Design, Deposition, Performance Evaluation, and Modulation Analysis of Nanocoatings for Cutting Tools: A Review

Abstract

1. Introduction

2. Coating Material Design

2.1. Component Design

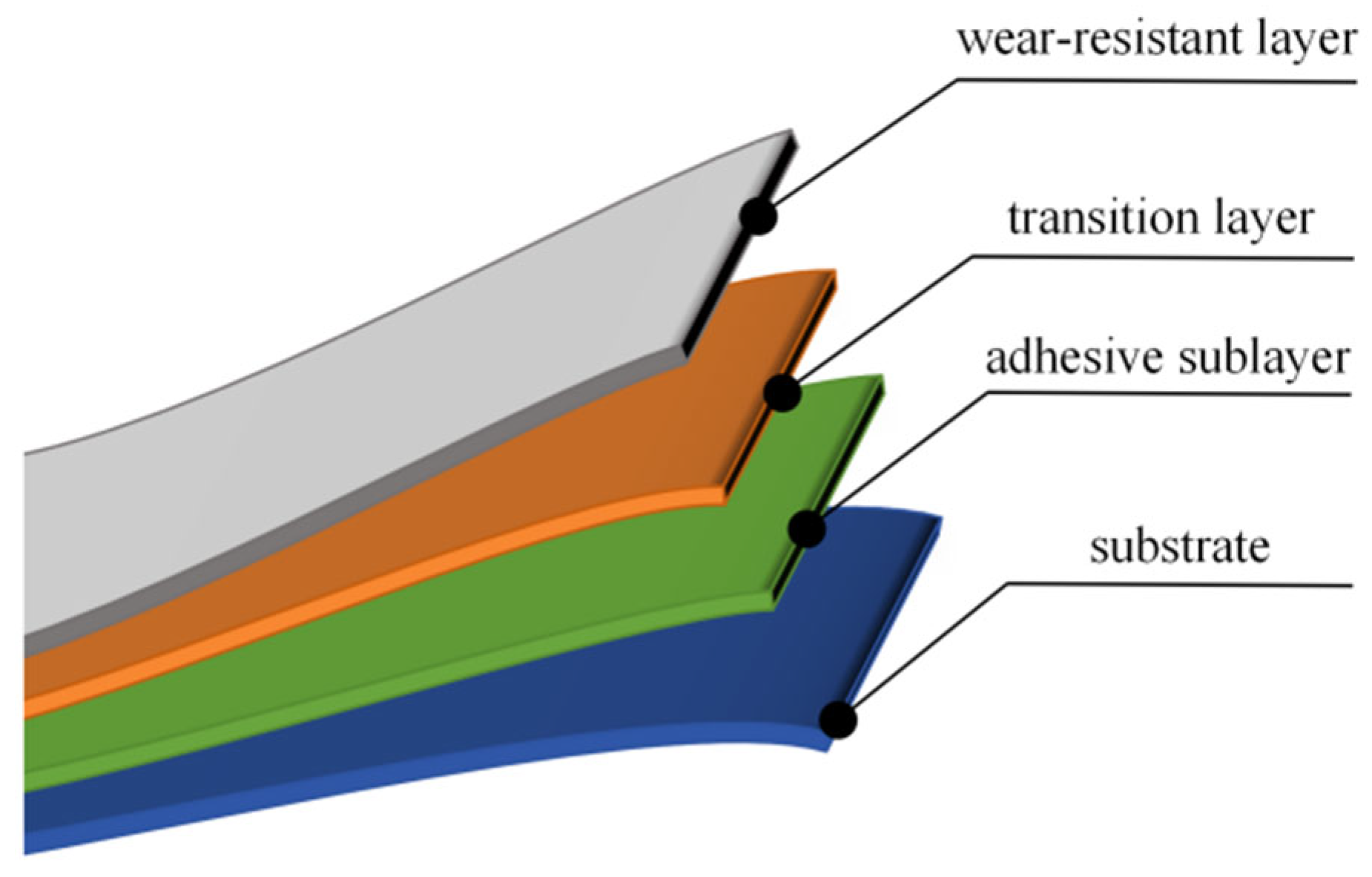

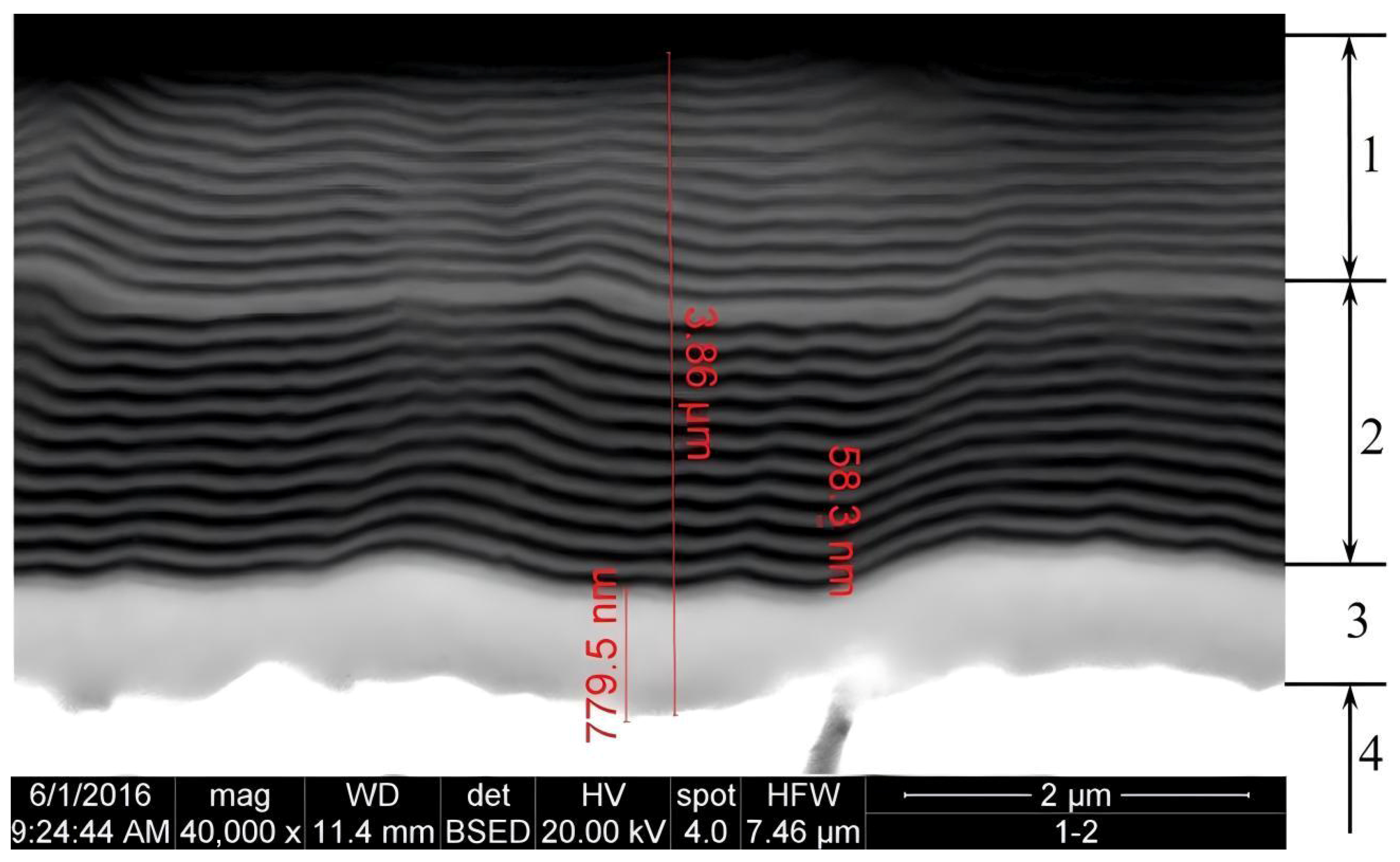

2.2. Structural Design

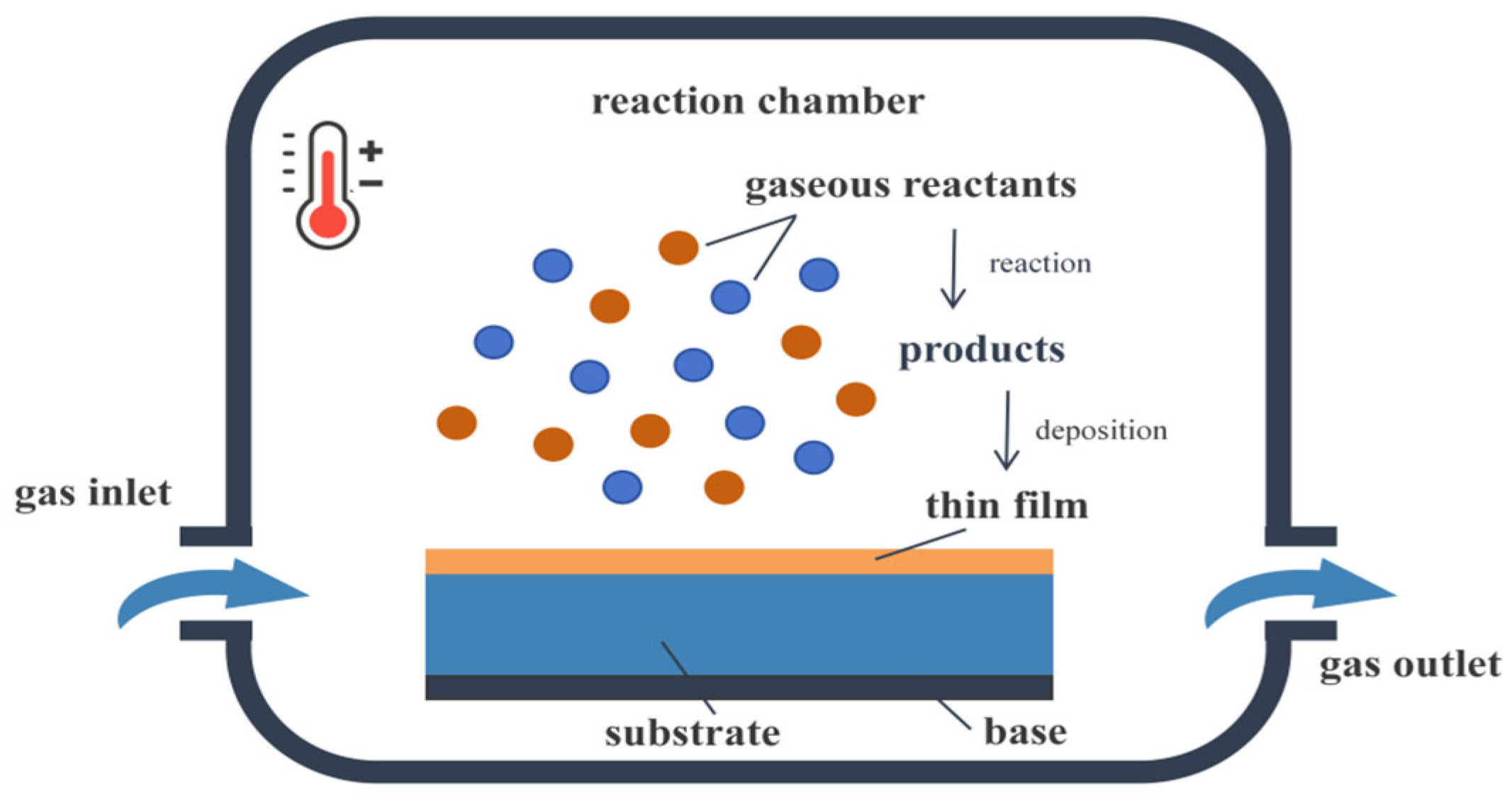

3. Selection of Deposition Method

3.1. Physical Vapor Deposition (PVD)

3.2. Chemical Vapor Deposition (CVD)

3.3. Thermoreactive Diffusion (TRD)

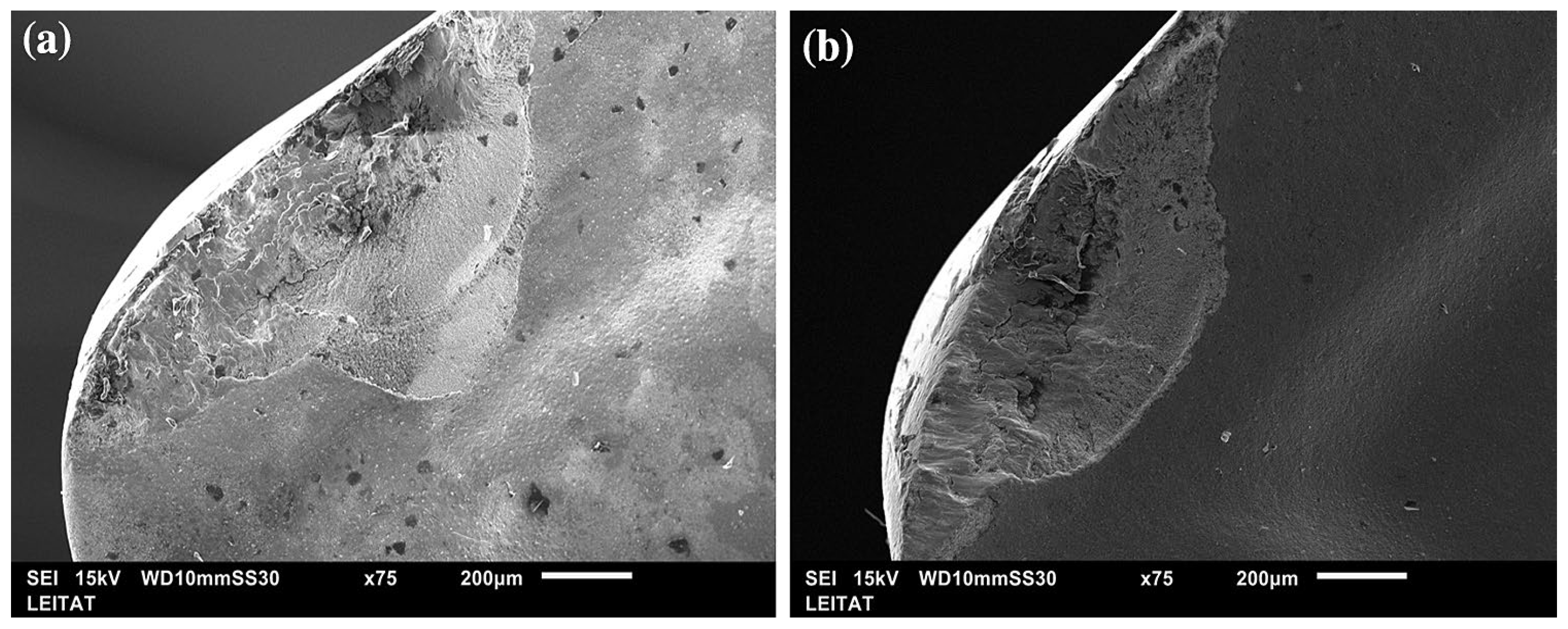

4. Performance Evaluation

4.1. Evaluation Indicators

4.2. Characterization Methods

5. Analysis of Performance Modulation

6. Summary and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hourmand, M.; Sarhan, A.A.; Sayuti, M.; Hamdi, M. A comprehensive review on machining of titanium alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Jouini, N.; Ghani, J.A.; Yaqoob, S.; Juri, A.Z. Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo + MQL Techniques. Processes 2025, 13, 739. [Google Scholar] [CrossRef]

- Pedroso, A.; Sousa, V.; Sebbe, N.; Silva, F.; Campilho, R.; Sales-Contini, R.; Jesus, A. A comprehensive review on the conventional and non-conventional machining and tool-wear mechanisms of INCONEL®. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Han, J.; Liu, Z.; Cao, K.; Xu, L.; Shi, T.; Liao, G. Cutting temperature measurement in turning using fiber-optic multi-spectral radiation thermometry and its application in tool wear status recognition. Measurement 2022, 198, 111413. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, Z.; Yang, F.; Zhong, Z.; Sun, S. Investigations on tool temperature with heat conduction and heat convection in high-speed slot milling of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2018, 96, 1847–1858. [Google Scholar] [CrossRef]

- Khan, M.A.; Jaffery, S.H.I.; Baqai, A.A.; Khan, M. Comparative analysis of tool wear progression of dry and cryogenic turning of titanium alloy Ti-6Al-4V under low, moderate and high tool wear conditions. Int. J. Adv. Manuf. Technol. 2022, 121, 1269–1287. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, B.; Jiao, F.; Zheng, J. Chip formation and its effects on cutting force, tool temperature, tool stress, and cutting edge wear in high-and ultra-high-speed milling. Int. J. Adv. Manuf. Technol. 2016, 83, 55–65. [Google Scholar] [CrossRef]

- Okada, M.; Hosokawa, A.; Tanaka, R.; Ueda, T. Cutting performance of PVD-coated carbide and CBN tools in hardmilling. Int. J. Mach. Tools Manuf. 2011, 51, 127–132. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J.; Wan, Y. Tool coating effects on cutting temperature during metal cutting processes: Comprehensive review and future research directions. Mech. Syst. Signal Process. 2021, 150, 107302. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Chowdhury, M.; Bose, B.; Yamamoto, K.; Shuster, L.; Paiva, J.; Fox-Rabinovich, G.; Veldhuis, S. Wear performance investigation of PVD coated and uncoated carbide tools during high-speed machining of TiAl6V4 aerospace alloy. Wear 2020, 446, 203168. [Google Scholar] [CrossRef]

- Sousa, V.F.; Silva, F.J. Recent advances on coated milling tool technology—A comprehensive review. Coatings 2020, 10, 235. [Google Scholar] [CrossRef]

- Sousa, V.F.; Silva, F.J. Recent advances in turning processes using coated tools—A comprehensive review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378, 43–57. [Google Scholar] [CrossRef]

- Vereschaka, A.; Migranov, M.; Oganyan, G.; Sotova, C.S.; Batako, A. Application of carbide cutting tools with nano-structured multilayer composite coatings for turning austenitic steels, type 16Cr-10NI. Mech. Ind. 2017, 18, 707. [Google Scholar] [CrossRef]

- Freitas, F.R.; Casais, R.C.; Silva, F.J.; Sebbe, N.P.; Martinho, R.P.; Sousa, V.F.; Sales-Contini, R.C.; Fernandes, F. Wear Behavior of TiAlN/DLC Coating on Tools in Milling Copper–Beryllium Alloy AMPCOLOY® 83. Coatings 2024, 14, 1354. [Google Scholar] [CrossRef]

- Kavishwar, S.; Bhaiswar, V.; Kochhar, S.; Fande, A.; Tandon, V. State-of-the-Art titanium carbide hard coatings: A comprehensive review of mechanical and tribological behaviour. Eng. Res. Express 2024, 6, 042401. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Sotova, C.; Oganian, G.; Sadov, I. Investigation of the properties of Ti-TiN-(Ti, Cr, Mo, Al) N multilayered composite coating with wear-resistant layer of nanolayer structure. Coatings 2020, 10, 1236. [Google Scholar] [CrossRef]

- Beake, B.D. Nano-and micro-scale impact testing of hard coatings: A review. Coatings 2022, 12, 793. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Wang, T.; Zha, X.; Chen, F.; Wang, J.; Li, Y.; Jiang, F. Mechanical impact test methods for hard coatings of cutting tools: A review. Int. J. Adv. Manuf. Technol. 2021, 115, 1367–1385. [Google Scholar] [CrossRef]

- Kang, K.; Su, S.; Yu, B.; Sun, Z.; Hu, S.; Wang, Z.; Zhao, C.; Wu, L.; Luo, G.; Wei, R. The review and prospect of tool coating technology. Int. J. Adv. Manuf. Technol. 2025, 137, 3107–3139. [Google Scholar] [CrossRef]

- Grzesik, W.; Małecka, J. The oxidation behaviour and notch wear formation of TiAlN coated tools using different oxidation techniques. Materials 2021, 14, 1330. [Google Scholar] [CrossRef]

- He, Q.; Saciotto, V.; DePaiva, J.M.; Guimaraes, M.C.; Kohlscheen, J.; Martins, M.M.; Veldhuis, S.C. Enhancing tool performance in high-speed end milling of Ti-6Al-4V alloy: The role of AlCrN PVD coatings and resistance to chipping wear. J. Manuf. Mater. Process. 2024, 8, 68. [Google Scholar] [CrossRef]

- Chavee, L.; Serag, E.; da Silva Pires, M.; Lucas, S.; Haye, E. A mechanistic approach of oxidation resistance, structural and mechanical behaviour of TiAlN coatings. Appl. Surf. Sci. 2022, 586, 152851. [Google Scholar] [CrossRef]

- Cheng, S. Effect of 10% Si addition on cathodic arc evaporated TiAlSiN coatings. Trans. Nonferrous Met. Soc. China 2016, 26, 1638–1646. [Google Scholar]

- Sui, X.; Li, G.; Qin, X.; Yu, H.; Zhou, X.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Zhi-Li, W.; Yu-Ge, L.; Bi, W.; Ming-Kai, L. Microstructure Controlling and Properties of TiAlSiN Nanocomposite Coatings Deposited by Modulated Pulsed Power Magnetron Sputtering. J. Inorg. Mater. 2015, 30, 1254–1260. [Google Scholar] [CrossRef]

- Dosbaeva, G.; Veldhuis, S.; Yamamoto, K.; Wilkinson, D.; Beake, B.; Jenkins, N.; Elfizy, A.; Fox-Rabinovich, G. Oxide scales formation in nano-crystalline TiAlCrSiYN PVD coatings at elevated temperature. Int. J. Refract. Met. Hard Mater. 2010, 28, 133–141. [Google Scholar] [CrossRef]

- Beake, B.D.; Fox-Rabinovich, G.S.; Losset, Y.; Yamamoto, K.; Agguire, M.H.; Veldhuis, S.C.; Endrino, J.L.; Kovalev, A.I. Why can TiAlCrSiYN-based adaptive coatings deliver exceptional performance under extreme frictional conditions? Faraday Discuss. 2012, 156, 267–277. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Konovalov, E.; Vakhrushev, V.; Dmitrievskii, S.; Endrino, J.; Fox-Rabinovich, G.; Tomchuk, A. The role of interatomic interactions in the tribooxidation and wear of the multilayer Ti0.2Al0.55Cr0.2Si0.03Y0.02N/Ti0.25Al0.65Cr0.1N coating at severe cutting conditions. Metallurgist 2024, 68, 477–484. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Rashkovskiy, A.; Fox-Rabinovich, G.; Veldhuis, S.; Agguire, M.; Yamamoto, K. Investigation of electronic and atomic structure of tribofilms on the surface of cutting tools with TiAlCrSiYN and multilayer TiAlCrSiYN/TiAlCrN coatings during machining of hardened steels. Surf. Interface Anal. 2010, 42, 1368–1372. [Google Scholar] [CrossRef]

- Luo, Y.; Dong, Y.; Xiao, C.; Wang, X.; Peng, H. Impact abrasive wear property of CrAlN/TiSiN multilayer coating at elevated temperatures. Materials 2022, 15, 2214. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-K.; Kim, S.-M.; Lee, S.-Y. Influence of interlayer materials on the mechanical properties and thermal stability of a CrAlN coating on a tungsten carbide substrate. Coatings 2022, 12, 1134. [Google Scholar] [CrossRef]

- Vereshchaka, A.; Vereshchaka, A.; Mgaloblishvili, O.; Morgan, M.; Batako, A. Nano-scale multilayered-composite coatings for the cutting tools. Int. J. Adv. Manuf. Technol. 2014, 72, 303–317. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Fyodorov, S.; Sitnikov, N.; Batako, A. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2017, 90, 3421–3435. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Vereschaka, A.S.; Batako, A.D.; Mokritskii, B.J.; Aksenenko, A.Y.; Sitnikov, N.N. Improvement of structure and quality of nanoscale multilayered composite coatings, deposited by filtered cathodic vacuum arc deposition method. Nanomater. Nanotechnol. 2016, 7, 1847980416680805. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2019, 420, 17–37. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.-Y.; Lee, G.; Kwon, S.-C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Fang, W.; Chen, J.; Zhou, Q.; Xue, H.; Cai, F.; Fang, L.; Zhang, S. Microstructure, mechanical properties and high-speed dry-cutting performance of AlCrSiCN composite coatings. J. Mater. Res. Technol. 2023, 25, 1800–1812. [Google Scholar] [CrossRef]

- Suresh Babu, P.; Venkatesh, L.; Srinivasa Rao, D.; Ravi, N. Fracture behaviour of nc-TiAlN/a-Si3N4 nanocomposite coatings under cyclic nano impact testing. Surf. Eng. 2020, 36, 671–679. [Google Scholar] [CrossRef]

- Das, P.; Anwar, S.; Bajpai, S.; Anwar, S. Structural and mechanical evolution of TiAlSiN nanocomposite coating under influence of Si3N4 power. Surf. Coat. Technol. 2016, 307, 676–682. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Lü, W.; Li, G.; Zhou, Y.; Liu, S.; Wang, K.; Wang, Q. Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Li, G.; Sun, J.; Xu, Y.; Xu, Y.; Gu, J.; Wang, L.; Huang, K.; Liu, K.; Li, L. Microstructure, mechanical properties, and cutting performance of TiAlSiN multilayer coatings prepared by HiPIMS. Surf. Coat. Technol. 2018, 353, 274–281. [Google Scholar] [CrossRef]

- Wang, M.; Toihara, T.; Sakurai, M.; Kurosaka, W.; Miyake, S. Surface morphology and tribological properties of DC sputtered nanoscale multilayered TiAlN/CNx coatings. Tribol. Int. 2014, 73, 36–46. [Google Scholar] [CrossRef]

- Li, G.; Lü, W.; Liu, S.; Li, C.; Zhou, Y.; Wang, Q. Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy. Compos. Part B Eng. 2021, 211, 108620. [Google Scholar] [CrossRef]

- Wang, P.; Pang, M.; Gao, L.-H. Research on the performance of nickel-based WC/MoS2 self-lubricating composite coatings laser cladding on 300 M ultra-high-strength steel surface. Mater. Today Commun. 2024, 39, 109334. [Google Scholar] [CrossRef]

- Jahaziel, R.B.; Krishnaraj, V.; Sudhagar, S.; Priyadarshini, B.G. Improving dry machining performance of surface modified cutting tools through combined effect of texture and TiN-WS2 coating. J. Manuf. Process. 2023, 85, 101–108. [Google Scholar] [CrossRef]

- Lukaszkowicz, K. Review of nanocomposite thin films and coatings deposited by PVD and CVD technology. In Nanomaterials; IntechOpen: London, UK, 2011; pp. 145–163. [Google Scholar]

- Guo, H.; Sun, Q.; Zhou, D.; Yu, M.; Wang, Y.; Wang, Q.; Li, X. Erosion behavior of CrN, CrAlN and CrAlN/CrN multilayer coatings deposited on Ti6Al4V. Surf. Coat. Technol. 2022, 437, 128284. [Google Scholar] [CrossRef]

- Gu, Y.; Xia, K.; Wu, D.; Mou, J.; Zheng, S. Technical characteristics and wear-resistant mechanism of nano coatings: A review. Coatings 2020, 10, 233. [Google Scholar] [CrossRef]

- Filip, A.V.; Sava, B.A.; Medianu, R.V.; Boroica, L.; Dinca, M.C.; Pascu, R.; Tigau, N.; Andrei, A.; Moldovan, A.; Dumitru, M. Ultrathin films of silver by Magnetron Sputtering. Inorganics 2022, 10, 235. [Google Scholar] [CrossRef]

- Benedicto, E.; Rubio, E.M.; Aubouy, L.; Sáenz-Nuño, M.A. Sustainable lubrication/cooling systems for efficient turning operations of γ-TiAl parts from the aeronautic industry. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 709–728. [Google Scholar] [CrossRef]

- Elmkhah, H.; Attarzadeh, F.; Fattah-Alhosseini, A.; Kim, K.H. Microstructural and electrochemical comparison between TiN coatings deposited through HIPIMS and DCMS techniques. J. Alloys Compd. 2018, 735, 422–429. [Google Scholar] [CrossRef]

- Ding, J.C.; Zhang, T.F.; Wang, Q.M.; Song, C.W.; Wang, T.-G.; Kim, K.-H. Microstructure and mechanical properties of the Cr–Mo–Si–N nanocomposite coatings prepared by a hybrid system of AIP and HiPIMS technologies. J. Alloys Compd. 2018, 740, 774–783. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Sugumaran, A.; Hovsepian, P.E.; Davies, C.; Hatto, P. Real-time monitoring of plasma synthesis of functional materials by high power impulse magnetron sputtering and other PVD processes: Towards a physics-constrained digital twin. J. Phys. D Appl. Phys. 2022, 56, 035302. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement and market trend demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Maier, H.; Heidenblut, T.; Kahra, C.; Carlet, M. Influence of residual stresses in hard tool coatings on the cutting performance. J. Manuf. Process. 2021, 69, 340–350. [Google Scholar] [CrossRef]

- Li, Y.; Cao, H.; Li, H.; Yang, J.; Qi, F.; Lu, L.; Zhao, N.; Zhou, Y.; Ouyang, X. Effect of buffer layer on oxidation and corrosion resistance of CrN coatings on Zr alloy prepared by FCVAD technology. Surf. Coat. Technol. 2022, 448, 128942. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Oganyan, G.V.; Batako, A. Working efficiency of cutting tools with multilayer nano-structured Ti-TiCN-(Ti, Al) CN and Ti-TiCN-(Ti, Al, Cr) CN coatings: Analysis of cutting properties, wear mechanism and diffusion processes. Surf. Coat. Technol. 2017, 332, 198–213. [Google Scholar] [CrossRef]

- Sun, L.; Yuan, G.; Gao, L.; Yang, J.; Chhowalla, M.; Gharahcheshmeh, M.H.; Gleason, K.K.; Choi, Y.S.; Hong, B.H.; Liu, Z. Chemical vapour deposition. Nat. Rev. Methods Primers 2021, 1, 5. [Google Scholar] [CrossRef]

- Tian, Y.; Yan, Z.; Jiang, L.; Liu, R.; Liu, B.; Shao, Y.; Yang, X.; Liu, M. Multiscale models of CVD process: Review and prospective. Materials 2024, 17, 5131. [Google Scholar] [CrossRef]

- Butt, M.A. Thin-film coating methods: A successful marriage of high-quality and cost-effectiveness—A brief exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Dutta, V.; Verma, R.; Gopalkrishnan, C.; Yuan, M.-H.; Batoo, K.M.; Jayavel, R.; Chauhan, A.; Lin, K.-Y.A.; Balasubramani, R.; Ghotekar, S. Bio-inspired synthesis of carbon-based nanomaterials and their potential environmental applications: A state-of-the-art review. Inorganics 2022, 10, 169. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Lin, H.; Chen, Y.; Ji, R. Effect of Substrate Pretreatment Process on the Cutting Performance of Diamond-Coated PCB Micro-Milling Tools. Micromachines 2022, 14, 73. [Google Scholar] [CrossRef] [PubMed]

- Saiki, Y.; Bando, T.; Harigai, T.; Takikawa, H.; Hattori, T.; Sugita, H.; Kawahara, N.; Tanaka, K. Sequential morphology of cobalt from cemented tungsten carbide in microcrystalline and nanocrystalline diamond films by HF-CVD. Diam. Relat. Mater. 2023, 132, 109643. [Google Scholar] [CrossRef]

- Wang, X.; Ye, J. Interface characteristics of CVD diamond coating on WC-Co cemented carbide substrate. Surf. Coat. Technol. 2024, 485, 130886. [Google Scholar] [CrossRef]

- Tu, L.; Tian, S.; Xu, F.; Wang, X.; Xu, C.; He, B.; Zuo, D.; Zhang, W. Cutting performance of cubic boron nitride-coated tools in dry turning of hardened ductile iron. J. Manuf. Process. 2020, 56, 158–168. [Google Scholar] [CrossRef]

- Zhu, W.; Su, Z.; Guo, J.; Li, K.; Chen, K.; Li, W.; Yi, A.; Liao, Z.; Luo, Y.; Hu, Y. Preparation and characterization of diamond-like carbon (DLC) film on 316L stainless steel by microwave plasma chemical vapor deposition (MPCVD). Diam. Relat. Mater. 2022, 122, 108820. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Z.; Peng, J.; Shen, Q.; Wang, C. In-situ formation, structural transformation and mechanical properties CrN coatings prepared by MPCVD. Surf. Coat. Technol. 2022, 441, 128522. [Google Scholar] [CrossRef]

- Calaph, Y.C.; Subramanian, K.M.; Nakandhrakumar, R.; Sowrirajan, M. Experimental tool life and wear analysis of different thickness pecvd TiAlSiN nanocoated cutting tool inserts. Proc. Inst. Mech. Eng. Part E 2022, 236, 2012–2023. [Google Scholar] [CrossRef]

- He, B.-C.; Wen, H.-C.; Lin, M.-H.; Lai, Y.-S.; Wu, W.-F.; Chou, C.-P. Effect of annealing treatment and nanomechanical properties for multilayer Si0.8Ge0.2–Si films. Microelectron. Reliab. 2010, 50, 851–856. [Google Scholar] [CrossRef]

- Lindquist, N.C.; Nagpal, P.; McPeak, K.M.; Norris, D.J.; Oh, S.-H. Engineering metallic nanostructures for plasmonics and nanophotonics. Rep. Prog. Phys. 2012, 75, 036501. [Google Scholar] [CrossRef]

- Maciulis, V.; Ramanaviciene, A.; Plikusiene, I. Recent advances in synthesis and application of metal oxide nanostructures in chemical sensors and biosensors. Nanomaterials 2022, 12, 4413. [Google Scholar] [CrossRef] [PubMed]

- Miikkulainen, V.; Leskelä, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 021301. [Google Scholar] [CrossRef]

- Hu, L.; Qi, W.; Li, Y. Coating strategies for atomic layer deposition. Nanotechnol. Rev. 2017, 6, 527–547. [Google Scholar] [CrossRef]

- Tang, S.; Liu, P.; Su, Z.; Lei, Y.; Liu, Q.; Liu, D. Preparation and cutting performance of nano-scaled Al2O3-coated micro-textured cutting tool prepared by atomic layer deposition. High Temp. Mater. Process. 2021, 40, 77–86. [Google Scholar] [CrossRef]

- Gui, S.-Y.; Gong, H.; Sun, Y.-J.; Feng, C. Experimental investigation of the EDM tools coated with nano-alumina film. Surf. Eng. 2023, 39, 506–513. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, X.-Q.; Zhou, M.-Y.; Huang, J.-Q. Mechanism, quantitative characterization, and inhibition of corrosion in lithium batteries. Nano Res. Energy 2023, 2, e9120046. [Google Scholar] [CrossRef]

- Kurt, B.; Özdoğan, L.; Güney, B.; Bölükbaşı, Ö.S.; Günen, A. Characterization and wear behavior of TiBC coatings formed by thermo-reactive diffusion technique on AISI D6 steel. Surf. Coat. Technol. 2020, 385, 125332. [Google Scholar] [CrossRef]

- Najari, M.R.; Sajjadi, S.A.; Ganji, O. Microstructural evolution and wear properties of chromium carbide coating formed by thermo-reactive diffusion (TRD) process on a cold-work tool steel. Results Surf. Interfaces 2022, 8, 100059. [Google Scholar] [CrossRef]

- Ertürk, Ş.; Kayabaşi, O. Investigation of the cutting performance of cutting tools coated with the thermo-reactive diffusion (TRD) technique. IEEE Access 2019, 7, 106824–106838. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Chen, H.; Wang, M. Modification methods of diamond like carbon coating and the performance in machining applications: A review. Coatings 2022, 12, 224. [Google Scholar] [CrossRef]

- Pramanik, A.; Littlefair, G. Machining of titanium alloy (Ti-6Al-4V)—Theory to application. Mach. Sci. Technol. 2015, 19, 1–49. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Current status of hard turning in manufacturing: Aspects of cooling strategy and sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Veiko, V.; Odintsova, G.; Gazizova, M.; Karlagina, Y.; Manokhin, S.; Yatsuk, R.; Vasilkov, S.; Kolobov, Y. The influence of laser micro-and nanostructuring on the wear resistance of Grade-2 titanium surface. Laser Phys. 2018, 28, 086002. [Google Scholar] [CrossRef]

- Proudhon, H.; Savkova, J.; Basseville, S.; Guipont, V.; Jeandin, M.; Cailletaud, G. Experimental and numerical wear studies of porous Reactive Plasma Sprayed Ti–6Al–4V/TiN composite coating. Wear 2014, 311, 159–166. [Google Scholar] [CrossRef]

- Drnovšek, A.; de Figueiredo, M.R.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Kolawole, F.O.; dos Santos, M.D.; Kolawole, S.K.; Vencovsky, P.K.; Ludewigs, D.A.; Tschiptschin, A.P. Nano-Scratch and Micro-Scratch Properties of CrN/DLC and DLC-W Coatings. Mater. Perform. Charact. 2023, 12, 320–340. [Google Scholar] [CrossRef]

- Vieira, V.F.; Shigaki, Y.; Martins, P.S.; Ba, E.C.T.; Dias, C.A.R. Nanoindentation test of a DLC coated high-speed steel substrate using a two-dimensional axisymmetric finite element method. Diam. Relat. Mater. 2023, 134, 109792. [Google Scholar] [CrossRef]

- Mei, H.; Wang, R.; Geng, D.; Cheng, L.; Huang, K.; Li, K.; Liang, H.; Zou, C.; Gong, W.; Wang, Q. Microstructure and mechanical properties of AlTiN/AlTiVCuN nano-multilayered coatings deposited by BPMS. Ceram. Int. 2025, 51, 18276–18287. [Google Scholar] [CrossRef]

- Zha, X.; Wang, T.; Guo, B.; Chen, F.; Lin, L.; Zhang, T.; Jiang, F. Research on the oxidation resistance and ultra-high frequency thermal fatigue shock failure mechanisms of the bilayer and multilayer nano-coatings on cemented carbide tools. Int. J. Refract. Met. Hard Mater. 2023, 110, 106043. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, M.-X.; Chang, C.-E.; Chang, B.-Y. Cyclic thermal shock resistance and tribological properties of AlCrSiN, AlTiSiN and AlCrSiN/AlTiSiN multilayer hard coatings. Surf. Coat. Technol. 2025, 496, 131650. [Google Scholar] [CrossRef]

- Wan, Q.; Chen, Y.; Liu, H.; Yang, B. Investigation on oxidation behaviors of Ti-Si-N coating at high temperature. Anti-Corros. Methods Mater. 2018, 65, 125–130. [Google Scholar] [CrossRef]

- Yang, Y.; Liao, N.; Zhang, M.; Li, F. Evaluation of the elastic-plastic properties of SiCN coating system by finite element simulations. J. Eur. Ceram. Soc. 2017, 37, 3891–3897. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Experimental and numerical investigations on the effect of varying AlTiN coating thickness on hard machining performance of Al2O3-TiCN mixed ceramic inserts. Surf. Coat. Technol. 2017, 309, 266–281. [Google Scholar] [CrossRef]

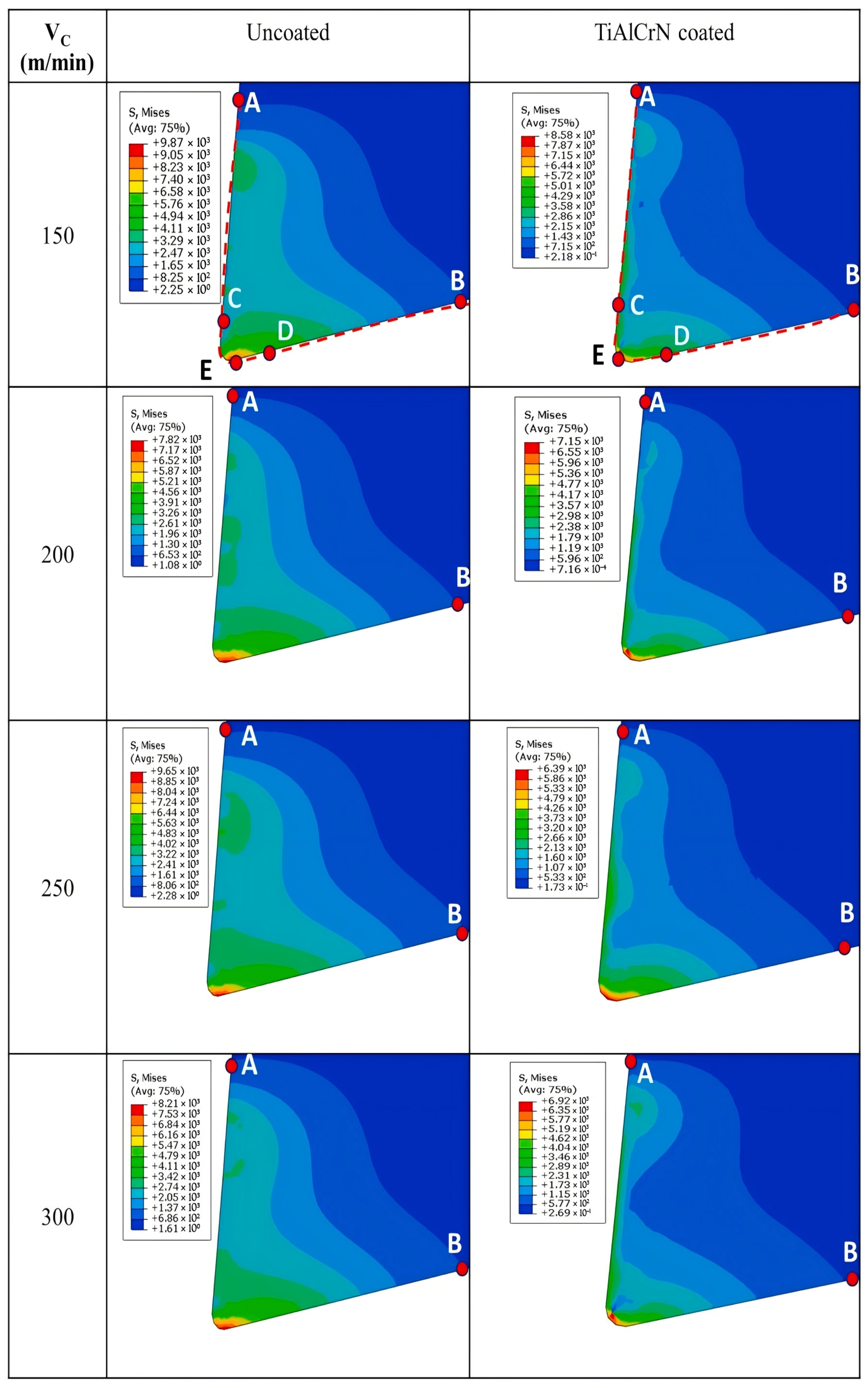

- Kumar, C.S.; Zeman, P.; Polcar, T. A 2D finite element approach for predicting the machining performance of nanolayered TiAlCrN coating on WC-Co cutting tool during dry turning of AISI 1045 steel. Ceram. Int. 2020, 46, 25073–25088. [Google Scholar] [CrossRef]

- Zha, X.; Jiang, F.; Xu, X. Investigating the high frequency fatigue failure mechanisms of mono and multilayer PVD coatings by the cyclic impact tests. Surf. Coat. Technol. 2018, 344, 689–701. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.; Xiong, Z.; Wang, Q. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer coatings. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar] [CrossRef]

- Bertoti, I. Characterization of nitride coatings by XPS. Surf. Coat. Technol. 2002, 151, 194–203. [Google Scholar] [CrossRef]

- Singh, V.; Singh, D. An overview on the preparation, characterization and properties of electrodeposited-metal matrix nanocomposites. Nanosci. Technol. 2014, 1, 1–20. [Google Scholar]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef]

- Modena, M.M.; Rühle, B.; Burg, T.P.; Wuttke, S. Nanoparticle characterization: What to measure? Adv. Mater. 2019, 31, 1901556. [Google Scholar] [CrossRef] [PubMed]

- Aljaafari, A.; Ahmed, F.; Shaalan, N.M.; Kumar, S.; Alsulami, A. Enhanced thermal stability of sputtered TiN thin films for their applications as diffusion barriers against copper interconnect. Inorganics 2023, 11, 204. [Google Scholar] [CrossRef]

- Wang, C.; Geng, Q.; Fan, L.; Li, J.-X.; Ma, L.; Li, C. Phase engineering oriented defect-rich amorphous/crystalline RuO2 nanoporous particles for boosting oxygen evolution reaction in acid media. Nano Res. Energy 2023, 2, e9120070. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Performance analysis and comparative assessment of nano-composite TiAlSiN/TiSiN/TiAlN coating in hard turning of AISI 52100 steel. Surf. Coat. Technol. 2018, 335, 265–279. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Huang, J.-W. Nanostructured AlTiSiN/CrVN/ZrN coatings synthesized by cathodic arc deposition-mechanical properties and cutting performance. Surf. Coat. Technol. 2022, 442, 128424. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Carlet, M.; Schmauder, S.; Guski, V.; Verestek, W.; Tayyab, M. 3D deformation modeling of CrAlN coated tool steel compound during nanoindentation. Surf. Coat. Technol. 2023, 453, 129148. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Tayyab, M. Influence of Cr+ Si content variation on cutting behavior of TiAlCrSiN HPPMS coatings. Surf. Coat. Technol. 2024, 483, 130783. [Google Scholar] [CrossRef]

- Fox-Rabinovitch, G.; Dosbaeva, G.; Kovalev, A.; Gershman, I.; Yamamoto, K.; Locks, E.; Paiva, J.; Konovalov, E.; Veldhuis, S. Enhancement of Multi-Scale Self-Organization Processes during Inconel DA 718 Machining through the Optimization of TiAlCrSiN/TiAlCrN Bi-Nano-Multilayer Coating Characteristics. Materials 2022, 15, 1329. [Google Scholar] [CrossRef]

- Chen, Z.; Lou, M.; Geng, D.; Xu, Y.X.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.; Kim, K.H. Effect of the modulation geometry on mechanical and tribological properties of TiSiN/TiAlN nano-multilayer coatings. Surf. Coat. Technol. 2021, 423, 127586. [Google Scholar] [CrossRef]

- Volosova, M.; Bublikov, J.; Sotova, C.; Sadov, I. Influence of the nanolayer structure of coatings on the cutting properties of tools. MATEC Web Conf. 2020, 329, 02035. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Sitnikov, N.; Aksenenko, A.; Milovich, F.; Andreev, N.; Oganyan, G.; Bublikov, J. Influence of the thickness of multilayer composite nano-structured coating Ti–TiN–(Ti, Al, Si) N on the tool life of metal-cutting tools and the nature of wear. Coatings 2019, 9, 730. [Google Scholar] [CrossRef]

| Base Coating Material | Added Element(s) | Final Nanocoating (Nanostructure) | Performance Enhanced by Added Element(s) | Synergistic Effects (Element–Element) | Verified Reference |

|---|---|---|---|---|---|

| TiN | Al | TiAlN | Al promotes Al2O3 passivation → Improve oxidation resistance | Ti–Al alloying stabilizes fcc structure → Improve hardness and thermal stability | [25] |

| TiAlN | Si | TiAlSiN | Si forms amorphous Si3N4 → Improve grain refinement and hardness | Si promotes nanocomposite structure → Improve oxidation temp and toughness | [26,27,28] |

| TiAlCrN | Si, Y | TiAlCrSiYN | Si refines grain size; Y suppresses grain growth | Multi-element design creates nanocomposite → Improve wear protection and oxidation resistance | [29,30,31,32] |

| Characterization Method | Function | Output Metrics |

|---|---|---|

| Scanning electron microscopy (SEM) | Analysis of surface roughness, wear morphology, and cross-sectional structure | Surface structure, fracture characteristics, coating thickness |

| Transmission electron microscopy (TEM) | Grain size, dislocation structure, and phase boundary clarity | Image of crystal defects, grain boundary structure, amorphous encased grains |

| X-ray diffraction (XRD) | Crystal phase structure, residual stress, average grain size | Grain size, stress state |

| Atomic force microscopy (AFM) | Surface roughness measurement, local hardness distribution analysis | Roughness, surface profile drawing |

| Energy-dispersive spectroscopy (EDS) | Compositional analysis, elemental diffusion analysis | Element types, contents, and distribution maps |

| X-ray photoelectron spectroscopy (XPS) | Analysis of surface oxide film composition, binding energy, and bonding state | Elemental valence, bond energy changes, chemical binding mechanisms |

| Raman spectroscopy | Crystal structure, composition analysis, stress/strain detection, phase transformation identification | Composite structure, residual stress distribution |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Q.; Huang, S.; Chang, J.; Wang, D.; Liu, X.; Wen, N.; Cao, X.; Lv, Y. Design, Deposition, Performance Evaluation, and Modulation Analysis of Nanocoatings for Cutting Tools: A Review. Inorganics 2025, 13, 281. https://doi.org/10.3390/inorganics13090281

Xi Q, Huang S, Chang J, Wang D, Liu X, Wen N, Cao X, Lv Y. Design, Deposition, Performance Evaluation, and Modulation Analysis of Nanocoatings for Cutting Tools: A Review. Inorganics. 2025; 13(9):281. https://doi.org/10.3390/inorganics13090281

Chicago/Turabian StyleXi, Qi, Siqi Huang, Jiang Chang, Dong Wang, Xiangdong Liu, Nuan Wen, Xi Cao, and Yuguang Lv. 2025. "Design, Deposition, Performance Evaluation, and Modulation Analysis of Nanocoatings for Cutting Tools: A Review" Inorganics 13, no. 9: 281. https://doi.org/10.3390/inorganics13090281

APA StyleXi, Q., Huang, S., Chang, J., Wang, D., Liu, X., Wen, N., Cao, X., & Lv, Y. (2025). Design, Deposition, Performance Evaluation, and Modulation Analysis of Nanocoatings for Cutting Tools: A Review. Inorganics, 13(9), 281. https://doi.org/10.3390/inorganics13090281