(LANGUAGE, “English”)) AND (LIMIT-TO(SRCTYPE, “j”)) |

| Journal Name | Number of Publications | Quartile and Indexed by | |

|---|---|---|---|

| Scopus | WoS | ||

| Foods | 15 | Q1 | Q1 |

| Journal of Food Science | 9 | Q2 | Q2 |

| Journal of the Science of Food and Agriculture | 6 | Q1 | Q1 |

| Journal of Food Engineering | 8 | Q1 | Q1 |

| LWT-Food Science and Technology | 4 | Q1 | Q1 |

| Food Science and Biotechnology | 3 | Q2 | Q3 |

| Innovative Food Science and Emerging Technologies | 3 | Q1 | Q1 |

| Food Research | 2 | Q3 | Q3 |

| Food Structure | 2 | Q1 | Q2 |

| International Journal of Food Science and Technology | 2 | Q1 | Q2 |

| Journal of Agricultural and Food Chemistry | 2 | Q1 | Q1 |

| Food Hydrocolloid | 2 | Q1 | Q1 |

| Journal of Cleaner Production | 2 | Q1 | Q1 |

| Authors (Year)/Theme | Objectives of Study | Type of Plant Protein | Product Type | Added Ingredient | Texturization Technique | Quality Assessment | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sub-themes | TT | M | FF | OP | SP | OPP | TVP | MA | BA | F | OI | SSE | TSE | SC | S | M/O | C/FP | PP | FF | NA | CQ | SE | OA |

| Aguilera et al. (1980) [20] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Arora et al. (2017) [66] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Arueya et al. (2017) [67] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Bakhsh et al. (2021a) [41] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| Bakhsh et al. (2021b) [68] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Bayram et al. (2007) [69] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Bruckner et al. (1987) [70] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Byun et al. (1978) [12] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Caporgno et al. (2020) [71] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Chen et al. (2021) [21] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Chiang et al. (2019) [72] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| Chiang et al. (2021) [22] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Cornet et al. (2021) [23] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Dahl and Villota (1991) [60] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| De Angelis et al. (2020) [49] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Emin et al. (2017) [73] | √ | √ | √ | CCR | √ | ||||||||||||||||||

| Fang et al. (2014) [74] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Ferawati et al. (2021) [24] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Filho et al. (2005) [75] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Gihyun et al. (2020) [50] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Grahl et al. (2018) [76] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Hashizume (1978) [19] | √ | √ | √ | FR | √ | ||||||||||||||||||

| Husain and Huda-F. (2020) [77] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Immonen et al. (2021) [51] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Jia et al. (2021) [78] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Kaleda et al. (2020) [52] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Kamani et al. (2019) [79] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| Kendler et al. (2021) [53] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Kim et al. (2011) [80] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Kozlowska et al. (1979) [81] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Krintiras et al. (2014) [82] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Krintiras et al. (2015) [83] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Krintiras et al. (2016) [17] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Lee et al. (2005) [84] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Lee et al. (2022) [85] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Lee and Hong (2020) [86] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Lin et al. (2000) [61] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Lin et al. (2002) [62] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Lindriati et al. (2020) [87] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Liu and Hsieh (2007) [88] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Liu and Hsieh (2008) [89] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Liu et al. (2021) [54] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Ma and Ryu (2019) [90] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Mattice and Marangoni (2020) [91] | √ | √ | √ | √ | √ | AS/ME | √ | √ | √ | ||||||||||||||

| Maung et al. (2020) [92] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Mazlan et al. (2020) [55] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| Murillo et al. (2019) [93] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Nayak and Panda (2016) [94] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Neumann et al. (1984) [95] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Omohimi et al. (2014) [96] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Osen et al. (2015) [32] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Osen et al. (2014) [31] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Palanisamy et al. (2019) [97] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Palanisamy et al. (2018) [98] | √ | √ | √ | √ | √ | PRE | √ | √ | √ | √ | √ | ||||||||||||

| Parmer and Wang (2004) [99] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Pietsch et al. (2019) [100] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Pori et al. (2022) [101] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| R. Alonso et al. (2000) [102] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Ranasinghesagara et al. (2006) [64] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Ranasinghesagara et al. (2009) [25] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Ranasinghesagara et al. (2005) [63] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Rehrah et al. (2009) [103] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Rousta et al. (2021) [56] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Saerens et al. (2021) [104] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| Sakai et al. (2021) [26] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| Saldanha do Carmo et al. (2021) [105] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Samard et al. (2019) [106] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Samard and Ryu (2019) [27] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Sharima et al. (2018) [107] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Stanley et al. (1972) [108] | |||||||||||||||||||||||

| Stephan et al. (2018) [109] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Taranto et al. (1978) [11] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Wen et al. (2017) [110] | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| Wittek et al. (2021a) [58] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Wittek et al. (2021b) [59] | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| Wu et al. (2018) [111] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Xia et al. (2022) [112] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Yao et al. (2004) [65] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Yuan et al. (2022) [57] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||

| Yuliarti et al. (2021) [113] | √ | √ | √ | FR | √ | √ | √ | √ | |||||||||||||||

| Zahari et al. (2020) [15] | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| Zahari et al. (2021) [14] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Zhang et al. (2019) [114] | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||

| Zhang et al. (2020) [115] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| Objectives of Study | Type of Plant Protein | Product Type | Added Ingredient | Texturization Technique | Quality Assessment | ||||||||||||||||||

| TT = texturization technique M = materials/ingredients FF = fiber formation OP = other properties (functional/protein interaction) | SP = soy protein OPP = other plant proteins (oilseed, mushroom, legumes) | TVP = texturized vegetable protein MA = meat analogues | BA = binding agent F = fat OI = other ingredients | SSE = single screw extrusion TSE = twin screw extrusion SC = shear/Couette cell S = spinning M/O = mixing/other methods (CCR = closed-cavity rheometer) (F = fermentation) (AS = antisolvent precipitation) (ME = mechanical elongation) (FR = freezing) (PRE = planetary roller extruder) | C/FP = chemical/functional properties PP = physical properties FF = fiber formation NA = nutritional analysis CQ = cooking quality SE = sensory evaluation OA = other assessment | ||||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahari, I.; Östbring, K.; Purhagen, J.K.; Rayner, M. Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review. Foods 2022, 11, 2870. https://doi.org/10.3390/foods11182870

Zahari I, Östbring K, Purhagen JK, Rayner M. Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review. Foods. 2022; 11(18):2870. https://doi.org/10.3390/foods11182870

Chicago/Turabian StyleZahari, Izalin, Karolina Östbring, Jeanette K. Purhagen, and Marilyn Rayner. 2022. "Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review" Foods 11, no. 18: 2870. https://doi.org/10.3390/foods11182870

APA StyleZahari, I., Östbring, K., Purhagen, J. K., & Rayner, M. (2022). Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review. Foods, 11(18), 2870. https://doi.org/10.3390/foods11182870