Mechanical Performance and Surface Roughness of Lithium Disilicate and Zirconia-Reinforced Lithium Silicate Ceramics Before and After Exposure to Acidic Challenge

Abstract

1. Introduction

- There would be no significant impact of glass ceramic composition and manufacturing techniques, pressed or CAD/CAM, on the surface micro-hardness, roughness, or biaxial flexural strength.

- There would be no significant difference between the tested properties of all ceramic groups, pressed and CAD/CAM, before and after exposure to acidic challenge.

2. Materials and Methods

2.1. Specimen Preparation and Glass Ceramic Processing:

- a.

- Fabrication of pressable glass ceramics:

- b.

- Fabrication of CAD/CAM glass ceramics

2.2. Mechanical Testing

- a.

- Biaxial flexural strength (BFS):

- b.

- Vicker’s surface microhardness:

2.3. Surface Roughness

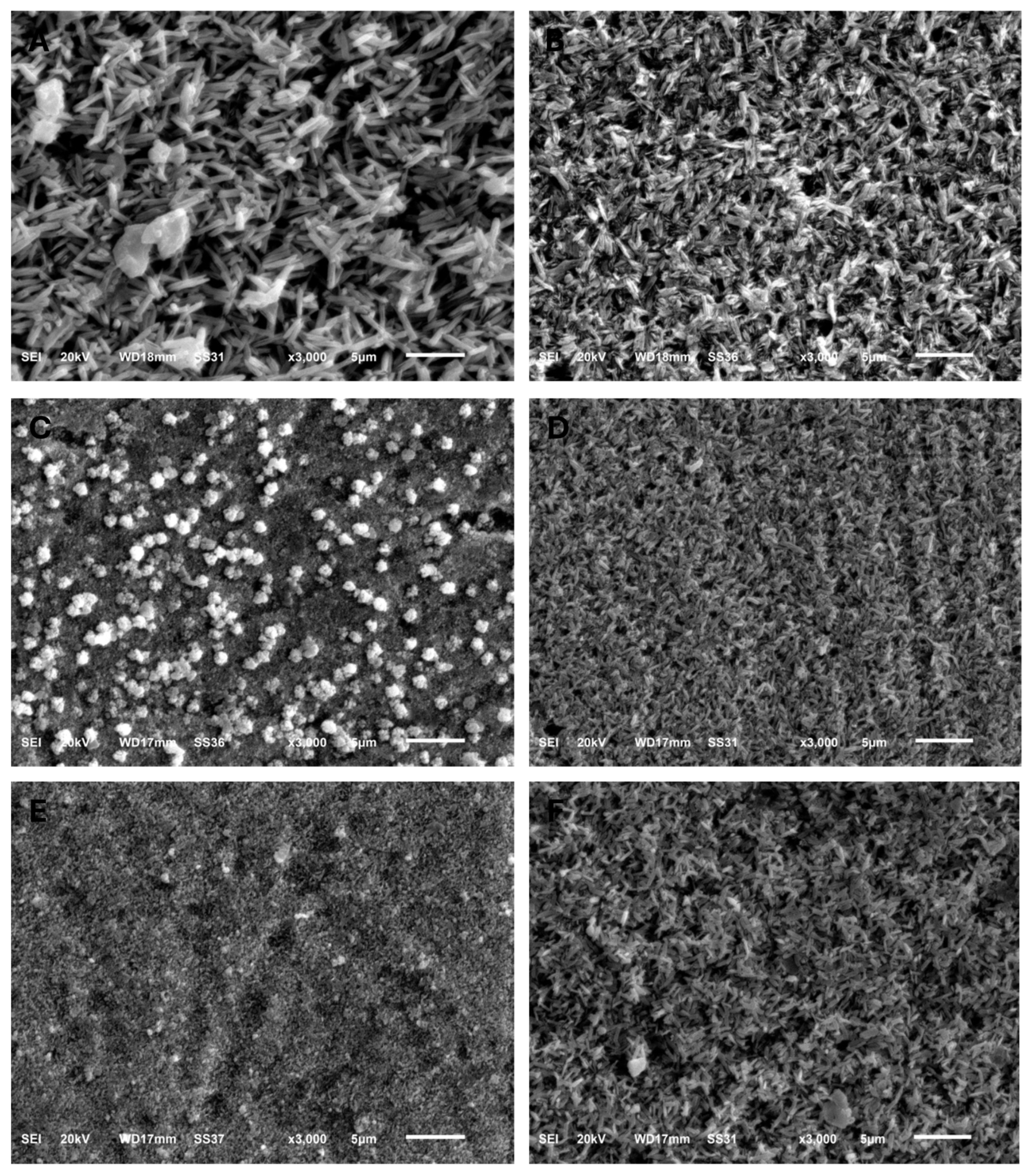

2.4. Scanning Electron Microscopy Analysis (SEM)

2.5. Statistical Analysis

3. Results

3.1. Mechanical Testing Results

- Biaxial flexural strength (BFS):

- b.

- Vicker’s surface microhardness:

3.2. Surface Roughness

3.3. Scanning Electron Microscope (SEM) Analysis

4. Discussion

5. Conclusions

- Pressed LDS-based glass ceramics show better mechanical performance than milled ones;

- IPS e.max showed a higher flexural strength and surface microhardness than advanced LDS and zirconia-toughened LSC;

- The acidic challenge showed strong impact on the BFS and surface microhardness of the tested ceramics;

- The Ra values of most studied ceramics were higher than the recommended values, and would favor dental plaque accumulation.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hallmann, L.; Ulmer, P.; Gerngross, M.-D.; Jetter, J.; Mintrone, M.; Lehmann, F.; Kern, M. Properties of hot-pressed lithium silicate glass-ceramics. Dent. Mater. 2019, 35, 713–729. [Google Scholar] [CrossRef]

- Sasany, R.; Yilmaz, B. Marginal discrepancy and fracture load of thermomechanically fatigued crowns fabricated with different CAD-CAM techniques. J. Prosthodont. Off. J. Am. Coll. Prosthodont. 2023, 32, 602–607. [Google Scholar] [CrossRef] [PubMed]

- Fathy, S.M.; Swain, M.V. In-vitro wear of natural tooth surface opposed with zirconia reinforced lithium silicate glass ceramic after accelerated ageing. Dent. Mater. 2018, 34, 551–559. [Google Scholar] [CrossRef]

- Theocharidou, A.; Kontonasaki, E.; Koukousaki, I.; Koumpouli, A.; Betsani, I.; Koidis, P. Effect of in vitro aging and acidic storage on color, translucency, and contrast ratio of monolithic zirconia and lithium disilicate ceramics. J. Prosthet. Dent. 2022, 127, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Vered, Y.; Lussi, A.; Zini, A.; Gleitman, J.; Sgan-Cohen, H.D. Dental erosive wear assessment among adolescents and adults utilizing the basic erosive wear examination (BEWE) scoring system. Clin. Oral Investig. 2014, 18, 1985–1990. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Attin, T.; Yu, H. Effect of acidic solutions on the surface roughness and microhardness of indirect restorative materials: A systematic review and meta-analysis. Int. J. Prosthodont. 2022, 36, 81–90. [Google Scholar] [CrossRef] [PubMed]

- Dutra, D.; Pereira, G.; Kantorski, K.; Valandro, L.; Zanatta, F. Does Finishing and Polishing of Restorative Materials Affect Bacterial Adhesion and Biofilm Formation? A Systematic Review. Oper. Dent. 2018, 43, E37–E52. [Google Scholar] [CrossRef]

- Rashid, H. The effect of surface roughness on ceramics used in dentistry: A review of literature. Eur. J. Dent. 2014, 8, 571–579. [Google Scholar] [CrossRef]

- Alkadi, L.; Ruse, N.D. Fracture toughness of two lithium disilicate dental glass ceramics. J. Prosthet. Dent. 2016, 116, 591–596. [Google Scholar] [CrossRef]

- Zarone, F.; Ferrari, M.; Mangano, F.G.; Leone, R.; Sorrentino, R. “Digitally Oriented Materials”: Focus on Lithium Disilicate Ceramics. Int. J. Dent. 2016, 2016, 9840594. [Google Scholar] [CrossRef]

- Lubauer, J.; Belli, R.; Peterlik, H.; Hurle, K.; Lohbauer, U. Grasping the Lithium hype: Insights into modern dental Lithium Silicate glass-ceramics. Dent. Mater. 2022, 38, 318–332. [Google Scholar] [CrossRef] [PubMed]

- Isgro, G.; Kleverlaan, C.; Wang, H.; Feilzer, A. The influence of multiple firing on thermal contraction of ceramic materials used for the fabrication of layered all-ceramic dental restorations. Dent. Mater. 2005, 21, 557–564. [Google Scholar] [CrossRef] [PubMed]

- Grzebieluch, W.; Kowalewski, P.; Sopel, M.; Mikulewicz, M. Influence of Artificial Aging on Mechanical Properties of Six Resin Composite Blocks for CAD/CAM Application. Coatings 2022, 12, 837. [Google Scholar] [CrossRef]

- Matsou, E.; Vouroutzis, N.; Kontonasaki, E.; Paraskevopoulos, K.M.; Koidis, P. Investigation of the influence of gastric acid on the surface roughness of ceramic materials of metal-ceramic restorations. An in vitro study. Int. J. Prosthodont. 2011, 24, 26–29. [Google Scholar]

- Kilic, K.; Kesim, B.; Sumer, Z.; Polat, Z.; Kesim, S. In vitro cytotoxicity of all-ceramic substructural materials after aging. J. Dent. Sci. 2013, 8, 231–238. [Google Scholar] [CrossRef][Green Version]

- Hjerppe, J.; Shahramian, K.; Rosqvist, E.; Lassila, L.V.J.; Peltonen, J.; Närhi, T.O. Gastric acid challenge of lithium disilicate–reinforced glass–ceramics and zirconia-reinforced lithium silicate glass–ceramic after polishing and glazing—Impact on surface properties. Clin. Oral Investig. 2023, 27, 6865–6877. [Google Scholar] [CrossRef]

- Chockattu, S.J.; Deepak, B.S.; Sood, A.; Niranjan, N.T.; Jayasheel, A.; Goud, M.K. Management of dental erosion induced by gastro-esophageal reflux disorder with direct composite veneering aided by a flexible splint matrix. Restor. Dent. Endod. 2018, 43, e13. [Google Scholar] [CrossRef]

- Elraggal, A.; Afifi, R.R.; Alamoush, R.A.; Raheem, I.A.; Watts, D.C. Effect of acidic media on flexural strength and fatigue of CAD-CAM dental materials. Dent. Mater. 2023, 39, 57–69. [Google Scholar] [CrossRef]

- Al-Thobity, A.M.; Alsalman, A. Flexural properties of three lithium disilicate materials: An in vitro evaluation. Saudi Dent. J. 2021, 33, 620–627. [Google Scholar] [CrossRef]

- Fouda, A.M.; Stawarczyk, B.; Özcan, M.; Singer, L.; Bourauel, C. Impact of glazing on wear, fracture load, and optical properties of a new fully crystallized lithium disilicate ceramic material. J. Mech. Behav. Biomed. Mater. 2023, 146, 106102. [Google Scholar] [CrossRef]

- Corado, H.P.R.; Da Silveira, P.H.P.M.; Ortega, V.L.; Ramos, G.G.; Elias, C.N. Flexural Strength of Vitreous Ceramics Based on Lithium Disilicate and Lithium Silicate Reinforced with Zirconia for CAD/CAM. Int. J. Biomater. 2022, 2022, 5896511. [Google Scholar] [CrossRef]

- Hashem, M.A. Mechanical and Physical Properties of Three CAD/CAM Glass-Ceramics. Master’s Thesis, Boston University, Boston, MA, USA, 2022. [Google Scholar]

- Dental Ceramics—Performance Criteria for Safety and Performance Based Pathway—Guidance for Industry and Food and Drug Administration Staff. FDA. 2024. Available online: https://www.fda.gov/media/182281/download (accessed on 30 September 2024).

- Zheng, X.; Wen, G.; Song, L.; Huang, X.X. Effects of P2O5 and heat treatment on crystallization and microstructure in lithium disilicate glass ceramics. Acta Mater. 2008, 56, 549–558. [Google Scholar] [CrossRef]

- Fabian Fonzar, R.; Carrabba, M.; Sedda, M.; Ferrari, M.; Goracci, C.; Vichi, A. Flexural resistance of heat-pressed and CAD-CAM lithium disilicate with different translucencies. Dent. Mater. 2017, 33, 63–70. [Google Scholar] [CrossRef]

- Ohashi, K.; Nihei, T.; Kameyama, Y.; Wada, Y.; Miyake, K.; Kunzelmann, K.-H.; Nihei, T. Evaluation and comparison of the characteristics of three pressable lithium disilicate glass ceramic materials. Int. J. Dev. Res. 2017, 7, 16711–16716. [Google Scholar]

- Borom, M.P.; Turkalo, A.M.; Doremus, R.H. Strength and Microstructure in Lithium Disilicate Glass-Ceramics. J. Am. Ceram. Soc. 1975, 58, 385–391. [Google Scholar] [CrossRef]

- Alayad, A.S.; AlDabeeb, D.S.; Algoblan, G.M.; Aldawsari, M.H.; Alghamdi, R.A.; Alqahtani, S.M. Flexural Strength of Recently Advanced Lithium Disilicate Glass-ceramic CEREC Tessera: An In-vitro Study. J. Clin. Diagn. Res. 2024, 18, ZC21–ZC24. [Google Scholar] [CrossRef]

- Demirel, M.; Diken Türksayar, A.A.; Donmez, M.B. Translucency, color stability, and biaxial flexural strength of advanced lithium disilicate ceramic after coffee thermocycling. J. Esthet. Restor. Dent. 2023, 35, 390–396. [Google Scholar] [CrossRef]

- Freitas, J.S.; Souza, L.F.B.; Pereira, G.K.R.; May, L.G. Surface properties and flexural fatigue strength of an advanced lithium disilicate. J. Mech. Behav. Biomed. Mater. 2023, 147, 106154. [Google Scholar] [CrossRef]

- Zhang, Y.; Vardhaman, S.; Rodrigues, C.S.; Lawn, B.R. A Critical Review of Dental Lithia-Based Glass–Ceramics. J. Dent. Res. 2023, 102, 245–253. [Google Scholar] [CrossRef]

- Elsaka, S.E.; Elnaghy, A.M. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 2016, 32, 908–914. [Google Scholar] [CrossRef]

- Sen, N.; Us, Y.O. Mechanical and optical properties of monolithic CAD-CAM restorative materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef] [PubMed]

- Juntavee, N.; Uasuwan, P. Flexural Strength of Different Monolithic Computer-Assisted Design and Computer-Assisted Manufacturing Ceramic Materials upon Different Thermal Tempering Processes. Eur. J. Dent. 2020, 14, 566–574. [Google Scholar] [CrossRef]

- Furtado De Mendonca, A.; Shahmoradi, M.; Gouvêa, C.V.D.D.; De Souza, G.M.; Ellakwa, A. Microstructural and Mechanical Characterization of CAD/CAM Materials for Monolithic Dental Restorations. J. Prosthodont. 2019, 28, E587–E594. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, A.L.; Rodrigues, C.S.; Guiberteau, F.; Zhang, Y. Microstructural development during crystallization firing of a dental-grade nanostructured lithia-zirconia glass-ceramic. J. Eur. Ceram. Soc. 2021, 41, 5728–5739. [Google Scholar] [CrossRef]

- Lubauer, J.; Belli, R.; Petschelt, A.; Cicconi, M.R.; Hurle, K.; Lohbauer, U. Concurrent kinetics of crystallization and toughening in multicomponent biomedical SiO2-Li2O-P2O5-ZrO2 glass-ceramics. J. Non-Cryst. Solids 2021, 554, 120607. [Google Scholar] [CrossRef]

- Ellakany, P.; Madi, M.; Aly, N.M.; Alshehri, T.; Alameer, S.T.; Al-Harbi, F.A. Influences of Different CAD/CAM Ceramic Compositions and Thicknesses on the Mechanical Properties of Ceramic Restorations: An In Vitro Study. Materials 2023, 16, 646. [Google Scholar] [CrossRef]

- Bebsh, M.; Haimeur, A.; França, R. The Effect of Different Surface Treatments on the Micromorphology and the Roughness of Four Dental CAD/CAM Lithium Silicate-Based Glass-Ceramics. Ceramics 2021, 4, 467–475. [Google Scholar] [CrossRef]

- Mota, E.G.; Smidt, L.N.; Fracasso, L.M.; Burnett, L.H.; Spohr, A.M. The effect of milling and postmilling procedures on the surface roughness of CAD/CAM materials. J. Esthet. Restor. Dent. 2017, 29, 450–458. [Google Scholar] [CrossRef]

- Kukiattrakoon, B.; Hengtrakool, C.; Kedjarune-Leggat, U. Effect of acidic agents on surface roughness of dental ceramics. Dent. Res. J. 2011, 8, 6–15. [Google Scholar]

- Belli, R.; Wendler, M.; De Ligny, D.; Cicconi, M.R.; Petschelt, A.; Peterlik, H.; Lohbauer, U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dent. Mater. 2017, 33, 84–98. [Google Scholar] [CrossRef]

- Wendler, M.; Belli, R.; Petschelt, A.; Mevec, D.; Harrer, W.; Lube, T.; Danzer, R.; Lohbauer, U. Chairside CAD/CAM materials. Part 2: Flexural strength testing. Dent. Mater. 2017, 33, 99–109. [Google Scholar] [CrossRef]

- Cruz, M.E.M.; Simões, R.; Martins, S.B.; Trindade, F.Z.; Dovigo, L.N.; Fonseca, R.G. Influence of simulated gastric juice on surface characteristics of CAD-CAM monolithic materials. J. Prosthet. Dent. 2020, 123, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Harryparsad, A.; Dullabh, H.; Sykes, L.; Herbst, D. The effects of hydrochloric acid on all-ceramic restorative materials: An in-vitro study. SADJ J. S. Afr. Dent. Assoc. Tydskr. Van Suid-Afr. Tandheelkd. Ver. 2014, 69, 106–111. [Google Scholar]

- Giordano, R.; Cima, M.; Pober, R. Effect of surface finish on the flexural strength of feldspathic and aluminous dental ceramics. Int. J. Prosthodont. 1995, 8, 311–319. [Google Scholar] [PubMed]

- Traini, T.; Sinjari, B.; Pascetta, R.; Serafini, N.; Perfetti, G.; Trisi, P.; Caputi, S. The zirconia-reinforced lithium silicate ceramic: Lights and shadows of a new material. Dent. Mater. J. 2016, 35, 748–755. [Google Scholar] [CrossRef] [PubMed]

- Yara, A.; Ogura, H.; Shinya, A.; Tomita, S.; Miyazaki, T.; Sugai, Y.; Sakamoto, Y. Durability of Diamond Burs for the Fabrication of Ceramic Crowns Using Dental CAD/CAM. Dent. Mater. J. 2005, 24, 134–139. [Google Scholar] [CrossRef]

- Mullan, F.; Austin, R.S.; Parkinson, C.R.; Bartlett, D.W. An in-situ pilot study to investigate the native clinical resistance of enamel to erosion. J. Dent. 2018, 70, 124–128. [Google Scholar] [CrossRef] [PubMed]

- Azadi-Schossig, P.; Becker, K.; Attin, T. Chelating effect of citric acid is negligible for development of enamel erosions. Clin. Oral Investig. 2016, 20, 1577–1587. [Google Scholar] [CrossRef]

| Type | Commercial Name | Constituents | Manufacturer | Patch No. |

|---|---|---|---|---|

| a. Pressable glass ceramics | ||||

| Lithium disilicate (Li2Si2O5) | IPS e.max® Press | SiO2 (57–80%), Li2O (11–19%), K2O (0–13%), P2O5 (0–11%), ZrO2 (0–8%), ZnO (0–8%), Coloring Oxides (0–12%) | Ivoclar Vivadent, Schaan, Liechtenstein | Z036XN |

| GC InitialTM LiSi Press | SiO2, Al2O3, LiO2, K2O, P2O5, ZrO2, Na2O, K2O [19] | GC, Tokyo, Japan | 170306A | |

| Zirconia-reinforced lithium silicate (Li2SiO3/Li2Si2O5) | Celtra ® Duo press | SiO2 (58%), ZrO2 (10%), P2O5, Al2O3, Li2O, and ZnO | Dentsply Sirona, NC, USA | 16010742 |

| b. CAD/CAM glass ceramics | ||||

| Lithium disilicate (Li2Si2O5) | IPS e.max® CAD | SiO2 (57–80%), Li2O (11–19%), K2O (0–13%), P2O5 (0–11%), ZrO2 (0–8%), ZnO (0–8%), Coloring Oxides (0–12%). | Ivoclar Vivadent, Schaan, Liechtenstein | Z01SBK |

| GC Initial LiSi Block | SiO2 (81%), P2O5 (8.1%), K2O (5.9%), Al2O3 (3.8%), TiO2 (0.5%), CeO2 (0.6%) [20] | GC, Tokyo, Japan | 2112221 | |

| CEREC Tessera | Li2Si2O5: (90%) Li3PO4: (5%) Li0.5Al0.5Si2.5O6 (virgilite): (5%) | Dentsply Sirona, York, PA, USA | 16013117 | |

| Material | Stand by Temperature (°C) | Closing Time (min) | Heating Rate (°C/min) | Holding Temperature (°C) | Holding Time (min) | Vacuum On/Off (°C) | Long-Term Cooling (°C) | |

|---|---|---|---|---|---|---|---|---|

| IPS e.max® Press | Pressing | 700 | __ | 60 | 920 | 15:00 | 500/920 | __ |

| Glazing | 403 | 6:00 | 60 | 770 | 1:00–2:00 | 450/769 | 500 | |

| GC-LiSi Press | Pressing | 700 | __ | 60 | 898 | 25:00 | __ | __ |

| Glazing | 480 | 2:00 | 45 | 810 | 1:00 | __ | __ | |

| Celtra Duo Press | Pressing | 700 | 3:00 | 40 | 860 | 30:00 | __ | __ |

| Glazing | 400 | 2:00 | 55 | 760 | 2:00 | __ | __ | |

| Materials | Stand-by Temperature (°C) | Closing Time (min) | Heating Rate (°C/min) | Heating Rate 2 (°C/min) | Holding Temperature (°C) | Holding Temperature 2 (°C) | Holding Time (min) | Holding Time 2 (min) | Vacuum On/Off (°C) | Long-Term Cooling (°C) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| IPS e.max® CAD | Crystallization | 403 | 6:00 | 60 | 30 | 770 | 850 | 0:10 | 10:00 | 770/850 | 700 |

| Glazing | 403 | 6:00 | 60 | __ | 725 | __ | 1:00 | __ | 450/724 | __ | |

| GC Initial LiSi Block | Crystallization | Not Required | |||||||||

| Glazing | 480 | 4:00 | 45 | __ | 740 | __ | 1:00 | __ | No | __ | |

| CEREC Tessera | Crystalliz-ation | Not Required | |||||||||

| Glazing | 400 | 3:30 | 60 | __ | 760 | __ | 2:00 | __ | __ | __ | |

| Source | BFS | Surface Microhardness | Surface Roughness (Ra) | |||

|---|---|---|---|---|---|---|

| F | p-Value | F | p-Value | F | p-Value | |

| Corrected model | 4.768 | 0.012 * | 34.718 | 0.000 * | 13.983 | 0.000 * |

| Intercept | 2.257 × 103 | 0.000 * | 2.256 × 105 | 0.000 * | 986.899 | 0.000 * |

| Composition | 11.625 | 0.002 * | 48.252 | 0.000 * | 3.199 | 0.083 |

| manufacture | 0.577 | 0.462 | 25.147 | 0.000 * | 18.321 | 0.000 * |

| Composition X manufacture | 0.007 | 0.993 | 24.374 | 0.000 * | 13.240 | 0.000 * |

| Source | BFS | Surface Microhardness | Surface Roughness (Ra) | |||

|---|---|---|---|---|---|---|

| F | p-Value | F | p-Value | F | p-Value | |

| Corrected model | 6.08 | 0.01 * | 219.39 | <0.01 * | 1.94 | 0.10 |

| Intercept | 2.39 × 103 | <0.01 * | 1.93 × 105 | <0.01 * | 1.26 × 103 | <0.01 * |

| Composition | 12.56 | <0.01 * | 149.70 | <0.01 * | 0.07 | 0.79 |

| Manufacture method | 4.30 | 0.06 | 157.53 | <0.01 * | 2.37 | 0.09 |

| Composition X manufacture method | 0.49 | 0.63 | 309.70 | <0.01 * | 2.14 | 0.12 |

| Groups | Means ± SD Before Aging | Means ± SD Before Aging | Student t-Test Before and After Aging |

|---|---|---|---|

| IPS e.max CAD | 400.10 ± 38 a | 366.86 ± 28 AB | t = 1.38 and p-value = 0.24 |

| IPS e.max Press | 409.95 ± 27 a | 401.05 ± 20 A | t = 0.41 and p-value = 0.70 |

| GC LiSi CAD | 308.56 ± 19 c | 282.59 ± 19 C | t = 1.47 and p-value = 0.22 |

| GC LiSi Press | 322.64 ± 28 ab | 311.67 ± 23 C | t = 0.47 and p-value = 0.66 |

| Cerec Tessera CAD | 367.65 ± 40 ab | 317.89 ± 40 C | t = 1.43 and p-value = 0.23 |

| Celtra Duo Press | 378.71 ± 38 ab | 329.26 ± 32 AB | t = 1.60 and p-value = 0.19 |

| p-value | p-value = 0.01 * | p-value = 0.01 * |

| Groups | Means ± SD Before Aging | Means ± SD After Aging | Student t-Test |

|---|---|---|---|

| IPS e.max CAD | 533.37 ± 1.76 ab | 497.17 ± 4.25 BC | t = −5.98 & p-value < 0.01 * |

| IPS e.max Press | 541.13 ± 1.40 a | 499.83 ± 5.21 BC | t = 13.26 & p-value < 0.01 * |

| GC LiSi CAD | 492.77 ± 3.67 d | 485.77 ± 2.32 C | t = −2.80 & p-value = 0.05 * |

| GC LiSi Press | 520.03 ± 3.35 bc | 481.70 ± 9.61 D | t = 6.52 & p-value < 0.01 * |

| Cerec Tessera CAD | 527.03 ± 1.59 ab | 383.00 ± 5.63 E | t = 42.60 & p-value < 0.01 * |

| Celtra Duo Press | 527.67 ± 2.50 ab | 509.83 ± 9.42 B | t = −3.17 & p-value = 0.03* |

| p-value | p-value < 0.01 * | p-value < 0.01 * |

| Groups | Means ± SD Before Aging | Means ± SD Before Aging | Student t-Test |

|---|---|---|---|

| IPS e.max CAD | 0.34 ± 0.04 a | 0.26 ± 0.05 | t = 2.68 and p-value = 0.03 * |

| IPS e.max Press | 0.36 ± 0.10 a | 0.32 ± 0.04 | t = 0.00 and p-value = 1.00 |

| GC LiSi CAD | 0.42 ± 0.06 a | 0.38 ± 0.03 | t = 1.42 and p-value = 0.19 |

| GC LiSi Press | 0.35 ± 0.01 a | 0.31 ± 0.07 | t = 1.95 and p-value = 0.09 |

| Cerec Tessera CAD | 0.19 ± 0.07 b | 0.36 ± 0.07 | t = −3.74 and p-value = 0.01 * |

| Celtra Duo Press | 0.18 ± 0.02 b | 0.33 ± 0.09 | t = −3.87 and p-value = 0.01 * |

| p-value | p-value < 0.01 * | p-value = 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsherbini, A.; Fathy, S.M.; Al-Zordk, W.; Özcan, M.; Sakrana, A.A. Mechanical Performance and Surface Roughness of Lithium Disilicate and Zirconia-Reinforced Lithium Silicate Ceramics Before and After Exposure to Acidic Challenge. Dent. J. 2025, 13, 117. https://doi.org/10.3390/dj13030117

Elsherbini A, Fathy SM, Al-Zordk W, Özcan M, Sakrana AA. Mechanical Performance and Surface Roughness of Lithium Disilicate and Zirconia-Reinforced Lithium Silicate Ceramics Before and After Exposure to Acidic Challenge. Dentistry Journal. 2025; 13(3):117. https://doi.org/10.3390/dj13030117

Chicago/Turabian StyleElsherbini, Ahmed, Salma M. Fathy, Walid Al-Zordk, Mutlu Özcan, and Amal A. Sakrana. 2025. "Mechanical Performance and Surface Roughness of Lithium Disilicate and Zirconia-Reinforced Lithium Silicate Ceramics Before and After Exposure to Acidic Challenge" Dentistry Journal 13, no. 3: 117. https://doi.org/10.3390/dj13030117

APA StyleElsherbini, A., Fathy, S. M., Al-Zordk, W., Özcan, M., & Sakrana, A. A. (2025). Mechanical Performance and Surface Roughness of Lithium Disilicate and Zirconia-Reinforced Lithium Silicate Ceramics Before and After Exposure to Acidic Challenge. Dentistry Journal, 13(3), 117. https://doi.org/10.3390/dj13030117