Monitoring the Calibration of In-Office 3D Printers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Slicing software (Chitubox, Shenzhen, China) for designing;

- 2 SLA 3D printers (Form 2, Formlabs, Somerville, MA, USA);

- Formlabs Dental SG and Grey V4 resins (Formlabs, Somerville, MA, USA);

- Resin cleaning station (Veri Wash, Whip Mix, Louisville, KY, USA);

- 99% isopropyl alcohol(Florida laboratories inc., Fort Lauderdale, FL, USA)

- Digital calipers. (IGaging Absolute Origin, IGaging, Los Angeles, CA, USA)

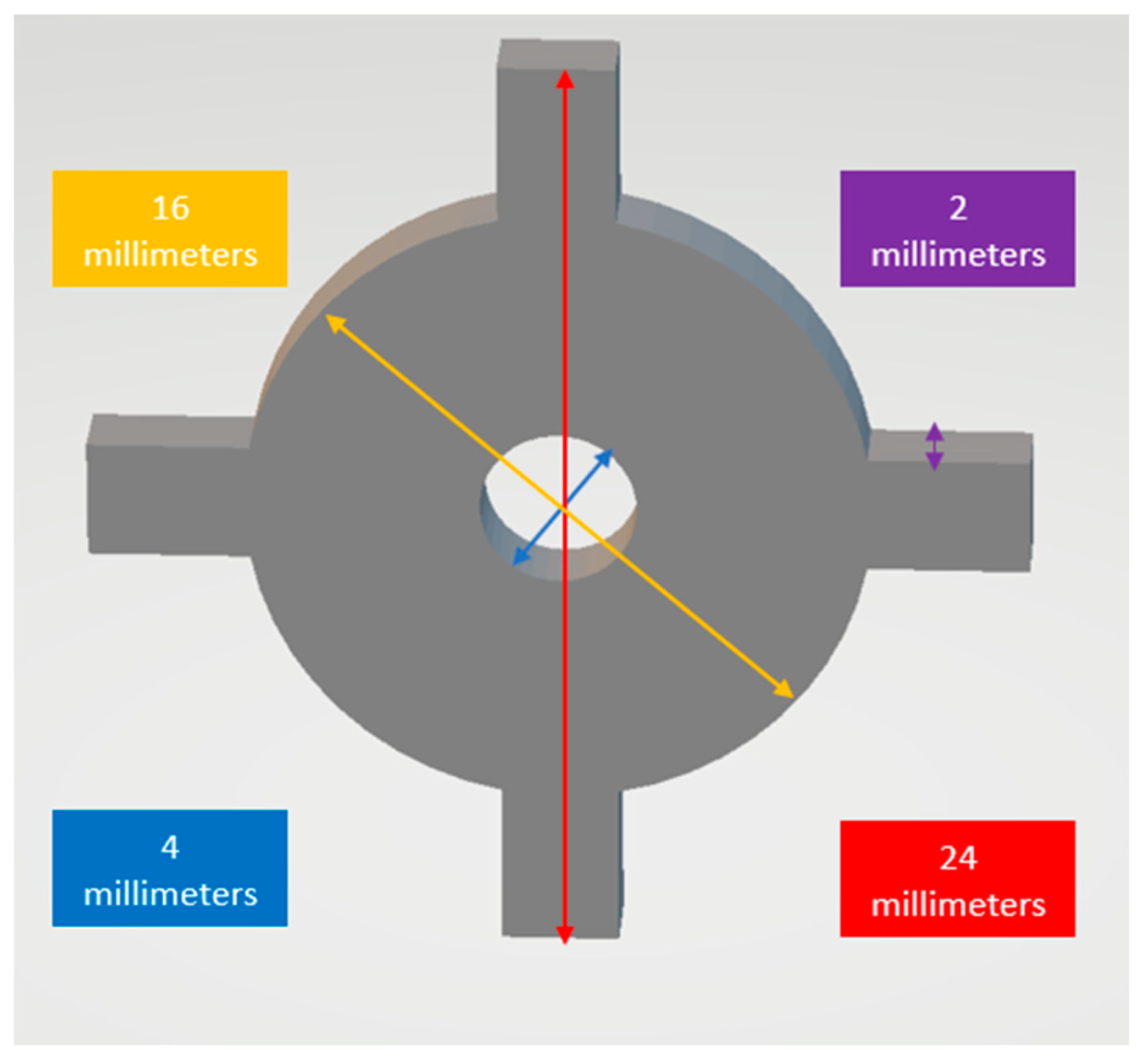

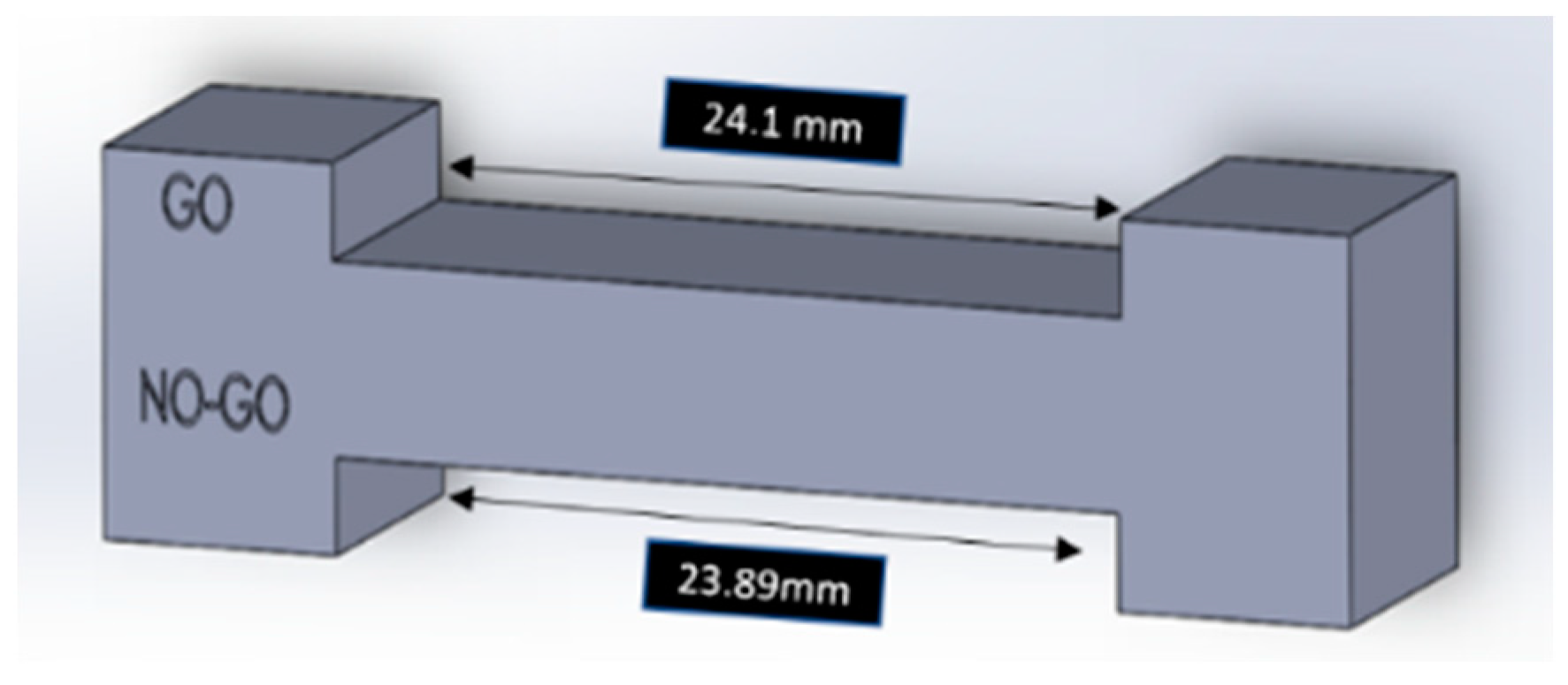

2.2. Designing the Coupon

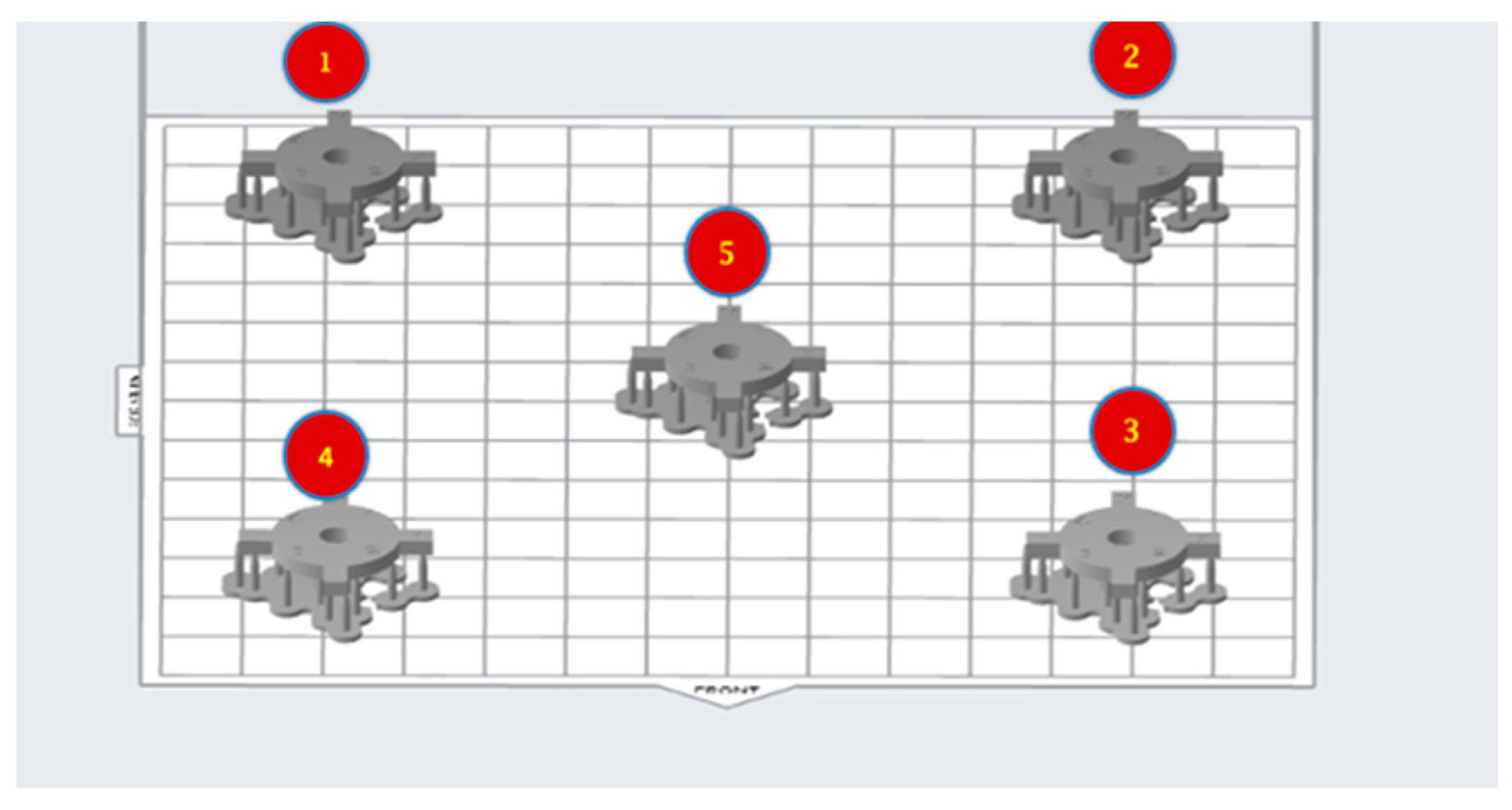

2.3. Positioning of Coupon and Printing Cycles

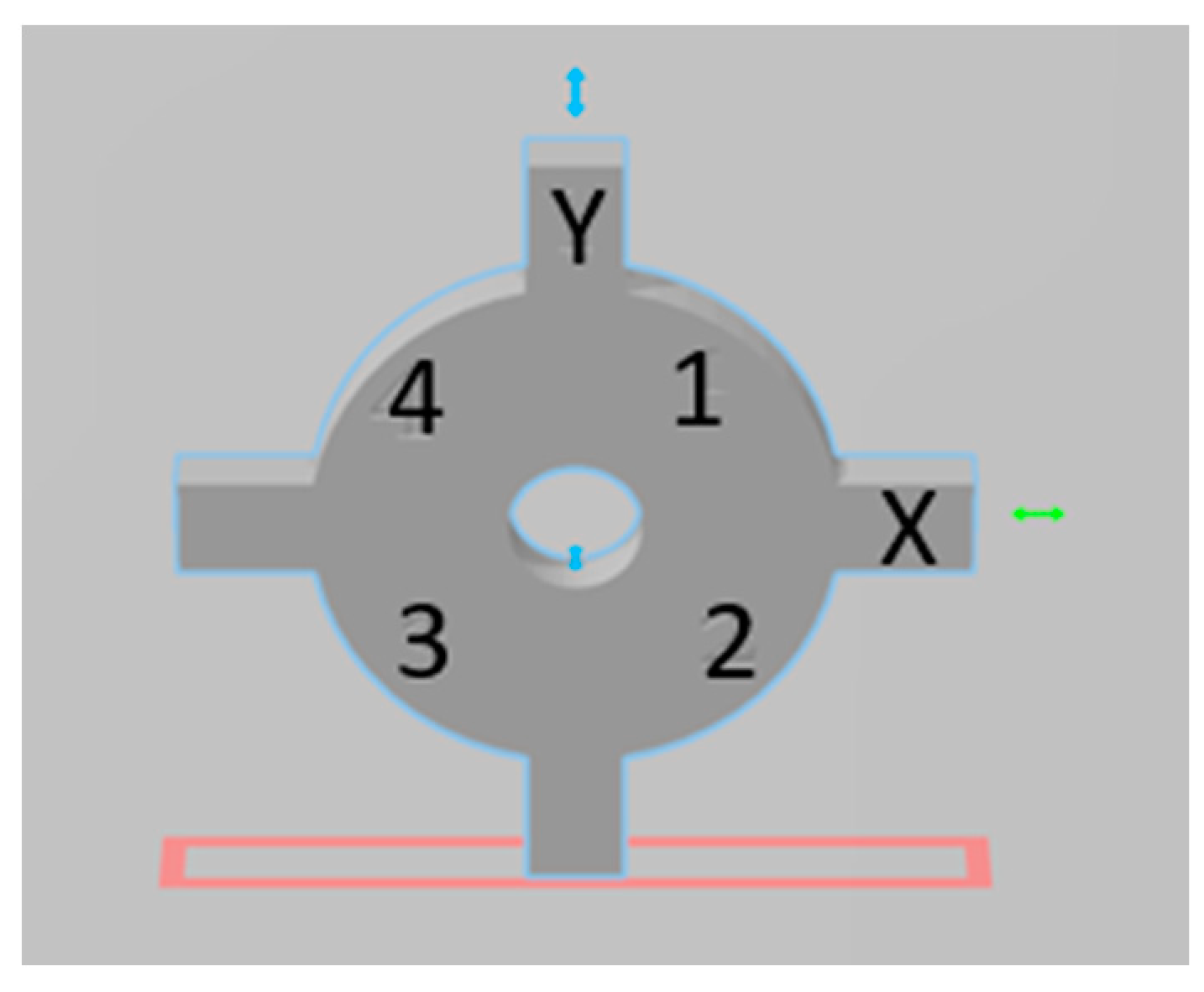

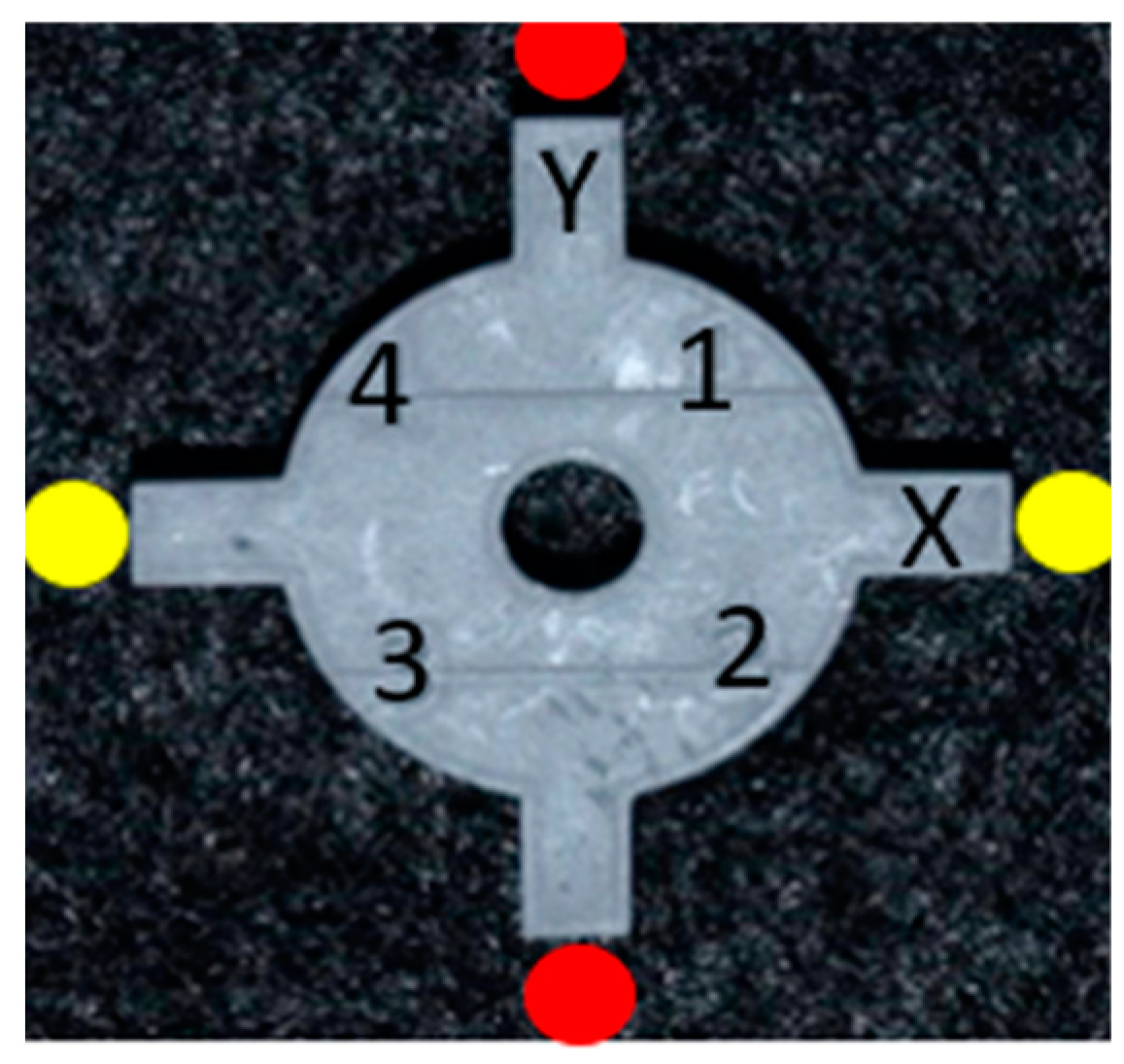

2.4. Measurement of the Coupon

2.5. Statistical Analyses

3. Results

3.1. Comparison of Two Different Resin Materials

3.2. Comparison of Different Positions on the Build Platform

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 11, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Wohlers, T.T. State of the Industry. In Virtual and Rapid Manufacturing: Advanced Research in Virtual and Rapid Prototyping, 1st ed.; CRC Press: London, UK, 2007; pp. 3–5. [Google Scholar]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 638905, 11 March 2023. [Google Scholar]

- Mathur, R. 3D printing in architecture. Int. J. Innov. 2016, 3, 583–591. [Google Scholar]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive manufacturing of structural materials. Mater. Sci. Eng. R. Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Stopp, S.; Wolff, T.; Irlinger, F.; Leuth, T. A new method for printer calibration and contour accuracy manufacturing with 3D-print technology. Rapid Prototyp. J. 2008, 14, 167–172. [Google Scholar] [CrossRef]

- Katreva, I.; Dikova, T.; Abadzhiev, M.; Tonchev, T.; Dzhendov, D.; Simov, M.; Angelova, S.; Pavlova, D.; Doychinova, M. 3D-printing in contemporary prosthodontic treatment. SSMD 2016, 2, 7–11. [Google Scholar] [CrossRef]

- Della Bona, A.; Cantelli, V.; Britto, V.T.; Collares, K.F.; Stansbury, J.W. 3D printing restorative materials using a stereolithographic technique: A systematic review. Dent. Mater. J. 2021, 37, 336–350. [Google Scholar] [CrossRef] [PubMed]

- Ersoy, A.E.; Turkyilmaz, I.; Ozan, O.; McGlumphy, E.A. Reliability of implant placement with stereolithographic surgical guides generated from computed tomography: Clinical data from 94 implants. J. Periodontol. 2008, 79, 1339–1345. [Google Scholar] [CrossRef]

- Bailey, C.; Stoyanov, S.; Tilford, T.; Tourloukis, G. 3D-printing and electronic packaging. Pan. Pacific. 2016, 1–7. [Google Scholar] [CrossRef]

- Meier, L.M.; Meineri, M.; Qua Hiansen, J.; Horlick, E.M. Structural and congenital heart disease interventions: The role of three-dimensional printing. Neth Heart J. 2017, 25, 65–75. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.; Jiang, H.B. A review of 3D printing in dentistry: Technologies, affecting factors, and applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Lüchtenborg, J.; Burkhardt, F.; Nold, J.; Rothlauf, S.; Wesemann, C.; Pieralli, S.; Wemken, G.; Witkowski, S.; Spies, B.C. Implementation of Fused Filament Fabrication in Dentistry. Appl. Sci. 2021, 11, 6444. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Gjelvold, B.; Mahmood, D.J.H.; Wennerberg, A. Accuracy of surgical guides from 2 different desktop 3D printers for computed tomography-guided surgery. J. Prosthet. Dent. 2019, 121, 498–503. [Google Scholar] [CrossRef] [PubMed]

- Deeb, G.R.; Allen, R.K.; Hall, V.P.; Whitley, D., III; Laskin, D.M.; Bencharit, S. How accurate are implant surgical guides produced with desktop stereolithographic 3-dimensional printers? J. Maxillofac. Surg. 2017, 75, 2559e1–2559e8. [Google Scholar] [CrossRef]

- Son, K.; Lee, K.B. A novel method for precise guided hole fabrication of dental implant surgical guide fabricated with 3d printing technology. Appl. Sci. 2020, 11, 49. [Google Scholar] [CrossRef]

- Mahesh, M.; Wong, Y.S.; Fuh, J.Y.H.; Loh, H.T. Benchmarking for comparative evaluation of RP systems and processes. Rapid Prototyp. J. 2004, 10, 123–135. [Google Scholar] [CrossRef]

- Dimitrov, D.; Schreve, K.; de Beer, N. Advances in three-dimensional printing–state of the art and future perspectives. Rapid Prototyp. J. 2006, 12, 136–147. [Google Scholar] [CrossRef]

- Zeller, A.N.; Goetze, E.; Thiem, D.G.; Bartella, A.K.; Seifert, L.; Beiglboeck, F.M.; Kröplin, J.; Hoffman, J.; Pabst, A. A survey regarding the organizational aspects and quality systems of in-house 3D printing in oral and maxillofacial surgery in Germany. Oral. Maxillofac. Surg. 2022, 1–13. [Google Scholar] [CrossRef]

- Fine-Tuning the Form 2. Available online: https://support.formlabs.com/s/article/Fine-Tuning-the-Form-2?language=en_US (accessed on 14 October 2022).

- Jeong, Y.G.; Lee, W.S.; Lee, K.B. Accuracy evaluation of dental models manufactured by CAD/CAM milling method and 3D printing method. J. Adv. Prosthodont. 2018, 10, 245–251. [Google Scholar] [CrossRef]

- Accuracy (Trueness and Precision) of Measurement Methods and Results-Part 1: General Principles and Definitions. International Organization for Standardization. 1994. Available online: https://www.iso.org/obp/ui/#iso:std:iso:5725:-1:ed-1:v1:en (accessed on 12 September 2022).

- Guide to 3D Printing Tolerances, Accuracy and Precision. Available online: https://formlabs.com/blog/understanding-accuracy-precision-tolerance-in-3d-printing/ (accessed on 1 September 2022).

- Minetola, P.; Calignano, F.; Galati, M. Comparing geometric tolerance capabilities of additive manufacturing systems for polymers. Addit. Manuf. 2020, 32, 101–103. [Google Scholar] [CrossRef]

- l’Alzit, F.R.; Cade, R.; Naveau, A.; Babilotte, J.; Meglioli, M.; Catros, S. Accuracy of commercial 3D printers for the fabrication of surgical guides in dental implantology. J. Dent. 2022, 117, 103909. [Google Scholar] [CrossRef] [PubMed]

- Herschdorfer, L.; Negreiros, W.M.; Gallucci, G.O.; Hamilton, A. Comparison of the accuracy of implants placed with CAD-CAM surgical templates manufactured with various 3D printers: An in vitro study. J. Prosthet. Dent. 2021, 125, 905–910. [Google Scholar] [CrossRef] [PubMed]

- Wegmüller, L.; Halbeisen, F.; Sharma, N.; Kühl, S.; Thieringer, F. M Consumer vs. High-End 3D Printers for Guided Implant Surgery—An In Vitro Accuracy Assessment Study of Different 3D Printing Technologies. J. Clin. Med. 2021, 10, 4894. [Google Scholar] [CrossRef] [PubMed]

- Yeung, M.; Abdulmajeed, A.; Carrico, C.K.; Deeb, G.R.; Bencharit, S. Accuracy and precision of 3D-printed implant surgical guides with different implant systems: An in vitro study. J. Prosthet. Dent. 2020, 123, 821–828. [Google Scholar] [CrossRef]

- Using Surgical Guide Resin. Available online: https://support.formlabs.com/s/article/Using-Surgical-Guide-Resin?language=en_US (accessed on 14 October 2022).

- Standard-Formlabs. Available online: https://formlabs-media.formlabs.com/datasheets/Standard-DataSheet.pdf (accessed on 17 October 2022).

| 3D Printing Technology | Mechanism | Advantages | Limitations |

|---|---|---|---|

| Stereolithography (SLA) | Liquid photopolymer in a vat is selectively cured by light-activated polymerization | Low cost, good surface quality of the print, and high resolution | Need for extensive postprocessing, longer print times |

| Selective laser sintering (SLS) | Thermal energy used for selective fusion of regions on a powder bed | Excellent surface quality, large build volumes, no supports, minimum postprocessing | High equipment cost, challenging to operate, maintain, and calibrate |

| Fused deposition modeling (FDM) | Selective extrusion of melted material through a nozzle or ban orifice | Easy to operate, wide spectrum of thermoplastic materials can be printed, used for bioprinting | Long print times, relatively lower print resolution |

| Photopolymer jetting (PPJ) | Layers of photopolymer laid down and light cured with every passage of printer head | High resolution, large build volume, wide spectrum of materials can be printed, multicolor printing, multiple print heads allow printing of complex structures | High cost of equipment and maintenance, printed objects are brittle in nature |

| Digital light processing (DLP) | Similar to SLA | Good surface finish, high accuracy, faster than SLA | Need for postprocessing |

| Printing Cycle | Position on the Platform | Dental SG Resin | Grey V4 Resin | ||

|---|---|---|---|---|---|

| X-Axis (In Millimeters) | Y-Axis (In Millimeters) | X-Axis (In Millimeters) | Y-Axis (In Millimeters) | ||

| 1 | 1 | 23.64 | 23.68 | 23.82 | 23.84 |

| 2 | 23.66 | 23.61 | 23.8 | 23.81 | |

| 3 | 23.72 | 23.69 | 23.79 | 23.78 | |

| 4 | 23.69 | 23.7 | 23.81 | 23.77 | |

| 5 | 23.67 | 23.65 | 23.81 | 23.82 | |

| 2 | 1 | 23.63 | 23.62 | 23.81 | 23.79 |

| 2 | 23.63 | 23.63 | 23.81 | 23.76 | |

| 3 | 23.66 | 23.72 | 23.78 | 23.78 | |

| 4 | 23.64 | 23.76 | 23.77 | 23.72 | |

| 5 | 23.62 | 23.64 | 23.78 | 23.82 | |

| 3 | 1 | 23.5 | 23.53 | 23.82 | 23.77 |

| 2 | 23.54 | 23.57 | 23.81 | 23.84 | |

| 3 | 23.59 | 23.68 | 23.77 | 23.77 | |

| 4 | 23.6 | 23.62 | 23.79 | 23.79 | |

| 5 | 23.63 | 23.57 | 23.85 | 23.84 | |

| 4 | 1 | 23.66 | 23.65 | 23.76 | 23.77 |

| 2 | 23.65 | 23.65 | 23.77 | 23.75 | |

| 3 | 23.65 | 23.69 | 23.75 | 23.74 | |

| 4 | 23.66 | 23.7 | 23.74 | 23.77 | |

| 5 | 23.64 | 23.56 | 23.78 | 23.73 | |

| 5 | 1 | 23.54 | 23.58 | 23.8 | 23.83 |

| 2 | 23.5 | 23.61 | 23.85 | 23.8 | |

| 3 | 23.6 | 23.71 | 23.82 | 23.79 | |

| 4 | 23.61 | 23.59 | 23.79 | 23.84 | |

| 5 | 23.53 | 23.57 | 23.83 | 23.84 | |

| 6 | 1 | 23.72 | 23.71 | 23.86 | 23.87 |

| 2 | 23.77 | 23.7 | 23.87 | 23.88 | |

| 3 | 23.74 | 23.84 | 23.83 | 23.85 | |

| 4 | 23.7 | 23.78 | 23.81 | 23.84 | |

| 5 | 23.71 | 23.69 | 23.85 | 23.9 | |

| 7 | 1 | 23.67 | 23.63 | 23.84 | 23.84 |

| 2 | 23.68 | 23.68 | 23.81 | 23.88 | |

| 3 | 23.68 | 23.77 | 23.81 | 23.82 | |

| 4 | 23.67 | 23.73 | 23.86 | 23.81 | |

| 5 | 23.69 | 23.66 | 23.9 | 23.9 | |

| 8 | 1 | 23.61 | 23.64 | 23.86 | 23.84 |

| 2 | 23.64 | 23.64 | 23.85 | 23.86 | |

| 3 | 23.66 | 23.74 | 23.85 | 23.84 | |

| 4 | 23.63 | 23.73 | 23.83 | 23.84 | |

| 5 | 23.6 | 23.59 | 23.84 | 23.88 | |

| 9 | 1 | 23.65 | 23.65 | 23.87 | 23.87 |

| 2 | 23.67 | 23.68 | 23.84 | 23.9 | |

| 3 | 23.68 | 23.78 | 23.86 | 23.83 | |

| 4 | 23.68 | 23.74 | 23.86 | 23.86 | |

| 5 | 23.68 | 23.67 | 23.84 | 23.9 | |

| 10 | 1 | 23.65 | 23.69 | 23.85 | 23.78 |

| 2 | 23.68 | 23.67 | 23.84 | 23.81 | |

| 3 | 23.72 | 23.75 | 23.75 | 23.73 | |

| 4 | 23.66 | 23.7 | 23.8 | 23.77 | |

| 5 | 23.68 | 23.65 | 23.79 | 23.81 | |

| Resin Material | Dimension | Position | N | Min | Max | Mean | Median | SD |

|---|---|---|---|---|---|---|---|---|

| Grey V4 | X | 1 | 10 | 23.76 | 23.87 | 23.83 | 23.83 | 0.034 |

| 2 | 10 | 23.77 | 23.87 | 23.83 | 23.83 | 0.032 | ||

| 3 | 10 | 23.75 | 23.86 | 23.81 | 23.81 | 0.039 | ||

| 4 | 10 | 23.74 | 23.86 | 23.81 | 23.81 | 0.039 | ||

| 5 | 10 | 23.78 | 23.90 | 23.83 | 23.84 | 0.036 | ||

| Y | 1 | 10 | 23.77 | 23.87 | 23.83 | 23.84 | 0.032 | |

| 2 | 10 | 23.75 | 23.90 | 23.83 | 23.84 | 0.051 | ||

| 3 | 10 | 23.74 | 23.85 | 23.80 | 23.80 | 0.035 | ||

| 4 | 10 | 23.72 | 23.86 | 23.80 | 23.81 | 0.043 | ||

| 5 | 10 | 23.73 | 23.90 | 23.85 | 23.81 | 0.043 | ||

| Dental SG | X | 1 | 10 | 23.50 | 23.72 | 23.63 | 23.64 | 0.064 |

| 2 | 10 | 23.50 | 23.77 | 23.64 | 23.66 | 0.075 | ||

| 3 | 10 | 23.74 | 23.59 | 23.67 | 23.67 | 0.049 | ||

| 4 | 10 | 23.60 | 23.70 | 23.65 | 23.66 | 0.033 | ||

| 5 | 10 | 23.53 | 23.71 | 23.64 | 23.66 | 0.055 | ||

| Y | 1 | 10 | 23.53 | 23.71 | 23.64 | 23.64 | 0.053 | |

| 2 | 10 | 23.57 | 23.70 | 23.64 | 23.64 | 0.040 | ||

| 3 | 10 | 23.68 | 23.84 | 23.74 | 23.73 | 0.050 | ||

| 4 | 10 | 23.59 | 23.78 | 23.69 | 23.70 | 0.061 | ||

| 5 | 10 | 23.56 | 23.69 | 23.62 | 23.62 | 0.048 |

| Position on the Build Platform | p-Value |

|---|---|

| 1 | 0.197 |

| 2 | 0.167 |

| 3 | 0.592 |

| 4 | 0.097 |

| 5 | 0.167 |

| Position on the Build Platform | p-Value |

|---|---|

| 1 | 0.289 |

| 2 | 0.348 |

| 3 | 0.348 |

| 4 | 0.278 |

| 5 | 0.732 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukherjee, E.; Malone, L.; Tackett, E.; Gunaratnam, B.; Grant, G.T. Monitoring the Calibration of In-Office 3D Printers. Dent. J. 2023, 11, 20. https://doi.org/10.3390/dj11010020

Mukherjee E, Malone L, Tackett E, Gunaratnam B, Grant GT. Monitoring the Calibration of In-Office 3D Printers. Dentistry Journal. 2023; 11(1):20. https://doi.org/10.3390/dj11010020

Chicago/Turabian StyleMukherjee, Esha, Luke Malone, Edward Tackett, Bakeerathan Gunaratnam, and Gerald Thomas Grant. 2023. "Monitoring the Calibration of In-Office 3D Printers" Dentistry Journal 11, no. 1: 20. https://doi.org/10.3390/dj11010020

APA StyleMukherjee, E., Malone, L., Tackett, E., Gunaratnam, B., & Grant, G. T. (2023). Monitoring the Calibration of In-Office 3D Printers. Dentistry Journal, 11(1), 20. https://doi.org/10.3390/dj11010020