Abstract

With the rapid development of advanced machining technologies such as high-speed cutting, dry cutting, and ultra-precision cutting, as well as the widespread application of various difficult-to-machine materials, the surface degradation problems such as wear, oxidation, and delamination faced by tools in the service process have become increasingly prominent, seriously restricting the performance and service life of tools. Nanocoatings, with their distinct nano-effects, provide superior hardness, thermal stability, and tribological properties, making them an effective solution for cutting tools in increasingly demanding working environments. For example, the hardness of the CrAlN/TiSiN nano-multilayer coating can reach 41.59 GPa, which is much higher than that of a single CrAlN coating (34.5–35.8 GPa). This paper summarizes the most common nanocoating material design, coating deposition technologies, performance evaluation indicators, and characterization methods currently used in cutting tools. It also discusses how to improve nanocoating performance using modulation analysis of element content, coating composition, geometric structure, and coating thickness. Finally, this paper considers the future development of nanocoatings for cutting tools in light of recent research hotspots.

1. Introduction

The materials used in mechanical processing are becoming more complex, and cutting conditions are becoming more demanding, posing significant challenges to the service performance of industrial cutting tools [1,2,3]. Cutting tools, as critical functional components directly involved in the material removal process, are frequently subjected to a multifactorial condition that includes high temperatures, high loads, intense friction, and intermittent impacts. Tool surfaces are highly susceptible to wear, oxidation, and mechanical fractures, which shorten tool life, weaken cutting quality, increase energy consumption and maintenance costs, limit production efficiency, and reduce product uniformity [4,5,6,7,8]. Although traditional tool materials such as high-speed steel and cemented carbide have been strengthened by heat treatment and alloying strategies to improve mechanical properties and wear resistance, simply strengthening the base material is no longer sufficient to meet today’s complex application demands.

Researchers have proposed surface coatings as a solution for the issues above. Surface coatings are applied to the base surface of cutting tools using particular techniques that deposit one or more layers of thin films produced from materials with unique qualities. The coatings insulate the cutting tool’s base from the working environment, boosting surface performance, flexibility to working circumstances, and stability, consequently increasing performance and extending service life [9,10,11]. Some coated cutting tools have performed exceptionally well in the laboratory and in industrial production, enhancing cutting performance, extending tool life, and lowering the number of tool changes and auxiliary processing time during mechanical processing [12,13]. This has contributed to the widespread usage of coating technology as a vital strategy for protecting cutting tool surfaces.

Coatings for cutting tools have evolved from microscale to nanoscale. Microscale coatings, which are often made up of single-layer or homogenous structures, such as TiN or TiC, produced by physical vapor deposition or chemical vapor deposition, provide modest wear resistance and thermal protection. However, the limitations of these coatings in terms of corrosion resistance, thermal stability, toughness, and hardness are gradually becoming apparent as processing requirements increase. With the continuous emergence of nanomaterial research results and in-depth studies on nanocoating technology, researchers have promoted the rapid development of nanocoatings in the field of cutting tools by precisely controlling the grain size, thickness, interlayer interface, and multi-element synergistic mechanisms of the coatings, opening up new ways to improve cutting tool performance.

Vereschaka et al. [14] reported that nano-multilayer Ti-TiN-(Ti, Al, Si)N coatings outperform micron-level coatings in terms of crack resistance and interface separation performance, prolonging the service life of high-speed cutting tools. Vereschaka et al. [15] investigated the increase of machining efficiency for austenitic stainless steels AISI 321 and S31600 by applying nanocomposite coatings on cutting tools. The multi-layer nanocomposite coatings investigated (Ti-TiN-(Ti,Al) N, (Zr,Nb) N-(Cr,Zr,Nb,Al) N, and (Zr,Nb) N-(Zr,Al,Nb) N) all increased tool life, with the greatest improvement reaching 2.5 times that of uncoated tools and outperforming typical TiN coatings.

Nanocoatings use surface effects, small size effects, and quantum effects of nanomaterials to achieve enhanced toughness, thermal stability, and interfacial bonding strength, all while preserving elevated hardness. Nanomaterials are defined as materials with at least one dimension in the nanoscale range (1–100 nm). Their distinct nano-effects provide physical and chemical capabilities unmatched by standard materials, exhibiting enormous potential across transdisciplinary domains. Coatings are developed with differentiated features using common materials such as TiC, TiN, TiAlN, TiCN, CrN, DLC (diamond-like carbon coating), and ZrN, allowing them to provide unique performance benefits and clarity of application placement in mechanical engineering areas [16,17,18,19]. To increase overall performance, nanocoating materials are investigated for critical indications such as hardness, wear resistance, and high-temperature stability. While pursuing high hardness, researchers are seeking ways to enhance the stability of the coating interface through structural control and composition design, thereby achieving synergistic optimization of multiple attributes.

Recently, tool coatings have emerged as a prominent research subject. Deng et al. [20] provided a comprehensive summary and outlook on coating deposition technologies. Wang et al. [21] reviewed different impact tests on hard tool coatings. Kang et al. [22] analyzed the effects of coating materials on tool performance and strategies for selecting coating deposition methods under varying working conditions. However, there has been no systematic review of the design, deposition methods, performance characterization, and performance regulation of nanocoatings for cutting tools. As a result, the scope of this review includes: (1) identifying the commonly used nanocoating material systems for industrial cutting tools; (2) summarizing and comparing the process characteristics of various deposition techniques; (3) summarizing coating performance evaluation indicators and evaluation methods; (4) analyzing strategies for improving coating performance through the regulation of composition ratios, structure, and periodic thickness. Finally, this paper provides an outlook on the future technical development directions for cutting tool nanocoatings.

2. Coating Material Design

2.1. Component Design

Nanocoating materials are frequently analyzed to enhance overall performance by focusing on critical parameters, including hardness, wear resistance, and high-temperature stability. Researchers are actively investigating methods to improve the toughness and interface stability of coatings while pursuing high hardness. This involves the component design of the coating.

In early tool coating development, materials based on binary systems such as nitrides, carbides, and oxides were extensively utilized, including TiN, TiC, CrN, Al2O3, and others. Because of their particular performance properties, these materials have limited applications. For example, the oxidation resistance temperature of TiN coatings is only 500 °C, limiting their use in high-temperature environments; while CrN has excellent chemical stability, it has low hardness and high friction resistance, making it suitable for lubricated or wet machining environments; TiC has the highest hardness, and the presence of carbon elements confers it with certain lubricating properties, but it has high brittleness and is prone to failure under high loads or thermal shock conditions.

To overcome the performance limits of binary coating materials, researchers began developing ternary coating systems. By adding alloy elements such as Al, Y, C, and Zr into TiN, CrN, and other materials, the coatings’ overall performance was enhanced through elemental synergistic strengthening. For example, the addition of Al elements into TiN and CrN produces the formation of new ternary coatings, TiAlN and CrAlN, which provide stable Al2O3 oxide layers at elevated temperatures, thereby improving oxidation resistance and hardness [10,23]. The coating’s thermal stability and hardness are further improved when the Al content is high, making it suitable for high-speed machining of difficult-to-machine materials like Ti-6Al-4V [24].

With the widespread use of difficult-to-machine materials such as high-strength steel, high-temperature alloys, and titanium alloys, as well as the emergence of extreme machining conditions such as high-speed cutting and dry cutting, tool coatings must have improved thermal stability and wear resistance. Therefore, the widely prevalent attention that multi-component nanocomposite coatings have attracted is a result of the necessity of better matching tool coatings with operating conditions. The addition of elements such as Si, Y, and O results in the formation of composite materials with a nano-multiphase structure, which allows the coating to maintain outstanding strength and oxidation resistance at high temperatures. For example, coatings of TiAlSiN and CrAlSiN can be produced by incorporating Si elements into TiAlN and CrAlN. The hardness and resistance to breaking of the coating can be improved by the promotion of the formation of the amorphous phase Si3N4 by Si elements.

The performance of multi-component composite coatings depends on the type and content of the doped elements, as well as their synergistic effects. Multi-element synergistic optimization has recently emerged as an essential method in coating design, notably for producing functional gradients, multi-layer structures, and nanoscale organizational control, and it shows great promise. To better illustrate the evolution of coating materials from basic design to high-performance nanostructures, Table 1 summarizes the formation processes of common nanocoating materials, the functional contributions of doped elements, and the performance enhancements caused by their synergistic interaction mechanisms.

Table 1.

Elemental design strategy and performance evolution of nanocoatings.

2.2. Structural Design

With the advancement of nanotechnology, nanostructured coatings have emerged as a hot topic in surface engineering. These coatings primarily include nano-multilayer coatings and nanocomposite coatings, each of which has distinct advantages in terms of structural configuration and performance enhancement [13].

Nano-multilayer coatings are produced by alternately depositing layers of several materials, integrating the performance benefits of each layer while also managing the distribution of residual stress. For example, the hardness of the CrAlN/TiSiN nano-multilayer coating can reach 41.59 GPa, which is much higher than that of a single CrAlN coating (34.5–35.8 GPa). This performance gain is mostly due to the interfacial barrier effect at the layer interfaces, which reduces dislocation movement and hence increases crack resistance [33,34].

Nanocomposite coatings are functional coatings composed of two or more nanoscale materials with unique characteristics combined in a homogenous dispersion or layered alternating structure. Researchers proposed the design concept of nano-multilayer composite coatings (NMCC) to achieve a better balance of high hardness and plasticity while also improving the coating’s overall performance. NMCCs are produced by layering or gradient structuring various functional materials, using the unique characteristics of each layer to solve the issues of peeling and cracking in traditional single-layer coatings in corrosive environments or high loads. This results in synergistic improvements in the structural strength and service life of the coating.

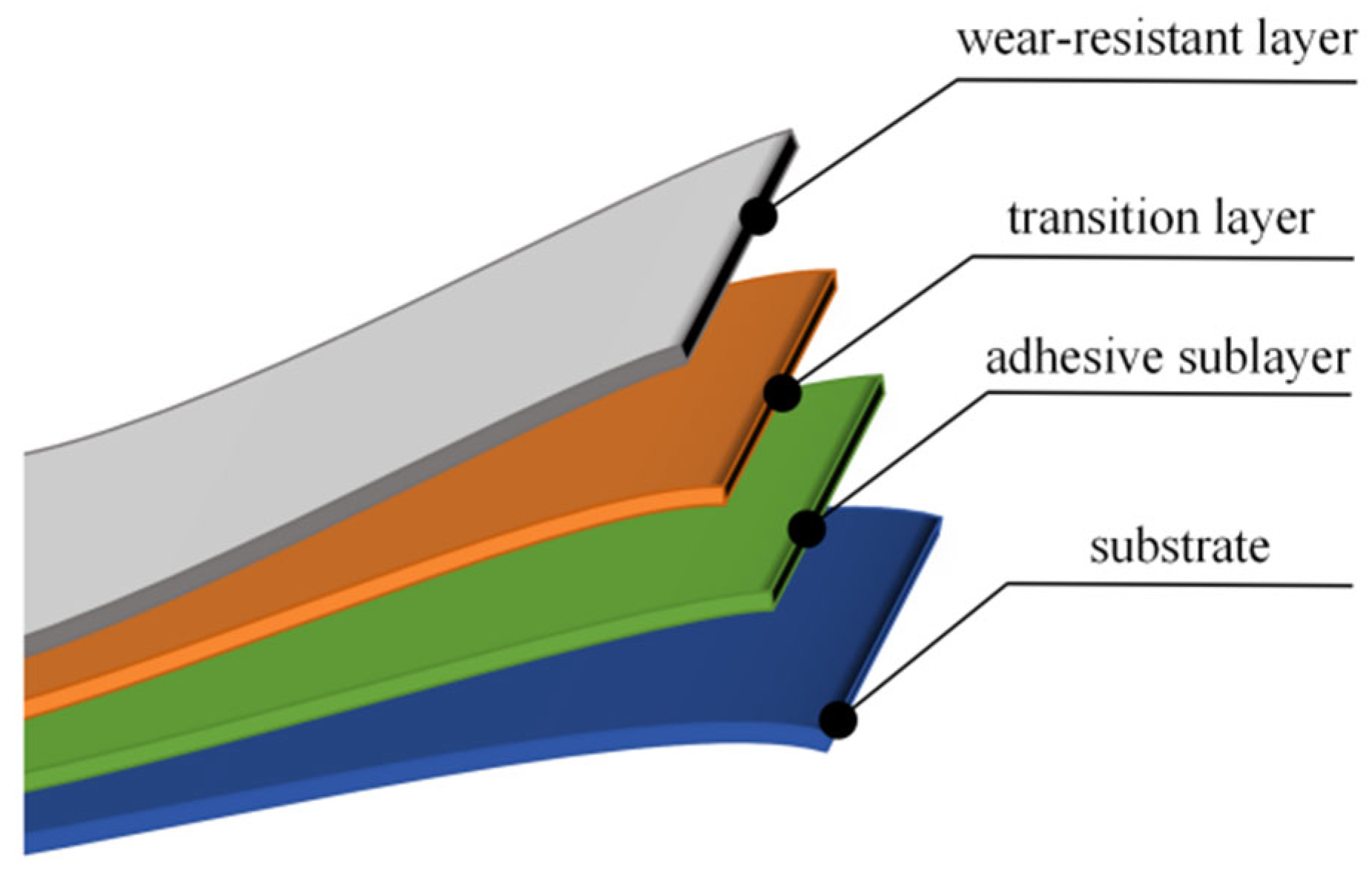

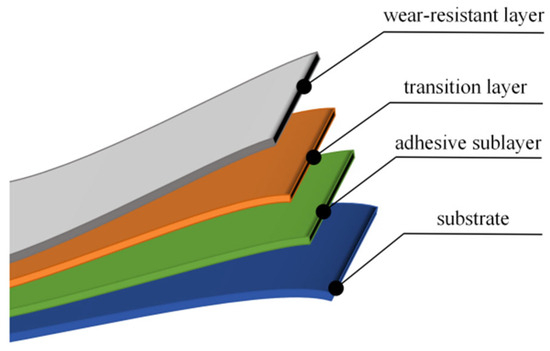

Figure 1 shows the three-layer architecture of NMCC. A three-layer composite structure design is adopted by the typical NMCC [35,36,37,38], which includes:

Figure 1.

Three-layered architecture of NMCC.

The outer wear-resistant layer is in direct contact with the workpiece material and primarily provides wear resistance, heat resistance, and chemical resistance. The middle transition layer connects the inner and outer layers, controls stress transfer, and improves overall structural integrity. The inner adhesive layer is directly connected to the tool substrate, increasing overall bonding strength.

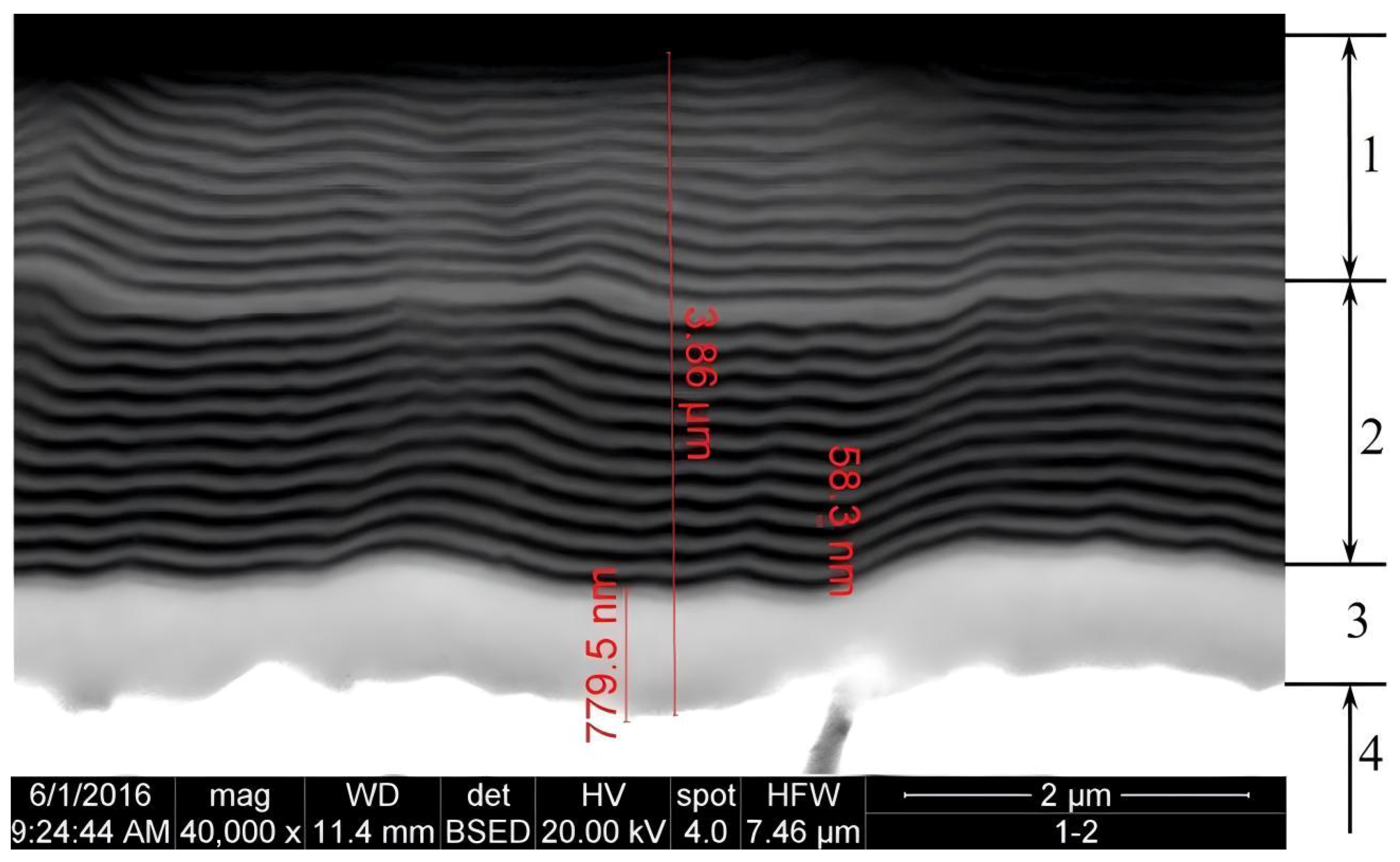

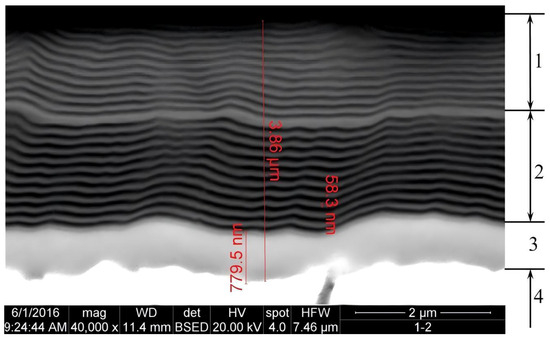

The outer layer must be hard, thermally stable, and chemically inert to the workpiece material, making it the core layer that defines tool coating performance. The intermediate layer is necessary to maintain a strong adhesive interaction between adjacent layers. The inner adhesive layer’s primary function is to strengthen the binding between the coating and the tool substrate, preventing the coating from flaking during use due to changes in load or temperature. Grigoriev et al. [36] used filtered cathode vacuum arc deposition (FCVAD) to form the structure of NMCC Zr–ZrN–(ZrCrAl)N on carbide cutting tools. Figure 2 shows the microstructure of this covering. The study found that this coating could considerably extend the life of tools. Wu et al. [39] prepared AlCrSiN multi-layer nanocomposite coating using cathodic arc ion plating technology. The inner layer of the coating is Cr, the intermediate transition layer is AlCrN, and the outer layer is AlCrSiN. This coating shows comprehensive performance, extending the service life of cutting tools compared to traditional AlCrN coatings. Fang et al. [40] prepared AlCrSiCN coating using cathodic vacuum arc technology. The coating consists of an adhesive layer of Cr + CrN, a transition layer of AlCrN, and an outer layer of AlCrSiCN. The coating was applied to high-speed and dry cutting tests, and the results showed that tools with AlCrSiCN coatings performed better than those with AlCrSiN coatings. The selection of materials for each layer of NMCC has a significant influence on the coating’s performance.

Figure 2.

Microstructure of the NMCC Zr–ZrN–(ZrCrAl)N on carbide cutting tools. 1—wear-resistant layer (thickness—1.55 μm, thickness of nanolayers 40–100 nm); 2—intermediate layer (thickness—1.53 μm, thickness of nanolayers 40–100 nm); 3—adhesive layer (thickness—780 nm); 4—carbide substrate. Copyright 2017 Springer Nature [36].

As research has progressed, nanocomposite coatings have emerged as a crucial technology for improving the surface performance of cutting tools. Examples of nanocrystalline/amorphous composites include nc-TiAlN/a-Si3N4 [41]. In this type of structure, the amorphous phase forms a three-dimensional network around the nanocrystals, considerably enhancing grain boundary density while efficiently limiting dislocation slip and fracture propagation. In TiAlSiN coatings, adding a proper quantity of Si3N4 to the basic nc-TiAlN material generates an isolation layer of amorphous Si3N4 at the grain boundaries. This inhibits dislocation movement and suppresses grain coarsening, which is the primary mechanism for increasing performance [42]. Furthermore, there is a solid solution effect between the elements in composite structures. The addition of a proper amount of Si into the CrAlN crystal lattice increases the coating’s hardness while boosting the chemical stability of the amorphous interface phase, increasing its oxidation resistance [43]. Nanocomposite coatings, such as TiAlSiN and CrAlSiN, which combine high hardness, higher wear resistance, and thermal stability, are seeing widespread application in high-speed cutting tools. Magnetron sputtering, cathode arc evaporation, and chemical vapor deposition are among the most common preparation processes. By utilizing these methods and precisely controlling parameters such as target material composition, gas partial pressure, and deposition conditions, amorphous/nanocrystalline interface structures can be optimized and uniformly distributed, resulting in improved mechanical and thermal properties.

Gradient coatings extend the scope of coating structure control. By continually modifying the component ratio throughout the coating’s thickness, interfacial stress concentration is effectively reduced, increasing interlayer bonding strength and peel resistance. According to research [44], in TiAlSiN gradient coatings, the Si concentration gradually increased from 0% to 6%, and the coating structure changed from coarse columnar crystals to ultra-fine nanocrystals, with interlayer bonding strength increasing by 300% to 100 N. When applied to TC4 titanium alloy machining, the gradient TiAlSiN coating greatly enhanced machining performance, lowering rear face wear by 45.6% compared to typical TiAlSiN coatings and extending machining distance. Gradient structures and nano-layered structures can be combined to build multilayered and gradient composite structure coatings that balance stress relief, fracture toughness, and high-temperature performance. This is one of the most important directions in the evolution of high-performance tool coating structures.

Researchers have achieved refined grain size and reduced surface roughness by adding specific elements, producing nanocoatings with outstanding tribological performance. The top layer determines the surface roughness of multilayer coatings in most instances [45]. Wang et al. [46] deposited four different coatings on WC substrates using DC magnetron sputtering: a TiAlN single layer, a TiAlN single layer with a CNx top layer, a TiAlN/CNx multi-layer, and a TiAlN/CNx multi-layer with a CNx top layer. The results indicated that the TiAlN/CNx coatings exhibited better wear resistance, with those featuring a CNx top layer performing well. It is attributed to the introduction of the CNx nanolayer, which suppresses TiAlN grain growth, refines the grains, and reduces surface roughness, thereby forming a hard coating.

Cutting tools are susceptible to damage in dry machining processes. To avoid such situations, researchers created hard coverings. While hard coatings improve tool performance, they frequently have a high coefficient of friction, leading to high temperatures at the tool-chip contact. As a result, researchers proposed adding a solid lubricant layer as a functionalized outer layer to the covered surface. These coatings can reduce the coefficient of friction and cutting force during machining, enhancing tool performance in both dry and high-speed cutting environments. MoS2 and WS2 are typical lubricant coatings [47,48]. Jahaziel et al. [49] evaluated the performance of TiN-WS2 nanocomposite coatings, textured tools, and textured tools coated with TiN-WS2 nanocomposite during dry machining of Ti-6Al-4V alloy, compared to that of commercial tools. The study found that using a combination of TiN-WS2 coating and texturing decreased cutting forces by 14% compared to commercial tools. The TiN-WS2 coating alone reduced forces by 12.46%. The combination of TiN-WS2 coating and texturing lowered the coefficient of friction by 47%, resulting in a 43% increase in tool life, compared to 35% for the TiN-WS2 coating alone. Therefore, the layered structure of a hard substrate combined with a solid lubricant outer layer achieves synergistic optimization of wear resistance and low friction, demonstrating its potential for application in machining difficult-to-cut materials.

The composition and structure of tool nanocoatings are changing from early single-element, single-layer setups to multi-element doping, composite structures, and multi-scale synergistic designs. Each material design optimization is an active response to complicated operating conditions, resulting from multidimensional synergistic advances in materials science, interface engineering, and thin-film deposition technology. The primary value of nanocoatings is their capacity to achieve tailored regulation of attributes like wear resistance and corrosion resistance. Coating design has to be guided by operating conditions, methodically combining component selection, structural configuration, and deposition parameters to create a truly operating-condition-driven high-performance coating system.

3. Selection of Deposition Method

3.1. Physical Vapor Deposition (PVD)

The performance of nanocoatings not only depends on their chemical composition and structural design but is also closely related to the preparation techniques used. The appropriate deposition process is the key foundation for achieving the functional structure, suitable thickness, grain size, and interface morphology of nanocoatings.

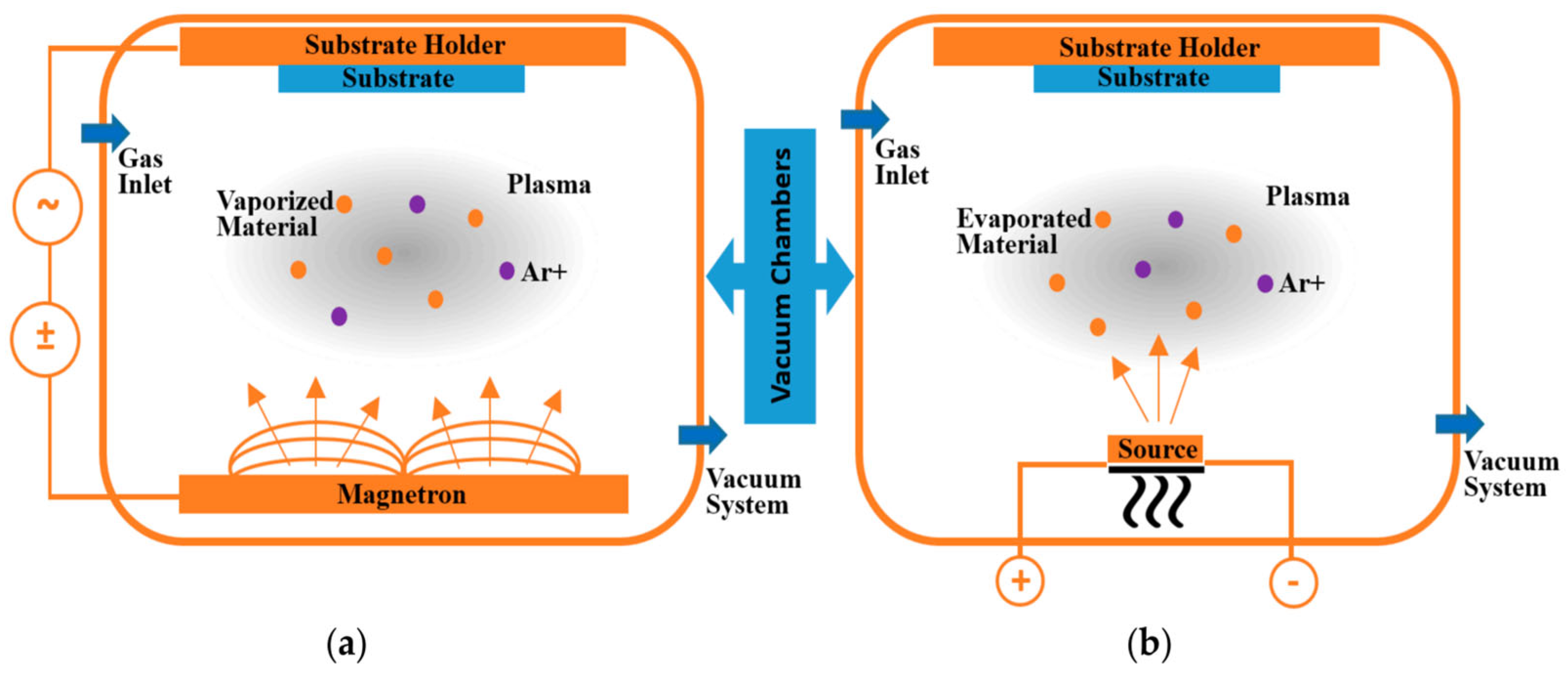

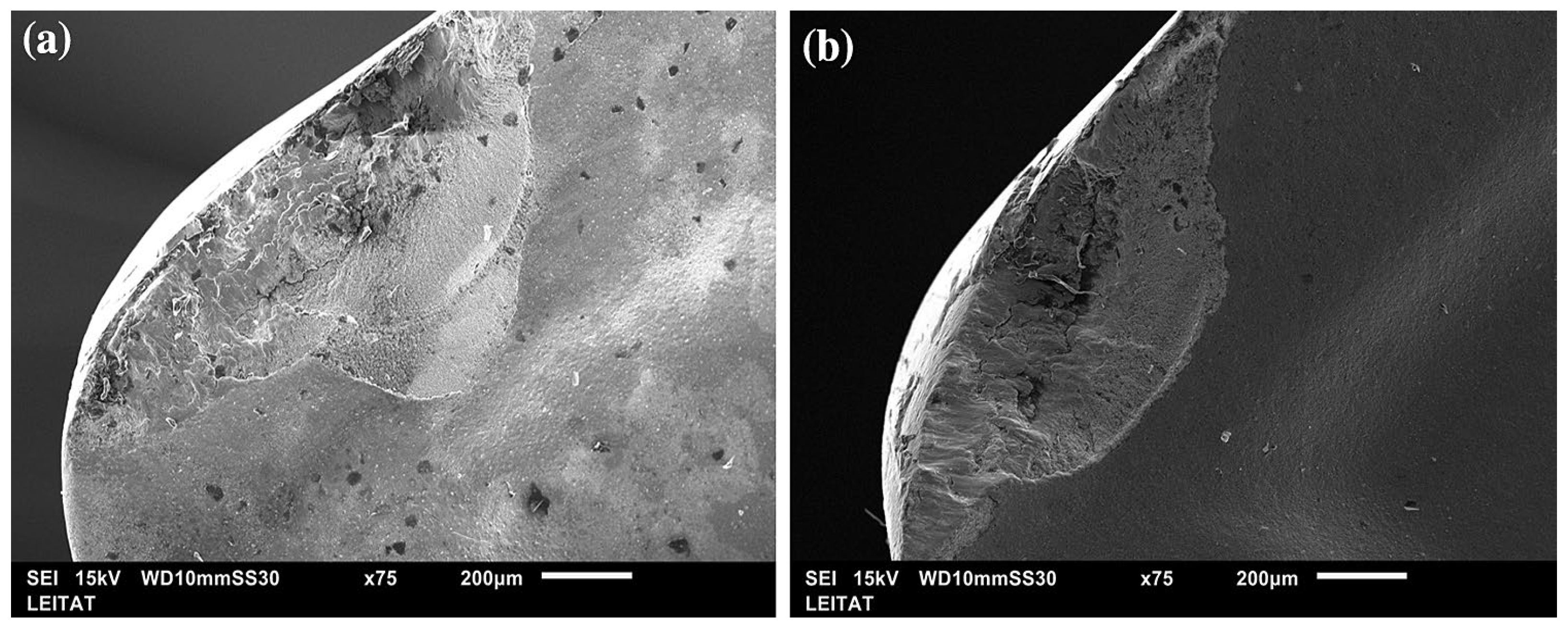

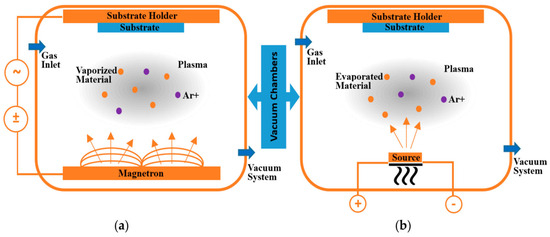

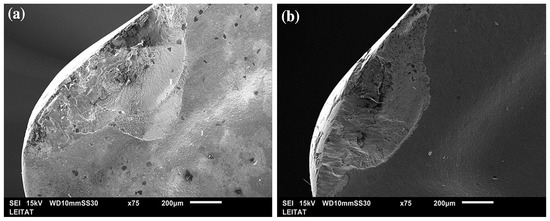

Physical vapor deposition (PVD) is one of the most widely used techniques for preparing nanocoatings on industrial tools. PVD is a process that takes place in a vacuum and uses certain physical methods to turn solid materials into gas, which then settles on a surface to create a thin film with tiny structures. PVD uses energy input methods such as heating and ion bombardment to provide sufficient energy to the atoms or molecules of the solid material, overcoming their internal bonding forces, converting them from solid to gaseous, and forming vapor. During the condensation process of the vapor on the substrate, the relatively low temperature of the substrate causes the atoms or molecules in the vapor to lose energy on the surface, resulting in condensation. The formed nanoparticles continuously accumulate, eventually forming a film composed of nanoparticles on the substrate [50]. Sputtering, vacuum evaporation, and ion plating are commonly used coating methods of PVD [51,52,53]. A schematic diagram of the sputtering and ionized argon gas evaporation PVD processes is shown in Figure 3. Benedicto et al. [54] used scanning electron microscope (SEM) pictures to compare the wear of uncoated and PVD-coated tools (Figure 4), showing the benefits of PVD technology in terms of tool surface protection, wear resistance, and service life extension. High power pulsed magnetron sputtering (HPPMS), also known as high power impulse magnetron sputtering (HiPIMS), is a commonly used advanced method for preparing nanocoatings [55,56]. Ehiasarian et al. [57] used digital twin technology to achieve real-time modeling of the deposition process, resulting in high-quality control and effective resource usage. The various steps of HiPIMS and traditional magnetron sputtering processes could be monitored using optical emission spectroscopy (OES) and process parameters, providing a reliable method for evaluating process repeatability and an accurate means of quality assurance. This study laid the foundation for future coating development using machine learning technology and promoted the advancement of PVD preparation technology towards intelligent manufacturing.

Figure 3.

Schematic drawing of two conventional PVD processes: (a) sputtering, (b) evaporating using ionized Argon (Ar+) gas [58].

Figure 4.

Rake face of cutting tool. (a) uncoated (883), (b) PVD coated insert (TS2500) [54].

When preparing nanocoatings with PVD technology, precise adjustment and control of deposition parameters, such as evaporation source temperature, evaporation rate, vacuum level, and substrate temperature, can effectively regulate the size, composition, and morphology of nanoparticles in the deposited film [59].

Filtered cathodic vacuum arc deposition (FCVAD) is a coating method that uses PVD. This method generates plasma through cathodic arc discharge and uses a filtration system (such as a magnetic field or electric field) to remove large particles produced during the deposition process, thereby forming a high-purity, low-defect film on the substrate surface. The coatings prepared using FCVAD have excellent quality. By filtering out large particles, the film surface is smooth, with high density, significantly improved hardness, and bonding strength. This method is widely used in the preparation of nano-multilayer coatings [14,60,61]. FCVAD has a high deposition efficiency, characterized by a high ionization rate of the plasma generated by arc discharge, fast film formation speed, and compatibility with various materials, including metals, alloys, and compounds. Moreover, the FCVAD process is highly flexible, allowing for precise control of coating composition and thickness by adjusting arc current, filtration parameters, and other factors. However, the complexity of FCVAD equipment is high, and the coating performance is highly sensitive to parameters such as arc current, gas flow, and bias voltage, requiring strict calibration.

The evolution of PVD processes through innovations in material system structures, parameter optimization, and technology integration enhances the wear resistance, corrosion resistance, and high-temperature stability of nanocoatings.

3.2. Chemical Vapor Deposition (CVD)

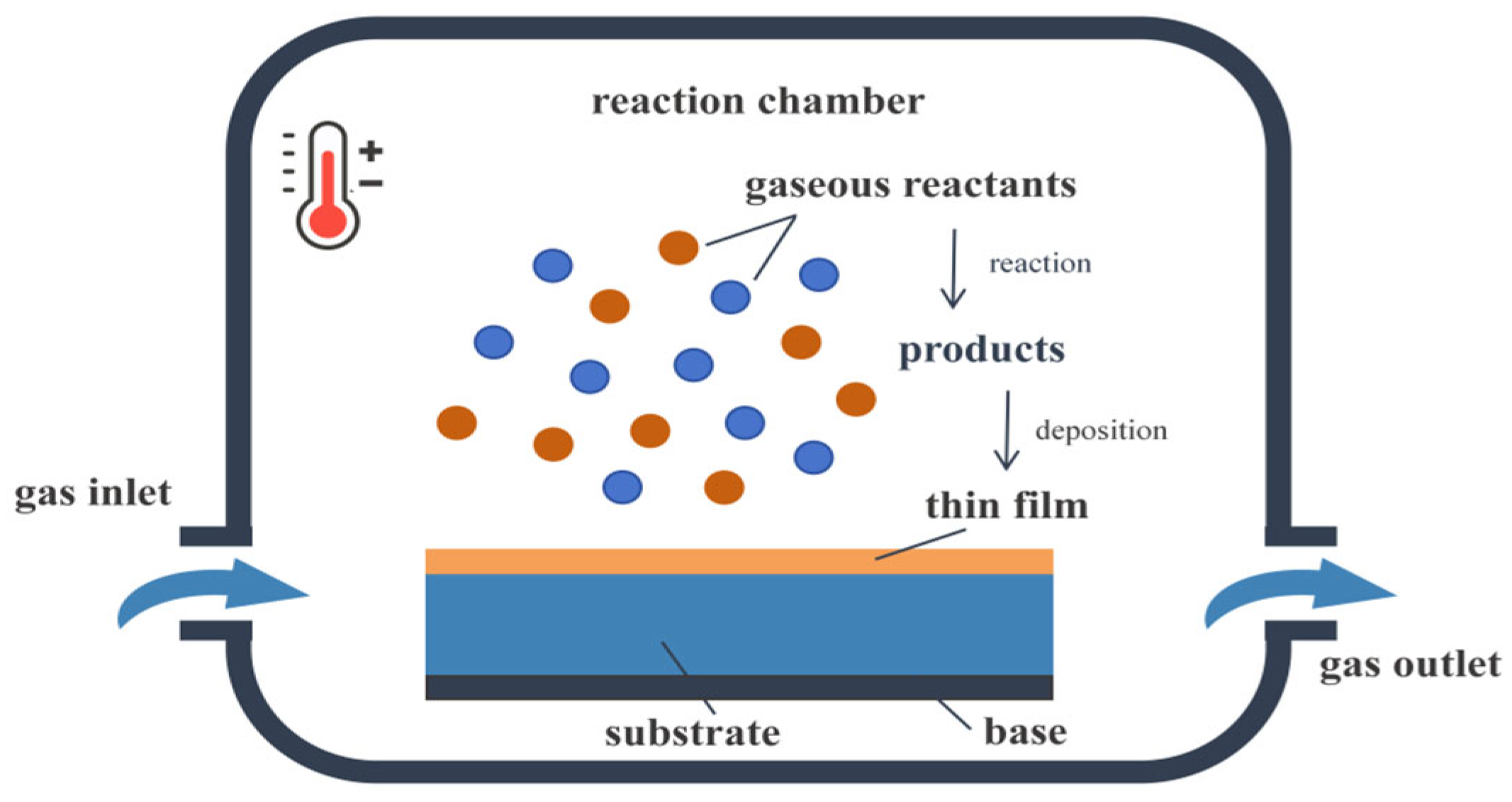

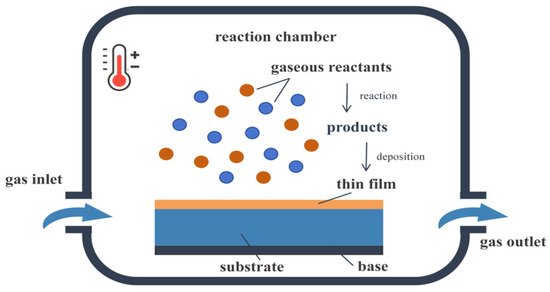

Chemical vapor deposition (CVD) is a technique that uses gaseous precursors as raw materials to deposit solid films on the substrate surface through chemical reactions. The principle is to introduce gaseous reactants into the reaction chamber, where a chemical reaction occurs at a specific temperature, and the reaction products deposit onto the substrate surface, forming a thin film with specific properties [62,63,64]. A schematic diagram of the CVD process is shown in Figure 5. By adjusting the flow rate, temperature, time, and other reaction conditions, the thickness, composition, and microstructure of the film can be precisely controlled, effectively improving the hardness, wear resistance, corrosion resistance, and conductivity of the material. This technology is widely used in the fields of semiconductors, optics, energy and environmental protection, and cutting tool coatings [65]. Common preparation methods include hot filament chemical vapor deposition (HFCVD) [66,67,68], microwave plasma chemical vapor deposition (MPCVD) [69,70,71], plasma enhanced chemical vapor deposition (PECVD) [72], and ultra-high vacuum chemical vapor deposition (UHV-CVD) [73].

Figure 5.

Schematic diagram of CVD technology.

A specific type of CVD is atomic layer deposition (ALD) [74,75]. ALD is a nanocoating preparation technology based on self-limiting chemical reactions of gaseous precursors. Its core principle is to alternately introduce two or more gaseous reactants, causing them to undergo chemical adsorption and reaction on the tool surface in sequence, thereby achieving layer-by-layer deposition of atomically thin coatings [76,77]. This technology has advantages that traditional coating techniques find difficult to match, including extremely high thickness control precision, very low surface defect rates, and satisfactory coverage of complex three-dimensional structures. In addition, the deposition temperature of the ALD process is relatively low, usually below 300 °C, which is compatible with heat-sensitive tool substrates such as high-speed steel, avoiding performance degradation of the substrate due to high temperatures. Tang et al. [78] coated microtextured YT5 cemented carbide tools with Al2O3 nanocoatings using ALD and tested them for dry cutting performance. The results showed that the surface-deposited Al2O3 nanoscale coatings could significantly reduce the cutting force and friction coefficient of the tools, verifying their advantages in microstructured tools. Gui et al. [79] conducted research on tool surface modification using ALD to address the issues of poor process stability and low shape accuracy caused by abnormal discharges between the tool’s side and the workpiece during electrical discharge machining (EDM) drilling of high aspect ratio small holes. They prepared a dense nano-alumina insulating film on the side of brass tools to suppress the impact of secondary discharges on the machining process. Experimental verification using nickel-based superalloy GH4099 as the workpiece demonstrated that the coating reduced tool wear by approximately 21.7% compared to uncoated conditions, significantly alleviating the side discharge pit. However, the slow deposition speed and high equipment cost of ALD limit its large-scale industrial application, and it is currently mainly used for producing high-end precision tool coatings and lithium battery protection coatings [80].

3.3. Thermoreactive Diffusion (TRD)

Thermalreaction diffusion (TRD) is a high-temperature surface treatment process that improves the base material’s wear resistance, corrosion resistance, and hardness by producing a hard coating on the surface. The TRD is regularly used to apply carbide, nitride, and boride coatings to the surfaces of tool steel, die steel, and other materials such as TiC, VC, and CrN. Unlike CVD, PVD, and other methods, which require precise process parameters, complex equipment, a high cost, and poor environmental performance, TRD technology is characterized by simple equipment, low costs, high environmental friendliness, and strong substrate adherence [81,82]. Thermal reaction diffusion consists essentially of three technologies: fluidized bed, embedded metal diffusion, and molten salt bath [80]. ERTÜRK et al. [83] investigated the cutting performance of tools coated in TRD. Circular cutting tools composed of AISI D2 and AISI M2 steel were coated with boron and boron + titanium coatings. Cylindrical turning tests were performed on DIN 1651 free-cutting steel, and tool cutting performance was compared to RCMT blades coated with PVD and CVD. The study found that the boron + titanium-coated samples wore about 50% less than the other samples. Tools coated with the TRD approach had better cutting performance than those coated with PVD and CVD. However, while the TRD process has demonstrated advantages in preparing micron-level coatings, its application in the field of nanocoatings remains in an exploratory phase.

Different preparation methods exhibit varying performance in terms of coating density, deposition rate, material compatibility, and film uniformity. As a result, the nanocoatings preparation method must be carefully examined and chosen based on the features of the tool substrate, intended performance indicators, process costs, and application conditions.

4. Performance Evaluation

4.1. Evaluation Indicators

The key to the application of nanocoatings on tool surfaces lies in their ability to effectively resist multiple failure mechanisms under actual working conditions. To this end, a scientifically sound performance evaluation system is not only the foundation for material selection and process optimization but also the bridge for translating experimental results into practical applications. The main failure modes faced by industrial processing tools during their service include wear failure (abrasive wear, adhesive wear, oxidative wear, and diffusion wear), corrosion failure (chemical corrosion and electrochemical corrosion), thermal failure (thermal stress cracking, thermal decomposition, and phase change), coating adhesion failure (interface peeling and coating cohesion failure), mechanical fracture failure (chipping), and various other forms of wear. Cutting tools’ failure modes vary depending on the working conditions [84,85,86]. Different failure mechanisms impose varying performance requirements on coatings, with wear resistance testing, mechanical performance testing, adhesion testing, thermal shock testing, thermal stability testing, and internal stress testing being common evaluation methods.

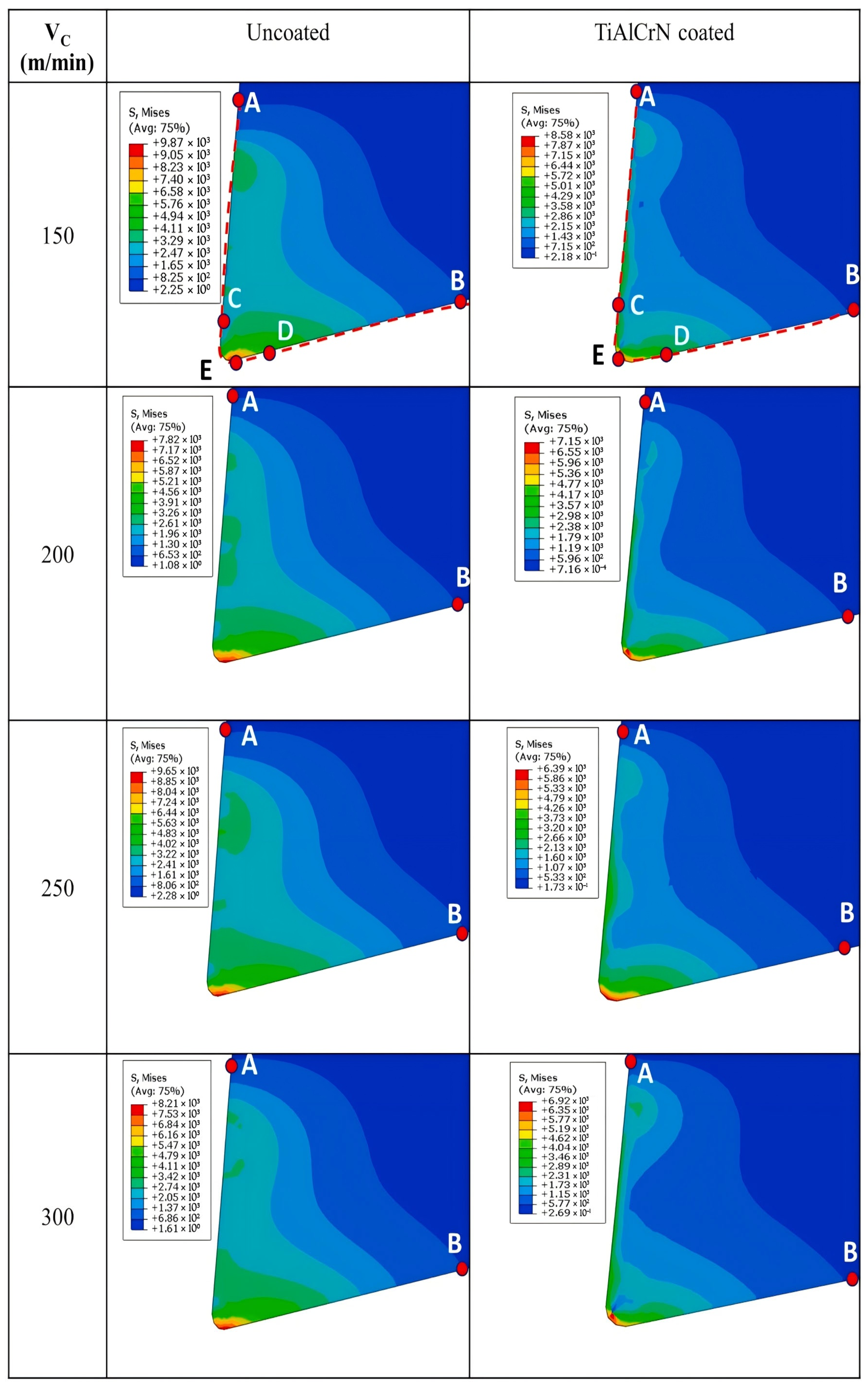

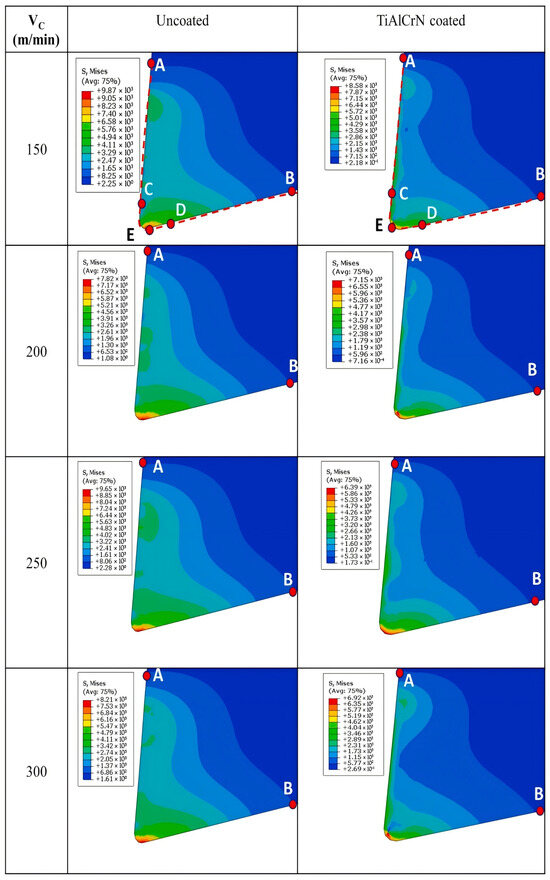

Wear resistance testing reflects the coating’s ability to withstand abrasive erosion, cutting stress, and particle impact, making it a core indicator of tool life. Common testing methods include ball-on-disk wear tests [87] and linear friction wear tests [88]. Mechanical performance and adhesion tests cover the hardness, elastic modulus, and fracture toughness of the coating itself, as well as the bonding quality between the coating and the substrate. Nanoindentation and scratch testing are typical assessment methods [89,90,91,92]. Thermal shock resistance and thermal stability testing are carried out under high-speed cutting or dry cutting settings to assess the coating’s structural stability and crack resistance during thermal load cycles. Common tests include high-temperature oxidation testing and thermal fatigue shock testing [93,94,95]. The existence of internal stress influences bond strength, crack propagation resistance, and fatigue resistance in coatings. Therefore, internal stress must be examined when studying the performance of coatings. Recently, several reports have demonstrated the benefits of using the finite element model (FEM) in studying coating performance [96,97]. As a result, some researchers combined nanoindentation with FEM to evaluate the internal stress of nanocoatings. Kumar et al. [98] developed a 2D FEM based on fracture energy to assess the cutting performance of WC-Co tools during dry turning of AISI 1045 steel with TiAlCrN nanolayer coatings. Figure 6 shows the stress distribution in uncoated and TiAlCrN coated cutting tools after machining. The application of TiAlCrN coating resulted in reduced tool stress because coated tools had lower friction and machining forces. This study demonstrated the effectiveness of FEM in evaluating the performance of nanocoatings on cutting tools.

Figure 6.

Stress (MPa) distribution in the uncoated and TiAlCrN-coated cutting tools after machining. AB—path, AC—the sliding zone, CD—the cutting zone. Copyright 2020 Elsevier [98].

Related experimental studies have shown that multilayer and composite nanocoatings exhibit significant advantages in the aforementioned evaluation dimensions. Zha et al. [99] used PVD to deposit TiAlN/TiSiN nano-multilayer coatings on a carbide milling tool substrate and found that it exhibited excellent fatigue resistance under low load in cyclic impact tests. Zha et al. [93] further studied and found that the introduction of interface structures in TiSiN/TiAlN nano-multilayer coatings effectively enhanced high-temperature oxidation resistance and resisted thermal fatigue shock. Xiao et al. [100] conducted a comparative study on the microstructure, mechanical properties, oxidation resistance, and cutting performance of AlCrN, AlTiSiN single-layer coatings, and AlCrN/AlTiSiN nano-multilayer coatings. The results showed that the AlCrN/AlTiSiN coating, which had a biphasic and denser microstructure, exhibited improved hardness and adhesion strength, as well as excellent oxidation resistance at a high temperature of 1000 °C. These characteristics enabled the AlCrN/AlTiSiN-coated tools to demonstrate better tool life in the turning test of SKD11 steel. There are differences between the turning and milling processes. Turning is a continuous cutting process that primarily produces sustained high temperatures, but milling is an intermittent cutting technique that generates high impact forces. As a result, turning focuses on the high-temperature performance of nanocoatings, while milling focuses on the impact resistance of coatings.

4.2. Characterization Methods

Performance evaluation reveals the coating’s overall performance, while structural characterization focuses on the mechanisms involved in coating creation. The characterization of surface and microstructure is critical in coating research. It not only evaluates deposition quality, interface integrity, and process stability, but it also reveals detailed information about phase transition behavior, failure sources, and interface stress distribution during the performance evolution process. Especially in multilayer coatings or composite structure systems, the transition quality between layers, grain boundary continuity, and the degree of amorphous phase encapsulation are microstructural features that often determine the overall mechanical stability and spalling resistance of the coating system. Structural characterization methods provide quantitative and visual support for these key indicators.

In addition to the macro outcomes shown in the performance assessment data, clarifying the principles of microstructural evolution of coatings under various deposition methods and service situations is critical for identifying failure reasons and optimizing structural design. Wear resistance, corrosion resistance, and bonding ability of coatings are all influenced by factors such as the crystal structure, phase composition, surface morphology, and interfacial bonding quality. As a result, a variety of microstructure and surface characterization techniques must be used to properly evaluate the coating from surface to interface, from nanocrystalline to amorphous phases, and from roughness to multilayer cross-sections. These characterization methods not only explain the fundamental mechanisms that determine performance results, but they also provide data for further deposition process parameter optimization, failure prediction model development, and multiscale modeling. Researchers can modify the technique and conditions to increase the coating’s practicality and functionality. Table 2 summarizes the commonly used characterization methods for coating surfaces and microstructures.

Table 2.

Common characterization methods for coating surface and microstructure [101,102,103,104,105,106].

In actual research, multiple characterization methods are often used together to reveal the properties of coatings. For example, the combination of SEM and EDS is used to express the morphology of composite materials and determine local compositions, revealing phase transitions and reflecting the interfacial performance of the composite materials [107]. The combination of SEM and TEM is used to study the cross-sectional morphology of the coating [108].

Although the methods mentioned above can determine the microstructure, crystal structure, and phase composition of coatings, conventional judgments have limits in preparing many batches of coatings, identifying complicated microstructures, and analyzing vast amounts of data. In recent years, machine learning (ML) has been used to characterize coating microstructures. Bobzin et al. [109] used ML to analyze SEM images of coated surfaces, extracting and categorizing grain and grain boundary information. By training machine learning models to recognize these features, the ML data was put into FEM to simulate the deformation behavior of CrAlN PVD coatings on HS6-5-2C tool steel composite materials during nanoindentation research. As a result, ML can be applied to the characterization of nanocoatings and other related applications.

5. Analysis of Performance Modulation

The performance of coatings is the result of the combined effects of composition, structure, and deposition processes, and it needs to be continuously optimized during the design, preparation, and characterization stages, rather than being a choice of priority along a single dimension. To ensure that the performance of nanocoatings precisely matches the requirements of specific application scenarios and to overcome single-performance bottlenecks to achieve the maximization of overall performance, it is necessary to optimize their composition, elemental content, structure, etc. Therefore, performance modulation of nanocoatings is required.

Some researchers have conducted studies on the impact of coating element content on coating performance. Bobzin et al. [110] prepared TiAlCrSiN nanocomposite coatings with three different Cr and Si contents on the same substrate using HPPMS technology. Through cutting tests and abrasion tests, they examined the impact of varying Cr and Si contents on the mechanical properties and cutting behavior of the coatings. Coatings with a higher Cr and Si content exhibited a more pronounced tendency for brittle fracture and higher workpiece adhesion, resulting in increased tool attrition and more frequent built-up edge formation, as indicated by the results. In contrast, coatings with low Cr + Si content exhibited a lower tendency for built-up edge formation, demonstrating superior cutting performance.

Some scholars have designed the coating composition to optimize the coating performance. Fox-Rabinovitch et al. [111] explored the optimization of the composition of a new type of TiAlCrSiN/TiAlCrN nano-multilayer coating to improve the machinability of difficult-to-cut materials (such as directly aged Inconel 718 alloy). The coatings were comprehensively characterized using XRD analysis, micro-mechanical testing, and tribological performance evaluation in this study, which evaluated three different chemically constituted TiAlCrSiN/TiAlCrN nano-multilayer coatings. The results indicated that the Ti0.18Al0.55Cr0.17Si0.05Y0.05N/Ti0.25Al0.65Cr0.1N nano-multilayer coating was more effective in establishing a protective friction film, which increased the lifespan of the tool.

Some researchers focus on the relationship between different geometric structures and coating performance. Chen et al. [112] studied the mechanical and tribological performances of TiSiN/TiAlN nano-multilayer coatings produced by PVD at various modulation periods and ratios. The results showed that when the modulation period was shortened to 8.5 nm and the modulation ratio was set to 1:2.3, the coating hardness increased dramatically to 36.8 GPa, while the wear resistance at room temperature also improved. Further study found that under high-temperature service conditions, the modulation structure has a significant impact on the coating’s chemical stability and the formation of the friction layer, increasing the coating’s adaptability to thermal friction conditions.

The hardness and wear resistance of the coating generally increase with the thickness of the coating, but when the thickness exceeds a certain value, this improvement tends to saturate or even decline [113]. Coating thickness has a considerable effect on internal stress. Thicker coatings are prone to higher internal stress, which may lead to internal cracks and interlayer delamination, thereby shortening tool life. Additionally, various machining conditions (such as cutting speed) have a major impact on coating thickness selections [114]. Therefore, it is necessary to consider factors such as hardness, wear resistance, and internal stress to determine the optimal coating thickness. Vereschaka et al. [114] experimentally analyzed the impact of Ti–TiN–(Ti,Al,Si)N multilayer nanocomposite coatings of different thicknesses on the lifespan of metal cutting tools. The study showed that in longitudinal turning tests of 45# steel (vc = 250, 300, and 350 m/min), coatings with a thickness of 5–7 μm could provide the longest tool life. Calaph et al. [72] explored the performance evaluation of cutting tools with TiAlSiN nanocoating of different thicknesses using PECVD. The research showed that when turning EN24 steel, tools with a coating thickness ranging from 5 to 8 μm exhibited a longer service life and a lower wear rate; in contrast, coatings with thicknesses of 1.5, 3, 10, and 12 μm showed a shorter service life and higher wear. The minimum tool wear occurred with a coating thickness of 6.5 μm, resulting in only 0.124 mm of wear at a cutting speed of 55 m/min, further validating the principle of optimal thickness control.

A number of researchers have confirmed the viability of performance modulation in overcoming the limits of single-performance coatings and adapting to complicated operating situations through experimental and theoretical studies. These findings show a natural connection between coating composition, structure, preparation process, and performance increase, providing theoretical support for the engineering application of nanocoatings.

6. Summary and Prospects

This review summarizes the latest research progress in the design, deposition methods, performance evaluation, and performance modulation of nanocoatings for cutting tools. Component design and multi-layer structures contribute to grain refinement and microstructural optimization. Mainstream technologies such as PVD and CVD continue to evolve to produce high-performance coatings, while the TRD method offers potential for environmentally friendly coating preparation. Wear resistance, mechanical properties, adhesion, thermal stability, and residual stress are core metrics for evaluating coating performance; by adjusting components, elemental content, structure, and thickness, the overall performance of coatings has been significantly improved.

Future study can focus on the following subjects: 1. Developing innovative multi-layer nanocomposite coatings that combine high hardness and self-lubricating characteristics. 2. Promoting green and sustainable preparation methods to reduce energy consumption and environmental effects. 3. Using finite element simulation, machine learning, and digital twin technologies to predict coating behavior, dynamically optimize processes, and rapidly iterate performance.

Author Contributions

Conceptualization, Q.X., N.W. and Y.L.; writing—original draft preparation, Q.X. and S.H.; writing—review and editing, D.W., X.L., X.C. and J.C.; funding acquisition, Q.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been supported by the Heilongjiang Provincial Colleges and Universities Fundamental Scientific Research Business Funds Scientific Research Project (No: 2020-KYYWF-0256).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hourmand, M.; Sarhan, A.A.; Sayuti, M.; Hamdi, M. A comprehensive review on machining of titanium alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Jouini, N.; Ghani, J.A.; Yaqoob, S.; Juri, A.Z. Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo + MQL Techniques. Processes 2025, 13, 739. [Google Scholar] [CrossRef]

- Pedroso, A.; Sousa, V.; Sebbe, N.; Silva, F.; Campilho, R.; Sales-Contini, R.; Jesus, A. A comprehensive review on the conventional and non-conventional machining and tool-wear mechanisms of INCONEL®. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Han, J.; Liu, Z.; Cao, K.; Xu, L.; Shi, T.; Liao, G. Cutting temperature measurement in turning using fiber-optic multi-spectral radiation thermometry and its application in tool wear status recognition. Measurement 2022, 198, 111413. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, Z.; Yang, F.; Zhong, Z.; Sun, S. Investigations on tool temperature with heat conduction and heat convection in high-speed slot milling of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2018, 96, 1847–1858. [Google Scholar] [CrossRef]

- Khan, M.A.; Jaffery, S.H.I.; Baqai, A.A.; Khan, M. Comparative analysis of tool wear progression of dry and cryogenic turning of titanium alloy Ti-6Al-4V under low, moderate and high tool wear conditions. Int. J. Adv. Manuf. Technol. 2022, 121, 1269–1287. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, B.; Jiao, F.; Zheng, J. Chip formation and its effects on cutting force, tool temperature, tool stress, and cutting edge wear in high-and ultra-high-speed milling. Int. J. Adv. Manuf. Technol. 2016, 83, 55–65. [Google Scholar] [CrossRef]

- Okada, M.; Hosokawa, A.; Tanaka, R.; Ueda, T. Cutting performance of PVD-coated carbide and CBN tools in hardmilling. Int. J. Mach. Tools Manuf. 2011, 51, 127–132. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J.; Wan, Y. Tool coating effects on cutting temperature during metal cutting processes: Comprehensive review and future research directions. Mech. Syst. Signal Process. 2021, 150, 107302. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Chowdhury, M.; Bose, B.; Yamamoto, K.; Shuster, L.; Paiva, J.; Fox-Rabinovich, G.; Veldhuis, S. Wear performance investigation of PVD coated and uncoated carbide tools during high-speed machining of TiAl6V4 aerospace alloy. Wear 2020, 446, 203168. [Google Scholar] [CrossRef]

- Sousa, V.F.; Silva, F.J. Recent advances on coated milling tool technology—A comprehensive review. Coatings 2020, 10, 235. [Google Scholar] [CrossRef]

- Sousa, V.F.; Silva, F.J. Recent advances in turning processes using coated tools—A comprehensive review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378, 43–57. [Google Scholar] [CrossRef]

- Vereschaka, A.; Migranov, M.; Oganyan, G.; Sotova, C.S.; Batako, A. Application of carbide cutting tools with nano-structured multilayer composite coatings for turning austenitic steels, type 16Cr-10NI. Mech. Ind. 2017, 18, 707. [Google Scholar] [CrossRef]

- Freitas, F.R.; Casais, R.C.; Silva, F.J.; Sebbe, N.P.; Martinho, R.P.; Sousa, V.F.; Sales-Contini, R.C.; Fernandes, F. Wear Behavior of TiAlN/DLC Coating on Tools in Milling Copper–Beryllium Alloy AMPCOLOY® 83. Coatings 2024, 14, 1354. [Google Scholar] [CrossRef]

- Kavishwar, S.; Bhaiswar, V.; Kochhar, S.; Fande, A.; Tandon, V. State-of-the-Art titanium carbide hard coatings: A comprehensive review of mechanical and tribological behaviour. Eng. Res. Express 2024, 6, 042401. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Sotova, C.; Oganian, G.; Sadov, I. Investigation of the properties of Ti-TiN-(Ti, Cr, Mo, Al) N multilayered composite coating with wear-resistant layer of nanolayer structure. Coatings 2020, 10, 1236. [Google Scholar] [CrossRef]

- Beake, B.D. Nano-and micro-scale impact testing of hard coatings: A review. Coatings 2022, 12, 793. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Wang, T.; Zha, X.; Chen, F.; Wang, J.; Li, Y.; Jiang, F. Mechanical impact test methods for hard coatings of cutting tools: A review. Int. J. Adv. Manuf. Technol. 2021, 115, 1367–1385. [Google Scholar] [CrossRef]

- Kang, K.; Su, S.; Yu, B.; Sun, Z.; Hu, S.; Wang, Z.; Zhao, C.; Wu, L.; Luo, G.; Wei, R. The review and prospect of tool coating technology. Int. J. Adv. Manuf. Technol. 2025, 137, 3107–3139. [Google Scholar] [CrossRef]

- Grzesik, W.; Małecka, J. The oxidation behaviour and notch wear formation of TiAlN coated tools using different oxidation techniques. Materials 2021, 14, 1330. [Google Scholar] [CrossRef]

- He, Q.; Saciotto, V.; DePaiva, J.M.; Guimaraes, M.C.; Kohlscheen, J.; Martins, M.M.; Veldhuis, S.C. Enhancing tool performance in high-speed end milling of Ti-6Al-4V alloy: The role of AlCrN PVD coatings and resistance to chipping wear. J. Manuf. Mater. Process. 2024, 8, 68. [Google Scholar] [CrossRef]

- Chavee, L.; Serag, E.; da Silva Pires, M.; Lucas, S.; Haye, E. A mechanistic approach of oxidation resistance, structural and mechanical behaviour of TiAlN coatings. Appl. Surf. Sci. 2022, 586, 152851. [Google Scholar] [CrossRef]

- Cheng, S. Effect of 10% Si addition on cathodic arc evaporated TiAlSiN coatings. Trans. Nonferrous Met. Soc. China 2016, 26, 1638–1646. [Google Scholar]

- Sui, X.; Li, G.; Qin, X.; Yu, H.; Zhou, X.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Zhi-Li, W.; Yu-Ge, L.; Bi, W.; Ming-Kai, L. Microstructure Controlling and Properties of TiAlSiN Nanocomposite Coatings Deposited by Modulated Pulsed Power Magnetron Sputtering. J. Inorg. Mater. 2015, 30, 1254–1260. [Google Scholar] [CrossRef]

- Dosbaeva, G.; Veldhuis, S.; Yamamoto, K.; Wilkinson, D.; Beake, B.; Jenkins, N.; Elfizy, A.; Fox-Rabinovich, G. Oxide scales formation in nano-crystalline TiAlCrSiYN PVD coatings at elevated temperature. Int. J. Refract. Met. Hard Mater. 2010, 28, 133–141. [Google Scholar] [CrossRef]

- Beake, B.D.; Fox-Rabinovich, G.S.; Losset, Y.; Yamamoto, K.; Agguire, M.H.; Veldhuis, S.C.; Endrino, J.L.; Kovalev, A.I. Why can TiAlCrSiYN-based adaptive coatings deliver exceptional performance under extreme frictional conditions? Faraday Discuss. 2012, 156, 267–277. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Konovalov, E.; Vakhrushev, V.; Dmitrievskii, S.; Endrino, J.; Fox-Rabinovich, G.; Tomchuk, A. The role of interatomic interactions in the tribooxidation and wear of the multilayer Ti0.2Al0.55Cr0.2Si0.03Y0.02N/Ti0.25Al0.65Cr0.1N coating at severe cutting conditions. Metallurgist 2024, 68, 477–484. [Google Scholar] [CrossRef]

- Kovalev, A.; Wainstein, D.; Rashkovskiy, A.; Fox-Rabinovich, G.; Veldhuis, S.; Agguire, M.; Yamamoto, K. Investigation of electronic and atomic structure of tribofilms on the surface of cutting tools with TiAlCrSiYN and multilayer TiAlCrSiYN/TiAlCrN coatings during machining of hardened steels. Surf. Interface Anal. 2010, 42, 1368–1372. [Google Scholar] [CrossRef]

- Luo, Y.; Dong, Y.; Xiao, C.; Wang, X.; Peng, H. Impact abrasive wear property of CrAlN/TiSiN multilayer coating at elevated temperatures. Materials 2022, 15, 2214. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-K.; Kim, S.-M.; Lee, S.-Y. Influence of interlayer materials on the mechanical properties and thermal stability of a CrAlN coating on a tungsten carbide substrate. Coatings 2022, 12, 1134. [Google Scholar] [CrossRef]

- Vereshchaka, A.; Vereshchaka, A.; Mgaloblishvili, O.; Morgan, M.; Batako, A. Nano-scale multilayered-composite coatings for the cutting tools. Int. J. Adv. Manuf. Technol. 2014, 72, 303–317. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Fyodorov, S.; Sitnikov, N.; Batako, A. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2017, 90, 3421–3435. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Vereschaka, A.S.; Batako, A.D.; Mokritskii, B.J.; Aksenenko, A.Y.; Sitnikov, N.N. Improvement of structure and quality of nanoscale multilayered composite coatings, deposited by filtered cathodic vacuum arc deposition method. Nanomater. Nanotechnol. 2016, 7, 1847980416680805. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2019, 420, 17–37. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.-Y.; Lee, G.; Kwon, S.-C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Fang, W.; Chen, J.; Zhou, Q.; Xue, H.; Cai, F.; Fang, L.; Zhang, S. Microstructure, mechanical properties and high-speed dry-cutting performance of AlCrSiCN composite coatings. J. Mater. Res. Technol. 2023, 25, 1800–1812. [Google Scholar] [CrossRef]

- Suresh Babu, P.; Venkatesh, L.; Srinivasa Rao, D.; Ravi, N. Fracture behaviour of nc-TiAlN/a-Si3N4 nanocomposite coatings under cyclic nano impact testing. Surf. Eng. 2020, 36, 671–679. [Google Scholar] [CrossRef]

- Das, P.; Anwar, S.; Bajpai, S.; Anwar, S. Structural and mechanical evolution of TiAlSiN nanocomposite coating under influence of Si3N4 power. Surf. Coat. Technol. 2016, 307, 676–682. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Lü, W.; Li, G.; Zhou, Y.; Liu, S.; Wang, K.; Wang, Q. Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Li, G.; Sun, J.; Xu, Y.; Xu, Y.; Gu, J.; Wang, L.; Huang, K.; Liu, K.; Li, L. Microstructure, mechanical properties, and cutting performance of TiAlSiN multilayer coatings prepared by HiPIMS. Surf. Coat. Technol. 2018, 353, 274–281. [Google Scholar] [CrossRef]

- Wang, M.; Toihara, T.; Sakurai, M.; Kurosaka, W.; Miyake, S. Surface morphology and tribological properties of DC sputtered nanoscale multilayered TiAlN/CNx coatings. Tribol. Int. 2014, 73, 36–46. [Google Scholar] [CrossRef]

- Li, G.; Lü, W.; Liu, S.; Li, C.; Zhou, Y.; Wang, Q. Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy. Compos. Part B Eng. 2021, 211, 108620. [Google Scholar] [CrossRef]

- Wang, P.; Pang, M.; Gao, L.-H. Research on the performance of nickel-based WC/MoS2 self-lubricating composite coatings laser cladding on 300 M ultra-high-strength steel surface. Mater. Today Commun. 2024, 39, 109334. [Google Scholar] [CrossRef]

- Jahaziel, R.B.; Krishnaraj, V.; Sudhagar, S.; Priyadarshini, B.G. Improving dry machining performance of surface modified cutting tools through combined effect of texture and TiN-WS2 coating. J. Manuf. Process. 2023, 85, 101–108. [Google Scholar] [CrossRef]

- Lukaszkowicz, K. Review of nanocomposite thin films and coatings deposited by PVD and CVD technology. In Nanomaterials; IntechOpen: London, UK, 2011; pp. 145–163. [Google Scholar]

- Guo, H.; Sun, Q.; Zhou, D.; Yu, M.; Wang, Y.; Wang, Q.; Li, X. Erosion behavior of CrN, CrAlN and CrAlN/CrN multilayer coatings deposited on Ti6Al4V. Surf. Coat. Technol. 2022, 437, 128284. [Google Scholar] [CrossRef]

- Gu, Y.; Xia, K.; Wu, D.; Mou, J.; Zheng, S. Technical characteristics and wear-resistant mechanism of nano coatings: A review. Coatings 2020, 10, 233. [Google Scholar] [CrossRef]

- Filip, A.V.; Sava, B.A.; Medianu, R.V.; Boroica, L.; Dinca, M.C.; Pascu, R.; Tigau, N.; Andrei, A.; Moldovan, A.; Dumitru, M. Ultrathin films of silver by Magnetron Sputtering. Inorganics 2022, 10, 235. [Google Scholar] [CrossRef]

- Benedicto, E.; Rubio, E.M.; Aubouy, L.; Sáenz-Nuño, M.A. Sustainable lubrication/cooling systems for efficient turning operations of γ-TiAl parts from the aeronautic industry. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 709–728. [Google Scholar] [CrossRef]

- Elmkhah, H.; Attarzadeh, F.; Fattah-Alhosseini, A.; Kim, K.H. Microstructural and electrochemical comparison between TiN coatings deposited through HIPIMS and DCMS techniques. J. Alloys Compd. 2018, 735, 422–429. [Google Scholar] [CrossRef]

- Ding, J.C.; Zhang, T.F.; Wang, Q.M.; Song, C.W.; Wang, T.-G.; Kim, K.-H. Microstructure and mechanical properties of the Cr–Mo–Si–N nanocomposite coatings prepared by a hybrid system of AIP and HiPIMS technologies. J. Alloys Compd. 2018, 740, 774–783. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Sugumaran, A.; Hovsepian, P.E.; Davies, C.; Hatto, P. Real-time monitoring of plasma synthesis of functional materials by high power impulse magnetron sputtering and other PVD processes: Towards a physics-constrained digital twin. J. Phys. D Appl. Phys. 2022, 56, 035302. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement and market trend demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Maier, H.; Heidenblut, T.; Kahra, C.; Carlet, M. Influence of residual stresses in hard tool coatings on the cutting performance. J. Manuf. Process. 2021, 69, 340–350. [Google Scholar] [CrossRef]

- Li, Y.; Cao, H.; Li, H.; Yang, J.; Qi, F.; Lu, L.; Zhao, N.; Zhou, Y.; Ouyang, X. Effect of buffer layer on oxidation and corrosion resistance of CrN coatings on Zr alloy prepared by FCVAD technology. Surf. Coat. Technol. 2022, 448, 128942. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Oganyan, G.V.; Batako, A. Working efficiency of cutting tools with multilayer nano-structured Ti-TiCN-(Ti, Al) CN and Ti-TiCN-(Ti, Al, Cr) CN coatings: Analysis of cutting properties, wear mechanism and diffusion processes. Surf. Coat. Technol. 2017, 332, 198–213. [Google Scholar] [CrossRef]

- Sun, L.; Yuan, G.; Gao, L.; Yang, J.; Chhowalla, M.; Gharahcheshmeh, M.H.; Gleason, K.K.; Choi, Y.S.; Hong, B.H.; Liu, Z. Chemical vapour deposition. Nat. Rev. Methods Primers 2021, 1, 5. [Google Scholar] [CrossRef]

- Tian, Y.; Yan, Z.; Jiang, L.; Liu, R.; Liu, B.; Shao, Y.; Yang, X.; Liu, M. Multiscale models of CVD process: Review and prospective. Materials 2024, 17, 5131. [Google Scholar] [CrossRef]

- Butt, M.A. Thin-film coating methods: A successful marriage of high-quality and cost-effectiveness—A brief exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Dutta, V.; Verma, R.; Gopalkrishnan, C.; Yuan, M.-H.; Batoo, K.M.; Jayavel, R.; Chauhan, A.; Lin, K.-Y.A.; Balasubramani, R.; Ghotekar, S. Bio-inspired synthesis of carbon-based nanomaterials and their potential environmental applications: A state-of-the-art review. Inorganics 2022, 10, 169. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Lin, H.; Chen, Y.; Ji, R. Effect of Substrate Pretreatment Process on the Cutting Performance of Diamond-Coated PCB Micro-Milling Tools. Micromachines 2022, 14, 73. [Google Scholar] [CrossRef] [PubMed]

- Saiki, Y.; Bando, T.; Harigai, T.; Takikawa, H.; Hattori, T.; Sugita, H.; Kawahara, N.; Tanaka, K. Sequential morphology of cobalt from cemented tungsten carbide in microcrystalline and nanocrystalline diamond films by HF-CVD. Diam. Relat. Mater. 2023, 132, 109643. [Google Scholar] [CrossRef]

- Wang, X.; Ye, J. Interface characteristics of CVD diamond coating on WC-Co cemented carbide substrate. Surf. Coat. Technol. 2024, 485, 130886. [Google Scholar] [CrossRef]

- Tu, L.; Tian, S.; Xu, F.; Wang, X.; Xu, C.; He, B.; Zuo, D.; Zhang, W. Cutting performance of cubic boron nitride-coated tools in dry turning of hardened ductile iron. J. Manuf. Process. 2020, 56, 158–168. [Google Scholar] [CrossRef]

- Zhu, W.; Su, Z.; Guo, J.; Li, K.; Chen, K.; Li, W.; Yi, A.; Liao, Z.; Luo, Y.; Hu, Y. Preparation and characterization of diamond-like carbon (DLC) film on 316L stainless steel by microwave plasma chemical vapor deposition (MPCVD). Diam. Relat. Mater. 2022, 122, 108820. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Z.; Peng, J.; Shen, Q.; Wang, C. In-situ formation, structural transformation and mechanical properties CrN coatings prepared by MPCVD. Surf. Coat. Technol. 2022, 441, 128522. [Google Scholar] [CrossRef]

- Calaph, Y.C.; Subramanian, K.M.; Nakandhrakumar, R.; Sowrirajan, M. Experimental tool life and wear analysis of different thickness pecvd TiAlSiN nanocoated cutting tool inserts. Proc. Inst. Mech. Eng. Part E 2022, 236, 2012–2023. [Google Scholar] [CrossRef]

- He, B.-C.; Wen, H.-C.; Lin, M.-H.; Lai, Y.-S.; Wu, W.-F.; Chou, C.-P. Effect of annealing treatment and nanomechanical properties for multilayer Si0.8Ge0.2–Si films. Microelectron. Reliab. 2010, 50, 851–856. [Google Scholar] [CrossRef]

- Lindquist, N.C.; Nagpal, P.; McPeak, K.M.; Norris, D.J.; Oh, S.-H. Engineering metallic nanostructures for plasmonics and nanophotonics. Rep. Prog. Phys. 2012, 75, 036501. [Google Scholar] [CrossRef]

- Maciulis, V.; Ramanaviciene, A.; Plikusiene, I. Recent advances in synthesis and application of metal oxide nanostructures in chemical sensors and biosensors. Nanomaterials 2022, 12, 4413. [Google Scholar] [CrossRef] [PubMed]

- Miikkulainen, V.; Leskelä, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 021301. [Google Scholar] [CrossRef]

- Hu, L.; Qi, W.; Li, Y. Coating strategies for atomic layer deposition. Nanotechnol. Rev. 2017, 6, 527–547. [Google Scholar] [CrossRef]

- Tang, S.; Liu, P.; Su, Z.; Lei, Y.; Liu, Q.; Liu, D. Preparation and cutting performance of nano-scaled Al2O3-coated micro-textured cutting tool prepared by atomic layer deposition. High Temp. Mater. Process. 2021, 40, 77–86. [Google Scholar] [CrossRef]

- Gui, S.-Y.; Gong, H.; Sun, Y.-J.; Feng, C. Experimental investigation of the EDM tools coated with nano-alumina film. Surf. Eng. 2023, 39, 506–513. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, X.-Q.; Zhou, M.-Y.; Huang, J.-Q. Mechanism, quantitative characterization, and inhibition of corrosion in lithium batteries. Nano Res. Energy 2023, 2, e9120046. [Google Scholar] [CrossRef]

- Kurt, B.; Özdoğan, L.; Güney, B.; Bölükbaşı, Ö.S.; Günen, A. Characterization and wear behavior of TiBC coatings formed by thermo-reactive diffusion technique on AISI D6 steel. Surf. Coat. Technol. 2020, 385, 125332. [Google Scholar] [CrossRef]

- Najari, M.R.; Sajjadi, S.A.; Ganji, O. Microstructural evolution and wear properties of chromium carbide coating formed by thermo-reactive diffusion (TRD) process on a cold-work tool steel. Results Surf. Interfaces 2022, 8, 100059. [Google Scholar] [CrossRef]

- Ertürk, Ş.; Kayabaşi, O. Investigation of the cutting performance of cutting tools coated with the thermo-reactive diffusion (TRD) technique. IEEE Access 2019, 7, 106824–106838. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Chen, H.; Wang, M. Modification methods of diamond like carbon coating and the performance in machining applications: A review. Coatings 2022, 12, 224. [Google Scholar] [CrossRef]

- Pramanik, A.; Littlefair, G. Machining of titanium alloy (Ti-6Al-4V)—Theory to application. Mach. Sci. Technol. 2015, 19, 1–49. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Current status of hard turning in manufacturing: Aspects of cooling strategy and sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Veiko, V.; Odintsova, G.; Gazizova, M.; Karlagina, Y.; Manokhin, S.; Yatsuk, R.; Vasilkov, S.; Kolobov, Y. The influence of laser micro-and nanostructuring on the wear resistance of Grade-2 titanium surface. Laser Phys. 2018, 28, 086002. [Google Scholar] [CrossRef]

- Proudhon, H.; Savkova, J.; Basseville, S.; Guipont, V.; Jeandin, M.; Cailletaud, G. Experimental and numerical wear studies of porous Reactive Plasma Sprayed Ti–6Al–4V/TiN composite coating. Wear 2014, 311, 159–166. [Google Scholar] [CrossRef]

- Drnovšek, A.; de Figueiredo, M.R.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Kolawole, F.O.; dos Santos, M.D.; Kolawole, S.K.; Vencovsky, P.K.; Ludewigs, D.A.; Tschiptschin, A.P. Nano-Scratch and Micro-Scratch Properties of CrN/DLC and DLC-W Coatings. Mater. Perform. Charact. 2023, 12, 320–340. [Google Scholar] [CrossRef]

- Vieira, V.F.; Shigaki, Y.; Martins, P.S.; Ba, E.C.T.; Dias, C.A.R. Nanoindentation test of a DLC coated high-speed steel substrate using a two-dimensional axisymmetric finite element method. Diam. Relat. Mater. 2023, 134, 109792. [Google Scholar] [CrossRef]

- Mei, H.; Wang, R.; Geng, D.; Cheng, L.; Huang, K.; Li, K.; Liang, H.; Zou, C.; Gong, W.; Wang, Q. Microstructure and mechanical properties of AlTiN/AlTiVCuN nano-multilayered coatings deposited by BPMS. Ceram. Int. 2025, 51, 18276–18287. [Google Scholar] [CrossRef]

- Zha, X.; Wang, T.; Guo, B.; Chen, F.; Lin, L.; Zhang, T.; Jiang, F. Research on the oxidation resistance and ultra-high frequency thermal fatigue shock failure mechanisms of the bilayer and multilayer nano-coatings on cemented carbide tools. Int. J. Refract. Met. Hard Mater. 2023, 110, 106043. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, M.-X.; Chang, C.-E.; Chang, B.-Y. Cyclic thermal shock resistance and tribological properties of AlCrSiN, AlTiSiN and AlCrSiN/AlTiSiN multilayer hard coatings. Surf. Coat. Technol. 2025, 496, 131650. [Google Scholar] [CrossRef]

- Wan, Q.; Chen, Y.; Liu, H.; Yang, B. Investigation on oxidation behaviors of Ti-Si-N coating at high temperature. Anti-Corros. Methods Mater. 2018, 65, 125–130. [Google Scholar] [CrossRef]

- Yang, Y.; Liao, N.; Zhang, M.; Li, F. Evaluation of the elastic-plastic properties of SiCN coating system by finite element simulations. J. Eur. Ceram. Soc. 2017, 37, 3891–3897. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Experimental and numerical investigations on the effect of varying AlTiN coating thickness on hard machining performance of Al2O3-TiCN mixed ceramic inserts. Surf. Coat. Technol. 2017, 309, 266–281. [Google Scholar] [CrossRef]

- Kumar, C.S.; Zeman, P.; Polcar, T. A 2D finite element approach for predicting the machining performance of nanolayered TiAlCrN coating on WC-Co cutting tool during dry turning of AISI 1045 steel. Ceram. Int. 2020, 46, 25073–25088. [Google Scholar] [CrossRef]

- Zha, X.; Jiang, F.; Xu, X. Investigating the high frequency fatigue failure mechanisms of mono and multilayer PVD coatings by the cyclic impact tests. Surf. Coat. Technol. 2018, 344, 689–701. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.; Xiong, Z.; Wang, Q. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer coatings. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar] [CrossRef]

- Bertoti, I. Characterization of nitride coatings by XPS. Surf. Coat. Technol. 2002, 151, 194–203. [Google Scholar] [CrossRef]

- Singh, V.; Singh, D. An overview on the preparation, characterization and properties of electrodeposited-metal matrix nanocomposites. Nanosci. Technol. 2014, 1, 1–20. [Google Scholar]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef]

- Modena, M.M.; Rühle, B.; Burg, T.P.; Wuttke, S. Nanoparticle characterization: What to measure? Adv. Mater. 2019, 31, 1901556. [Google Scholar] [CrossRef] [PubMed]

- Aljaafari, A.; Ahmed, F.; Shaalan, N.M.; Kumar, S.; Alsulami, A. Enhanced thermal stability of sputtered TiN thin films for their applications as diffusion barriers against copper interconnect. Inorganics 2023, 11, 204. [Google Scholar] [CrossRef]

- Wang, C.; Geng, Q.; Fan, L.; Li, J.-X.; Ma, L.; Li, C. Phase engineering oriented defect-rich amorphous/crystalline RuO2 nanoporous particles for boosting oxygen evolution reaction in acid media. Nano Res. Energy 2023, 2, e9120070. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Performance analysis and comparative assessment of nano-composite TiAlSiN/TiSiN/TiAlN coating in hard turning of AISI 52100 steel. Surf. Coat. Technol. 2018, 335, 265–279. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Huang, J.-W. Nanostructured AlTiSiN/CrVN/ZrN coatings synthesized by cathodic arc deposition-mechanical properties and cutting performance. Surf. Coat. Technol. 2022, 442, 128424. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Carlet, M.; Schmauder, S.; Guski, V.; Verestek, W.; Tayyab, M. 3D deformation modeling of CrAlN coated tool steel compound during nanoindentation. Surf. Coat. Technol. 2023, 453, 129148. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Tayyab, M. Influence of Cr+ Si content variation on cutting behavior of TiAlCrSiN HPPMS coatings. Surf. Coat. Technol. 2024, 483, 130783. [Google Scholar] [CrossRef]

- Fox-Rabinovitch, G.; Dosbaeva, G.; Kovalev, A.; Gershman, I.; Yamamoto, K.; Locks, E.; Paiva, J.; Konovalov, E.; Veldhuis, S. Enhancement of Multi-Scale Self-Organization Processes during Inconel DA 718 Machining through the Optimization of TiAlCrSiN/TiAlCrN Bi-Nano-Multilayer Coating Characteristics. Materials 2022, 15, 1329. [Google Scholar] [CrossRef]

- Chen, Z.; Lou, M.; Geng, D.; Xu, Y.X.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.; Kim, K.H. Effect of the modulation geometry on mechanical and tribological properties of TiSiN/TiAlN nano-multilayer coatings. Surf. Coat. Technol. 2021, 423, 127586. [Google Scholar] [CrossRef]

- Volosova, M.; Bublikov, J.; Sotova, C.; Sadov, I. Influence of the nanolayer structure of coatings on the cutting properties of tools. MATEC Web Conf. 2020, 329, 02035. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Sitnikov, N.; Aksenenko, A.; Milovich, F.; Andreev, N.; Oganyan, G.; Bublikov, J. Influence of the thickness of multilayer composite nano-structured coating Ti–TiN–(Ti, Al, Si) N on the tool life of metal-cutting tools and the nature of wear. Coatings 2019, 9, 730. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).