Effect of Heat-Moisture Treatments on Digestibility and Physicochemical Property of Whole Quinoa Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Enzyme Solution

2.2. Preparation of Samples

2.3. Nutrient Composition Analysis

2.4. Digestibility In Vitro

2.5. Thermal Property

2.6. Crystalline Analysis

2.7. Granule Morphology

2.8. Statistical Analysis

3. Results and Discussion

3.1. The Effects of Different Treatments on the Nutrient Composition of WQ

3.2. The Effects of Different Treatments on the Digestibility In Vivo of WQ

3.3. The Effects of Different Treatments on the Thermal Property of WQ

3.4. The Effects of Different Treatments on the Crystalline Property of WQ

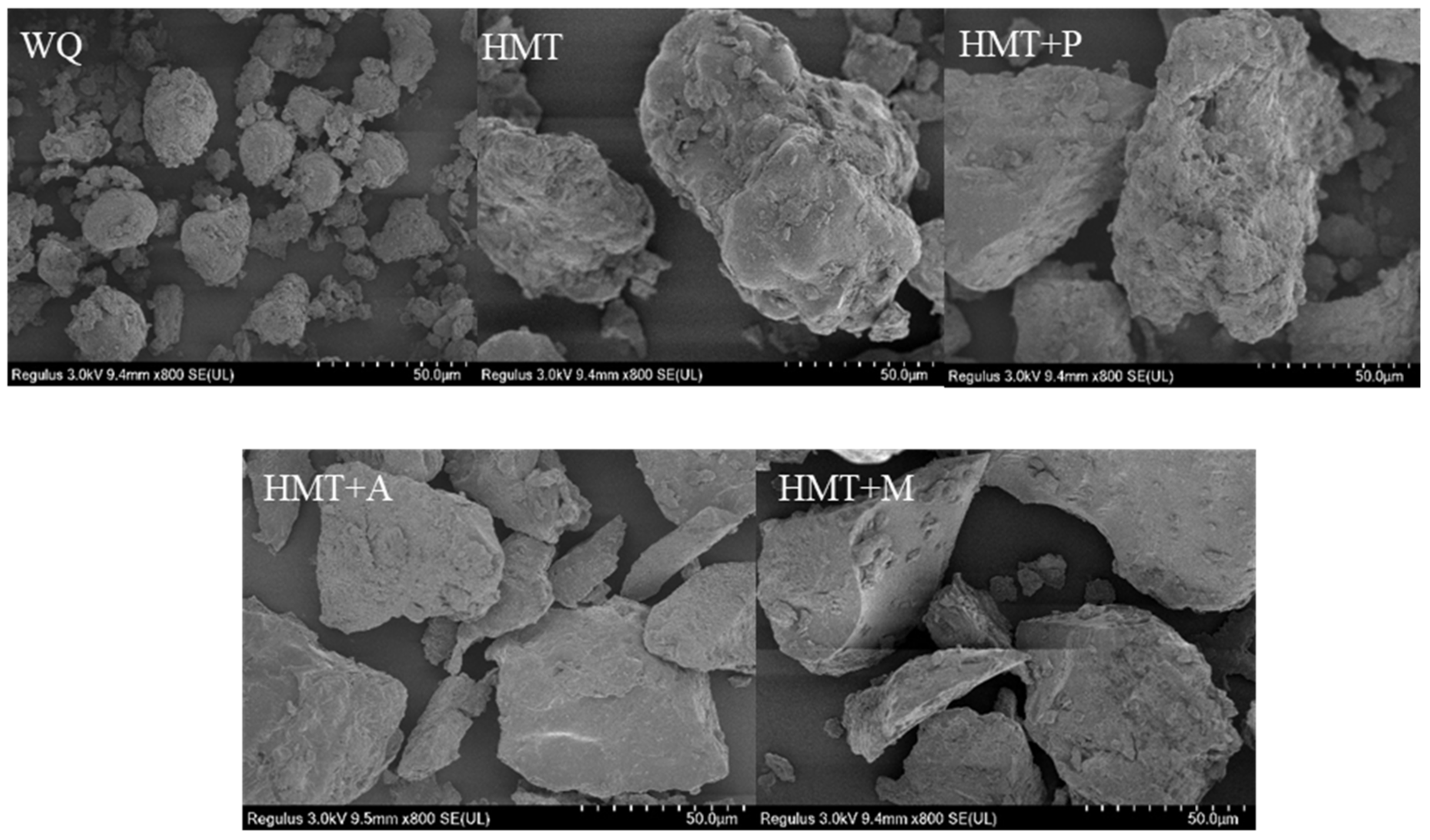

3.5. The Effects of Different Treatments on the Microstructure of WQ

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Williams, R.; Karuranga, S.; Malanda, B.; Saeedi, P.; Basit, A.; Besançon, S.; Bommer, C.; Esteghamati Alireza, O.K.; Zhang, P.; Colagiuri, S. Global and regional estimates and projections of diabetes-related health expenditure: Results from the International Diabetes Federation Diabetes Atlas, 9th edition. Diabetes Res. Clin. Pract. 2020, 162, 108072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aalim, H.; Belwal, T.; Wang, Y.; Luo, Z.; Hu, J. Purification and identification of rice bran (Oryza sativa L.) phenolic compounds with in-vitro antioxidant and antidiabetic activity using macroporous resins. Int. J. Food Sci. Technol. 2019, 54, 715–722. [Google Scholar] [CrossRef]

- Zhu, Y.; Dong, L.; Huang, L.; Shi, Z.; Shen, R. Effects of oat β-glucan, oat resistant starch, and the whole oat flour on insulin resistance, inflammation, and gut microbiota in high-fat-diet-induced type 2 diabetic rats. J. Funct. Foods 2020, 69, 103939. [Google Scholar] [CrossRef]

- Luo, K.; Zhang, G. Nutritional property of starch in a whole-grain-like structural form. J. Cereal Sci. 2018, 79, 113–117. [Google Scholar] [CrossRef]

- Oliveira, C.D.; Bet, C.D.; Bisinella, R.; Waiga, L.H.; Colman, T.; Schnitzler, E. Heat-moisture treatment (HMT) on blends from potato starch (PS) and sweet potato starch (SPS). J. Therm. Anal. Calorim. 2018, 133, 1491–1498. [Google Scholar] [CrossRef]

- Jacobs, H.; Delcour, J. Hydrothermal modifications of granular starch with retention of granular structure: A review. J. Agric. Food Chem. 1998, 46, 2895–2905. [Google Scholar] [CrossRef]

- Piecyk, M.; Domian, K. Effects of heat-moisture treatment conditions on the physicochemical properties and digestibility of field bean starch (Vicia faba var. minor). Int. J. Biol. Macromol. 2021, 182, 425–433. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Siroha, A.K.; Punia, S.; Nehra, M. Effect of heat moisture treatment on rheological and in vitro digestibility properties of pearl millet starches. Carbohydr. Polym. Technol. Appl. 2020, 1, 100002. [Google Scholar] [CrossRef]

- Asranudin Holilah Kholidha, S.A.N.; Setyo, P.A.; Ansharullah Ahmad, F. The effect of heat moisture treatment on crystallinity and physicochemical-digestibility properties of purple yam flour. Food Hydrocoll. 2021, 120, 106889. [Google Scholar] [CrossRef]

- Shaikh, F.; Ali, T.M.; Mustafa, G.; Hasnain, A. Comparative study on effects of citric and lactic acid treatment on morphological, functional, resistant starch fraction and glycemic index of corn and sorghum starches. Int. J. Biol. Macromol. 2019, 135, 314–327. [Google Scholar] [CrossRef]

- Cheng, K.C.; Chen, S.H.; Yeh, A. Physicochemical properties and in vitro digestibility of rice after parboiling with heat moisture treatment-Science Direct. J. Cereal Sci. 2019, 85, 98–104. [Google Scholar] [CrossRef]

- Zheng, B.; Zhong, S.; Tang, Y.; Chen, L. Understanding the nutritional functions of thermally-processed whole grain highland barley in vitro and in vivo. Food Chem. 2020, 310, 125979. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Wei, T.; Shen, J.; Wang, M. Differences in physicochemical properties and in vitro digestibility between tartary buckwheat flour and starch modified by heat-moisture treatment. LWT-Food Sci. Technol. 2017, 86, 285–292. [Google Scholar] [CrossRef]

- Chen, X.; He, X.; Fu, X.; Huang, Q. In vitro digestion and physicochemical properties of wheat starch/flour modified by heat-moisture treatment. J. Cereal Sci. 2015, 63, 109–115. [Google Scholar] [CrossRef]

- Angeli, V.; Miguel Silva, P.; Crispim Massuela, D.; Khan, M.W.; Hamar, A.; Khajehei, F.; Graeff-Hönninger SPiatti, C. Quinoa (Chenopodium quinoa Willd.): An overview of the potentials of the “golden grain” and socio-economic and environmental aspects of its cultivation and marketization. Foods 2020, 9, 216. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Luo, Z.; Yang, Q.; Xiao, Z.; Lu, X. Effect of quinoa flour on baking performance, antioxidant properties and digestibility of wheat bread. Food Chem. 2019, 294, 87–95. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Wang, Z.; Hao, Y.; Wang, Y.; Yang, Z.; Li, W.; Wang, J. Physicochemical and functional properties of soluble dietary fiber from different colored quinoa varieties (Chenopodium quinoa Willd). J. Cereal Sci. 2020, 95, 103045. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Kim, Y.; Yoon, K.S. Antioxidant and antimicrobial activities of quinoa (Chenopodium quinoa Willd.) seeds cultivated in Korea. Preventive. Nutr. Food Sci. 2017, 22, 195–202. [Google Scholar]

- Wang, X.; Lao, X.; Bao, Y.; Guan, X.; Li, C. Effect of whole quinoa flour substitution on the texture and in vitro starch digestibility of wheat bread. Food Hydrocoll. 2021, 119, 106840. [Google Scholar] [CrossRef]

- Yu, W.; Zou, W.; Dhital, S.; Peng, W.; Gilbert, R.G. The adsorption of α-amylase on barley proteins affects the in vitro digestion of starch in barley flour. Food Chem. 2017, 241, 493–501. [Google Scholar] [CrossRef]

- Goñi, I.; Garcia-Alonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Huang, L.; Dong, J.L.; Zhang, K.Y.; Zhu, Y.Y.; Qu, L.B. Thermal processing influences the physicochemical properties, in vitro digestibility and prebiotics potential of germinated highland barley. LWT-Food Sci. Technol. 2020, 140, 110814. [Google Scholar] [CrossRef]

- Jan, K.N.; Panesar, P.S.; Rana, J.C.; Singh, S. Structural, thermal and rheological properties of starches isolated from Indian quinoa varieties. Int. J. Biol. Macromol. 2017, 102, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Gu, Z.; Zhu, L.; Hong, Y. Comparative study on the interaction between native corn starch and different hydrocolloids during gelatinization. Int. J. Biol. Macromol. 2018, 116, 136–143. [Google Scholar] [CrossRef]

- Mccann, T.H.; Leder, A.; Buckow, R.; Li, D. Modification of structure and mixing properties of wheat flour through high-pressure processing. Food Res. Int. 2013, 53, 352–361. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. Application of heat moisture treatment in wheat pasta production. Food Control 2021, 128, 108176. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. Simultaneous optimization of wheat heat moisture treatment and grape peels addition for pasta making. LWT-Food Sci. Technol. 2021, 150, 112011. [Google Scholar] [CrossRef]

- Gelencsér, T.; Gál, V.; Hódsági, M.; Salgó, A. Evaluation of quality and digestibility characteristics of resistant starch-enriched pasta. Food Bioprocess Technol. 2008, 1, 171–179. [Google Scholar] [CrossRef]

- Niu, L.; Zhang, S.; Guo, Y.; Wang, J. Effect of microwave heat-moisture treatment on resistant starch content and properties of potato starches. Sci. Technol. Food Ind. 2013, 14, 156–159. [Google Scholar]

- Zavareze, E.D.R.; Dias, A.R.G. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr. Polym. 2011, 83, 317–328. [Google Scholar] [CrossRef]

- Adawiyah, D.R.; Akuzawa, S.; Sasaki, T.; Kohyama, K. A comparison of the effects of heat moisture treatment (HMT) on rheological properties and amylopectin structure in sago (Metroxylon sago) and arenga (Arenga pinnata) starches. J. Food Sci. Technol. 2017, 54, 3404–3410. [Google Scholar] [CrossRef] [PubMed]

- Hung, P.; Binh, V.; Nhi, P.; Phi, N. Effect of heat-moisture treatment of unpolished red rice on its starch properties and in vitro and in vivo digestibility. Int. J. Biol. Macromol. 2020, 154, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Chung, H.J.; Liu, Q.; Hoover, R. Impact of annealing and heat-moisture treatment on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydr. Polym. 2009, 75, 436–447. [Google Scholar] [CrossRef]

- Resio, A.C.; Suarez, C. Gelatinization kinetics of amaranth starch. Int. J. Food Sci. Technol. 2001, 36, 441–448. [Google Scholar] [CrossRef]

- Liu, H.; Lv, M.; Peng, Q.; Shan, F.; Wang, M. Physicochemical and textural properties of tartary buckwheat starch after heat-moisture treatment at different moisture levels. Starch-Starke 2015, 67, 276–284. [Google Scholar] [CrossRef]

- Yang, X.; Chi, C.; Liu, X.; Zhang, Y.; Wang, H. Understanding the structural and digestion changes of starch in heat-moisture treated polished rice grains with varying amylose content. Int. J. Biol. Macromol. 2019, 139, 785–792. [Google Scholar] [CrossRef]

- Delinski, B.C.; Cristina, S.D.O.; Colman, T.; Marinho, M.T.; Lacerda, L.G.; Ramos, A.P.; Schnitzler, E. Organic amaranth starch: A study of its technological properties after heat-moisture treatment. Food Chem. 2018, 264, 435–442. [Google Scholar]

- Guo, Y.; Xu, T.; Li, N.; Cheng, Q.; Qiao, D.; Zhang, B. Supramolecular structure and pasting/digestion behaviors of rice starches following concurrent microwave and heat moisture treatment. Int. J. Biol. Macromol. 2019, 135, 437–444. [Google Scholar] [CrossRef]

- Sun, Q.; Han, Z.; Wang, L.; Xiong, L. Physicochemical differences between sorghum starch and sorghum flflour modifified by heat-moisture treatment. Food Chem. 2014, 145, 756–764. [Google Scholar] [CrossRef]

- Han, Z.; Li, Y.; Luo, D.H.; Zhao, Q.; Cheng, J.H.; Wang, J.H. Structural variations of rice starch affected by constant power microwave treatment. Food Chem. 2021, 359, 129887. [Google Scholar] [CrossRef]

- Hung, P.V.; Huong, N.; Phi, N.; Tien, N. Physicochemical characteristics and in vitro digestibility of potato and cassava starches under organic acid and heat-moisture treatments. Int. J. Biol. Macromol. 2017, 95, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Wang, L.; Li, Z. Modification of protein structure and dough rheological properties of wheat flour through superheated steam treatment. J. Cereal Sci. 2017, 76, 222–228. [Google Scholar] [CrossRef]

| Nutrients | WQ | HMT | HMT+P | HMT+M | HMT+A |

|---|---|---|---|---|---|

| Protein | 14.88 ± 0.93 a | 14.70 ± 0.95 a | 15.18 ± 0.99 a | 15.03 ± 0.96 a | 14.39 ± 0.94 a |

| Total fat | 6.83 ± 0.07 a | 6.52 ± 0.08 b | 6.29 ± 0.10 b | 6.34 ± 0.06 b | 6.47 ± 0.03 b |

| Ash | 2.48 ± 0.08 a | 2.46 ± 0.07 a | 2.39 ± 0.10 a | 2.47 ± 0.09 a | 2.50 ± 0.11 a |

| Total starch | 61.56 ± 1.86 a | 61.68 ± 1.88 a | 60.76 ± 1.76 a | 61.56 ± 1.77 a | 61.55 ± 1.74 a |

| TDF | 13.15 ± 0.56 d | 13.70 ± 0.48 c | 15.23 ± 0.58 a | 14.36 ± 0.41 b | 13.9 ± 0.52 c |

| Amylose | 7.44 ± 0.38 e | 9.25 ± 0.41 d | 31.24 ± 0.44 a | 22.91 ± 0.39 b | 19.86 ± 0.41 c |

| Amylopectin | 54.12 ± 1.10 a | 52.43 ± 1.09 b | 30.02 ± 1.09 e | 38.45 ± 1.10 d | 41.69 ± 1.09 c |

| Samples | WQ | HMT | HMT+P | HMT+M | HMT+A |

|---|---|---|---|---|---|

| RS | 2.89 ± 0.55 e | 5.32 ± 0.52 d | 15.71 ± 0.56 a | 7.74 ± 0.54 c | 12.49 ± 0.58 b |

| SDS | 18.54 ± 0.46 c | 18.35 ± 0.43 c | 21.86 ± 0.40 b | 25.09 ± 0.43 a | 22.07 ± 0.41 b |

| RDS | 40.12 ± 1.54 a | 38.01 ± 1.52 a | 23.65 ± 1.51 c | 28.43 ± 1.49 b | 26.99 ± 1.50 b,c |

| eGI | 74.36 ± 1.96 a | 70.59 ± 1.88 b | 65.87 ± 1.76 c | 69.79 ± 1.87 b | 69.12 ± 1.56 b |

| Samples | T0 | Tp | Tc | △H (J/g) |

|---|---|---|---|---|

| WQ | 65.05 ± 0.37 e | 72.78 ± 0.42 e | 81.09 ± 0.35 e | 4.33 ± 0.003 a |

| HMT | 97.84 ± 0.46 d | 107.84 ± 0.53 d | 117.86 ± 0.70 d | 1.05 ± 0.001 b |

| HMT+P | 100.75 ± 0.74 c | 109.91 ± 0.43 c | 117.35 ± 0.61 c | 1.07 ± 0.006 b |

| HMT+M | 104.06 ± 0.53 b | 112.77 ± 0.67 b | 124.37 ± 0.53 b | 0.53 ± 0.002 c |

| HMT+A | 113.75 ± 0.93 a | 115.54 ± 0.73 a | 132.67 ± 0.65 a | 0.64 ± 0.008 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Huang, L.; Chen, W.; Zhu, Y.; Dun, B.; Shen, R. Effect of Heat-Moisture Treatments on Digestibility and Physicochemical Property of Whole Quinoa Flour. Foods 2021, 10, 3042. https://doi.org/10.3390/foods10123042

Dong J, Huang L, Chen W, Zhu Y, Dun B, Shen R. Effect of Heat-Moisture Treatments on Digestibility and Physicochemical Property of Whole Quinoa Flour. Foods. 2021; 10(12):3042. https://doi.org/10.3390/foods10123042

Chicago/Turabian StyleDong, Jilin, Lu Huang, Wenwen Chen, Yingying Zhu, Baoqing Dun, and Ruiling Shen. 2021. "Effect of Heat-Moisture Treatments on Digestibility and Physicochemical Property of Whole Quinoa Flour" Foods 10, no. 12: 3042. https://doi.org/10.3390/foods10123042

APA StyleDong, J., Huang, L., Chen, W., Zhu, Y., Dun, B., & Shen, R. (2021). Effect of Heat-Moisture Treatments on Digestibility and Physicochemical Property of Whole Quinoa Flour. Foods, 10(12), 3042. https://doi.org/10.3390/foods10123042