Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel

Abstract

1. Introduction

2. Materials and Methods

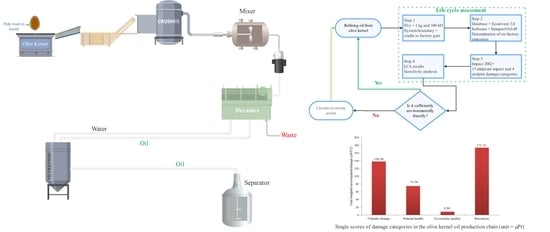

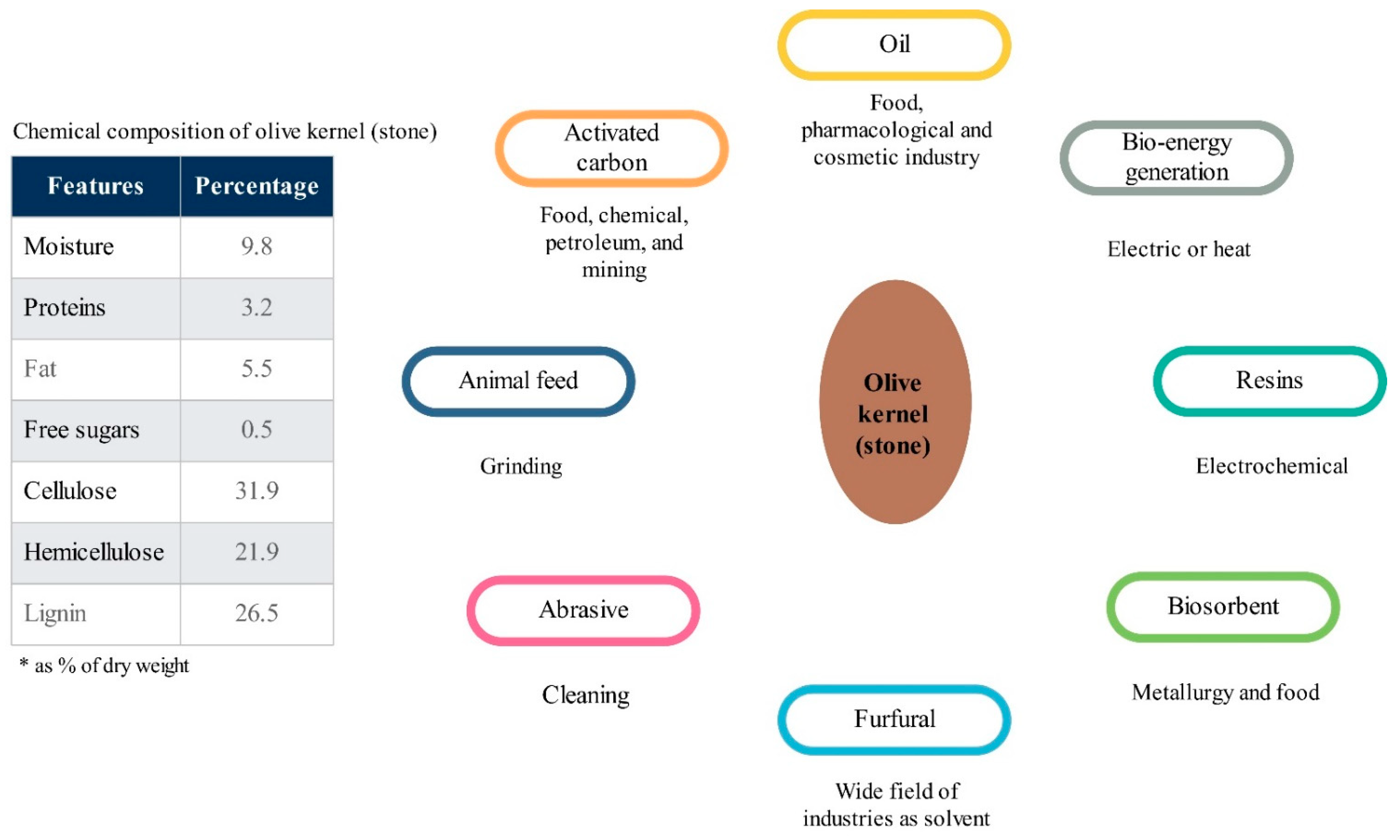

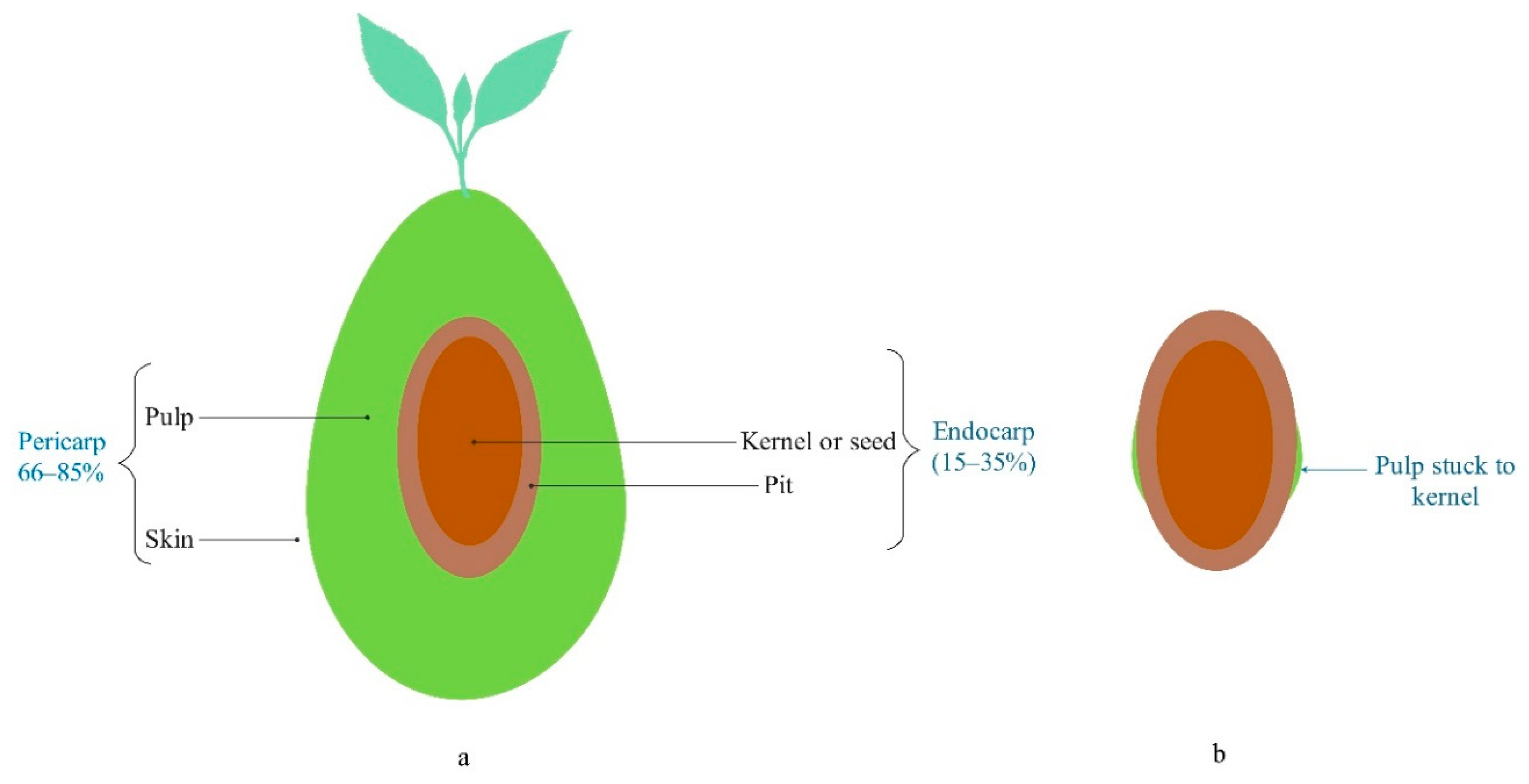

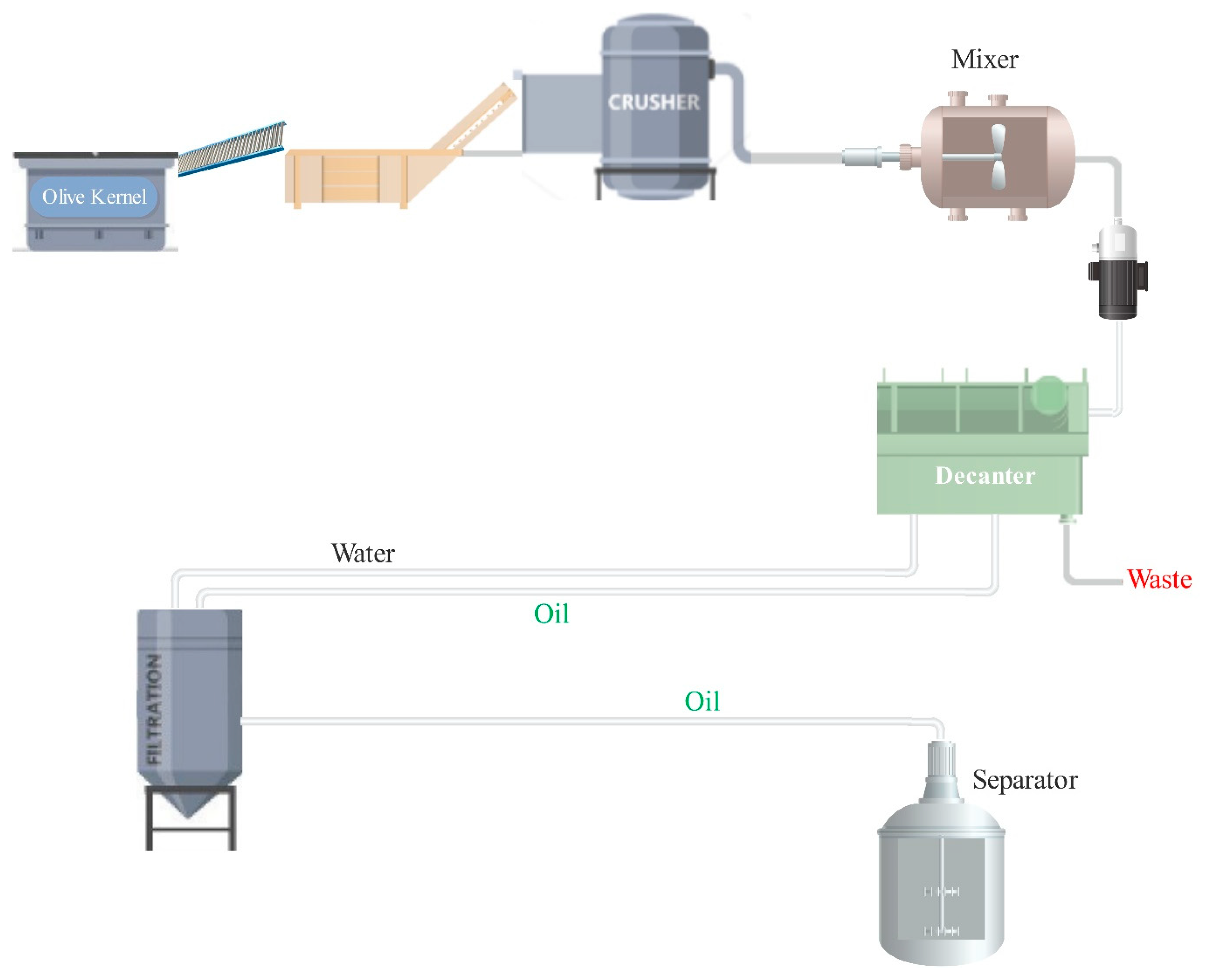

2.1. Refining Oil from Olive Kernel

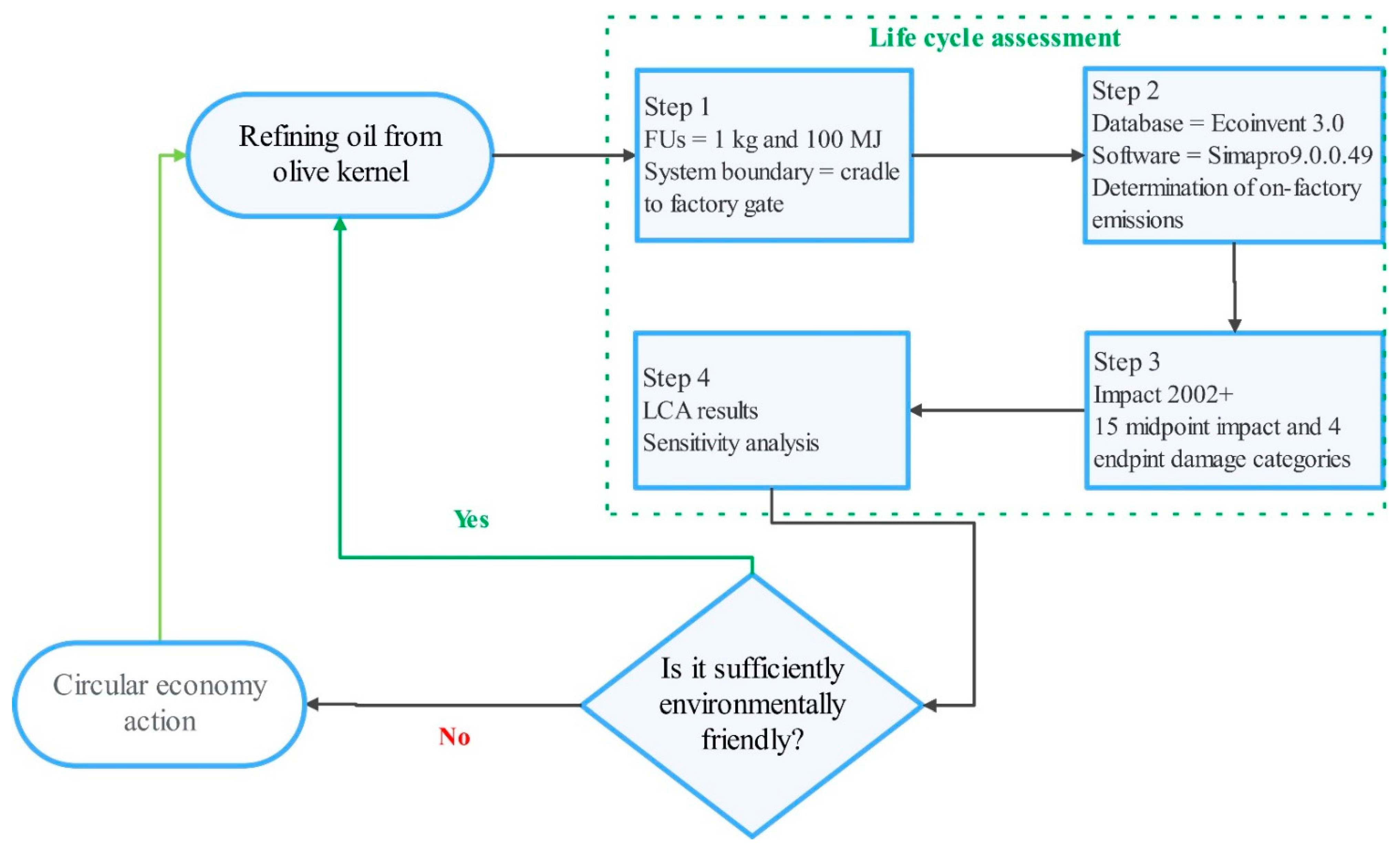

2.2. Measuring Circularity Using LCA

3. Results and Discussion

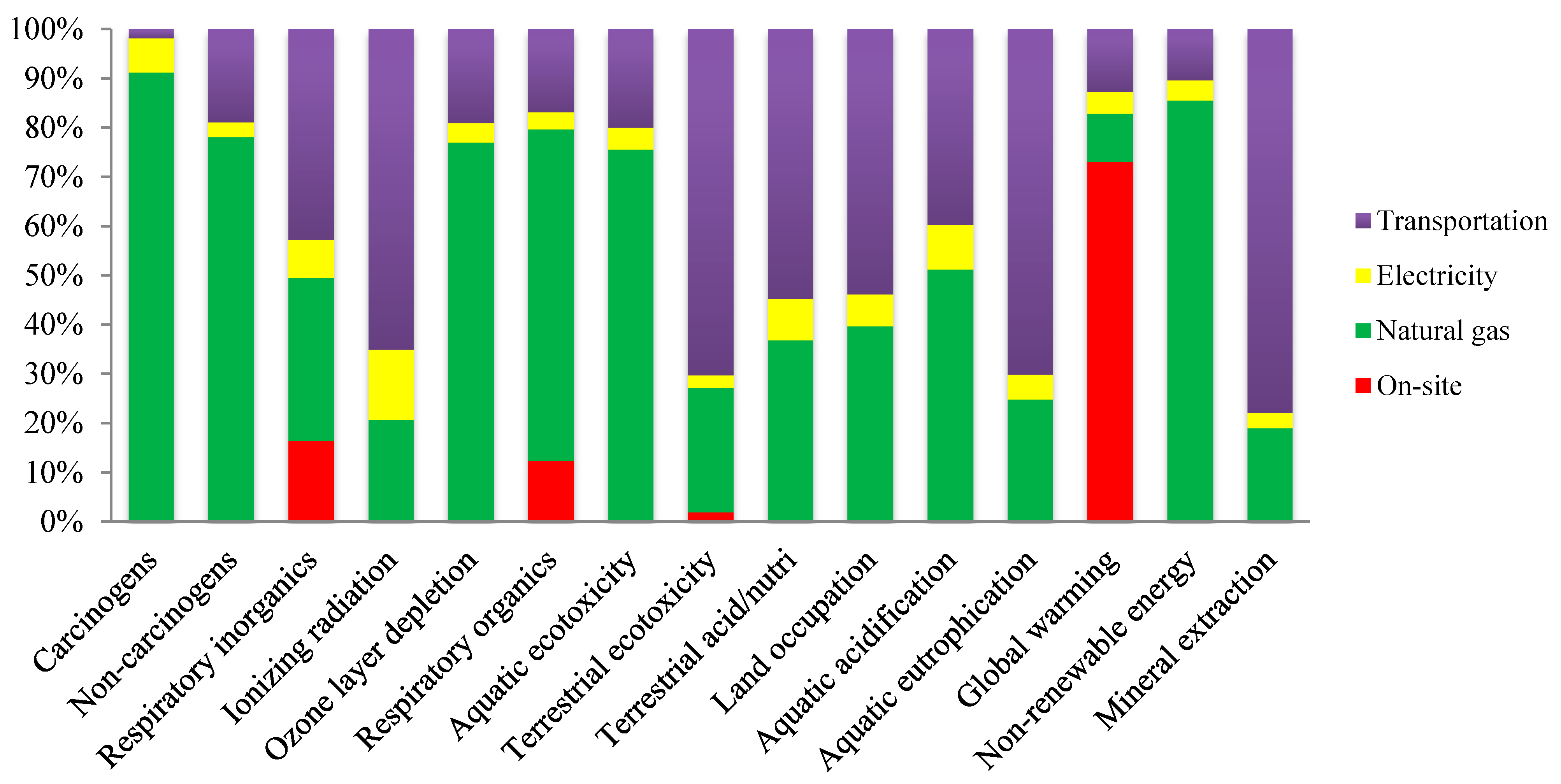

3.1. Interpretation of Mid-Point LCA Results

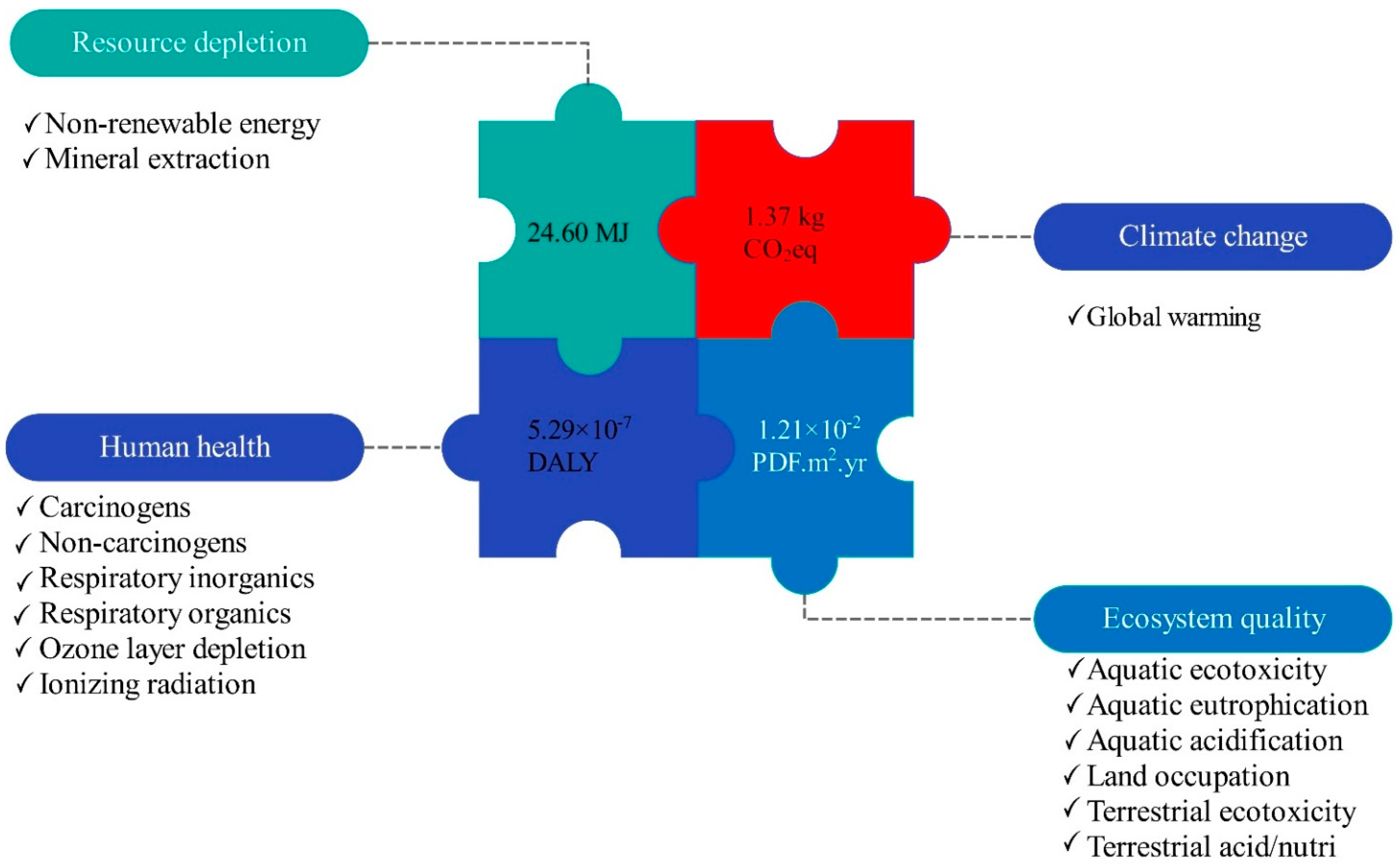

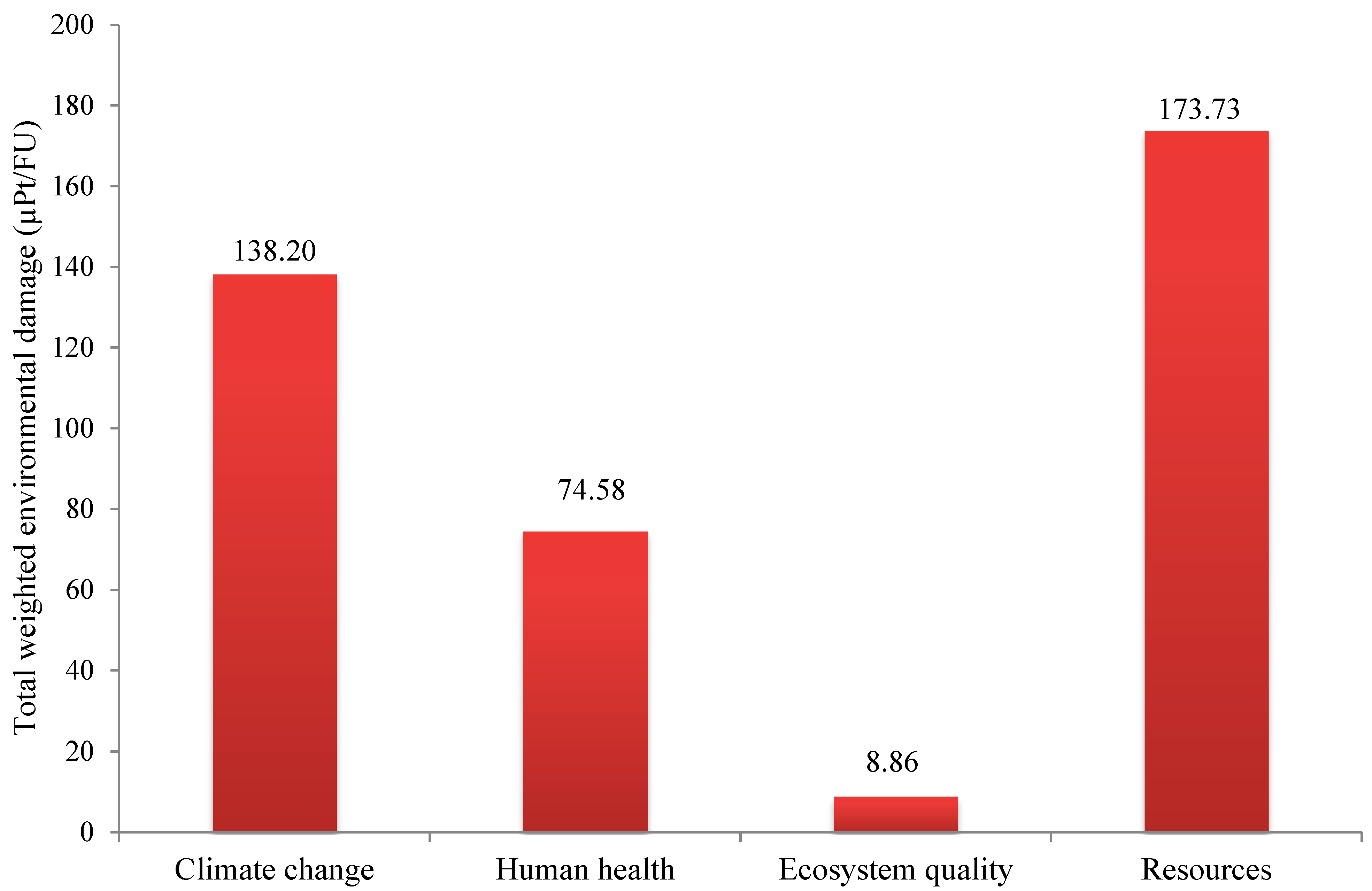

3.2. Interpretation of End-Point Damage Assessment

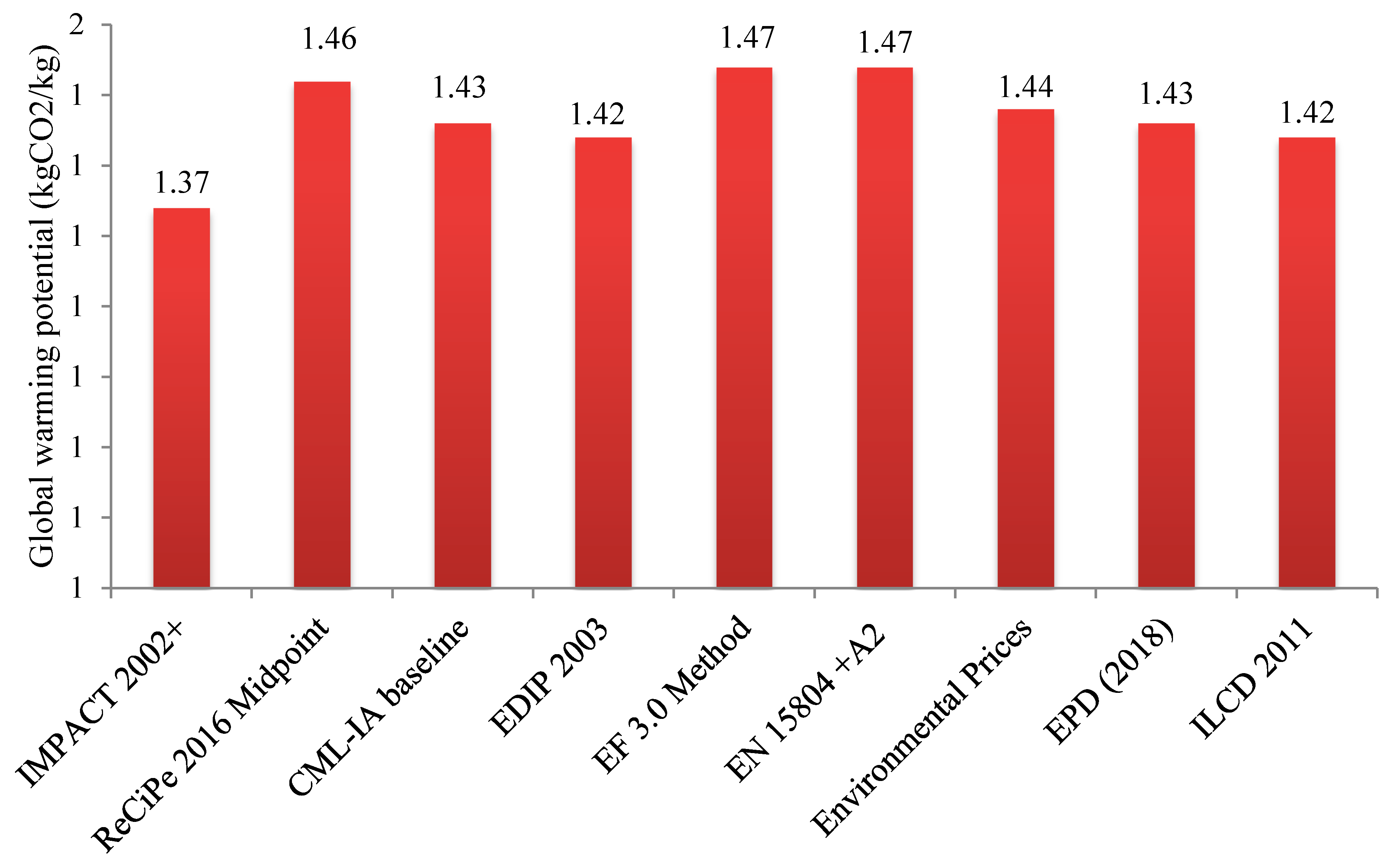

3.3. Uncertainty of GWP’s Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Activity | Database | Category | Unit | Activity Uuid/Source |

|---|---|---|---|---|

| Electricity | Ecoinvent 3 | IR | kWh | 668baf12-38db-47b7-8517-c0a18aa122f4 |

| Natural gas | Ecoinvent 3 | GLO | M 3 | 65f221cf-b821-4da1-a2ed-a67994b10f42 |

| Transport | Ecoinvent 3 | GLO | t.km | 413c356e-677d-4676-b816-0c0b20768d7a_03bf1369-1eec-49d0-bc4b-8b29efa826b9.spold |

| Water-Unspecified origins | Input from nature | IR | M 3 | - |

| Emission | Coefficients [66,67] | Quantity (per on kg Produced Olive Kernel Oil) |

|---|---|---|

| Carbon dioxide (CO2) | 38.70 | 996.14 |

| Methane (CH4) | 7.40 × 10−4 | 1.90 × 10−2 |

| Dinitrogen monoxide (N2O) | 7.11 × 10−4 | 1.83 × 10−2 |

| Sulfur dioxide (SO2) | 1.93 × 10−4 | 4.97 × 10−3 |

| Nickel (Ni) | 6.78 × 10−7 | 1.75 × 10−5 |

| Lead | 1.61 × 10−7 | 4.14 × 10−6 |

| Zinc (Zn) | 9.37 × 10−6 | 2.41 × 10−4 |

| Benzo(a)pyrene | 3.87 × 10−9 | 9.96 × 10−8 |

| Selenium (Se) | 7.75 × 10−9 | 1.99 × 10−7 |

| Organic compound | 3.50 × 10−3 | 9.01 × 10−2 |

| Volatile organic compound (VOC) | 1.70 × 10−3 | 4.38 × 10−2 |

| Particulates (<2.5 μm) | 2.45 × 10−3 | 6.31 × 10−2 |

References

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1, 100005. [Google Scholar] [CrossRef]

- Secondi, L. A Regression-Adjustment Approach with Control-Function for Estimating Economic Benefits of Targeted Circular Economy Practices: Evidence from European SMEs. Stud. Appl. Econ. 2020, 39. [Google Scholar] [CrossRef]

- Ruggieri, A.; Braccini, A.M.; Poponi, S.; Mosconi, E.M. A meta-model of inter-organisational cooperation for the transition to a circular economy. Sustainability 2016, 8, 1153. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Gaustad, G.; Fisher, A.; Chen, W.Q.; Liu, G. Closing the loop on circular economy research: From theory to practice and back again. Resour. Conserv. Recycl. 2018, 135, 1–2. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- European Environment Agency. Signals: Well-Being and the Environment—Building a Resource-Efficient and Circular Economy in Europe Luxembourg; Publications Office of the European Union: Copenhagen, Denmark, 2014. [Google Scholar]

- Haupt, M.; Zschokke, M. How can LCA support the circular economy?—63rd discussion forum on life cycle assessment, Zurich, Switzerland, November 30, 2016. Int. J. Life Cycle Assess. 2017, 22, 832–837. [Google Scholar] [CrossRef]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a circular economy: An emerging economies context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bassi, F.; Dias, J.G. The use of circular economy practices in SMEs across the EU. Resour. Conserv. Recycl. 2019, 146, 523–533. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation; Granta Design. An Approach Tomeasuring Circularity—Methodology; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Di Maio, F.; Rem, P.C. A robust indicator for promoting circular economy through recycling. J. Environ. Protect. 2015, 6, 1095. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef]

- Vilariño, M.V.; Franco, C.; Quarrington, C. Food loss and waste reduction as an integral part of a circular economy. Front. Environ. Sci. 2017, 5, 21. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Environmental Management: Life Cycle Assessmente; Principles and Framework; British Standards Institution: London, UK, 2006; Volume 14040. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management: Life Cycle Assessment; Requirements and Guidelines; International Standard Organisation: Geneva, Switzerland, 2006. [Google Scholar]

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Lokesh, K.; Matharu, A.S.; Kookos, I.K.; Ladakis, D.; Koutinas, A.; Morone, P.; Clark, J. Hybridised sustainability metrics for use in life cycle assessment of bio-based products: Resource efficiency and circularity. Green Chem. 2020, 22, 803–813. [Google Scholar] [CrossRef]

- Dahiya, S.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Biobased Products and Life Cycle Assessment in the Context of Circular Economy and Sustainability. Mater. Circ. Econ. 2020, 2, 1–28. [Google Scholar] [CrossRef]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the environmental sustainability of food packaging: An extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Dahiya, S.; Kumar, A.N.; Sravan, J.S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef] [PubMed]

- Shafiee-Jood, M.; Cai, X. Reducing food loss and waste to enhance food security and environmental sustainability. Environ. Sci. Technol. 2016, 50, 8432–8443. [Google Scholar] [CrossRef] [PubMed]

- Wesana, J.; Gellynck, X.; Dora, M.K.; Pearce, D.; De Steur, H. Measuring Food Losses in the Supply Chain through Value Stream Mapping: A Case Study in the Dairy Sector. In Saving Food; Academic Press: New York, NY, USA, 2019; pp. 249–277. [Google Scholar]

- Strotmann, C.; Göbel, C.; Friedrich, S.; Kreyenschmidt, J.; Ritter, G.; Teitscheid, P. A participatory approach to minimizing food waste in the food industry—A manual for managers. Sustainability 2017, 9, 66. [Google Scholar] [CrossRef]

- Principato, L.; Ruini, L.; Guidi, M.; Secondi, L. Adopting the circular economy approach on food loss and waste: The case of Italian pasta production. Resour. Conserv. Recycl. 2019, 144, 82–89. [Google Scholar] [CrossRef]

- Muhammad, N.I.S.; Rosentrater, K.A. Comparison of global-warming potential impact of food waste fermentation to landfill disposal. SN Appl. Sci. 2020, 2, 261. [Google Scholar] [CrossRef]

- Ingrao, C.; Faccilongo, N.; Di Gioia, L.; Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod. 2018, 184, 869–892. [Google Scholar] [CrossRef]

- Negro, M.J.; Manzanares, P.; Ruiz, E.; Castro, E.; Ballesteros, M. The biorefinery concept for the industrial valorization of residues from olive oil industry. In Olive Mill Waste; Academic Press: New York, NY, USA, 2017; pp. 57–78. [Google Scholar]

- Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Moustakas, K.; Talebi, A.F.; Goli, S.A.H.; Rajaeifar, M.A.; Khoshnevisan, B.; Jouzani, G.S.; Peng, W.; Kim, K.H.; et al. Environmental life cycle assessment of different biorefinery platforms valorizing olive wastes to biofuel, phosphate salts, natural antioxidant, and an oxygenated fuel additive (triacetin). J. Clean. Prod. 2021, 278, 123916. [Google Scholar] [CrossRef]

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and trends for Life Cycle Assessment of olive oil production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef]

- Nunes, M.A.; Pimentel, F.B.; Costa, A.S.; Alves, R.C.; Oliveira, M.B.P. Olive by-products for functional and food applications: Challenging opportunities to face environmental constraints. Innov. Food Sci. Emerg. Technol. 2016, 35, 139–148. [Google Scholar] [CrossRef]

- Gomez-Martin, A.; Chacartegui, R.; Ramirez-Rico, J.; Martinez-Fernandez, J. Performance improvement in olive stone’s combustion from a previous carbonization transformation. Fuel 2018, 228, 254–262. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolanos, J. Olive stone an attractive source of bioactive and valuable compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef] [PubMed]

- Batuecas, E.; Tommasi, T.; Battista, F.; Negro, V.; Sonetti, G.; Viotti, P.; Fino, D.; Mancini, G. Life Cycle Assessment of waste disposal from olive oil production: Anaerobic digestion and conventional disposal on soil. J. Environ. Manag. 2019, 237, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, G.; Vander Heyden, Y.; Rabiei, Z.; Sadeghi, N.; Oveisi, M.R.; Jannat, B.; Araghi, V.; Hassani, S.; Behzad, M.; Hajimahmoodi, M. Characterization of different olive pulp and kernel oils. J. Food Compos. Anal. 2012, 28, 54–60. [Google Scholar] [CrossRef]

- Martins, F.P.; Kiritsakis, A. Olives and Olive Oil as Functional Foods: Bioactivity, Chemistry and Processing, 1st ed.; Kiritsakis, A., Shahidi, F., Eds.; Wiley: Hoboken, NJ, USA, 2017; pp. 81–105. [Google Scholar]

- Kiritsakis, A.; Turkan, K.M.; Kiritsakis, K. Bailey’s Industrial Oil and Fat Products, 7th ed.; Shahidi, F., Ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Cappelletti, G.M.; Ioppolo, G.; Nicoletti, G.M.; Russo, C. Energy requirement of extra virgin olive oil production. Sustainability 2014, 6, 4966–4974. [Google Scholar] [CrossRef]

- Sundaram, S.; Siew, K.; Martinez-Hernandez, E. Biorefineries and chemical processes: Design, integration and sustainability analysis. Green Process. Synth. 2015, 4, 65–66. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef]

- Zargar-Ershadi, S.Z.; Heidari, M.D.; Dutta, B.; Dias, G.; Pelletier, N. Comparative life cycle assessment of technologies and strategies to improve nitrogen use efficiency in egg supply chains. Resour. Conserv. Recycl. 2021, 166, 105275. [Google Scholar] [CrossRef]

- Vásquez-Ibarra, L.; Rebolledo-Leiva, R.; Angulo-Meza, L.; González-Araya, M.C.; Iriarte, A. The joint use of life cycle assessment and data envelopment analysis methodologies for eco-efficiency assessment: A critical review, taxonomy and future research. Sci. Total Environ. 2020, 139538. [Google Scholar] [CrossRef]

- Fathollahi, H.; Mousavi-Avval, S.H.; Akram, A.; Rafiee, S. Comparative energy, economic and environmental analyses of forage production systems for dairy farming. J. Clean. Prod. 2018, 182, 852–862. [Google Scholar] [CrossRef]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA case study due to allocation approaches and life cycle impact assessment methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Noya, I.; González-García, S.; Bacenetti, J.; Fiala, M.; Moreira, M.T. Environmental impacts of the cultivation-phase associated with agricultural crops for feed production. J. Clean. Prod. 2018, 172, 3721–3733. [Google Scholar] [CrossRef]

- Rezaei, M.; Soheilifard, F.; Keshvari, A. Impact of agrochemical emission models on the environmental assessment of paddy rice production using life cycle assessment approach. Energy Sources 2021, 1–16. [Google Scholar] [CrossRef]

- Paramesh, V.; Arunachalam, V.; Nikkhah, A.; Das, B.; Ghnimi, S. Optimization of energy consumption and environmental impacts of arecanut production through coupled data envelopment analysis and life cycle assessment. J. Clean. Prod. 2018, 203, 674–684. [Google Scholar] [CrossRef]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.; van Zelm, R. A taste of the new ReCiPe for life cycle assessment: Consequences of the updated impact assessment method on food product LCAs. Int. J. Life Cycle Assess. 2019, 1–10. [Google Scholar] [CrossRef]

- Guinée, J.B.; Lindeijer, E. Handbook on Life Cycle Assessment—Operational Guide to the ISO Standards. In Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards Series: Eco-Efficiency in Industry and Science; Guinée, J.B., Ed.; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Hauschild, M.Z.; Wenzel, H. Environmental Assessment of Products, Volume 2: Scientific Background; Springer: New York, NY, USA, 1998. [Google Scholar]

- Huijbregts, M.A.; Hellweg, S.; Frischknecht, R.; Hungerbühler, K.; Hendriks, A.J. Ecological footprint accounting in the life cycle assessment of products. Ecol. Econ. 2008, 64, 798–807. [Google Scholar] [CrossRef]

- EN 15804, BS EN 15804:2012. Standards Publication Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2014; Volume 70. [Google Scholar]

- De Bruyn, S.; Ahdour, S.; Bijleveld, M.; De Graaff, L.; Schep, E.; Schroten, A.; Vergeer, R. Environmental Prices Handbook 2017-Methods and Numbers for Valuation of Environmental Impacts. 2018. Available online: https://www.cedelft.eu/en/publications/2113/envionmental-prices-handbook-2017 (accessed on 12 January 2021).

- PRE. SimaPro Database Manual Methods Library. 2019. Available online: https://simapro.com/ (accessed on 28 January 2021).

- Chomkhamsri, K.; Wolf, M.A.; Pant, R. International reference life cycle data system (ILCD) handbook: Review schemes for life cycle assessment. Towards Life Cycle Sustain. Manag. 2011, 107–117. [Google Scholar] [CrossRef]

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?–a comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Banerjee, R.; Rao, A.B. Life cycle assessment of sugar and electricity production under different sugarcane cultivation and cogeneration scenarios in India. J. Clean. Prod. 2020, 290, 125170. [Google Scholar] [CrossRef]

- Salomone, R.; Cappelletti, G.M.; Malandrino, O.; Mistretta, M.; Neri, E.; Nicoletti, G.M.; Notarnicola, B.; Pattara, C.; Russo, C.; Saija, G. Life Cycle Assessment in the Olive Oil Sector. In Life Cycle Assessment in the Agri-food Sector; Springer: Cham, Switzerland, 2015; pp. 57–121. [Google Scholar]

- El Hanandeh, A. Carbon abatement via treating the solid waste from the Australian olive industry in mobile pyrolysis units: LCA with uncertainty analysis. Waste Manag. Res. 2013, 31, 341–352. [Google Scholar] [CrossRef]

- Intini, F.; Kuhtz, S.; Rospi, G. Life cycle assessment (LCA) of an energy recovery plant in the olive oil industries. Int. J. Energy Environ. 2012, 3, 541–552. [Google Scholar]

- Martinez-Hernandez, E.; Martinez-Herrera, J.; Campbell, G.M.; Sadhukhan, J. Process integration, energy and GHG emission analyses of Jatropha-based biorefinery systems. Biomass Convers. Biorefinery 2014, 4, 105–124. [Google Scholar] [CrossRef]

- EPA-Environmental Protection Agency Emission Factor Documentation for AP-42 Section 1.4-Natural Gas Combustion, Technical Support Division, Office of Air Quality Planning and Standards, Research Triangle Park, NC, USA, 1998. Available online: http://www3.epa.gov/ttnchie1/ap42/ch01/bgdocs/b01s04.pdf (accessed on 8 January 2021).

- Farahani, S.S.; Soheilifard, F.; Raini, M.G.N.; Kokei, D. Comparison of different tomato puree production phases from an environmental point of view. Int. J. Life Cycle Assess. 2019, 24, 1817–1827. [Google Scholar] [CrossRef]

| Inputs and Outputs | Unit | Quantity | |

|---|---|---|---|

| Per 1 kg Produced Oil | Per 100 MJ Produced Oil | ||

| Inputs | |||

| —Olive kernel | kg | 47.72 | 150.83 |

| —Water consumption | m3 | 0.05 | 0.14 |

| —Natural gas | m3 | 0.52 | 1.65 |

| —Electricity | kWh | 0.10 | 0.31 |

| —Human labor | h | 0.16 | 0.50 |

| —Transportation of the produced oil | ton × km | 0.34 | 1.07 |

| Outputs | |||

| —Olive kernel oil | 1 kg | 100 MJ | |

| —Efficiency (oil/olive kernel) | % | 2.09 | 2.09 |

| Impact Category | Unit | Quantity | |

|---|---|---|---|

| Per 1 kg Produced Oil | Per 100 MJ Produced Energy | ||

| Global warming | kg CO2eq | 1.37 | 4.32 |

| Non-renewable energy | MJ primary | 26.40 | 83.44 |

| Mineral extraction | MJ surplus | 0.005 | 0.02 |

| Ozone layer depletion | kg CFC-11eq | 1.57 × 10−7 | 4.97 × 10−7 |

| Non-carcinogens | kg C2H3Cl eq | 0.02 | 0.05 |

| Carcinogens | kg C2H3Cl eq | 0.08 | 0.24 |

| Ionizing radiation | Bq C-14 eq | 1.94 | 6.14 |

| Respiratory organics | kg C2H4 eq | 3.84 × 10−4 | 1.39 × 10−3 |

| Respiratory inorganics | kg PM2.5eq | 4.40 × 10−4 | 1.21 × 10−3 |

| Aquatic ecotoxicity | kg TEG water | 68.07 | 215.16 |

| Terrestrial ecotoxicity | kg TEG soil | 12.71 | 40.16 |

| Aquatic eutrophication | kg PO4 P-lim | 3.28 × 10−5 | 1.04 × 10−4 |

| Terrestrial acid/nutri | kg SO2eq | 0.007 | 0.02 |

| Land occupation | m2org.arable | 0.009 | 0.03 |

| Aquatic acidification | kg SO2eq | 0.002 | 0.01 |

| Off-Site | On-Site | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electricity | Natural Gas | Transportation | On-Factory | |||||||||

| Damage Category | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted | Damage Assessment | Normalized | Weighted |

| Human health | 3.78 × 10−8 DALY | 2.53 × 10−6 | 5.23 | 3.20 × 10−7 DALY | 4.51 × 10−5 | 45.07 | 1.28 × 10−7 DALY | 1.80 × 10−5 | 17.98 | 4.46 × 10−8 DALY | 6.29 × 10−6 | 6.29 |

| Ecosystem quality | 3.95 × 10−3 PDF.m2.yr | 2.8 × 10−7 | 0.29 | 3.46 × 10−2 PDF.m2.yr | 2.53 × 10−6 | 2.53 | 8.08 × 10−2 PDF.m2.yr | 5.89 × 10−6 | 5.89 | 2.02 × 10−3 PDF.m2.yr | 1.47 × 10−7 | 0.15 |

| Climate change | 0.06 kg CO2eq | 6.28 × 10−6 | 6.28 | 0.13 kg CO2eq | 1.35 × 10−5 | 13.48 | 0.17 kg CO2eq | 1.75 × 10−5 | 17.52 | 1.00 kg CO2eq | 1.01 × 10−4 | 100.91 |

| Resource depletion | 1.08 MJ | 7.12 × 10−6 | 7.12 | 22.57 MJ | 1.49 × 10−4 | 148.52 | 2.75 MJ | 1.81 × 10−5 | 18.09 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikkhah, A.; Firouzi, S.; Dadaei, K.; Van Haute, S. Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods 2021, 10, 590. https://doi.org/10.3390/foods10030590

Nikkhah A, Firouzi S, Dadaei K, Van Haute S. Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods. 2021; 10(3):590. https://doi.org/10.3390/foods10030590

Chicago/Turabian StyleNikkhah, Amin, Saeed Firouzi, Keyvan Dadaei, and Sam Van Haute. 2021. "Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel" Foods 10, no. 3: 590. https://doi.org/10.3390/foods10030590

APA StyleNikkhah, A., Firouzi, S., Dadaei, K., & Van Haute, S. (2021). Measuring Circularity in Food Supply Chain Using Life Cycle Assessment; Refining Oil from Olive Kernel. Foods, 10(3), 590. https://doi.org/10.3390/foods10030590