3.2. Optimal Roasting and Smoking Conditions of APR

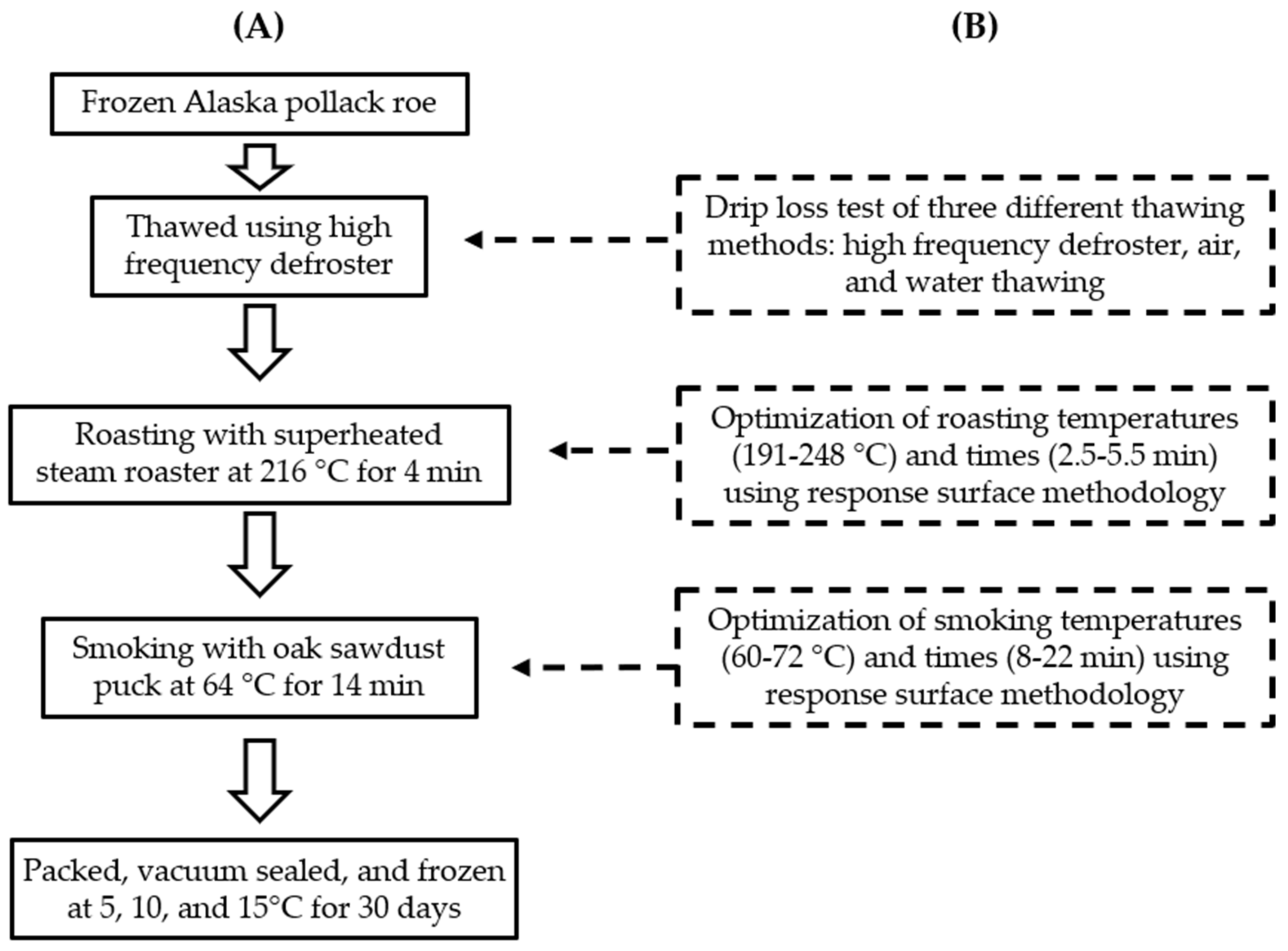

Optimal roasting and smoking conditions were analyzed using the RSM. Several combinations of processing temperature (X

1) and time (X

2) were set as independent variables, while sensorial properties were set as dependent variables (Y). The design of the experiment and sensorial property response (appearance, aroma, taste, texture, and OA) are shown in

Table 3.

The sensorial properties were analyzed to obtain the model equation. Initially, response surface regression analysis was performed using a full quadratic model. The models were determined based on the significance of ANOVA in response surface regression. Therefore, only statistically significant (

p < 0.05) responses and terms were further tested for model determination. The models and their fitness values are listed in

Table 4. The full quadratic models were not significant for the interaction term. Thus, the predictive models were re-tested by removing these interactions. All responses showed a significant linear quadratic model, except for the appearance of smoke-roasted APR, indicating that smoking did not result in significant differences in appearance among the various smoking conditions in this study. The roasting treatment of APR showed different responses for all sensory properties. The coefficient of determination (R

2) indicates the level of model fit to the response data [

36]. Texture had the lowest R

2 value in both roasted and smoke-roasted APRs, implying that different combinations of roasting and smoking temperature and time had less effect on texture than on other sensory properties. Compared with aroma and texture, the appearance, taste, and OA of roasted APR had a greater R

2, indicating that roasting APR substantially influenced these variables.

Since appearance did not significantly differ in the smoking treatment, the corresponding predictive model was not built in the optimization process. In contrast to roasting, smoking gave high R

2 values not only for taste and OA, but also for aroma. The purpose of smoking is to provide a distinctive aroma and taste experience, leading to an increase in the OA score when evaluating sensorial properties [

16,

37]. The

p-value for the model’s lack of fit in

Table 4 was not significant (

p > 0.05). Thus, the developed models accurately predicted the optimal temperature and time for both roasting and smoking.

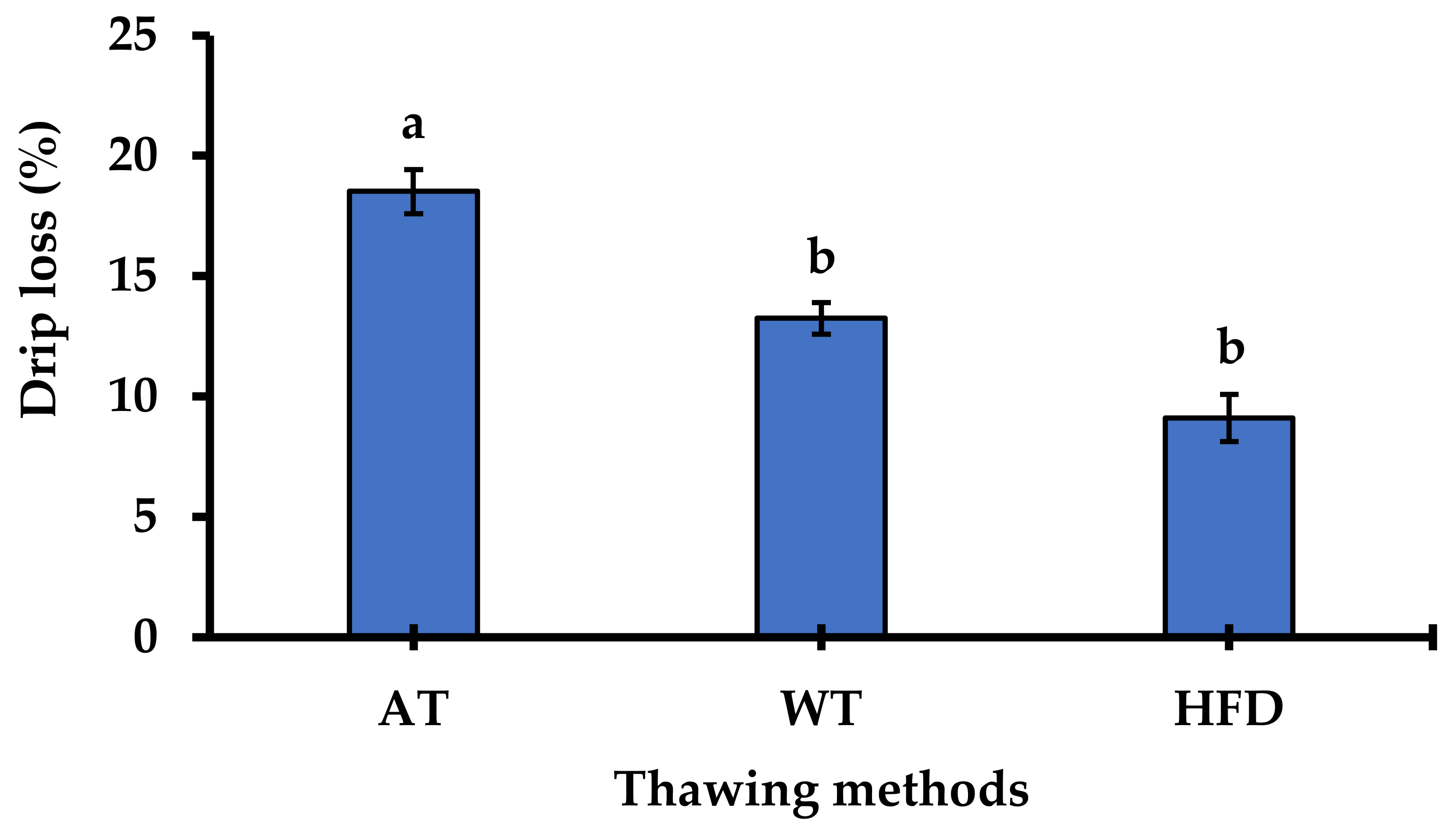

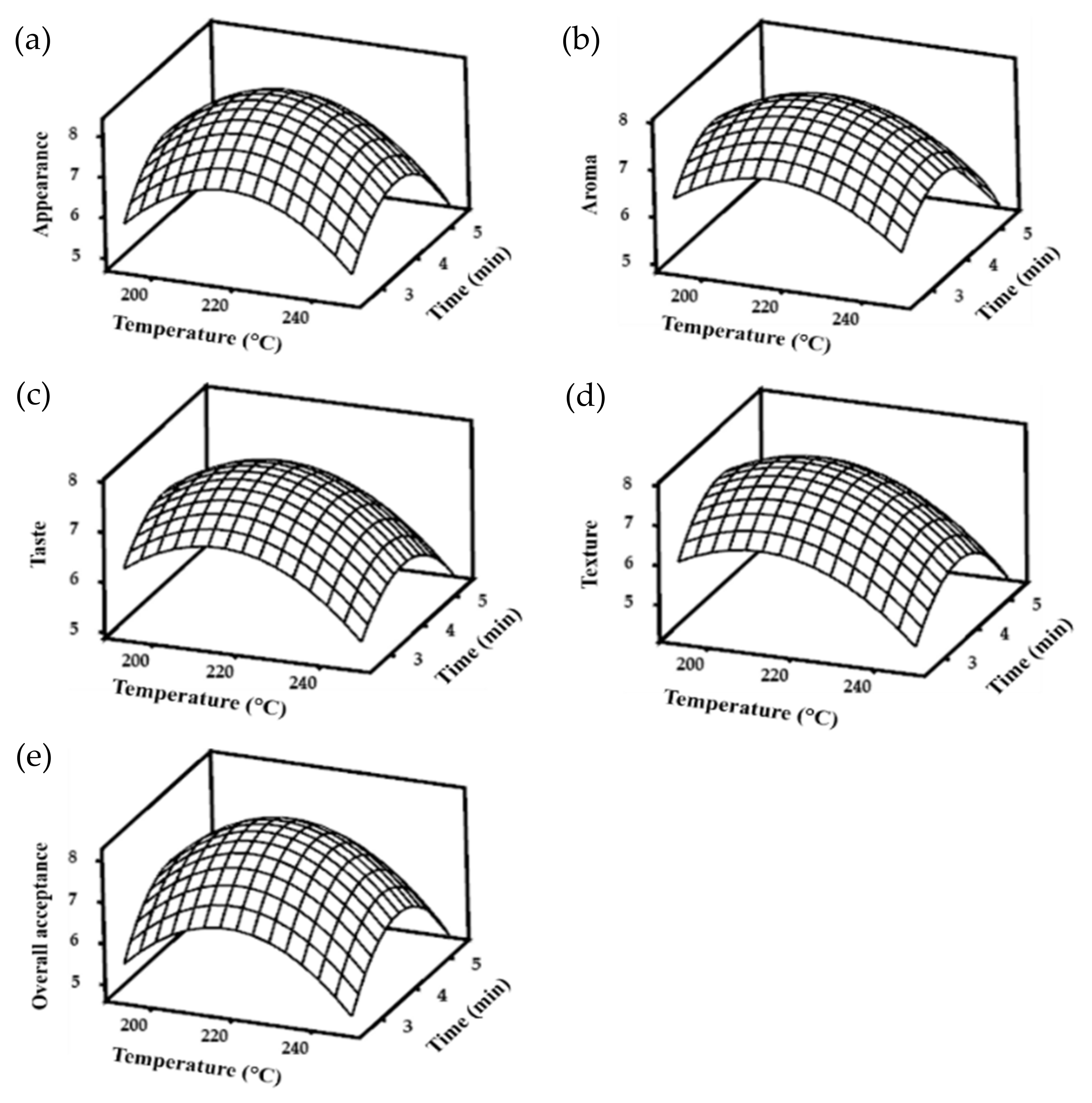

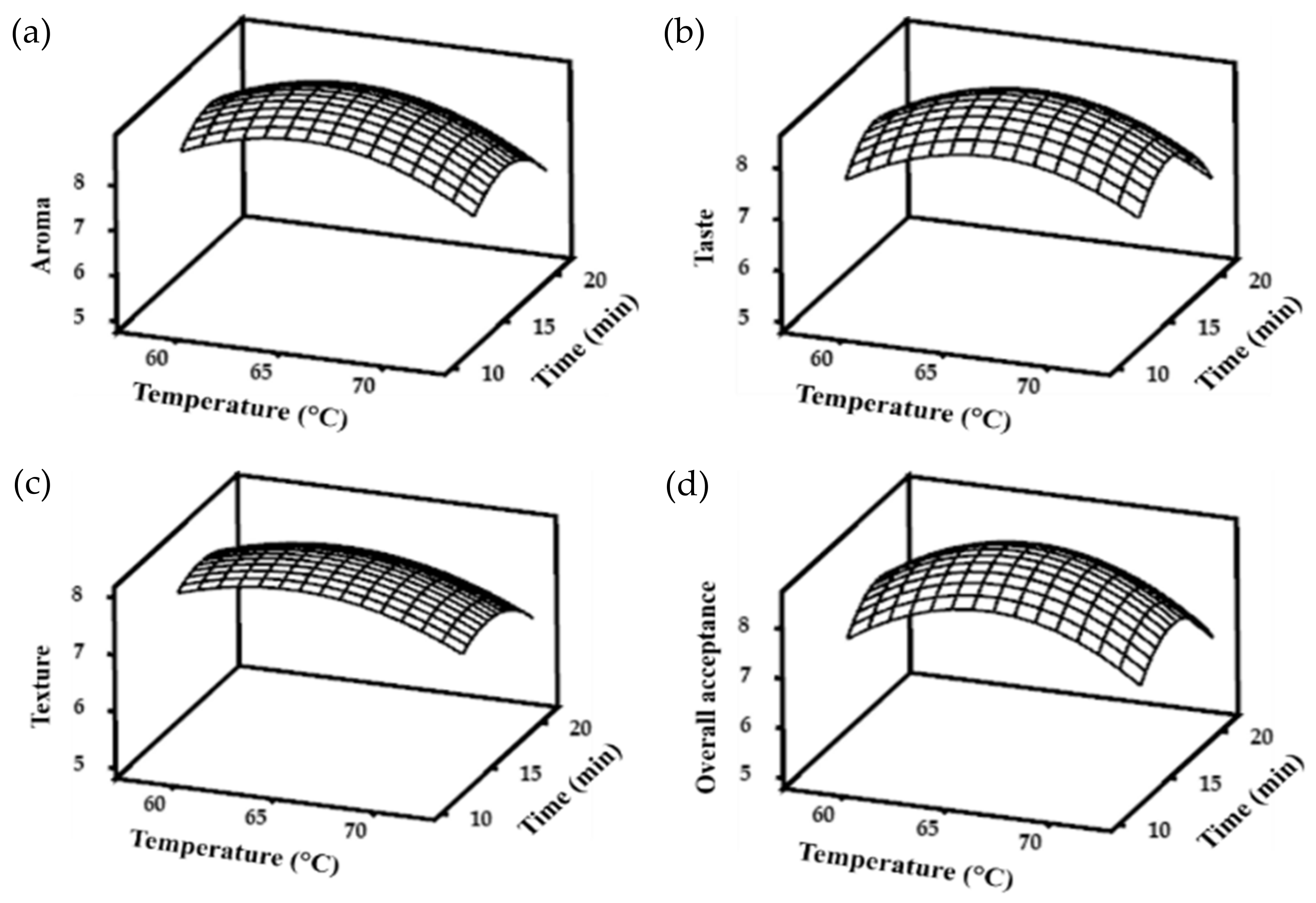

The predictive models were used to build the three-dimensional response wireframe graph of sensory properties of roasted and smoke-roasted APR. These graphs show the relationship between the temperature and time settings used for both roasted and smoke-roasted APR. Roasting at shorter time intervals resulted in undercooked APR and low sensorial scores (

Figure 3). Undercooked conditions might cause a fishy taste and aroma APR, while overcooking might produce a bitter taste and burnt aroma. Similarly, the smoke-roasted APR developed lower sensorial scores with longer times and temperatures of smoking (

Figure 4). This might be due to the product accumulating substances from combustion. In addition, the product could get dryer and its texture might be altered.

To obtain optimal roasting and smoking conditions, the analysis was performed using the Response Optimizer in the Minitab program for significant model responses. The optimal roasting conditions were 215.8 °C for 3.9 min, rounded to 216 °C for 4 min following the available setting on the SSR. The samples were roasted under optimal conditions for the optimization of smoking conditions. The optimal smoking conditions were obtained at 64.4 °C for 13.8 min, rounded to 64 °C for 14 min.

3.3. Nutritional Composition

The nutritional composition of smoke-roasted APR was evaluated and compared with that of seasoned raw APR based on proximate (

Table 5), amino acid (

Table 6), and fatty acid (

Table 7) compositions. The 14 dietary ingredients were evaluated as recommended by the US Food and Drug Administration for nutritional labeling. The results show that seasoned raw and smoke-roasted APR did not contain sugars, trans fat, dietary fiber, or vitamin D. The processing of APR by roasting and smoking increased all measured dietary ingredients due to an increase in dry matter. The roasting treatment decreased the APR moisture as a pre-smoking treatment to prolong shelf life [

17]. The highest nutrient content in both seasoned raw and smoke-roasted APR was protein. Consuming 100 g of smoke-roasted APR provides up to 60% of the daily protein needs; the protein content of seasoned raw APR (22%) was higher than that previously reported (19%) [

8,

9]. The nutritional composition of roe can be affected by roe species and maturity, fish environment, and processing conditions. In addition, different environmental factors impact diet composition and, as a result, influence roe content [

10,

38]. Park et al. [

39] showed that the protein content of APR ranged from 17.27 to 21.79%, with larger APR having higher protein content. The fat content of APR (2.8%) is lower than that of salmon (12.7%), caviar (14.6–15.9%), and mullet (36.8%) [

1]. Salmon produces high-fat and -protein roe to provide a consistent supply of nutrients to newborns for extended periods in nutrient-poor environments. However, marine fish roe, such as APR, have little nutrient storage owing to their high-nutrient environment [

9].

The development of ready-to-eat APR in the present study resulted in lower sodium levels than processing by salting and fermentation (3.6–7.0%) [

13,

41]. The sodium content of seasoned raw and smoke-roasted APR was 0.15 and 0.22%, respectively. The seasoned raw APR in this study had a lower sodium level than that reported by Vasconi et al. [

9]. This might be due to pre-treatment during seasoning, which involved washing and disinfection treatments. The salt content in smoke-roasted APR contributed 9.8% of the daily value, making smoke-roasted APR a good protein source with a low risk of diseases associated with high salt intake.

The amino acid profile, both essential and non-essential, of smoke-roasted APR showed an increasing trend similar to that of protein content. The essential amino acids of raw and processed APR were lower than those of the non-essential amino acids (

Table 6). The total amino acid content of raw APR (20%) was similar to that reported in previous studies [

12]. Smoke-roasted APR is rich in leucine, lysine, alanine, aspartic acid, and glutamic acid. These amino acid contents are commonly high in fish roes, as reported by Mol et al. [

1]. The leucine content of seasoned raw APR (1.9%) was higher than that of various caviars (0.28–0.37%), red salmon roe (0.46%), and mullet roe (0.33%), but the lysine content was 41–75% lower than that of other roes. The aspartic acid (1.6%) and glutamic acid (2.9%) contents in seasoned raw APR were lower than those in other fish roes (2.9–3.3% and 4.5–4.9%, respectively). The differences in these contents are related to the species and age of the fish and roe, and the fish habitat [

1], and are increased by roasting and smoking treatments due to the increase in dry matter. The high aspartic and glutamic acid content in smoke-roasted APR might contribute to the umami and sweet tastes [

41]. Furthermore, Lee [

13] found that processed APR with a high amino nitrogen content also had a high sensory attribute score.

The 4.3% fat content of smoke-roasted APR consisted of fats good for human consumption. As shown in

Table 7, almost 50% of the fat consisted of polyunsaturated fatty acids (PUFAs). EPA and DHA are the major fatty acids in APR, thereby increasing PUFA content. Other major fatty acids were palmitic and oleic acids, such as saturated fatty acids (SFA) and monounsaturated fatty acids (MUFAs), respectively. Comparable results were reported by Mol and Turan [

1], who observed that fish roe fatty acids are highly abundant in palmitic and oleic acids, EPA, and DHA. The total ꞷ-3 fatty acids of raw and processed APR were 44.32–44.34%, while total ꞷ-6 was 2.01–2.17%. The high total amount of ꞷ-3 fatty acids resulted in a low ꞷ-6 and ꞷ-3 ratio (0.045–0.049). These conditions are favorable for the human diet because higher ꞷ-6 and ꞷ-3 ratios have the potential to increase the risk of cardiovascular, inflammatory, and autoimmune diseases [

42]. Therefore, healthy diets are recommended to have a ꞷ-6 to ꞷ-3 ratio of 1–4 or below [

43]. The fatty acid composition showed similar results after roasting and smoking treatments of seasoned raw APR.

3.4. Quality of Smoke-Roasted APR during Storage

The quality of smoke-roasted APR was indicated by OA, VBN, TBARS, and TBC. The changes in these indicators are shown in

Table 8. The quality of the product decreased significantly with increasing storage temperature and time (

p < 0.05). Sensory and microbial changes indicate product quality, which may affect the shelf life of processed fish [

44]. OA decreased significantly on day 14 of storage at temperatures of 5 and 10 °C, and decreased more rapidly on day 8 at a temperature of 15 °C. (

p < 0.05). These results show that storage temperatures less than 10 °C maintained better sensorial scores. The chemical and microbial properties of fish products are related to their sensory properties. Furthermore, during the storage period, microbial activity contributes to an unpleasant taste and aroma of the products [

45,

46]. The OA score represents sensory evaluation performed using a 9-point hedonic scale. The evaluation criteria were determined such that the initial quality level was 9 points and the quality limit was 5 points. However, the smoke-roasted APR showed an OA score of more than 5 during 30 days of storage, which is considered acceptable.

The VBN value of smoke-roasted APR increased significantly, compared with that of seasoned raw APR, from 21.80 to 25.86 mg% (

p < 0.05), indicating that the increasing VBN value was related to the roasting and smoking treatments. Thermal processing breaks down the protein in foods and increases its digestibility [

47]. Since protein breakdown is associated with the VBN value [

48], the high temperature during roasting and smoking could increase the VBN values in processed APR. The breakdown of proteins can also be caused by microbial and enzymatic activities [

49]. The presence of microbial activity might explain the increase in VBN values during storage in the present study.

Table 8 shows that the TBC increased during storage and is positively correlated with VBN values (

r = 0.745 by Pearson’s correlation). Jeong et al. [

50] reported that the VBN values of various grades of raw APR ranged from 15.7 to 28.2 mg%, consistent with the VBN values of APR before processing in the current study. The VBN values tended to increase rapidly at higher storage temperatures. After 30 days of storage, the VBN values of smoke-roasted APR refrigerated at 5 °C increased significantly, but increased more rapidly at 10 and 15 °C after 20 days (

p < 0.05). The assessment of spoilage based on the VBN value in fish is divided into several categories: perfect (5–10 mg%), good (15–25 mg%), and spoiled (>40 mg%) [

50]. Considering the aforementioned categories, only the sample on day 30 at a storage temperature of 15 °C had a VBN value indicating spoilage. Based on these categories, the shelf life of smoke-roasted APR was determined to have a quality limit of 40 mg%.

The TBARS value reflects the amount of malondialdehyde (MDA) produced by lipid oxidation; MDA generates a rancid flavor and is associated with the spoilage of meat and fish products [

51,

52]. The TBARS value of seasoned raw APR was 0.36 mg MDA/kg, which slightly increased (14%) after smoke-roasting treatment. Food processing time and temperature influences lipid oxidation [

53,

54]. The use of SSR in the current study facilitated the suppression of APR oxidation, resulting in a negligible increase in TBARS. SSR facilitates faster processing in oxygen-deficient environments, thus minimizing oxidation in foods [

55]. TBARS values increased gradually during storage, significantly increasing after 14 days at all storage temperatures (

p < 0.05). Yildiz [

56] categorized TBARS values in seafood into three categories: perfect (<3 mg MDA/kg), good (3–5 mg MDA/kg), and consumable limit (7–8 mg MDA/kg). TBARS values in the present study were low and thus categorized as perfect.

Smoking, charcoal grilling, and roasting are known as the potential sources of B

aP. B

aP is one of the carcinogenic polycyclic aromatic hydrocarbons (PAHs) formed by the combustion of wood in smoking process [

57]. In this study, B

aP content was not detected in the smoke-roasted APR. Further research is needed to evaluate the hazardous substances, such as acrylamide, heavy metals, and other PAHs contents, in APR treated by this method. Based on the European Union (EU) regulation, the maximum level of B

aP in smoked foods is limited to 5.0 µg/kg [

58]. As a result, the smoke-roasted APR in this study was considered safe.

Changes in microbial conditions may determine the safety of the food. In the present study, pathogenic microbes, including

E. coli, Salmonella spp. and

S. aureus, were not detected during storage at all temperatures. This indicates that raw material processing was performed hygienically. The microbial (TBC) change in smoke-roasted APR during 30 days of storage is shown in

Table 8. The TBC of seasoned raw APR significantly decreased (38.6%) after roasting and smoking treatments (

p < 0.05), but increased with storage time. The highest TBC value was 4.97 log CFU/g, contained in the sample at 15 °C after storage for 30 days. Vacuum packing, pasteurization, and low-temperature storage are some of the methods for reducing microbial activity [

17]. Microbial activity is slowed at lower temperatures; hence, temperature reduction reduces the development of spoilage-causing microbes [

59]. Unpasteurized smoke-roasted APR contained a TBC of more than 5 log CFU/g after 7 days of storage (data not shown). Farag et al. [

2] suggested that the pasteurization temperature for fish roe is between 50 and 70 °C due to its thermal sensitivity. Fish roe preserves its physical appearance within this temperature range, with no protein coagulation affecting protein quality. The smoke-roasted APR samples in the present study were packed under vacuum-pasteurized conditions. Therefore, the TBC values of all samples until 30 days of storage were less than 5 log CFU/g, which is considered safe for human consumption [

60]. Thus, the evaluation criteria for shelf life were determined at a TBC quality limit of 5 log CFU/g.

The shelf life of the smoke-roasted APR was estimated according to the changes in the quality indicators in

Table 8. As a result, the shelf life of smoke-roasted APR based on OA, VBN, TBARS, and TBC was 41.9, 30.3, 86.0, and 55.8 days. In addition, the shortest shelf life was selected from the calculated quality indicators to determine product shelf life. Accordingly, 30.3 days was selected as the shortest shelf life, which was multiplied by 0.82 as the safety factor. This safety factor considers temperature changes during distribution in the market [

30]. Therefore, the shelf life of the product was 24 days. Studies on changes in product quality in frozen storage could be considered for further research in order to obtain a longer shelf life.