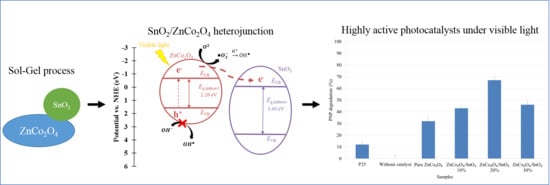

Visible Light Sensitive SnO2/ZnCo2O4 Material for the Photocatalytic Removal of Organic Pollutants in Water

Abstract

1. Introduction

2. Results and Discussion

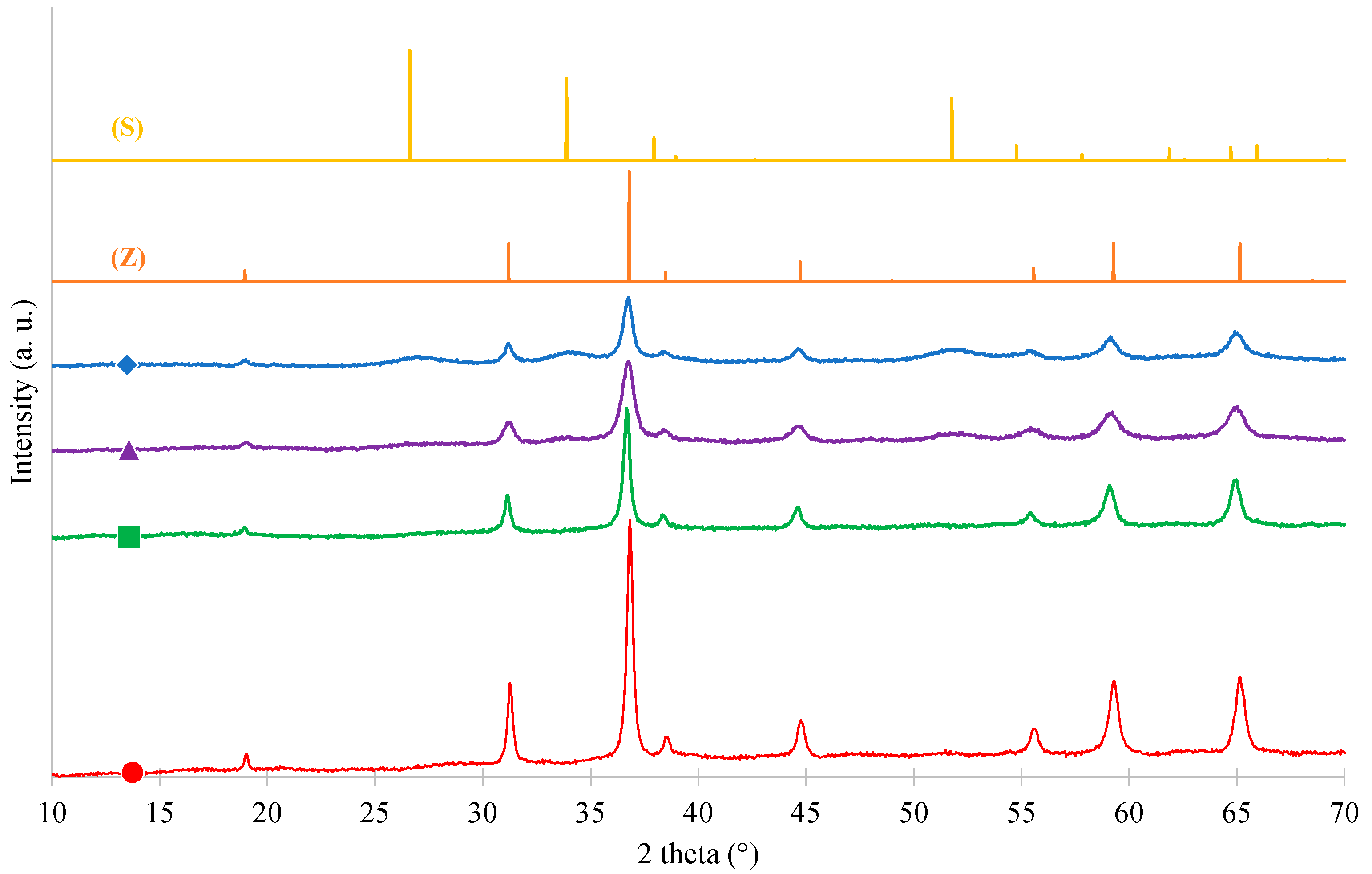

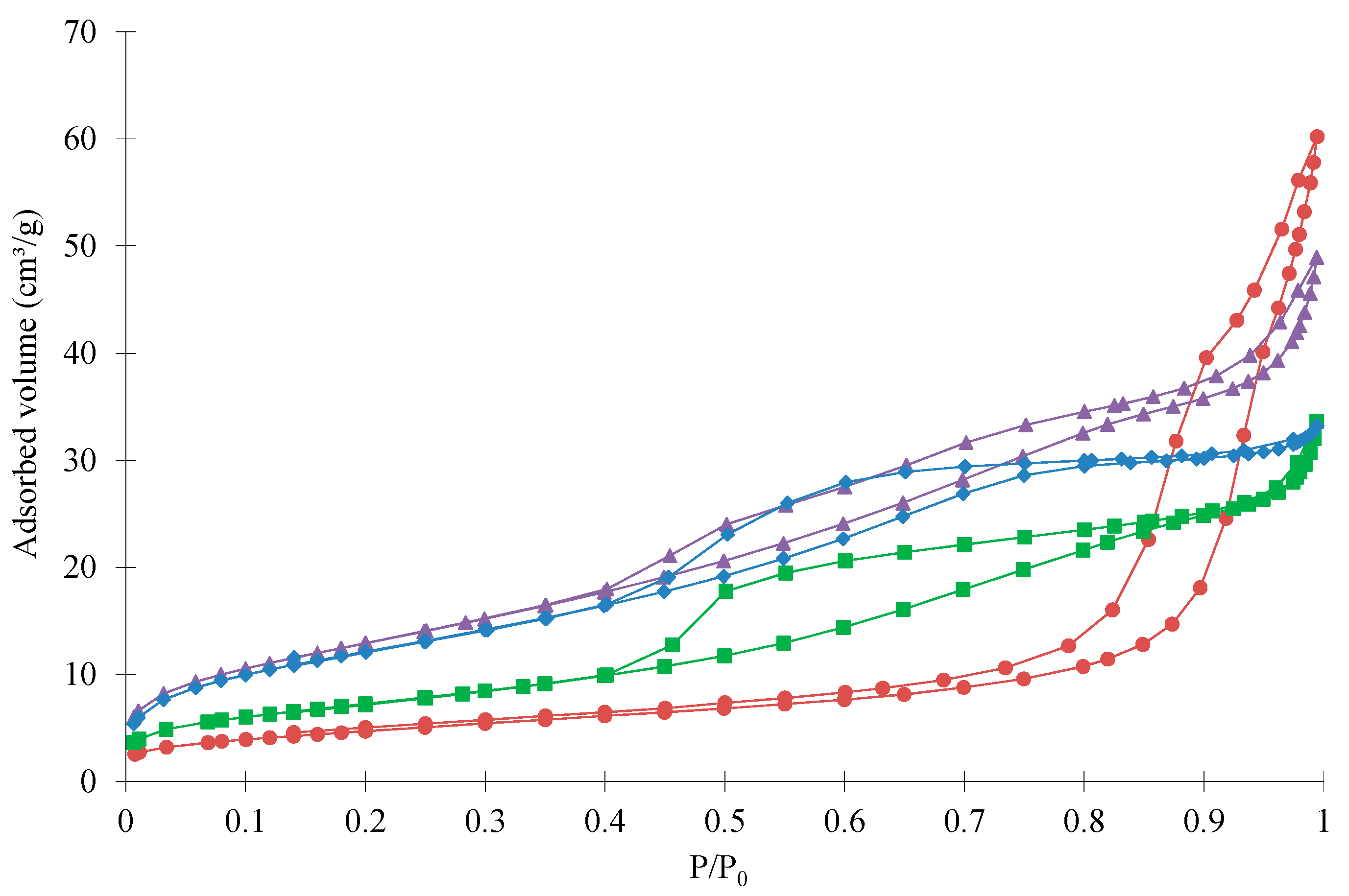

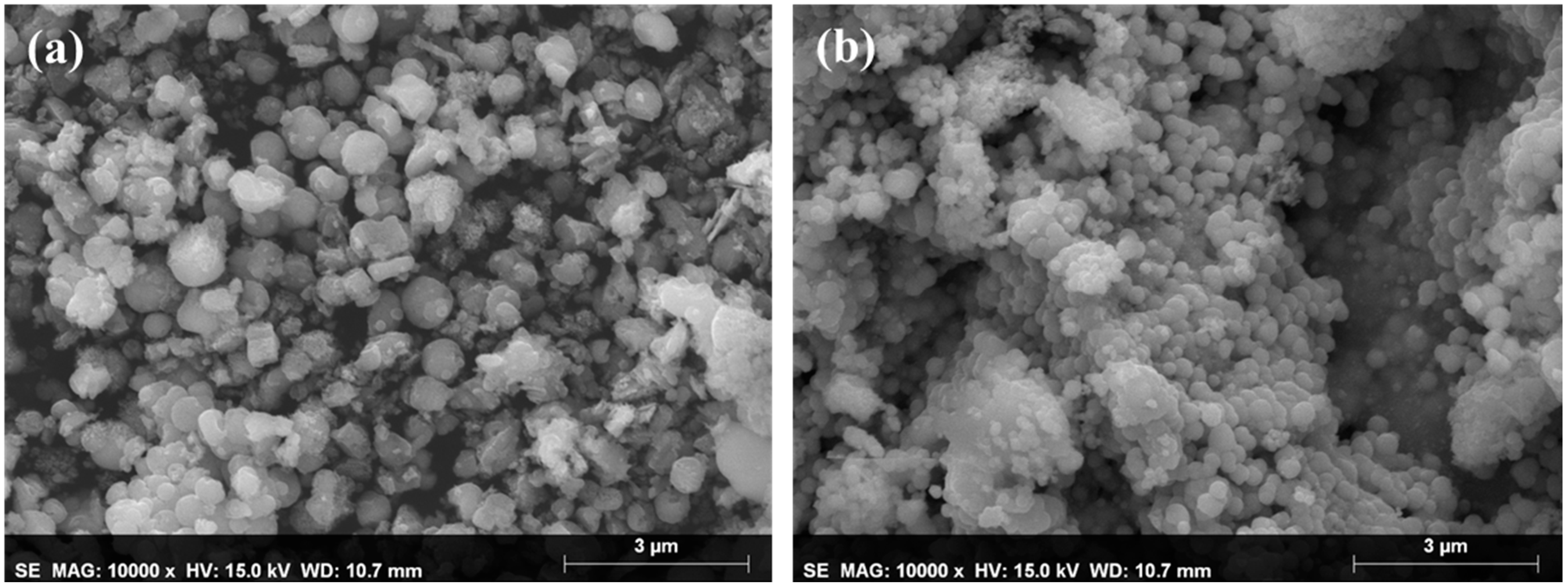

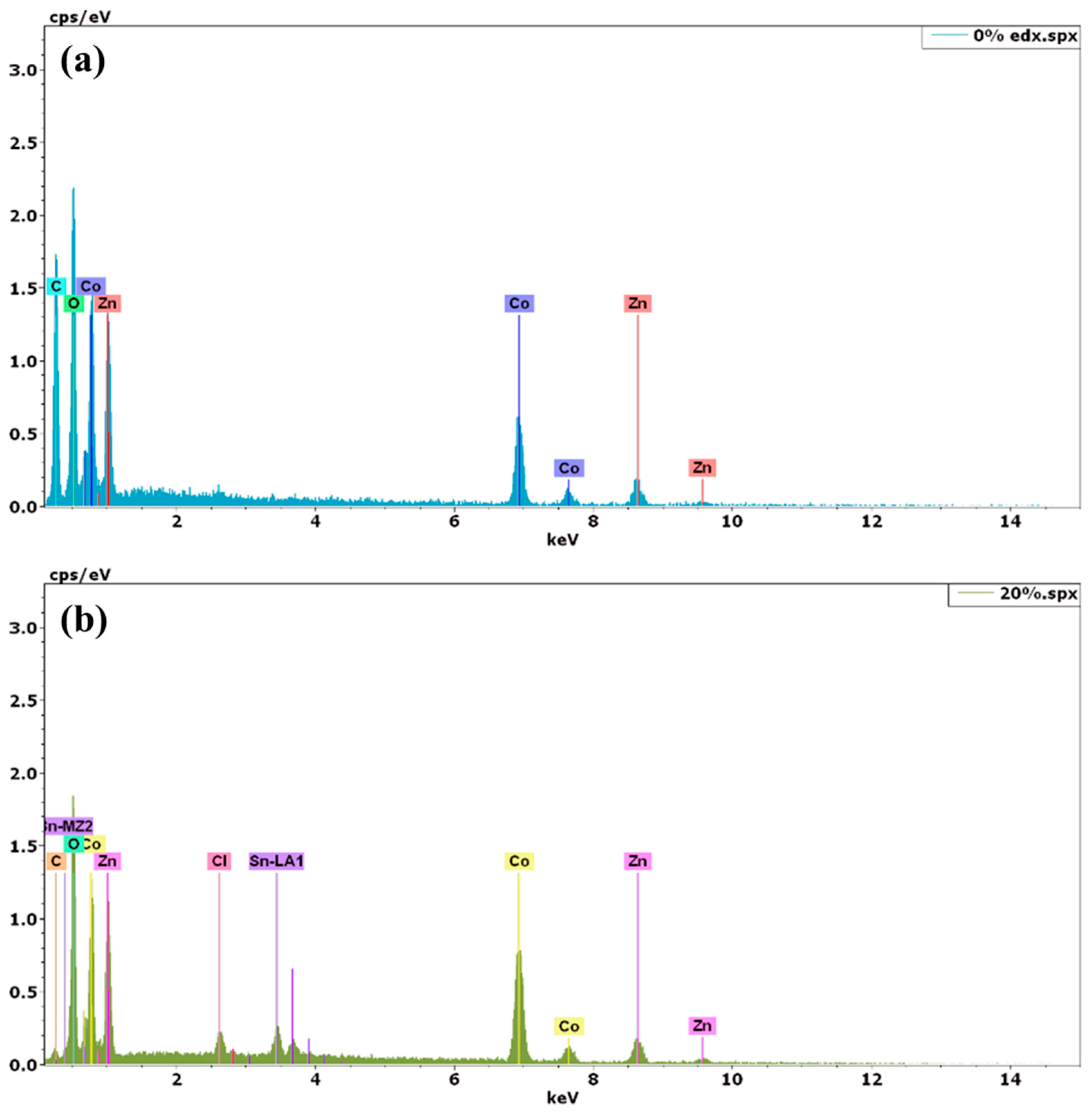

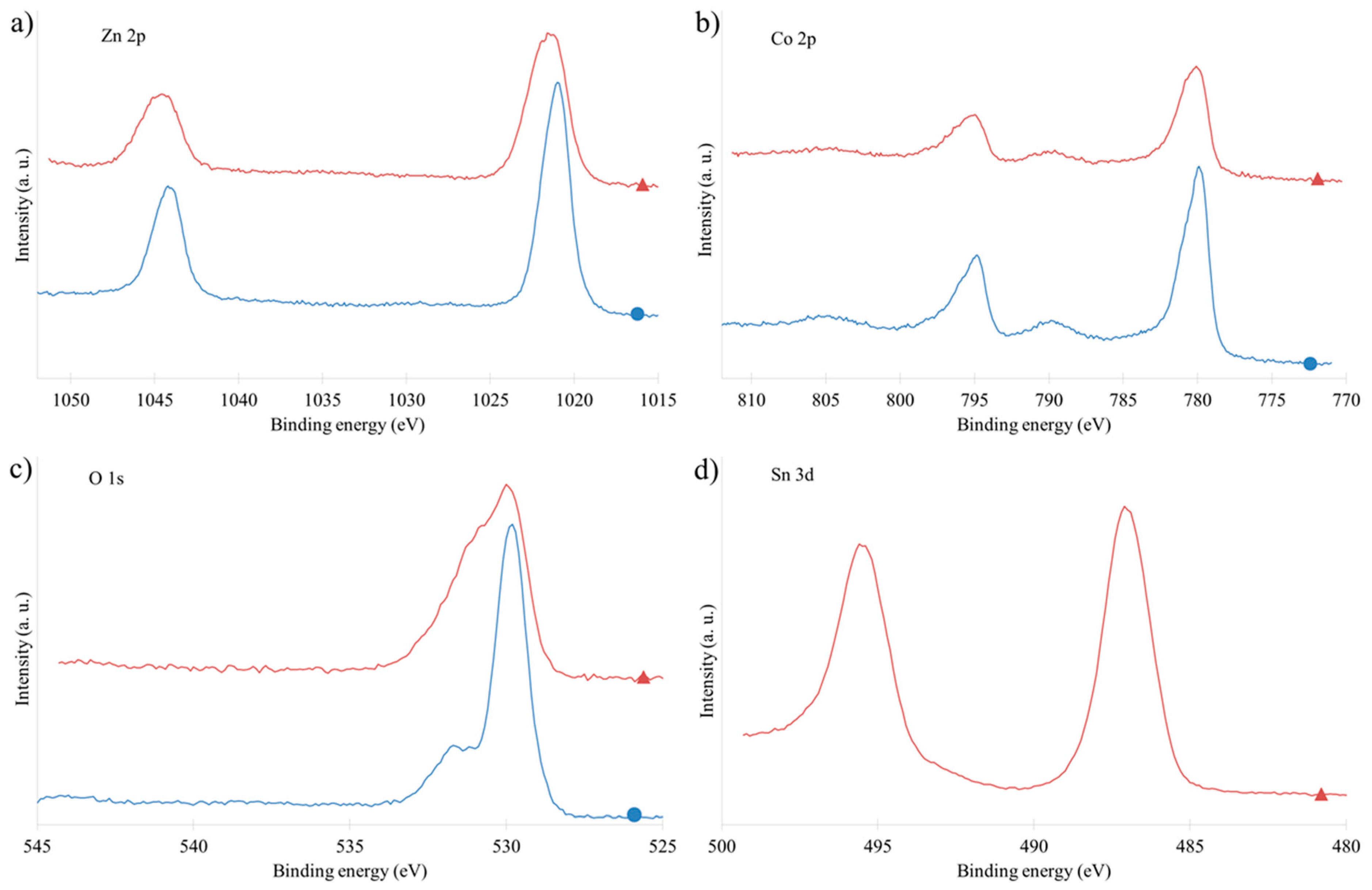

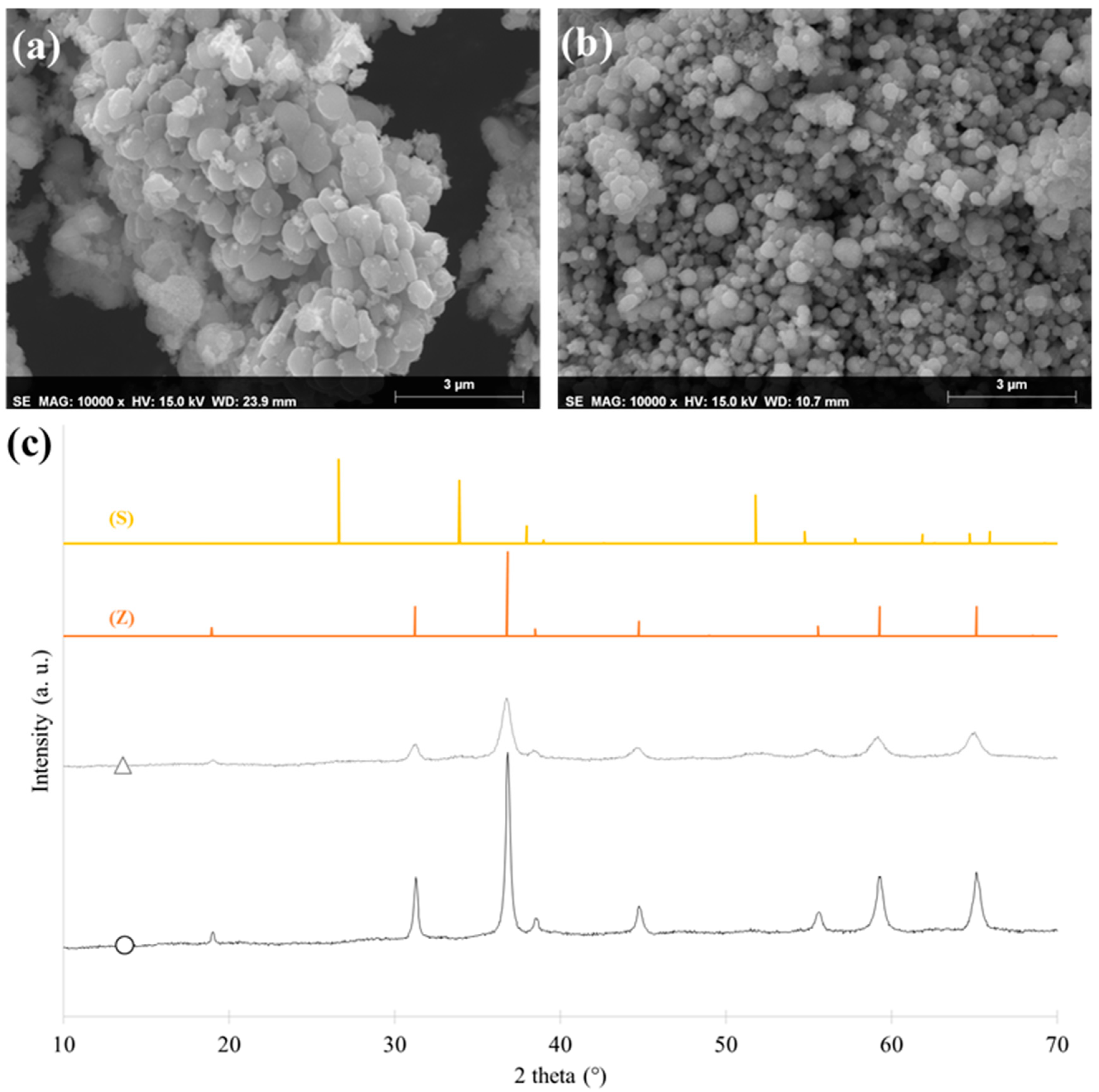

2.1. Morphology and Composition

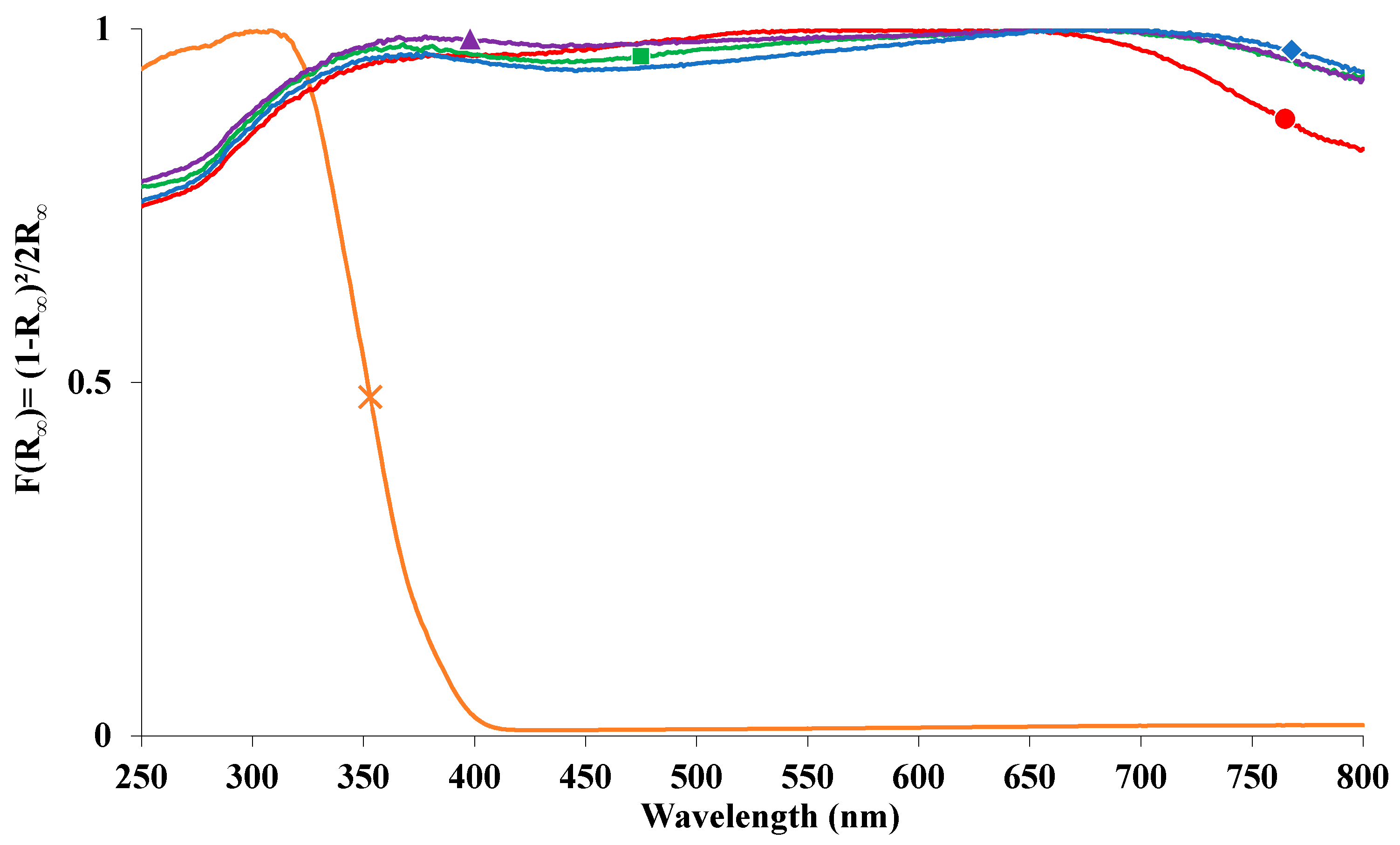

2.2. Optical Properties

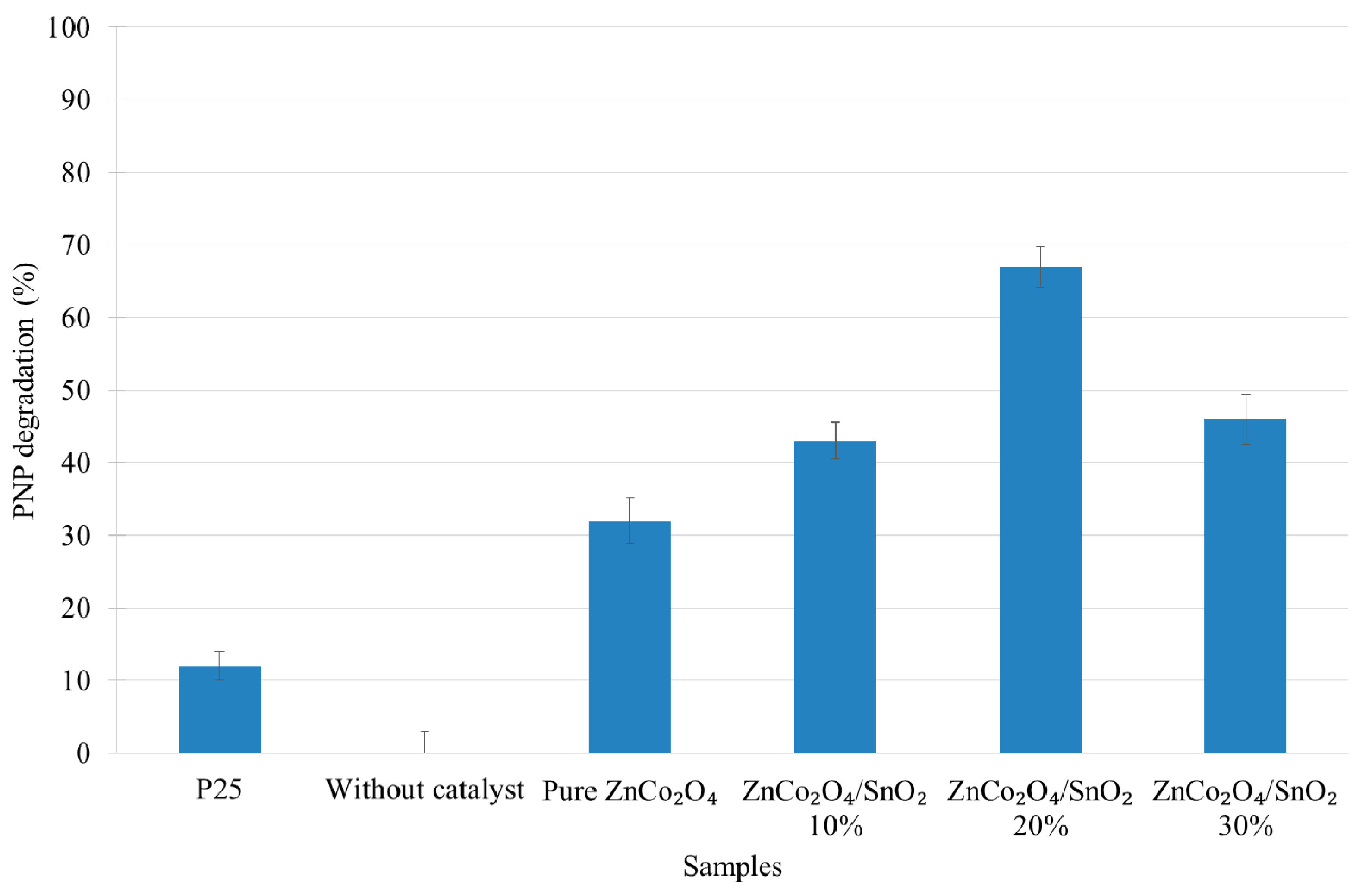

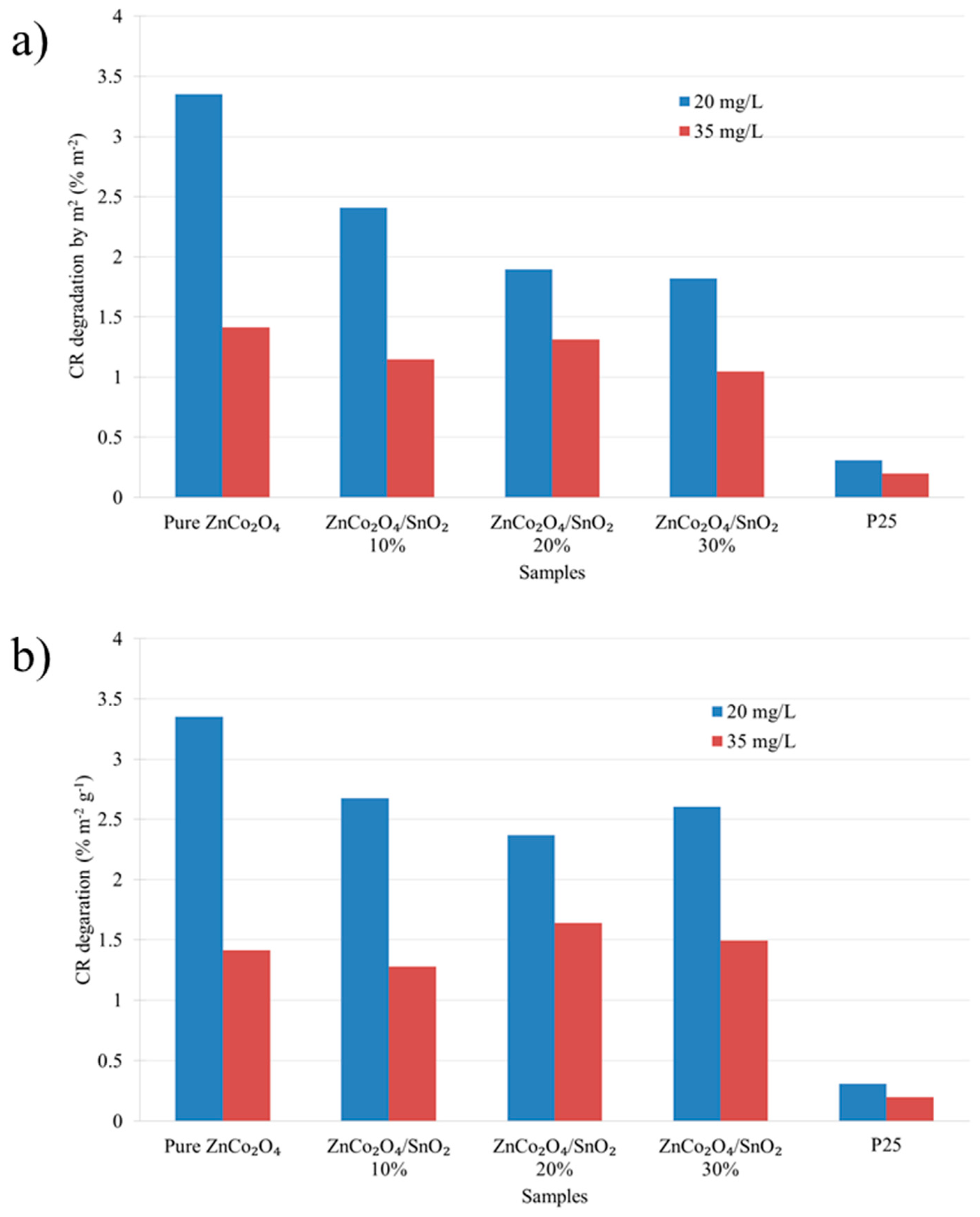

2.3. Photocatalytic Performance

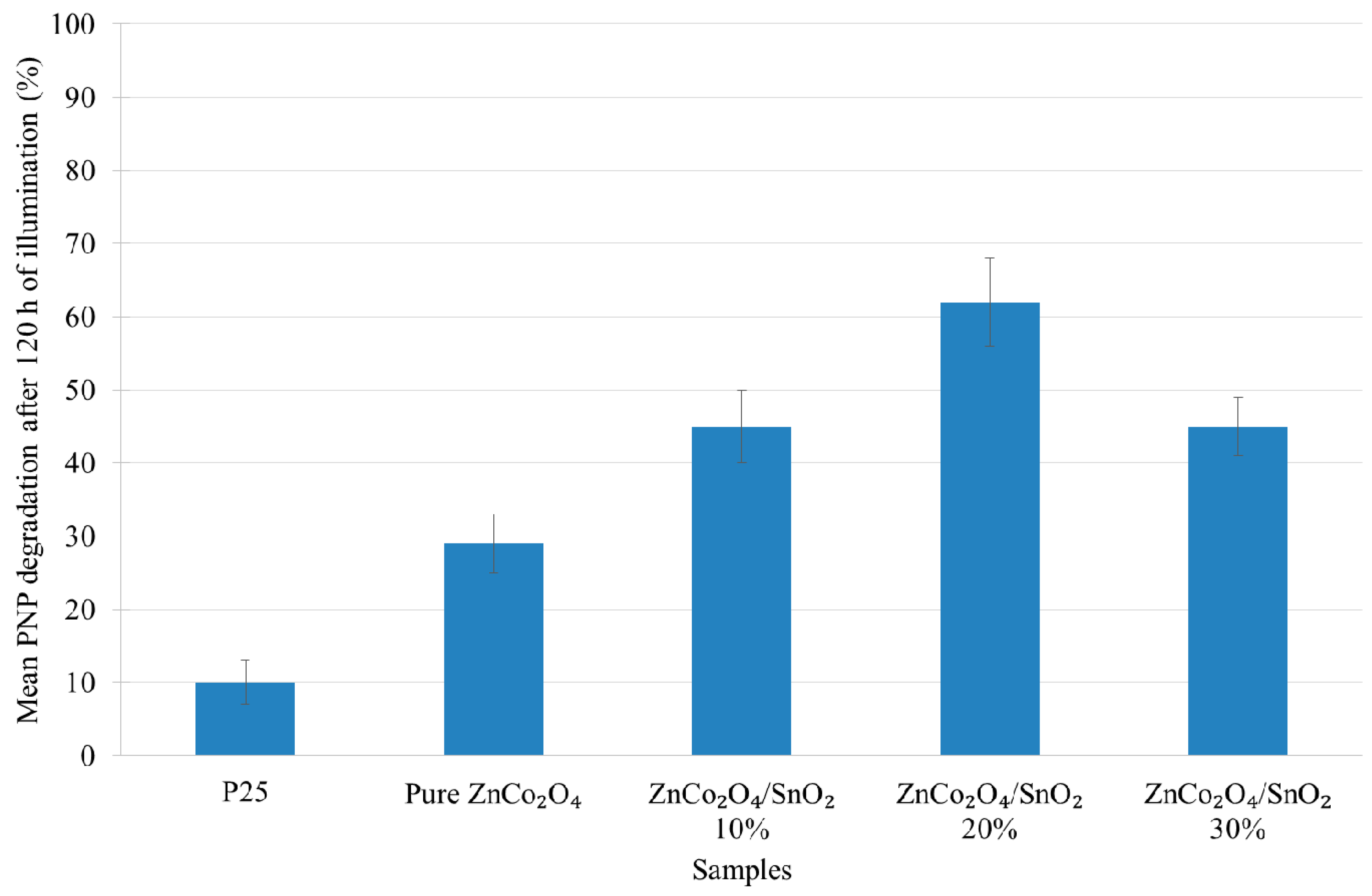

2.4. Photocatalytic Stability

3. Materials and Methods

3.1. Chemicals

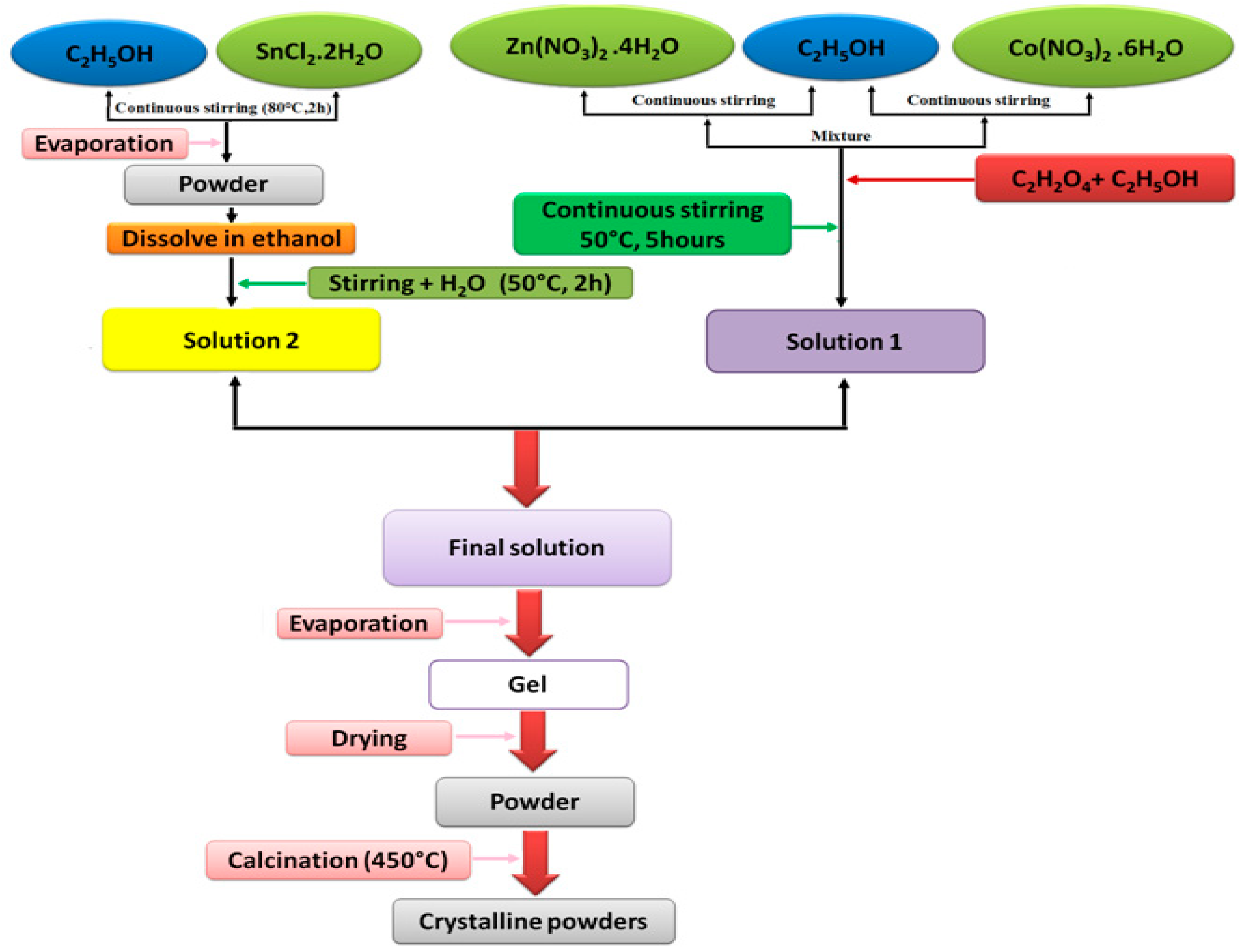

3.2. Material Synthesis

3.3. Material Characterization

3.4. Photocatalytic Activity under Visible Light

3.5. Recycling Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vosoughifar, M. Preparation, characterization, and morphological control of MnWO4 nanoparticles through novel method and its photocatalyst application. J. Mater. Sci. Mater. Electron. 2017, 28, 2135–2140. [Google Scholar] [CrossRef]

- Shah, M.P. Industrial Wastewater Treatment: A Challenging Task in the Industrial. Adv. Recycl. Waste Manag. 2016, 2, 115. [Google Scholar] [CrossRef]

- Bhatkhande, D.S.; Pangarkar, V.G.; Beenackers, A.A.C.M. Photocatalytic degradation for environmental applications—A review. J. Chem. Technol. Biotechnol. 2001, 77, 102–106. [Google Scholar] [CrossRef]

- Azam, A.; Ahmed, A.S.; Oves, M. Size-dependent antimicrobial properties of CuO nanoparticles against Gram-positive and -negative bacterial strains. Int. J. Nanomed. 2012, 7, 3527–3535. [Google Scholar] [CrossRef] [PubMed]

- Léonard, G.L.-M.; Pàez, C.A.; Ramírez, A.E.; Mahy, J.G.; Heinrichs, B. Interactions between Zn2+ or ZnO with TiO2 to produce an efficient photocatalytic, superhydrophilic and aesthetic glass. J. Photochem. Photobiol. A Chem. 2018, 350, 32–43. [Google Scholar] [CrossRef]

- Tian, Q.; Wei, W.; Dai, J.; Sun, Q.; Zhuang, J.; Zheng, Y.; Liu, P.; Fan, M.; Chen, L. Porous core-shell TixSn1−xO2 solid solutions with broad-light response: One-pot synthesis and ultrahigh photooxidation performance. Appl. Catal. B Environ. 2019, 244, 45–55. [Google Scholar] [CrossRef]

- Wu, M.; Leung, D.Y.C.; Zhang, Y.; Huang, H.; Xie, R.; Szeto, W.; Li, F. Toluene degradation over Mn-TiO2/CeO2 composite catalyst under vacuum ultraviolet (VUV) irradiation. Chem. Eng. Sci. 2019, 195, 985–994. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.M.; Hamilton, J.W.J.; Byrne, J.A.; O’Shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef]

- Linsebigler, A.L.; Lu, G.; Yates, J.T. Photocatalysis on TiO2 Surfaces: Principles, Mechanisms, and Selected Results. Chem. Rev. 1995, 95, 735–758. [Google Scholar] [CrossRef]

- Malengreaux, C.M.; Douven, S.; Poelman, D.; Heinrichs, B.; Bartlett, J.R. An ambient temperature aqueous sol-gel processing of efficient nanocrystalline doped TiO2-based photocatalysts for the degradation of organic pollutants. J. Sol-Gel Sci. Technol. 2014, 71, 557–570. [Google Scholar] [CrossRef]

- Lee, A.; Libera, J.A.; Waldman, R.Z.; Ahmed, A.; Avila, J.R.; Elam, J.W.; Darling, S.B. Conformal Nitrogen-Doped TiO2 Photocatalytic Coatings for Sunlight-Activated Membranes. Adv. Sustain. Syst. 2017, 1, 1600041. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Wexler, D.; Shi, D.; Liang, J.; Liu, H.; Xiong, S.; Qian, Y. Simple synthesis of yolk-shelled ZnCo2O4 microspheres towards enhancing the electrochemical performance of lithium-ion batteries in conjunction with a sodium carboxymethyl cellulose binder. J. Mater. Chem. A 2013, 1, 15292–15299. [Google Scholar] [CrossRef]

- Chen, J.; Zhan, J.; Lu, E.; Wan, Y.; Jin, Z.; Qi, H. Facile template-free fabrication of mesoporous ZnCo2O4 fibers with enhanced photocatalytic activity under visible-light irradiation. Mater. Lett. 2018, 220, 66–69. [Google Scholar] [CrossRef]

- Liu, B.; Liu, H.; Liang, M.; Liu, L.; Lv, Z.; Zhou, H.; Guo, H. Controlled synthesis of hollow octahedral ZnCo2O4 nanocages assembled by untrathin 2D nanosheets for enhanced lithium storage. Nanoscale 2017, 9, 17174–17180. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.W.; Woo, M.A.; Regis, M.; Choi, K. Electrochemical Synthesis of Spinel Type ZnCo2O4 Electrodes for Use as Oxygen Evolution Reaction Catalysts. J. Phys. Chem. Lett. 2014, 5, 2370–2374. [Google Scholar] [CrossRef] [PubMed]

- Goswami, K.; Ananthakrishnan, R.; Mandal, S. Facile synthesis of cation doped ZnO-ZnCo2O4 hetero-nanocomposites for photocatalytic decomposition of aqueous organics under visible light. Mater. Chem. Phys. 2018, 206, 174–185. [Google Scholar] [CrossRef]

- Sarkar, A.; Karmakar, K.; Khan, G.G. Designing Co-Pi Modified One-Dimensional n–p TiO2/ZnCo2O4 Nanoheterostructure Photoanode with Reduced Electron—Hole Pair Recombination and Excellent Photoconversion Efficiency (>3%). J. Phys. Chem. C 2017, 121, 25705–25717. [Google Scholar] [CrossRef]

- Rashid, J.; Barakat, M.A.; Mohamed, R.M.; Ibrahim, I.A. Enhancement of photocatalytic activity of zinc/cobalt spinel oxides by doping with ZrO2 for visible light photocatalytic degradation of 2-chlorophenol in wastewater. J. Photochem. Photobiol. A Chem. 2014, 284, 1–7. [Google Scholar] [CrossRef]

- Valverde Aguilar, G.; Jaime Fonseca, M.R.; Mantilla Ramirez, A.; Juarez Gracia, A.G. Photoluminescence Studies on ZnO Thin Films Obtained by Sol-Gel Method. In Recent Applications in Sol-Gel Synthesis; Intechopen: London, UK, 2017; pp. 197–212. [Google Scholar]

- Bodson, C.J.; Heinrichs, B.; Tasseroul, L.; Bied, C.; Mahy, J.G.; Wong Chi Man, M.; Lambert, S.D. Efficient P- and Ag-doped titania for the photocatalytic degradation of waste water organic pollutants. J. Alloys Compd. 2016, 682, 144–153. [Google Scholar] [CrossRef]

- Bischoff, B.; Anderson, M. Peptization Process in the Sol-Gel Preparation of Porous Anatase (TiO2). Chem. Mater. 1995, 7, 1772–1778. [Google Scholar] [CrossRef]

- Gratzel, M. Sol-gel processed TiO2 films for photovoltaic applications. J. Sol-Gel Sci. Technol. 2001, 22, 7–13. [Google Scholar] [CrossRef]

- Mahy, J.G.; Deschamps, F.; Collard, V.; Jérôme, C.; Bartlett, J.; Lambert, S.D.; Heinrichs, B. Acid acting as redispersing agent to form stable colloids from photoactive crystalline aqueous sol–gel TiO2 powder. J. Sol-Gel Sci. Technol. 2018, 87, 568–583. [Google Scholar] [CrossRef]

- Belet, A.; Wolfs, C.; Mahy, J.G.; Poelman, D.; Vreuls, C. Sol-gel Syntheses of Photocatalysts for the Removal of Pharmaceutical Products in Water. Nanomaterials 2019, 9, 126. [Google Scholar] [CrossRef] [PubMed]

- Balamurugan, J.S.S.; Prabha, K.U.D.; Nagarethinam, M.S.V.S. Visible light irradiated photocatalytic and magnetic properties of Fe-doped SnS2 nanopowders. J. Mater. Sci. Mater. Electron. 2018, 29, 9016–9024. [Google Scholar]

- Ehsan, M.F.; Bashir, S.; Hamid, S.; Zia, A.; Abbas, Y.; Umbreen, K.; Naeem, M.; Shah, A. One-pot facile synthesis of the ZnO/ZnSe heterostructures for e ffi cient photocatalytic degradation of azo dye. Appl. Surf. Sci. 2018, 459, 194–200. [Google Scholar] [CrossRef]

- Akika, F.Z.; Benamira, M.; Lahmar, H.; Tibera, A.; Chabi, R.; Avramova, I.; Suzer, Ş.; Trari, M. Structural and optical properties of Cu-substitution of NiAl2O4 and their photocatalytic activity towards Congo red under solar light irradiation. J. Photochem. Photobiol. A Chem. 2018, 364, 542–550. [Google Scholar] [CrossRef]

- Mahy, J.G.; Paez, C.A.; Carcel, C.; Bied, C.; Tatton, A.S.; Damblon, C.; Heinrichs, B.; Wong Chi Man, M.; Lambert, S.D. Porphyrin-based hybrid silica-titania as a visible-light photocatalyst. J. Photochem. Photobiol. A Chem. 2019, 373, 66–76. [Google Scholar] [CrossRef]

- Rochkind, M.; Pasternak, S.; Paz, Y. Using dyes for evaluating photocatalytic properties: A critical review. Molecules 2015, 20, 88–110. [Google Scholar] [CrossRef]

- Zhu, Y.; Cao, C.; Zhang, J.; Xu, X. Two-dimensional ultrathin ZnCo2O4 nanosheets: General formation and lithium storage application. J. Mater. Chem. A 2015, 3, 9556–9564. [Google Scholar] [CrossRef]

- Qiu, Y.; Yang, S.; Deng, H.; Li, W. A novel nanostructured spinel ZnCo2O4 electrode material: Morphology conserved transformation from a hexagonal shaped nanodisk precursor and application in lithium ion batteries. J. Mater. Chem. 2010, 20, 4439–4444. [Google Scholar] [CrossRef]

- Léonard, G.L.-M.; Malengreaux, C.M.; Mélotte, Q.; Lambert, S.D.; Bruneel, E.; Van Driessche, I.; Heinrichs, B. Doped sol–gel films vs. powders TiO2: On the positive effect induced by the presence of a substrate. J. Environ. Chem. Eng. 2016, 4, 449–459. [Google Scholar] [CrossRef]

- Bhagwat, A.D.; Sawant, S.S.; Ankamwar, B.G.; Mahajan, C.M. Synthesis of Nanostructured Tin Oxide (SnO2) Powders and Thin Films Prepared by Sol-Gel Method. J. Nano- Electron. Phys. 2015, 7, 04037. [Google Scholar]

- Singh, R.P.P.; Hudiara, I.S.; Panday, S.; Rana, S.B. Effect of Ni Doping on Structural, Optical, and Magnetic Properties of Fe-Doped ZnO Nanoparticles. J. Supercond. Nov. Magn. 2015, 28, 3685–3691. [Google Scholar] [CrossRef]

- Lecloux, A. Exploitation des isothermes d’adsorption et de désorption d’azote pour l’étude de la texture des solides poreux. Mémoires Société des Sciences de Liege Belgium 1971, 1, 169–209. [Google Scholar]

- Kustova, G.N.; Burgina, E.B.; Volkova, G.G.; Yurieva, T.M.; Plyasova, L.M. IR spectroscopic investigation of cation distribution in Zn–Co oxide catalysts with spinel type structure. J. Mol. Catal. A Chem. 2000, 158, 293–296. [Google Scholar] [CrossRef]

- Wei, X.; Chen, D.; Tang, W. Preparation and characterization of the spinel oxide ZnCo2O4 obtained by sol-gel method. Mater. Chem. Phys. 2007, 103, 54–58. [Google Scholar] [CrossRef]

- Barakat, N.A.M.; Khil, M.S.; Sheikh, F.A.; Kim, H.Y. Synthesis and Optical Properties of Two Cobalt Oxides (CoO and Co3O4) Nanofibers Produced by Electrospinning Process. J. Phys. Chem. C 2008, 112, 12225–12233. [Google Scholar] [CrossRef]

- Paramarta, V.; Taufik, A.; Saleh, R. Better adsorption capacity of SnO2 nanoparticles with different graphene addition. J. Phys. Conf. Ser. 2016, 776, 012039. [Google Scholar] [CrossRef]

- Druska, P.; Steinike, U.; Šepelák, V. Surface structure of mechanically activated and of mechanosynthesized zinc ferrite. J. Solid State Chem. 1999, 146, 13–21. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Lau, L.W.M.; Grosvenor, A.P.; Smart, R.S.C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 2010, 257, 887–898. [Google Scholar] [CrossRef]

- Chuang, T.J.; Brundle, C.R.; Rice, D.W. Interpretation of the x-ray photoemission spectra of cobalt oxides and cobalt oxide surfaces. Surf. Sci. 1976, 59, 413–429. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Payne, B.P.; Grosvenor, A.P.; Lau, L.W.M.; Gerson, A.R.; Smart, R.S.C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 2011, 257, 2717–2730. [Google Scholar] [CrossRef]

- Oku, M.; Hirokawa, K. X-ray photoelectron spectroscopy of Co3O4, Fe3O4, Mn3O4, and related compounds. J. Electron Spectros. Relat. Phenom. 1976, 8, 475–481. [Google Scholar] [CrossRef]

- Yuan, C.; Li, J.; Hou, L.; Lin, J.; Zhang, X.; Xiong, S. Polymer-assisted synthesis of a 3D hierarchical porous network-like spinel NiCo2O4 framework towards high-performance electrochemical capacitors. J. Mater. Chem. A 2013, 1, 11145–11151. [Google Scholar] [CrossRef]

- Lu, Y.; Lin, Y.; Wang, D.; Wang, L.; Xie, T.; Jiang, T. A high performance cobalt-doped ZnO visible light photocatalyst and its photogenerated charge transfer properties. Nano Res. 2011, 4, 1144–1152. [Google Scholar] [CrossRef]

- Moses, P.R.; Wier, L.M.; Lennox, J.C.; Finklea, H.O.; Lenhard, J.R.; Murray, R.W. X-ray photoelectron spectroscopy of alkylaminesilanes bound to metal oxide electrodes. Anal. Chem. 1978, 50, 576–585. [Google Scholar] [CrossRef]

- Ben Haj Othmen, W.; Hamdi, A.; Addad, A.; Sieber, B.; Elhouichet, H.; Szunerits, S.; Boukherroub, R. Fe-doped SnO2 decorated reduced graphene oxide nanocomposite with enhanced visible light photocatalytic activity. J. Photochem. Photobiol. A Chem. 2018, 367, 145–155. [Google Scholar] [CrossRef]

- Janus, M.; Morawski, A.W. New method of improving photocatalytic activity of commercial Degussa P25 for azo dyes decomposition. Appl. Catal. B Environ. 2007, 75, 118–123. [Google Scholar] [CrossRef]

- Hachem, C.; Bocquillon, F.; Zahraa, O.; Bouchy, M. Decolourization of textile industry wastewater by the photocatalytic degradation process. Dyes Pigments 2001, 49, 117–125. [Google Scholar] [CrossRef]

- Devi, L.G.; Kumar, S.G.; Reddy, K.M. Photo fenton like process Fe3+/(NH4)2 S2O8/UV for the degradation of Di azo dye congo red using low iron concentration. Cent. Eur. J. Chem. 2009, 7, 468–477. [Google Scholar]

- Shaban, M.; Abukhadra, M.R.; Hamd, A.; Amin, R.R.; Abdel Khalek, A. Photocatalytic removal of Congo red dye using MCM-48/Ni2O3 composite synthesized based on silica gel extracted from rice husk ash; fabrication and application. J. Environ. Manag. 2017, 204, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Mahy, J.G.; Lambert, S.D.; Léonard, G.L.-M.; Zubiaur, A.; Olu, P.-Y.; Mahmoud, A.; Boschini, F.; Heinrichs, B. Towards a large scale aqueous sol-gel synthesis of doped TiO2: Study of various metallic dopings for the photocatalytic degradation of p-nitrophenol. J. Photochem. Photobiol. A Chem. 2016, 329, 189–202. [Google Scholar] [CrossRef]

- Mahy, J.G.; Cerfontaine, V.; Poelman, D.; Devred, F.; Gaigneaux, E.M.; Heinrichs, B.; Lambert, S.D. Highly efficient low-temperature N-doped TiO2 catalysts for visible light photocatalytic applications. Materials 2018, 11, 584. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Shao, Q.; Zhao, J.; Pan, D.; Dong, M.; Jia, C.; Ding, T. Microwave solvothermal carboxymethyl chitosan templated synthesis of TiO2/ZrO2 composites toward enhanced photocatalytic degradation of Rhodamine B. J. Colloid Interface Sci. 2019, 541, 18–29. [Google Scholar] [CrossRef] [PubMed]

- Renuka, L.; Anantharaju, K.S.; Vidya, Y.S.; Nagaswarupa, H.P.; Prashantha, S.C. A simple combustion method for the synthesis of multi-functional ZrO2/CuO nanocomposites: Excellent performance as Sunlight photocatalysts and enhanced latent fingerprint detection. Appl. Catal. B Environ. 2017, 210, 97–115. [Google Scholar] [CrossRef]

- Xu, Y.; Schoonen, M.A.A. The absolute energy positions of conduction and valence bands of selected semiconducting minerals. Am. Mineral. 2000, 85, 543–556. [Google Scholar] [CrossRef]

- Amini, M.N.; Dixit, H.; Saniz, R.; Lamoen, D.; Partoens, B. The origin of p-type conductivity in ZnM2O4 (M = Co, Rh, Ir) spinels. Phys. Chem. Chem. Phys. 2014, 16, 2588–2596. [Google Scholar] [CrossRef]

- Benhebal, H.; Chaib, M.; Léonard, A.; Lambert, S.D.; Crine, M. Synthesis, characterization and photocatalytic properties of alkali metals doped tin dioxide. J. Mol. Struct. 2011, 1004, 222–226. [Google Scholar] [CrossRef]

- Yi, S.; Yue, X.; Xu, D.; Liu, Z.; Zhao, F.; Wang, D.; Lin, Y. Study on photogenerated charge transfer properties and enhanced visible-light photocatalytic activity of p-type Bi2O3/n-type ZnO heterojunctions. New J. Chem. 2015, 39, 2917–2924. [Google Scholar] [CrossRef]

- Novinrooz, A.; Sarabadani, P.; Garouse, J. Characterization of Pure and Antimony Doped SnO2 Thin Films Prepared by the Sol-Gel Technique. Iran. J. Chem. Chem. Eng. 2006, 25, 31–38. [Google Scholar]

- Mahy, J.G.; Tasseroul, L.; Zubiaur, A.; Geens, J.; Brisbois, M.; Herlitschke, M.; Hermann, R.; Heinrichs, B.; Lambert, S.D. Highly dispersed iron xerogel catalysts for p-nitrophenol degradation by photo-Fenton effects. Microporous Mesoporous Mater. 2014, 197, 164–173. [Google Scholar] [CrossRef]

- Reenu, J.; Harikrishnan, N.; Jayakumari, I. Structural and Morphological Studies of Nano-crystalline Ceramic BaSr0.9Fe0.1TiO4. Int. Lett. Chem. Phys. Astron. 2015, 41, 100–117. [Google Scholar]

- Kubelka, P.; Munk, F. Ein Beitrag zur Optik der Farban striche. Z. Tech. Phys. 1931, 12, 593–603. [Google Scholar]

- Kubelka, P. New contributions to the optics of intensely light-scattering materials. J. Opt. Soc. Am. 1948, 38, 448–457. [Google Scholar] [CrossRef] [PubMed]

- Malengreaux, C.M.; Pirard, S.L.; Léonard, G.; Mahy, J.G.; Herlitschke, M.; Klobes, B.; Hermann, R.; Heinrichs, B.; Bartlett, J.R. Study of the photocatalytic activity of Fe3+, Cr3+, La3+ and Eu3+ single-doped and co-doped TiO2 catalysts produced by aqueous sol-gel processing. J. Alloys Compd. 2017, 691, 726–738. [Google Scholar] [CrossRef]

- Páez, C.A.; Liquet, D.Y.; Calberg, C.; Lambert, S.D.; Willems, I.; Germeau, A.; Pirard, J.P.; Heinrichs, B. Study of photocatalytic decomposition of hydrogen peroxide over ramsdellite-MnO2 by O2-pressure monitoring. Catal. Commun. 2011, 15, 132–136. [Google Scholar] [CrossRef]

| Samples | SnO2 Theoretical Content (wt %) | SnO2 Actual Content (wt %) | SBET (m2·g−1) ±5 | VDR (cm3·g−1) ±0.01 | dXRD (nm) ±1 |

|---|---|---|---|---|---|

| Pure ZnCo2O4 | - | - | 17 | 0.01 | 30 |

| ZnCo2O4/SnO2-10% | 10 | 11 | 27 | 0.02 | 24 |

| ZnCo2O4/SnO2-20% | 20 | 20 | 48 | 0.03 | 16 |

| ZnCo2O4/SnO2-30% | 30 | 32 | 45 | 0.03 | 16 |

| Sample | (10−7 mol/L/h) | (10−7 mol/L/h) |

|---|---|---|

| No catalyst | 0 | 0 |

| P25 | 5 | 2.1 |

| Pure ZnCo2O4 | 13.3 | 5.9 |

| ZnCo2O4/SnO2-10% | 17.9 | 7.1 |

| ZnCo2O4/SnO2-20% | 27.9 | 12.0 |

| ZnCo2O4/SnO2-30% | 19.2 | 9.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benhebal, H.; Wolfs, C.; Kadi, S.; Tilkin, R.G.; Allouche, B.; Belabid, R.; Collard, V.; Felten, A.; Louette, P.; Lambert, S.D.; et al. Visible Light Sensitive SnO2/ZnCo2O4 Material for the Photocatalytic Removal of Organic Pollutants in Water. Inorganics 2019, 7, 77. https://doi.org/10.3390/inorganics7060077

Benhebal H, Wolfs C, Kadi S, Tilkin RG, Allouche B, Belabid R, Collard V, Felten A, Louette P, Lambert SD, et al. Visible Light Sensitive SnO2/ZnCo2O4 Material for the Photocatalytic Removal of Organic Pollutants in Water. Inorganics. 2019; 7(6):77. https://doi.org/10.3390/inorganics7060077

Chicago/Turabian StyleBenhebal, Hadj, Cédric Wolfs, Samir Kadi, Rémi G. Tilkin, Boualem Allouche, Radhwane Belabid, Valérie Collard, Alexandre Felten, Pierre Louette, Stéphanie D. Lambert, and et al. 2019. "Visible Light Sensitive SnO2/ZnCo2O4 Material for the Photocatalytic Removal of Organic Pollutants in Water" Inorganics 7, no. 6: 77. https://doi.org/10.3390/inorganics7060077

APA StyleBenhebal, H., Wolfs, C., Kadi, S., Tilkin, R. G., Allouche, B., Belabid, R., Collard, V., Felten, A., Louette, P., Lambert, S. D., & Mahy, J. G. (2019). Visible Light Sensitive SnO2/ZnCo2O4 Material for the Photocatalytic Removal of Organic Pollutants in Water. Inorganics, 7(6), 77. https://doi.org/10.3390/inorganics7060077