Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study

Abstract

1. Introduction

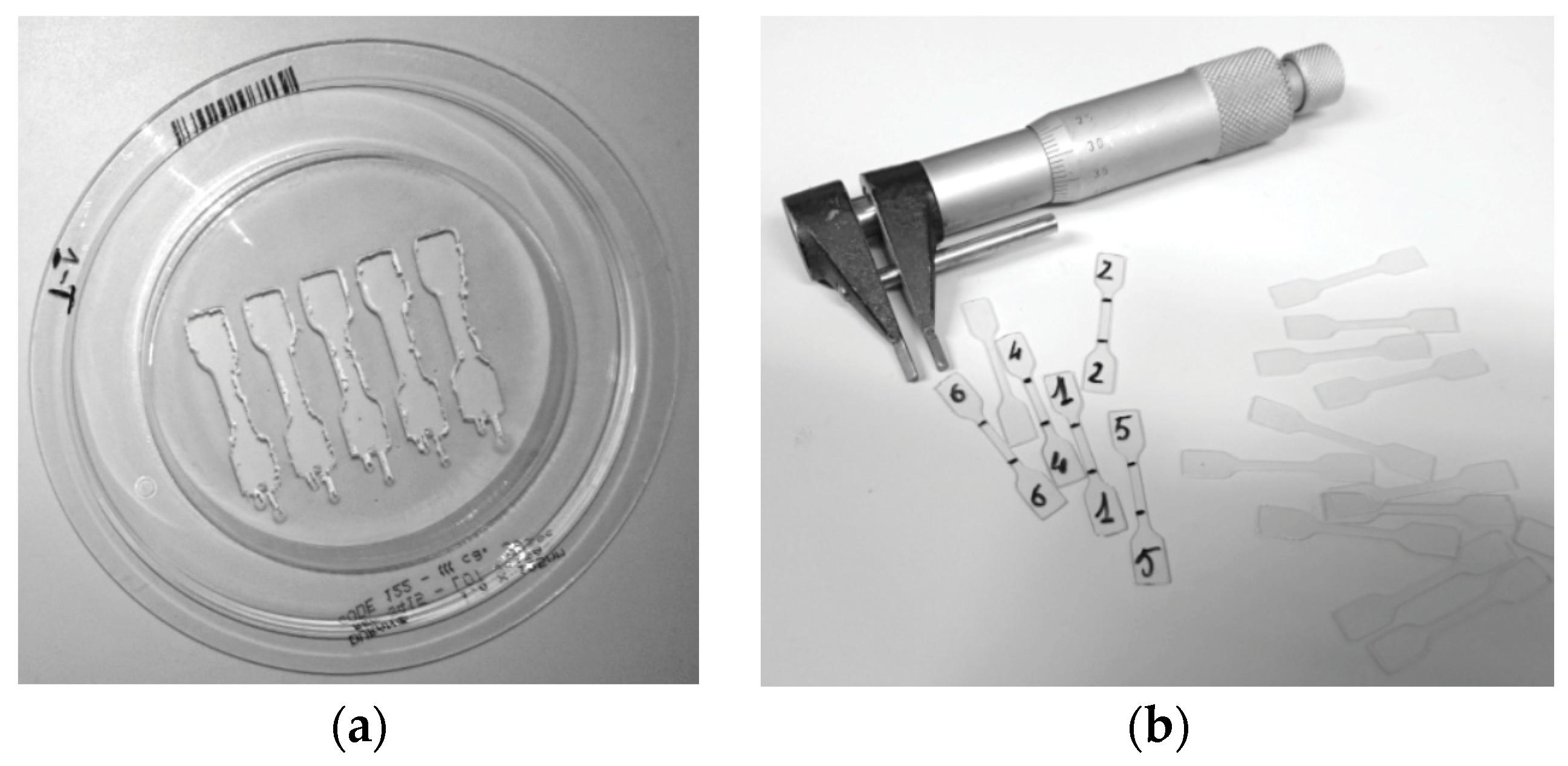

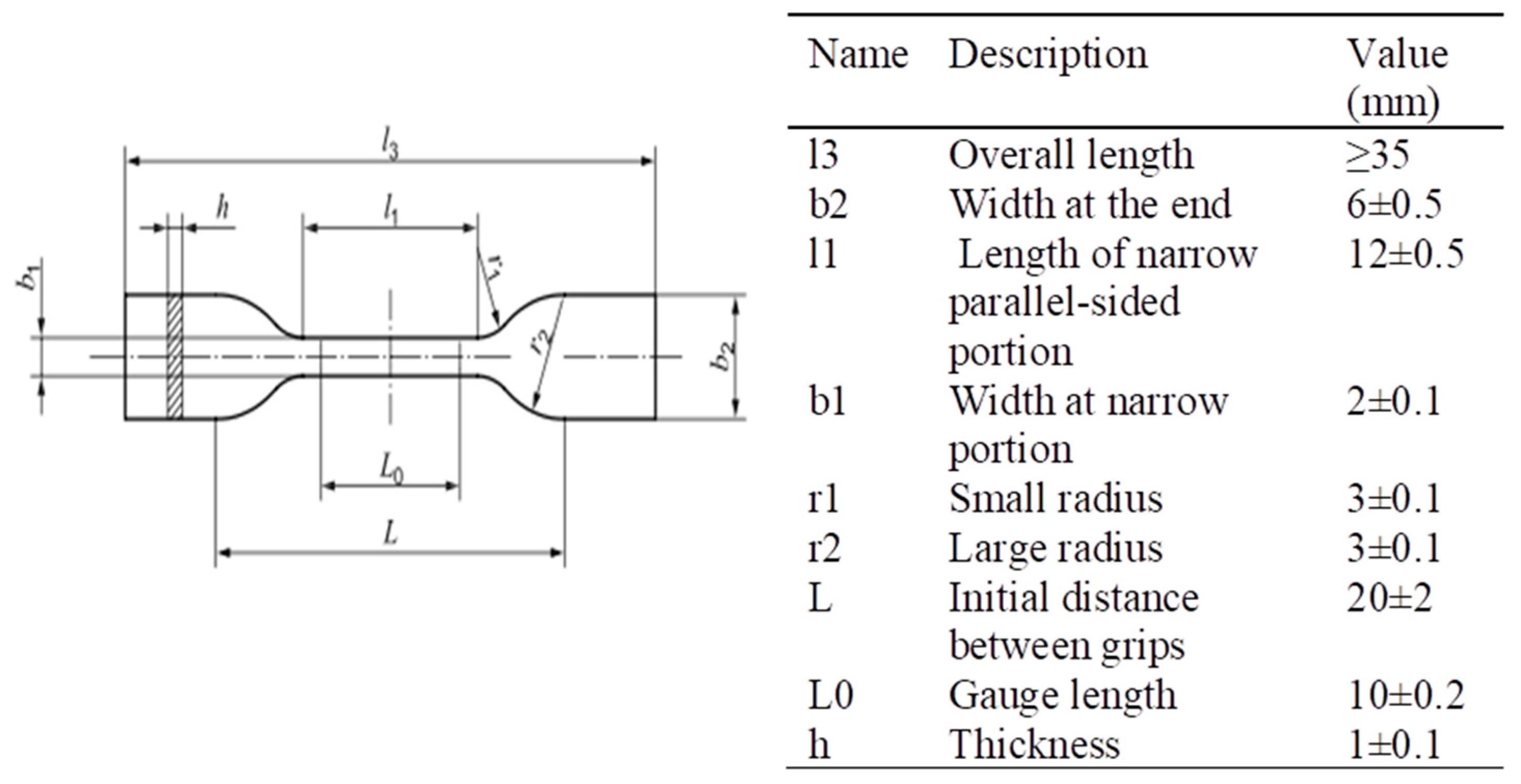

2. Materials and Methods

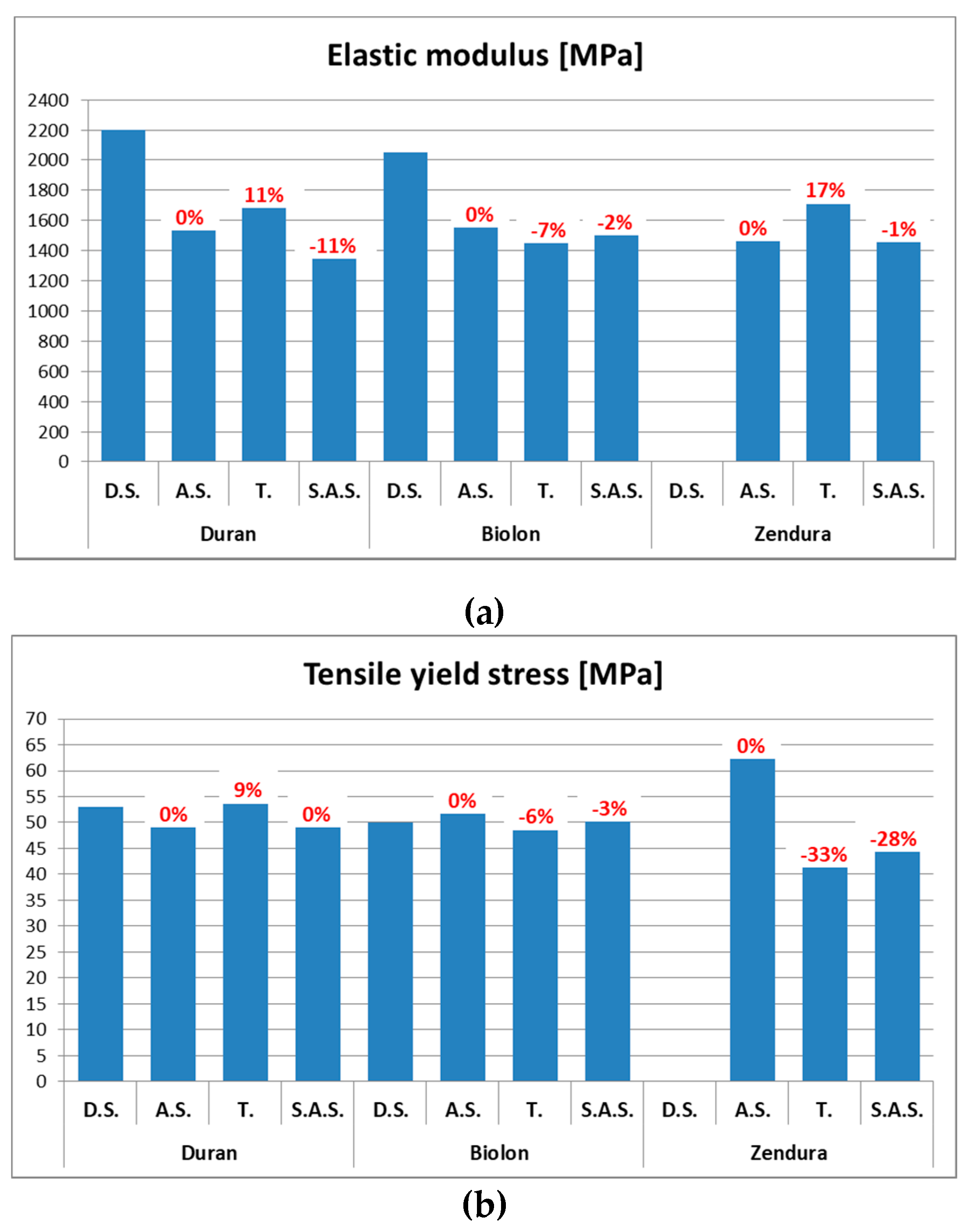

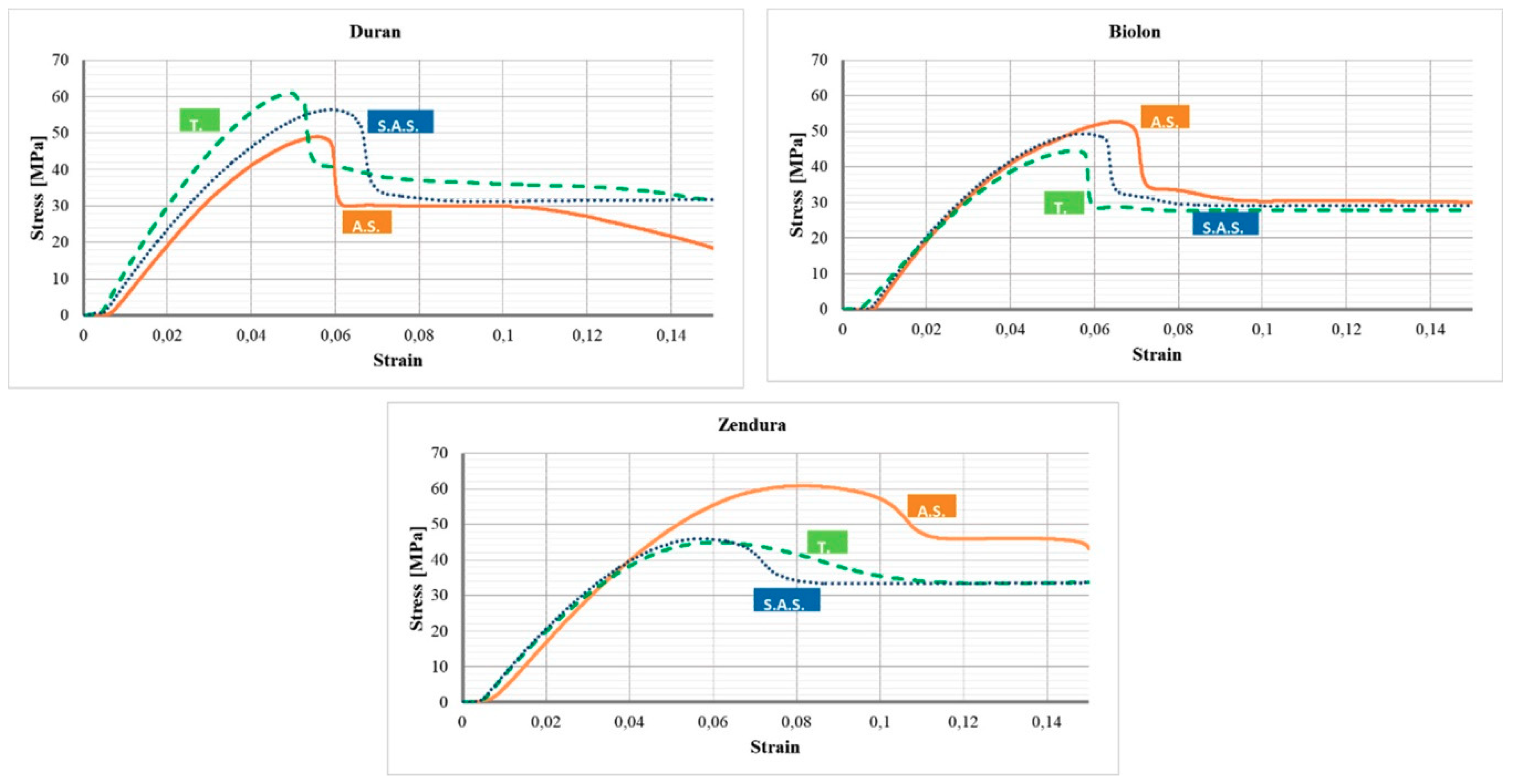

3. Results

4. Discussion

5. Conclusions

- the elastic modulus increases after thermoforming, except for Biolon®;

- the elastic modulus, compared to the material A.S., notably decreases after S.A.S. for Duran®. A slight decrease, instead, is observed in case of Biolon® and Zendura®;

- the tensile yield stress increases after T. in the case of Duran®, slightly decreases in the case of Biolon® and significantly decreases in the case of Zendura® (from 62.37 MPa to 41.92 MPa);

- the tensile yield stress after S.A.S., compared to A.S., slightly increases for Duran®, decreases for Biolon® and significantly decreases for Zendura®, but it is higher than after T.

Author Contributions

Funding

Conflicts of Interest

References

- Bucci, R.; Rongo, R.; Zito, E.; Valletta, R.; Michelotti, A.; D’Antò, V. Translation and validation of the italian version of the Psychosocial Impact of Dental Aesthetics Questionnaire (pidaq) among adolescents. Eur. J. Paediatr. Dent. 2017, 18, 158–162. [Google Scholar] [PubMed]

- Bucci, R.; Rongo, R.; Zito, E.; Galeotti, A.; Valletta, R.; D’Antò, V. Cross-cultural adaptation and validation of the Italian Psychosocial Impact of Dental Aesthetics Questionnaire (PIDAQ). Qual. Life Res. 2014, 24, 747–752. [Google Scholar] [CrossRef] [PubMed]

- Miller, K.B.; McGorray, S.P.; Womack, R.; Quintero, J.C.; Perelmuter, M.; Gibson, J.; Dolan, T.A.; Wheeler, T.T. A comparison of treatment impacts between Invisalign aligner and fixed appliance therapy during the first week of treatment. Am. J. Orthod. Dentofac. Orthop. 2007, 131, 302.e1–302.e9. [Google Scholar] [CrossRef] [PubMed]

- Rossini, G.; Parrini, S.; Castroflorio, T. Efficacy of Clear Aligners in Controlling Orthodontic Tooth Movement: A Systematic Review. Smile Dent. J. 2015, 10, 36. [Google Scholar] [CrossRef]

- Papadimitriou, A.; Mousoulea, S.; Gkantidis, N.; Kloukos, D. Clinical effectiveness of Invisalign (R) orthodontic treatment: A systematic review. Prog. Orthod. 2018, 19, 37. [Google Scholar] [CrossRef]

- Cervinara, F.; Cianci, C.; De Cillis, F.; Pappalettera, G.; Pappalettere, C.; Siciliani, G.; Lombardo, L. Experimental Study of the Pressures and Points of Application of the Forces Exerted between Aligner and Tooth. Nanomaterials 2019, 9, 1010. [Google Scholar] [CrossRef]

- Kohda, N.; Iijima, M.; Muguruma, T.; A Brantley, W.; Ahluwalia, K.S.; Mizoguchi, I. Effects of mechanical properties of thermoplastic materials on the initial force of thermoplastic appliances. Angle Orthod. 2012, 83, 476–483. [Google Scholar] [CrossRef]

- Savignano, R.; Viecilli, R.F.; Paoli, A.; Razionale, A.; Barone, S. Nonlinear dependency of tooth movement on force system directions. Am. J. Orthod. Dentofac. Orthop. 2016, 149, 838–846. [Google Scholar] [CrossRef]

- Barone, S.; Paoli, A.; Razionale, A. Computer-aided modelling of three-dimensional maxillofacial tissues through multi-modal imaging. Proc. Inst. Mech. Eng. Part H 2013, 227, 89–104. [Google Scholar] [CrossRef]

- Barone, S.; Paoli, A.; Razionale, A. Multiple alignments of range maps by active stereo imaging and global marker framing. Opt. Lasers Eng. 2013, 51, 116–127. [Google Scholar] [CrossRef]

- Alexandropoulos, A.; Al Jabbari, Y.S.; Zinelis, S.; Eliades, T. Chemical and mechanical characteristics of contemporary thermoplastic orthodontic materials. Aust. Orthod. J. 2015, 31, 165–170. [Google Scholar] [PubMed]

- Ryu, J.-H.; Kwon, J.-S.; Jiang, H.B.; Cha, J.-Y.; Kim, K.-M. Effects of thermoforming on the physical and mechanical properties of thermoplastic materials for transparent orthodontic aligners. Korean J. Orthod. 2018, 48, 316–325. [Google Scholar] [CrossRef] [PubMed]

- Bradley, T.G.; Teske, L.; Eliades, T.; Zinelis, S. Do the mechanical and chemical properties of Invisalign TM appliances change after use? A retrieval analysis. Eur. J. Orthod. 2015, 38, 27–31. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.S.; Fang, D.Y.; Zhang, N.; Ding, X.J.; Zhang, K.Y.; Bai, Y.X. Mechanical Properties of Orthodontic Thermoplastics PETG/ PC2858 after Blending. Chin. J. Dent. Res. 2016, 19, 43–48. [Google Scholar] [PubMed]

- Barone, S.; Paoli, A.; Neri, P.; Razionale, A.; Giannese, M. Mechanical and Geometrical Properties Assessment of Thermoplastic Materials for Biomedical Application. In Advances on Mechanics, Design Engineering and Manufacturing; Springer: Cham, Switzerland, 2016; pp. 437–446. [Google Scholar]

- Papadopoulou, A.K.; Cantele, A.; Polychronis, G.; Zinelis, S.; Eliades, T. Changes in Roughness and Mechanical Properties of Invisalign((R)) Appliances after One- and Two-Weeks Use. Materials 2019, 12, 2406. [Google Scholar] [CrossRef]

- Standardization IOf. ISO 527-1:2012 Plastics–Determination of Tensile Properties; Standardization IOf: Geneva, Switzerland, 2012. [Google Scholar]

- Walele, S.P.A.; Chaudhari, A.; Patil, C.; Yaragamblimath, P.; Survase, R. Leaching from Thermoplastic Sheets-A Quantitative Assessment. Int. J. Contemp. Med Res. 2016, 3, 1518–1521. [Google Scholar]

- Duffo, G.S.; Quezada-Castillo, E. Development of an Artificial Saliva Solution for Studying the Corrosion Behavior of Dental Alloys. Corrosion 2004, 60, 594–602. [Google Scholar] [CrossRef]

- Porcayo-Calderon, J.; Casales-Diaz, M.; Salinas-Bravo, V.M.; Martinez-Gomez, L. Corrosion Performance of Fe-Cr-Ni Alloys in Artificial Saliva and Mouthwash Solution. Bioinorg. Chem. Appl. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Eliades, T.; Bourauel, C. Intraoral aging of orthodontic materials: The picture we miss and its clinical relevance. Am. J. Orthod. Dentofac. Orthop. 2005, 127, 403–412. [Google Scholar] [CrossRef]

- Condo’, R.; Pazzini, L.; Cerroni, L.; Pasquantonio, G.; Lagana’, G.; Pecora, A.; Mussi, V.; Rinaldi, A.; Mecheri, B.; Licoccia, S.; et al. Mechanical properties of “two generations” of teeth aligners: Change analysis during oral permanence. Dent. Mater. J. 2018, 37, 835–842. [Google Scholar] [CrossRef]

- Fang, D.; Zhang, N.; Chen, H.; Bai, Y. Dynamic stress relaxation of orthodontic thermoplastic materials in a simulated oral environment. Dent. Mater. J. 2013, 32, 946–951. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, L.; Martines, E.; Mazzanti, V.; Arreghini, A.; Mollica, F.; Siciliani, G. Stress relaxation properties of four orthodontic aligner materials: A 24-hour in vitro study. Angle Orthod. 2017, 87, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F. Hugh Shercliff, and David Cebon, Materials: Engineering, Science, Processing and Design; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Yang, B.; Huang, W.; Li, C.; Li, L. Effects of moisture on the thermomechanical properties of a polyurethane shape memory polymer. Polymer 2006, 47, 1348–1356. [Google Scholar] [CrossRef]

- Hancock, B.; Zografi, G. The Relationship Between the Glass Transition Temperature and the Water Content of Amorphous Pharmaceutical Solids. Pharm. Res. 1994, 11, 471–477. [Google Scholar] [CrossRef]

| Material | Heating Time (s) | Cooling Time (s) |

|---|---|---|

| Duran | 30 | 60 |

| Biolon | 40 | 50 |

| Zendura | 35 | 50 |

| Compound | Content (g/L) |

|---|---|

| NaCl | 0.6 |

| KCL | 0.72 |

| CaCl2·2H2O | 0.22 |

| KH2PO4 | 0.68 |

| Na2HPO4·12H2O | 0.856 |

| KSCN | 0.06 |

| NaHCO3 | 1.5 |

| C₆H₈O₇ | 0.03 |

| Material | Before Storage in Artificial Saliva (g) | After Storage in Artificial Saliva (g) | Variation % |

|---|---|---|---|

| Duran | 0.1334 | 0.1339 | 0.375 |

| Biolon | 0.1255 | 0.1261 | 0.438 |

| Zendura | 0.0974 | 0.0981 | 0.719 |

| Material | Testing Condition | E (MPa) | STDEV | σy (MPa) | STDEV |

|---|---|---|---|---|---|

| Duran | D.S. | 2200 | - | 53 | - |

| A.S. | 1531 | 41 | 49.29 | 0.45 | |

| T. | 1693 | 51 | 53.52 | 4.84 | |

| S.A.S. | 1368 | 35 | 49.49 | 1.76 | |

| Biolon | D.S. | 2050 | - | 50 | - |

| A.S. | 1556 | 48 | 52.10 | 1.49 | |

| T. | 1447 | 42 | 48.75 | 2.57 | |

| S.A.S. | 1519 | 62 | 50.62 | 2.88 | |

| Zendura | D.S. | - | - | - | - |

| A.S. | 1478 | 88 | 62.37 | 0.90 | |

| T. | 1730 | 77 | 41.92 | 2.94 | |

| S.A.S. | 1466 | 72 | 44.61 | 1.82 |

| Material | Conditions | p-Value, E | p-Value, σy |

|---|---|---|---|

| Duran | A.S. vs. T. | 0.0026 | 0.1325 |

| T. vs. S.A.S. | 0 | 0.2355 | |

| A.S. vs. S.A.S. | 0.0009 | 0.8285 | |

| Biolon | A.S. vs. T. | 0.0886 | 0.0790 |

| T. vs. S.A.S. | 0.4107 | 0.4155 | |

| A.S. vs. S.A.S. | 0.3729 | 0.3957 | |

| Zendura | A.S. vs. T. | 0.0013 | 0.0001 |

| T. vs. S.A.S. | 0.0005 | 0.1706 | |

| A.S. vs. S.A.S. | 0.8220 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamburrino, F.; D’Antò, V.; Bucci, R.; Alessandri-Bonetti, G.; Barone, S.; Razionale, A.V. Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study. Dent. J. 2020, 8, 47. https://doi.org/10.3390/dj8020047

Tamburrino F, D’Antò V, Bucci R, Alessandri-Bonetti G, Barone S, Razionale AV. Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study. Dentistry Journal. 2020; 8(2):47. https://doi.org/10.3390/dj8020047

Chicago/Turabian StyleTamburrino, Francesco, Vincenzo D’Antò, Rosaria Bucci, Giulio Alessandri-Bonetti, Sandro Barone, and Armando Viviano Razionale. 2020. "Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study" Dentistry Journal 8, no. 2: 47. https://doi.org/10.3390/dj8020047

APA StyleTamburrino, F., D’Antò, V., Bucci, R., Alessandri-Bonetti, G., Barone, S., & Razionale, A. V. (2020). Mechanical Properties of Thermoplastic Polymers for Aligner Manufacturing: In Vitro Study. Dentistry Journal, 8(2), 47. https://doi.org/10.3390/dj8020047