Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sausage Formulation and Processing

2.3. Proximate Composition

2.4. Water Activity and pH

2.5. Color

2.6. Cooking Loss and Water Holding Capacity (WHC)

2.7. Textural Profile Analysis (TPA)

2.8. Free Amino Acids

2.9. Sensory Evaluation

2.10. Statistical Analysis

3. Results

3.1. Proximate Composition

3.2. Water Activity and pH

3.3. Color

3.4. Cooking Loss and Water Holding Capacity (WHC)

3.5. Textural Profile Analysis (TPA)

3.6. Free Amino Acids

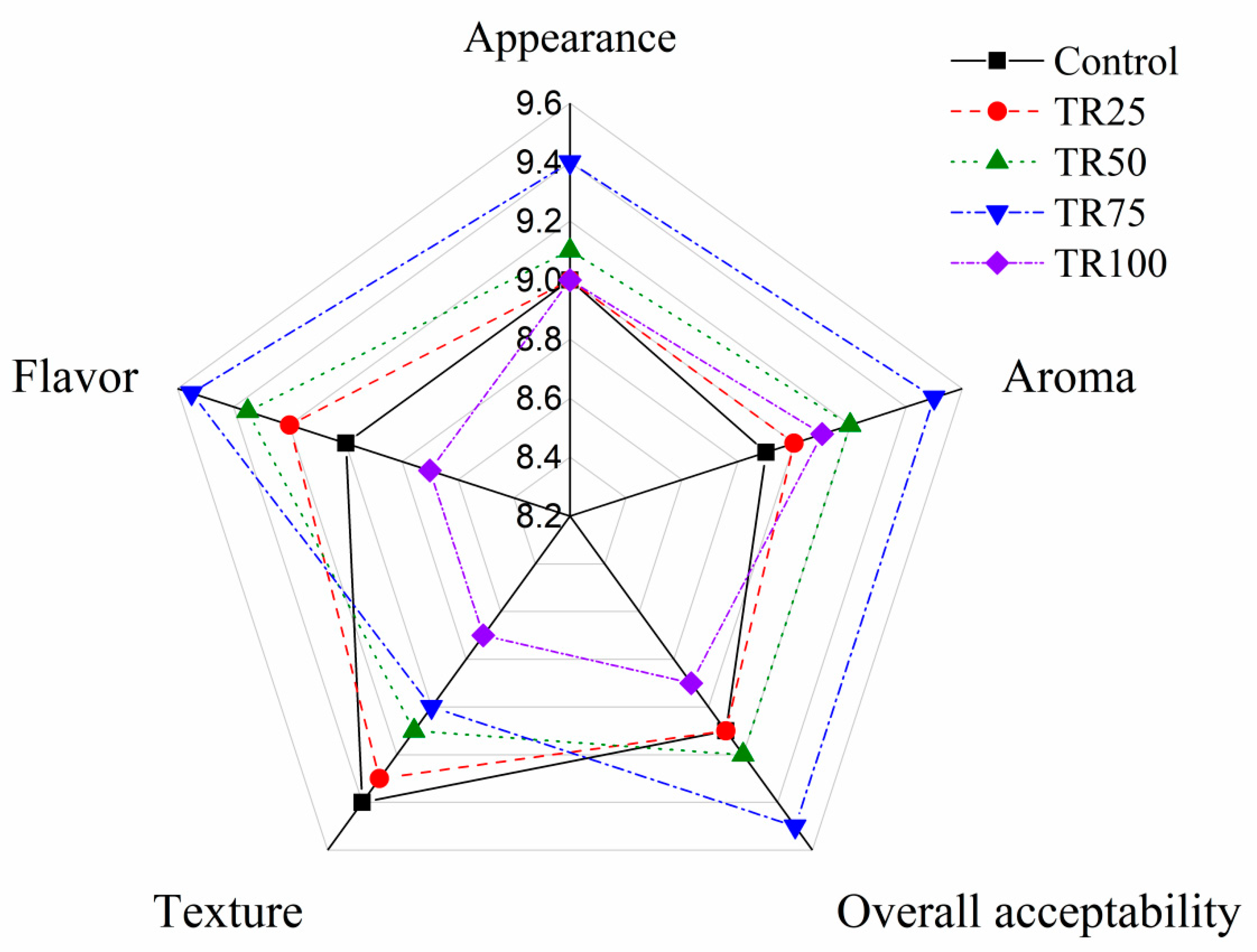

3.7. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pintado, T.; Herrero, A.; Jiménez-Colmenero, F.; Cavalheiro, C.P.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- Baker, R.C. Type and level of fat and amount of protein and their effect on the quality of chicken frankfurters. Food Technol. 1969, 23, 808–811. [Google Scholar]

- Paglarini, C.D.S.; Furtado, G.D.F.; Honório, A.R.; Mokarzel, L.; Vidal, V.A.S.; Ribeiro, A.P.B.; Cunha, R.L.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- Carballo, J.; Barreto, G.; Colmenero, F.J. Starch and egg white influence on properties of bologna sausage as related to fat content. J. Food Sci. 1995, 60, 673–677. [Google Scholar] [CrossRef]

- Yoo, S.S.; Kook, S.H.; Park, S.Y.; Shim, J.-H.; Chin, K.B. Physicochemical characteristics, textural properties and volatile compounds in comminuted sausages as affected by various fat levels and fat replacers. Int. J. Food Sci. Technol. 2007, 42, 1114–1122. [Google Scholar] [CrossRef]

- Sun, L.; Chen, W.; Liu, Y.; Li, J.; Yu, H. Soy protein isolate/cellulose nanofiber complex gels as fat substitutes: Rheological and textural properties and extent of cream imitation. Cellulose 2015, 22, 2619–2627. [Google Scholar] [CrossRef]

- Zhu, Y.; Guo, L.; Tang, W.; Yang, Q. Beneficial effects of Jerusalem artichoke powder and olive oil as animal fat replacers and natural healthy compound sources in Harbin dry sausages. Poult. Sci. 2020, 99, 7147–7158. [Google Scholar] [CrossRef]

- Yinyu, Z.; Qin, H.; Xinbo, Z. Effect of regenerated cellulose fiber on the physicochemical properties and sensory characteristics of fat-reduced emulsified sausage. LWT 2018, 97, 157–163. [Google Scholar]

- Utama, D.T.; Jeong, H.S.; Kim, J.; Barido, F.H.; Lee, S.K. Fatty acid composition and quality properties of chicken sausage formulated with pre-emulsified perilla-canola oil as an animal fat replacer. Poult. Sci. 2019, 98, 3059–3066. [Google Scholar] [CrossRef]

- Najjar, R.; Heidari, S.; Tazerout, M. Formulation of an economical microemulsion of diesel/colza oil fuel and investigation of some physical parameters for its stability. Environ. Prog. Sustain. Energy 2018, 37, 1762–1769. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Y.; Li, X.; Liu, Y.; Yan, W. Effects of partial replacement of pork back fat by a camellia oil gel on certain quality characteristics of a cooked style Harbin sausage. Meat Sci. 2018, 146, 154–159. [Google Scholar] [CrossRef]

- El Zeny, T.; Essa, R.; Bisar, B.; Metwalli, S. Effect of using chicory roots powder as a fat replacer on beef burger quality. Slov. Vet. Res. 2019, 56 (Suppl. 22), 509–514. [Google Scholar] [CrossRef] [Green Version]

- Kılıç, B.; Özer, C.O. Potential use of interesterified palm kernel oil to replace animal fat in frankfurters. Meat Sci. 2018, 148, 206–212. [Google Scholar] [CrossRef] [PubMed]

- Oh, I.; Lee, J.; Lee, H.G.; Lee, S. Feasibility of hydroxypropyl methylcellulose oleogel as an animal fat replacer for meat patties. Food Res. Int. 2019, 122, 566–572. [Google Scholar] [CrossRef] [PubMed]

- Saygi, D.; Ercoşkun, H.; Şahin, E. Hazelnut as functional food component and fat replacer in fermented sausage. J. Food Sci. Technol. 2018, 55, 3385–3390. [Google Scholar] [CrossRef] [PubMed]

- Hjelm, L.; Mielby, L.; Gregersen, S.; Eggers, N.; Bertram, H.C. Partial substitution of fat with rye bran fibre in Frankfurter sausages—Bridging technological and sensory attributes through inclusion of collagenous protein. LWT 2018, 101, 607–617. [Google Scholar] [CrossRef]

- Kim, D.H.; Shin, D.M.; Seo, H.G.; Han, S.G. Effects of konjac gel with vegetable powders as fat replacers in frankfurter-type sausage. Asian-Australas. J. Anim. Sci. 2019, 32, 1195–1204. [Google Scholar] [CrossRef] [Green Version]

- Hautrive, T.P.; Piccolo, J.; Rodrigues, A.S.; Campagnol, P.C.B.; Kubota, E.H. Effect of fat replacement by chitosan and golden flaxseed flour (wholemeal and defatted) on the quality of hamburgers. LWT 2018, 102, 403–410. [Google Scholar] [CrossRef]

- Reshetnikov, S.V.; Wasser, S.P.; Duckman, I.; Tsukor, K. Medicinal value of the genus Tremella Pers. (Heterobasidiomycetes). Int. J. Med. Mushrooms 2000, 2. [Google Scholar] [CrossRef]

- Yang, D.; Lian, J.; Wang, L.; Liu, X.; Wang, Y.; Zhao, X.; Zhang, X.; Hu, W. The anti-fatigue and anti-anoxia effects of Tremella extract. Saudi J. Biol. Sci. 2019, 26, 2052–2056. [Google Scholar] [CrossRef]

- Horwitz, W. Official methods of analysis of AOAC International. Trends Food Sci. Technol. 1995, 6, 382. [Google Scholar]

- Wang, L.; Guo, H.; Liu, X.; Jiang, G.; Li, C.; Li, X.; Li, Y. Roles of Lentinula edodes as the pork lean meat replacer in production of the sausage. Meat Sci. 2019, 156, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, C.; Ren, L.; Guo, H.; Li, Y. Production of Pork Sausages Using Pleaurotus eryngii with Different Treatments as Replacements for Pork Back Fat. J. Food Sci. 2019, 84, 3091–3098. [Google Scholar] [CrossRef]

- Shin, D.-J.; Lee, H.J.; Lee, D.; Jo, C.; Choe, J. Fat replacement in chicken sausages manufactured with broiler and old laying hens by different vegetable oils. Poult. Sci. 2020, 99, 2811–2818. [Google Scholar] [CrossRef]

- Jo, Y.; An, K.-A.; Arshad, M.S.; Kwon, J.-H. Effects of e-beam irradiation on amino acids, fatty acids, and volatiles of smoked duck meat during storage. Innov. Food Sci. Emerg. Technol. 2018, 47, 101–109. [Google Scholar] [CrossRef]

- Lee, C.H.; Chin, K.B. Effects of pork gelatin levels on the physicochemical and textural properties of model sausages at different fat levels. LWT 2016, 74, 325–330. [Google Scholar] [CrossRef]

- Nacak, B.; Öztürk-Kerimoğlu, B.; Yıldız, D.; Çağındı, Ö.; Serdaroğlu, M. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci. 2021, 176, 108464. [Google Scholar] [CrossRef] [PubMed]

- Stefanello, F.S.; Cavalheiro, C.P.; Lüdtke, F.L.; Silva, M.D.S.D.; Fries, L.L.M.; Kubota, E.H. Oxidative and microbiological stability of fresh pork sausage with added sun mushroom powder. Ciência Agrotecnologia 2015, 39, 381–389. [Google Scholar] [CrossRef] [Green Version]

- Sousa, S.C.; Fragoso, S.P.; Penna, C.R.; Arcanjo, N.M.; da Silva, F.A.P.; Ferreira, V.; Barreto, M.D.; Araújo, B. Quality parameters of frankfurter-type sausages with partial replacement of fat by hydrolyzed collagen. LWT 2017, 76, 320–325. [Google Scholar] [CrossRef]

- Hamdi, M.; Nasri, R.; Dridi, N.; Moussa, H.; Ashour, L.; Nasri, M. Improvement of the quality and the shelf life of reduced-nitrites turkey meat sausages incorporated with carotenoproteins from blue crabs shells. Food Control 2018, 91, 148–159. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, E.; Pérez-Alvarez, J.A. Meat products as functional foods: A review. J. Food Sci. 2005, 70, R37–R43. [Google Scholar] [CrossRef]

- Faria, M.D.O.; Cipriano, T.M.; da Cruz, A.G.; dos Santos, B.A.; Pollonio, M.; Campagnol, P.C.B. Properties of bologna-type sausages with pork back-fat replaced with pork skin and amorphous cellulose. Meat Sci. 2015, 104, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Chau, V.; Tobias, J.; Bachmair, A.; Marriott, D.; Ecker, D.; Gonda, D.; Varshavsky, A. A multiubiquitin chain is confined to specific lysine in a targeted short-lived protein. Science 1989, 243, 1576–1583. [Google Scholar] [CrossRef] [PubMed]

- Szabados, L.; Savouré, A. Proline: A multifunctional amino acid. Trends Plant Sci. 2010, 15, 89–97. [Google Scholar] [CrossRef] [PubMed]

| Formulations (%) | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| Pork lean meat | 49 | 49 | 49 | 49 | 49 |

| pork fat | 21 | 15.75 | 10.5 | 5.25 | 0 |

| tremella | 0 | 5.25 | 10.5 | 15.75 | 21 |

| Salt | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sugar | 1 | 1 | 1 | 1 | 1 |

| White pepper | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Carrageenan | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Isolated soy protein | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Dry starch | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 |

| Ice | 20 | 20 | 20 | 20 | 20 |

| Total | 100 | 100 | 100 | 100 | 100 |

| Parameters | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| Protein (%) | 12.65 ± 0.14 a | 13.24 ± 0.16 b | 13.63 ± 0.04 c | 14.16 ± 0.03 d | 14.52 ± 0.38 e |

| Fat (%) | 17.77 ± 0.65 e | 15.18 ± 0.5 d | 8.40 ± 0.08 c | 6.17 ± 0.13 b | 1.96 ± 0.27 a |

| Ash (%) | 3.12 ± 0.0 a | 3.25 ± 0.02 b | 3.36 ± 0.04 c | 3.52 ± 0.01 d | 3.57 ± 0.01 e |

| Moisture (%) | 46.63 ± 0.02 a | 58.01 ± 0.0 b | 67.08 ± 0.01 c | 69.08 ± 0.02 d | 73.29 ± 0.01 e |

| Aw | 0.99 ± 0.0 a | 0.98 ± 0.00 a | 0.99 ± 0.00 a | 0.99 ± 0.00 a | 0.99 ± 0.00 a |

| pH | 6.46 ± 0.05 b | 6.45 ± 0.02 c | 6.33 ± 0.03 b | 6.27 ± 0.01 a | 6.26 ± 0.01 a |

| Parameters | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| L* | 54.37 ± 0.06 a | 54.46 ± 0.12 a | 55.24 ± 0.10 b | 55.91 ± 0.03 c | 56.72 ± 0.12 d |

| a* | 16.06 ± 0.15 a | 16.21 ± 0.17 ab | 16.36 ± 0.01 b | 16.44 ± 0.09 b | 17.03 ± 0.07 c |

| b* | 15.08 ± 0.16 d | 14.65 ± 0.05 c | 14.02 ± 0.11 b | 13.79 ± 0.26 b | 12.94 ± 0.04 a |

| ΔE* | 45.76 ± 0.37 d | 45.73 ± 0.06 d | 44.92 ± 0.12 c | 44.29 ± 0.07 b | 43.58 ± 0.14 a |

| whiteness | 49.44 ± 0.33 a | 49.49 ± 0.07 a | 50.32 ± 0.12 b | 50.97 ± 0.07 c | 51.72 ± 0.14 d |

| Parameters | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| Cooking loss (%) | 5.13 ± 0.00 a | 12.07 ± 0.04 c | 12.54 ± 0.05 d | 12.00 ± 0.03 b | 14.79 ± 0.15 e |

| WHC | 82.08 ± 0.10 a | 83.04 ± 0.13 a | 85.79 ± 0.11 b | 88.39 ± 0.08 bc | 90.11 ± 0.21 c |

| Parameters | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| Hardness (N) | 155.63 ± 10.14 c | 148.50 ± 6.02 bc | 140.60 ± 4.46 abc | 138.90 ± 6.40 ab | 126.80 ± 5.36 a |

| Cohesiveness | 0.55 ± 0.03 b | 0.44 ± 0.04 a | 0.43 ± 0.02 a | 0.41 ± 0.03 a | 0.39 ± 0.02 a |

| Springiness | 3.50 ± 0.22 a | 4.35 ± 0.14 b | 4.60 ± 0.12 bc | 4.86 ± 0.22 c | 5.47 ± 0.24 d |

| Gumminess (N) | 85.23 ± 3.31 c | 61.10 ± 1.28 b | 56.10 ± 3.42 ab | 51.30 ± 2.60 ab | 46.60 ± 2.50 a |

| Chewiness (N) | 248.49 ± 8.06 a | 257.08 ± 7.35 a | 296.79 ± 10.51 b | 316.75 ± 6.32 b | 371.16 ± 5.62 c |

| Amino Acid | Control | TR25 | TR50 | TR75 | TR100 |

|---|---|---|---|---|---|

| Essential | |||||

| Val | 1.06 ± 0.02 e | 0.99 ± 0.00 d | 0.85 ± 0.01 c | 0.73 ± 0.00 b | 0.68 ± 0.05 a |

| Thr | 1.14 ± 0.00 b | 1.11 ± 0.00 b | 0.98 ± 0.01 b | 0.82 ± 0.02 a | 0.79 ± 0.00 a |

| Lys | 1.37 ± 0.00 a | 1.59 ± 0.00 b | 1.92 ± 0.00 c | 1.98 ± 0.00 d | 2.02 ± 0.06 e |

| Met | 0.08 ± 0.00 a | 0.09 ± 0.00 a | 0.11 ± 0.01 ab | 0.11 ± 0.00 ab | 0.16 ± 0.01 b |

| Ile | 0.80 ± 0.01 a | 0.82 ± 0.00 a | 1.02 ± 0.01 b | 1.12 ± 0.00 c | 1.17 ± 0.00 d |

| Leu | 1.89 ± 0.01 d | 1.79 ± 0.03 c | 1.75 ± 0.00 c | 1.26 ± 0.01 a | 1.43 ± 0.03 b |

| Phe | 0.99 ± 0.01 c | 0.92 ± 0.00 b | 0.89 ± 0.00 a | 0.90 ± 0.03 a | 0.95 ± 0.00 b |

| His | 0.79 ± 0.02 b | 0.79 ± 0.06 b | 0.72 ± 0.01 a | 0.70 ± 0.00 a | 0.78 ± 0.00 b |

| Val | 1.06 ± 0.02 e | 0.99 ± 0.00 d | 0.85 ± 0.01 c | 0.73 ± 0.00 b | 0.68 ± 0.05 a |

| Non-Essential | |||||

| Ser | 0.98 ± 0.00 c | 0.88 ± 0.00 a | 0.92 ± 0.00 b | 0.85 ± 0.01 a | 0.93 ± 0.01 b |

| Arg | 1.42 ± 0.04 e | 1.38 ± 0.00 d | 1.29 ± 0.00 c | 1.14 ± 0.00 b | 0.93 ± 0.03 a |

| Gly | 1.11 ± 0.00 d | 1.12 ± 0.00 d | 0.83 ± 0.00 b | 0.89 ± 0.00 c | 0.74 ± 0.00 a |

| ASP | 2.62 ± 0.00 e | 2.36 ± 0.03 d | 2.27 ± 0.06 c | 1.89 ± 0.05 b | 1.73 ± 0.01 a |

| Glu | 4.02 ± 0.03 d | 3.84 ± 0.05 c | 3.79 ± 0.03 c | 3.58 ± 0.01 b | 2.78 ± 0.05 a |

| Ala | 1.30 ± 0.00 d | 0.88 ± 0.04 a | 1.18 ± 0.00 c | 0.93 ± 0.00 b | 1.19 ± 0.03 c |

| Pro | 1.68 ± 0.03 a | 1.75 ± 0.00 b | 2.07 ± 0.02 c | 2.09 ± 0.03 c | 2.40 ± 0.26 d |

| Cys | 0.06 ± 0.00 a | 0.03 ± 0.00 a | 0.05 ± 0.00 a | 0.03 ± 0.01 a | 0.05 ± 0.33 a |

| Tyr | 0.48 ± 0.01 a | 0.55 ± 0.00 b | 0.65 ± 0.00 c | 0.68 ± 0.00 c | 0.74 ± 0.01 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Li, Y.; Zhang, L.; Tu, H.; Wang, X.; Ren, L.; Dai, S.; Wang, L. Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage. Foods 2021, 10, 2167. https://doi.org/10.3390/foods10092167

Hu H, Li Y, Zhang L, Tu H, Wang X, Ren L, Dai S, Wang L. Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage. Foods. 2021; 10(9):2167. https://doi.org/10.3390/foods10092167

Chicago/Turabian StyleHu, Hewen, Yue Li, Long Zhang, Huajie Tu, Xinyu Wang, Lili Ren, Siqi Dai, and Liyan Wang. 2021. "Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage" Foods 10, no. 9: 2167. https://doi.org/10.3390/foods10092167

APA StyleHu, H., Li, Y., Zhang, L., Tu, H., Wang, X., Ren, L., Dai, S., & Wang, L. (2021). Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage. Foods, 10(9), 2167. https://doi.org/10.3390/foods10092167