Delayed Quality Deterioration of Low-Moisture Cereal-Based Snack by Storing in an Active Filler-Embedded LDPE Zipper Bag

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Active Zipper Bag

2.3. Particle Size Measurement

2.4. Scanning Electron Microscopy

2.5. Water Vapor Permeability Test

2.6. Storage for the Cereal-Based Snacks

2.7. Assessment of Total Weight

2.8. Analyses of Moisture Content, Water Activity, and Texture

2.9. Statistical Analysis

3. Results and Discussion

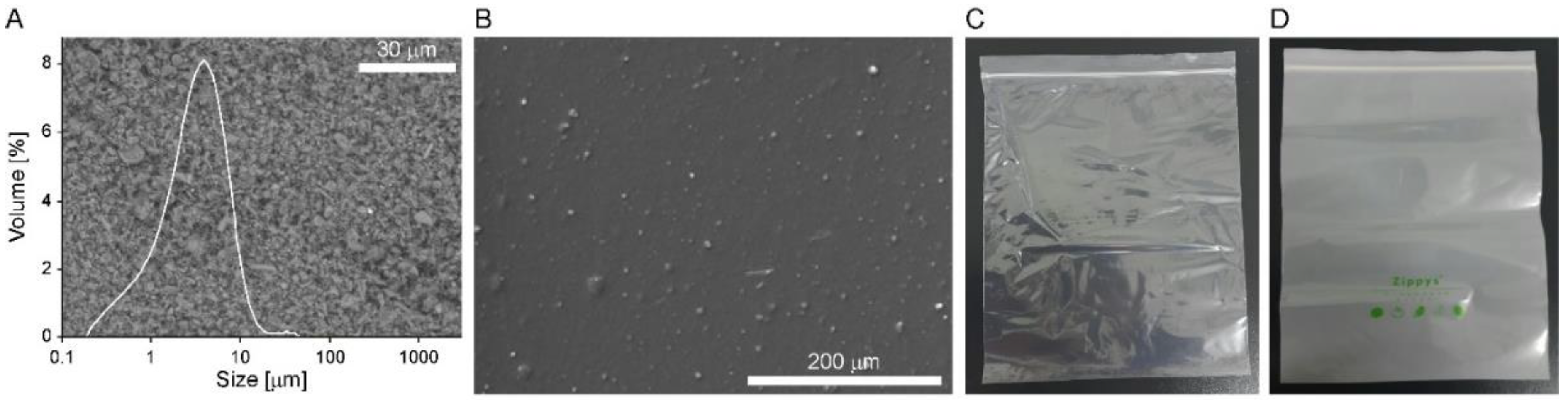

3.1. Characteristics of the Active Zipper Bag

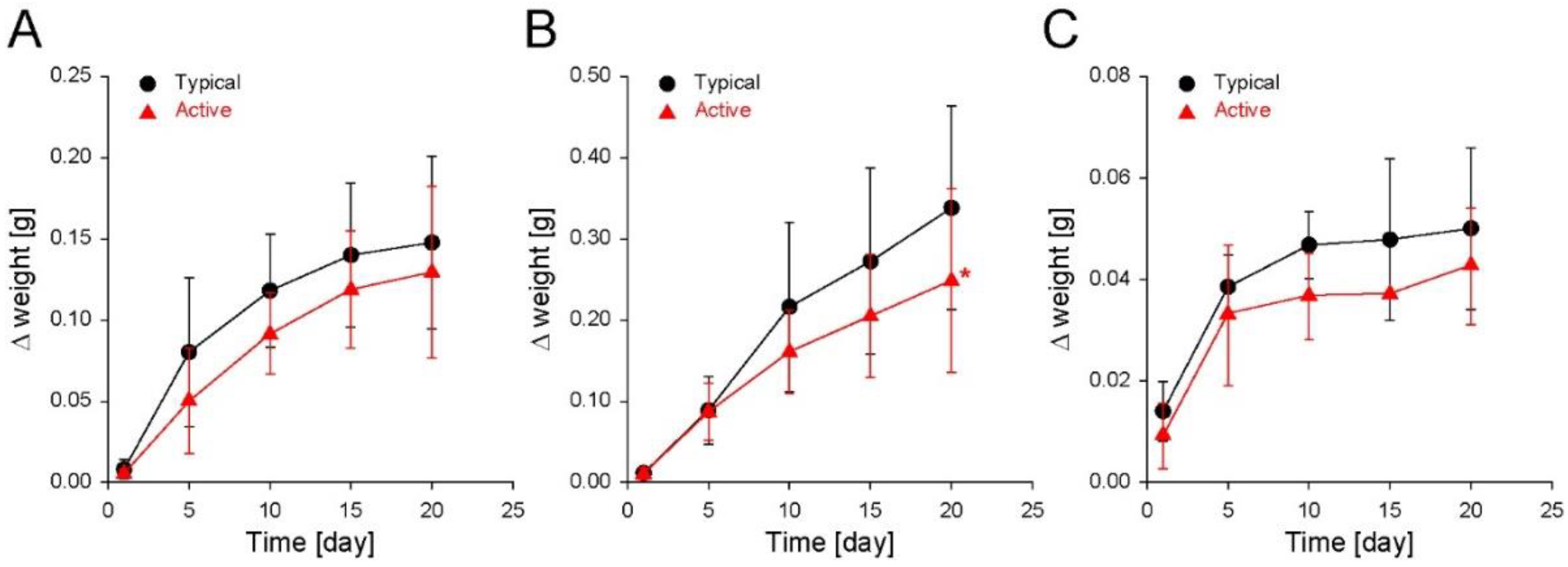

3.2. Total Weight of the Cereal-Based Snacks during Storage

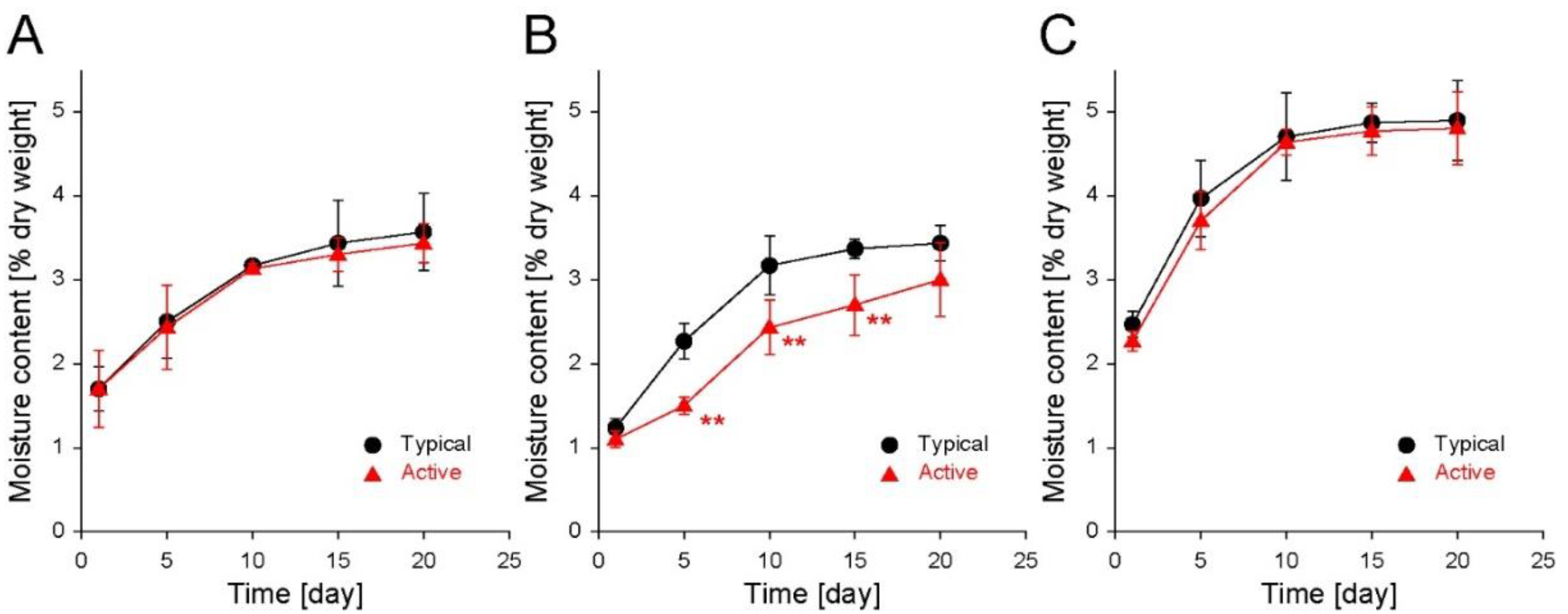

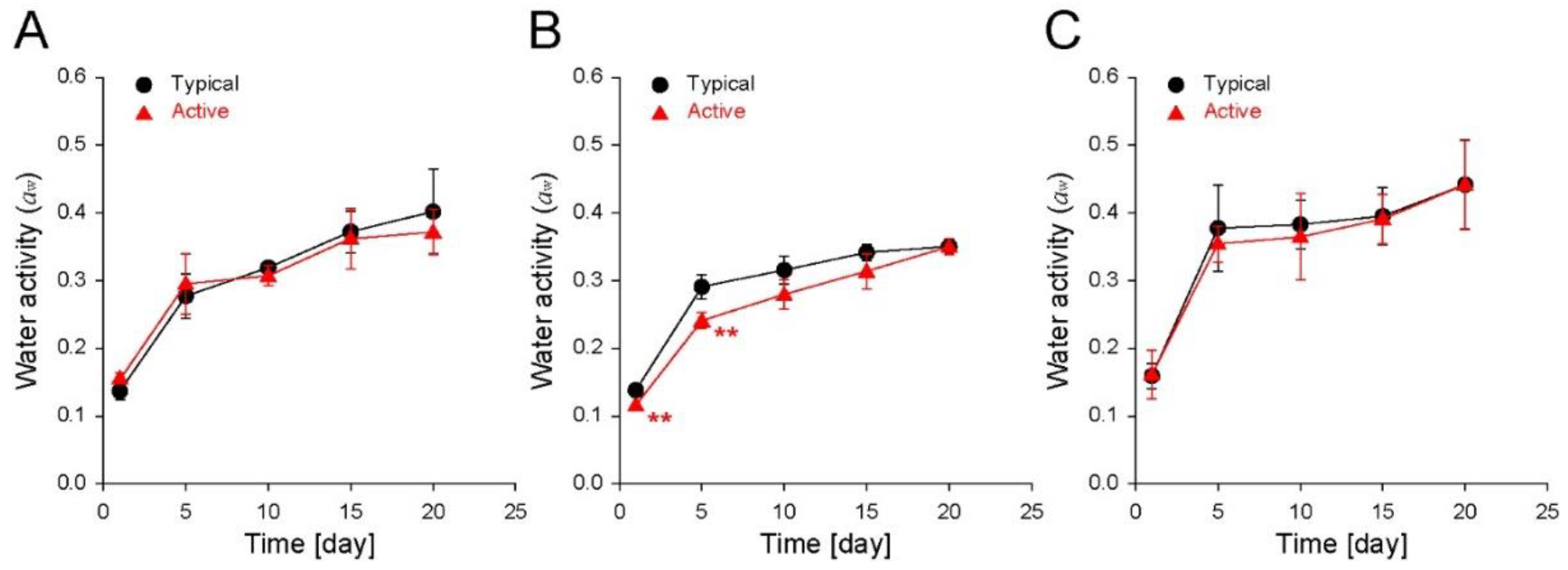

3.3. Moisture Content and Water Activity of the Cereal-Based Snacks during Storage

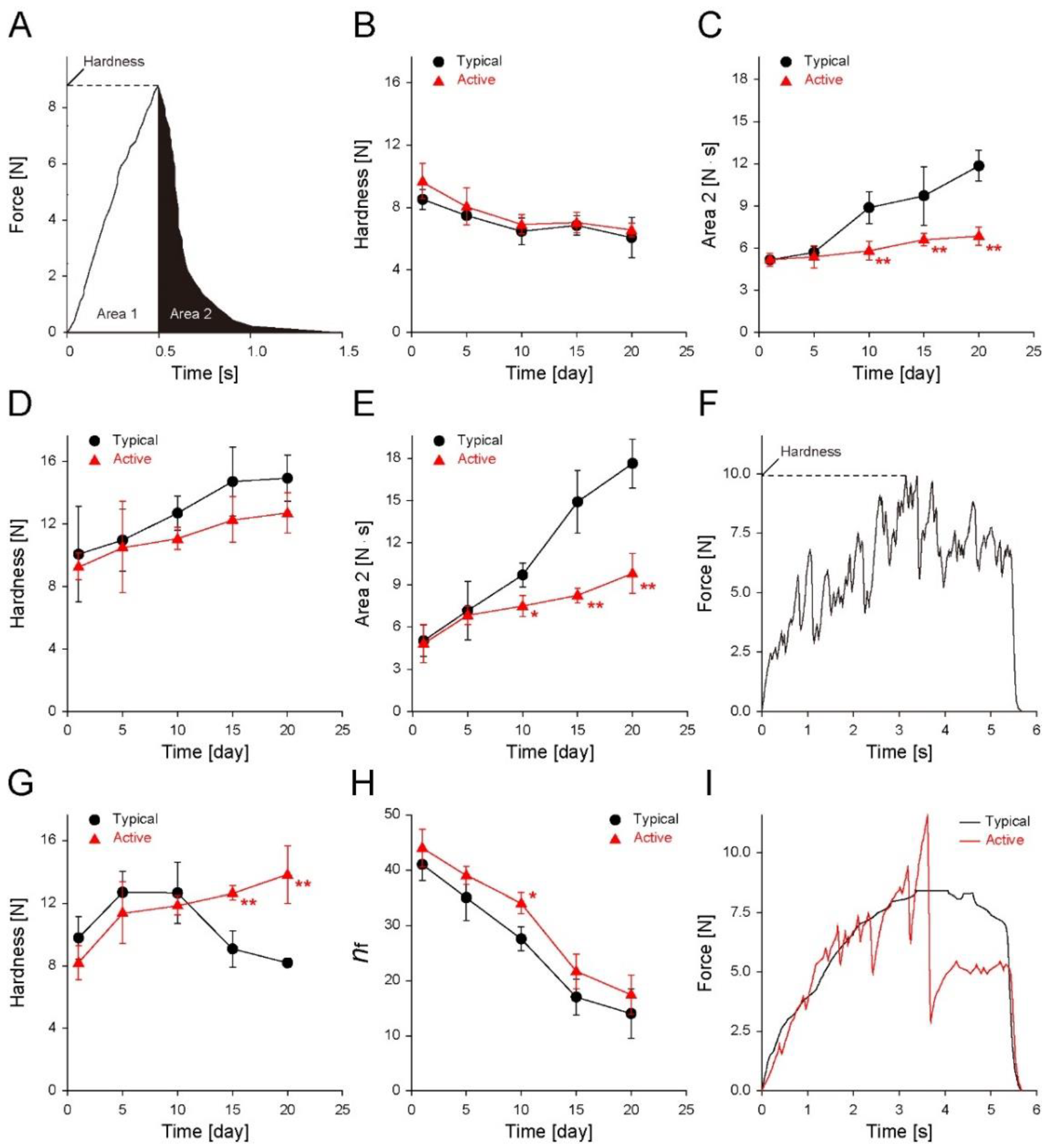

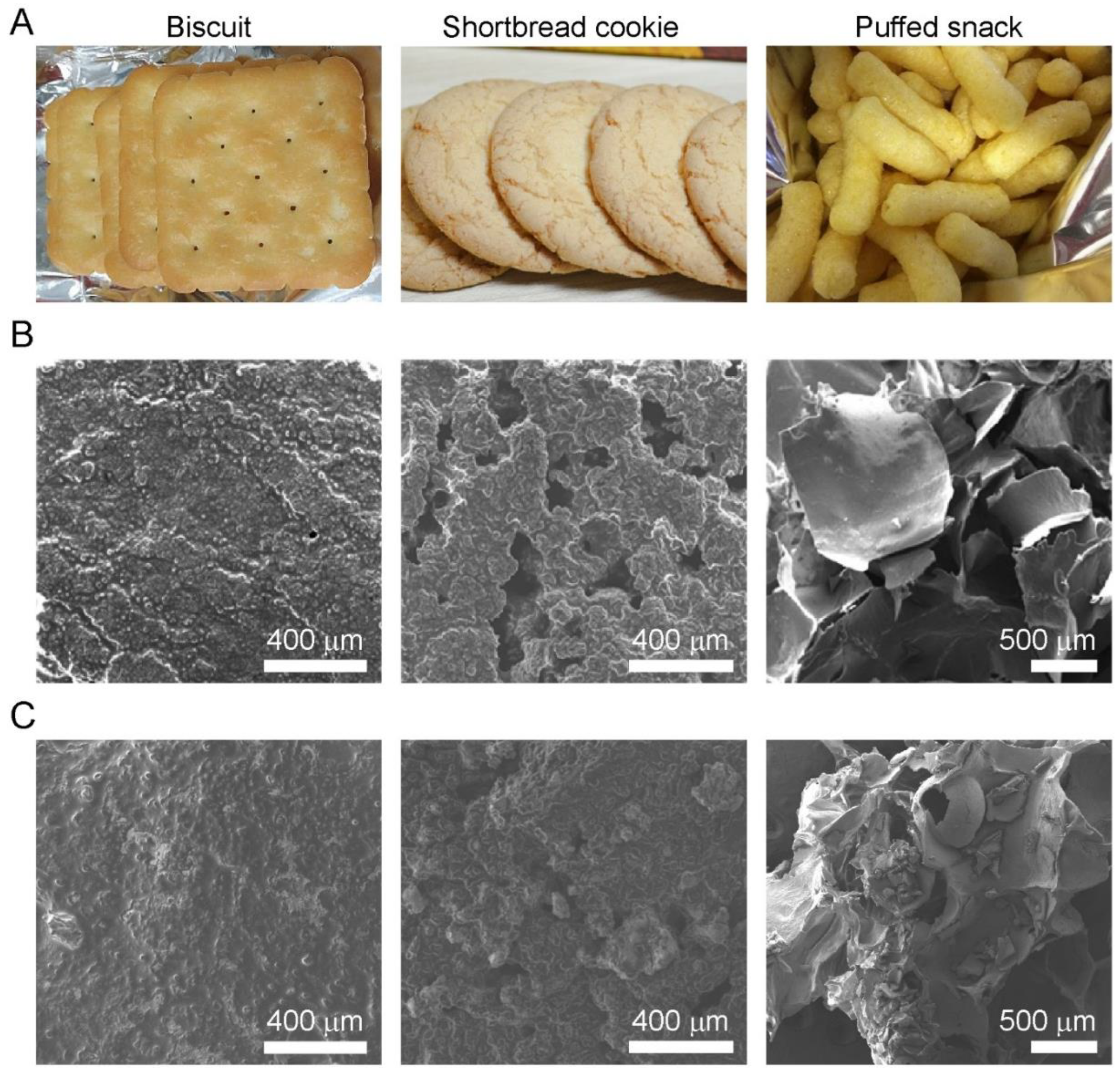

3.4. Texture and Microstructure of the Cereal-Based Snacks during Storage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaviklo, A.R.; Azaribeh, M.; Moradi, Y.; Zangeneh, P. Formula optimization and storage stability of extruded puffed corn-shrimp snacks. LWT 2015, 63, 307–314. [Google Scholar] [CrossRef]

- Shaviklo, G.R.; Thorkelsson, G.; Rafipour, F.; Sigurgisladottir, S. Quality and storage stability of extruded puffed corn-fish snacks during 6-month storage at ambient temperature. J. Sci. Food Agric. 2011, 91, 886–893. [Google Scholar] [CrossRef] [PubMed]

- Roudaut, G.; Dacremont, C.; Le Meste, M. Influence of water on the crispness of cereal-based foods: Acoustic, mechanical, and sensory studies. J. Texture Stud. 1998, 29, 199–213. [Google Scholar] [CrossRef]

- Masavang, S.; Roudaut, G.; Champion, D. Identification of complex glass transition phenomena by dsc in expanded cereal-based food extrudates: Impact of plasticization by water and sucrose. J. Food Eng. 2019, 245, 43–52. [Google Scholar] [CrossRef]

- Labuza, T.; Roe, K.; Payne, C.; Panda, F.; Labuza, T.J.; Labuza, P.S.; Krusch, L. Storage Stability of Dry Food Systems: Influence of State Changes during Drying and Storage. In Proceedings of the 14th International Drying Symposium (IDS 2004), Sao Paulo, Brazil, 22–25 August 2004; pp. 48–68. [Google Scholar]

- Chakraborty, S.K.; Kumbhar, B.K.; Chakraborty, S.; Yadav, P. Influence of processing parameters on textural characteristics and overall acceptability of millet enriched biscuits using response surface methodology. J. Food Sci. Technol. 2011, 48, 167–174. [Google Scholar] [CrossRef] [Green Version]

- Goswami, M.; Sharma, B.; Mendiratta, S.; Pathak, V.; Kumar, R.; Talukdar, S.; Sharma, H. Standardization of formulation and processing conditions for development of nutritional carabeef cookies. Nutr. Food Sci. 2015, 45, 677–687. [Google Scholar] [CrossRef]

- Hashemi, N.; Mortazavi, S.A.; Milani, E.; Yazdi, F.T. Microstructural and textural properties of puffed snack prepared from partially deffated almond powder and corn flour. J. Food Process. Preserv. 2017, 41, e13210. [Google Scholar] [CrossRef]

- Jensen, P.N.; Risbo, J. Oxidative stability of snack and cereal products in relation to moisture sorption. Food Chem. 2007, 103, 717–724. [Google Scholar] [CrossRef]

- Baek, N.; Kim, Y.; Duncan, S.; Leitch, K.; O’Keefe, S. (−)-Epigallocatechin gallate stability in ready-to-drink (RTD) green tea infusions in TiO2 and oleic-acid-modified TiO2 polylactic acid film packaging stored under fluorescent light during refrigerated storage at 4 °C. Foods 2021, 10, 723. [Google Scholar] [CrossRef]

- Chowdhury, S.; Teoh, Y.L.; Ong, K.M.; Zaidi, N.S.R.; Mah, S.-K. Poly (vinyl) alcohol crosslinked composite packaging film containing gold nanoparticles on shelf life extension of banana. Food Packag. Shelf Life 2020, 24, 100463. [Google Scholar] [CrossRef]

- Eghbalian, M.; Shavisi, N.; Shahbazi, Y.; Dabirian, F. Active packaging based on sodium caseinate-gelatin nanofiber mats encapsulated with Mentha spicata L. essential oil and MgO nanoparticles: Preparation, properties, and food application. Food Packag. Shelf Life 2021, 29, 100737. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Rhim, J.-W. Development of multifunctional pullulan/chitosan-based composite films reinforced with ZnO nanoparticles and propolis for meat packaging applications. Foods 2021, 10, 2789. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Wang, W.; Kong, F.; Lin, M.; Mustapha, A. Cellulose nanofibril/silver nanoparticle composite as an active food packaging system and its toxicity to human colon cells. Int. J. Biol. Macromol. 2019, 129, 887–894. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Rhim, J.-W. Titanium dioxide (TiO2) for the manufacture of multifunctional active food packaging films. Food Packag. Shelf Life 2022, 31, 100806. [Google Scholar] [CrossRef]

- Dash, K.K.; Ali, N.A.; Das, D.; Mohanta, D. Thorough evaluation of sweet potato starch and lemon-waste pectin based-edible films with nano-titania inclusions for food packaging applications. Int. J. Biol. Macromol. 2019, 139, 449–458. [Google Scholar] [CrossRef]

- Sahu, C.; Patel, S. Moisture sorption characteristics and quality changes during storage in defatted soy incorporated maize-millet based extruded product. LWT 2020, 133, 110153. [Google Scholar] [CrossRef]

- Wani, S.A.; Kumar, P. Moisture sorption isotherms and evaluation of quality changes in extruded snacks during storage. LWT 2016, 74, 448–455. [Google Scholar] [CrossRef]

- Guillard, V.; Broyart, B.; Guilbert, S.; Bonazzi, C.; Gontard, N. Moisture diffusivity and transfer modelling in dry biscuit. J. Food Eng. 2004, 64, 81–87. [Google Scholar] [CrossRef]

- Gulati, T.; Datta, A.K.; Doona, C.J.; Ruan, R.R.; Feeherry, F.E. Modeling moisture migration in a multi-domain food system: Application to storage of a sandwich system. Food Res. Int. 2015, 76, 427–438. [Google Scholar] [CrossRef]

- Sablani, S.S.; Kasapis, S.; Rahman, M.S. Evaluating water activity and glass transition concepts for food stability. J. Food Eng. 2007, 78, 266–271. [Google Scholar] [CrossRef]

- Slade, L.; Levine, H.; Reid, D.S. Beyond water activity: Recent advances based on an alternative approach to the assessment of food quality and safety. Crit. Rev. Food Sci. Nutr. 1991, 30, 115–360. [Google Scholar] [CrossRef] [PubMed]

- Mathlouthi, M. Water content, water activity, water structure and the stability of foodstuffs. Food Control 2001, 12, 409–417. [Google Scholar] [CrossRef]

- Liu, C.-J.; Xue, Y.-L.; Guo, J.; Ren, H.-C.; Jiang, S.; Li, D.-J.; Song, J.-F.; Zhang, Z.-Y. Citric acid and sucrose pretreatment improves the crispness of puffed peach chips by regulating cell structure and mechanical properties. LWT 2021, 142, 111036. [Google Scholar] [CrossRef]

- Primo-Martín, C.; Sözer, N.; Hamer, R.J.; Van Vliet, T. Effect of water activity on fracture and acoustic characteristics of a crust model. J. Food Eng. 2009, 90, 277–284. [Google Scholar] [CrossRef]

- Lekjing, S.; Venkatachalam, K. Influences of storage time and temperature on sensory and measured quality of green gram savory crackers. LWT 2019, 113, 108310. [Google Scholar] [CrossRef]

- Handa, C.; Goomer, S.; Siddhu, A. Physicochemical properties and sensory evaluation of fructoligosaccharide enriched cookies. J. Food Sci. Technol. 2012, 49, 192–199. [Google Scholar] [CrossRef] [Green Version]

- Barrett, A.H.; Kaletunc, G. Quantitative description of fracturability changes in puffed corn extrudates affected by sorption of low levels of moisture. Cereal Chem. 1998, 75, 695–698. [Google Scholar] [CrossRef]

- Roopa, B.S.; Mazumder, P.; Bhattacharya, S. Fracture behavior and mechanism of puffed cereal during compression. J. Texture Stud. 2009, 40, 157–171. [Google Scholar] [CrossRef]

- van Hecke, E.; Allaf, K.; Bouvier, J.M. Texture and structure of crispy-puffed food products part II: Mechanical properties in puncture. J. Texture Stud. 1998, 29, 617–632. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, L.; McCarthy, O.J.; Moughan, P.J.; Singh, H. Development and characterization of extruded snacks from New Zealand Taewa (Maori potato) flours. Food Res. Int. 2009, 42, 666–673. [Google Scholar] [CrossRef]

- Rodríguez-García, J.; Laguna, L.; Puig, A.; Salvador, A.; Hernando, I. Effect of fat replacement by inulin on textural and structural properties of short dough biscuits. Food Bioprocess Technol. 2013, 6, 2739–2750. [Google Scholar] [CrossRef]

- Chevallier, S.; Colonna, P.; Buleon, A.; Della Valle, G. Physicochemical behaviors of sugars, lipids, and gluten in short dough and biscuit. J. Agric. Food Chem. 2000, 48, 1322–1326. [Google Scholar] [CrossRef] [PubMed]

- Mamat, H.; Hill, S.E. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J. Food Sci. Technol. 2014, 51, 1998–2005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shahmohammadi, H.R.; Bakar, J.; Rahman, R.A.; Adzhan, N.M. Studying the effects of nucleating agents on texture modification of puffed corn-fish snack. J. Food Sci. 2014, 79, E178–E183. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, Y.; Kim, E.; Kim, S.; Ban, C.; Lim, S. Delayed Quality Deterioration of Low-Moisture Cereal-Based Snack by Storing in an Active Filler-Embedded LDPE Zipper Bag. Foods 2022, 11, 1704. https://doi.org/10.3390/foods11121704

Jo Y, Kim E, Kim S, Ban C, Lim S. Delayed Quality Deterioration of Low-Moisture Cereal-Based Snack by Storing in an Active Filler-Embedded LDPE Zipper Bag. Foods. 2022; 11(12):1704. https://doi.org/10.3390/foods11121704

Chicago/Turabian StyleJo, Youngje, Eunghee Kim, Sangoh Kim, Choongjin Ban, and Seokwon Lim. 2022. "Delayed Quality Deterioration of Low-Moisture Cereal-Based Snack by Storing in an Active Filler-Embedded LDPE Zipper Bag" Foods 11, no. 12: 1704. https://doi.org/10.3390/foods11121704

APA StyleJo, Y., Kim, E., Kim, S., Ban, C., & Lim, S. (2022). Delayed Quality Deterioration of Low-Moisture Cereal-Based Snack by Storing in an Active Filler-Embedded LDPE Zipper Bag. Foods, 11(12), 1704. https://doi.org/10.3390/foods11121704