Potential Applications of Frass Derived from Black Soldier Fly Larvae Treatment of Food Waste: A Review

Abstract

:1. Introduction

2. Methodology

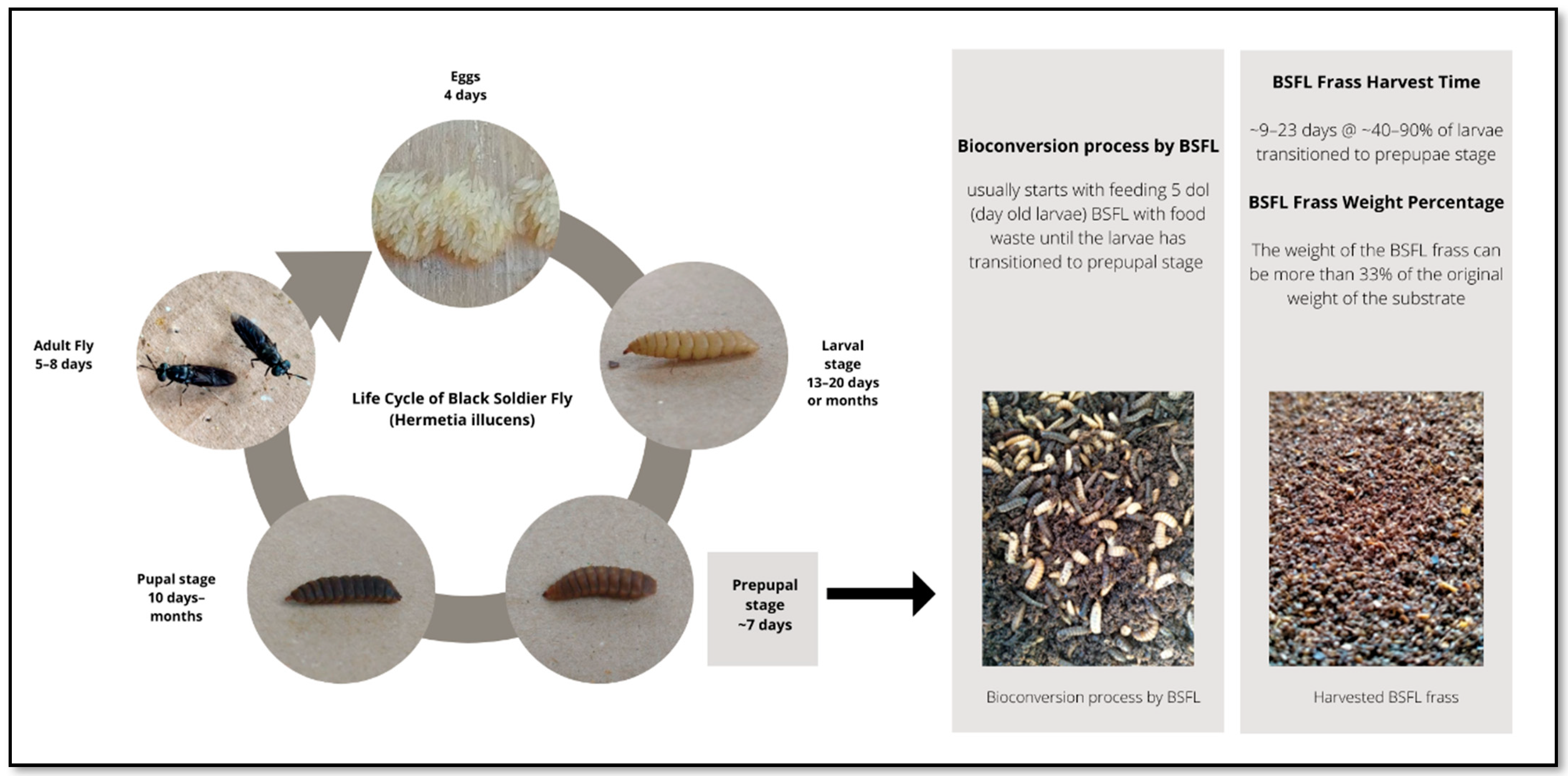

3. Black Soldier Fly Larvae Frass

3.1. Harvesting BSFL Frass

3.2. BSFL Frass Weight

4. Physiochemical Characteristics of BSFL Frass

4.1. Temperature

4.2. The pH of the BSFL Frass

4.3. Moisture Content of the BSFL Frass

4.4. The C/N Ratio of the BSFL Frass

4.5. Nutrient Content (NPK) of the BSFL Frass

4.6. Nutrient Composition of Food Waste Attribute to the BSFL Frass Composition

4.7. Heavy Metals in BSFL Frass

4.8. Maturity and Stability of BSFL Frass

5. Benefits of BSFL Frass

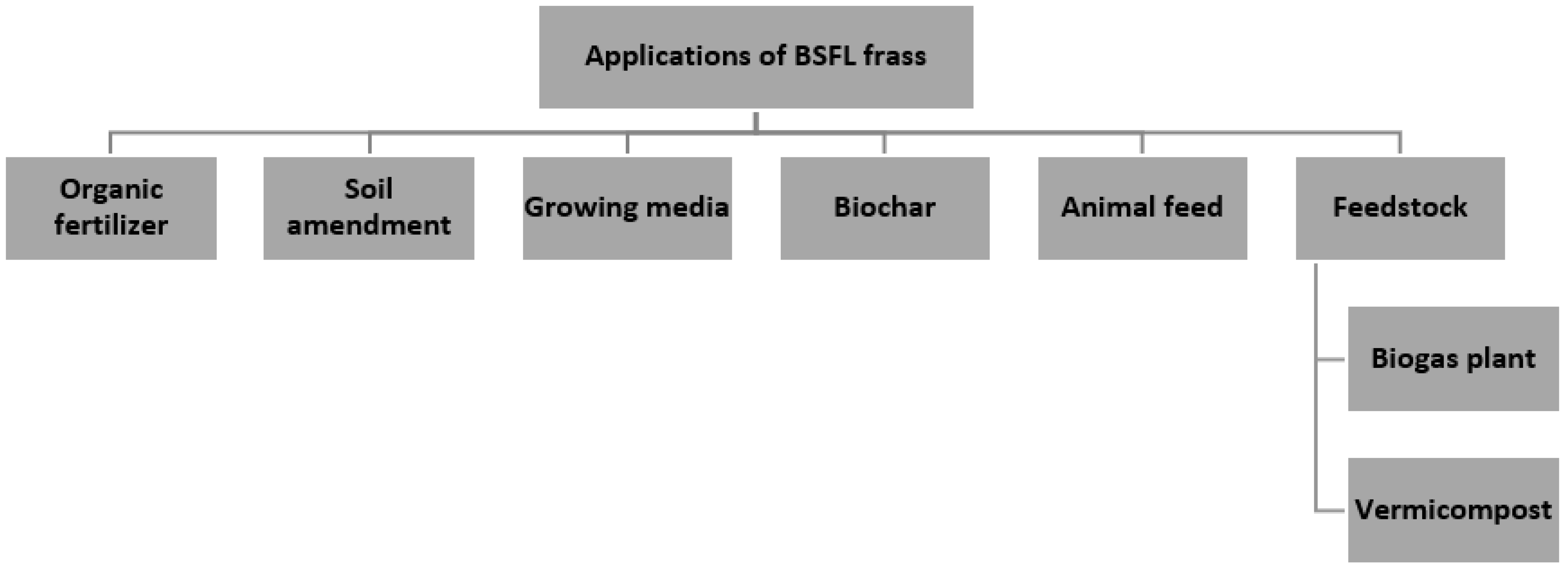

6. Applications of BSFL Frass

6.1. Organic Fertiliser

6.2. Soil Amendments

6.3. Growing Media

6.4. Biochar

6.5. Animal Feed

6.6. Feedstock

7. Challenges of BSFL Frass on a Food Waste Substrate

7.1. High Moisture Content

7.2. Ecological Risk

8. Pre-Treatment of the Substrate

8.1. Substrate Particle Size

8.2. Substrate Moisture Content

8.3. Addition of Effective Microorganisms (EM)

8.4. Addition of Protein-Rich Substrate

9. Post-Treatment of BSFL Frass

10. Direction of Future Research

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention. Rome. 2011. Available online: https://www.fao.org/3/i2697e/i2697e.pdf (accessed on 23 May 2022).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Liu, T.; Awasthi, M.K.; Awasthi, S.K.; Duan, Y.; Zhang, Z. Effects of black soldier fly larvae (Diptera: Stratiomyidae) on food waste and sewage sludge composting. J. Environ. Manag. 2019, 256, 109967. [Google Scholar] [CrossRef]

- Rodzi, R.M.; Nopiah, Z.M.; Basri, N.E.A. Analysis of Solid Waste Generation and Composition in Malaysia TVET Campus. Int. J. Integr. Eng. 2019, 11, 158–170. [Google Scholar] [CrossRef]

- Mertenat, A.; Diener, S.; Zurbrügg, C. Black Soldier Fly biowaste treatment—Assessment of global warming potential. Waste Manag. 2019, 84, 173–181. [Google Scholar] [CrossRef]

- Park, H. Black Soldier Fly Larvae Manual. Stud. Showc. 2016, 14, 1–13. Available online: http://scholarworks.umass.edu/sustainableumass_studentshowcase/14 (accessed on 1 March 2022).

- Gold, M.; Tomberlin, J.K.; Diener, S.; Zurbrügg, C.; Mathys, A. Decomposition of biowaste macronutrients, microbes, and chemicals in black soldier fly larval treatment: A review. Waste Manag. 2018, 82, 302–318. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Kumari, K. An inclusive approach for organic waste treatment and valorisation using Black Soldier Fly larvae: A review. J. Environ. Manag. 2019, 251, 109569. [Google Scholar] [CrossRef]

- Kabir Ahmad, I.; Samba Mohamed, Z.; Fardilla Amrul, N.; Wai Quan, C.; Ain Abdul Jalil, N.; Ezlin Ahmad Basri, N.; Reza Azmi, M. Composting Fruit and Vegetable Waste Using Black Soldier Fly Larvae. J. Kejuruter. 2021, 33, 837–843. [Google Scholar] [CrossRef]

- Izzati, N.; Rahman, A.; Khoiry, M.A.; Rahim, S.; Ezlin, N.; Basri, A. Review on Current Municipal Solid Waste Management in Malaysia. Int. J. Disaster Recovery Bus. Contin. 2020, 11, 2230–2242. [Google Scholar]

- Čičková, H.; Newton, G.L.; Lacy, R.C.; Kozánek, M. The use of fly larvae for organic waste treatment. Waste Manag. 2015, 35, 68–80. [Google Scholar] [CrossRef]

- Diener, S.; Zurbrügg, C.; Roa Gutiérrez, F.; Hong Nguyen, D.; Morel, A.; Koottatep, T.; Tockner, K. Black Soldier Fly Larvae for Organic Waste Treatment—Prospects and Constraints. In Proceedings of the WasteSafe 2011—2nd International Conference on Solid Waste Management in the Developing Countries, Khulna, Bangladesh, 13–15 February 2011; Available online: https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/BSF/Black_soldier_fly_larvae_for_organic_waste_treatment.pdf (accessed on 7 April 2022).

- Salomone, R.; Saija, G.; Mondello, G.; Giannetto, A.; Fasulo, S.; Savastano, D. Environmental impact of food waste bioconversion by insects: Application of Life Cycle Assessment to process using Hermetia illucens. J. Clean. Prod. 2017, 140, 890–905. [Google Scholar] [CrossRef]

- Amrul, N.F.; Ahmad, I.K.; Basri, N.E.A.; Suja, F.; Jalil, N.A.A.; Azman, N.A. A Review of Organic Waste Treatment Using Black Soldier Fly (Hermetia illucens). Sustainability 2022, 14, 4565. [Google Scholar] [CrossRef]

- Schmitt, E.; de Vries, W. Potential benefits of using Hermetia illucens frass as a soil amendment on food production and for environmental impact reduction. Curr. Opin. Green Sustain. Chem. 2020, 25, 100335. [Google Scholar] [CrossRef]

- Green, T.R.; Popa, R. Enhanced Ammonia Content in Compost Leachate Processed by Black Soldier Fly Larvae. Appl. Biochem. Biotechnol. 2012, 166, 1381–1387. [Google Scholar] [CrossRef] [PubMed]

- Quilliam, R.; Nuku-Adeku, C.; Maquart, P.-O.; Little, D.; Newton, R.; Murray, F. Integrating insect frass biofertilisers into sustainable peri-urban agro-food systems. J. Insects Food Feed 2020, 6, 315–322. [Google Scholar] [CrossRef]

- Zahn, N.H. The Effects of Insect Frass Created by Hermetia Illucens on Spring Onion Growth and Soil Fertility. Univ. Stirling 2017, 1, 1–65. Available online: https://www.researchgate.net/publication/321831639_The_effects_of_insect_frass_created_by_Hermetia_illucens_on_spring_onion_growth_and_soil_fertility (accessed on 1 January 2022).

- Bortolini, S.; Macavei, L.I.; Saadoun, J.H.; Foca, G.; Ulrici, A.; Bernini, F.; Malferrari, D.; Setti, L.; Ronga, D.; Maistrello, L. Hermetia illucens (L.) larvae as chicken manure management tool for circular economy. J. Clean. Prod. 2020, 262, 121289. [Google Scholar] [CrossRef]

- Attiogbe, F.K.; Ayim, N.Y.K.; Martey, J. Effectiveness of black soldier fly larvae in composting mercury contaminated organic waste. Sci. Afr. 2019, 6, e00205. [Google Scholar] [CrossRef]

- Xiao, X.; Mazza, L.; Yu, Y.; Cai, M.; Zheng, L.; Tomberlin, J.K.; Yu, J.; van Huis, A.; Yu, Z.; Fasulo, S.; et al. Efficient co-conversion process of chicken manure into protein feed and organic fertilizer by Hermetia illucens L. (Diptera: Stratiomyidae) larvae and functional bacteria. J. Environ. Manag. 2018, 217, 668–676. [Google Scholar] [CrossRef]

- Zurbrügg, C.; Dortmans, B.; Fadhila, A.; Verstappen, B.; Diener, S. From pilot to full scale operation of a waste-to-protein treatment facility. Detritus 2018, 1, 18–22. Available online: https://digital.detritusjournal.com/articles/from-pilot-to-full-scale-operation-of-a-waste-to-protein-treatment-facility/17 (accessed on 26 August 2022). [CrossRef]

- Klammsteiner, T.; Turan, V.; Juárez, M.F.-D.; Oberegger, S.; Insam, H. Suitability of Black Soldier Fly Frass as Soil Amendment and Implication for Organic Waste Hygienization. Agronomy 2020, 10, 1578. [Google Scholar] [CrossRef]

- Lalander, C.; Diener, S.; Magri, M.E.; Zurbrügg, C.; Lindström, A.; Vinnerås, B. Faecal sludge management with the larvae of the black soldier fly (Hermetia illucens)—From a hygiene aspect. Sci. Total Environ. 2013, 458–460, 312–318. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, W.; Lu, X.; Zhu, F.; Liu, W.; Wang, X.; Lei, C. Bioconversion performance and life table of black soldier fly (Hermetia illucens) on fermented maize straw. J. Clean. Prod. 2019, 230, 974–980. [Google Scholar] [CrossRef]

- Ur Rehman, K.; Ur Rehman, R.; Somroo, A.A.; Cai, M.; Zheng, L.; Xiao, X.; Ur Rehman, A.; Rehman, A.; Tomberlin, J.K.; Yu, Z.; et al. Enhanced bioconversion of dairy and chicken manure by the interaction of exogenous bacteria and black soldier fly larvae. J. Environ. Manag. 2019, 237, 75–83. [Google Scholar] [CrossRef]

- Alattar, M.A.; Alattar, F.N.; Popa, R. Effects of microaerobic fermentation and black soldier fly larvae food scrap processing residues on the growth of corn plants (Zea mays). Plant Sci. Today 2016, 3, 57–62. [Google Scholar] [CrossRef]

- Lohri, C.R.; Diener, S.; Zabaleta, I.; Mertenat, A.; Zurbrügg, C. Treatment technologies for urban solid biowaste to create value products: A review with focus on low- and middle-income settings. Rev. Environ. Sci. Bio/Technol. 2017, 16, 81–130. [Google Scholar] [CrossRef]

- Ravi, H.; Degrou, A.; Costil, J.; Trespeuch, C.; Chemat, F.; Vian, M. Larvae Mediated Valorization of Industrial, Agriculture and Food Wastes: Biorefinery Concept through Bioconversion, Processes, Procedures, and Products. Processes 2020, 8, 857. [Google Scholar] [CrossRef]

- Sarpong, D.; Oduro-Kwarteng, S.; Gyasi, S.F.; Buamah, R.; Donkor, E.; Awuah, E.; Baah, M.K. Biodegradation by composting of municipal organic solid waste into organic fertilizer using the black soldier fly (Hermetia illucens) (Diptera: Stratiomyidae) larvae. Int. J. Recycl. Org. Waste Agric. 2019, 8, 45–54. [Google Scholar] [CrossRef]

- Pang, W.; Hou, D.; Chen, J.; Nowar, E.; Li, Z.; Hu, R.; Tomberlin, J.K.; Yu, Z.; Li, Q.; Wang, S. Reducing greenhouse gas emissions and enhancing carbon and nitrogen conversion in food wastes by the black soldier fly. J. Environ. Manag. 2020, 260, 110066. [Google Scholar] [CrossRef]

- Liu, Q.; Tomberlin, J.K.; Brady, J.A.; Sanford, M.R.; Yu, Z. Black Soldier Fly (Diptera: Stratiomyidae) Larvae Reduce Escherichia coli in Dairy Manure. Environ. Entomol. 2008, 37, 1525–1530. [Google Scholar] [CrossRef]

- Surendra, K.; Tomberlin, J.K.; van Huis, A.; Cammack, J.A.; Heckmann, L.-H.L.; Khanal, S.K. Rethinking organic wastes bioconversion: Evaluating the potential of the black soldier fly (Hermetia illucens (L.)) (Diptera: Stratiomyidae) (BSF). Waste Manag. 2020, 117, 58–80. [Google Scholar] [CrossRef]

- Choi, S.; Hassanzadeh, N. A Novel Biofertilizer for Improving Plant Health While Minimizing Environmental Impact. J. Can. Sci. Fair 2019, 2, 41–46. [Google Scholar] [CrossRef]

- Ritika, P.; Rajendra, S.S.P. Study on occurrence of black soldier fly larvae in composting of kitchen waste. Int. J. Res. Biosci. 2015, 4, 38–45. Available online: http://www.ijesm.co.in/uploads/23/1140_pdf.pdf (accessed on 26 June 2022).

- Kawasaki, K.; Kawasaki, T.; Hirayasu, H.; Matsumoto, Y.; Fujitani, Y. Evaluation of Fertilizer Value of Residues Obtained after Processing Household Organic Waste with Black Soldier Fly Larvae (Hermetia illucens). Sustainability 2020, 12, 4920. [Google Scholar] [CrossRef]

- Song, S.; Ee, A.W.L.; Tan, J.K.N.; Cheong, J.C.; Chiam, Z.; Arora, S.; Lam, W.N.; Tan, H.T.W. Upcycling food waste using black soldier fly larvae: Effects of further composting on frass quality, fertilising effect and its global warming potential. J. Clean. Prod. 2020, 288, 125664. [Google Scholar] [CrossRef]

- Beesigamukama, D.; Mochoge, B.; Korir, N.K.; Fiaboe, K.K.M.; Nakimbugwe, D.; Khamis, F.M.; Subramanian, S.; Dubois, T.; Musyoka, M.W.; Ekesi, S.; et al. Exploring Black Soldier Fly Frass as Novel Fertilizer for Improved Growth, Yield, and Nitrogen Use Efficiency of Maize Under Field Conditions. Front. Plant Sci. 2020, 11, 574592. [Google Scholar] [CrossRef]

- Dortmans, B.; Diener, S.; Verstappen, B.; Zurbrügg, C. Black Soldier Fly Biowaste Processing—A Step-by-Step Guide Eawag; Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2017; pp. 6–54. Available online: https://www.researchgate.net/publication/353923113_Black_Soldier_Fly_Biowaste_Processing_-_A_Step-by-Step_Guide_2nd_Edition (accessed on 26 August 2022).

- Lopes, I.G.; Yong, J.W.; Lalander, C. Frass derived from black soldier fly larvae treatment of biodegradable wastes. A critical review and future perspectives. Waste Manag. 2022, 142, 65–76. [Google Scholar] [CrossRef]

- Diaz, L.F.; de Bertoldi, M.; Bidlingmaie, W. (Eds.) Compost Science and Technology; Elservier: Amsterdam, The Netherlands, 2007; Volume 8, pp. 1–364. ISBN 9780080545981. [Google Scholar]

- Chen, J.; Hou, D.; Pang, W.; Nowar, E.E.; Tomberlin, J.K.; Hu, R.; Chen, H.; Xie, J.; Zhang, J.; Yu, Z.; et al. Effect of moisture content on greenhouse gas and NH3 emissions from pig manure converted by black soldier fly. Sci. Total Environ. 2019, 697, 133840. [Google Scholar] [CrossRef]

- Kamaruzzaman, F.; Zain, S.M.; Saad, N.F.M.; Basri, H.; Basri, N.E.A. Effective Use of Indigenous Microorganism (IMO) in Composting a Mixture of Food and Yard Wastes on an Industrial Scale. Kejuruter. SI 2018, 1, 53–58. [Google Scholar]

- Hamid, H.A.; Lim, P.; Qi, H.; Harun, N.M.; Sunar, H.; Ahmad, M.S.; Muhamad, N.H. Development of Organic Fertilizer from Food Waste by Composting in UTHM Campus Pagoh. J. Appl. Chem. Nat. Resour. 2019, 1, 1–6. Available online: https://fazpublishing.com/jacnar/index.php/jacnar/article/view/4 (accessed on 26 August 2022).

- Bhave, P.P.; Kulkarni, B.N. Effect of active and passive aeration on composting of household biodegradable wastes: A decentralized approach. Int. J. Recycl. Org. Waste Agric. 2019, 8, 335–344. [Google Scholar] [CrossRef]

- Manu, M.; Li, D.; Liwen, L.; Jun, Z.; Varjani, S.; Wong, J.W. A review on nitrogen dynamics and mitigation strategies of food waste digestate composting. Bioresour. Technol. 2021, 334, 125032. [Google Scholar] [CrossRef] [PubMed]

- Ho TT, K.; Tra, V.T.; Le, T.H.; Nguyen NK, Q.; Tran, C.S.; Nguyen, P.T.; Vo TD, H.; Thai, V.N.; Bui, X.T. Compost to improve sustainable soil cultivation and crop productivity. Case Stud. Chem. and Envi. Eng. 2022, 6, 100211. [Google Scholar] [CrossRef]

- El-Haggar, S.M. Sustainability of Agricultural and Rural Waste Management. Sustain. Ind. Des. Waste Manag. 2007, 2007, 223–260. [Google Scholar] [CrossRef]

- Stehouwer, R.; Cooperband, L.; Rynk, R.; Biala, J.; Bonhotal, J.; Antler, S.; Lewandowski, T.; Nichols, H. Compost characteristics and quality. In The Composting Handbook; Academic Press: Cambridge, MA, USA, 2022; pp. 737–775. [Google Scholar] [CrossRef]

- Palma, L.; Fernández-Bayo, J.; Putri, F.; VanderGheynst, J.S. Almond by-product composition impacts the rearing of black soldier fly larvae and quality of the spent substrate as a soil amendment. J. Sci. Food Agric. 2020, 100, 4618–4626. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Liang, J.; Zeng, G.; Chen, M.; Mo, D.; Li, G.; Zhang, D. Seed germination test for toxicity evaluation of compost: Its roles, problems and prospects. J. Waste Manag. 2018, 71, 109–114. [Google Scholar] [CrossRef]

- Cooperband, L. The Art and Science of Composting, A resource for Farmers and Compost Producers, Centre for Integrated Agricultural Systems; University of Wisconsin: Madison, WI, USA, 2002; Available online: https://cias.wisc.edu/crop-soil/the-art-and-science-of-composting/ (accessed on 13 May 2022).

- Gold, M.; Von Allmen, F.; Zurbrügg, C.; Zhang, J.; Mathys, A. Identification of Bacteria in Two Food Waste Black Soldier Fly Larvae Rearing Residues. Front. Microbiol. 2020, 11, 582867. [Google Scholar] [CrossRef]

- Beesigamukama, D.; Mochoge, B.; Korir, N.K.; Fiaboe, K.K.; Nakimbugwe, D.; Khamis, F.M.; Subramanian, S.; Wangu, M.M.; Dubois, T.; Ekesi, S.; et al. Low-cost technology for recycling agro-industrial waste into nutrient-rich organic fertilizer using black soldier fly. Waste Manag. 2021, 119, 183–194. [Google Scholar] [CrossRef]

- Lalander, C.H.; Fidjeland, J.; Diener, S.; Eriksson, S.; Vinneras, B. High waste-to-biomass conversion and efficient Salmonella spp. reduction using black soldier fly for waste recycling. Agron. Sustain. Dev. 2015, 35, 261–271. [Google Scholar] [CrossRef]

- Setti, L.; Francia, E.; Pulvirenti, A.; Gigliano, S.; Zaccardelli, M.; Pane, C.; Caradonia, F.; Bortolini, S.; Maistrello, L.; Ronga, D. Use of black soldier fly (Hermetia illucens (L.), Diptera: Stratiomyidae) larvae processing residue in peat-based growing media. Waste Manag. 2019, 95, 278–288. [Google Scholar] [CrossRef]

- Yang, S.-S.; Chen, Y.-D.; Kang, J.-H.; Xie, T.-R.; He, L.; Xing, D.-F.; Ren, N.-Q.; Ho, S.-H.; Wu, W.-M. Generation of high-efficient biochar for dye adsorption using frass of yellow mealworms (larvae of Tenebrio molitor Linnaeus) fed with wheat straw for insect biomass production. J. Clean. Prod. 2019, 227, 33–47. [Google Scholar] [CrossRef]

- Barbusiński, K.; Salwiczek, S.; Paszewska, A. The Use of Chitosan for Removing Selected Pollutants from Water and Wastewater—Short Review. Arch. Civ. Eng. Environ. 2016, 9, 107–115. [Google Scholar] [CrossRef]

- Yildirim-Aksoy, M.; Eljack, R.; Schrimsher, C.; Beck, B.H. Use of dietary frass from black soldier fly larvae, Hermetia illucens, in hybrid tilapia (Nile x Mozambique, Oreocromis niloticus x O. mozambique) diets improves growth and resistance to bacterial diseases. Aquac. Rep. 2020, 17, 100373. [Google Scholar] [CrossRef]

- Newton, L.; Sheppard, C.; Wes, D.W.; Burtle, G.; Dove, R. Using the black soldier fly, Hermetia illucens, as a value-added tool for the management of swine manure. J. Korean Entomol. Appl. Sci. 2005, 36, 17. [Google Scholar]

- Lalander, C.; Ermolaev, E.; Wiklicky, V.; Vinnerås, B. Process efficiency and ventilation requirement in black soldier fly larvae composting of substrates with high water content. Sci. Total Environ. 2020, 729, 138968. [Google Scholar] [CrossRef]

- USDA. Soil Nitrate. NRCS East Natl. Technol. Support Cent. 2014, 3, 1–2. Available online: https://www.nrcs.usda.gov/wps/PA_NRCSConsumption/download?cid=stelprdb1269818&ext=pdf (accessed on 26 August 2022).

- Cheng, J.Y.; Chiu, S.L.; Lo, I.M. Effects of moisture content of food waste on residue separation, larval growth and larval survival in black soldier fly bioconversion. Waste Manag. 2017, 67, 315–323. [Google Scholar] [CrossRef]

- Wynants, E.; Frooninckx, L.; Crauwels, S.; Verreth, C.; De Smet, J.; Sandrock, C.; Wohlfahrt, J.; Van Schelt, J.; Depraetere, S.; Lievens, B.; et al. Assessing the Microbiota of Black Soldier Fly Larvae (Hermetia illucens) Reared on Organic Waste Streams on Four Different Locations at Laboratory and Large Scale. Microb. Ecol. 2019, 77, 913–930. [Google Scholar] [CrossRef]

- Raksasat, R.; Lim, J.W.; Kiatkittipong, W.; Kiatkittipong, K.; Ho, Y.C.; Lam, M.K.; Font-Palma, C.; Zaid, H.F.M.; Cheng, C.K. A review of organic waste enrichment for inducing palatability of black soldier fly larvae: Wastes to valuable resources. Environ. Pollut. 2020, 267, 115488. [Google Scholar] [CrossRef]

- Xiao, Y.; Geng, W.; Yang, Y.; Wang, X.; Xu, X. Study on the Difference of Transformation of Livestock and Poultry Feces by Black Soldier Fly. IOP Conf. Ser. Earth Environ. Sci. 2020, 450, 6–12. [Google Scholar] [CrossRef]

- Liu, Z.; Minor, M.; Morel, P.C.H.; Rodriguez, A.N. Bioconversion of Three Organic Wastes by Black Soldier Fly (Diptera: Stratiomyidae) Larvae. Environ. Entomol. 2018, 47, 1609–1617. [Google Scholar] [CrossRef]

- Isibika, A.; Vinnerås, B.; Kibazohi, O.; Zurbrügg, C.; Lalander, C. Pre-treatment of banana peel to improve composting by black soldier fly (Hermetia illucens (L.), Diptera: Stratiomyidae) larvae. Waste Manag. 2019, 100, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Spranghers, T.; Ottoboni, M.; Klootwijk, C.; Ovyn, A.; Deboosere, S.; De Meulenaer, B.; Michiels, J.; Eeckhout, M.; De Clercq, P.; De Smet, S. Nutritional composition of black soldier fly (Hermetia illucens) prepupae reared on different organic waste substrates. J. Sci. Food Agric. 2017, 97, 2594–2600. [Google Scholar] [CrossRef] [PubMed]

- Mohd-Noor, S.N.; Wong, C.Y.; Lim, J.W.; Mah-Hussin MI, A.; Uemura, Y.; Lam, M.K.; Ramli, A.; Bashir MJ, K.; Tham, L. Optimization of self-fermented period of waste coconut endosperm destined to feed black soldier fly larvae in enhancing the lipid and protein yields. J. Renew. Energy 2017, 111, 646–654. [Google Scholar] [CrossRef]

- Diener, S.; Zurbrügg, C.; Tockner, K. Conversion of organic material by black soldier fly larvae: Establishing optimal feeding rates. Waste Manag. Res. J. Sustain. Circ. Econ. 2009, 27, 603–610. [Google Scholar] [CrossRef] [PubMed]

- Sheppard, D.C.; Tomberlin, J.K.; Joyce, J.A.; Kiser, B.C.; Sumner, S.M. Rearing Methods for the Black Soldier Fly (Diptera: Stratiomyidae): Table 1. J. Med. Entomol. 2002, 39, 695–698. [Google Scholar] [CrossRef]

- Barry, T. Evaluation of the Economic, Social, and Biological Feasibility of Bioconverting Food Wastes with the Black Soldier fly (Hermetia illucens). UNT Digit. Libr. 2004, 176. Available online: https://digital.library.unt.edu/ark:/67531/metadc4639/ (accessed on 26 August 2022).

- Lalander, C.; Nordberg, Å.; Vinneras, B. A comparison in product-value potential in four treatment strategies for food waste and faeces—Assessing composting, fly larvae composting and anaerobic digestion. GCB Bioenergy 2018, 10, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Enviroflight. BSFL Frass as Fertilizer: Use of Insect Larvae Residuals as Soil Amendment for Lawn and Garden, Fruit and Vegetable, and Crop Production. Enviroflight. USA. 2020. Available online: https://d1ip4j1950xau.cloudfront.net/Enviroflight/BSFL%20Frass%20as%20Fertilizer.pdf (accessed on 24 May 2022).

- Jalil, N.; Abdullah, S.; Ahmad, I.; Basri, N.; Mohamed, Z. Decomposition of food waste from protein and carbohydrate sources by black soldier fly larvae, Hermetia illucens L. J. Environ. Biol. 2021, 42, 756–761. [Google Scholar] [CrossRef]

- Chua, G.K.; Tan, F.H.Y.; Chew, F.N.; Mohd-Hairul, A.R. Nutrients content of food wastes from different sources and its pre-treatment. AIP Conf. Proc. 2019, 2124, 20031. [Google Scholar] [CrossRef]

| Type of Food Waste | pH | C/N Ratio | Moisture (%) | Temperature (°C) | Total Nitrogen as N (%) | Total Phosphorus as P2O5 (%) | Total Potassium as K2O (%) | References |

|---|---|---|---|---|---|---|---|---|

| Kitchen waste | 7.0 | 8:1 | 50 | - | - | - | - | [35] |

| Kitchen waste | 7.4 | 17:1 | 63 | - | - | - | - | [3] |

| Municipal food waste | 7.3–7.4 | 8:1–9:1 | 63–65 | 26.3–26.5 | - | - | - | [30] |

| Household food waste | 7.4 | 17:1 | 56 | - | 2.2 | 0.1 | 0.1 | [36] |

| Food waste, chicken faeces, and sawdust (3:2:1 ratio) | 6.1–8.0 | - | 72 | 27.0 | 1.7 | 1.1 | 2.1 | [20] |

| Fruits and vegetables | 5.6 | 27:1 | 10 | - | 1.8 | - | - | [23] |

| Maize straw | 8.0 | - | 38 | - | 0.6 | 2.5 | 2.1 | [25] |

| Okara and wheat bran | 7.5 | 8:1 | - | - | 4.8 | 1.0 | 0.9 | [37] |

| Okara and wheat bran | 7.7 | 10:1 | - | - | 3.2 | 0.8 | 0.5 | [37] * |

| Brewery spent grain | 7.7 | 17:1 | 30 | - | 2.1 | 1.2 | 0.2 | [38] |

| Type of Fertilisers | Type of Food Waste | pH | C/N Ratio | Moisture (%) | Temperature (°C) | Total Nitrogen as N (%) | Total Phosphorus as P2O5 (%) | Total Potassium as K2O (%) | References |

|---|---|---|---|---|---|---|---|---|---|

| Compost from windrow composting | Food waste and yard waste | 6.8–7.4 | 17:1–23:1 | 46–61 | 26–28 | - | - | - | [43] |

| Compost from composting bin | Cafeteria food waste and yard waste | 7.5 | - | - | 30 | 0.9 | 0.8 | 0.4 | [44] |

| Compost from aerated composting | Household food waste | 6.5–7.5 | 36:1 | 32–33 | 32 | 0.9–1.0 | 0.6–0.7 | 0.9–1.0 | [45] |

| Digestate from anaerobic digester | Municipal food waste | 8.1 | 11:1 | 85 | - | 9.6 | 2.4 | 2.3 | [46] |

| Commercial organic fertiliser | - | - | - | - | 2.3 | 2.3 | 2.3 | [44] | |

| Commercial chemical fertiliser | - | - | - | - | 16 | 16 | 16 | [44] | |

| Preferred for agronomic purposes | 6–8 | <30:1 | 30–45 | Ambient temperature | >0.6 | >0.22 | >0.25 | [30,37,44,47,48,49] |

| Sample | Type of Waste | Nutrient Composition e | BSFL Frass Composition | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Protein | Fat | Calcium | Starch | Sugar | NH4-N f | PO4-P f | K e | References | ||

| 1 | Pollinator hulls a,b | 40.1 | 31.0 | 2.4 | 5.33 | 152.7 | 615.0 | 355.0 | 35.4 | [50] |

| 2 | Nonpareil Hulls b,c | 46.3 | 20.5 | 2.1 | 3.57 | 243.5 | 5695.0 | 227.5 | 38.5 | [50] |

| 3 | Pollinator Hulls b,c | 41.0 | 24.8 | 2.3 | 5.03 | 178.1 | 755.0 | 405.0 | 44.6 | [50] |

| 4 | Nonpareil Hulls c,d | 55.3 | 22.3 | 2.2 | 4.23 | 291.3 | 5052.5 | 515.0 | 44.6 | [50] |

| 5 | Monterey Hulls c,d | 67.7 | 26.5 | 2.8 | 4.33 | 119.2 | 400 | 825.0 | 43.4 | [50] |

| 6 | Pollinator Hulls c,d | 40.6 | 22.9 | 2.6 | 4.93 | 202.1 | 1420.0 | 485.0 | 36.0 | [50] |

| 7 | Mixed Almond Shells c,d | 42.6 | 14.6 | 1.9 | 3.65 | 53.2 | 2595.0 | 245.0 | 17.9 | [50] |

| Benefits of BSFL Frass | Reference |

|---|---|

| BSFL frass contains chitin that improves the soil microbiome | [15] |

| Rich in nutrients (macronutrients, micronutrients, and organic matter) | [19,20,25,30] |

| High phosphorus concentrations in the BSFL frass promote nitrogen accumulation in plants | [23] |

| BSFL frass contains chitin that naturally produces antimicrobial peptides, which serve as a defence barrier for the plant | [34] |

| Beneficial microorganism population for plant uptake | [34,53] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basri, N.E.A.; Azman, N.A.; Ahmad, I.K.; Suja, F.; Jalil, N.A.A.; Amrul, N.F. Potential Applications of Frass Derived from Black Soldier Fly Larvae Treatment of Food Waste: A Review. Foods 2022, 11, 2664. https://doi.org/10.3390/foods11172664

Basri NEA, Azman NA, Ahmad IK, Suja F, Jalil NAA, Amrul NF. Potential Applications of Frass Derived from Black Soldier Fly Larvae Treatment of Food Waste: A Review. Foods. 2022; 11(17):2664. https://doi.org/10.3390/foods11172664

Chicago/Turabian StyleBasri, Noor Ezlin Ahmad, Nur Asyiqin Azman, Irfana Kabir Ahmad, Fatihah Suja, Nurul Ain Abdul Jalil, and Nur Fardilla Amrul. 2022. "Potential Applications of Frass Derived from Black Soldier Fly Larvae Treatment of Food Waste: A Review" Foods 11, no. 17: 2664. https://doi.org/10.3390/foods11172664

APA StyleBasri, N. E. A., Azman, N. A., Ahmad, I. K., Suja, F., Jalil, N. A. A., & Amrul, N. F. (2022). Potential Applications of Frass Derived from Black Soldier Fly Larvae Treatment of Food Waste: A Review. Foods, 11(17), 2664. https://doi.org/10.3390/foods11172664