The Effect of Material Thickness, Load Density, External Airflow, and Relative Humidity on the Drying Efficiency and Quality of EHD-Dried Apples

Abstract

:1. Introduction

2. Materials and Methods

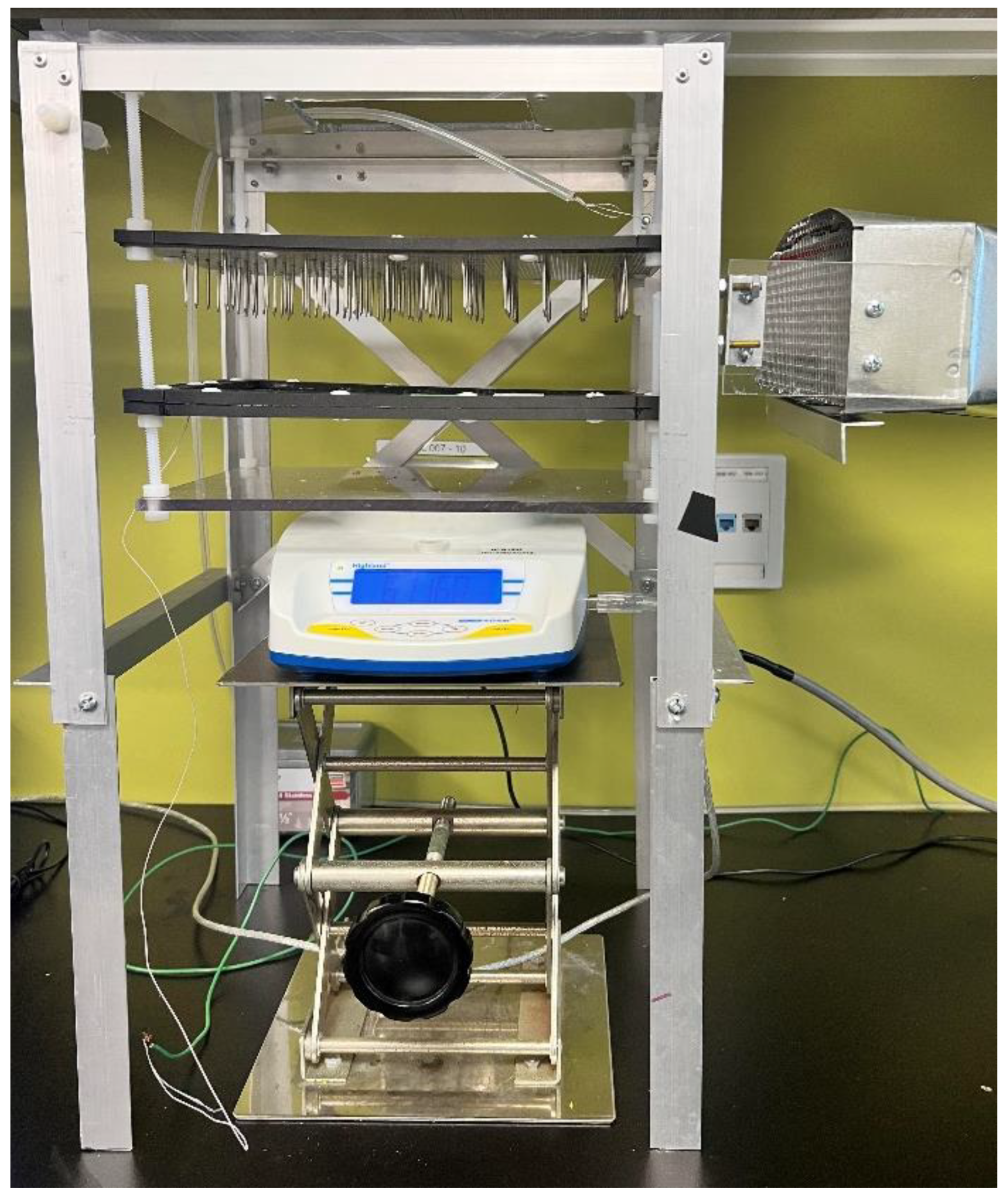

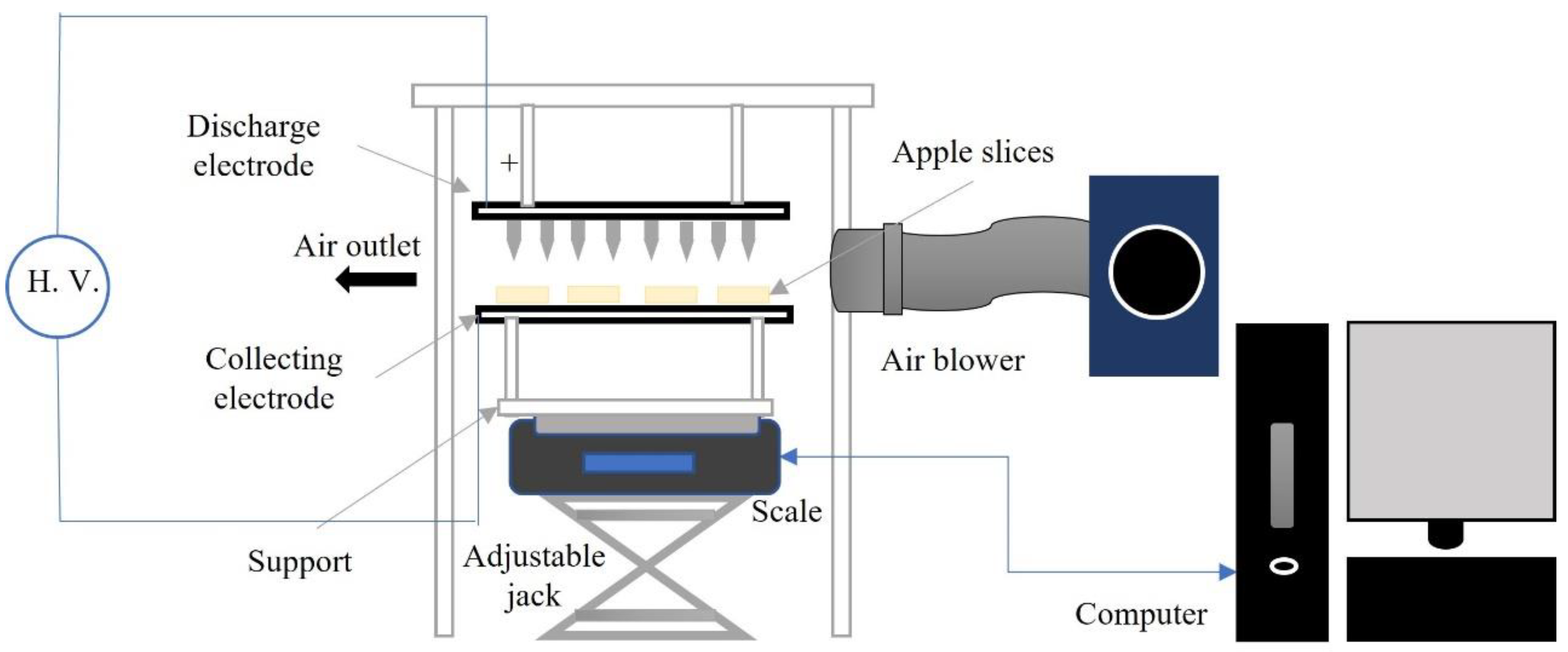

2.1. Experimental Apparatus

2.2. Drying Experiment

2.3. Drying Characteristics

2.3.1. Drying Kinetics

2.3.2. Drying Rate Constant

2.3.3. Effective Moisture Diffusivity

2.3.4. Specific Energy Consumption (SEC)

2.4. Quality Attributes

2.4.1. Shrinkage

2.4.2. Color

2.4.3. Rehydration Ratio

2.4.4. Disintegration Index

2.4.5. Total Phenolic Content (TPC)

2.5. Statistical Analysis

3. Results and Discussion

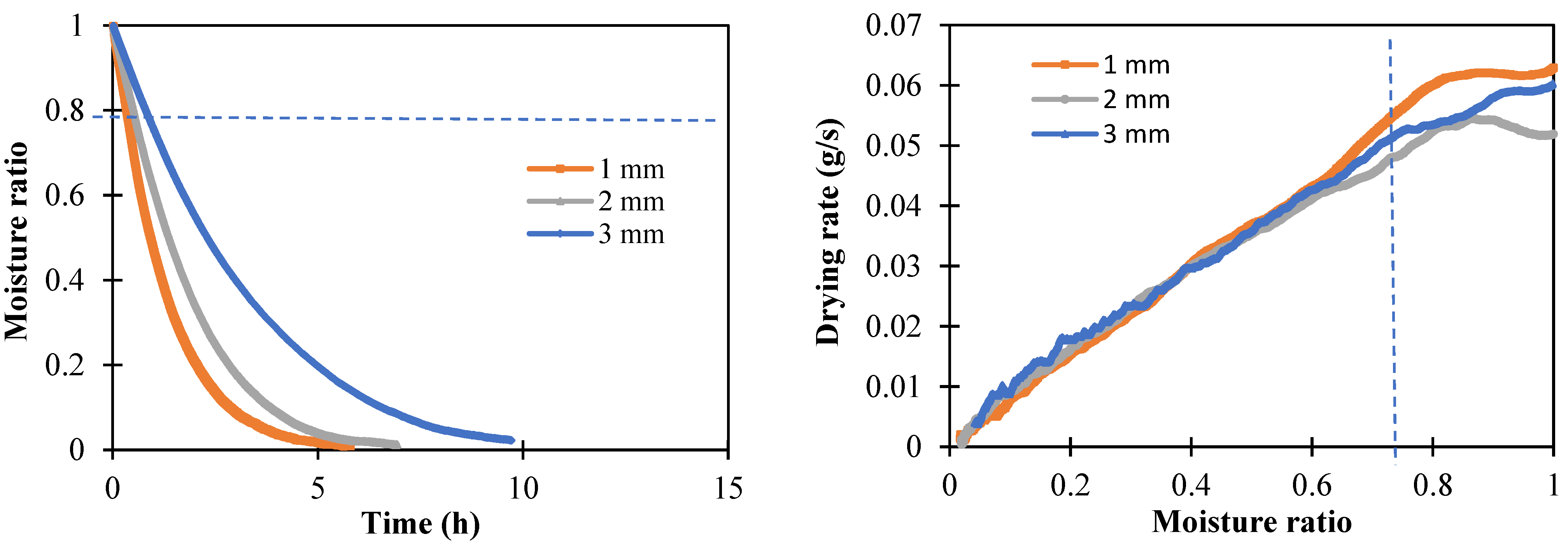

3.1. Drying Characteristics

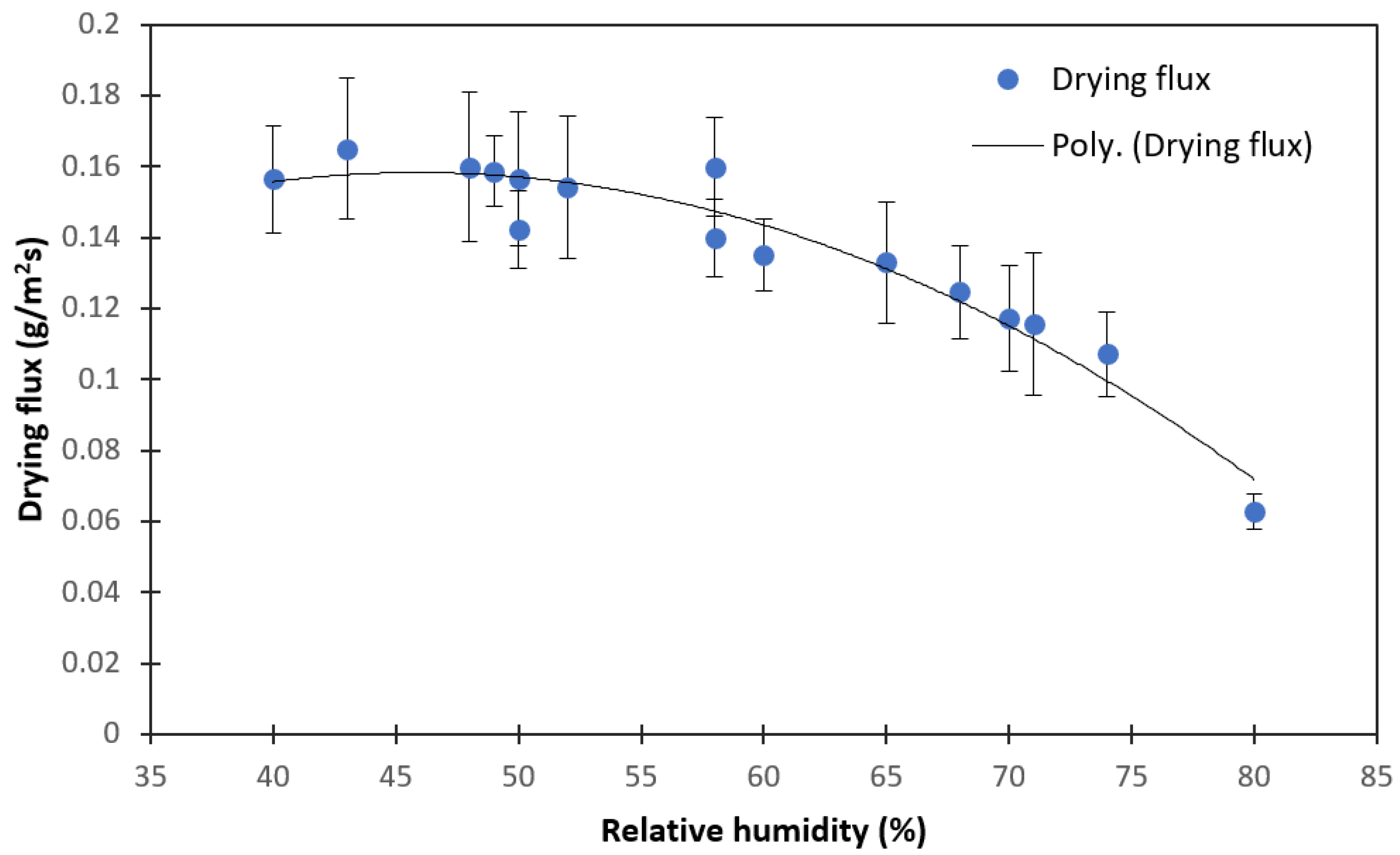

3.1.1. Drying Flux

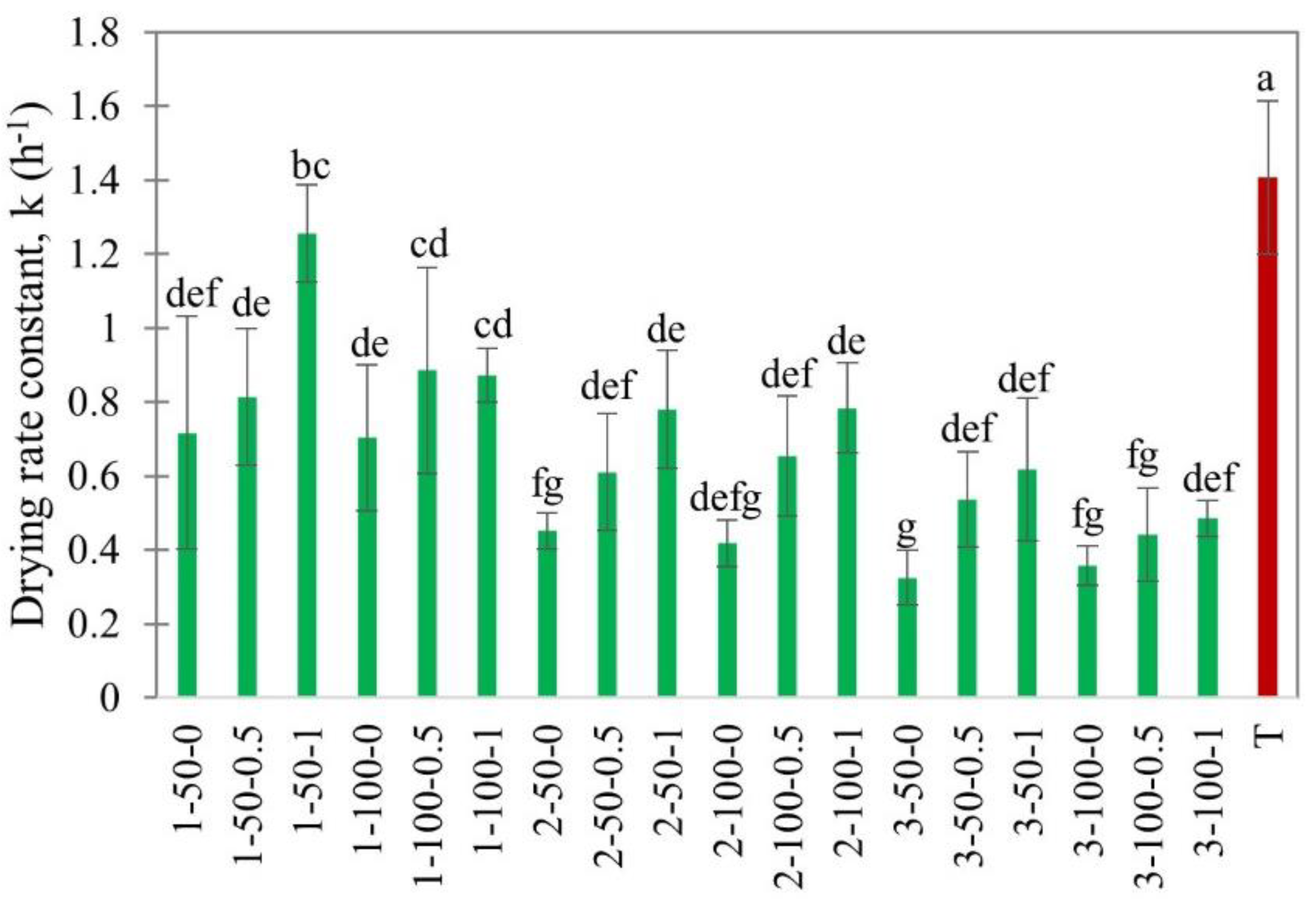

3.1.2. Drying Rate Constant

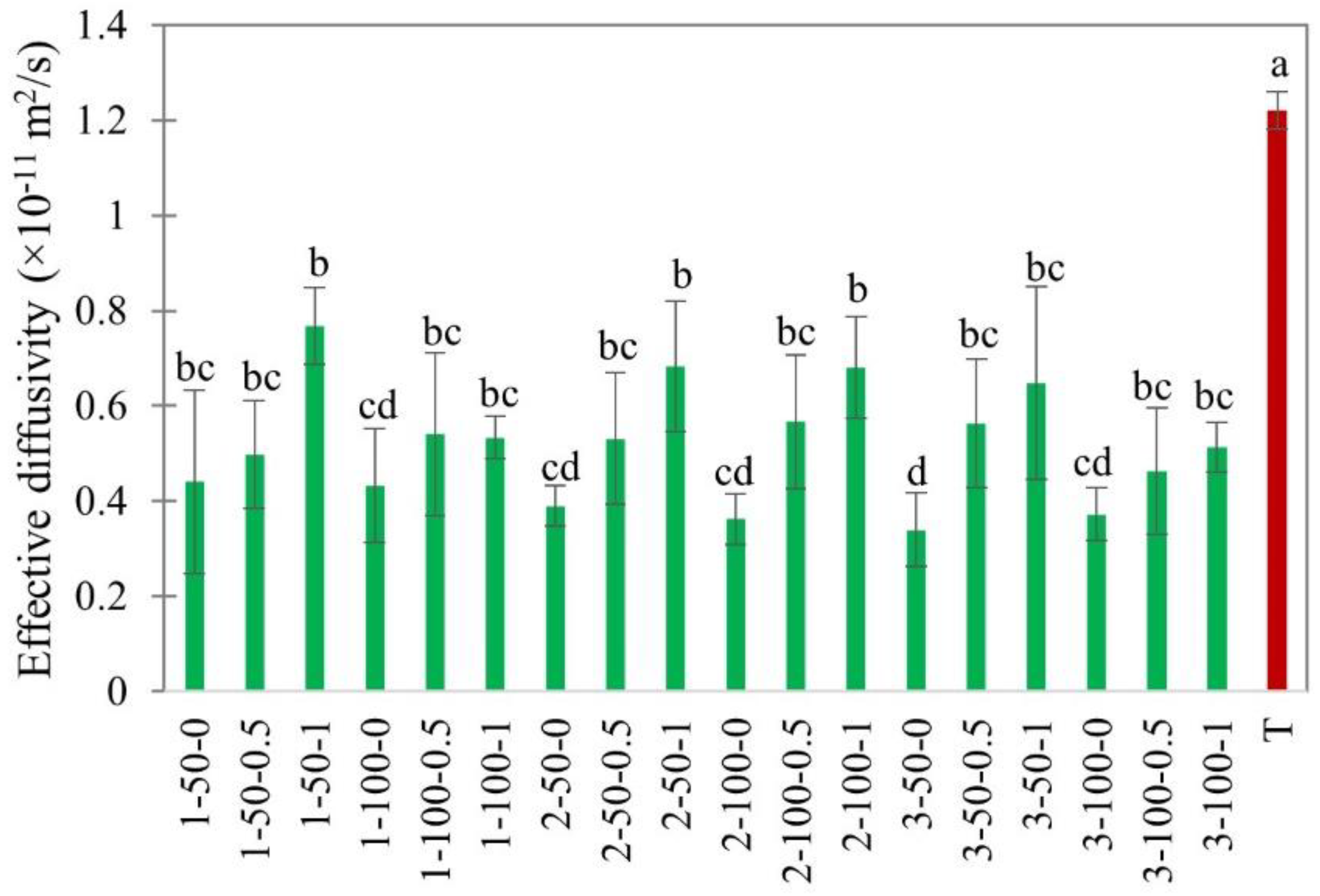

3.1.3. Effective Diffusivity

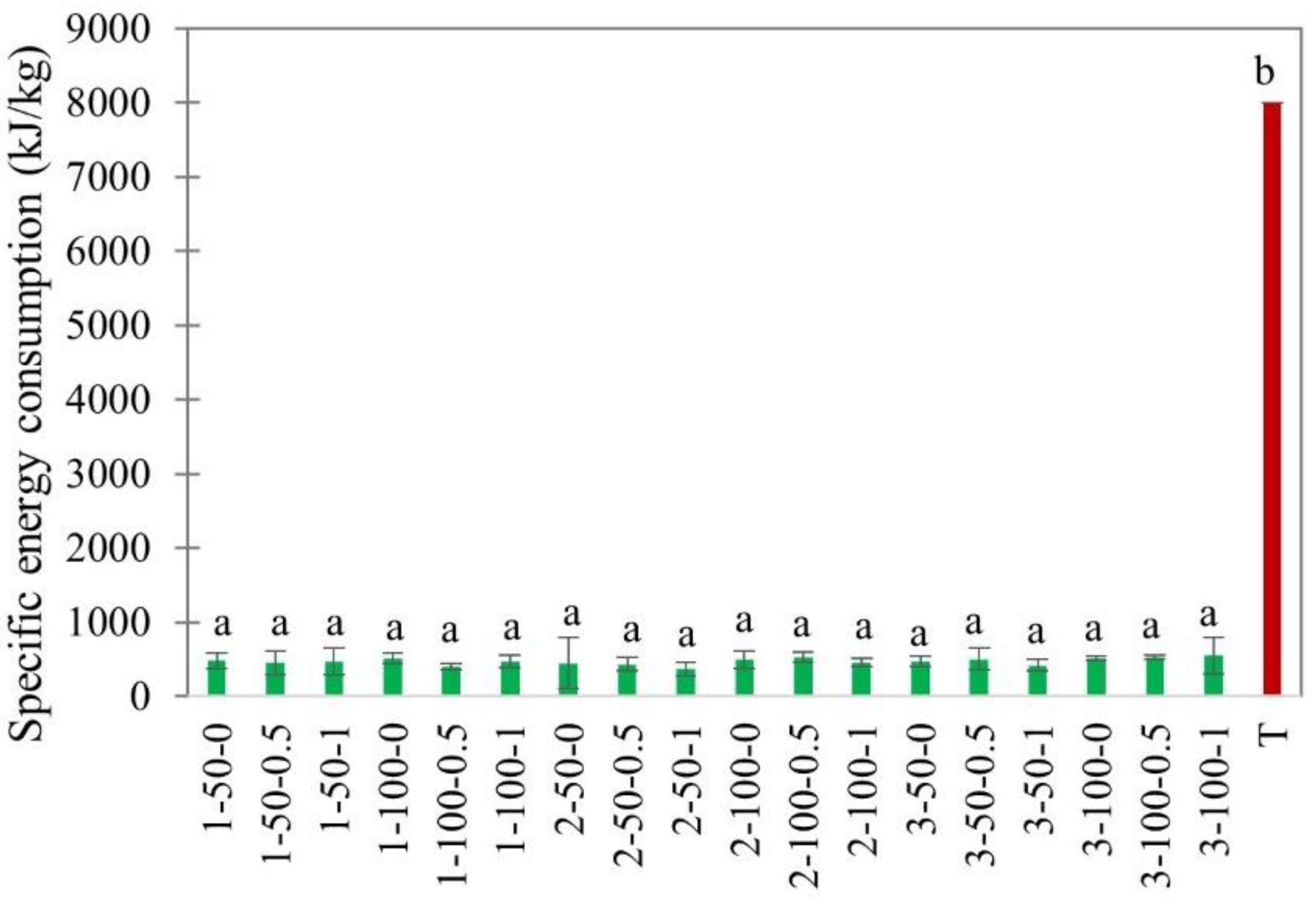

3.1.4. Specific Energy Consumption

3.1.5. Statistical Analysis

3.2. Quality

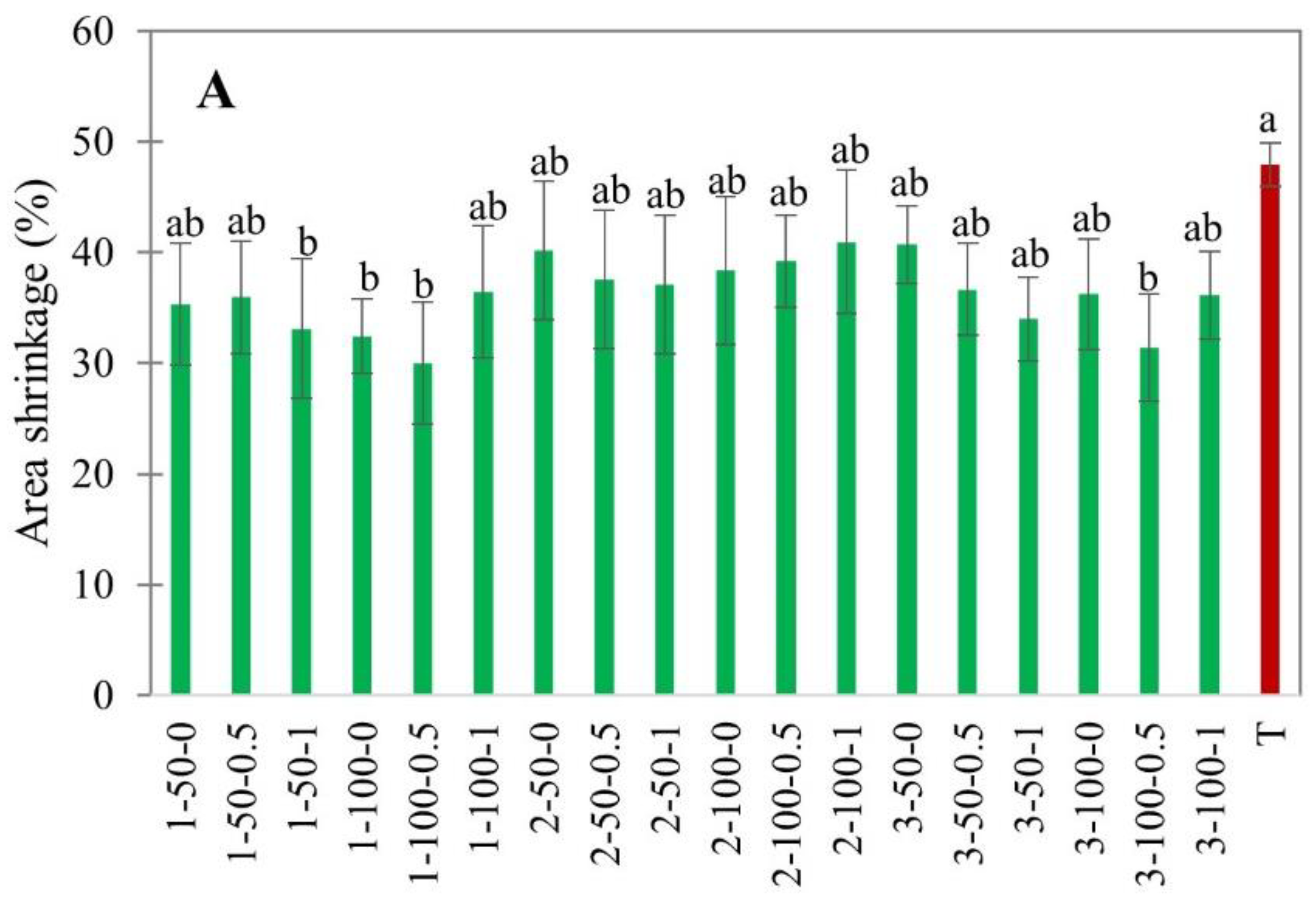

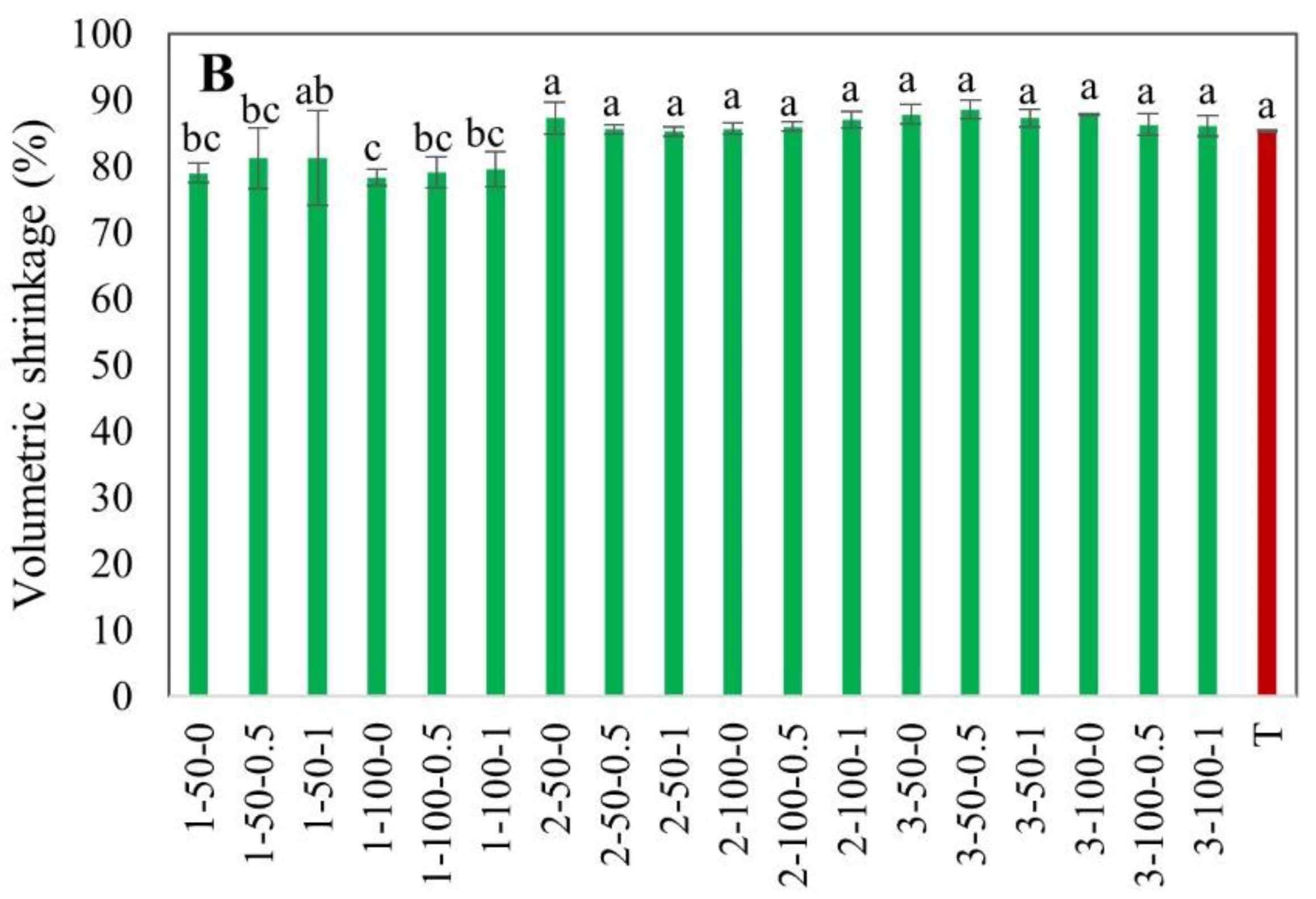

3.2.1. Shrinkage

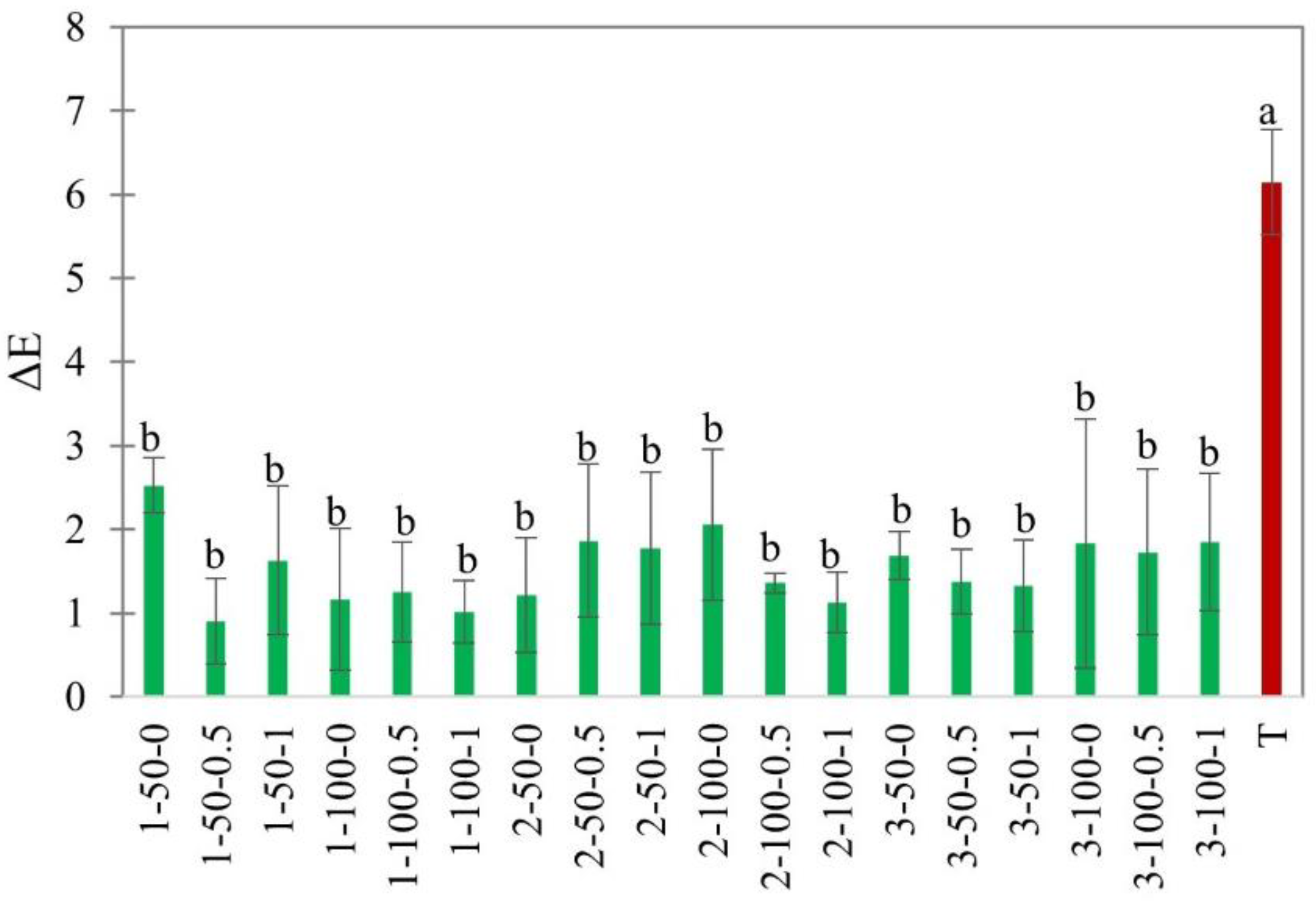

3.2.2. Color

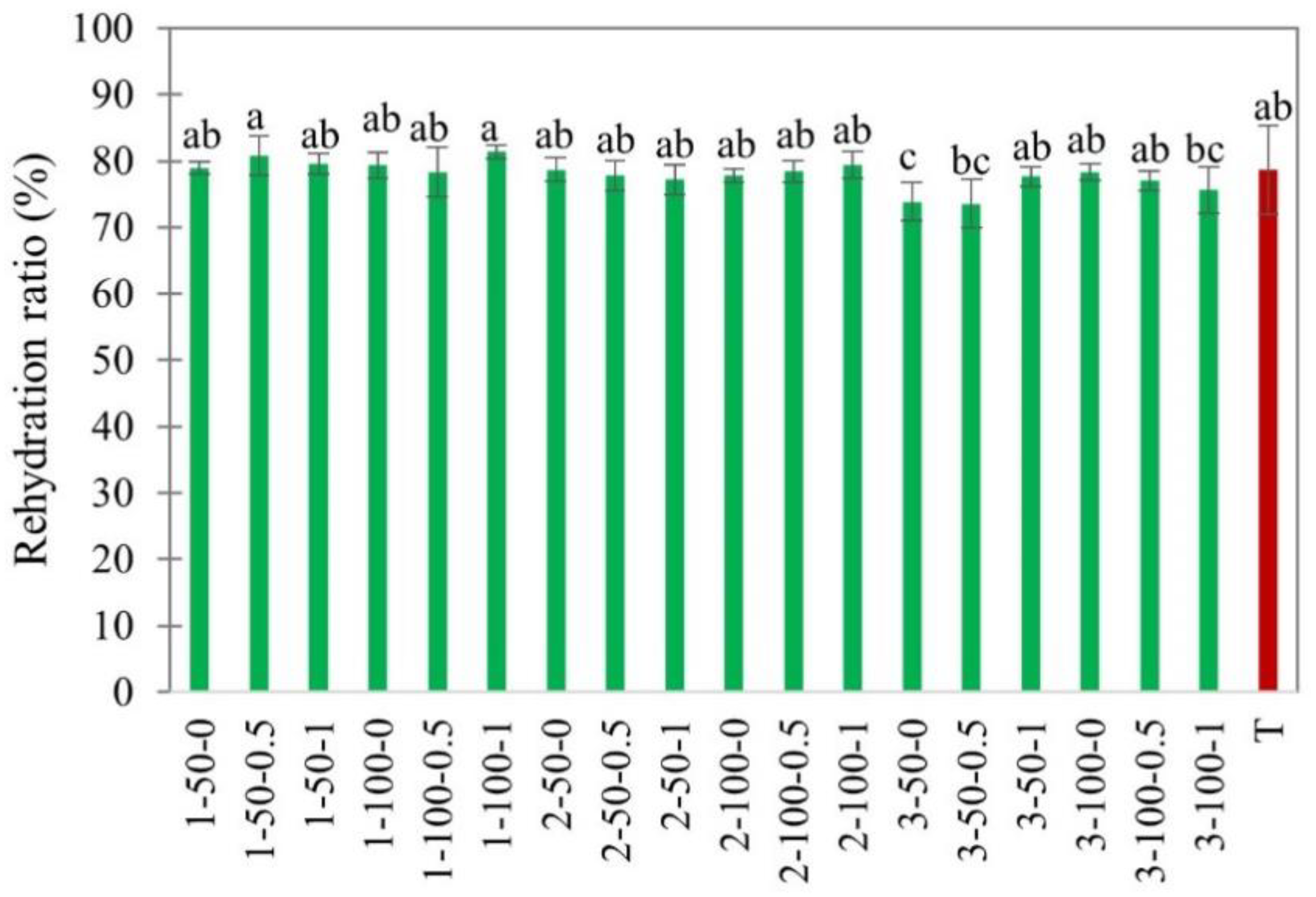

3.2.3. Rehydration Ratio

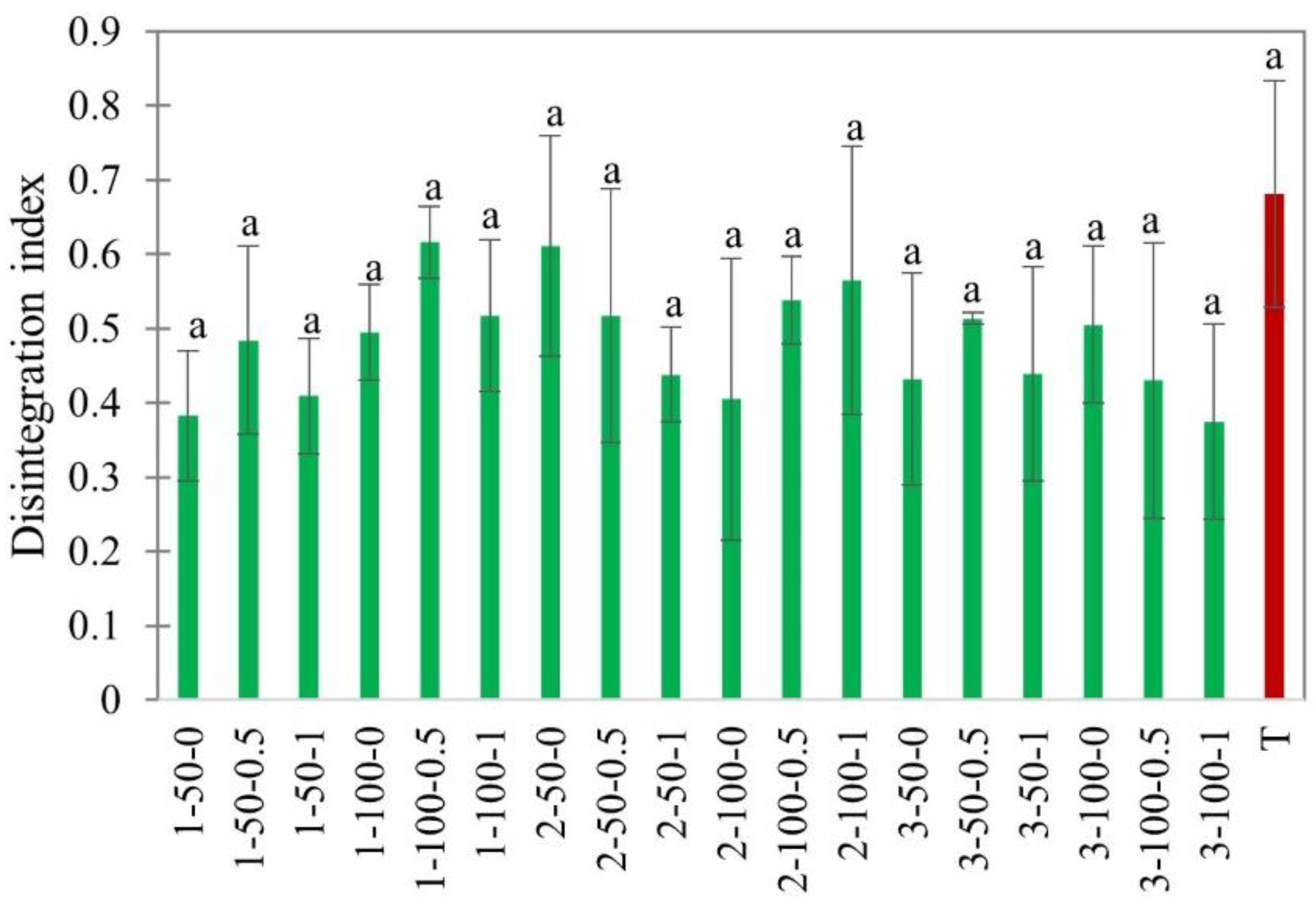

3.2.4. Disintegration Index

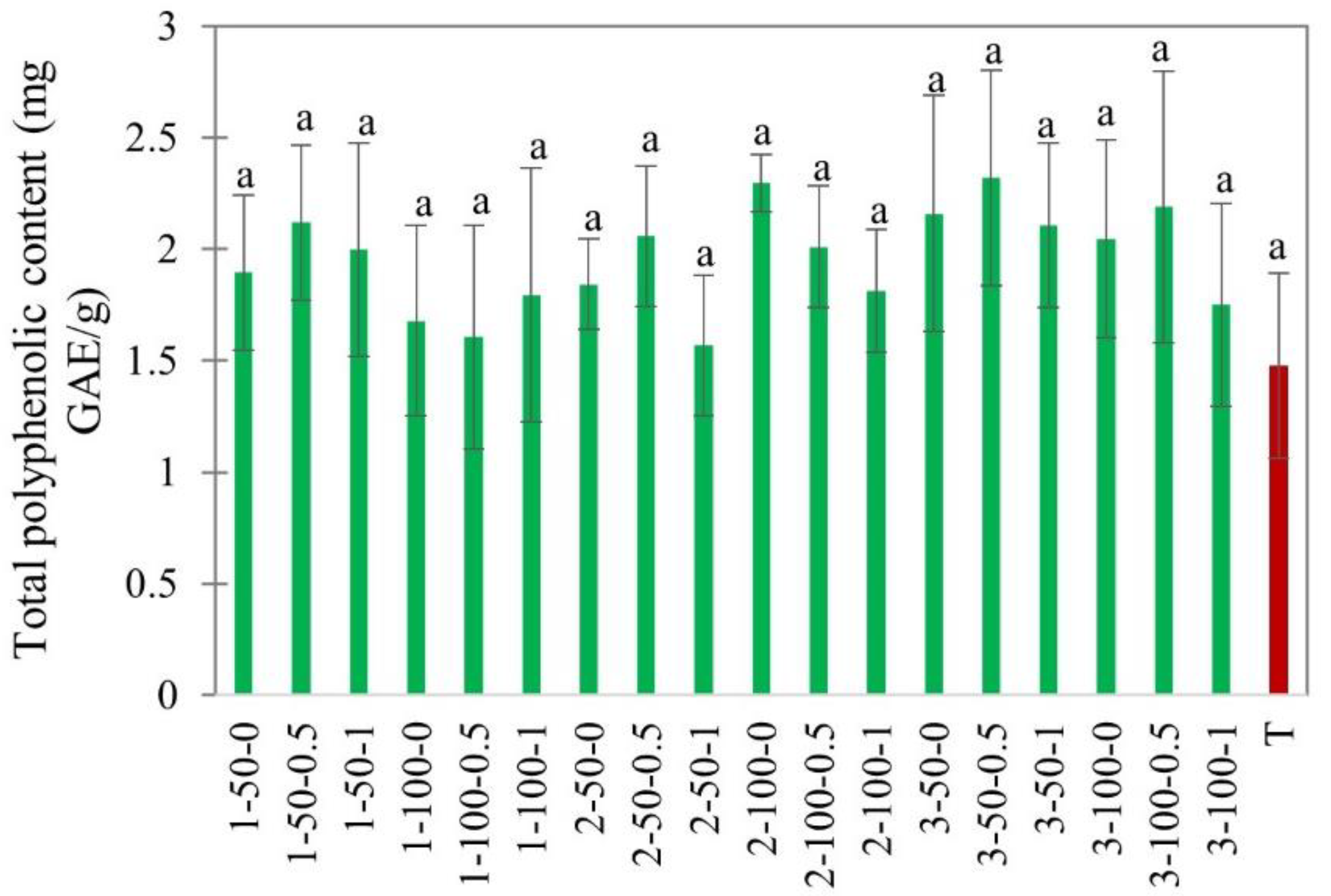

3.2.5. Total Polyphenol Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, A.; Orsat, V.; Raghavan, V. A comprehensive review on electrohydrodynamic drying and high-voltage electric field in the context of food and bioprocessing. Dry. Technol. 2012, 30, 1812–1820. [Google Scholar] [CrossRef]

- Bashkir, I.; Defraeye, T.; Kudra, T.; Martynenko, A. Electrohydrodynamic drying of plant-based foods and food model systems. Food Eng. Rev. 2020, 12, 473–497. [Google Scholar] [CrossRef]

- Paul, A.; Martynenko, A. Electrohydrodynamic drying: Effects on food quality. Dry. Technol. 2021, 39, 1745–1761. [Google Scholar] [CrossRef]

- Liang, Y.Z.; Ding, C.J. High voltage electric field drying. In Modern Drying Technologies; Pan, Y., Wang, X., Liu, X., Eds.; Chemical Industry Press: Beijing, China, 2006; pp. 840–858. ISBN 9787502593612. (In Chinese) [Google Scholar]

- Chen, Y.; Barthakur, N.N.; Arnold, N.P. Electrohydrodynamic (EHD) drying of potato slabs. J. Food Eng. 1994, 23, 107–119. [Google Scholar] [CrossRef]

- Bai, Y.; Li, X.; Sun, Y.; Shi, H. Thin layer electrohydrodynamic (EHD) drying and mathematical modeling of fish. Int. J. Appl. Electromagn. Mech. 2011, 36, 217–228. [Google Scholar] [CrossRef]

- Ding, C.; Lu, J.; Song, Z.; Bao, S. The drying efficiency of electrohydrodynamic (EHD) systems based on the drying characteristics of cooked beef and mathematical modeling. Int. J. Appl. Electromagn. Mech. 2014, 46, 455–461. [Google Scholar] [CrossRef]

- Onwude, D.I.; Iranshahi, K.; Rubinetti, D.; Martynenko, A.; Defraeye, T. Scaling-up electrohydrodynamic drying for energy-efficient food drying via physics-based simulations. J. Clean. Prod. 2021, 329, 129690. [Google Scholar] [CrossRef]

- Lai, F.C.; Lai, K.W. EHD-enhanced drying with wire electrode. Dry. Technol. 2002, 20, 1393–1405. [Google Scholar] [CrossRef]

- Zhong, C.; Martynenko, A.; Wells, P.; Adamiak, K. Numerical investigation of the multi-pin electrohydrodynamic dryer: Effect of cross-flow air stream. Dry. Technol. 2019, 37, 1665–1677. [Google Scholar] [CrossRef]

- Dinani, S.T.; Havet, M. Effect of voltage and air flow velocity of combined convective-electrohydrodynamic drying system on the physical properties of mushroom slices. Ind. Crops Prod. 2015, 70, 417–426. [Google Scholar] [CrossRef]

- Martynenko, A.; Bashkir, I.; Kudra, T. Electrically enhanced drying of white champignons. Dry. Technol. 2021, 39, 234–244. [Google Scholar] [CrossRef]

- Zhang, W.P.; Yang, X.H.; Mujumdar, A.S.; Ju, H.Y.; Xiao, H.W. The influence mechanism and control strategy of relative humidity on hot air drying of fruits and vegetables: A review. Dry. Technol. 2021, 40, 2217–2234. [Google Scholar] [CrossRef]

- Bajgai, T.R.; Hashinaga, F. Drying of spinach with a high electric field. Dry. Technol. 2001, 19, 2331–2341. [Google Scholar] [CrossRef]

- Ding, C.; Lu, J.; Song, Z. Electrohydrodynamic drying of carrot slices. PLoS ONE 2015, 10, e0124077. [Google Scholar] [CrossRef]

- Rezaee, F.; Esehaghbeygi, A.; Mirhosseini, M.; Alemrajabi, A.A. Electrohydrodynamic drying of kiwi (Actinidia Chinensis) slices. Agric. Eng. Int. CIGR J. 2020, 22, 221–228. [Google Scholar]

- Alemrajabi, A.A.; Rezaee, F.; Mirhosseini, M.; Esehaghbeygi, A. Comparative evaluation of the effects of electrohydrodynamic, oven, and ambient air on carrot cylindrical slices during drying process. Dry. Technol. 2012, 30, 88–96. [Google Scholar] [CrossRef]

- Hashinaga, F.; Bajgai, T.R.; Isobe, S.; Barthakur, N.N. Electrohydrodynamic (EHD) drying of apple slices. Dry. Technol. 1999, 17, 479–495. [Google Scholar] [CrossRef]

- Yang, M.; Ding, C.; Zhu, J. The drying quality and energy consumption of chinese wolfberry fruits under electrohydrodynamic system. Int. J. Appl. Electromagn. Mech. 2017, 55, 101–112. [Google Scholar] [CrossRef]

- Yu, H.J.; Bai, A.Z.; Yang, X.W.; Wang, Y.L. Electrohydrodynamic drying of potato and process optimization. J. Food Process. Preserv. 2017, 42, e13492. [Google Scholar] [CrossRef]

- Ni, J.; Ding, C.; Zhang, Y.; Song, Z.; Hu, X.; Hao, T. Electrohydrodynamic drying of Chinese wolfberry in a multiple needle-to-plate electrode system. Foods 2019, 8, 152. [Google Scholar] [CrossRef]

- Bajgai, T.R.; Hashinaga, F. High electric field drying of Japanese radish. Dry. Technol. 2001, 19, 2291–2302. [Google Scholar] [CrossRef]

- Bai, Y.; Qu, M.; Luan, Z.; Li, X.; Yang, Y. Electrohydrodynamic drying of sea cucumber (Stichopus japonicus). LWT Food Sci. Technol. 2013, 54, 570–576. [Google Scholar] [CrossRef]

- Elmizadeh, A.; Shahedi, M.; Hamdami, N. Quality assessment of electrohydrodynamic and hot-air drying of quince slice. Ind. Crops Prod. 2018, 116, 35–40. [Google Scholar] [CrossRef]

- Ni, J.; Ding, C.; Zhang, Y.; Song, Z. Impact of different pretreatment methods on drying characteristics and microstructure of goji berry under electrohydrodynamic (EHD) drying process. Innov. Food Sci. Emerg. Technol. 2020, 61, 102318. [Google Scholar] [CrossRef]

- Polat, A.; Izli, N. Drying characteristics and quality evaluation of ‘ankara’ pear dried by electrohydrodynamic-hot air (EHD) method. Food Control 2021, 134, 108774. [Google Scholar] [CrossRef]

- Yang, M.; Ding, C. Electrohydrodynamic (EHD) Drying of the Chinese wolfberry fruits. Springerplus 2016, 5, 1–20. [Google Scholar] [CrossRef]

- Singh, A.; Vanga, S.K.; Nair, G.R.; Gariepy, Y.; Orsat, V.; Raghavan, V. Electrohydrodynamic drying (EHD) of wheat and its effect on wheat protein conformation. LWT Food Sci. Technol. 2015, 64, 750–758. [Google Scholar] [CrossRef]

- Xiao, A.; Ding, C. Effect of electrohydrodynamic (EHD) on drying kinetics and quality characteristics of shiitake mushroom. Foods 2022, 11, 1303. [Google Scholar] [CrossRef]

- Martynenko, A.; Zheng, W. Electrohydrodynamic drying of apple slices: Energy and quality aspects. J. Food Eng. 2016, 168, 215–222. [Google Scholar] [CrossRef]

- Ni, J.; Ding, C.; Zhang, Y.; Song, Z.; Xu, W. Influence of ultrasonic pretreatment on electrohydrodynamic drying process of goji berry. J. Food Process. Preserv. 2020, 44, e14600. [Google Scholar] [CrossRef]

- Paul, A.; Astatkie, E.; Martynenko, A. Electrohydrodynamic drying of fruit slices: Effect on drying kinetics, energy consumption, and product quality. J. Food Process. Preserv. 2022, e16812. [Google Scholar] [CrossRef]

- Chemists, A.A.; Horwitz, W. Official Methods of Analysis, 15th ed.; AOAC: Arlington, VA, USA, 1990; Volume I, p. 489. [Google Scholar]

- Demarchi, S.M.; Quintero Ruiz, N.A.; De Michelis, A.; Giner, S.A. Sorption characteristics of rosehip, apple and tomato pulp formulations as determined by gravimetric and hygrometric methods. LWT Food Sci. Technol. 2013, 52, 21–26. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Zhao, D.; Wei, J.; Hao, J.; Han, X.; Ding, S.; Yang, L.; Zhang, Z. Effect of Sodium Carbonate solution pretreatment on drying kinetics, antioxidant capacity changes, and final quality of wolfberry (Lycium barbarum) during drying. LWT 2019, 99, 254–261. [Google Scholar] [CrossRef]

- Iranshahi, K.; Onwude, D.I.; Martynenko, A.; Defraeye, T. Dehydration mechanisms in electrohydrodynamic drying of plant-based foods. Food Bioprod. Process. 2021, 131, 202–216. [Google Scholar] [CrossRef]

- Sakata, S.; Okada, T. Effect of humidity on hydrated cluster-ion formation in a clean room corona discharge neutralizer. J. Aerosol Sci. 1994, 25, 879–893. [Google Scholar] [CrossRef]

- Zhang, B.; He, J.; Ji, Y. Dependence of the average mobility of ions in air with pressure and humidity. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 923–929. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Handbook of Industrial Drying, 4th ed.; CRC Press: Boca Raton, FL, USA, 2015; ISBN 0-08-025537-X Hardcover. [Google Scholar]

- Pirnazari, K.; Esehaghbeygi, A.; Sadeghi, M. Modeling the electrohydrodynamic (EHD) drying of banana slices. Int. J. Food Eng. 2016, 12, 17–26. [Google Scholar] [CrossRef]

- Dinani, S.T.; Havet, M.; Hamdami, N.; Shahedi, M. Drying of mushroom slices using hot air combined with an electrohydrodynamic (EHD) drying system. Dry. Technol. 2014, 32, 597–605. [Google Scholar] [CrossRef]

- Martynenko, A.; Bashkir, I.; Kudra, T. The energy efficiency of electrohydrodynamic (EHD) drying of foods. Trends Food Sci. Technol. 2021, 118, 744–764. [Google Scholar] [CrossRef]

- Kudra, T.; Martynenko, A. Energy aspects in electrohydrodynamic drying. Dry. Technol. 2015, 33, 1534–1540. [Google Scholar] [CrossRef]

- Mahiuddin, M.; Khan, M.I.H.; Kumar, C.; Rahman, M.M.; Karim, M.A. Shrinkage of food materials during drying: Current status and challenges. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1113–1126. [Google Scholar] [CrossRef] [PubMed]

- Bajgai, T.R.; Raghavan, G.S.V.; Hashinaga, F.; Ngadi, M.O. Electrohydrodynamic drying—A concise overview. Dry. Technol. 2007, 24, 905–910. [Google Scholar] [CrossRef]

- Martynenko, A. Computer vision for real-time control in drying. Food Eng. Rev. 2017, 9, 91–111. [Google Scholar] [CrossRef]

- Esehaghbeygi, A.; Basiry, M. Electrohydrodynamic (EHD) drying of tomato slices (Lycopersicon esculentum). J. Food Eng. 2011, 104, 628–631. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Duszczyk, E. Color change of selected vegetables during convective air drying. Int. J. Food Prop. 1998, 1, 263–273. [Google Scholar] [CrossRef]

- Martinez, M.V.; Whitaker, J.R. The biochemistry and control of enzymatic browning. Trends Food Sci. Technol. 1995, 6, 195–200. [Google Scholar] [CrossRef]

- Singh, D.B.; Ahmed, N.; Pal, A.A.; Kumar, R.; Mirza, A.A. Effect of anti browning agents and slice thickness on drying and quality of apple slices var. red chief. J. Appl. Hortic. 2015, 17, 48–51. [Google Scholar] [CrossRef]

- Misra, N.N.; Pankaj, S.K.; Segat, A.; Ishikawa, K. Cold plasma interactions with enzymes in foods and model systems. Trends Food Sci. Technol. 2016, 55, 39–47. [Google Scholar] [CrossRef]

- Marabi, A.; Saguy, I.S. Effect of porosity on rehydration of dry food particulates. J. Sci. Food Agric. 2004, 84, 1105–1110. [Google Scholar] [CrossRef]

- Rahaman, A.; Siddeeg, A.; Manzoor, M.F.; Zeng, X.A.; Ali, S.; Baloch, Z.; Li, J.; Wen, Q.H. Impact of pulsed electric field treatment on drying kinetics, mass transfer, colour parameters and microstructure of plum. J. Food Sci. Technol. 2019, 56, 2670–2678. [Google Scholar] [CrossRef] [PubMed]

- Shoji, T. Polyphenols as natural food pigments: Changes during food processing. Am. J. Food Technol. 2007, 2, 570–581. [Google Scholar] [CrossRef]

- Elmizadeh, A.; Shahedi, M.; Hamdami, N. Comparison of electrohydrodynamic and hot-air drying of the quince slices. Innov. Food Sci. Emerg. Technol. 2017, 43, 130–135. [Google Scholar] [CrossRef]

| No. | Sample Code | Thickness (mm) | Load Density (%) | Airflow (m/s) |

|---|---|---|---|---|

| 1 | 1-50-0 | 1 | 50 | 0 |

| 2 | 1-50-0.5 | 1 | 50 | 0.5 |

| 3 | 1-50-1 | 1 | 50 | 1 |

| 4 | 1-100-0 | 1 | 100 | 0 |

| 5 | 1-100-0.5 | 1 | 100 | 0.5 |

| 6 | 1-100-1 | 1 | 100 | 1 |

| 7 | 2-50-0 | 2 | 50 | 0 |

| 8 | 2-50-0.5 | 2 | 50 | 0.5 |

| 9 | 2-50-1 | 2 | 50 | 1 |

| 10 | 2-100-0 | 2 | 100 | 0 |

| 11 | 2-100-0.5 | 2 | 100 | 0.5 |

| 12 | 2-100-1 | 2 | 100 | 1 |

| 13 | 3-50-0 | 3 | 50 | 0 |

| 14 | 3-50-0.5 | 3 | 50 | 0.5 |

| 15 | 3-50-1 | 3 | 50 | 1 |

| 16 | 3-100-0 | 3 | 100 | 0 |

| 17 | 3-100-0.5 | 3 | 100 | 0.5 |

| 18 | 3-100-1 | 3 | 100 | 1 |

| Factors | Drying Flux (g/m2s) | k (h−1) | Deff (×10−11 m2/s) | SEC (kJ/kg) |

|---|---|---|---|---|

| Thickness | 0.206 | 0.000 | 0.218 | 0.212 |

| Load | 0.000 | 0.123 | 0.123 | 0.031 |

| Airflow | 0.041 | 0.000 | 0.000 | 0.445 |

| Thickness*load | 0.018 | 0.433 | 0.494 | 0.154 |

| Thickness*airflow | 0.896 | 0.549 | 0.710 | 0.290 |

| Load*airflow | 0.041 | 0.084 | 0.132 | 0.614 |

| Thickness*load*airflow | 0.614 | 0.181 | 0.336 | 0.738 |

| Lack-of-Fit | 0.311 | 0.504 | 0.844 | 0.132 |

| Factors | Area Shrinkage | Volume Shrinkage | ΔE | Rehydration Ratio | Disintegration Index | Total Polyphenolic Content |

|---|---|---|---|---|---|---|

| Thickness | 0.031 | 0.000 | 0.547 | 0.000 | 0.256 | 0.108 |

| Load | 0.493 | 0.055 | 0.540 | 0.088 | 0.436 | 0.304 |

| Airflow | 0.544 | 0.967 | 0.216 | 0.388 | 0.267 | 0.171 |

| Thickness*load | 0.561 | 0.235 | 0.105 | 0.202 | 0.116 | 0.061 |

| Thickness*airflow | 0.879 | 0.197 | 0.654 | 0.806 | 0.751 | 0.451 |

| Load*airflow | 0.161 | 0.644 | 0.736 | 0.740 | 0.709 | 0.513 |

| Thickness*load*airflow | 0.934 | 0.325 | 0.042 | 0.003 | 0.140 | 0.831 |

| Lack-of-Fit | 0.897 | 0.729 | 0.359 | 0.497 | 0.679 | 0.124 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, A.; Martynenko, A. The Effect of Material Thickness, Load Density, External Airflow, and Relative Humidity on the Drying Efficiency and Quality of EHD-Dried Apples. Foods 2022, 11, 2765. https://doi.org/10.3390/foods11182765

Paul A, Martynenko A. The Effect of Material Thickness, Load Density, External Airflow, and Relative Humidity on the Drying Efficiency and Quality of EHD-Dried Apples. Foods. 2022; 11(18):2765. https://doi.org/10.3390/foods11182765

Chicago/Turabian StylePaul, Anjaly, and Alex Martynenko. 2022. "The Effect of Material Thickness, Load Density, External Airflow, and Relative Humidity on the Drying Efficiency and Quality of EHD-Dried Apples" Foods 11, no. 18: 2765. https://doi.org/10.3390/foods11182765

APA StylePaul, A., & Martynenko, A. (2022). The Effect of Material Thickness, Load Density, External Airflow, and Relative Humidity on the Drying Efficiency and Quality of EHD-Dried Apples. Foods, 11(18), 2765. https://doi.org/10.3390/foods11182765