Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution

Abstract

:1. Introduction

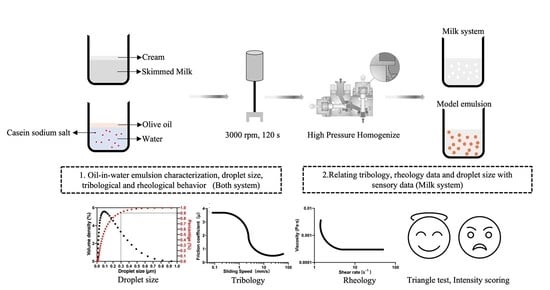

2. Materials and Methods

2.1. Sample Preparation

2.2. Droplet Size Studies

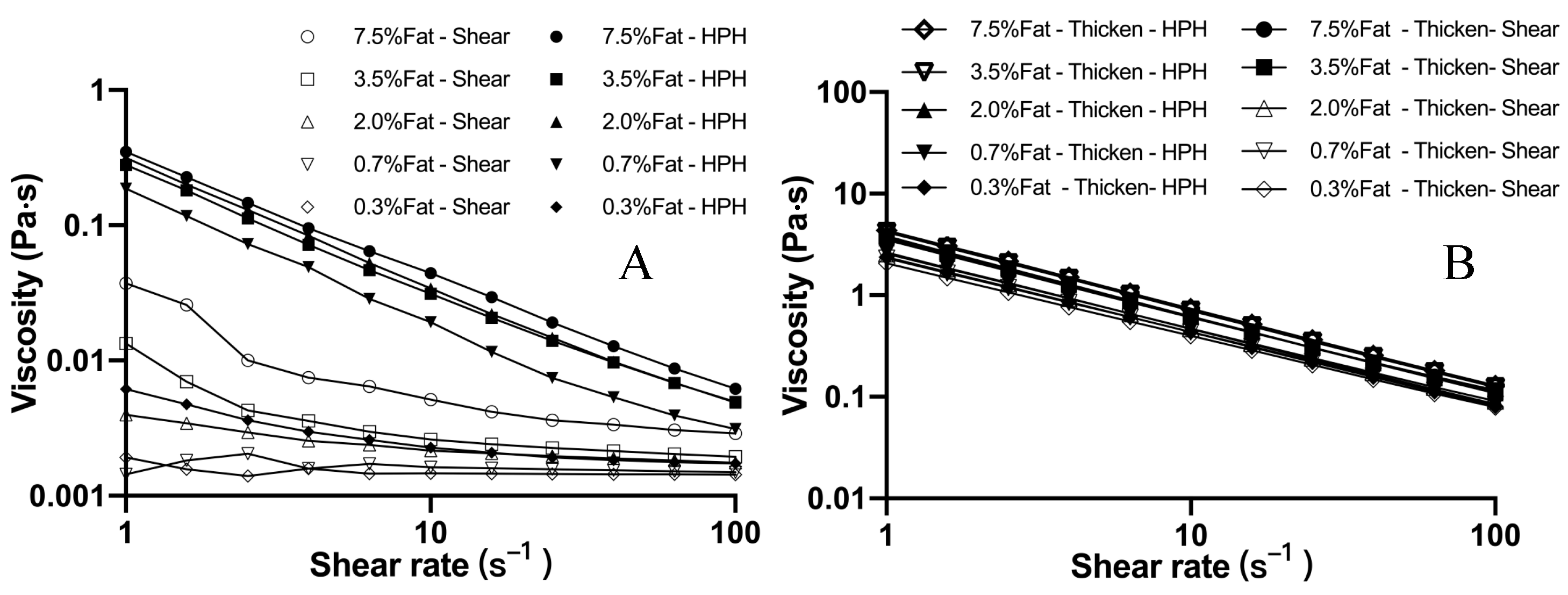

2.3. Flow Behavior and Apparent Viscosity

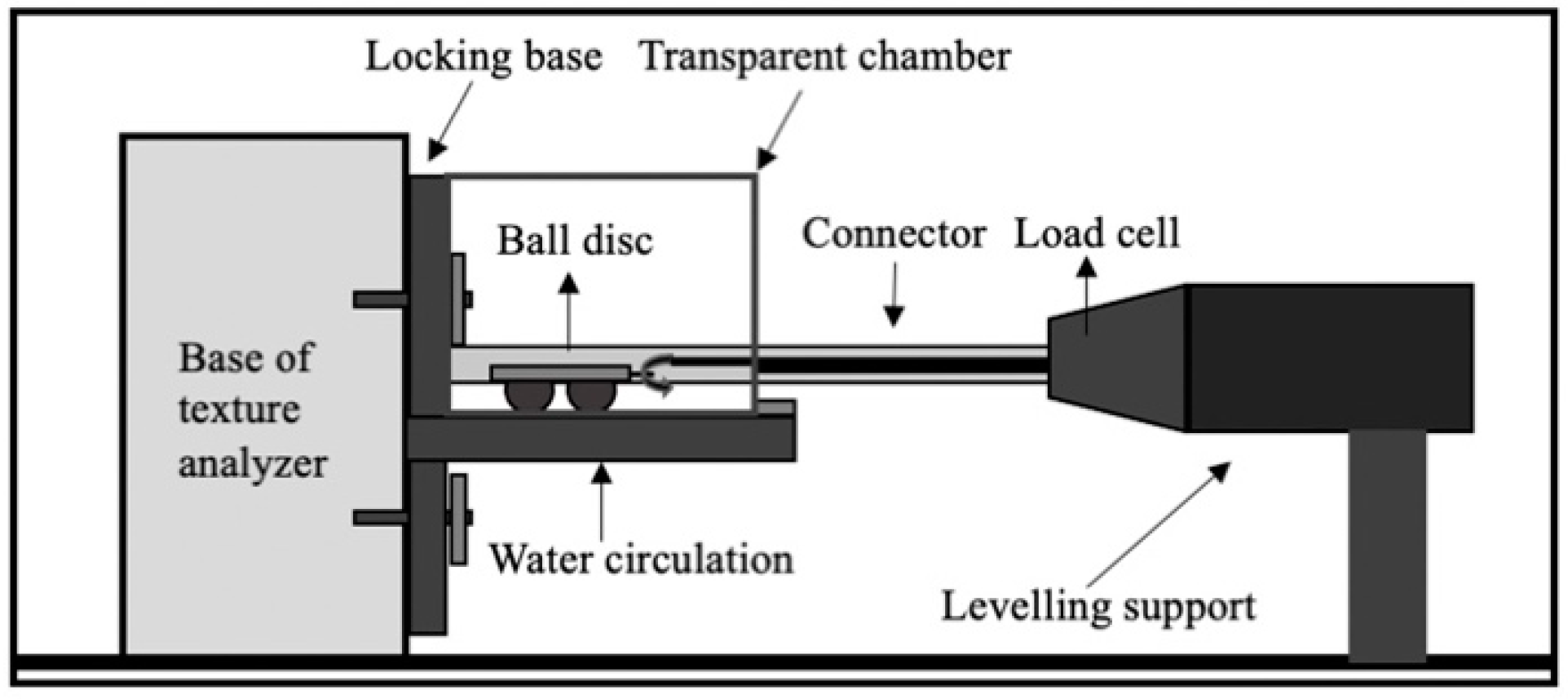

2.4. Tribology Measurement

2.5. Sensory Analysis

2.6. Triangle Test and Intensity Scoring with Sensory Descriptors

2.7. Statistical Analyze

3. Results and Discussion

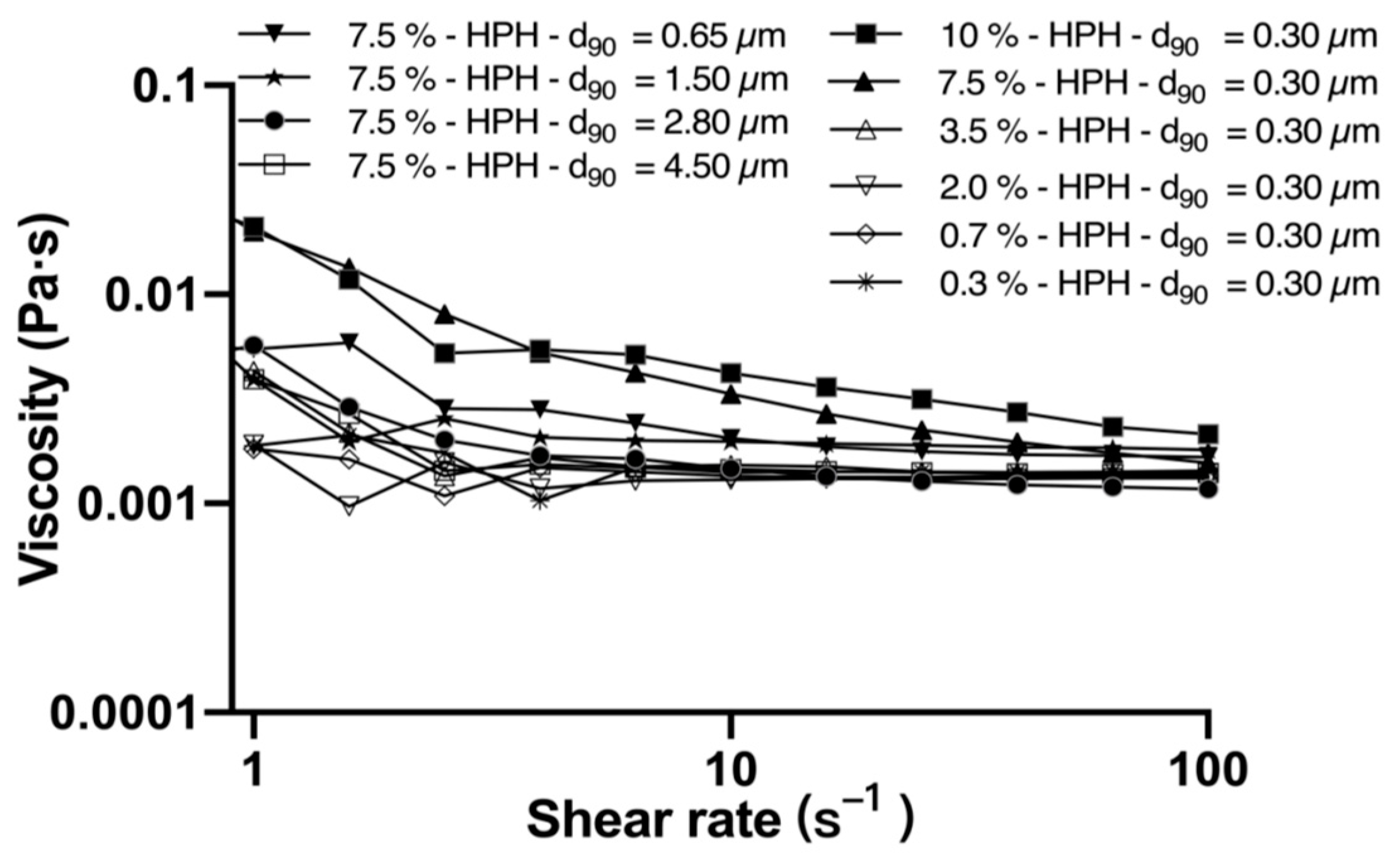

3.1. Emulsion Characteristics

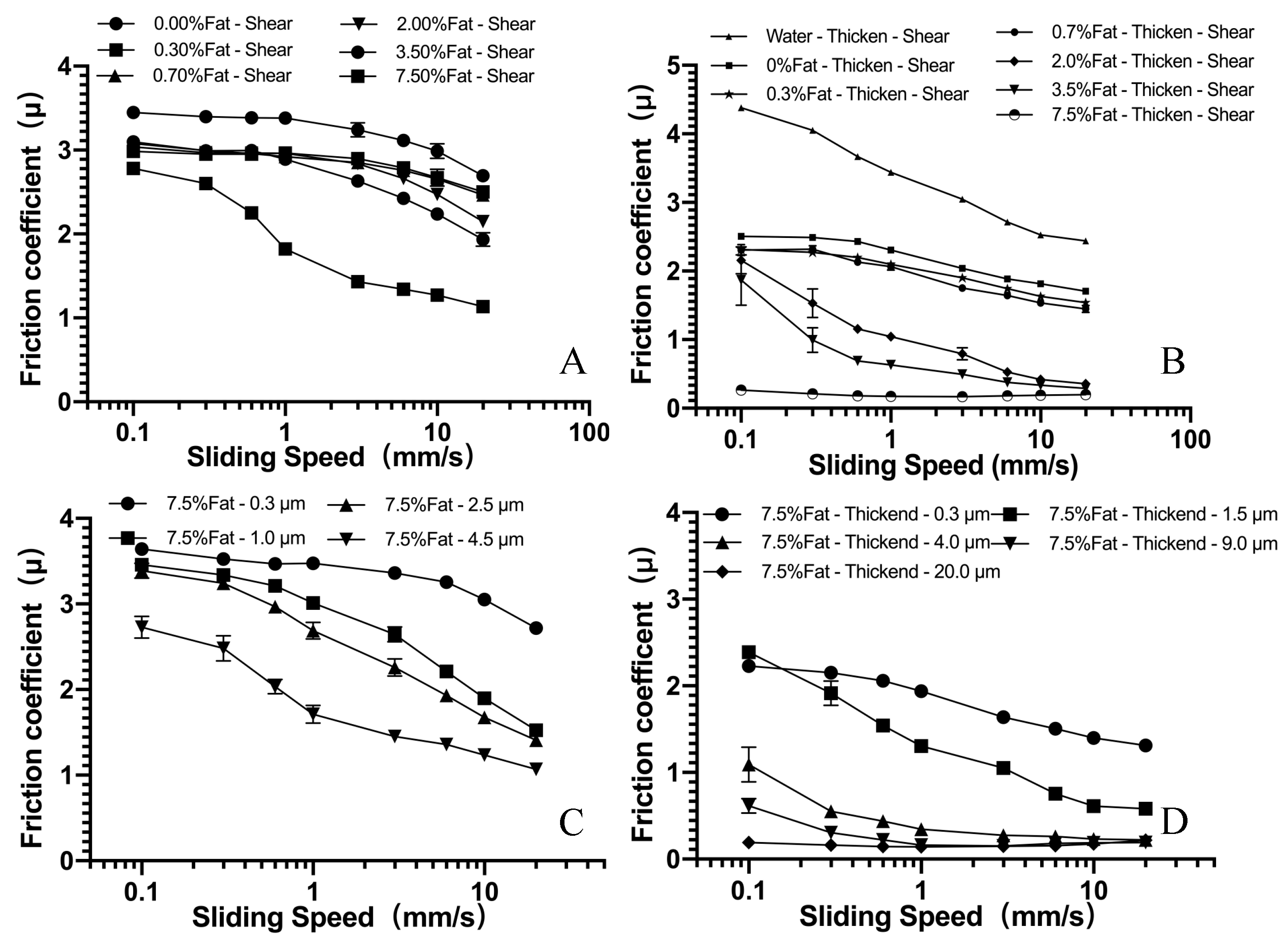

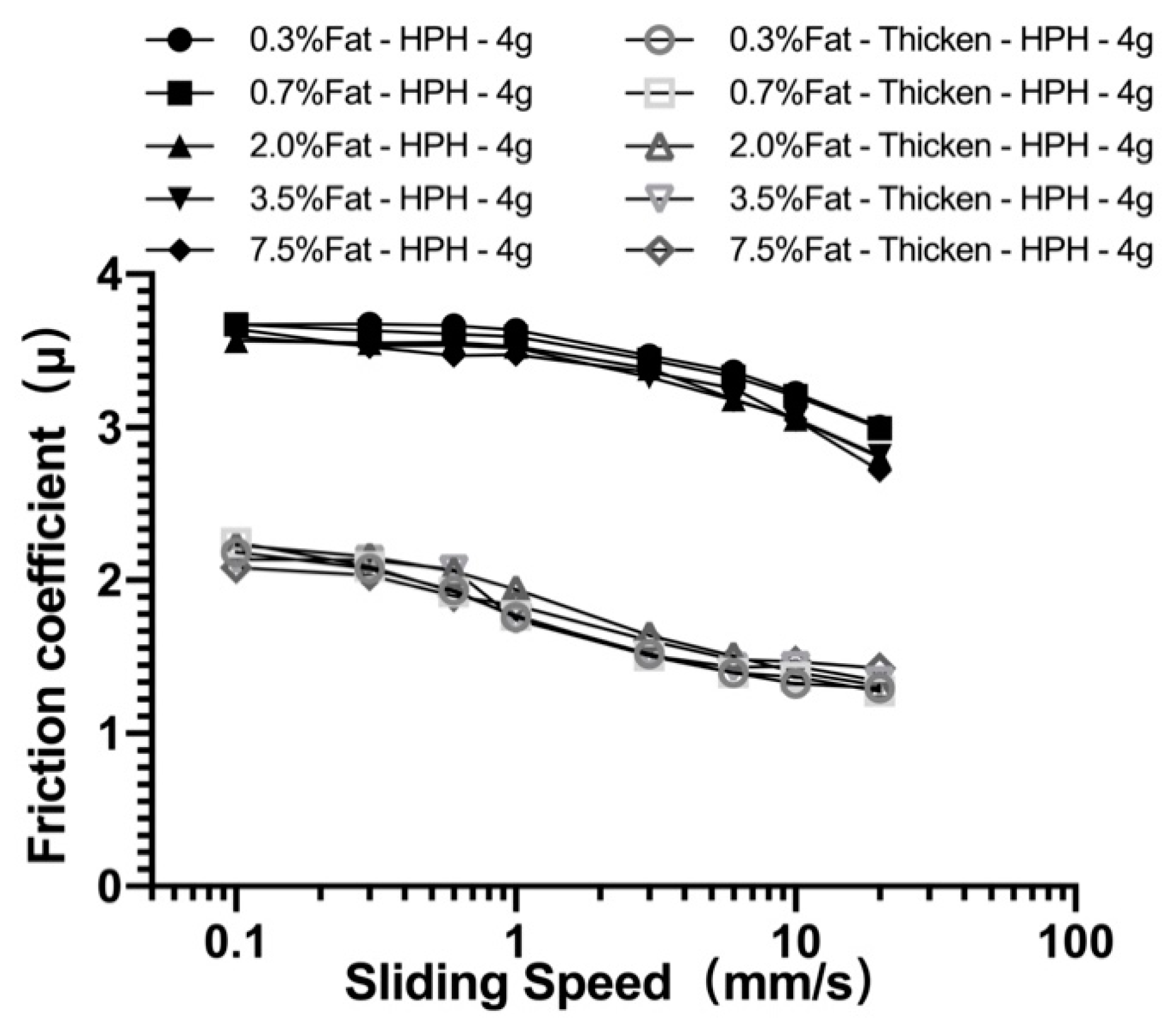

3.2. Tribology: Lubrication Behavior of Milk and Thickened Milk Samples

3.2.1. Effect of Oil/Fat Mass Fraction on Lubrication Behavior

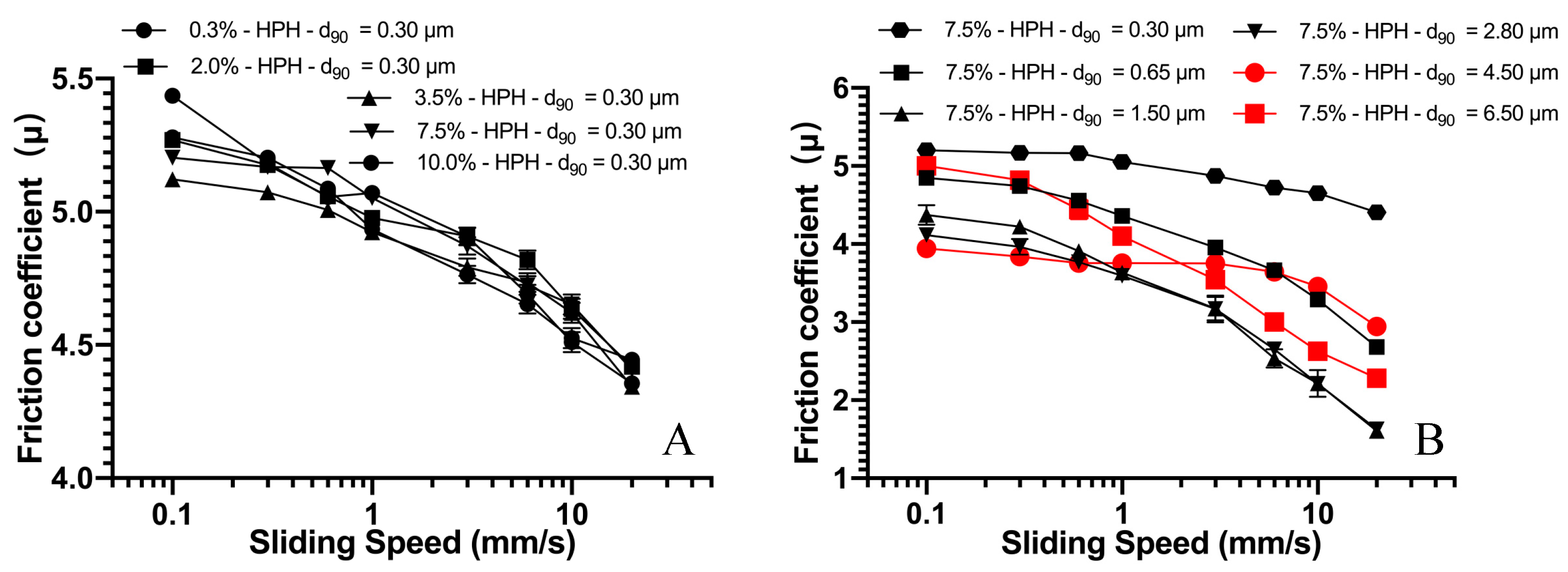

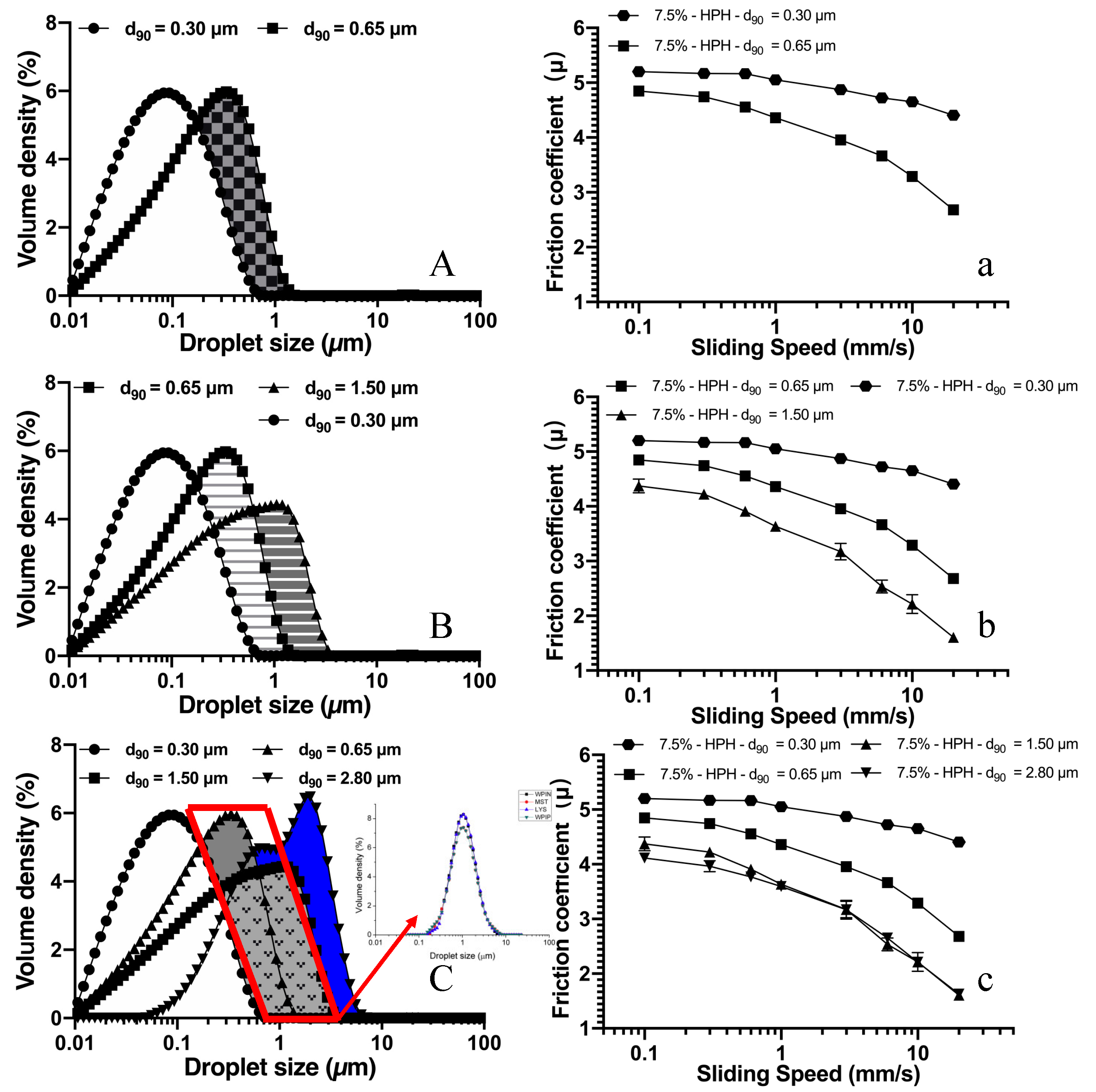

3.2.2. Effect of Oil/Fat Droplet Size on Lubrication Behavior

3.2.3. Relating Lubrication Behavior of Model Emulsion with Oil Droplet Size

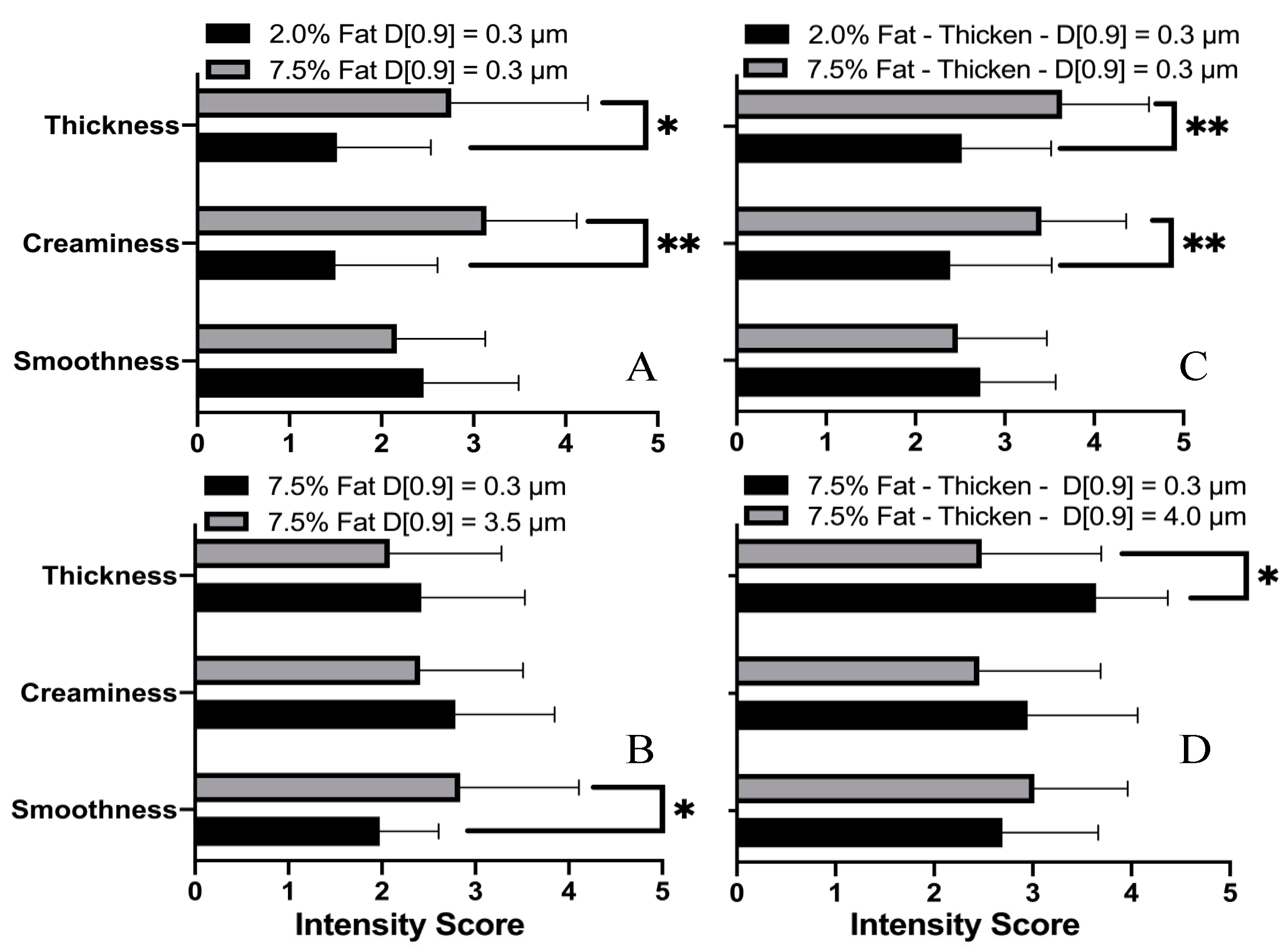

3.3. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bluher, M. Obesity: Global epidemiology and pathogenesis. Nat. Rev. Endocrinol. 2019, 15, 288–298. [Google Scholar] [CrossRef]

- McClements, D.J.; Barrangou, R.; Hill, C.; Kokini, J.L.; Lila, M.A.; Meyer, A.S.; Yu, L.L. Building a Resilient, Sustainable, and Healthier Food Supply Through Innovation and Technology. Annu. Rev. Food Sci. Technol. 2021, 12, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.; Degner, B.; McClements, D.J. Designing reduced-fat food emulsions: Locust bean gum-fat droplet interactions. Food Hydrocoll. 2013, 32, 263–270. [Google Scholar] [CrossRef]

- Di Cicco, F.; Oosterlinck, F.; Tromp, H.; Sein, A. Comparative study of whey protein isolate gel and polydimethylsiloxane as tribological surfaces to differentiate friction properties of commercial yogurts. Food Hydrocoll. 2019, 97, 105204. [Google Scholar] [CrossRef]

- Laiho, S.; Williams, R.P.W.; Poelman, A.; Appelqvist, I.; Logan, A. Effect of whey protein phase volume on the tribology, rheology and sensory properties of fat-free stirred yoghurts. Food Hydrocoll. 2017, 67, 166–177. [Google Scholar] [CrossRef]

- McClements, D.J. Colloidal basis of emulsion color. Curr. Opin. Colloid Interface Sci. 2002, 7, 451–455. [Google Scholar] [CrossRef]

- Benjamins, J.; Vingerhoeds, M.H.; Zoet, F.D.; de Hoog, E.H.A.; van Aken, G.A. Partial coalescence as a tool to control sensory perception of emulsions. Food Hydrocoll. 2009, 23, 102–115. [Google Scholar] [CrossRef]

- Mosca, A.C.; Rocha, J.A.; Sala, G.; van de Velde, F.; Stieger, M. Inhomogeneous distribution of fat enhances the perception of fat-related sensory attributes in gelled foods. Food Hydrocoll. 2012, 27, 448–455. [Google Scholar] [CrossRef]

- Liu, K.; Stieger, M.; van der Linden, E.; van de Velde, F. Fat droplet characteristics affect rheological, tribological and sensory properties of food gels. Food Hydrocoll. 2015, 44, 244–259. [Google Scholar] [CrossRef]

- Li, Y.; Joyner, H.S.; Carter, B.G.; Drake, M.A. Effects of fat content, pasteurization method, homogenization pressure, and storage time on the mechanical and sensory properties of bovine milk. J. Dairy Sci. 2018, 101, 2941–2955. [Google Scholar] [CrossRef]

- Jones, S.A.; Roller, S. Handbook of Fat Replacers, 1st ed.; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar] [CrossRef]

- Upadhyay, R.; Aktar, T.; Chen, J. Perception of creaminess in foods. J. Texture Stud. 2020, 51, 375–388. [Google Scholar] [CrossRef] [PubMed]

- Cutler, A.N.; Morris, E.R.; Taylor, L.J. Oral perception of viscosity in fluid foods and model systems. J. Texture Stud. 1983, 14, 377–395. [Google Scholar] [CrossRef]

- Dickie, A.M.; Kokini, J.L. An improved model for food thickness from non-Newtonian fluid mechanics in the mouth. J. Food Sci. 1983, 48, 57–61. [Google Scholar] [CrossRef]

- Stanley, N.L.; Taylor, L.J. Rheological basis of oral characteristics of fluid and semi-solid foods: A review. Acta Psychol. 1993, 84, 79–92. [Google Scholar] [CrossRef]

- Chen, J.; Stokes, J.R. Rheology and tribology: Two distinctive regimes of food texture sensation. Trends Food Sci. Technol. 2012, 25, 4–12. [Google Scholar] [CrossRef]

- Sarkar, A.; Andablo-Reyes, E.; Bryant, M.; Dowson, D.; Neville, A. Lubrication of soft oral surfaces. Curr. Opin. Colloid Interface Sci. 2019, 39, 61–75. [Google Scholar] [CrossRef]

- Shewan, H.M.; Pradal, C.; Stokes, J.R. Tribology and its growing use toward the study of food oral processing and sensory perception. J. Texture Stud. 2020, 51, 7–22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bongaerts, J.H.H.; Fourtouni, K.; Stokes, J.R. Soft-tribology: Lubrication in a compliant PDMS–PDMS contact. Tribol. Int. 2007, 40, 1531–1542. [Google Scholar] [CrossRef]

- Taylor, B.L.; Mills, T.B. Using a three-ball-on-plate configuration for soft tribology applications. J. Food Eng. 2020, 274, 109838. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Chen, J. A new design of soft texture analyzer tribometer (STAT) for in vitro oral lubrication study. Food Hydrocoll. 2020, 110, 106146. [Google Scholar] [CrossRef]

- de Vicente, J.; Stokes, J.R.; Spikes, H.A. Soft lubrication of model hydrocolloids. Food Hydrocoll. 2006, 20, 483–491. [Google Scholar] [CrossRef]

- de Vicente, J.; Stokes, J.; Spikes, H.A. The Frictional Properties of Newtonian Fluids in Rolling–Sliding soft-EHL Contact. Tribol. Lett. 2005, 20, 273–286. [Google Scholar] [CrossRef]

- Selway, N.; Stokes, J.R. Insights into the dynamics of oral lubrication and mouthfeel using soft tribology: Differentiating semi-fluid foods with similar rheology. Food Res. Int. 2013, 54, 423–431. [Google Scholar] [CrossRef]

- Laguna, L.; Farrell, G.; Bryant, M.; Morina, A.; Sarkar, A. Relating rheology and tribology of commercial dairy colloids to sensory perception. Food Funct. 2017, 8, 563–573. [Google Scholar] [CrossRef] [PubMed]

- Malone, M.E.; Appelqvist, I.A.M.; Norton, I.T. Oral behaviour of food hydrocolloids and emulsions. Part 1. Lubrication and deposition considerations. Food Hydrocoll. 2003, 17, 763–773. [Google Scholar] [CrossRef]

- Upadhyay, R.; Chen, J. Smoothness as a tactile percept: Correlating ‘oral’ tribology with sensory measurements. Food Hydrocoll. 2019, 87, 38–47. [Google Scholar] [CrossRef]

- Chojnicka-Paszun, A.; de Jongh, H.H.J.; de Kruif, C.G. Sensory perception and lubrication properties of milk: Influence of fat content. Int. Dairy J. 2012, 26, 15–22. [Google Scholar] [CrossRef]

- Dresselhuis, D.M.; de Hoog, E.H.A.; Stuart, M.A.C.; Vingerhoeds, M.H.; van Aken, G.A. The occurrence of in-mouth coalescence of emulsion droplets in relation to perception of fat. Food Hydrocoll. 2008, 22, 1170–1183. [Google Scholar] [CrossRef]

- Douaire, M.; Stephenson, T.; Norton, I.T. Soft tribology of oil-continuous emulsions. J. Food Eng. 2014, 139, 24–30. [Google Scholar] [CrossRef]

- Dresselhuis, D.M.; Klok, H.J.; Stuart, M.A.C.; de Vries, R.J.; van Aken, G.A.; de Hoog, E.H.A. Tribology of o/w emulsions under mouth-like conditions: Determinants of friction. Food Biophys. 2007, 2, 158–171. [Google Scholar] [CrossRef] [Green Version]

- Fuhrmann, P.L.; Kalisvaart, L.C.M.; Sala, G.; Scholten, E.; Stieger, M. Clustering of oil droplets in o/w emulsions enhances perception of oil-related sensory attributes. Food Hydrocoll. 2019, 97, 105215. [Google Scholar] [CrossRef]

- Lett, A.M.; Norton, J.E.; Yeomans, M.R. Emulsion oil droplet size significantly affects satiety: A pre-ingestive approach. Appetite 2016, 96, 18–24. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Liu, Z.; Prakash, S. Lubrication studies of fluid food using a simple experimental set up. Food Hydrocoll. 2014, 42, 100–105. [Google Scholar] [CrossRef]

- Smułek, W.; Siejak, P.; Fathordoobady, F.; Masewicz, Ł.; Guo, Y.; Jarzębska, M.; Kitts, D.D.; Kowalczewski, P.Ł.; Baranowska, H.M.; Stangierski, J.; et al. Whey proteins as a potential co-surfactant with Aesculus hippocastanum L. as a stabilizer in nanoemulsions derived from hempseed oil. Molecules 2021, 26, 5856. [Google Scholar] [CrossRef] [PubMed]

- Jarzębski, M.; Siejak, P.; Smułek, W.; Fathordoobady, F.; Guo, Y.; Pawlicz, J.; Trzeciak, T.; Kowalczewski, P.Ł.; Kitts, D.D.; Singh, A.; et al. Plant extracts containing saponins affects the stability and biological activity of hempseed oil emulsion system. Molecules 2020, 25, 2696. [Google Scholar] [CrossRef] [PubMed]

- Hinderink, E.B.A.; Kaade, W.; Sagis, L.; Schroën, K.; Berton-Carabin, C.C. Microfluidic investigation of the coalescence susceptibility of pea protein-stabilised emulsions: Effect of protein oxidation level. Food Hydrocoll. 2020, 102, 105610. [Google Scholar] [CrossRef]

- Van Aken, G.A.; Zoet, F.D. Coalescence in highly concentrated coarse emulsions. Langmuir 2000, 16, 7131–7138. [Google Scholar] [CrossRef]

- McClements, D.J. Food emulsions: Principles, practices, and techniques: Second edition. In Food Emulsions: Principles, Practices, and Techniques, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Nguyen, P.T.M.; Bhandari, B.; Prakash, S. Tribological method to measure lubricating properties of dairy products. J. Food Eng. 2016, 168, 27–34. [Google Scholar] [CrossRef]

- Grotenhuis, E.; Tuinier, R.; De Kruif, C.G. Phase stability of concentrated dairy products. J. Dairy Sci. 2003, 86, 764–769. [Google Scholar] [CrossRef] [Green Version]

- Chojnicka-Paszun, A.; de Jongh, H.H.J. Friction properties of oral surface analogs and their interaction with polysaccharide/MCC particle dispersions. Food Res. Int. 2014, 62, 1020–1028. [Google Scholar] [CrossRef]

- Godoi, F.C.; Bhandari, B.R.; Prakash, S. Tribo-rheology and sensory analysis of a dairy semi-solid. Food Hydrocoll. 2017, 70, 240–250. [Google Scholar] [CrossRef] [Green Version]

- Joyner, H.; Pernell, C.W.; Daubert, C. Impact of Oil-in-Water emulsion composition and preparation method on emulsion physical properties and friction behaviors. Tribol. Lett. 2014, 56, 143–160. [Google Scholar] [CrossRef]

- Kokini, J.L.; Kadane, J.B.; Cussler, E.L. Liquid texture perceived in the mouth. J. Texture Stud. 1977, 8, 195–218. [Google Scholar] [CrossRef]

- Chen, J.; Eaton, L. Multimodal mechanisms of food creaminess sensation. Food Funct. 2012, 3, 1265–1270. [Google Scholar] [CrossRef] [PubMed]

- Sonne, A.; Busch-Stockfisch, M.; Weiss, J.; Hinrichs, J. Improved mapping of in-mouth creaminess of semi-solid dairy products by combining rheology, particle size, and tribology data. LWT Food Sci. Technol. 2014, 59, 342–347. [Google Scholar] [CrossRef]

| Sample Name | Protein Concentration (wt.%) | Fat Concentration (wt.%) | Xanthan Concentration (wt.%) |

|---|---|---|---|

| 0.3%Fat-Shear/HPH | 3.74 | 0.30 | None |

| 0.7%Fat-Shear/HPH | 3.57 | 0.70 | |

| 2.0%Fat-Shear/HPH | 3.51 | 2.00 | |

| 3.5%Fat-Shear/HPH | 3.44 | 3.50 | |

| 7.5%Fat-Shear/HPH | 3.25 | 7.50 | |

| 0.3%Fat-T-Shear/HPH | 3.74 | 0.30 | 0.86 |

| 0.7%Fat-T-Shear/HPH | 3.57 | 0.70 | |

| 2.0%Fat-T-Shear/HPH | 3.51 | 2.00 | |

| 3.5%Fat-T-Shear/HPH | 3.44 | 3.50 | |

| 7.5%Fat-T-Shear/HPH | 3.25 | 7.50 |

| 7.5 wt.% Milk | 7.5 wt.% Thickened Milk | |||

|---|---|---|---|---|

| Fat Droplet Size (d90, µm) | Viscosity (50 s−1) (Pa∙s) | Fat Droplet Size (d90, µm) | Viscosity (50 s−1) (Pa∙s) | |

| 4.617 | 0.00915 | 20.733 | 0.153 | |

| 2.370 | 0.00855 | 8.686 | 0.163 | |

| 0.990 | 0.00939 | 4.070 | 0.151 | |

| 0.299 | 0.0111 | 1.460 | 0.169 | |

| 0.301 | 0.213 | |||

| Significance | None | None | ||

| Sample | Number of Correct Answers | Total Responses |

|---|---|---|

| 2%/7.5% fat milk with same fat droplet size (d90 = 0.3 µm) | 12 * | 22 |

| 7.5% fat milk with different fat droplet size (d90 = 0.3/3.5 µm) | 13 * | 22 |

| 2%/7.5% fat thickened milk with same fat droplet size (d90 = 0.3 µm) | 20 *** | 22 |

| 7.5% fat thickened milk with different fat droplet size (d90 = 0.3/4 µm) | 17 *** | 22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhu, Y.; Ji, Z.; Chen, J. Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution. Foods 2021, 10, 3024. https://doi.org/10.3390/foods10123024

Wang Q, Zhu Y, Ji Z, Chen J. Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution. Foods. 2021; 10(12):3024. https://doi.org/10.3390/foods10123024

Chicago/Turabian StyleWang, Qi, Yang Zhu, Zhichao Ji, and Jianshe Chen. 2021. "Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution" Foods 10, no. 12: 3024. https://doi.org/10.3390/foods10123024

APA StyleWang, Q., Zhu, Y., Ji, Z., & Chen, J. (2021). Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution. Foods, 10(12), 3024. https://doi.org/10.3390/foods10123024