Oat Protein Concentrates with Improved Solubility Produced by an Enzyme-Aided Ultrafiltration Extraction Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Optimization of Protein-Glutaminase Deamidation and Protein Solubilization

2.3. Deamidation Degree and Protein Solubility

2.4. The Batchwise Enzyme-Aided Extraction of Oat Proteins with Optimized Deamidation Parameters in a Pilot-Scale

2.5. Characteristics and Functionality of Oat Protein Concentrates

2.5.1. Proximate Composition of the Raw Material and Oat Protein Concentrations

2.5.2. Characterization of Proteins

2.5.3. Protein Solubility

2.5.4. Preparation of Heat-Induced Gels

2.5.5. Rheological Measurements

2.6. Statistical Analysis

3. Results and Discussion

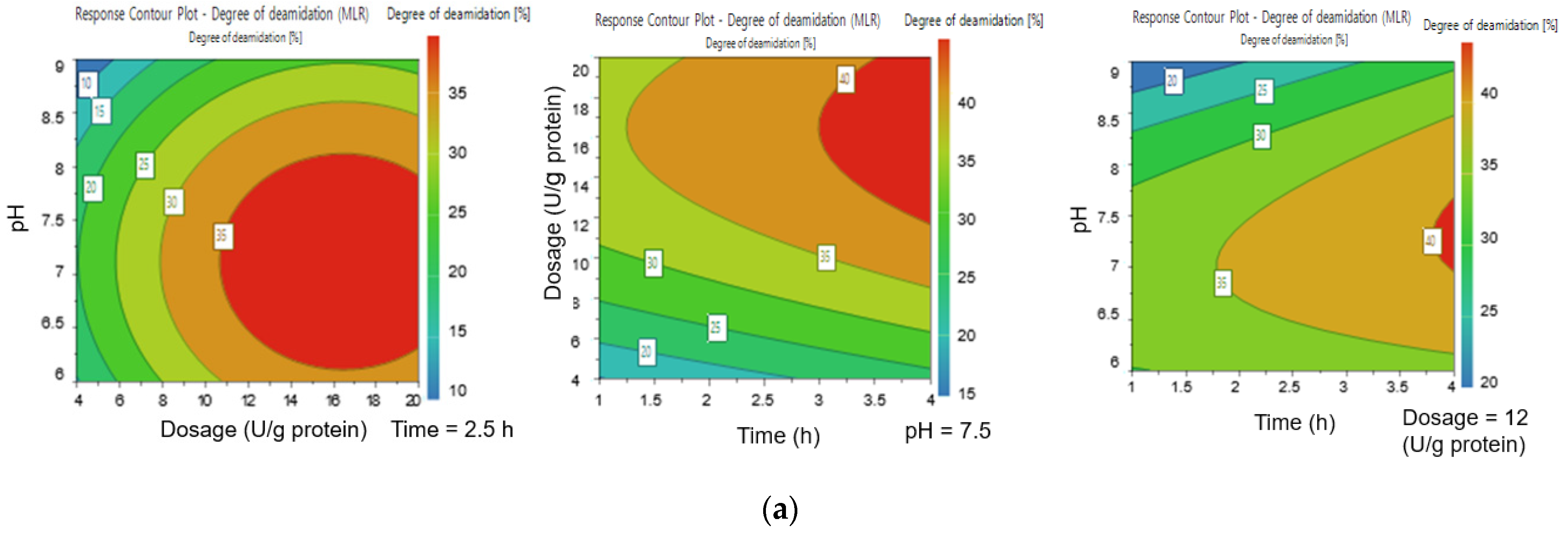

3.1. Optimization of PG Deamidation and Protein Solubility of Oat Protein

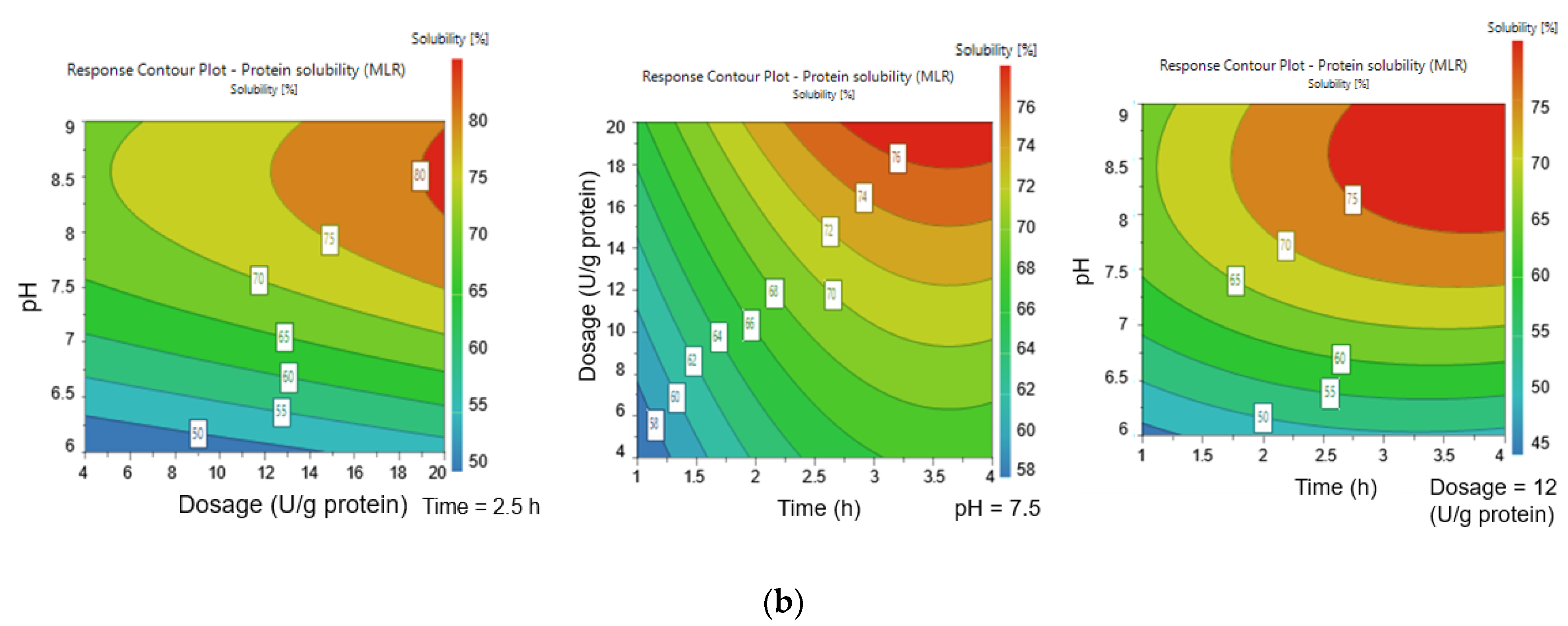

3.2. The Batchwise Enzyme-Aided Extraction of Oat Proteins at Pilot-Scale

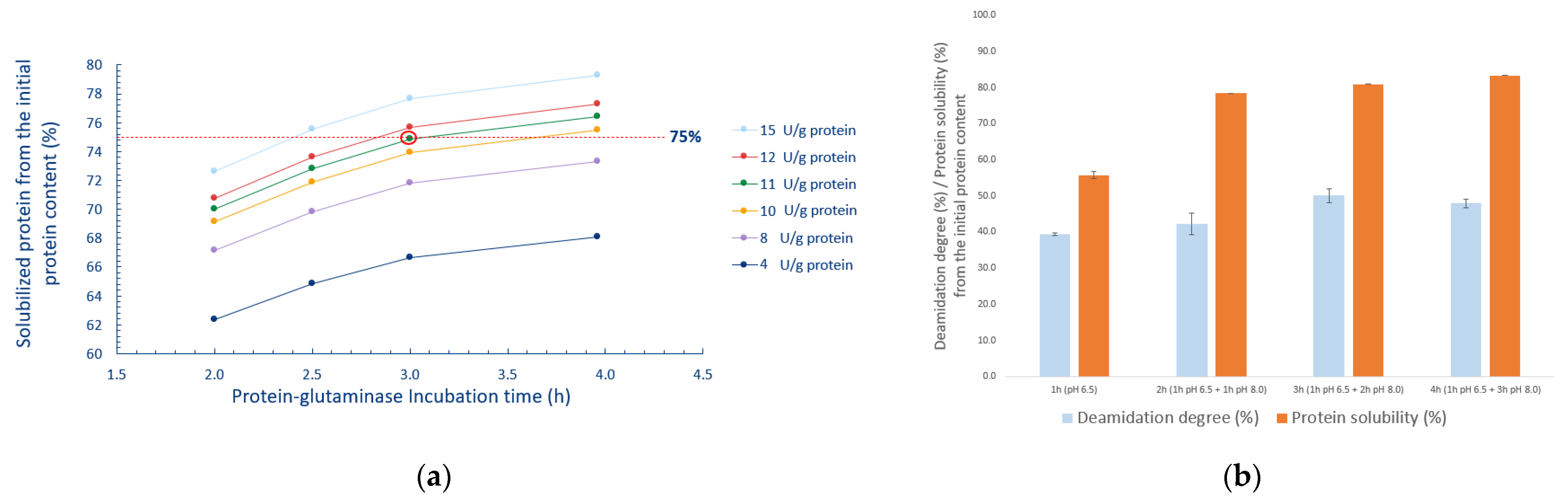

3.3. Characterization of Oat Proteins

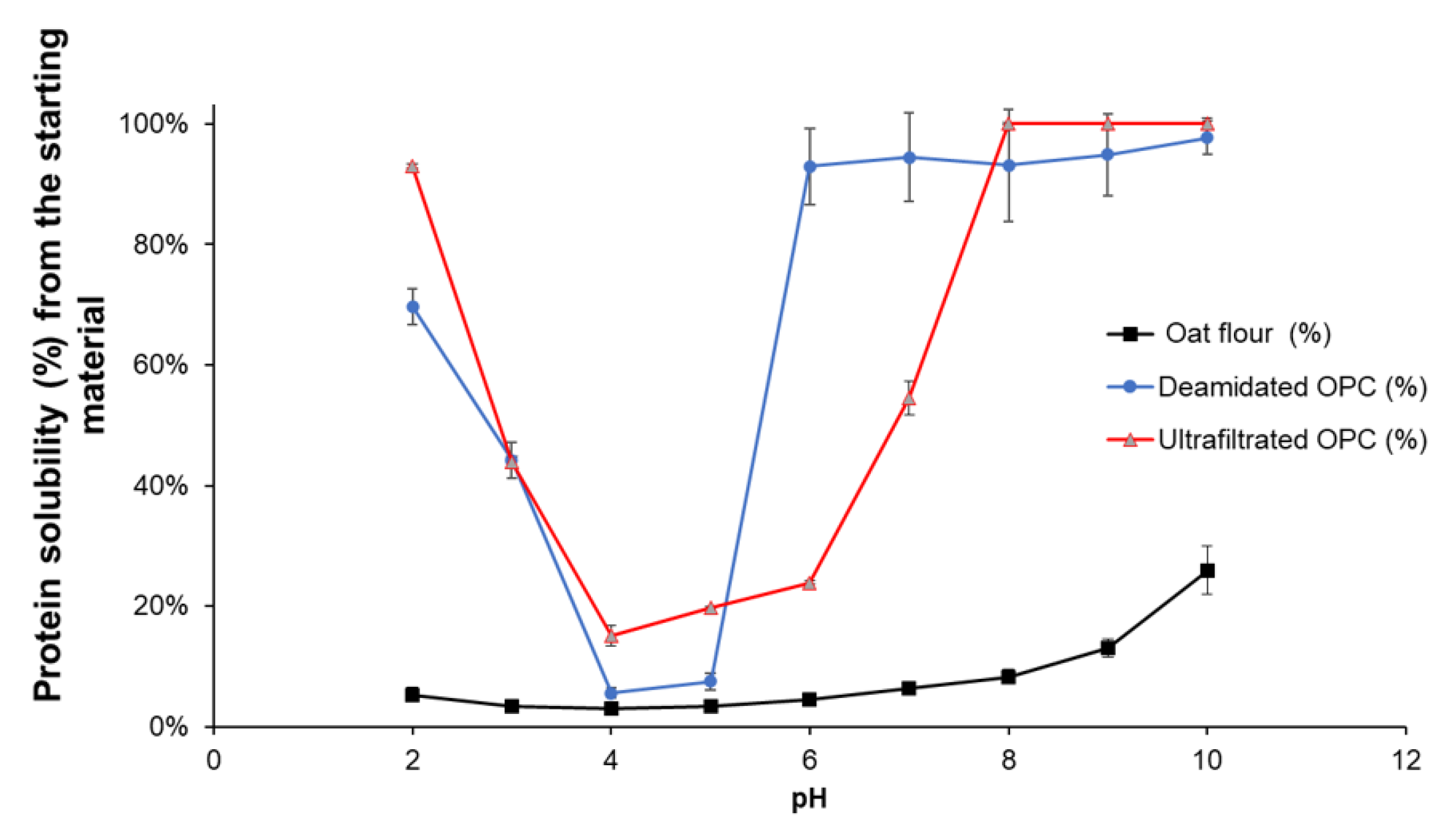

3.4. Solubility of the Oat Protein Concentrates as a Function of pH

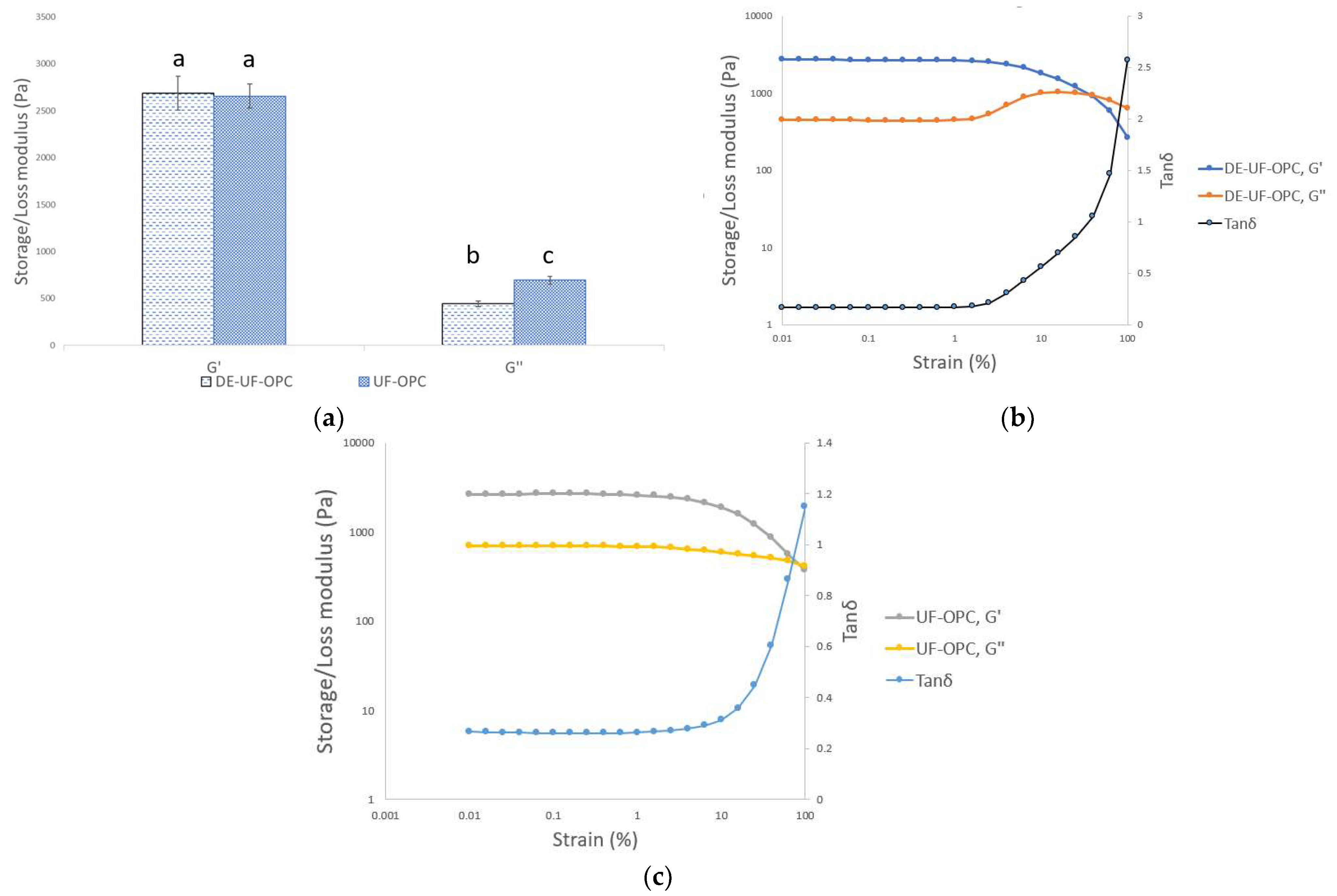

3.5. Rheological Properties of Heat-Induced Oat Protein Concentrate Gels

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peterson, D. Storage proteins. In Oats Chemistry and Technology; Webster, F., Wood, P., Eds.; AACC International: St. Paul, MI, USA, 2011; Chapter 8; pp. 123–141. ISBN 978-1-891127-64-9. [Google Scholar]

- Youngs, V.L. Protein distribution in the oat kernel. Cereal Chem. 1972, 4, 407–411. [Google Scholar]

- Wu, Y.V.; Sexson, K.R.; Cavins, J.F.; Inglett, G.E. Oats and Their Dry-Milled Fractions. Protein Isolation and Properties of Four Varieties. J. Agric. Food Chem. 1972, 20, 757–761. [Google Scholar] [CrossRef]

- Chang, Y.-W.; Alli, I.; Konishi, Y.; Ziomek, E. Characterization of Protein Fractions from Chickpea (Cicer arietinum L.) and Oat (Avena sativa L.) Seeds Using Proteomic Techniques. Food Res. Int. 2011. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Sozer, N.; Ercili-Cura, D.; Poutanen, K. Protein from oat: Structure, Processes, Functionality, and Nutriotion. In Sustainable Protein Sources; Nadathur, S.R., Wanasundara, J.P.D., Scanlin, L., Eds.; Academic Press in an Imprint of Elsevier: Amsterdam, The Netherlands, 2017; Chapter 6; pp. 105–115. ISBN 978-0-12-802778-3. [Google Scholar]

- Wu, Y.V.; Sexson, K.R.; Cluskey, J.E.; Inglett, G.E. Protein Isolate from High-Protein Oats: Preparation, Composition and Properties. J. Food Sci. 1977, 42, 1383–1386. [Google Scholar] [CrossRef]

- Sibakov, J.; Myllymäki, O.; Holopainen, U.; Kaukovirta-Norja, A.; Hietaniemi, V.; Pihlava, J.M.; Poutanen, K.; Lehtinen, P. Lipid Removal Enhances Separation of Oat Grain Cell Wall Material from Starch and Protein. J. Cereal Sci. 2011, 54, 104–109. [Google Scholar] [CrossRef]

- Jodayree, S.; Smith, J.C.; Tsopmo, A. Use of Carbohydrase to Enhance Protein Extraction Efficiency and Antioxidative Properties of Oat Bran Protein Hydrolysates. Food Res. Int. 2012, 46, 69–75. [Google Scholar] [CrossRef]

- Ruiz, G.A.; Xiao, W.; van Boekel, M.; Minor, M.; Stieger, M. Effect of Extraction pH on Heat-Induced Aggregation, Gelation and Microstructure of Protein Isolate from Quinoa (Chenopodium quinoa Willd). Food Chem. 2016, 209, 203–210. [Google Scholar] [CrossRef]

- Gao, Z.; Shen, P.; Lan, Y.; Cui, L.; Ohm, J.-B.; Chen, B.; Rao, J. Effect of Alkaline Extraction PH on Structure Properties, Solubility, and Beany Flavor of Yellow Pea Protein Isolate. Food Res. Int. 2020, 131, 109045. [Google Scholar] [CrossRef]

- Tanger, C.; Engel, J.; Kulozik, U. Influence of Extraction Conditions on the Conformational Alteration of Pea Protein Extracted from Pea Flour. Food Hydrocoll. 2020, 107, 105949. [Google Scholar] [CrossRef]

- Sibakov, J.; Myllymäki, O.; Suortti, T.; Kaukovirta-Norja, A.; Lehtinen, P.; Poutanen, K. Comparison of Acid and Enzymatic Hydrolyses of Oat Bran β-Glucan at Low Water Content. Food Res. Int. 2013, 52, 99–108. [Google Scholar] [CrossRef]

- Arte, E.; Katina, K.; Holopainen-Mantila, U.; Nordlund, E. Effect of Hydrolyzing Enzymes on Wheat Bran Cell Wall Integrity and Protein Solubility. Cereal Chem. 2016, 93, 162–171. [Google Scholar] [CrossRef]

- Prosekov, A.; Babich, O.; Kriger, O.; Ivanova, S.; Pavsky, V.; Sukhikh, S.; Yang, Y.; Kashirskih, E. Functional Properties of the Enzyme-Modified Protein from Oat Bran. Food Biosci. 2018, 24, 46–49. [Google Scholar] [CrossRef]

- Loponen, J.; Laine, P.; Sontag-Strohm, T.; Salovaara, H. Behaviour of Oat Globulins in Lactic Acid Fermentation of Oat Bran. Eur. Food Res. Technol. 2007, 225, 105–110. [Google Scholar] [CrossRef]

- Zhao, C.-B.; Zhang, H.; Xu, X.-Y.; Cao, Y.; Zheng, M.-Z.; Liu, J.-S.; Wu, F. Effect of Acetylation and Succinylation on Physicochemical Properties and Structural Characteristics of Oat Protein Isolate. Process Biochem. 2017, 57, 117–123. [Google Scholar] [CrossRef]

- Jiang, Z.; Sontag-Strohm, T.; Salovaara, H.; Sibakov, J.; Kanerva, P.; Loponen, J. Oat Protein Solubility and Emulsion Properties Improved by Enzymatic Deamidation. J. Cereal Sci. 2015, 64, 126–132. [Google Scholar] [CrossRef]

- Mirmoghtadaie, L.; Kadivar, M.; Shahedi, M. Effects of Succinylation and Deamidation on Functional Properties of Oat Protein Isolate. Food Chem. 2009, 114, 127–131. [Google Scholar] [CrossRef]

- Brückner-Gühmann, M.; Heiden-Hecht, T.; Sözer, N.; Drusch, S. Foaming Characteristics of Oat Protein and Modification by Partial Hydrolysis. Eur. Food Res. Technol. 2018, 244, 2095–2106. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Jeenes, D.J.; Archer, D.B. Protein-Glutaminase from Chryseobacterium proteolyticum, an Enzyme That Deamidates Glutaminyl Residues in Proteins: Purification, Characterization and Gene Cloning. Eur. J. Biochem. 2001, 268, 1410–1421. [Google Scholar] [CrossRef]

- Xiaoping, Z.; Yinmao, D.; Yonggua, L.; Yan, S.; Qing, R. Separation of oat protein hollow fiber ultrafiltration membrane and cleaning method. Trans. Chin. Soc. Agric. Eng. 2010, 26, 332–340. [Google Scholar]

- Каширскихшиpcких, E.; Kashirskich, E.; Бaбич, O.; Babich, O.; Kpигep, O.; Kriger, O. Production Technology for Oat Protein with Advanced Physicochemical, Functional, and Technological Properties. Food Process. Tech. Technol. 2019, 49, 216–226. [Google Scholar] [CrossRef]

- Yong, Y.H.; Yamaguchi, S.; Gu, Y.S.; Mori, T.; Matsumura, Y. Effects of Enzymatic Deamidation by Protein-Glutaminase on Structure and Functional Properties of α-Zein. J. Agric. Food Chem. 2004, 52, 7094–7100. [Google Scholar] [CrossRef] [PubMed]

- Rosa-Sibakov, N.; Re, M.; Karsma, A.; Laitila, A.; Nordlund, E. Phytic Acid Reduction by Bioprocessing as a Tool To Improve the In Vitro Digestibility of Faba Bean Protein. J. Agric. Food Chem. 2018, 66, 10394–10399. [Google Scholar] [CrossRef]

- Suppavorasatit, I.; De Mejia, E.G.; Cadwallader, K.R. Optimization of the Enzymatic Deamidation of Soy Protein by Protein-Glutaminase and Its Effect on the Functional Properties of the Protein. J. Agric. Food Chem. 2011, 59, 11621–11628. [Google Scholar] [CrossRef] [PubMed]

- Kunarayakul, S.; Thaiphanit, S.; Anprung, P.; Suppavorasatit, I. Optimization of Coconut Protein Deamidation Using Protein-Glutaminase and Its Effect on Solubility, Emulsification, and Foaming Properties of the Proteins. Food Hydrocoll. 2018, 79, 197–207. [Google Scholar] [CrossRef]

- Gu, Y.S.; Matsumura, Y.; Yamaguchi, S.; Mori, T. Action of Protein-Glutaminase on α-Lactalbumin in the Native and Molten Globule States. J. Agric. Food Chem. 2001, 49, 5999–6005. [Google Scholar] [CrossRef] [PubMed]

- Hamada, J.S. Effects of Heat and Proteolysis on Deamidation of Food Proteins Using Peptidoglutaminase. J. Agric. Food Chem. 1992, 40, 719–723. [Google Scholar] [CrossRef]

- Konak, Ü.İ.; Ercili-Cura, D.; Sibakov, J.; Sontag-Strohm, T.; Certel, M.; Loponen, J. CO2-Defatted Oats: Solubility, Emulsification and Foaming Properties. J. Cereal Sci. 2014, 60, 37–41. [Google Scholar] [CrossRef]

- Ma, C.Y.; Harwalkar, V.R. Chemical Characterization and Functionality Assessment of Oat Protein Fractions. J. Agric. Food Chem. 1984, 32, 144–149. [Google Scholar] [CrossRef]

- Deleu, L.J.; Lambrecht, M.A.; Van de Vondel, J.; Delcour, J.A. The Impact of Alkaline Conditions on Storage Proteins of Cereals and Pseudo-Cereals. Curr. Opin. Food Sci. 2019, 25, 98–103. [Google Scholar] [CrossRef]

- Jarpa-Parra, M.; Bamdad, F.; Wang, Y.; Tian, Z.; Temelli, F.; Han, J.; Chen, L. Optimization of Lentil Protein Extraction and the Influence of Process PH on Protein Structure and Functionality. LWT Food Sci. Technol. 2014, 57, 461–469. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Dai, C.; He, R.; Ma, H. Alkali Extraction of Rice Residue Protein Isolates: Effects of Alkali Treatment Conditions on Lysinoalanine Formation and Structural Characterization of Lysinoalanine-Containing Protein. Food Chem. 2018, 261, 176–183. [Google Scholar] [CrossRef] [PubMed]

- Liukkonen, K. Improvement of Lipid Stability in Aqueous Processing of Oats. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, February 1994. [Google Scholar]

- Dyshlyuk, L.S.; Izgaryshev, A.V.; Garmashov, S.Y.; Sukhikh, A.; Kashirskih, E.V. Studying the Features of the Protein Extraction from Oat Grains. J. Pharm. Sci. 2017, 9, 6. [Google Scholar]

- Liu, J.; Guan, X.; Zhu, D.; Sun, J. Optimization of the Enzymatic Pretreatment in Oat Bran Protein Extraction by Particle Swarm Optimization Algorithms for Response Surface Modeling. LWT Food Sci. Technol. 2008, 41, 1913–1918. [Google Scholar] [CrossRef]

- Guan, X.; Yao, H. Optimization of Viscozyme L-Assisted Extraction of Oat Bran Protein Using Response Surface Methodology. Food Chem. 2008, 106, 345–351. [Google Scholar] [CrossRef]

- Walburg, G.; Larkins, B.A. Oat Seed Globulin: Subunit Characterization and Demonstration of Its Synthesis as a Precursor. Plant Physiol. 1983, 72, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Immonen, M.; Chandrakusuma, A.; Sibakov, J.; Poikelispää, M.; Sontag-Strohm, T. Texturization of a Blend of Pea and Destarched Oat Protein Using High-Moisture Extrusion. Foods 2021, 10, 1517. [Google Scholar] [CrossRef] [PubMed]

- Nieto Nieto, T.V.; Wang, Y.; Ozimek, L.; Chen, L. Improved Thermal Gelation of Oat Protein with the Formation of Controlled Phase-Separated Networks Using Dextrin and Carrageenan Polysaccharides. Food Res. Int. 2016, 82, 95–103. [Google Scholar] [CrossRef]

- Brückner-Gühmann, M.; Kratzsch, A.; Sozer, N.; Drusch, S. Oat Protein as Plant-Derived Gelling Agent: Properties and Potential of Modification. Future Foods 2021, 4, 100053. [Google Scholar] [CrossRef]

- Yang, J.; Zamani, S.; Liang, L.; Chen, L. Extraction Methods Significantly Impact Pea Protein Composition, Structure and Gelling Properties. Food Hydrocoll. 2021, 117, 106678. [Google Scholar] [CrossRef]

- Kornet, R. Less Is More: Limited Fractionation Yields Stronger Gels for Pea Proteins. Food Hydrocoll. 2021, 112, 106285. [Google Scholar] [CrossRef]

- Nivala, O.; Nordlund, E.; Kruus, K.; Ercili-Cura, D. The Effect of Heat and Transglutaminase Treatment on Emulsifying and Gelling Properties of Faba Bean Protein Isolate. LWT Food Sci Technol. 2021, 139, 110517. [Google Scholar] [CrossRef]

- Bi, C.; Wang, L.; Li, D.; Huang, Z.; Adhikari, B.; Chen, X.D. Non-Linear Rheological Properties of Soy Protein Isolate Dispersions and Acid-Induced Gels. Int. J. Food Eng. 2017, 13. [Google Scholar] [CrossRef]

- Böni, L.; Rühs, P.A.; Windhab, E.J.; Fischer, P.; Kuster, S. Gelation of Soy Milk with Hagfish Exudate Creates a Flocculated and Fibrous Emulsion- and Particle Gel. PLoS ONE 2016, 11, e0147022. [Google Scholar] [CrossRef] [Green Version]

- Hyun, K.; Kim, S.H.; Ahn, K.H.; Lee, S.J. Large Amplitude Oscillatory Shear as a Way to Classify the Complex Fluids. J. Non-Newtonian Fluid Mech. 2002, 107, 51–65. [Google Scholar] [CrossRef]

| Design Points | Independent Variables | Dependent Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| NO. | x1 | x2 | x3 | Time | pH | PG Dosage | DD | PS |

| 1 | −1 | −1 | −1 | 1 | 6 | 4 | 13.7 | 40.8 |

| 2 | +1 | −1 | −1 | 4 | 6 | 4 | 15.1 | 47.4 |

| 3 | −1 | +1 | −1 | 1 | 9 | 4 | 0.0 | 58.0 |

| 4 | +1 | +1 | −1 | 4 | 9 | 4 | 9.7 | 71.1 |

| 5 | −1 | −1 | +1 | 1 | 6 | 20 | 33.1 | 47.4 |

| 6 | +1 | −1 | +1 | 4 | 6 | 20 | 35.2 | 49.8 |

| 7 | −1 | +1 | +1 | 1 | 9 | 20 | 14.2 | 67.8 |

| 8 | +1 | +1 | +1 | 4 | 9 | 20 | 28.3 | 83.3 |

| 9 | −1 | 0 | 0 | 1 | 7.5 | 12 | 27.7 | 58.8 |

| 10 | +1 | 0 | 0 | 4 | 7.5 | 12 | 43.5 | 74.3 |

| 11 | 0 | −1 | 0 | 2.5 | 6 | 12 | 28.9 | 48.2 |

| 12 | 0 | +1 | 0 | 2.5 | 9 | 12 | 25.6 | 75.2 |

| 13 | 0 | 0 | −1 | 2.5 | 7.5 | 4 | 20.0 | 58.0 |

| 14 | 0 | 0 | +1 | 2.5 | 7.5 | 20 | 37.2 | 75.2 |

| 15 | 0 | 0 | 0 | 2.5 | 7.5 | 12 | 37.5 | 73.5 |

| 16 | 0 | 0 | 0 | 2.5 | 7.5 | 12 | 35.5 | 71.1 |

| 17 | 0 | 0 | 0 | 2.5 | 7.5 | 12 | 35.3 | 71.9 |

| Deamidation Degree | Coefficient | p-Value | ||

|---|---|---|---|---|

| Constant | 36.094 | 1.804 × 10−11 | Q2 = 0.904 | |

| x1 (Time) | 4.3100 | 0.000496 | R2 = 0.968 | |

| x2 (pH) | −4.8200 | 0.000211 | R2 adj. = 0.949 | |

| x3 (Dosage) | 8.9500 | 1.019 × 10−6 | ||

| x2 × x2 (pH × pH) | −9.3301 | 0.000128 | Cond. no. = 3.978 | |

| x3 × x3 (Dosage × Dosage) | −7.9801 | 0.000431 | RSD = 2.697 | |

| x1 × x3 (Time × Dosage) | 2.5375 | 0.023848 | Confidence = 0.95 | |

| Protein Solubility | Coefficient | p-Value | ||

| Constant | 1.8434 | 1.564 × 10−19 | Q2 = 0.913 | |

| x1 (Time) | 0.0366 | 0.000300 | R2 = 0.967 | |

| x2 (pH) | 0.0900 | 1.109 × 10−7 | R2 adj. = 0.947 | |

| x3 (Dosage) | 0.0335 | 0.000572 | ||

| x1 × x1 (Time × Time) | −0.0246 | 0.073512 * | Cond. no. = 3.978 | |

| x2 × x2 (pH × pH) | −0.0651 | 0.000351 | RSD = 0.02143 | |

| x1 × x3 (Time × Dosage) | 0.0114 | 0.162965 * | Confidence = 0.95 | |

| Sample | Protein (%) | Fat (%) | Ash (%) | Starch (%) | Glucose (%) | Moisture (%) |

|---|---|---|---|---|---|---|

| Oat flour | 12.8 ± 0.1 a | 8.2 ± 0.1 d | 1.8 ± 0.0 g | 49.0 ± 1.1 | - | 8.1 ± 0.0 |

| Ultrafiltered oat protein concentrate | 45.0 ± 0.1 b | 27.6 ± 0.1 e | 2.9 ± 0.0 h | 2.5 ± 0.0 | 4.0 ± 0.0 | 1.7 ± 0.0 |

| Deamidated and ultrafiltered oat protein concentrate | 52.4 ± 0.6 c | 22.3 ± 0.1 f | 3.0 ± 0.1 h | 2.4 ± 0.2 | 6.7 ± 0.1 | 2.0 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Immonen, M.; Myllyviita, J.; Sontag-Strohm, T.; Myllärinen, P. Oat Protein Concentrates with Improved Solubility Produced by an Enzyme-Aided Ultrafiltration Extraction Method. Foods 2021, 10, 3050. https://doi.org/10.3390/foods10123050

Immonen M, Myllyviita J, Sontag-Strohm T, Myllärinen P. Oat Protein Concentrates with Improved Solubility Produced by an Enzyme-Aided Ultrafiltration Extraction Method. Foods. 2021; 10(12):3050. https://doi.org/10.3390/foods10123050

Chicago/Turabian StyleImmonen, Mika, Julia Myllyviita, Tuula Sontag-Strohm, and Päivi Myllärinen. 2021. "Oat Protein Concentrates with Improved Solubility Produced by an Enzyme-Aided Ultrafiltration Extraction Method" Foods 10, no. 12: 3050. https://doi.org/10.3390/foods10123050

APA StyleImmonen, M., Myllyviita, J., Sontag-Strohm, T., & Myllärinen, P. (2021). Oat Protein Concentrates with Improved Solubility Produced by an Enzyme-Aided Ultrafiltration Extraction Method. Foods, 10(12), 3050. https://doi.org/10.3390/foods10123050