Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Wheat Flour Formulated with Mealworm Powder

2.3. Pasting Characteristics

2.4. Farinographic and Extensograph Property

2.5. Biscuit Preparation

2.6. Physiochemical Analysis

2.6.1. Color

2.6.2. Texture

2.6.3. Baking Expansion Ratio

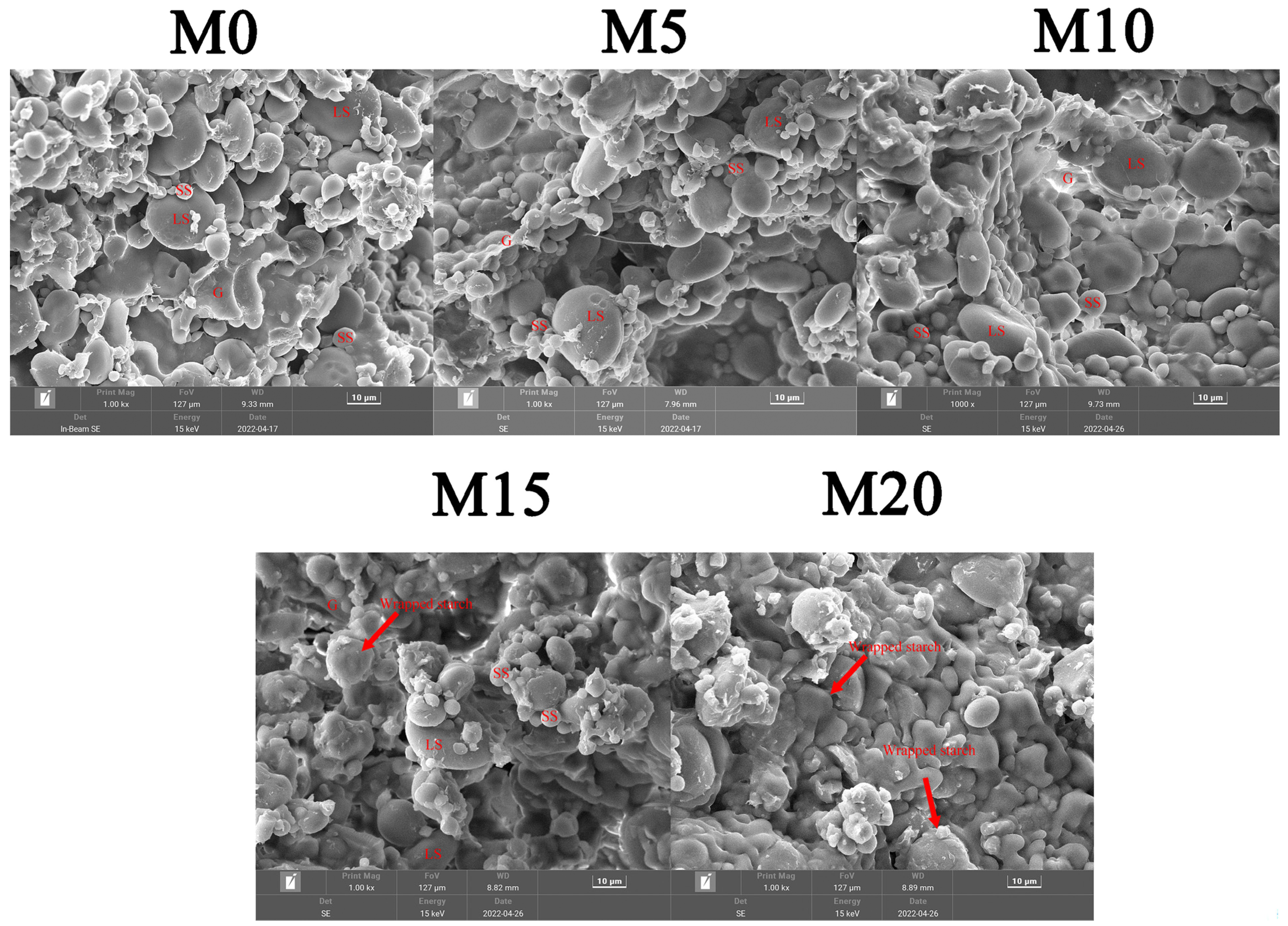

2.6.4. Scanning Electron Microscopy (SEM)

2.6.5. Proximate Compositions and Amino Acid Compositions

2.7. Sensory Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Pasting Properties

3.2. Farinograph Properties

3.3. Physical Properties of Biscuit

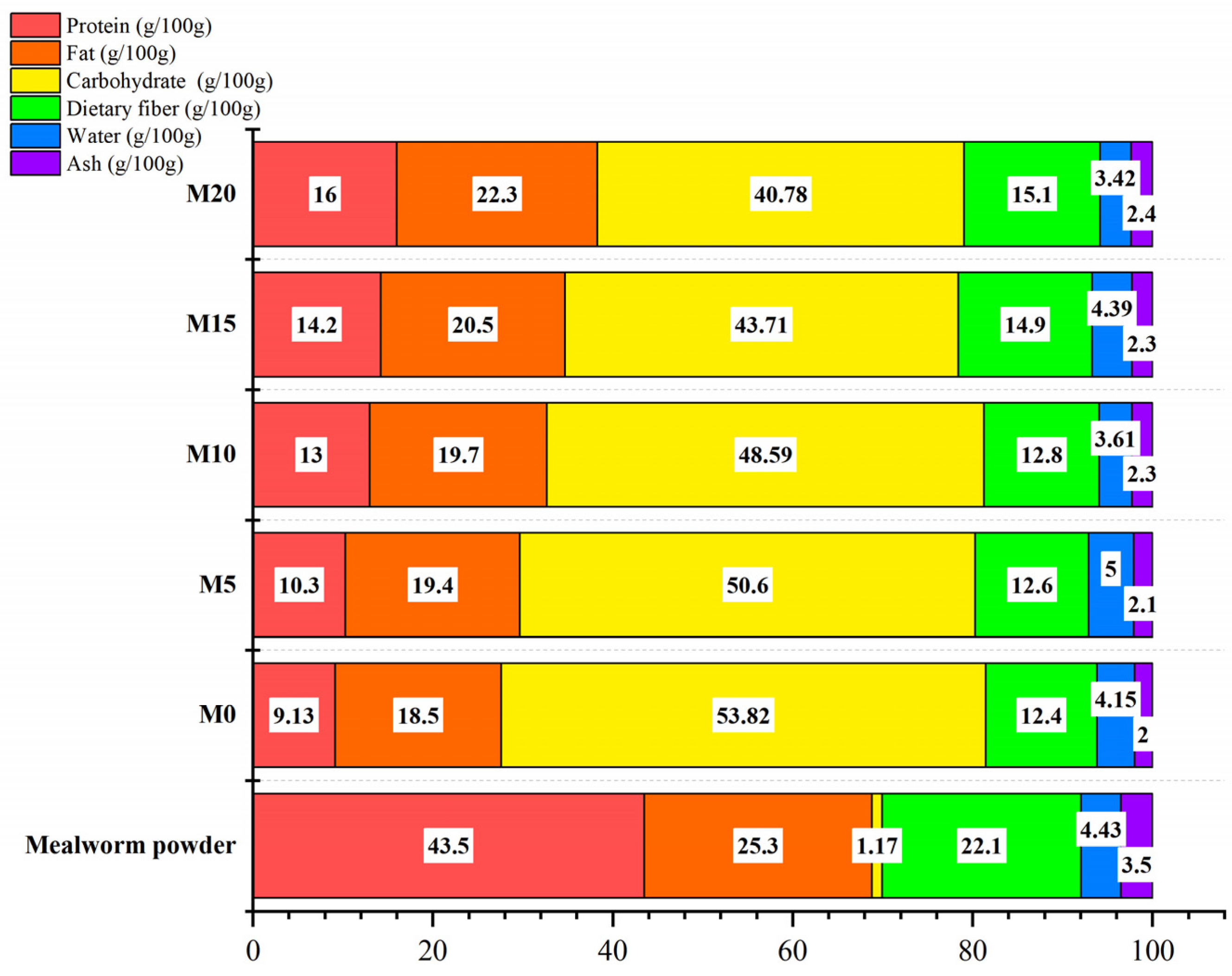

3.4. Nutritional Values

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orkusz, A. Edible insects versus meat—Nutritional comparison: Knowledge of their composition is the key to good health. Nutrients 2021, 13, 1207. [Google Scholar] [CrossRef] [PubMed]

- Jagtap, S.; Garcia-Garcia, G.; Duong, L.; Swainson, M.; Martindale, W. Codesign of food system and circular economy approaches for the development of livestock feeds from insect larvae. Foods 2021, 10, 1701. [Google Scholar] [CrossRef] [PubMed]

- Roncolini, A.; Milanović, V.; Cardinali, F.; Osimani, A.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R. Protein fortification with mealworm (Tenebrio molitor L.) powder: Effect on textural, microbiological, nutritional and sensory features of bread. PLoS ONE 2019, 14, e0211747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kowalski, S.; Mikulec, A.; Mickowska, B.; Skotnicka, M.; Mazurek, A. Wheat bread supplementation with various edible insect flours. Influence of chemical composition on nutritional and technological aspects. LWT 2022, 159, 113220. [Google Scholar] [CrossRef]

- Sriprablom, J.; Kitthawee, S.; Suphantharika, M. Functional and physicochemical properties of cookies enriched with edible insect (Tenebrio molitor and Zophobas atratus) powders. J. Food Meas. Charact. 2022, 16, 2181–2190. [Google Scholar] [CrossRef]

- Duda, A.; Adamczak, J.; Chełmińska, P.; Juszkiewicz, J.; Kowalczewski, P. Quality and nutritional/textural properties of durum wheat pasta enriched with cricket powder. Foods 2019, 8, 46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petrescu-Mag, R.M.; Rastegari Kopaei, H.; Petrescu, D.C. Consumers’ acceptance of the first novel insect food approved in the European Union: Predictors of yellow mealworm chips consumption. Food Sci. Nutr. 2022, 10, 846–862. [Google Scholar] [CrossRef]

- Chen, X.; Chen, H.; Zhao, M.; Yang, Z.; Feng, Y. Insect industrialization and prospect in commerce: A case of China. Entomol. Res. 2022, 52, 178–194. [Google Scholar] [CrossRef]

- EFSA Panel on Nutrition, Novel Foods and Food Allergens; Turck, D.; Bohn, T.; Castenmiller, J.; De Henauw, S.; Hirsch-Ernst, K.I.; Maciuk, A.; Mangelsdorf, I.; McArdle, H.J.; Naska, A. Safety of frozen and dried formulations from whole yellow mealworm (Tenebrio molitor larva) as a novel food pursuant to Regulation (EU) 2015/2283. EFSA J. 2021, 19, e06778. [Google Scholar]

- Son, Y.-J.; Choi, S.Y.; Hwang, I.-K.; Nho, C.W.; Kim, S.H. Could defatted mealworm (Tenebrio molitor) and mealworm oil be used as food ingredients? Foods 2020, 9, 40. [Google Scholar] [CrossRef] [Green Version]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef]

- Sui, W.; Xie, X.; Liu, R.; Wu, T.; Zhang, M. Effect of wheat bran modification by steam explosion on structural characteristics and rheological properties of wheat flour dough. Food Hydrocoll. 2018, 84, 571–580. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanović, V.; Aquilanti, L.; Cardinali, F.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Belleggia, L.; Pasquini, M.; Mozzon, M. Lesser mealworm (Alphitobius diaperinus) powder as a novel baking ingredient for manufacturing high-protein, mineral-dense snacks. Food Res. Int. 2020, 131, 109031. [Google Scholar] [CrossRef] [PubMed]

- Osimani, A.; Milanović, V.; Cardinali, F.; Roncolini, A.; Garofalo, C.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; Raffaelli, N. Bread enriched with cricket powder (Acheta domesticus): A technological, microbiological and nutritional evaluation. Innov. Food Sci. Emerg. Technol. 2018, 48, 150–163. [Google Scholar] [CrossRef]

- Yang, T.; Wang, P.; Wang, F.; Zhou, Q.; Wang, X.; Cai, J.; Huang, M.; Jiang, D. Influence of starch physicochemical properties on biscuit-making quality of wheat lines with high-molecular-weight glutenin subunit (HMW-GS) absence. LWT 2022, 158, 113166. [Google Scholar] [CrossRef]

- Rakshit, M.; Srivastav, P.P. Sensory evaluation and storage stability of fat reduced shortdough biscuit using hydrolysable tannin encapsulated double emulsion as fat replacer. LWT 2022, 154, 112816. [Google Scholar] [CrossRef]

- Asadi, S.Z.; Khan, M.A.; Zaidi, S. A study on the shelf life of cookies incorporated with sapota and beetroot leaf powders. J. Food Sci. Technol. 2022, 1–9. [Google Scholar] [CrossRef]

- Paula da Silva, S.; Ferreira do Valle, A.; Perrone, D. Microencapsulated Spirulina maxima biomass as an ingredient for the production of nutritionally enriched and sensorially well-accepted vegan biscuits. LWT 2021, 142, 110997. [Google Scholar] [CrossRef]

- Lu, L.; He, C.; Liu, B.; Wen, Q.; Xia, S. Incorporation of chickpea flour into biscuits improves the physicochemical properties and in vitro starch digestibility. LWT 2022, 159, 113222. [Google Scholar] [CrossRef]

- Jia, S.; Cao, J.; Dai, Y.; Hou, H.; Wang, W.; Ding, X.; Zhang, H. Effect of potassium carbonate on rheological properties of dough and its mechanism. LWT 2021, 152, 112335. [Google Scholar] [CrossRef]

- de Castro, G.T.; Tridapalli, L.P.; Fernandes, A.M.D.; Bona, E.; Leimann, F.V.; Droval, A.A.; Cardoso, F.A.R.; Marques, L.L.M.; Consolin-Filho, N.; Fuchs, R.H.B. Evaluation of the substitution of common flours for gluten-free flours in cookies. J. Food Process. Preserv. 2022, 46, e16215. [Google Scholar] [CrossRef]

- Ran, M.; Chen, C.; Li, C.; He, L.; Zeng, X. Effects of replacing fat with Perilla seed on the characteristics of meatballs. Meat Sci. 2020, 161, 107995. [Google Scholar] [CrossRef] [PubMed]

- Chauvin, M.A.; Younce, F.; Ross, C.; Swanson, B. Standard scales for crispness, crackliness and crunchiness in dry and wet foods: Relationship with acoustical determinations. J. Texture Stud. 2008, 39, 345–368. [Google Scholar] [CrossRef]

- Karakurt, G.; Özkaya, B.; Saka, İ. Chemical composition and quality characteristics of cookies enriched with microfluidized flaxseed flour. LWT 2022, 154, 112773. [Google Scholar] [CrossRef]

- Tian, S.; Wang, F.; Luo, M.; Yan, F.; Ke, D.; Chen, H.; Gao, S. Effect of Chlorella pyrenoidosa powder on rheological properties and fermentation characteristics of dough. J. Food Process. Preserv. 2022, 46, e16446. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, X.; Xiong, H.; Zhu, T. Effect of modified soy protein isolate on dough rheological properties and noodle qualities. J. Food Process. Preserv. 2022, 46, e16371. [Google Scholar] [CrossRef]

- Wu, Y.; Ye, G.; Li, X.; Wang, L.; Liu, Y.; Tan, B.; Shen, W.; Zhou, J. Comparison of quality characteristics of six reconstituted whole wheat flour with different modified bran. LWT 2022, 153, 112543. [Google Scholar] [CrossRef]

- Gałkowska, D.; Witczak, T.; Witczak, M. Ancient Wheat and Quinoa Flours as Ingredients for Pasta Dough—Evaluation of Thermal and Rheological Properties. Molecules 2021, 26, 7033. [Google Scholar] [CrossRef]

- Nawaz, A.; Li, E.; Khalifa, I.; Walayat, N.; Liu, J.; Nilofar; Ahsan, H.M.; Irshad, S.; Barakat, H.; Lorenzo, J.M.; et al. Effect of structurally different pectin on dough rheology, structure, pasting and water distribution properties of partially meat-based sugar snap cookies. Foods 2021, 10, 2692. [Google Scholar] [CrossRef]

- Zarzycki, P.; Wirkijowska, A.; Nawrocka, A.; Kozłowicz, K.; Krajewska, M.; Kłosok, K.; Krawęcka, A. Effect of Moldavian dragonhead seed residue on the baking properties of wheat flour and bread quality. LWT 2022, 155, 112967. [Google Scholar] [CrossRef]

- Waseem, M.; Akhtar, S.; Manzoor, M.F.; Mirani, A.A.; Ali, Z.; Ismail, T.; Ahmad, N.; Karrar, E. Nutritional characterization and food value addition properties of dehydrated spinach powder. Food Sci. Nutr. 2021, 9, 1213–1221. [Google Scholar] [CrossRef]

- Fang, F.; Diatta, A.; Simsek, S.; Torres-Aguilar, P.; Watanabe, H.; Higashiyama, T.; Campanella, O.H.; Hamaker, B.R. Effect of isomaltodextrin on dough rheology and bread quality. Int. J. Food Sci. Technol. 2022, 57, 1554–1562. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L. The Effect of the Addition of Hazelnut or Walnut Flour on the Rheological Characteristics of Wheat Dough. Materials 2022, 15, 782. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.; Yang, G.; Kwon, H.; Lee, S. Effects of wheat flour supplemented with soy protein concentrate on the rheology, microstructure and water mobility of protein-fortified precooked noodles. Int. J. Food Sci. Technol. 2022, 57, 4107–4118. [Google Scholar] [CrossRef]

- Guo, J.; Liu, F.; Gan, C.; Wang, Y.; Wang, P.; Li, X.; Hao, J. Effects of Konjac glucomannan with different viscosities on the rheological and microstructural properties of dough and the performance of steamed bread. Food Chem. 2022, 368, 130853. [Google Scholar] [CrossRef]

- Schouten, M.A.; Tappi, S.; Glicerina, V.; Rocculi, P.; Angeloni, S.; Cortese, M.; Caprioli, G.; Vittori, S.; Romani, S. Formation of acrylamide in biscuits during baking under different heat transfer conditions. LWT 2022, 153, 112541. [Google Scholar] [CrossRef]

- González, C.M.; Garzón, R.; Rosell, C.M. Insects as ingredients for bakery goods. A comparison study of H. illucens, A. domestica and T. molitor flours. Innov. Food Sci. Emerg. Technol. 2019, 51, 205–210. [Google Scholar] [CrossRef]

- Khuenpet, K.; Pakasap, C.; Vatthanakul, S.; Kitthawee, S. Effect of larval-stage mealworm (Tenebrio molitor) powder on qualities of bread. Int. J. Agric. Technol. 2020, 16, 283–296. [Google Scholar]

- Park, J.; Choi, I.; Kim, Y. Cookies formulated from fresh okara using starch, soy flour and hydroxypropyl methylcellulose have high quality and nutritional value. LWT 2015, 63, 660–666. [Google Scholar] [CrossRef]

- Bohrer, B.M. Nutrient density and nutritional value of meat products and non-meat foods high in protein. Trends Food Sci. Technol. 2017, 65, 103–112. [Google Scholar] [CrossRef]

- Selaledi, L.; Mabelebele, M. The influence of drying methods on the chemical composition and body color of yellow mealworm (Tenebrio molitor L.). Insects 2021, 12, 333. [Google Scholar] [CrossRef]

- Wendin, K.; Berg, J.; Jönsson, K.I.; Andersson, P.; Birch, K.; Davidsson, F.; Gerberich, J.; Rask, S.; Langton, M. Introducing mealworm as an ingredient in crisps and pâtés–sensory characterization and consumer liking. Future Foods 2021, 4, 100082. [Google Scholar] [CrossRef]

| Peak Viscosity (cp) | Trough (cp) | Breakdown (cp) | Final Viscosity (cp) | Setback (cp) | Peak Time (min) | Pasting Temperature (°C) | |

|---|---|---|---|---|---|---|---|

| M0 | 1591 ± 2.65 a | 1087.67 ± 11.02 a | 503.33 ± 10.69 a | 2044.67 ± 28.73 a | 957.00 ± 18.33 a | 5.93 ± 0.01 a | 85.87 ± 0.08 b |

| M5 | 1371.67 ± 9.50 b | 940 ± 13.45 b | 431.67 ± 9.24 b | 1775.67 ± 15.37 b | 835.67 ± 3.06 b | 5.80 ± 0.07 b | 85.30 ± 0.48 b |

| M10 | 1180.33 ± 11.02 c | 811.33 ± 8.08 c | 369 ± 4.00 c | 1524.67 ± 20.01 c | 713.33 ± 12.01 c | 5.71 ± 0.03 b | 87.48 ± 0.03 a |

| M15 | 1023 ± 8.66 d | 689 ± 5.2 d | 334 ± 3.46 d | 1286.67 ± 12.58 d | 597.67 ± 8.08 d | 5.47 ± 0.01 c | 87.5 ± 0.01 a |

| M20 | 907 ± 14.4 e | 580.33 ± 20.55 e | 326.67 ± 7.09 d | 1071.33 ± 35.92 e | 491 ± 16.52 e | 5.29 ± 0.03 d | 87.48 ± 0.06 a |

| WA (%) | DDT (min) | ST (min) | DS (FU) | FQN | Stretching Energy (cm2) | Extensibility (mm) | Stretching Resistance (BU) | Stretch Ratio | |

|---|---|---|---|---|---|---|---|---|---|

| M0 | 60.97 ± 0.26 a | 1.30 ± 0.08 b | 1.37 ± 0.12 b | 143.33 ± 8.18 a | 21.67 ± 1.25 b | 54.33 ± 2.49 a | 94.00 ± 2.94 a | 427.67 ± 5.91 a | 4.57 ± 0.12 a |

| M5 | 55.67 ± 0.34 b | 1.20 ± 0.00 b | 1.53 ± 0.17 b | 113.33 ± 8.81 bc | 19.33 ± 1.70 b | 47.00 ± 1.63 b | 88.67 ± 1.25 ab | 403.67 ± 23.34 a | 4.57 ± 0.33 a |

| M10 | 54.50 ± 0.43 c | 1.17 ± 0.05 b | 1.50 ± 0.16 b | 123.33 ± 11.26 ab | 19.33 ± 2.49 b | 33.00 ± 2.16 c | 92.67 ± 4.64 a | 268.00 ± 17.28 b | 2.90 ± 0.29 b |

| M15 | 54.20 ± 0.14 c | 1.30 ± 0.08 b | 1.57 ± 0.12 b | 120.00 ± 3.56 abc | 20.00 ± 0.82 b | 26.67 ± 0.94 d | 87.00 ± 3.74 ab | 221.00 ± 13.06 b | 2.57 ± 0.26 b |

| M20 | 52.50 ± 0.08 d | 2.60 ± 0.00 a | 3.27 ± 0.05 a | 95.67 ± 4.50 c | 56.67 ± 1.25 a | 27.67 ± 1.25 cd | 81.00 ± 3.56 b | 241.67 ± 2.05 b | 3.00 ± 0.14 b |

| L* (Lightness) | a* (Redness) | b* (Yellowness) | Hardness (N) | Springiness (mm) | Cohesiveness | Gumminess (N) | Resilience | |

|---|---|---|---|---|---|---|---|---|

| M0 | 82.31 ± 1.87 a | −0.21 ± 0.19 d | 18.68 ± 2.52 a | 1317.17 ± 185.42 b | 0.69 ± 0.04 b | 0.63 ± 0.03 ab | 833.24 ± 109.66 b | 0.13 ± 0.01 ab |

| M5 | 72.66 ± 1.05 b | 3.70 ± 0.52 b | 22.07 ± 1.15 a | 1618.56 ± 87.33 a | 0.79 ± 0.06 a | 0.70 ± 0.08 a | 1140.48 ± 191.43 a | 0.16 ± 0.04 a |

| M10 | 66.36 ± 3.58 c | 5.3 ± 0.45 c | 22.17 ± 1.94 a | 1469.10 ± 122.12 ab | 0.67 ± 0.05 b | 0.57 ± 0.04 b | 839.63 ± 125.82 b | 0.09 ± 0.01 bc |

| M15 | 60.24 ± 2.17 d | 6.53 ± 0.61 a | 22.41 ± 2.12 a | 1487.66 ± 142.75 ab | 0.67 ± 0.02 b | 0.56 ± 0.05 b | 829.22 ± 108.96 b | 0.10 ± 0.01 bc |

| M20 | 58.49 ± 1.54 e | 6.26 ± 0.33 a | 21.24 ± 0.94 a | 1293.90 ± 87.14 c | 0.66 ± 0.02 b | 0.53 ± 0.03 b | 693.17 ± 78.93 b | 0.08 ± 0.01 c |

| L* (Lightness) | a* (Redness) | b* (Yellowness) | Baking Expansion Ratio/% | Hardness (N) | Cohesiveness | Chewiness | Resilience | |

|---|---|---|---|---|---|---|---|---|

| M0 | 81.47 ± 1.52 a | −0.41 ± 0.18 b | 22.0 ± 2.12 b | 239.4 ± 12.5 a | 10,348 ± 1662 a | 0.437 ± 0.084 b | 2516 ± 978 c | 0.327 ± 0.087 d |

| M5 | 63.81 ± 3.02 b | 9.60 ± 2.17 a | 32.83 ± 1.79 a | 191.0 ± 9.6 b | 11,019 ± 2030 a | 0.544 ± 0.057 a | 3505 ± 1347 b | 0.438 ± 0.059 b |

| M10 | 59.74 ± 0.87 b | 9.84 ± 0.94 a | 32.23 ± 1.06 a | 165.9 ± 1.8 c | 11,416 ± 2065 a | 0.599 ± 0.059 a | 3903 ± 1260 c | 0.516 ± 0.073 c |

| M15 | 52.56 ± 4.11 b | 11.80 ± 3.12 a | 28.73 ± 1.57 c | 150.4 ± 7.3 cd | 10,925 ± 1657 a | 0.660 ± 0.049 a | 4093 ± 1124 a | 0.594 ± 0.070 a |

| M20 | 50.63 ± 5.33 b | 11.43 ± 2.27 a | 28.27 ± 1.81 c | 147.5 ± 2.1 d | 7967 ± 1487 b | 0.558 ± 0.073 a | 2114 ± 740 c | 0.490 ± 0.087 bc |

| g/100 g Sample (mg/g Protein) | Wheat Flour | Mealworm Powder | M0 | M5 | M10 | M15 | M20 |

|---|---|---|---|---|---|---|---|

| Essential amino acids (EEA) | |||||||

| His | 0.30 (35.29) | 2.41 (55.40) | 0.34 (37.24) | 0.36 (34.95) | 0.46 (35.38) | 0.52 (36.62) | 0.62 (38.75) |

| Lys | 0.14 (16.47) | 2.92 (67.13) | 0.16 (17.52) | 0.26 (25.24) | 0.35 (25.24) | 0.45 (31.69) | 0.54 (33.75) |

| Met + Cys | 0.18 (21.18) | 1.02 (23.45) | 0.15 (16.43) | 0.20 (19.42) | 0.22 (16.92) | 0.23 (16.20) | 0.25 (15.63) |

| Phe + Tyr | 0.65 (76.47) | 5.97 (137.24) | 0.64 (70.10) | 0.77 (74.76) | 0.98 (75.38) | 1.23 (86.62) | 1.49 (93.13) |

| Thr | 0.21 (24.17) | 2.17 (49.89) | 0.21 (23.00) | 0.32 (31.07) | 0.39 (30.00) | 0.51 (35.92) | 0.57 (35.63) |

| Ile | 0.29 (34.12) | 2.67 (61.38) | 0.29 (31.76) | 0.36 (34.95) | 0.40 (30.77) | 0.57 (40.14) | 0.67 (41.88) |

| Leu | 0.56 (65.88) | 3.73 (85.75) | 0.55 (60.24) | 0.71 (68.93) | 0.77 (59.23) | 0.94 (66.20) | 1.07 (66.88) |

| Val | 0.31 (36.47) | 3.21 (73.79) | 0.34 (37.24) | 0.35 (33.98) | 0.51 (39.23) | 0.76 (53.52) | 0.81 (50.63) |

| Nonessential amino acid | |||||||

| Ala | 0.47 (55.29) | 5.55 (127.59) | 0.29 (31.76) | 0.51 (49.51) | 0.74 (56.92) | 1.04 (73.24) | 1.18 (73.75) |

| Asp | 0.31 (36.47) | 4.04 (92.87) | 0.25 (27.38) | 0.54 (52.43) | 0.63 (48.46) | 0.87 (61.27) | 1.02 (63.75) |

| Arg | 0.32 (37.65) | 2.75 (63.22) | 0.20 (21.91) | 0.35 (33.98) | 0.40 (30.77) | 0.54 (38.03) | 0.63 (39.38) |

| Glu | 2.69 (316.47) | 6.34 (145.75) | 1.66 (181.82) | 2.40 (233.01) | 2.47 (190.00) | 2.76 (194.37) | 2.87 (179.38) |

| Gly | 0.30 (35.29) | 2.53 (58.16) | 0.25 (27.38) | 0.38 (36.89) | 0.46 (35.38) | 0.61 (42.96) | 0.69 (43.13) |

| Pro | 1.11 (130.59) | 3.79 (87.13) | 0.80 (87.62) | 1.25 (121.36) | 1.35 (103.85) | 1.29 (90.85) | 1.49 (93.13) |

| Ser | 0.31 (36.47) | 2.17 (48.89) | 0.28 (30.67) | 0.40 (38.83) | 0.47 (36.15) | 0.58 (40.85) | 0.65 (40.63) |

| Total EEA | 2.64 (310.59) | 24.1 (554.02) | 2.68 (293.54) | 3.33 (323.30) | 4.08 (313.85) | 5.21 (366.90) | 6.02 (376.25) |

| Appearance | Odor | Texture | Taste | Saltiness | Overall Acceptability | |

|---|---|---|---|---|---|---|

| M0 | 6.24 ± 1.20 a | 6.08 ± 1.15 a | 6.12 ± 1.01 a | 5.48 ± 1.12 a | 5.52 ± 1.36 a | 5.64 ± 1.03 a |

| M5 | 5.68 ± 0.90 ab | 6.00 ± 1.00 a | 5.92 ± 1.03 ab | 5.44 ± 1.38 a | 5.60 ± 1.50 a | 5.65 ± 1.15 a |

| M10 | 5.44 ± 1.08 ab | 5.60 ± 1.08 a | 5.76 ± 1.23 ab | 5.16 ± 1.59 a | 5.04 ± 1.56 ab | 5.09 ± 1.47 ab |

| M15 | 5.56 ± 1.15 ab | 5.40 ± 1.25 a | 5.84 ± 1.07 ab | 4.88 ± 1.73 a | 5.12 ± 1.16 ab | 5.13 ± 1.28 ab |

| M20 | 5.12 ± 1.09 b | 5.36 ± 0.81 a | 5.00 ± 1.50 b | 4.32 ± 1.67 a | 4.28 ± 1.56 b | 4.35 ± 1.49 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Yuan, Z.; Fu, K.; An, J.; Deng, L. Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties. Foods 2022, 11, 2156. https://doi.org/10.3390/foods11142156

Xie X, Yuan Z, Fu K, An J, Deng L. Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties. Foods. 2022; 11(14):2156. https://doi.org/10.3390/foods11142156

Chicago/Turabian StyleXie, Xinyuan, Zhihe Yuan, Kai Fu, Jianhui An, and Lingli Deng. 2022. "Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties" Foods 11, no. 14: 2156. https://doi.org/10.3390/foods11142156

APA StyleXie, X., Yuan, Z., Fu, K., An, J., & Deng, L. (2022). Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties. Foods, 11(14), 2156. https://doi.org/10.3390/foods11142156