Assessment of Environmental Impacts from Different Perspectives—Case Study of Egg Value Chain System in Serbia

Abstract

:1. Introduction

| No. | Authors | Country | Research Focus | System Boundaries | GWP [kg CO2eq/FU] | CED [MJe/FU] | ODS [mg R11e/FU] | HTP [kg 1.4 DBe/FU] | AP [g SO2e/FU] | EP [g PO4e/FU] | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||||||||

| 1 | Wiedemann and McGahan [17] | Australia | The impact of egg production in cages and from free-range on greenhouse gas emissions, and water and energy consumption. | √ | - | - | Cage 1.3 ± 0.2 Free range 1.6 ± 0.2 | 0.7 ± 0.9 13.1 ± 1.1 | - | - | - | - |

| 2 | Leinonen et al. [18] | United Kingdom | The impact of four different production systems (cage, barn, free range and organic) on global warming potential, acidification, eutrophication and energy consumption. | √ | - | - | Cage 2.92 ± 0.21 Barn 3.45 ± 0.26 Organic 3.42 ± 0.34 Free range 3.38 ± 0.27 | 16.88 ± 1.1 22.20 ± 1.2 26.41 ± 1.6 18.78 ± 1.1 | - | - | 53.14 ± 5.2 59.43 ± 5.9 91.63 ± 8.6 64.13 ± 6.9 | 18.47 ± 1.5 20.32 ± 1.7 37.61 ± 4.2 22.03 ± 2.0 |

| 3 | Pelletier et al. [19] | United States | The impact of intensive egg production and processing on greenhouse gas emissions. | √ | - | - | 5.0 (4.23–5.99) | - | - | - | - | - |

| 4 | Nielsen et al. [20] | Denmark | The impact of organic egg production on greenhouse gas emissions. | √ | - | - | 1.52 (1.34–1.82) | - | - | - | - | - |

| 5 | Taylor et al. [21] | United Kingdom | The impact of free-range egg production in small commercial units on mixed farms on greenhouse gas emissions. | √ | - | - | 1.6–1.8 | - | - | - | - | - |

| 6 | Pelletier et al. [22] | United States | Comparison of the ecological impact of egg production in the period 1960 to 2010. | √ | - | - | 1960 year 7.23 2010 year 2.08 | 18 12 | - | - | 200 70 | 70 20 |

| 7 | Ghasempour and Ahmadi, [23] | Iran | Ecological impact of laying hen diet in intensive egg production. | √ | - | - | 4.07 | 30.09 | 0.12 | 8.80 | 43.89 | 5.42 |

| 8 | Pelletier, [9] | Canada | Comparison of the impact of five different egg production systems on the environment. | √ | - | - | Cage 2.44 Enriched cage 2.30 Free run 2.40 Free range 2.39 Organic 1.36 | 11.24 12.06 11.81 11.47 7.95 | - | - | 78.4 82.5 80.6 69.8 46.6 | 24.4 26.8 25.6 23.8 14.8 |

| 9 | Vetter et al. [24] | United States | Exploring the potential for reducing emissions in organic egg production using a GHG calculator. | √ | - | - | 1–5 (total 0.7–1.8) | |||||

| 10 | Abín et al. [1] | Spain | The impact of intensive egg production on the environment (carbon footprint). | √ | - | - | 3.4 | - | - | - | - | - |

| 11 | Estrada-González et al. [25] | Mexico | Implementation of an eco-efficient scheme to reduce the environmental impact of egg production farms. | √ | - | - | Egg posture phase 4.4 Total 5.6 | - | - | 0.14 0.16 | - | - |

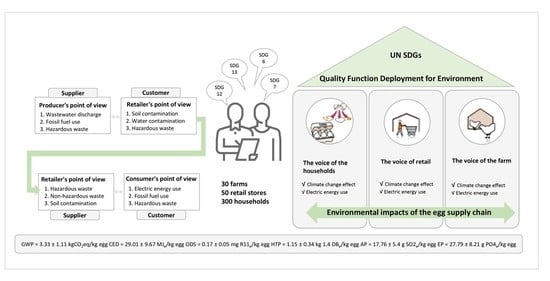

2. Materials and Methods

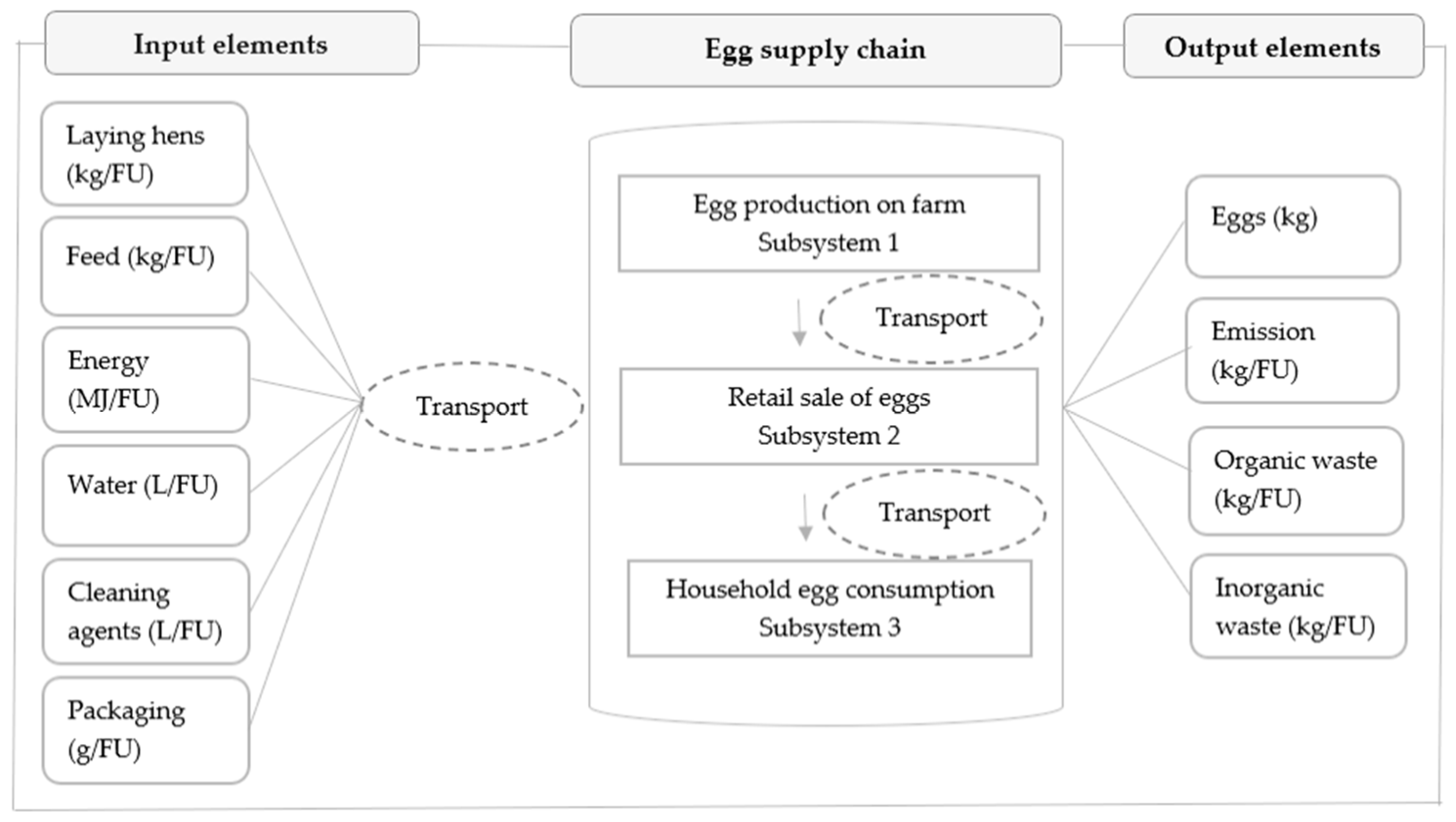

2.1. Life Cycle Assessment (LCA)

2.1.1. Determining the Subject and Scope of the LCA Study

2.1.2. Inventory Analysis

2.1.3. Calculation and Analysis of Environmental Impact

2.2. Customer-Supplier Interaction

2.3. Production Planning with Respect to Environmental Requirements

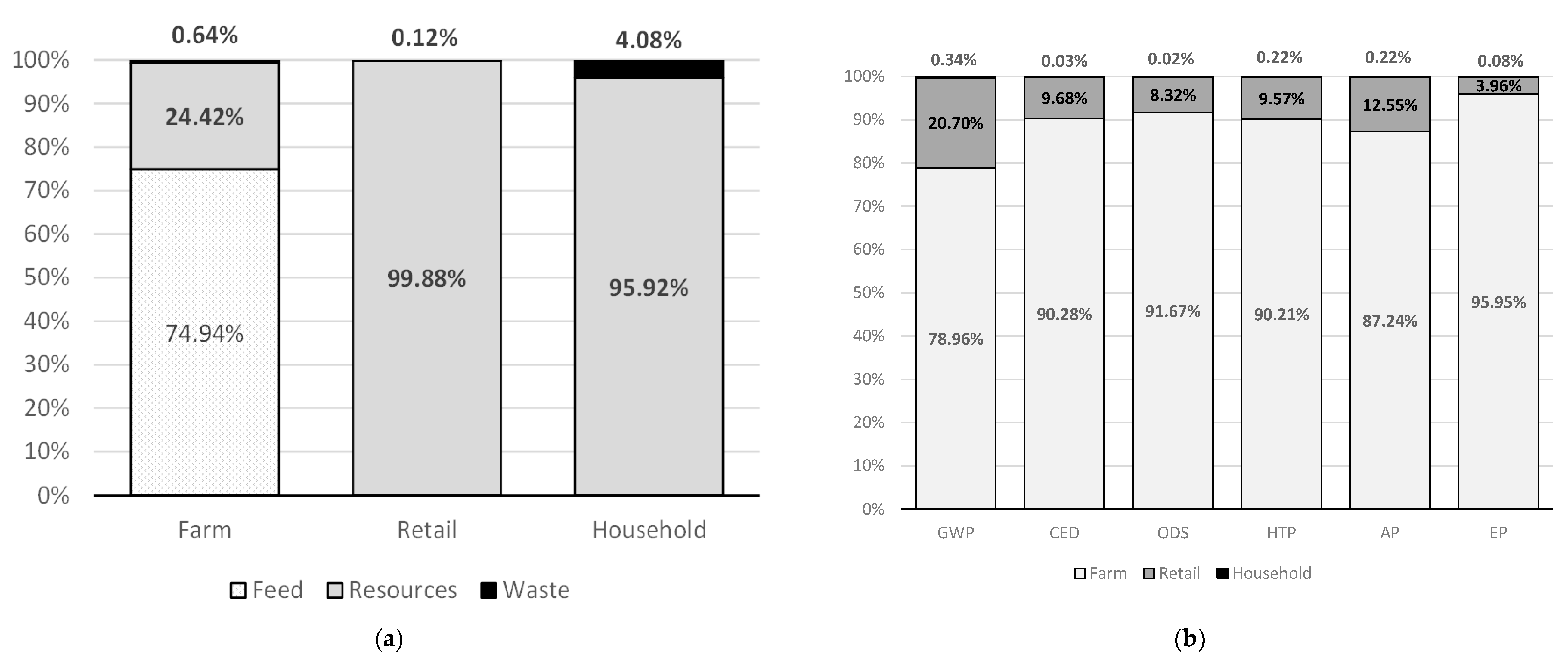

3. Results and Discussion

3.1. Assessment of the Impact of the Egg Supply Chain on the Environment

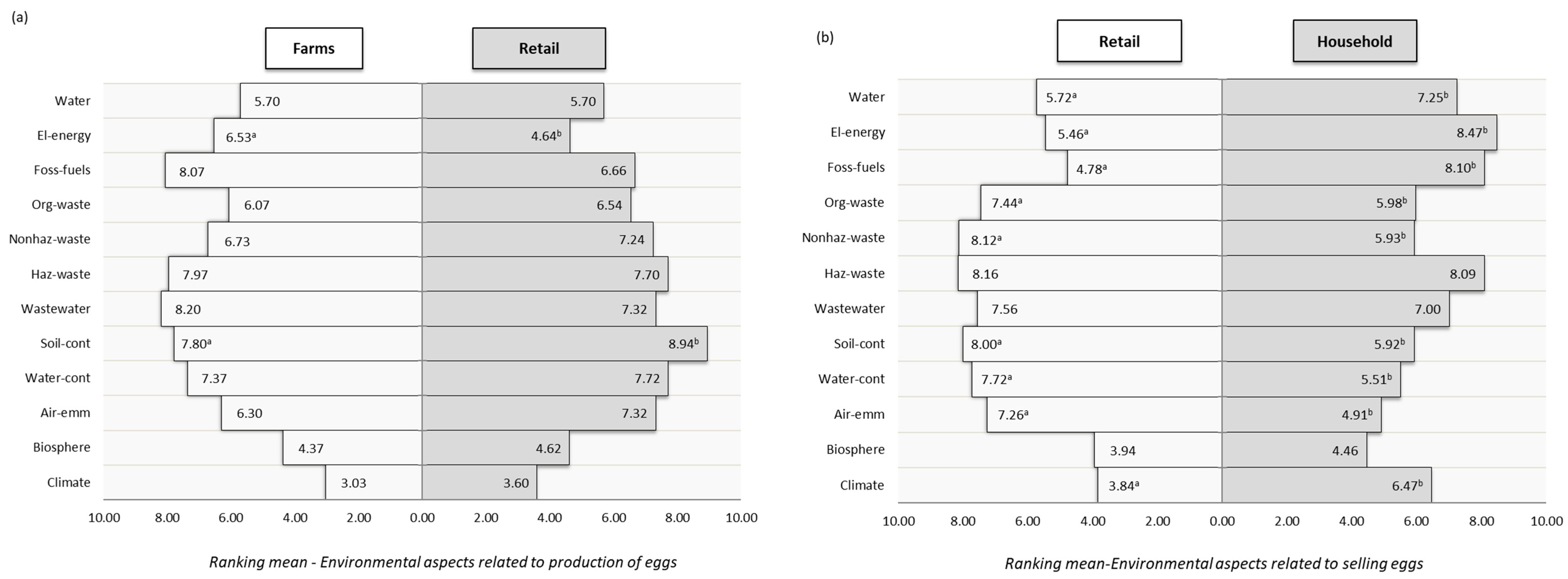

3.2. Assessment of Environmental Aspects in the Comparison of Customer–Supplier Interaction

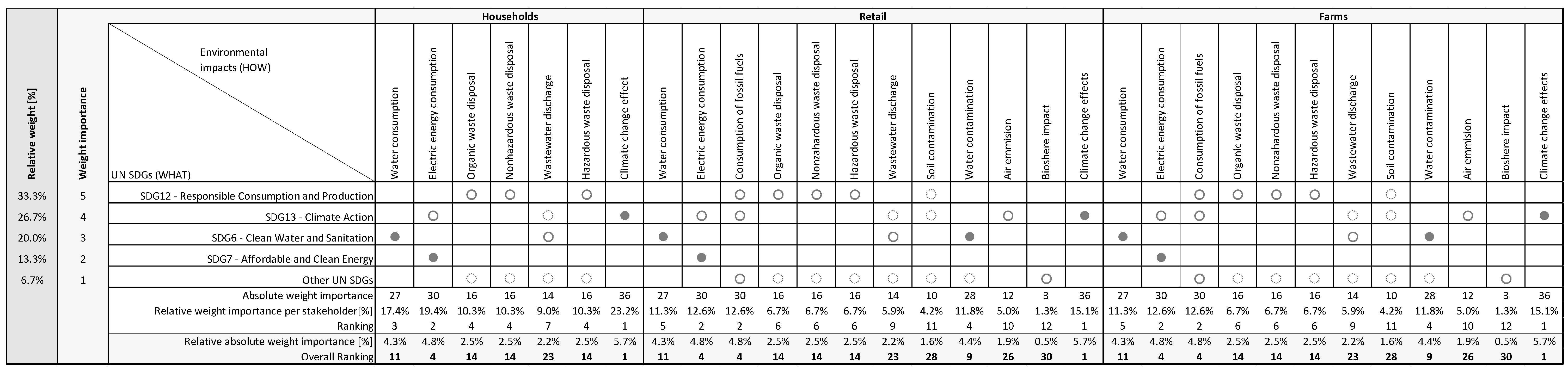

3.3. Application of the QFDE Method in the Egg Supply Chain

3.4. Implications in Practice

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abín, R.; Laca, A.; Laca, A.; Díaz, M. Environmental assessment of intensive egg production: A Spanish case study. J. Clean. Prod. 2018, 179, 160–168. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Wu, S.; Zhang, H.; Qi, G. Nutritional modulation of health, egg quality and environmental pollution of the layers. Anim. Nutr. 2017, 3, 91–96. [Google Scholar] [CrossRef] [PubMed]

- FAO. FAO and the 17 Sustainable Development Goals; Food and Agriculture Organization of the United Nations: Rome, Italy, 2015. [Google Scholar]

- COP26. COP26: THE GLASGOW CLIMATE PACT. 26th UN Climate Change Conference, Glasgow. 2021. Available online: https://ukcop26.org/the-conference/%20cop26-outcomes/page/2/ (accessed on 1 December 2021).

- Van Berkum, S.; Dengerink, J.; Ruben, R. The Food System Approach: Sustainable Solutions for a Sufficient Supply of Healthy Food; 2018-064; Wageningen Economic Research: The Hague, The Netherlands, 2018. [Google Scholar] [CrossRef] [Green Version]

- Djekic, I.; Batlle-Bayer, L.; Bala, A.; Fullana-i-Palmer, P.; Jambrak, A.R. Role of the Food Supply Chain Stakeholders in Achieving UN SDGs. Sustainability 2021, 13, 9095. [Google Scholar] [CrossRef]

- Berkhout, P.; Achterbosch, T.; Van Berkum, S.; Dagevos, H.; Dengerink, J.; Van Duijn, A.P.; Terluin, I.J. Global Implications of the European Food System: A Food Systems Approach; Report 2018-051; Wageningen Economic Research: Wageningen, The Netherlands, 2018. [Google Scholar] [CrossRef] [Green Version]

- Posthumus, H.; Steenhuijsen-Piters, B.; Dengerink, J.; Vellema, S. Food Systems: From Concept to Practice and Vice Versa; Wageningen University & Research: Wageningen, The Netherlands; KIT Royal Tropical Institute: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Pelletier, N. Life cycle assessment of Canadian egg products, with differentiation by hen housing system type. J. Clean. Prod. 2017, 152, 167–180. [Google Scholar] [CrossRef]

- Andretta, I.; Hickmann, F.M.W.; Remus, A.; Franceschi, C.H.; Mariani, A.B.; Orso, C.; Kipper, M.; Létourneau-Montminy, M.P.; Pomar, C. Environmental Impacts of Pig and Poultry Production: Insights From a Systematic Review. Front. Vet. Sci. 2021, 27, 750733. [Google Scholar] [CrossRef]

- Kebreab, E.; Liedke, A.; Caro, D.; Deimling, S.; Binder, M.; Finkbeiner, M. Environmental impact of using specialty feed ingredients in swine and poultry production: A life cycle assessment. J. Anim. Sci. 2016, 94, 2664–2681. [Google Scholar] [CrossRef]

- Benavides, P.T.; Cai, H.; Wang, M.; Bajjalieh, N. Life-cycle analysis of soybean meal, distiller-dried grains with solubles, and synthetic amino acid-based animal feeds for swine and poultry production. Anim. Feed Sci. Technol. 2020, 268, 114607. [Google Scholar] [CrossRef]

- Molnár, S.; Szőllősi, L. Sustainability and Quality Aspects of Different Table Egg Production Systems: A Literature Review. Sustainability 2020, 12, 7884. [Google Scholar] [CrossRef]

- Lovelin Jerald, A. Life Cycle Assessment for Food Processing. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 677–680. [Google Scholar]

- Masui, K.; Sakao, T.; Kobayashi, M.; Inaba, A. Applying Quality Function Deployment to environmentally conscious design. Int. J. Qual. Reliab. Manag. 2003, 20, 90–106. [Google Scholar] [CrossRef]

- Younesi, M.; Roghanian, E. A framework for sustainable product design: A hybrid fuzzy approach based on Quality Function Deployment for Environment. J. Clean. Prod. 2015, 108, 385–394. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; McGahan, E.J. A Report for the Australian Egg Corporation Limited. 69. 2011. Available online: https://www.fao.org/sustainable-food-value-chains/library/detalles/es/c/263419/ (accessed on 7 January 2022).

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Egg production systems. Poult. Sci. 2012, 91, 26–40. [Google Scholar] [CrossRef] [PubMed]

- Pelletier, N.; Ibarburu, M.; Xin, H. A carbon footprint analysis of egg production and processing supply chains in the Midwestern United States. J. Clean. Prod. 2013, 54, 108–114. [Google Scholar] [CrossRef]

- Nielsen, N.I.; Jørgensen, M.; Knude Rasmussen, I. Greenhouse Gas Emission from Danish Organic Egg Production estimated via LCA Methodology. Knowledge Centre for Agriculture, Denmark. 2013. Available online: https://sp.landbrugsinfo.dk/Sider/Startside.aspx (accessed on 7 January 2022).

- Taylor, R.C.; Omed, H.; Edwards-Jones, G. The greenhouse emissions footprint of free-range eggs. Poult. Sci. 2014, 93, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Pelletier, N.; Ibarburu, M.; Xin, H. Comparison of the environmental footprint of the egg industry in the United States in 1960 and 2010. Poult. Sci. 2014, 93, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Ghasempour, A.; Ahmadi, E. Assessment of environment impacts of egg production chain using life cycle assessment. J. Environ. Manag. 2016, 183, 980–987. [Google Scholar] [CrossRef] [PubMed]

- Vetter, S.H.; Malin, D.; Smith, P.; Hillier, J. The potential to reduce GHG emissions in egg production using a GHG calculator—A Cool Farm Tool case study. J. Clean. Prod. 2018, 202, 1068–1076. [Google Scholar] [CrossRef] [Green Version]

- Estrada-González, I.E.; Taboada-González, P.A.; Guerrero-García-Rojas, H.; Márquez-Benavides, L. Decreasing the Environmental Impact in an Egg-Producing Farm through the Application of LCA and Lean Tools. Appl. Sci. 2020, 10, 1352. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Skunca, D.; Tomasevic, I.; Nastasijevic, I.; Tomovic, V.; Djekic, I. Life cycle assessment of the chicken meat chain. J. Clean. Prod. 2018, 184, 440–450. [Google Scholar] [CrossRef]

- Statistical Yearbook of the Republic of Serbia for 2020; Statistical Office of the Republic of Serbia: Belgrade, Serbia, 2020.

- Djekic, I.; Petrović, J.; Božićković, A.; Djordjević, V.; Tomasevic, I. Main environmental impacts associated with production and consumption of milk and yogurt in Serbia—Monte Carlo approach. Sci. Total Environ. 2019, 695, 133917. [Google Scholar] [CrossRef]

- Djekic, I.; Božićković, I.; Djordjević, V.; Smetana, S.; Terjung, N.; Ilic, J.; Doroski, A.; Tomasevic, I. Can we associate environmental footprints with production and consumption using Monte Carlo simulation? Case study with pork meat. J. Sci. Food Agric. 2021, 101, 960–969. [Google Scholar] [CrossRef] [PubMed]

- CCaLC. Carbon Calculations over the Life Cycle of Industrial Activities; The University of Manchester: Manchester, UK, 2021. [Google Scholar]

- Serbian Regulation. Regulation on amending regulation on annual reporting about achieving energy saving objectives/Pravilnik o izmenama pravilnika o obrascu godišnjeg izveštaja o ostvarivanju ciljeva uštede energije. In Official Gazette of the Republic of Serbia; No. 65/2018; Government of the Republic of Serbia: Belgrade, Serbia, 2018.

- Mitrovic, M.; Tomasevic, I.; Djekic, I. Quality perception throughout the table egg supply chain. Br. Food J. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Pusporini, P.; Abhary, K.; Luong, L. Integrating Environmental Requirements into Quality Function Deployment for Designing Eco-Friendly Product. Int. J. Mater. Mech. Manuf. 2013, 1, 80–84. [Google Scholar] [CrossRef] [Green Version]

- Djekic, I.; Operta, S.; Djulancic, N.; Lorenzo, J.M.; Barba, F.J.; Djordjević, V.; Tomasevic, I. Quantities, environmental footprints and beliefs associated with household food waste in Bosnia and Herzegovina. Waste Manag. Res. 2019, 37, 1250–1260. [Google Scholar] [CrossRef]

- De Cardoso, J.F.; Casarotto Filho, N.; Cauchick Miguel, P.A. Application of Quality Function Deployment for the development of an organic product. Food Qual. Prefer. 2015, 40, 180–190. [Google Scholar] [CrossRef]

- Park, S.-H.; Ham, S.; Lee, M.-A. How to improve the promotion of Korean beef barbecue, bulgogi, for international customers. An application of quality function deployment. Appetite 2012, 59, 324–332. [Google Scholar] [CrossRef]

- Heiko, A. Consensus measurement in Delphi studies. Technol. Forecast. Soc. Chang. 2012, 79, 1525–1536. [Google Scholar] [CrossRef]

- Mitrovic, M.; Tomasevic, I.; Djekic, I. Toxic elements in eggs and egg-based products: Occurrence, exposure assessment and risk characterisation for the Serbian population. Int. J. Food Sci. Technol. 2021, 56, 6685–6696. [Google Scholar] [CrossRef]

- Zhang, R.; El-Mashad, H. Waste management in egg production. In Achieving Sustainable Production of Eggs; Roberts, J., Ed.; Burleigh Dodds Science Publishing: London, UK, 2017; p. 24. [Google Scholar] [CrossRef]

- Filimonau, V.; Gherbin, A. An exploratory study of food waste management practices in the UK grocery retail sector. J. Clean. Prod. 2017, 167, 1184–1194. [Google Scholar] [CrossRef] [Green Version]

- Sonesson, U.; Davis, J.; Ziegler, F. Food Production and Emissions of Greenhouse Gases: An Overview of the Climate Impact of Different Product Groups. SIK—Report No. 802-210, The Swedish Institute for Food and Biotechnology. 2010. Available online: https://www.semanticscholar.org/paper/ (accessed on 24 January 2022).

- Serbian Regulation. Regulation on egg quality/Pravilnik o kvalitetu jaja. In Official Gazette of the Republic of Serbia; No. 7/2019; Government of the Republic of Serbia: Belgrade, Serbia, 2019.

| GWP (kgCO2/IU) | CED (MJe/IU) | ODS (kg R11e/IU) | HTP (kg 1.4 DBe/IU) | AP (kg SO2e/IU) | EP (kg PO4e/IU) | Source | ||

|---|---|---|---|---|---|---|---|---|

| Energy | Electricity (Serbian profile) | 1.099 | 8.31 × 10−1 | 1.78 × 10−9 | 2.28 × 10−1 | 3.42 × 10−3 | 1.96 × 10−3 | Serbian legislation [32] |

| Liquefied petroleum gas | 2.961 | 1.56 | 1.97 × 10−7 | 2.53 × 10−1 | 3.39 × 10−3 | 6.51 × 10−4 | CCaLC database [31]; Serbian legislation [32] | |

| Diesel | 2.76 | 4.01 × 10−1 | 3.31 × 10−7 | 3.87 × 10−1 | 6.10 × 10−3 | 8.82 × 10−3 | CCaLC database [31]; Serbian legislation [32] | |

| Petrol | 2.209 | 5.68 × 10−1 | 4.71 × 10−7 | 4.24 × 10−1 | 7.96 × 10−3 | 9.37 × 10−3 | CCaLC database [31]; Serbian legislation [32] | |

| Natural gas | 1.852 | 4.29 × 10−1 | 1.45 × 10−9 | 8.33 × 10−1 | 2.54 × 10−2 | 1.47 × 10−3 | CCaLC database [31]; Serbian legislation [32] | |

| Wood (chips and logs) | 18 | 35 | 1.21 × 10−6 | 24.3 | 1.44 × 10−1 | 7.10 × 10−2 | CCaLC database [31]; Serbian legislation [32] | |

| Pellets | 0.131 | 1.49 | 7.05 × 10−9 | 253 | 7.50 × 10−2 | 1.45 × 10−3 | CCaLC database [31]; Serbian legislation [32] | |

| Feed | Maize for feed | 4.90 × 10−1 | 2.02 | 3.50 × 10−8 | 1.27 × 10−1 | 3.08 × 10−3 | 4.21 × 10−3 | CCaLC database [31] |

| Wheat for feed | 6.40 × 10−1 | 2.02 × 10−1 | 4.13 × 10−8 | 4.22 × 10−1 | 4.32 × 10−3 | 7.55 × 10−3 | CCaLC database [31] | |

| Soybean for feed | 9.00 × 10−1 | 2.59 | 4.33 × 10−8 | 3.55 × 10−1 | 6.65 × 10−3 | 1.50 × 10−2 | CCaLC database [31] | |

| Sunflower for feed | 1.02 | 35.9 | 7.63 × 10−8 | 4.05 × 10−1 | 4.64 × 10−3 | 1.31 × 10−2 | CCaLC database [31] | |

| Barley for feed | 4.85 × 10−1 | 1.96 | 3.19 × 10−8 | 3.25 × 10−1 | 3.83 × 10−3 | 8.57 × 10−3 | CCaLC database [31] | |

| Feed mixes for chicken | 4.58 × 10−1 | 12.5 | 4.55 × 10−8 | 3.27 × 10−1 | 4.50 × 10−3 | 9.68 × 10−3 | CCaLC database [31] | |

| Packaging materials | Carton | 8.62 × 10−1 | 21.9 | 9.57 × 10−8 | 1.72 × 10−4 | 2.86 × 10−3 | 2.15 × 10−3 | CCaLC database [31] |

| Styrofoam | 3.30 | 0.00 | 0.00 | 1.50 × 10−3 | 1.08 × 10−2 | 9.30 × 10−4 | CCaLC database [31] | |

| Polyvinyl chloride (PVC) | 3.22 | 0.00 | 0.00 | 1.15 × 10−3 | 1.39 × 10−2 | 1.19 × 10−3 | CCaLC database [31] | |

| Polyethylene (HDPE) | 3.26 | 0.00 | 0.00 | 1.54 × 10−3 | 1.52 × 10−2 | 1.18 × 10−3 | CCaLC database [31] | |

| Cleaning agents | Acid chemicals | 1.1 | 22.8 | 6.69 × 10−8 | 8.91 × 10−1 | 5.27 × 10−3 | 3.70 × 10−3 | CCaLC database [31] |

| Alkaline chemicals | 3.17 | 13.4 | 1.04 × 10−7 | 2.10 × 10−1 | 1.59 × 10−2 | 3.35 × 10−4 | CCaLC database [31] | |

| Water | Tap water at user | 0.0005 | 0.00 | 6.76 × 10−12 | 2.44 × 10−5 | 1.40 × 10−6 | 4.45 × 10−7 | CCaLC database [31] |

| Well water | 0.0003 | 6.17 × 10−3 | 1.61 × 10−11 | 0.0001847 | 1.39 × 10−6 | 8.73 × 10−7 | CCaLC database [31] | |

| Waste | Manure | 0.004 | 5.30 × 10−2 | 4.02 × 10−10 | 1.13 × 10−1 | 5.68 × 10−4 | 1.12 × 10−3 | CCaLC database [31] |

| Waste-wood | 1.42 | 0.00 | 2.78 × 10−9 | 2.83 × 10−3 | 5.35 × 10−4 | 2.02 × 10−4 | CCaLC database [31] | |

| Waste-plastic | 0.071 | 0.00 | 2.782 × 10−9 | 2.30 × 10−3 | 2.44 × 10−4 | 1.06 × 10−4 | CCaLC database [31] | |

| Waste-paper | 0.008 | 0.00 | 4.1 × 10−12 | 1.68 × 10−3 | 1.94 × 10−6 | 2.03 × 10−7 | CCaLC database [31] | |

| Waste-carton | 0.119 | 0.00 | 2.128 × 10−9 | 1.55 × 10−6 | 4.22 × 10−5 | 1.03 × 10−5 | CCaLC database [31] | |

| Waste-Styrofoam | 0.008 | 0.00 | 4.1 × 10−12 | 1.68 × 10−3 | 1.94 × 10−6 | 2.03 × 10−7 | CCaLC database [31] | |

| Food waste (eggshells) | 0.513 | 3.79 × 10−1 | 2.78 × 10−9 | 2.41 × 10−3 | 3.56 × 10−4 | 1.28 × 10−3 | CCaLC database [31] | |

| Food waste (oil) | 0.513 | 3.79 × 10−1 | 2.78 × 10−9 | 2.41 × 10−3 | 3.56 × 10−4 | 1.28 × 10−3 | CCaLC database [31] | |

| Landfill-municipal waste | 0.513 | 3.79 × 10−1 | 2.78 × 10−9 | 2.41 × 10−3 | 3.56 × 10−4 | 1.28 × 10−3 | CCaLC database [31] | |

| Wastewater-industrial treatment | 0.00241 | 6.49 × 10−3 | 2.20 × 10−10 | 1.20 × 10−3 | 6.92 × 10−5 | 2.60 × 10−5 | CCaLC database [31] | |

| Impact Category | Unit | Farm | Retail | Household | Supply Chain |

|---|---|---|---|---|---|

| GWP | (kgCO2eq/FU) | 2.63 ± 0.80 a | 0.69 ± 0.30 b | 0.0113 ± 0.0071 c | 3.33 ± 1.11 |

| CED | (MJe/FU) | 26.20 ± 8.78 a | 2.81 ± 0.88 b | 0.0096 ± 0.0051 c | 29.01 ± 9.67 |

| ODS | (mg R11e/FU) | 0.15 ± 0.05 a | 0.01 ± 0.01 b | 0.00003 ± 0.00001 c | 0.17 ± 0.05 |

| HTP | (kg 1.4 DBe/FU) | 1.04 ± 0.28 a | 0.11 ± 0.05 b | 0.0025 ± 0.0012 c | 1.15 ± 0.34 |

| AP | (g SO2e/FU) | 15.49 ± 4.36 a | 2.23 ± 1.00 b | 0.0382 ± 0.0114 c | 17.76 ± 5.4 |

| EP | (g PO4e/FU) | 26.67 ± 7.70 a | 1.10 ± 0.48 b | 0.0229 ± 0.0118 c | 27.79 ± 8.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitrovic, M.; Tomasevic, I.; Djekic, I. Assessment of Environmental Impacts from Different Perspectives—Case Study of Egg Value Chain System in Serbia. Foods 2022, 11, 1697. https://doi.org/10.3390/foods11121697

Mitrovic M, Tomasevic I, Djekic I. Assessment of Environmental Impacts from Different Perspectives—Case Study of Egg Value Chain System in Serbia. Foods. 2022; 11(12):1697. https://doi.org/10.3390/foods11121697

Chicago/Turabian StyleMitrovic, Marija, Igor Tomasevic, and Ilija Djekic. 2022. "Assessment of Environmental Impacts from Different Perspectives—Case Study of Egg Value Chain System in Serbia" Foods 11, no. 12: 1697. https://doi.org/10.3390/foods11121697

APA StyleMitrovic, M., Tomasevic, I., & Djekic, I. (2022). Assessment of Environmental Impacts from Different Perspectives—Case Study of Egg Value Chain System in Serbia. Foods, 11(12), 1697. https://doi.org/10.3390/foods11121697