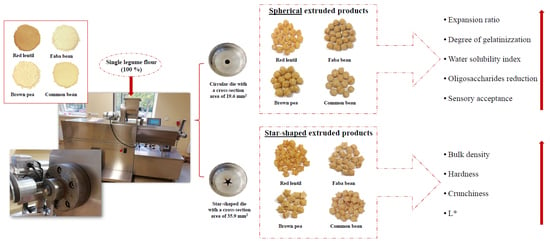

Effect of Die Configuration on the Physico-Chemical Properties, Anti-Nutritional Compounds, and Sensory Features of Legume-Based Extruded Snacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Flour Conditioning

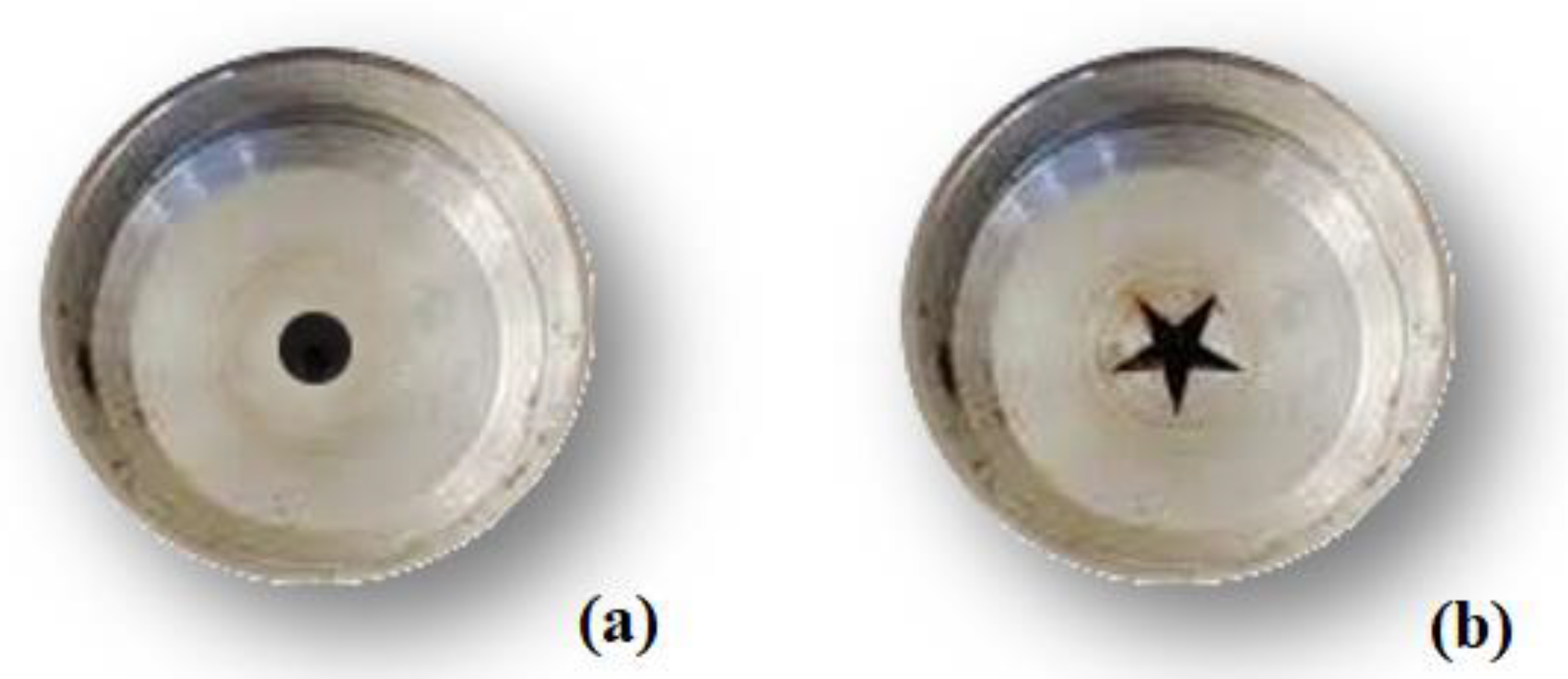

2.3. Extrusion-Cooking Process

2.4. Bulk Density and Expansion Ratio

2.5. Water Absorption Index and Water Solubility Index

2.6. Degree of Starch Gelatinization (DG)

2.7. Texture Analysis

2.8. Bowl Life Analysis

2.9. Color Determination

2.10. Determination of Total Phytates Content

2.11. Determination of Oligosaccharides

2.12. Sensory Evaluation

2.13. Statistical Analysis

3. Results and Discussion

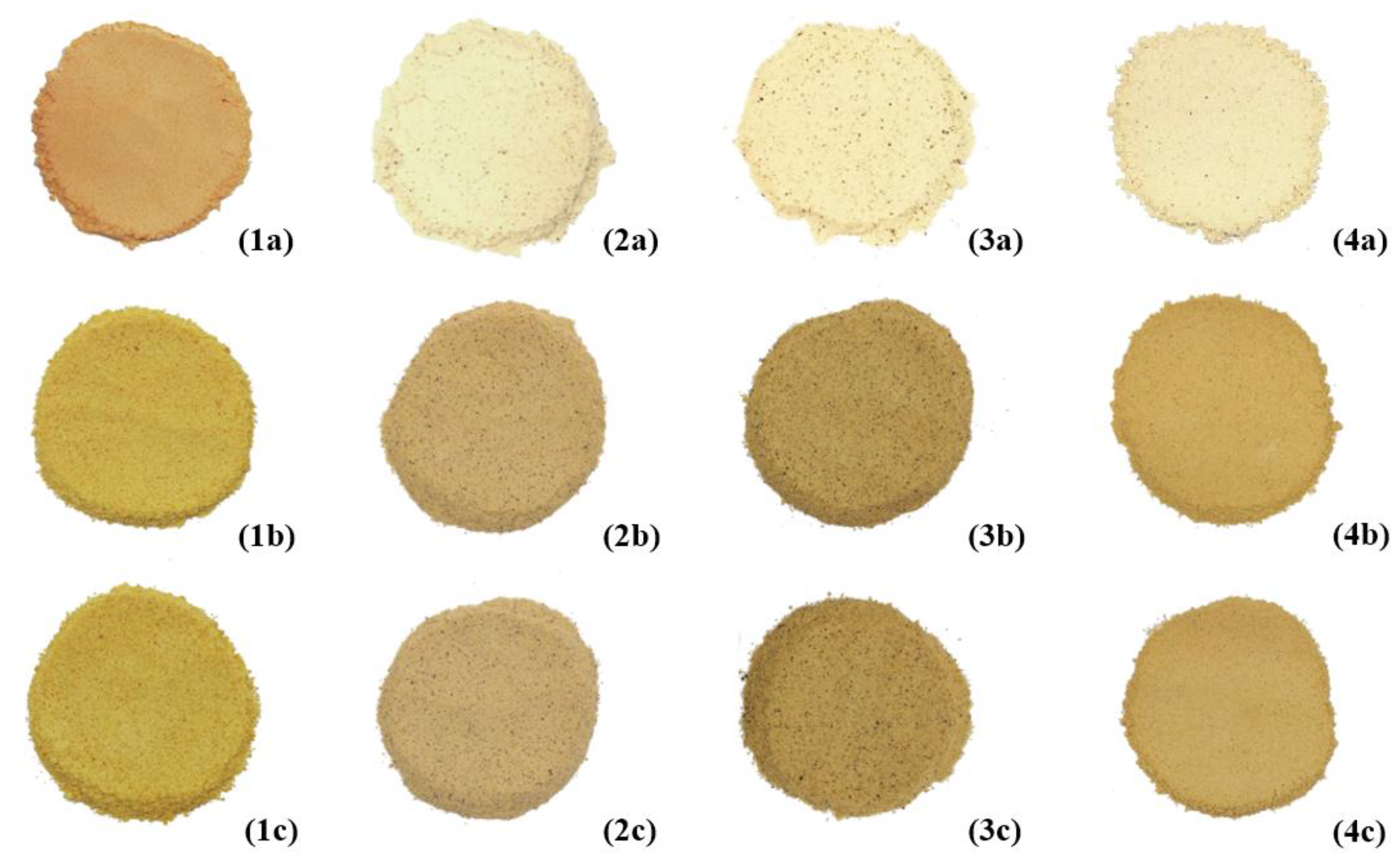

3.1. Characteristics of Flours Used in the Experiments

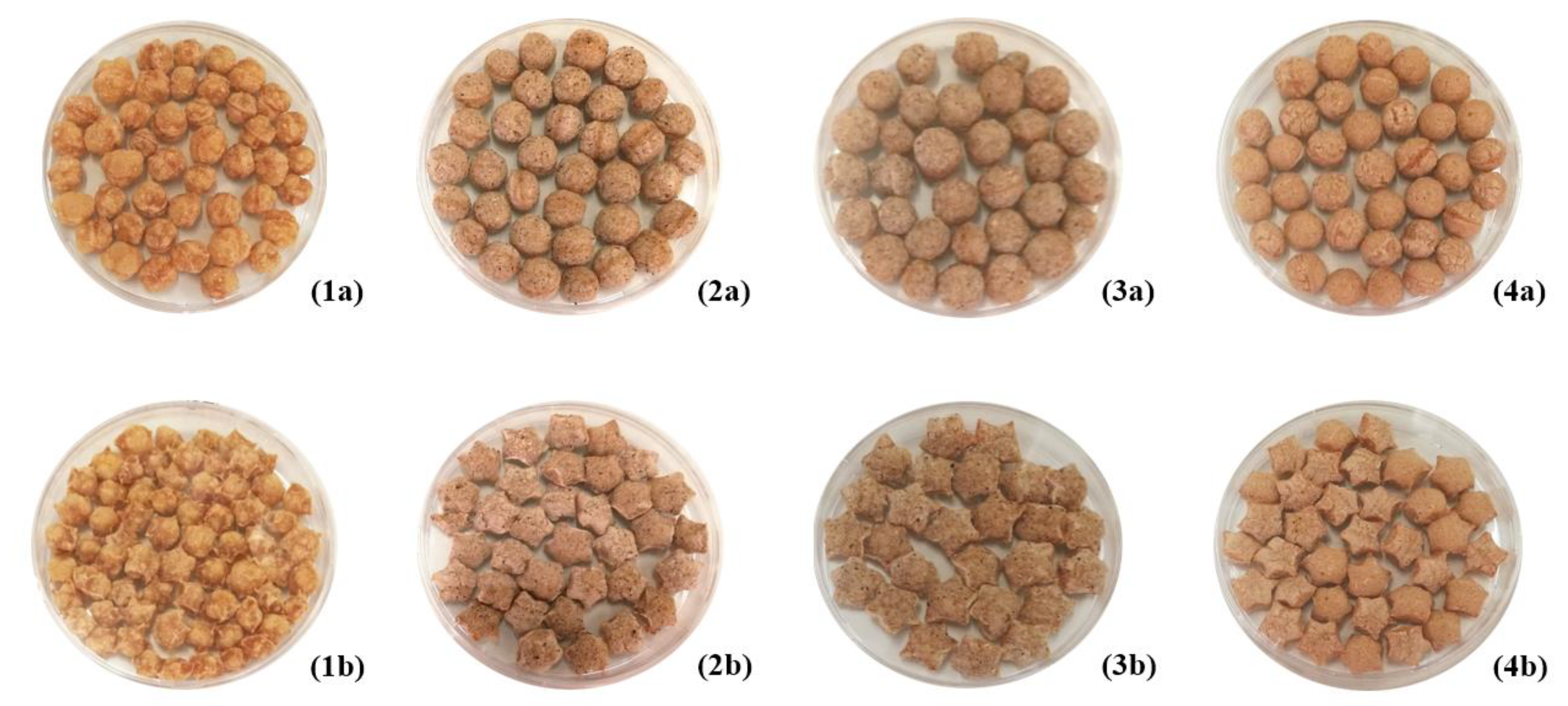

3.2. Physico-Chemical Properties of Extruded Products

3.3. Texture of Dry and Milk-Soaked Extruded Products

3.4. Color of Extruded Products

3.5. Anti-Nutritional Compounds of Flour and Extruded Products

3.6. Sensory Evaluation of the Extruded Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arribas, C.; Cabellos, B.; Sánchez, C.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. The impact of extrusion on the nutritional composition, dietary fiber and in vitro digestibility of gluten-free snacks based on rice, pea and carob flour blends. Food Funct. 2017, 8, 3654–3663. [Google Scholar] [CrossRef]

- Asif, M.; Rooney, L.W.; Ali, R.; Riaz, M.N. Application and opportunities of pulses in food system: A review. Crit. Rev. Food Sci. Nutr. 2013, 53, 1168–1179. [Google Scholar] [CrossRef]

- Rebello, C.J.; Greenway, F.L.; Finley, J.W. A review of the nutritional value of legumes and their effects on obesity and its related co-morbidities. Obes. Rev. 2014, 15, 392–407. [Google Scholar] [CrossRef]

- Ganjyal, G.M. Extrusion Cooking: Cereal Grains Processing, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2020; p. 564. [Google Scholar]

- Altaf, U.; Hussain, S.Z.; Qadri, T.; Ishrat, S.A.; Kanojia, V. Optimization of extrusion process for development of nutritious snacks using rice and chickpea flour. J. Sci. Ind. Res. 2020, 79, 430–436. [Google Scholar]

- Strauta, L.; Muižniece-Brasava, S.; Gedrovica, I. Physical and chemical properties of extruded pea product. Agron. Res. 2016, 14, 1467–1474. [Google Scholar]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of legumes in extrusion cooking: A review. Foods 2020, 9, 958. [Google Scholar] [CrossRef] [PubMed]

- Geetha, R.; Mishra, H.N.; Srivastav, P.P. Twin screw extrusion of kodo millet-chickpea blend: Process parameter optimization, physico-chemical and functional properties. J. Food Sci. Technol. 2014, 51, 3144–3153. [Google Scholar] [CrossRef]

- Liene, S.; Sandra, M.B. The characteristics of extruded faba beans (Vicia faba L.). Rural Sustain. Res. 2016, 36, 42–48. [Google Scholar] [CrossRef]

- Fenta, T.; Kumar, Y. Evaluation of processing conditions for lentil and corn blend extrudate. In Advances of Science and Technology, 6th ed.; Zimale, F., Enku Nigussie, T., Fanta, S., Eds.; Springer: New York, NY, USA, 2019; Volume 6, pp. 65–82. [Google Scholar] [CrossRef]

- Rathod, R.P.; Annapure, U.S. Antioxidant activity and polyphenolic compound stability of lentil-orange peel powder blend in an extrusion process. J. Food Sci. Technol. 2017, 54, 954–963. [Google Scholar] [CrossRef] [PubMed]

- Félix-Medina, J.V.; Montes-Ávila, J.; Reyes-Moreno, C.; Perales-Sánchez, J.X.K.; Gómez-Favela, M.A.; Aguilar-Palazuelos, E.; Gutiérrez-Dorado, R. Second-generation snacks with high nutritional and antioxidant value produced by an optimized extrusion process from corn/common bean flours mixtures. LWT Food Sci. Technol. 2020, 124, 109172. [Google Scholar] [CrossRef]

- Guillermic, R.M.; Aksoy, E.C.; Aritan, S.E.R.D.A.R.; Erkinbaev, C.; Paliwal, J.; Koksel, F. X-Ray microtomography imaging of red lentil puffed snacks: Processing conditions, microstructure and texture. Food Res. Int. 2021, 140, 109996. [Google Scholar] [CrossRef] [PubMed]

- Bekele, E.K.; Nosworthy, M.G.; Henry, C.J.; Shand, P.J.; Tyler, R.T. Oxidative stability of direct-expanded chickpea–sorghum snacks. Food Sci. Nutr. 2020, 8, 4340–4351. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Labarbuta, R.; Summo, C. Production of extruded-cooked lentil flours at industrial level: Effect of processing conditions on starch gelatinization, dough rheological properties and techno-functional parameters. LWT-Food Sci. Technol. 2021, 147, 111580. [Google Scholar] [CrossRef]

- Liu, S.Q.; Bogicevic, V.; Mattila, A.S. Circular vs. angular servicescape: “Shaping” customer response to a fast service encounter pace. J. Bus. Res. 2018, 89, 47–56. [Google Scholar] [CrossRef]

- Li, S.; Zeng, Y.; Zhou, S. The congruence effect of food shape and name typeface on consumers’ food preferences. Food Qual. Prefer. 2020, 86, 104017. [Google Scholar] [CrossRef]

- Cafieri, S.; Chillo, S.; Mastromatteo, M.; Suriano, N.; Del Nobile, M.A. A mathematical model to predict the effect of shape on pasta hydration kinetic during cooking and overcooking. J. Cereal Sci. 2008, 48, 857–862. [Google Scholar] [CrossRef]

- Wang, Q.J.; Carvalho, F.R.; Persoone, D.; Spence, C. Assessing the effect of shape on the evaluation of expected and actual chocolate flavour. Flavour 2017, 6, 1–6. [Google Scholar] [CrossRef]

- Koksel, F.; Masatcioglu, M.T. Physical properties of puffed yellow pea snacks produced by nitrogen gas assisted extrusion cooking. LWT Food Sci. Technol. 2018, 93, 592–598. [Google Scholar] [CrossRef]

- Janve, M.; Singhal, R.S. Fortification of puffed rice extrudates and rice noodles with different calcium salts: Physico-chemical properties and calcium bioaccessibility. LWT Food Sci. Technol. 2018, 97, 67–75. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Luo, S.; Li, C.; Ye, J.; Liu, C.; Gilbert, R.G. Physico-chemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohydr. Polym. 2017, 175, 265–272. [Google Scholar] [CrossRef]

- Smith, J.; Hardacre, A. Development of an extruded snack product from the legume Vicia faba minor. Procedia Food Sci. 2011, 1, 1573–1580. [Google Scholar] [CrossRef]

- Luo, S.; Chan, E.; Masatcioglu, M.T.; Erkinbaev, C.; Paliwal, J.; Koksel, F. Effects of extrusion conditions and nitrogen injection on physical, mechanical, and microstructural properties of red lentil puffed snacks. Food Bioprod. Process. 2020, 121, 143–153. [Google Scholar] [CrossRef]

- Oliveira, L.C.; Schmiele, M.; Steel, C.J. Development of whole grain wheat flour extruded cereal and process impacts on color, expansion, and dry and bowl-life texture. LWT Food Sci. Technol. 2017, 75, 261–270. [Google Scholar] [CrossRef]

- Summo, C.; De Angelis, D.; Ricciardi, L.; Caponio, F.; Lotti, C.; Pavan, S.; Pasqualone, A. Nutritional, physico-chemical and functional characterization of a global chickpea collection. J. Food Compost. Anal. 2019, 84, 103306. [Google Scholar] [CrossRef]

- De Angelis, D.; Pasqualone, A.; Allegretta, I.; Porfido, C.; Terzano, R.; Squeo, G.; Summo, C. Antinutritional factors, mineral composition and functional properties of dry fractionated flours as influenced by the type of pulse. Heliyon 2021, 7, e06177. [Google Scholar] [CrossRef]

- EN ISO. Sensory Analysis Methodology Ranking, 2006; 8587:2006; EN ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Popova, A.; Mihaylova, D. Antinutrients in plant-based foods: A review. Open Biotechnol. J. 2019, 13, 68–76. [Google Scholar] [CrossRef]

- Samtiya, M.; Aluko, R.E.; Dhewa, T. Plant food anti-nutritional factors and their reduction strategies: An overview. Food Product. Process. Nutr. 2020, 2, 1–14. [Google Scholar] [CrossRef]

- Ojo, M.A. Phytic acid in legumes: A review of nutritional importance and hydrothermal processing effect on underutilised species. Food Res. 2020, 5, 22–28. [Google Scholar] [CrossRef]

- Liu, Y.; Ragaee, S.; Marcone, M.F.; Abdel-Aal, E.S.M. Effect of different cooking methods and heating solutions on nutritionally-important starch fractions and flatus oligosaccharides in selected pulses. Cereal Chem. 2020, 97, 1216–1226. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Stockmann, R.; Ng, K.; Ajlouni, S. Revisiting phytate-element interactions: Implications for iron, zinc and calcium bioavailability, with emphasis on legumes. Crit. Rev. Food Sci. Nutr. 2020, 60, 1–17. [Google Scholar] [CrossRef]

- Kannan, U.; Sharma, R.; Gangola, M.P.; Chibbar, R.N. Improving grain quality in pulses: Strategies to reduce raffinose family oligosaccharides in seeds. Ekin J. Crop Breed. Genetic. 2018, 4, 70–88. [Google Scholar]

- Vidal-Valverde, C.; Frias, J.; Hernández, A.; Martín-Alvarez, P.J.; Sierra, I.; Rodríguez, C.; Blazquez, I.; Vicente, G. Assessment of nutritional compounds and antinutritional factors in pea (Pisum sativum) seeds. J. Sci. Food Agric. 2003, 83, 298–306. [Google Scholar] [CrossRef]

- Tahir, M.; Vandenberg, A.; Chibbar, R.N. Influence of environment on seed soluble carbohydrates in selected lentil cultivars. J. Food Compost. Anal. 2011, 24, 596–602. [Google Scholar] [CrossRef]

- Abbas, Y.; Ahmad, A. Impact of processing on nutritional and anti-nutritional factors of legumes: A review. Annals. Food Sci. Technol. 2018, 19, 99–215. [Google Scholar]

- Mohamed, S. Factors affecting extrusion characteristics of expanded starch-based products. J. Food Process. Preserv. 1990, 14, 437–452. [Google Scholar] [CrossRef]

- Adekola, K.A. Engineering review food extrusion technology and its applications. J. Food Eng. 2016, 6, 149–168. [Google Scholar] [CrossRef][Green Version]

- Altan, A.; McCarthy, K.L.; Maskan, M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

- Pérez-Navarrete, C.; Gonzalez, R.; Chel-Guerrero, L.; Betancur-Ancona, D. Effect of extrusion on nutritional quality of maize and Lima bean flour blends. J. Sci. Food Agric. 2006, 86, 2477–2484. [Google Scholar] [CrossRef]

- Liu, Y.; Hsieh, F.; Heymann, H.; Huff, H.E. Effect of process conditions on the physical and sensory properties of extruded oat-corn puff. J. Food Sci. 2000, 65, 1253–1259. [Google Scholar] [CrossRef]

- Shirazi, S.L.; Koocheki, A.; Milani, E.; Mohebbi, M. Production of high fiber ready-to-eat expanded snack from barley flour and carrot pomace using extrusion cooking technology. J. Food Sci. Technol. 2020, 57, 1–13. [Google Scholar]

- Lue, S.; Hsieh, F.; Huff, H.E. Extrusion cooking of corn meal and sugar beet fiber: Effects on expansion properties, starch gelatinization, and dietary fiber content. Cereal Chem. 1991, 68, 227–234. [Google Scholar]

- Tas, A.A.; Shah, A.U. The replacement of cereals by legumes in extruded snack foods: Science, technology and challenges. Trends Food Sci. Technol. 2021, 116, 701–711. [Google Scholar] [CrossRef]

- Kallu, S.; Kowalski, R.J.; Ganjyal, G.M. Impacts of cellulose fiber particle size and starch type on expansion during extrusion processing. J. Food Sci. 2017, 82, 1647–1656. [Google Scholar] [CrossRef]

- Ding, Q.; Ainsworth, P.; Tucker, G.; Marson, H. The effect of extrusion conditions on the physico-chemical properties and sensory characteristics of rice-based expanded snacks. J. Food Eng. 2005, 66, 283–289. [Google Scholar] [CrossRef]

- Hashimoto, J.M.; Grossmann, M.V.E. Effects of extrusion conditions on quality of cassava bran/cassava starch extrudates. Int. J. Food Sci. Technol. 2003, 38, 511–517. [Google Scholar] [CrossRef]

- Shirani, G.; Ganesharanee, R. Extruded products with Fenugreek (Trigonella foenum-graecum) chickpea and rice: Physical properties, sensory acceptability and glycaemic index. J. Food Eng. 2009, 90, 44–52. [Google Scholar] [CrossRef]

- Philipp, C.; Buckow, R.; Silcock, P.; Oey, I. Instrumental and sensory properties of pea protein-fortified extruded rice snacks. Food Res. Int 2017, 102, 658–665. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.C.; Alencar, N.M.; Steel, C.J. Improvement of sensorial and technological characteristics of extruded breakfast cereals enriched with whole grain wheat flour and jabuticaba (Myrciaria cauliflora) peel. LWT Food Sci. Technol. 2018, 90, 207–214. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-eat snack products: The role of extrusion technology in developing consumer acceptable and nutritious snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Luyten, H.; Plijter, J.J.; Vliet, T.V. Crispy/crunchy crusts of cellular solid foods: A literature review with discussion. J. Texture Stud. 2004, 35, 445–492. [Google Scholar] [CrossRef]

- Tunick, M.H.; Onwulata, C.I.; Thomas, A.E.; Phillips, J.G.; Mukhopadhyay, S.; Sheen, S.; Liu, C.K.; Latona, N.; Pimentel, M.R.; Cooke, P.H. Critical evaluation of crispy and crunchy textures: A review. Int. J. Food Prop. 2013, 16, 949–963. [Google Scholar] [CrossRef]

- Solomon, W.K. Hydration kinetics of direct expanded tef flour breakfast cereals in water and milk. Food Sci. Nutr. 2014, 2, 39–45. [Google Scholar] [CrossRef]

- Chan, E.; Masatcioglu, T.M.; Koksel, F. Effects of different blowing agents on physical properties of extruded puffed snacks made from yellow pea and red lentil flours. J. Food Process Eng. 2019, 42, e12989. [Google Scholar] [CrossRef]

- Ilo, S.; Berghofer, E. Kinetics of colour changes during extrusion cooking of maize grits. J. Food Eng. 1999, 39, 73–80. [Google Scholar] [CrossRef]

- Andersson, Y.; Hedlund, B. Extruded wheat flour: Correlation between processing and product quality parameters. Food Qual. Prefer. 1990, 2, 201–216. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. The effect of extrusion on the bioactive compounds and antioxidant capacity of novel gluten-free expanded products based on carob fruit, pea and rice blends. Innov. Food Sci. Emerg. Technol. 2019, 52, 100–107. [Google Scholar] [CrossRef]

- Ciudad-Mulero, M.; Fernández-Ruiz, V.; Cuadrado, C.; Arribas, C.; Pedrosa, M.M.; Berrios, J.D.J.; Pan, J.; Morales, P. Novel gluten-free formulations from lentil flours and nutritional yeast: Evaluation of extrusion effect on phytochemicals and non-nutritional factors. Food Chem. 2020, 315, 126175. [Google Scholar] [CrossRef]

- Morales, P.; Berrios, J.D.J.; Varela, A.; Burbano, C.; Cuadrado, C.; Muzquiz, M.; Pedrosa, M.M. Novel fiber-rich lentil flours as snack-type functional foods: An extrusion cooking effect on bioactive compounds. Food Funct. 2015, 6, 3135–3143. [Google Scholar] [CrossRef] [PubMed]

- Borejszo, Z.B.; Khan, K.H. Reduction of flatulence-causing sugars by high temperature extrusion of pinto bean high starch fractions. J. Food Sci. 1992, 57, 771–777. [Google Scholar] [CrossRef]

- Hardacre, A.K.; Clark, S.M.; Riviere, S.; Monro, J.A.; Hawkins, A.J. Some textural, sensory and nutritional properties of expanded snack food wafers made from corn, lentil and other ingredients. J. Texture Stud. 2006, 37, 94–111. [Google Scholar] [CrossRef]

- Velasco, C.; Woods, A.T.; Deroy, O.; Spence, C. Hedonic mediation of the crossmodal correspondence between taste and shape. Food Qual. Prefer. 2015, 41, 151–158. [Google Scholar] [CrossRef]

| Red Lentil | Faba Bean | Brown Pea | Common Bean | |

|---|---|---|---|---|

| Fats (g/100 g) | 1.10 | 1.39 | 1.97 | 1.51 |

| Carbohydrates (g/100 g) | 29.50 | 58.90 | 47.80 | 49.88 |

| Total dietary fibers (g/100 g) | 30.50 | 8.40 | 10.50 | 15.50 |

| Proteins (g/100 g) | 25.80 | 17.80 | 25.10 | 21.40 |

| Energy value (kcal/100 g) | 292.10 | 336.00 | 330.00 | 329.71 |

| Red Lentil | Faba Bean | Brown Pea | Common Bean | |

|---|---|---|---|---|

| L* | 84.79 ± 0.36 c | 87.56 ± 0.03 b | 87.85 ± 0.31 b | 89.12 ± 0.37 a |

| a* | 9.45 ± 0.12 a | −0.49 ± 0.03 b | −0.75 ± 0.03 c | −0.56 ± 0.02 b |

| b* | 21.85 ± 0.25 a | 14.50 ± 0.05 b | 13.16 ± 0.02 c | 12.93 ± 0.04 c |

| Red Lentil | Faba Bean | Brown Pea | Common Bean | |

|---|---|---|---|---|

| Phytates (mg phytic acid/g d.m.) | 3.49 ± 0.09 d | 7.51 ± 0.09 b | 4.69 ± 0.02 c | 9.09 ± 0.11 a |

| Verbascose (mg/g d.m.) | 16.09 ± 0.09 b | 12.74 ± 0.10 c | 29.66 ± 0.23 a | 12.65 ± 0.40 c |

| Stachyose (mg/g d.m.) | 28.89 ± 0.67 c | 39.32 ± 1.11 a | 19.16 ± 0.85 d | 35.37 ± 0.98 b |

| Raffinose (mg/g d.m.) | 16.28 ± 0.68 a | 2.80 ± 0.14 d | 10.10 ± 0.88 b | 5.99 ± 0.43 c |

| Die Configuration | Legume | Physico-Chemical Parameter | ||||

|---|---|---|---|---|---|---|

| BD (g/cm3) | ER | WAI (g/g) | WSI (g/100 g) | DG (g/100 g) | ||

| Spherical | Red lentil | 0.41 ± 0.01 b | 2.10 ± 0.22 c | 3.83 ± 0.18 a | 9.32 ± 0.30 d | 95.21 ± 0.63 c |

| Faba bean | 0.21 ± 0.02 d | 2.46 ± 0.09 b | 3.22 ± 0.05 b | 16.79 ± 0.25 a | 98.29 ± 0.20 a | |

| Brown pea | 0.21 ± 0.00 d | 2.78 ± 0.12 a | 3.34 ± 0.14 b | 12.99 ± 0.89 b | 96.96 ± 0.66 b | |

| Common bean | 0.20 ± 0.01 d | 2.56 ± 0.23 b | 2.49 ± 0.09 c | 12.95 ± 0.61 b | 98.05 ± 0.05 a | |

| Star-shaped | Red lentil | 0.60 ± 0.03 a | 1.14 ± 0.04 f | 4.05 ± 0.20 a | 7.68 ± 0.36 e | 96.82 ± 0.21 b |

| Faba bean | 0.27 ± 0.02 c | 1.56 ± 0.05 de | 2.60 ± 0.03 c | 13.08 ± 0.56 b | 93.25 ± 0.14 d | |

| Brown pea | 0.27 ± 0.01 c | 1.70 ± 0.17 d | 3.33 ± 0.02 b | 10.62 ± 0.20 cd | 92.75 ± 0.40 d | |

| Common bean | 0.25 ± 0.01 c | 1.42 ± 0.07 e | 2.81 ± 0.18 c | 11.77 ± 0.61 bc | 96.99 ± 0.01 b | |

| Legume | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | |

| Die | p < 0.001 | p < 0.001 | p = 0.659 | p < 0.001 | p < 0.001 | |

| Legume × die | p < 0.001 | p < 0.05 | p < 0.001 | p < 0.01 | p < 0.001 | |

| Die Configuration | Legume | Dry | Milk-Soaked (Bowl Life) | ||||

|---|---|---|---|---|---|---|---|

| Hardness (N) | Crunchiness (N.s N·s) | Crispness | Hardness (N) | Crunchiness (N·s) | Crispness | ||

| Spherical | Red lentil | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| Faba bean | 606 ± 7 c | 1799 ± 84 c | 51.3 ± 2.1 cd | 395 ± 3 a | 610 ± 10 a | 14.3 ± 2.9 b | |

| Brown pea | 477 ± 13 d | 2354 ± 105 b | 71.0 ± 3.6 a | 384 ± 16 ab | 665 ± 75 a | 27.0 ± 1.7 a | |

| Common bean | 604 ± 39 c | 1469 ± 68 d | 53.3 ± 5.5 cd | 303 ± 1 d | 350 ± 3 c | 8.0 ± 1.0 c | |

| Star-shaped | Red lentil | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| Faba bean | 747 ± 21 b | 2582 ± 87 ab | 59.7 ± 2.5 bc | 355 ± 6 c | 513 ± 22 b | 15.0 ± 2.0 b | |

| Brown pea | 688 ± 13 b | 2629 ± 80 a | 65.7 ± 2.3 ab | 366 ± 9 bc | 497 ± 4 b | 19.0 ± 1.0 b | |

| Common bean | 1030 ± 41 a | 2372 ± 129 ab | 50.0 ± 1.0 d | 393 ± 8 a | 429 ± 20 bc | 9.3 ± 1.2 c | |

| Legume | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | |

| Die | p < 0.001 | p < 0.001 | p = 0.942 | p < 0.05 | p < 0.05 | p < 0.05 | |

| Legume × die | p < 0.001 | p < 0.001 | p < 0.01 | p < 0.001 | p < 0.001 | p = 0.001 | |

| Die Configuration | Legume | Color Parameters | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Spherical | Red lentil | 74.64 ± 0.07 b | 4.18 ± 0.03 c | 31.88 ± 0.02 b |

| Faba bean | 70.45 ± 0.21 f | 2.75 ± 0.06 e | 20.94 ± 0.07 f | |

| Brown pea | 70.46 ± 0.09 f | 2.55 ± 0.05 f | 19.54 ± 0.03 h | |

| Common bean | 72.64 ± 0.04 d | 4.91 ± 0.01 a | 24.54 ± 0.05 c | |

| Star-shaped | Red lentil | 74.87 ± 0.06 a | 4.52 ± 0.03 b | 33.24 ± 0.04 a |

| Faba bean | 72.24 ± 0.06 e | 2.22 ± 0.02 h | 20.70 ± 0.08 g | |

| Brown pea | 73.25 ± 0.09 c | 2.39 ± 0.02 g | 21.09 ± 0.07 e | |

| Common bean | 75.04 ± 0.02 a | 4.09 ± 0.01 d | 24.12 ± 0.02 d | |

| Legume | p < 0.001 | p < 0.001 | p < 0.001 | |

| Die | p < 0.001 | p < 0.001 | p < 0.001 | |

| Legume × die | p < 0.001 | p < 0.001 | p < 0.001 | |

| Die Configuration | Legume | Phytates Content (mg Phytic Acid/g d.m.) | Oligosaccharide Content (mg/g d.m.) | ||

|---|---|---|---|---|---|

| Verbascose | Stachyose | Raffinose | |||

| Spherical | Red lentil | 3.55 ± 0.05 d | 17.02 ± 0.27 b | 31.09 ± 0.15 d | 14.18 ± 0.14 b |

| Faba bean | 6.53 ± 0.21 b | 13.69 ± 0.06 c | 41.45 ± 0.64 a | 3.84 ± 0.02 f | |

| Brown pea | 4.47 ± 0.04 c | 28.48 ± 0.48 a | 22.04 ± 0.38 e | 11.43 ± 0.30 c | |

| Common bean | 6.89 ± 0.09 a | 12.51 ± 0.42 d | 34.76 ± 0.42 c | 5.54 ± 0.40 e | |

| Star-shaped | Red lentil | 3.55 ± 0.11 d | 14.50 ± 0.44 c | 30.58 ± 0.67 d | 17.43 ± 0.10 a |

| Faba bean | 6.66 ± 0.22 ab | 14.08 ± 0.62 c | 42.52 ± 0.07 a | 3.67 ± 0.32 f | |

| Brown pea | 4.17 ± 0.03 c | 28.70 ± 0.12 a | 22.45 ± 0.38 e | 11.08 ± 0.04 c | |

| Common bean | 6.98 ± 0.03 a | 11.41 ± 0.41 d | 37.31 ± 1.04 b | 6.93 ± 0.36 d | |

| Legume | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | |

| Die | p = 0.655 | p < 0.001 | p = 0.001 | p < 0.001 | |

| Legume × die | p < 0.05 | p < 0.001 | p < 0.01 | p < 0.001 | |

| Die Configuration | Legume | Appearance | Texture | Taste | Aftertaste |

|---|---|---|---|---|---|

| Spherical | Red lentil | 127 bc* | 178 b | 167 a | 149 ab |

| Faba bean | 106 cd | 98 cd | 124 b | 121 bc | |

| Brown pea | 107 cd | 105 cd | 101 bc | 113 bc | |

| Common bean | 76 d | 75 d | 75 c | 103 c | |

| Star-shaped | Red lentil | 199 a | 215 a | 199 a | 183 a |

| Faba bean | 160 b | 119 c | 126 b | 121 bc | |

| Brown pea | 132 bc | 123 c | 116 b | 115 bc | |

| Common bean | 101 cd | 95 cd | 100 bc | 102 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costantini, M.; Sabovics, M.; Galoburda, R.; Kince, T.; Straumite, E.; Summo, C.; Pasqualone, A. Effect of Die Configuration on the Physico-Chemical Properties, Anti-Nutritional Compounds, and Sensory Features of Legume-Based Extruded Snacks. Foods 2021, 10, 3015. https://doi.org/10.3390/foods10123015

Costantini M, Sabovics M, Galoburda R, Kince T, Straumite E, Summo C, Pasqualone A. Effect of Die Configuration on the Physico-Chemical Properties, Anti-Nutritional Compounds, and Sensory Features of Legume-Based Extruded Snacks. Foods. 2021; 10(12):3015. https://doi.org/10.3390/foods10123015

Chicago/Turabian StyleCostantini, Michela, Martins Sabovics, Ruta Galoburda, Tatjana Kince, Evita Straumite, Carmine Summo, and Antonella Pasqualone. 2021. "Effect of Die Configuration on the Physico-Chemical Properties, Anti-Nutritional Compounds, and Sensory Features of Legume-Based Extruded Snacks" Foods 10, no. 12: 3015. https://doi.org/10.3390/foods10123015

APA StyleCostantini, M., Sabovics, M., Galoburda, R., Kince, T., Straumite, E., Summo, C., & Pasqualone, A. (2021). Effect of Die Configuration on the Physico-Chemical Properties, Anti-Nutritional Compounds, and Sensory Features of Legume-Based Extruded Snacks. Foods, 10(12), 3015. https://doi.org/10.3390/foods10123015