The Fabrication and Characterization of Pickering Emulsion Gels Stabilized by Sorghum Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. The Preparation and Chemical Composition Determination of Sorghum Flour

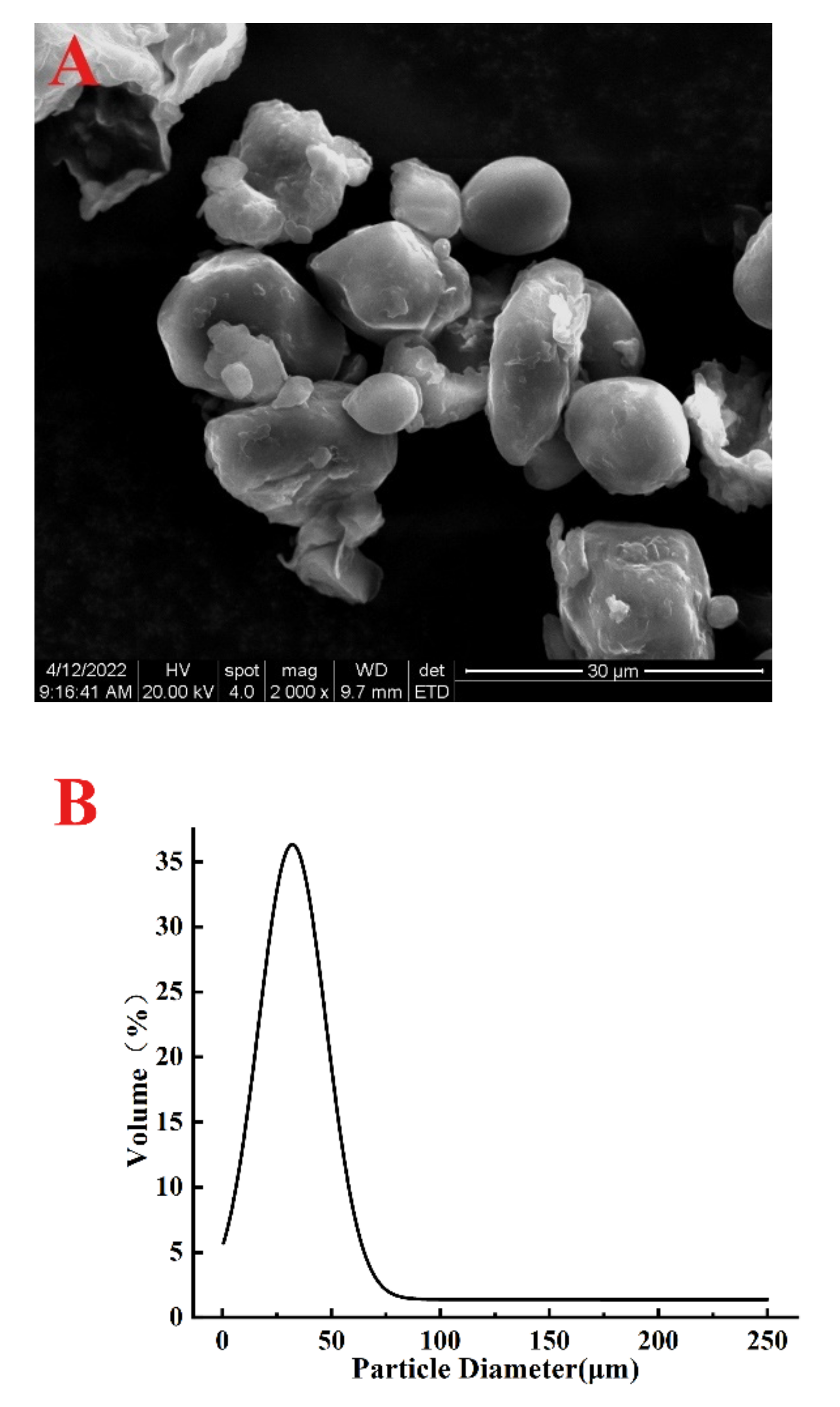

2.3. The Appearance Observation and Particle Size Determination of the Sorghum Flour

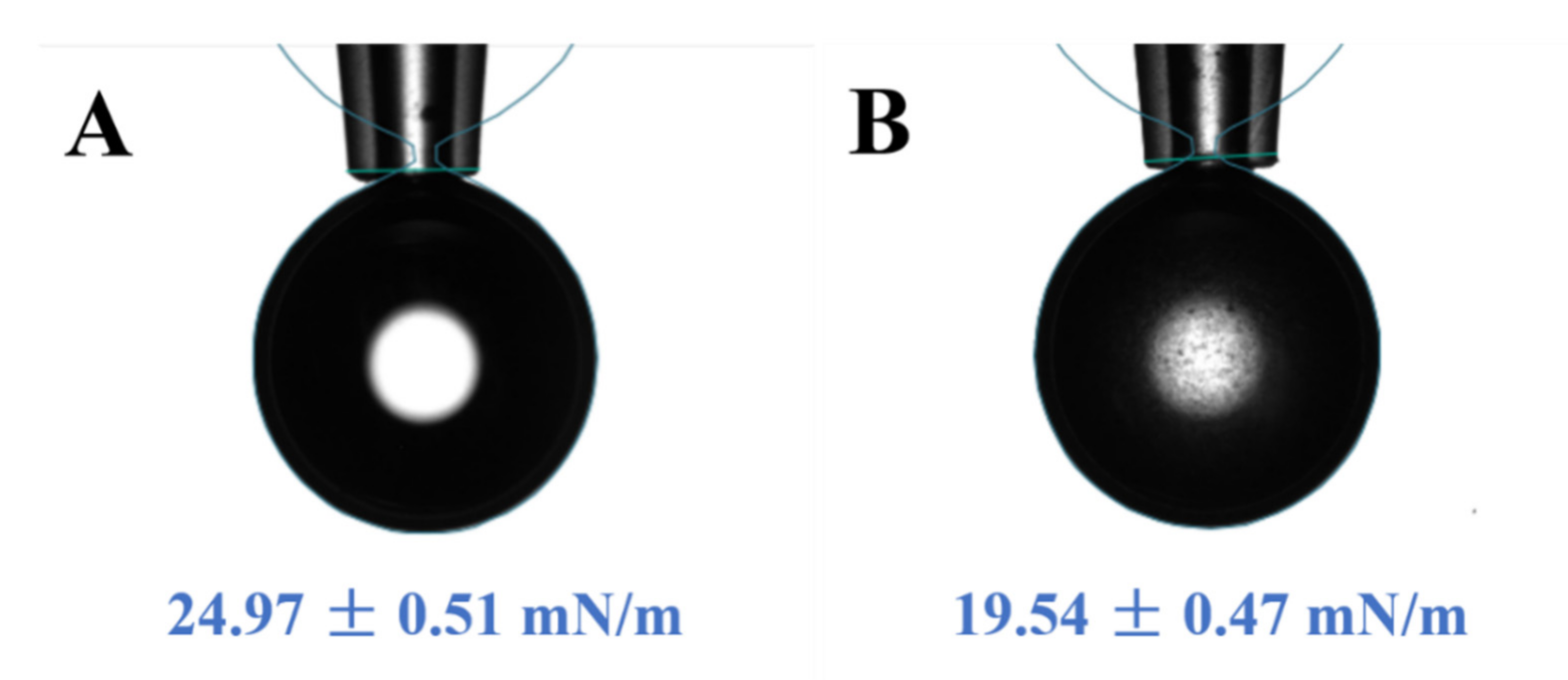

2.4. The Determination of the Interfacial Tension of the Sorghum Flour

2.5. The Determination of the Contact Angle of the Sorghum Flour

2.6. The Preparation of the Pickering Emulsion Gels

2.7. The Microscopic Observation of the Pickering Emulsion Gels

2.8. The Measurement of the Gel Strength of the Pickering Emulsion Gels

2.9. Measurement of Microrheological Properties of Pickering Emulsion Gels

2.10. Determination of β-Carotene Protective Capacity of Pickering Emulsion Gels

2.11. Statistical Analysis

3. Results and Discussion

3.1. The Characterization of the Sorghum Flour

3.2. The Wettability of the Sorghum Flour

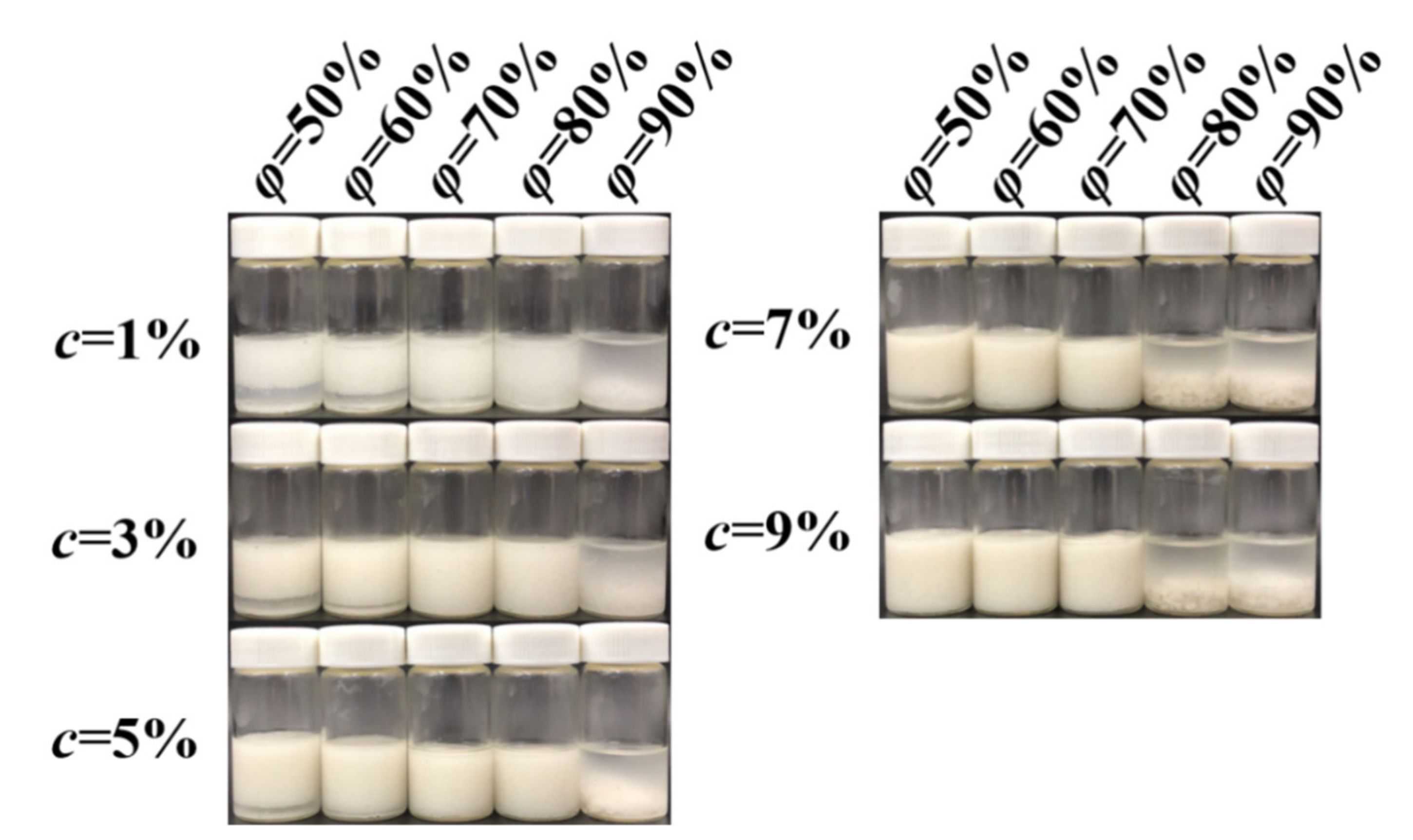

3.3. The Formation of the Pickering Emulsion Gels

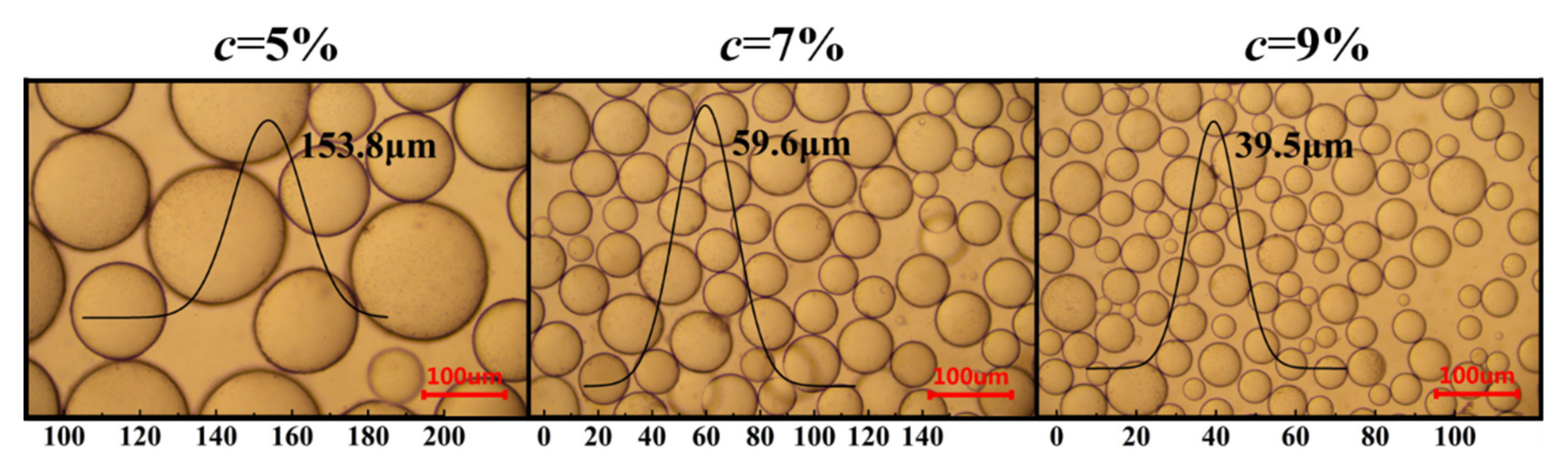

3.4. Microscopic Observation Analysis of Pickering Emulsion Gels

3.5. The Gel Strength of the Pickering Emulsion Gels

3.6. The Microrheological Analysis of the Pickering Emulsion Gels

3.7. The β-Carotene Protective Capacity of the Pickering Emulsion Gels

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abreha, K.B.; Enyew, M.; Carlsson, A.S.; Vetukuri, R.R.; Feyissa, T.; Motlhaodi, T.; Ng’uni, D.; Geleta, M. Sorghum in dryland: Morphological, physiological, and molecular responses of sorghum under drought stress. Planta 2022, 255, 20. [Google Scholar] [CrossRef] [PubMed]

- Saithalavi, K.M.; Bhasin, A.; Yaqoob, M. Impact of sprouting on physicochemical and nutritional properties of sorghum: A review. J. Food Meas. Charact. 2021, 15, 4190–4204. [Google Scholar] [CrossRef]

- Rumler, R.; Bender, D.; Schonlechner, R. Sorghum and its potential for the Western diet. J. Cereal Sci. 2022, 104, 103425. [Google Scholar] [CrossRef]

- Palavecino, P.M.; Curti, M.I.; Bustos, M.C.; Penci, M.C.; Ribotta, P.D. Sorghum pasta and noodles: Technological and nutritional aspects. Plant Foods Hum. Nutr. 2020, 75, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Tenorio-Garcia, E.; Araiza-Calahorra, A.; Simone, E.; Sarkar, A. Recent advances in design and stability of double emulsions: Trends in Pickering stabilization. Food Hydrocoll. 2022, 128, 107601. [Google Scholar] [CrossRef]

- Geng, S.; Li, Y.; Lv, J.; Ma, H.; Liang, G.; Liu, B. Fabrication of food-grade Pickering high internal phase emulsions (HIPEs) stabilized by a dihydromyricetin and lysozyme mixture. Food Chem. 2022, 373, 131576. [Google Scholar] [CrossRef]

- Klojdová, I.; Stathopoulos, C. The potential application of Pickering multiple emulsions in food. Foods 2022, 11, 1558. [Google Scholar] [CrossRef]

- Zhu, F. Starch based Pickering emulsions: Fabrication, properties, and application. Trends Food Sci. Technol. 2019, 85, 129–137. [Google Scholar] [CrossRef]

- Lu, X.; Xiao, J.; Huang, Q. Pickering emulsions stabilized by media-milled starch particles. Food Res. Int. 2018, 105, 140–149. [Google Scholar] [CrossRef]

- Yan, X.; Ma, C.; Cui, F.; McClements, D.J.; Liu, X.; Liu, F. Protein-stabilized Pickering emulsions: Formation, stability, properties, and applications in foods. Trends Food Sci. Technol. 2020, 103, 293–303. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Geng, S.; Mo, H.; Liu, B. Fabrication of food-grade Pickering high internal phase emulsions stabilized by the mixture of β-cyclodextrin and sugar beet pectin. Int. J. Biol. Macromol. 2021, 182, 252–263. [Google Scholar] [CrossRef] [PubMed]

- Geng, S.; Jiang, Z.; Ma, H.; Pu, P.; Liu, B.; Liang, G. Fabrication and characterization of novel edible Pickering emulsion gels stabilized by dihydromyricetin. Food Chem. 2021, 343, 128486. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Huang, Q. Nano/Submicrometer milled red rice particles-stabilized Pickering emulsions and their antioxidative properties. J. Agric. Food Chem. 2020, 68, 292–300. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Huang, Q.; Xiao, J.; Wang, Y. Milled miscellaneous black rice particles stabilized Pickering emulsions with enhanced antioxidation activity. Food Chem. 2022, 385, 132639. [Google Scholar] [CrossRef]

- Huang, Q.; Huang, Q.; Wang, Y.; Lu, X. Development of wet media milled purple sweet potato particle-stabilized Pickering emulsions: The synergistic role of bioactives, starch and cellulose. LWT-Food Sci. Technol. 2022, 155, 112964. [Google Scholar] [CrossRef]

- Liu, Z.; Geng, S.; Jiang, Z.; Liu, B. Fabrication and characterization of food-grade Pickering high internal emulsions stabilized with β-cyclodextrin. LWT-Food Sci. Technol. 2020, 134, 110134. [Google Scholar] [CrossRef]

- Liu, X.; Geng, S.; He, C.; Sun, J.; Ma, H.; Liu, B. Preparation and characterization of a dihydromyricetin-sugar beet pectin covalent polymer. Food Chem. 2022, 376, 131952. [Google Scholar] [CrossRef]

- Schmiele, M.; Jaekel, L.Z.; Patricio, S.M.C.; Steel, C.J.; Chang, Y.K. Rheological properties of wheat flour and quality characteristics of pan bread as modified by partial additions of wheat bran or whole grain wheat flour. Int. J. Food Sci. Technol. 2012, 47, 2141–2150. [Google Scholar] [CrossRef]

- Chevalier, Y.; Bolzinger, M.A. Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf. A-Physicochem. Eng. Asp. 2013, 439, 23–34. [Google Scholar] [CrossRef]

- Xie, J.; Li, Y.; Huang, Q. Recent advances on food-grade particles stabilized Pickering emulsions: Fabrication, characterization and research trends. Trends Food Sci. Technol. 2016, 55, 48–60. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.; Salentinig, S. Protein nanocage-stabilized Pickering emulsions. Curr. Opin. Colloid Interface Sci. 2021, 56, 101485. [Google Scholar] [CrossRef]

- Lu, X.; Liu, H.; Huang, Q. Fabrication and characterization of resistant starch stabilized Pickering emulsions. Food Hydrocoll. 2020, 103, 105703. [Google Scholar] [CrossRef]

- Marefati, A.; Matos, M.; Wiege, B.; Haase, N.U.; Rayner, M. Pickering emulsifiers based on hydrophobically modified small granular starches Part II-Effects of modification on emulsifying capacity. Carbohydr. Polym. 2018, 201, 416–424. [Google Scholar] [CrossRef]

- Yan, C.; McClements, D.J.; Zou, L.; Liu, W. A stable high internal phase emulsion fabricated with OSA-modified starch: An improvement in β-carotene stability and bioaccessibility. Food Funct. 2019, 10, 5446–5460. [Google Scholar] [CrossRef]

- Li, J.; Geng, S.; Zhen, S.; Lv, X.; Liu, B. Fabrication and characterization of oil-in-water emulsions stabilized by whey protein isolate/phloridzin/sodium alginate ternary complex. Food Hydrocoll. 2022, 129, 107625. [Google Scholar] [CrossRef]

- Larsen, T.H.; Furst, E.M. Microrheology of the liquid-solid transition during gelation. Phys. Rev. Lett. 2008, 100, 146001. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, X.; Qiu, D.; Pei, Y.; Li, Y.; Li, B.; Liu, S. Effect of surface charge density of bacterial cellulose nanofibrils on the rheology property of O/W Pickering emulsions. Food Hydrocoll. 2021, 120, 106944. [Google Scholar] [CrossRef]

- Singh, R.V.; Sambyal, K. An overview of β-carotene production: Current status and future prospects. Food Biosci. 2022, 47, 101717. [Google Scholar] [CrossRef]

- Links, M.R.; Taylor, J.; Kruger, M.C.; Naidoo, V.; Taylor, J.R.N. Kafirin microparticle encapsulated sorghum condensed tannins exhibit potential as an anti-hyperglycaemic agent in a small animal model. J. Funct. Foods 2016, 20, 394–399. [Google Scholar] [CrossRef] [Green Version]

- Palacios, C.E.; Nagai, A.; Torres, P.; Rodrigues, J.A.; Salatino, A. Contents of tannins of cultivars of sorghum cultivated in Brazil, as determined by four quantification methods. Food Chem. 2021, 33, 127970. [Google Scholar] [CrossRef]

| Water (%) | Protein (%) | Starch (%) | Lipid (%) | Mineral (%) |

|---|---|---|---|---|

| 10.58 ± 0.08 | 8.50 ± 0.09 | 68.28 ± 0.80 | 2.91 ± 0.06 | 1.93 ± 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Zhang, S.; Liu, B. The Fabrication and Characterization of Pickering Emulsion Gels Stabilized by Sorghum Flour. Foods 2022, 11, 2056. https://doi.org/10.3390/foods11142056

Song L, Zhang S, Liu B. The Fabrication and Characterization of Pickering Emulsion Gels Stabilized by Sorghum Flour. Foods. 2022; 11(14):2056. https://doi.org/10.3390/foods11142056

Chicago/Turabian StyleSong, Linlin, Sheng Zhang, and Benguo Liu. 2022. "The Fabrication and Characterization of Pickering Emulsion Gels Stabilized by Sorghum Flour" Foods 11, no. 14: 2056. https://doi.org/10.3390/foods11142056

APA StyleSong, L., Zhang, S., & Liu, B. (2022). The Fabrication and Characterization of Pickering Emulsion Gels Stabilized by Sorghum Flour. Foods, 11(14), 2056. https://doi.org/10.3390/foods11142056