Effect of Different Aging Methods on the Formation of Aroma Volatiles in Beef Strip Loins

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Aging Process

2.2. Volatile Compound Analysis

2.3. Mold Distribution

2.4. Free Fatty Acids

2.5. Statistical Analysis

3. Results

3.1. Volatile Profiling of Aged Beef

3.1.1. Aldehydes, Furans and Ketones

3.1.2. N-Containing Compounds

3.1.3. S-Containing Compounds

3.1.4. Alcohols

3.1.5. Hydrocarbons, Esters, and Acids

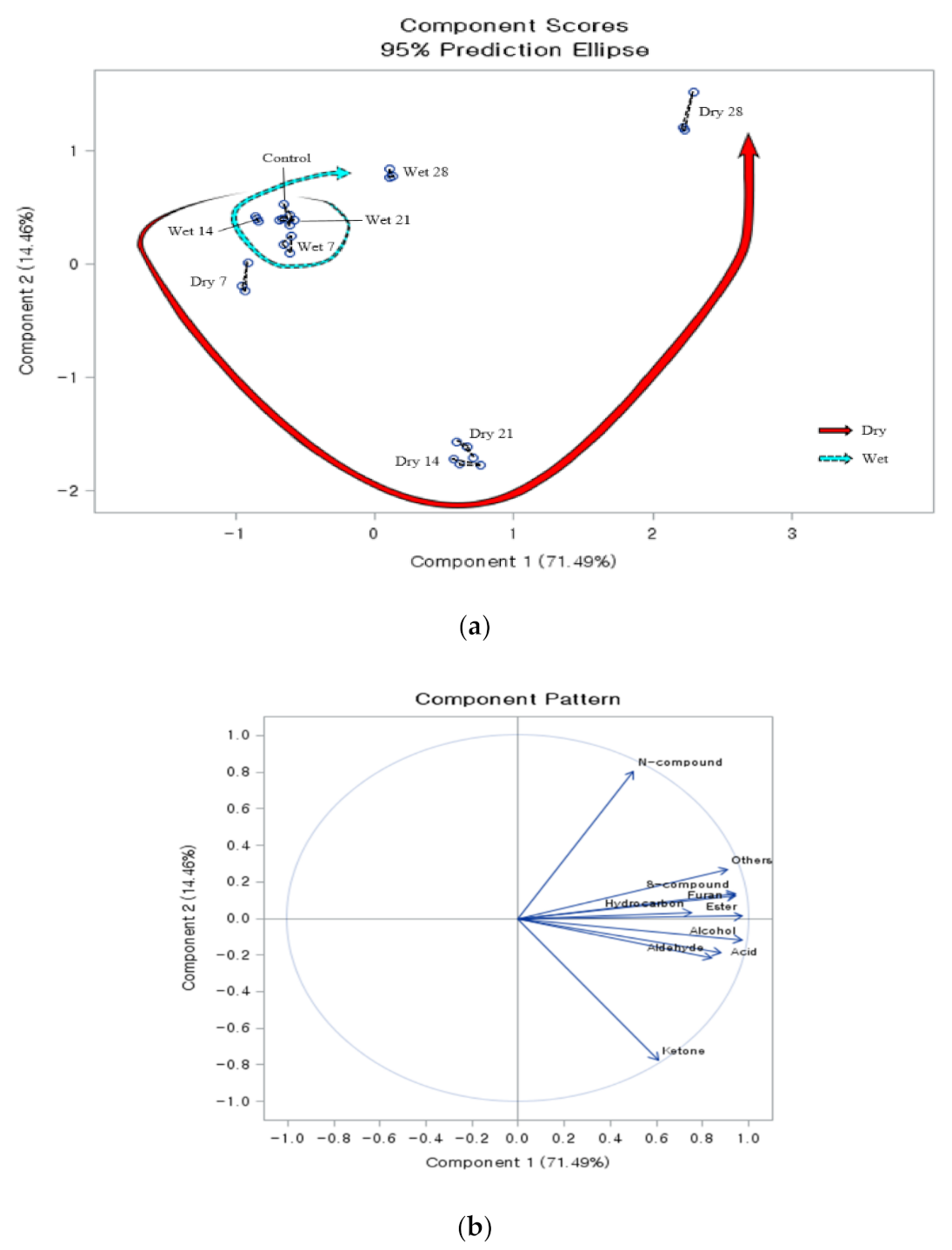

3.2. Volatile Patterns of Aged Beef

3.3. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, S.K.; Yim, D.G. Comparison of effects of two aging methods on the physicochemical traits of pork loin. Food Sci. Anim. Resour. 2020, 40, 844–851. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, D.H.; Ji, D.S.; Lee, H.J.; Yoon, D.K.; Lee, C.H. Effect of aging process and time on physicochemical and sensory evaluation of raw beef top round and shank muscles using an electronic tongue. Korean J. Food Sci. Anim. Resour. 2017, 37, 823–832. [Google Scholar] [PubMed]

- Lee, H.J.; Yoon, J.W.; Kim, M.; Oh, H.; Yoon, Y.; Jo, C. Changes in microbial composition on the crust by different air flow velocities and their effect on sensory properties of dry-aged beef. Meat Sci. 2019, 153, 152–158. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Choe, J.; Lee, H.J.; Yoon, Y.; Yoon, S.; Jo, C. Effects of aging and aging method on physicochemical and sensory traits of different beef cuts. Food Sci. Anim. Resour. 2019, 39, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Ba, H.V.; Hwang, I.; Jeong, D.; Touseef, A. Principle of meat aroma flavors and future prospect. In Latest Research into Quality Control; Akyar, I., Ed.; InTech: Rijeka, Croatia, 2012; pp. 146–176. [Google Scholar]

- Aaslyng, M.D.; Meinert, L. Meat flavor in pork and beef—From animal to meal. Meat Sci. 2017, 132, 112–117. [Google Scholar] [CrossRef] [PubMed]

- Mottram, D.S. Flavour formation in meat and meat products: A review. Food Chem. 1998, 62, 415–424. [Google Scholar] [CrossRef]

- Lee, H.J.; Choe, J.; Kim, M.; Kim, H.C.; Yoon, J.W.; Oh, S.W.; Jo, C. Role of moisture evaporation in the taste attributes of dry- and wet-aged beef determined by chemical and electronic tongue analyses. Meat Sci. 2019, 151, 82–88. [Google Scholar] [CrossRef]

- Watanabe, A.; Kamada, G.; Imanari, M.; Shiba, N.; Yonai, M.; Muramoto, T. Effect of aging on volatile compounds in cooked beef. Meat Sci. 2015, 107, 12–19. [Google Scholar] [CrossRef]

- Yang, J.; Dashdorj, D.; Hwang, I. Volatile flavor components as a function of electrical stimulation and chiller aging for m. longissimus and biceps femoris of Hanwoo beef. Food Sci. Anim. Resour. 2019, 39, 474–493. [Google Scholar] [CrossRef]

- Chung, K.Y.; Lee, S.H.; Cho, S.H.; Kwon, E.G.; Lee, J.H. Current situation and future prospects for beef production in South Korea—A review. Asian-Australas. J. Anim. Sci. 2018, 31, 951–960. [Google Scholar] [CrossRef]

- Oh, J.; Lee, H.J.; Yoon, J.W.; Choe, J.; Jo, C. Electrical resistance and mold distribution on beef surface as indicators of dry aging. J. Food Process Eng. 2019, 42, e13122. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Wang, L.; Niu, Y.; Xiao, Z. Evaluation of the synergism among volatile compounds in Oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. 2017, 221, 1484–1490. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Tao, N.P.; Gu, S. Characterization of the key odor-active compounds in steamed meat of Coilia ectenes from Yangtze River by GC-MS-O. Eur. Food Res. Technol. 2014, 238, 237–245. [Google Scholar] [CrossRef]

- Madruga, M.S.; Elmore, J.S.; Oruna-Concha, M.J.; Balagiannis, D.; Mottram, D.S. Determination of some water-soluble aroma precursors in goat meat and their enrolment on flavour profile of goat meat. Food Chem. 2010, 123, 513–520. [Google Scholar] [CrossRef]

- American Industrial Hygiene Association. Odor Thresholds for Chemicals with Established Occupational Health Standards, 2nd ed.; American Industrial Hygiene Association: Fairfax, VA, USA, 1989; pp. 14–28. [Google Scholar]

- Keatkrai, J.; Jirapakkul, W. Volatile profile of khanom jeen, Thai fermented rice noodles, and the changes during the fermentation process. Sci. Asia 2010, 36, 46–51. [Google Scholar] [CrossRef]

- Nagata, Y. Measurement of Odor Threshold by Triangle Odor Bag Method. Japan Environmental Sanitation Center; Retrieved; February 2010. Available online: http://www.env.go.jp/en/air/odor/olfactory_mm/04ref_2.pdf (accessed on 14 December 2020).

- Hou, L.; Zhang, Y.; Wang, X. Characterization of the volatile compounds and taste attributes of sesame pastes processed at different temperatures. J. Oleo Sci. 2019, 68, 551–558. [Google Scholar] [CrossRef]

- Giannoukos, S.; Brkić, B.; Taylor, S. Direct analysis and monitoring of organosulphur compounds in the gaseous phase using portable mass spectrometry. Anal. Methods 2019, 11, 4882–4889. [Google Scholar] [CrossRef]

- Dregus, M.; Engel, K.H. Volatile constituents of uncooked rhubarb (Rheum rhabarbarum L.) stalks. J. Agric. Food Chem. 2003, 51, 6530–6536. [Google Scholar] [CrossRef]

- Saini, R.; Jaitak, V.; Guleria, S.; Kaul, V.K.; Kiran Babu, G.D.; Singh, B.; Lal, B.; Singh, R.D. Comparison of headspace analysis of volatile constituents with GCMS analysis of hydrodistilled and supercritical fluid extracted oil of Capillipedium parviflorum. J. Essent. Oil Res. 2012, 24, 315–320. [Google Scholar] [CrossRef]

- Yu, H.; Seow, Y.X.; Ong, P.K.; Zhou, W. Effects of ultrasonic processing and oil type on Maillard reaction of D-glucose and L-alanine in oil-in-water systems. Food Bioproc. Tech. 2019, 12, 325–337. [Google Scholar] [CrossRef]

- Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Gebicki, J.; Namieśnik, J. Poultry meat freshness evaluation using electronic nose technology and ultra-fast gas chromatography. Monatsh. Chem. 2017, 148, 1631–1637. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Wang, R.; Xiao, Z.; Zhu, J.; Sun, X.; Wang, P. Characterization of ester odorants of apple juice by gas chromatography-olfactometry, quantitative measurements, odour threshold, aroma intensity and electronic nose. Food Res. Int. 2019, 120, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Blank, I.; Sen, A.; Grosch, W. Sensory study on the character-impact flavour compounds of dill herb (Anethum graveolens L.). Food Chem. 1992, 43, 337–343. [Google Scholar] [CrossRef]

- Casaburi, A.; Piombino, P.; Nychas, G.J.; Villani, F.; Ercolini, D. Bacterial populations and the volatilome associated to meat spoilage. Food Microbiol. 2015, 45, 83–102. [Google Scholar] [CrossRef]

- Ozkara, K.T.; Amanpour, A.; Guclu, G.; Kelebek, H.; Selli, S. GC-MS-Olfactometric differentiation of aroma-active compounds in turkish heat-treated sausages by application of aroma extract dilution analysis. Food Anal. Methods 2019, 12, 729–741. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H.J.; Kim, M.; Yoon, J.W.; Shin, D.J.; Jo, C. Storage stability of vacuum-packaged dry-aged beef during refrigeration at 4 °C. Food Sci. Anim. Resour. 2019, 39, 266–275. [Google Scholar] [CrossRef]

- Kahraman, H.A.; Gurbuz, U. Effects of three aging methods on the Longissimus lumborum muscle from Holstein-Friesian steers. Med. Weter. 2019, 75, 179–184. [Google Scholar] [CrossRef]

- Muriel, E.; Antequera, T.; Petrón, M.J.; Andrés, A.I.; Ruiz, J. Volatile compounds in Iberian dry-cured loin. Meat Sci. 2004, 68, 391–400. [Google Scholar] [CrossRef]

- Kim, Y.H.B.; Kemp, R.; Samuelsson, L.M. Effects of dry-aging on meat quality attributes and metabolite profiles of beef loins. Meat Sci. 2016, 111, 168–176. [Google Scholar] [CrossRef]

- Bruna, J.M.; Hierro, E.M.; de la Hoz, L.; Mottram, D.S.; Fernández, M.; Ordóñez, J.A. The contribution of Penicillium aurantiogriseum to the volatile composition and sensory quality of dry fermented sausages. Meat Sci. 2001, 59, 97–107. [Google Scholar] [CrossRef]

- Domínguez, R.; Purriños, L.; Pérez-Santaescolástica, C.; Pateiro, M.; Barba, F.J.; Tomasevic, I.; Campagnol, P.C.B.; Lorenzo, J.M. Characterization of volatile compounds of dry-cured meat products using HS-SPME-GC/MS technique. Food Anal. Methods 2019, 12, 1263–1284. [Google Scholar] [CrossRef]

- Iucci, L.; Patrignani, F.; Belletti, N.; Ndagijimana, M.; Guerzoni, M.E.; Gardini, F.; Lanciotti, R. Role of surface-inoculated Debaryomyces hansenii and Yarrowia lipolytica strains in dried fermented sausage manufacture. Part 2: Evaluation of their effects on sensory quality and biogenic amine content. Meat Sci. 2007, 75, 669–675. [Google Scholar] [CrossRef] [PubMed]

- Iida, F.; Miyazaki, Y.; Tsuyuki, R.; Kato, K.; Egusa, A.; Ogoshi, H.; Nishimura, T. Changes in taste compounds, breaking properties, and sensory attributes during dry aging of beef from Japanese black cattle. Meat Sci. 2016, 112, 46–51. [Google Scholar] [CrossRef] [PubMed]

- Sekhon, R.K.; Schilling, M.W.; Phillips, T.W.; Aikins, M.J.; Hasan, M.M.; Corzo, A.; Mikel, W.B. Effects of phosphine and methyl bromide fumigation on the volatile flavor profile and sensory quality of dry cured ham. Meat Sci. 2010, 86, 411–417. [Google Scholar] [CrossRef] [PubMed]

- Flores, M. Understanding the implications of current health trends on the aroma of wet and dry cured meat products. Meat Sci. 2018, 144, 53–61. [Google Scholar] [CrossRef]

- Ma, Q.L.; Hamid, N.; Bekhit, A.E.D.; Robertson, J.; Law, T.F. Evaluation of pre-rigor injection of beef with proteases on cooked meat volatile profile after 1 day and 21 days post-mortem storage. Meat Sci. 2012, 92, 430–439. [Google Scholar] [CrossRef] [PubMed]

- Maggiolino, A.; Lorenzo, J.M.; Marino, R.; Della Malva, A.; Centoducati, P.; De Palo, P. Foal meat volatile compounds: Effect of vacuum ageing on semimembranosus muscle. J. Sci. Food Agric. 2019, 99, 1660–1667. [Google Scholar] [CrossRef]

- Corral, S.; Belloch, C.; López-Díez, J.J.; Flores, M. Lipolysis and aroma generation as mechanisms involved in masking boar taint in sodium reduced fermented sausages inoculated with Debaryomyces hansenii yeast. J. Sci. Food. Agric. 2018, 98, 2121–2130. [Google Scholar] [CrossRef]

- Oh, H.; Lee, H.J.; Lee, J.; Jo, C.; Yoon, Y. Identification of microorganisms associated with the quality improvement of dry-aged beef through microbiome analysis and DNA sequencing, and evaluation of their effects on beef quality. J. Food Sci. 2019, 84, 2944–2954. [Google Scholar] [CrossRef]

| Parameter | Condition | |

|---|---|---|

| Headspace generation | Incubation temperature | 80 °C |

| Incubation time | 10 min | |

| Trap | Initial temperature | 40 °C |

| Split | 10 mL/min | |

| Trapping duration | 30 s | |

| Final temperature | 240 °C | |

| Injector | Carrier gas | Hydrogen |

| Injected volume | 5 mL | |

| Injected speed | 250 µL/s | |

| Injector temperature | 200 °C | |

| Column | Column temperature | 40 °C for 5 s |

| Increased at 0.5 °C/s, held for 5 s at 150 °C | ||

| Increased at 5 °C/s, held for 30 s at 260 °C | ||

| Acquisition duration | 282 s | |

| Detector | Type | Flame ionized detector (dual) |

| No. | Volatile Compound | RT 1 | RI 2 | Aroma Description | Odor Threshold (ppm) |

|---|---|---|---|---|---|

| Aldehydes, furans, and ketones | |||||

| 1 | (E, E)-2, 4-Hexadienal | 116.86 | 81.10 | Citrus, floral, green, spicy, sweet | 94.8 [13] |

| 2 | 2-Methylbutanal | 28.30 | 92.02 | Ethereal, nutty, sweet [14] | 1 [14] |

| 3 | 2-Methylpropanal | 16.39 | 51.36 | Camphor, green, malty, pungent, sharp [15] | 0.7 [13] |

| 4 | Propanal | 14.13 | 65.50 | Almond, cherry, green, fruity [14] | 25.1 [14] |

| 5 | Tetrahydrofuran | 21.72 | 93.82 | Aromatic, burnt, fruity, sulfurous, sweet | 92-61,000 [16] |

| 6 | 3-Heptanone | 87.14 | 90.67 | Fatty, fruity, green, spicy, sweet | 140 [17] |

| N-containing compounds | |||||

| 1 | 1-Butanamine | 25.03 | 85.38 | Ammoniacal, fishy | 170 [18] |

| 2 | Ethenyl-dimethylpyrazine | 147.23 | 93.75 | Earthy, musty | no reference |

| 3 | 2-Pentylpyridine | 108.94 | 84.18 | Fatty, green, mushroom, pepper, tallowy | 5 [19] |

| 4 | Trimethylamine | 11.10 | 74.73 | Ammoniacal, fishy, fruity, oily, pungent, rancid, sweaty | 2.4 [14] |

| S-containing compounds | |||||

| 1 | 2-Methyl-2-propanethiol | 17.99 | 88.64 | Sulfurous | 0.33 [20] |

| 2 | Carbon disulfide | 17.30 | 71.60 | Burnt, cabbage, fruity, sulfurous [15] | 210 [18] |

| 3 | Dimethyl trisulfide | 101.67 | 85.46 | Alliaceous, cabbage, fishy, meaty, onion, sulfurous | 0.1 [14] |

| Alcohols | |||||

| 1 | 1-Methoxy-2-propanol | 34.76 | 76.18 | Mild | 839-33,000 [16] |

| 2 | 2-Butanol | 28.35 | 56.68 | Pleasant, strong, sweet, wine | 220 [18] |

| 3 | 4-Methyl-1-hexanol | 97.21 | 92.13 | Grassy, sweaty, nutty, oily, roasty | 2000 [21] |

| 4 | 4-Nonanol | 139.31 | 76.28 | Sweet [21,22] | no reference |

| Hydrocarbons, esters, and acids | |||||

| 1 | 2, 2-Dichloropropane | 21.81 | 89.93 | no reference | no reference |

| 2 | 3-Methyldecane | 134.73 | 82.85 | Balsamic, mild, phenolic | no reference |

| 3 | 4-Methyldecane | 132.13 | 91.50 | Fatty, fresh, waxy [23] | no reference |

| 4 | Butane | 11.08 | 68.12 | Faint | 1,200,000 [18] |

| 5 | Ethylcyclopentane | 38.58 | 76.25 | Alkane, fruity, gasoline, sweet | no reference |

| 6 | Heptane | 33.95 | 60.05 | Floral, fruity, sweet | 400,000 [24] |

| 7 | Octane | 41.04 | 95.87 | Alkane, fruity, sweet, fatty, solvent [15] | 1700 [18] |

| 8 | Ethyl propanoate | 31.10 | 86.29 | Burnt, fermented, fruity, green, malty, nutty, sour | 0.01 [25] |

| 9 | Methyl 2-methylbutanoate | 44.63 | 90.84 | Fatty, fruity, green | 0.4 [26] |

| 10 | Methyl 2-butenoate | 41.36 | 77.98 | Blackcurrant, fruity | no reference |

| 11 | Propyl propanoate | 58.53 | 90.15 | Fruity, green, sweet | 0.88 [25] |

| 12 | 2-Methylpropanoic acid | 49.12 | 77.12 | Dairy, fatty, pungent, rancid, sour, sweaty | 50 [17] |

| 13 | Hexanoic acid | 110.28 | 91.42 | Cheesy, fatty, pungent, rancid, sour, sweaty | 3,000,000 [27] |

| Others | |||||

| 1 | 1, 2, 4-Thiadiazole, 5-ethoxy-3-(trichloromethyl)- | 248.10 | 87.34 | Mild | no reference |

| 2 | Demeton-O | 264.10 | 59.09 | no reference | no reference |

| 3 | Diisopropyl ether | 16.83 | 89.64 | Ethereal | no reference |

| 4 | Ethyl chloride | 13.93 | 92.29 | Ethereal, pungent | 3800–379,000 [16] |

| 5 | Limonene | 125.69 | 78.19 | Citrus, fruity, minty | 38 [18] |

| 6 | P-cymene | 121.27 | 93.22 | Citrus, fruity, herbaceous, pleasant, solvent, spicy, sweet | 120 [28] |

| 7 | Perfluorononane | 9.25 | 87.80 | no reference | no reference |

| Compound | Aging Method | Aging Period (d) | SEM 1 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | |||

| Aldehyde | |||||||

| (E, E)-2, 4-Hexadienal | Dry | 376 a | 137 bx | 99 c | 113 cy | 153 bx | 6.5 |

| Wet | 376 a | 121 by | 94 c | 137 bx | 56 dy | 6.7 | |

| SEM 2 | 10.5 | 2.9 | 8.8 | 4.1 | 2.5 | ||

| 2-Methylbutanal | Dry | 845 c | 742 cx | 2495 bx | 1667 cx | 4503 ax | 246.9 |

| Wet | 845 b | 529 cy | 341 dy | 639 cy | 1827 ay | 47.8 | |

| SEM 2 | 7.8 | 46.1 | 353.7 | 40.5 | 170.9 | ||

| 2-Methylpropanal | Dry | 506 b | 657 by | 864 bx | 1077 bx | 2458 ax | 309.1 |

| Wet | 506 b | 821 ax | nd cy | nd cy | nd cy | 7.3 | |

| SEM 2 | 11.4 | 9.0 | 38.2 | 9.4 | 487.1 | ||

| Propanal | Dry | 17,635 c | 9067 dy | 43,508 ax | 20,185 cx | 38,743 bx | 1139.6 |

| Wet | 17,635 a | 14,111 bx | 16,915 ay | 12,344 cy | 14,394 by | 275.4 | |

| SEM 2 | 300.0 | 663.7 | 676.5 | 838.4 | 1321.1 | ||

| Total | Dry | 19,361 b | 10,603 cy | 46,966 ax | 23,042 bx | 45,857 ax | 1174.5 |

| Wet | 19,361 a | 15,582 cx | 17,349 by | 13,119 dy | 16,277 cy | 313.7 | |

| SEM 2 | 296.2 | 683.3 | 1027.0 | 841.9 | 1173.3 | ||

| Furan | |||||||

| Tetrahydrofuran | Dry | 292 e | 900 d | 2143 cx | 3731 bx | 6262 ax | 60.6 |

| Wet | 292 e | 960 d | 1128 cy | 1399 by | 3068 ay | 21.4 | |

| SEM 2 | 9.4 | 31.2 | 28.6 | 35.8 | 84.6 | ||

| Ketone | |||||||

| 3-Heptanone | Dry | 104 e | 352 dx | 1237 bx | 1465 ax | 675 cx | 19.4 |

| Wet | 104 a | 83 by | nd dy | nd dy | 60 cy | 3.6 | |

| SEM 2 | 6.6 | 17.4 | 7.3 | 22.6 | 8.0 | ||

| Compound | Aging Method | Aging Period (d) | SEM 1 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | |||

| 1-Butanamine | Dry | 274 b | 72 by | 334 bx | 133 by | 3048 ax | 62.9 |

| Wet | 274 a | 135 cx | 145 cy | 218 bx | 87 dy | 5.5 | |

| SEM 2 | 11.4 | 7.6 | 4.8 | 10.9 | 98.2 | ||

| Ethenyl-dimethylpyrazine | Dry | 443 b | 751 ax | 441 bx | 488 bx | 507 b | 41.9 |

| Wet | 443 a | 357 by | 246 cy | 218 cy | 364 b | 10.1 | |

| SEM 2 | 6.5 | 42.5 | 20.5 | 7.1 | 48.1 | ||

| 2-Pentylpyridine | Dry | nd b | nd b | nd b | nd by | 425 ax | 1.4 |

| Wet | nd c | nd c | nd c | 361 ax | 188 by | 8.4 | |

| SEM 2 | - | - | - | 1.1 | 13.4 | ||

| Trimethylamine | Dry | 11,806 b | 4728 c | 2045 dy | 1052 dy | 17,487 ax | 546.6 |

| Wet | 11,806 a | 4924 d | 6727 cx | 6949 cx | 9019 by | 212.8 | |

| SEM 2 | 110.4 | 611.2 | 145.3 | 232.9 | 631.7 | ||

| Total | Dry | 12,523 b | 5551 c | 2820 dy | 1673 dy | 21,466 ax | 605.5 |

| Wet | 12,523 a | 5415 d | 7117 cx | 7746 cx | 9658 by | 216.6 | |

| SEM 2 | 127.4 | 601.9 | 154.1 | 220.4 | 763.5 | ||

| Compound | Aging Method | Aging Period (d) | SEM 1 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | |||

| 2-Methyl-2-propanethiol | Dry | 1025 d | 875 dy | 5342 bx | 2729 cx | 9680 ax | 142.8 |

| Wet | 1025 c | 1644 ax | 1015 cy | 754 dy | 1477 by | 30.6 | |

| SEM 2 | 41.2 | 24.0 | 193.9 | 76.1 | 87.7 | ||

| Carbon disulfide | Dry | 1174 d | 758 dy | 4401 cx | 5267 bx | 8403 ay | 168.3 |

| Wet | 1174 e | 3628 bx | 1523 dy | 1989 cy | 9787 ax | 62.7 | |

| SEM 2 | 8.4 | 67.6 | 68.2 | 234.8 | 127.1 | ||

| Dimethyl trisulfide | Dry | 122 a | 125 ay | 138 ax | 101 bx | 79 c | 4.7 |

| Wet | 122 b | 133 ax | 79 cy | 59 ey | 66 d | 1.7 | |

| SEM 2 | 2.7 | 1.3 | 4.1 | 4.5 | 4.1 | ||

| Total | Dry | 2320 d | 1758 dy | 9882 bx | 8097 cx | 18,162 ax | 261.7 |

| Wet | 2320 e | 5405 bx | 2616 dy | 2802 cy | 11,330 ay | 49.9 | |

| SEM 2 | 32.5 | 63.0 | 223.2 | 300.5 | 179.7 | ||

| Compound | Aging Method | Aging Period (d) | SEM 1 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | |||

| 1-Methoxy-2-propanol | Dry | 749 d | 723 dx | 2532 ax | 2212 bx | 1515 cx | 36.8 |

| Wet | 749 a | 291 by | 106 cy | 17 dy | 316 by | 20.7 | |

| SEM 2 | 33.7 | 37.3 | 24.9 | 17.8 | 31.4 | ||

| 2-Butanol | Dry | 102 c | nd dy | 891 c | 2005 bx | 5308 ax | 231.3 |

| Wet | 102 d | 146 dx | 236 c | 402 by | 890 ay | 19.1 | |

| SEM 2 | 3.9 | 4.2 | 280.7 | 41.5 | 232.5 | ||

| 4-Methyl-1-hexanol | Dry | nd d | nd d | 120 cx | 168 ax | 131 bx | 3.2 |

| Wet | nd | nd | nd y | nd y | nd y | - | |

| SEM 2 | - | - | 2.2 | 1.9 | 4.2 | ||

| 4-Nonanol | Dry | nd c | nd c | 19 bx | 60 b | 135 a | 14.1 |

| Wet | nd c | nd c | nd cy | 60 b | 177 a | 11.0 | |

| SEM 2 | - | - | 13.2 | 3.3 | 24.9 | ||

| Total | Dry | 850 d | 723 dx | 3562 cx | 4444 bx | 7089 ax | 215.8 |

| Wet | 850 b | 437 cy | 342 dy | 479 cy | 1382 ay | 28.2 | |

| SEM 2 | 31.3 | 38.1 | 266.2 | 50.9 | 206.2 | ||

| Compound | Aging Method | Aging Period (d) | SEM 1 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | |||

| Hydrocarbon | |||||||

| 2, 2-Dichloropropane | Dry | 2604 e | 4274 d | 12,837 bx | 11,361 c | 15,398 ay | 319.2 |

| Wet | 2604 c | 4931 c | 5041 cy | 7597 b | 20,477 ax | 659.1 | |

| SEM 2 | 35.8 | 231.0 | 405.9 | 992.9 | 368.0 | ||

| 3-Methyldecane | Dry | nd b | nd b | nd b | nd b | 98 ax | 1.2 |

| Wet | nd | nd | nd | nd | nd y | - | |

| SEM 2 | - | - | - | - | 1.9 | ||

| 4-Methyldecane | Dry | nd b | nd b | nd b | nd b | 149 ax | 1.7 |

| Wet | nd | nd | nd | nd | nd y | - | |

| SEM 2 | - | - | - | - | 2.6 | ||

| Butane | Dry | 251 d | 316 bx | 280 cx | 297 bcx | 715 ax | 8.5 |

| Wet | 251 b | 203 dy | 233 cy | 251 by | 261 ay | 1.7 | |

| SEM 2 | 1.1 | 2.7 | 0.6 | 2.9 | 13.1 | ||

| Ethylcyclopentane | Dry | nd c | nd c | 799 bx | 1430 ax | 1372 ax | 48.9 |

| Wet | nd | nd | nd y | nd y | nd y | - | |

| SEM 2 | - | - | 31.7 | 61.9 | 33.9 | ||

| Heptane | Dry | nd d | nd d | 169 ax | 127 cy | 149 by | 6.3 |

| Wet | nd d | nd d | 28 cy | 1370 bx | 1537 ax | 40.5 | |

| SEM 2 | - | - | 20.5 | 35.4 | 50.2 | ||

| Octane | Dry | 803 d | 937 cd | 998 cx | 1300 bx | 1791 ax | 44.0 |

| Wet | 803 b | 844 b | 485 cy | 967 ay | 602 cy | 36.2 | |

| SEM 2 | 60.5 | 44.3 | 18.0 | 14.9 | 44.0 | ||

| Total | Dry | 3658 d | 5527 c | 15,083 bx | 14,515 bx | 19,671 ay | 340.0 |

| Wet | 3658 c | 5978 c | 5787 cy | 10,184 by | 22,877 ax | 692.2 | |

| SEM 2 | 58.2 | 265.9 | 426.9 | 1043.7 | 375.7 | ||

| Ester | |||||||

| Ethyl propanoate | Dry | 1009 c | 381 d | 2854 bx | 3087 bx | 6761 ax | 107.5 |

| Wet | 1009 a | 327 b | 254 by | 298 by | 829 ay | 73.3 | |

| SEM 2 | 154.2 | 74.8 | 25.8 | 35.1 | 105.0 | ||

| Methyl 2-methylbutanoate | Dry | 326 b | 205 dy | 261 cx | 367 ax | 358 a | 7.6 |

| Wet | 326 b | 234 dx | 202 ey | 280 cy | 372 a | 8.2 | |

| SEM 2 | 13.2 | 6.7 | 4.2 | 5.6 | 6.6 | ||

| Methyl 2-butenoate | Dry | nd b | nd b | 123 ax | 187 ax | 158 ax | 30.9 |

| Wet | nd | nd | nd y | nd y | nd y | - | |

| SEM 2 | - | - | 3.8 | 5.9 | 48.3 | ||

| Propyl propanoate | Dry | 3015 a | 80 ey | 715 bx | 322 dx | 471 cy | 15.1 |

| Wet | 3015 a | 380 cx | 150 dy | 176 dy | 1183 bx | 20.5 | |

| SEM 2 | 23.4 | 19.9 | 11.9 | 8.0 | 21.6 | ||

| Total | Dry | 4349 b | 666 d | 3953 cx | 3964 cx | 7748 ax | 88.5 |

| Wet | 4349 a | 941 c | 606 dy | 754 cdy | 2383 by | 65.8 | |

| SEM 2 | 136.2 | 77.5 | 29.6 | 44.5 | 54.7 | ||

| Acid | |||||||

| 2-Methylpropanoic acid | Dry | nd c | nd c | 87 ax | 82 ax | 64 bx | 1.9 |

| Wet | nd | nd | nd y | nd y | nd y | - | |

| SEM 2 | - | - | 2.6 | 1.0 | 1.2 | ||

| Hexanoic acid | Dry | 167 b | nd cy | 165 bx | 140 bx | 248 ax | 9.5 |

| Wet | 167 a | 99 bx | nd cy | 108 by | 119 by | 8.7 | |

| SEM 2 | 15.8 | 6.7 | 5.5 | 5.9 | 7.6 | ||

| Total | Dry | 167 d | nd ey | 252 bx | 222 cx | 311 ax | 8.9 |

| Wet | 167 a | 99 bx | nd cy | 108 by | 119 by | 8.7 | |

| SEM 2 | 15.8 | 6.7 | 4.1 | 5.6 | 6.6 | ||

| Chemical Group | Mold Distribution | Unsaturated Fatty Acids | ||

|---|---|---|---|---|

| Dry | Wet | Dry | Wet | |

| Acid | 0.63 * | - | 0.83 ** | ns |

| Alcohol | 0.84 *** | - | 0.61 * | ns |

| Aldehyde | 0.59 * | - | 0.84 *** | −0.71 ** |

| Ester | 0.81 ** | - | 0.67 ** | ns |

| Furan and ketone | 0.78 ** | - | ns | ns |

| Hydrocarbon | 0.71 ** | - | 0.63 * | ns |

| N-compound | 0.80 ** | - | ns | ns |

| S-compound | 0.87 *** | - | 0.62 * | ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Lee, H.J.; Yoon, J.W.; Kim, M.; Jo, C. Effect of Different Aging Methods on the Formation of Aroma Volatiles in Beef Strip Loins. Foods 2021, 10, 146. https://doi.org/10.3390/foods10010146

Lee D, Lee HJ, Yoon JW, Kim M, Jo C. Effect of Different Aging Methods on the Formation of Aroma Volatiles in Beef Strip Loins. Foods. 2021; 10(1):146. https://doi.org/10.3390/foods10010146

Chicago/Turabian StyleLee, Dongheon, Hyun Jung Lee, Ji Won Yoon, Minsu Kim, and Cheorun Jo. 2021. "Effect of Different Aging Methods on the Formation of Aroma Volatiles in Beef Strip Loins" Foods 10, no. 1: 146. https://doi.org/10.3390/foods10010146

APA StyleLee, D., Lee, H. J., Yoon, J. W., Kim, M., & Jo, C. (2021). Effect of Different Aging Methods on the Formation of Aroma Volatiles in Beef Strip Loins. Foods, 10(1), 146. https://doi.org/10.3390/foods10010146