Introductory Overview of Layer Formation Techniques of Ag Nanowires on Flexible Polymeric Substrates

Abstract

1. Introduction

2. Methods for Ag nanowire Layer Formation

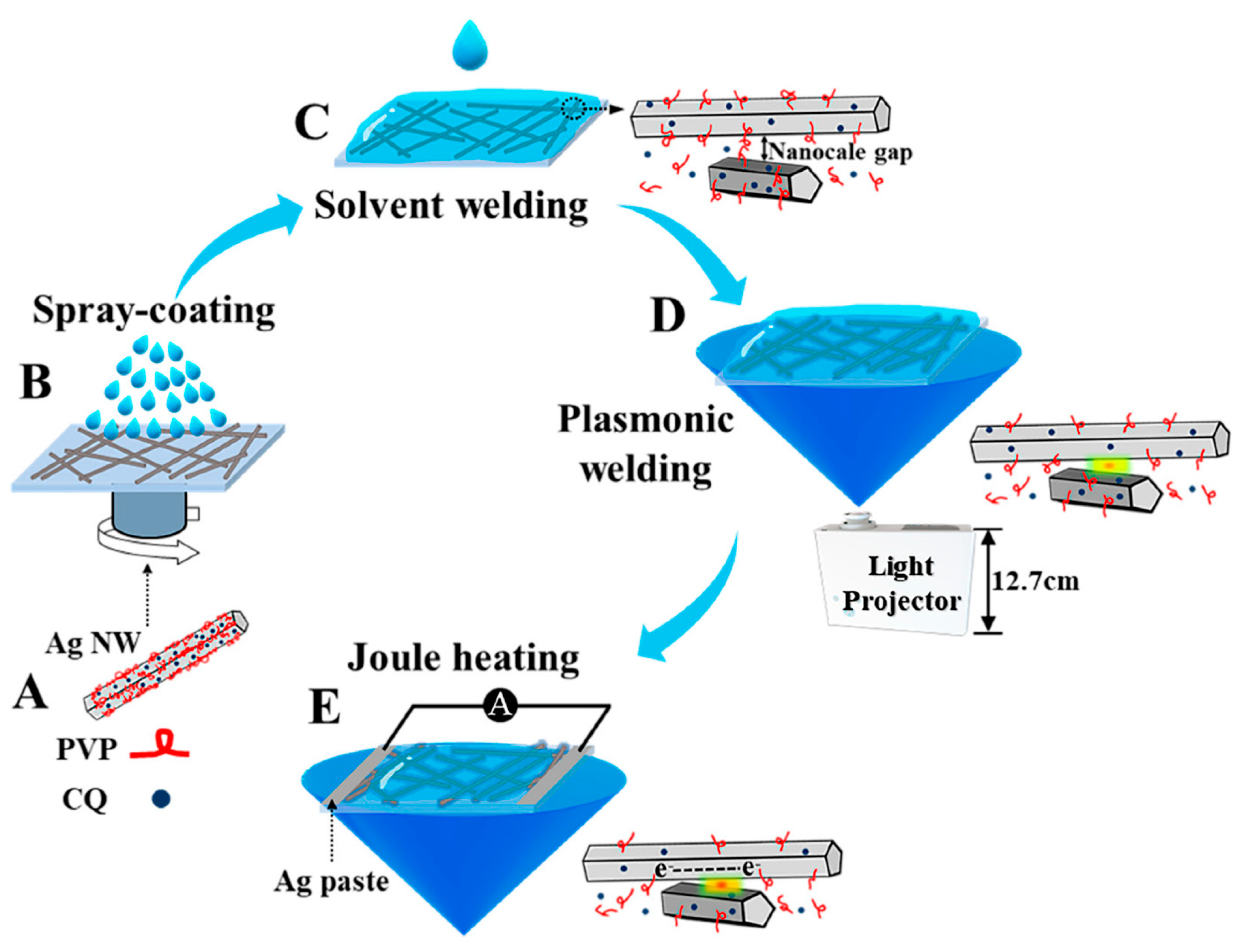

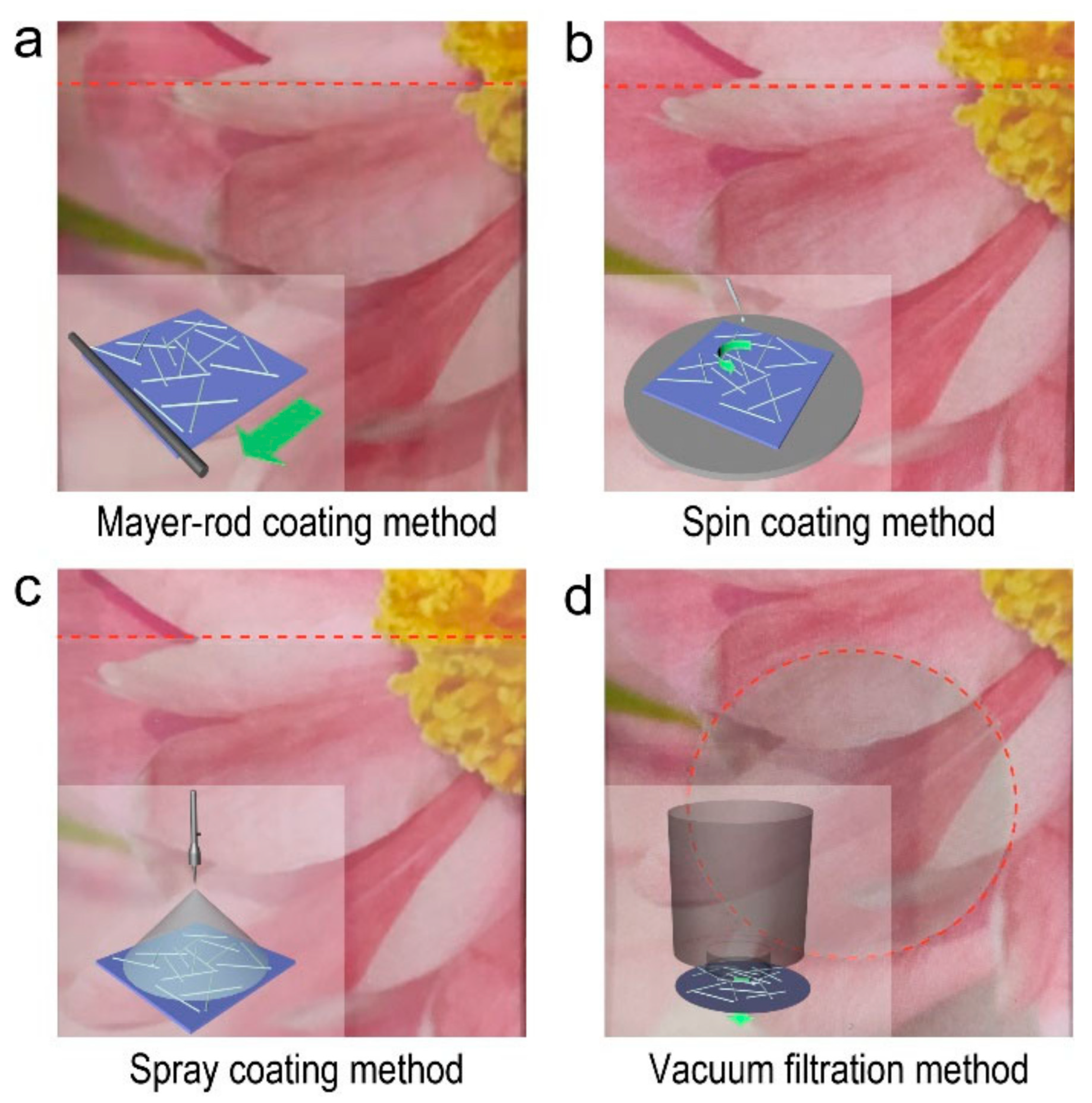

2.1. Spray Coating

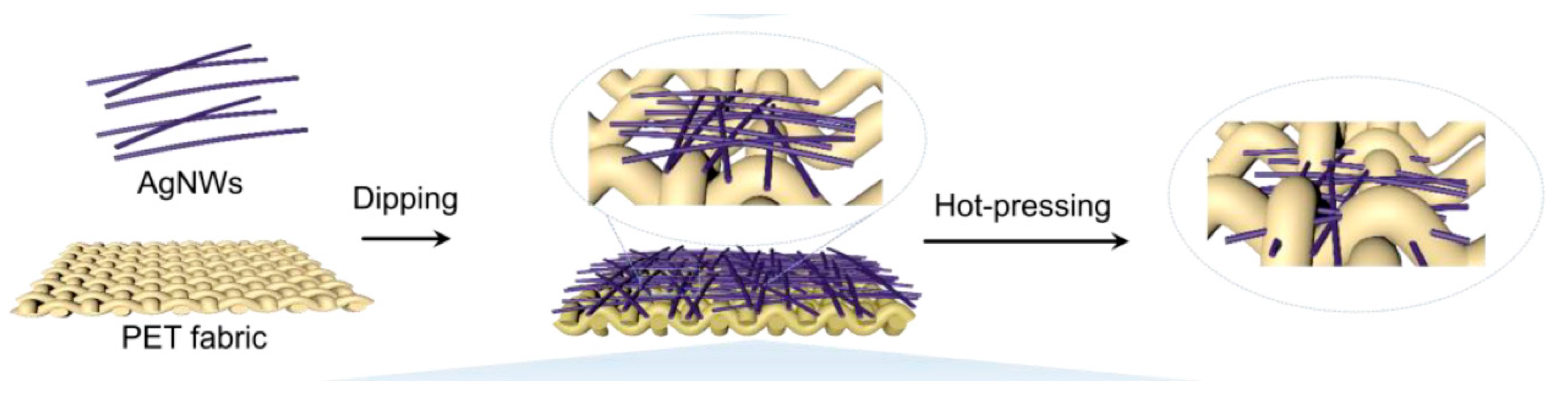

2.2. Dip Coating

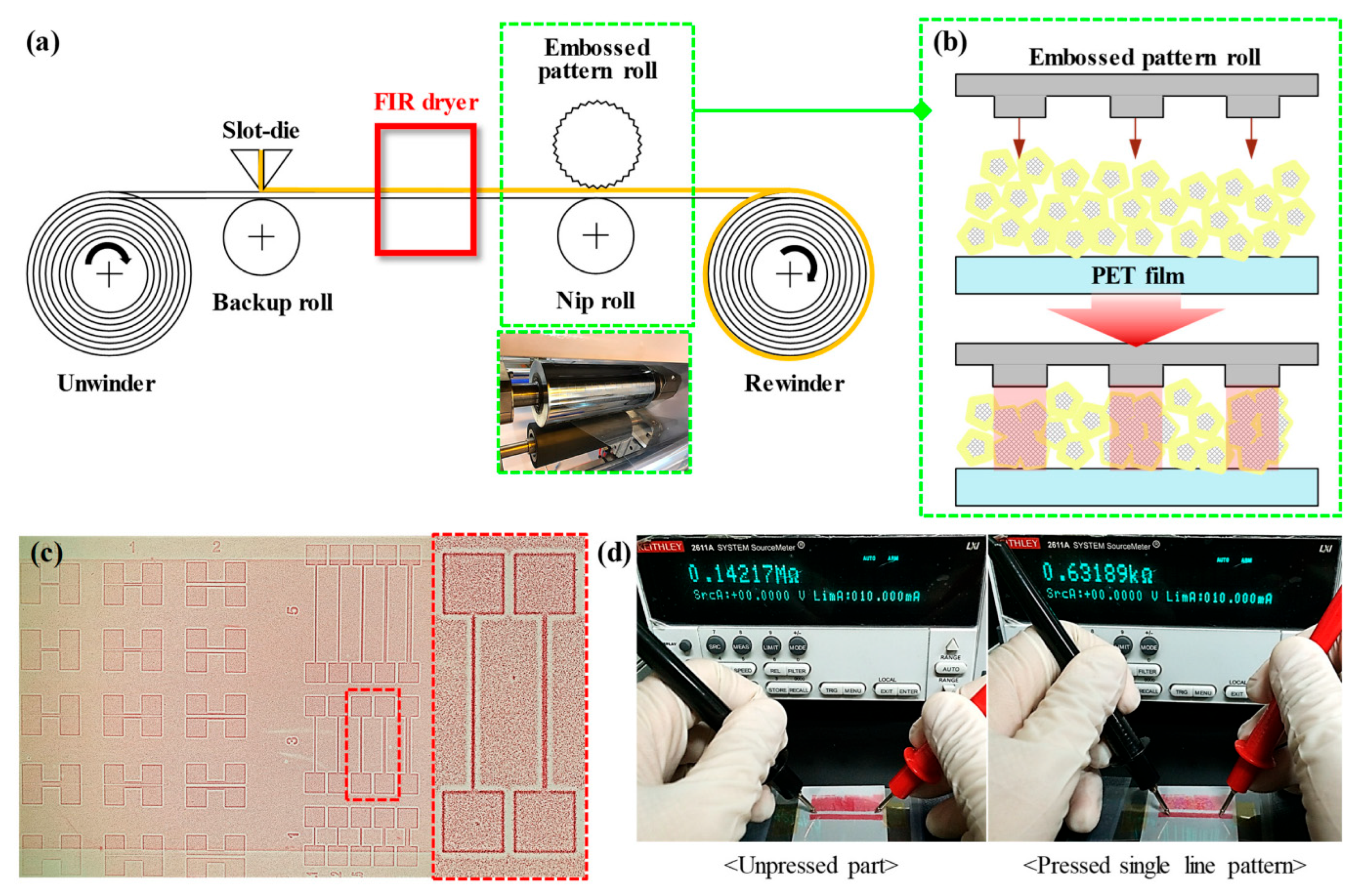

2.3. Roll-to-Roll Coating

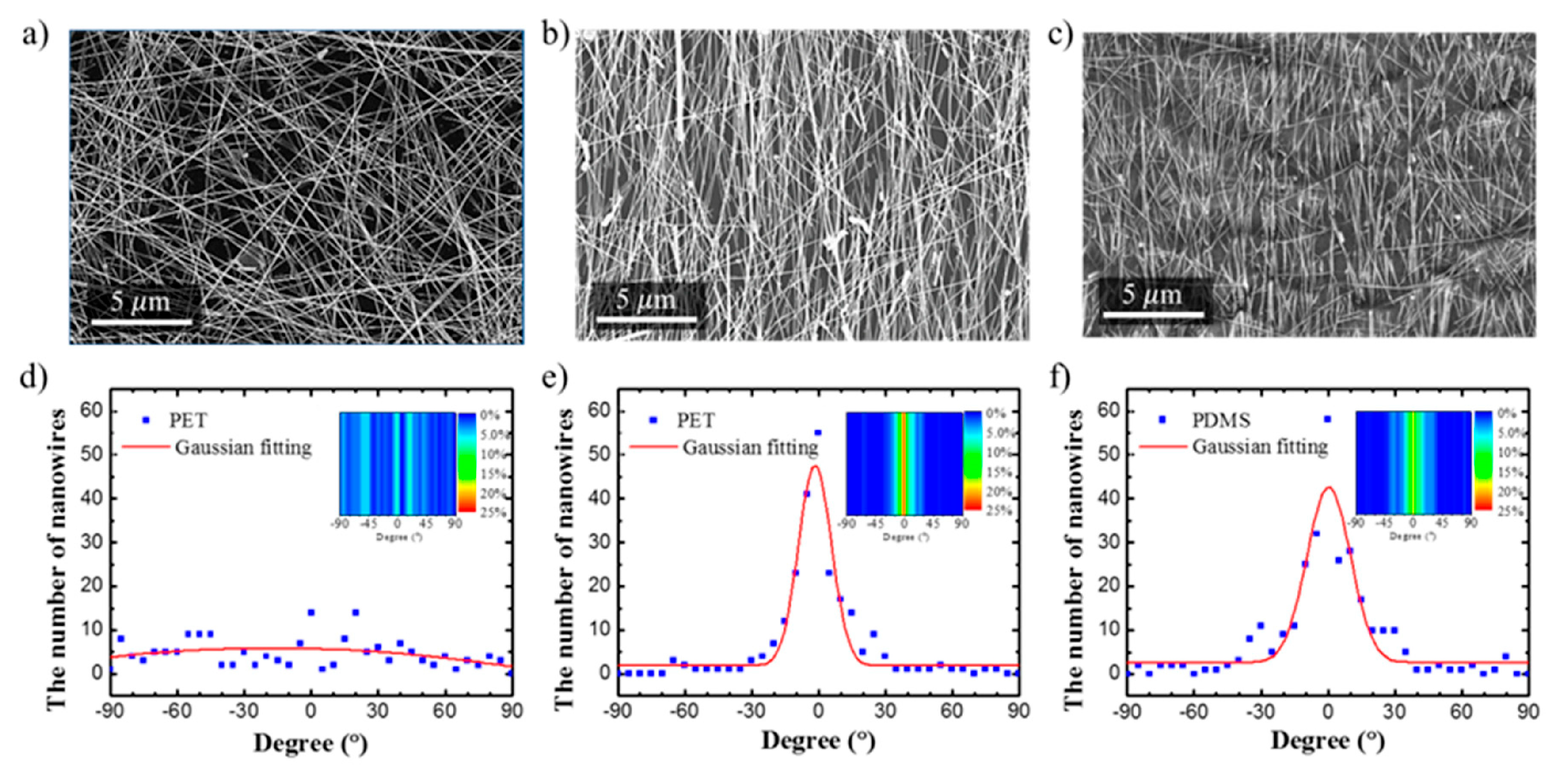

2.4. Spin Coating

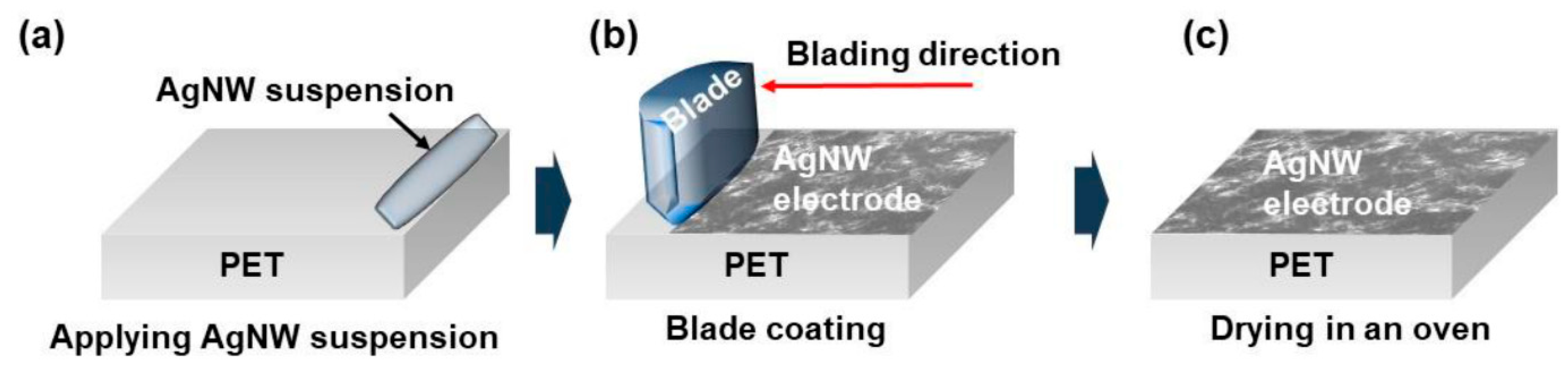

2.5. Doctor-Blade Coating

2.6. Inkjet Printing

2.7. Electrospinning

2.8. Gravure Printing

3. Additional Considerations for Ag Nanowire Layer Formation

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahn, Y.; Jeong, Y.; Lee, Y. Improved Thermal Oxidation Stability of Solution-Processable Silver Nanowire Transparent Electrode by Reduced Graphene Oxide. ACS Appl. Mater. Interfaces 2012, 4, 6410–6414. [Google Scholar] [CrossRef]

- Bai, S.; Guo, X.; Chen, T.; Zhang, Y.; Zhang, X.; Yang, H.; Zhao, X. Solution processed fabrication of silver nanowire-MXene@PEDOT: PSS flexible transparent electrodes for flexible organic light-emitting diodes. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106088. [Google Scholar] [CrossRef]

- Bhadra, R.; Jana, T.; Mitra, A.; Sahoo, P. Effect of CNT radius on flattening contact behaviour of CNT-Al nanocomposite: A numerical approch. Rep. Mech. Eng. 2023, 4, 121–130. [Google Scholar] [CrossRef]

- Basarir, F.; Madani, Z.; Vapaavuori, J. Recent Advances in Silver Nanowire Based Flexible Capacitive Pressure Sensors: From Structure, Fabrication to Emerging Applications. Adv. Mater. Interfaces 2022, 9, 2200866. [Google Scholar] [CrossRef]

- Bobinger, M.; Hinterleuthner, S.; Becherer, M.; Keddis, S.; Schwesinger, N.; Lugli, P. Energy harvesting from ambient light using PVDF with highly conductive and transparent silver nanowire/PEDOT:PSS hybride electrodes. In Proceedings of the 2017 IEEE 17th International Conference on Nanotechnology (IEEE-NANO), Pittsburgh, PA, USA, 25–28 July 2017; pp. 426–429. [Google Scholar]

- Hwang, B.; Han, Y.; Matteini, P. Bending Fatigue Behavior of Ag Nanowire/Cu Thin-Film Hybrid Interconnects for Wearable Electronics. Facta Univ. Ser. Mech. Eng. 2022, 20, 553–560. [Google Scholar] [CrossRef]

- Milić, P.; Marinković, D.; Klinge, S.; Cojbašić, Ž. Reissner-Mindlin Based Isogeometric Finite Element Formulation for Piezoelectric Active Laminated Shells. Teh. Vjesn. 2023, 30, 416–425. [Google Scholar] [CrossRef]

- Milić, P.; Marinković, D.; Ćojbašić, Ž. Geometrically Nonlinear Analysis of Piezoelectric Active Laminated Shells by Means of Isogeometric Fe Formulation. Facta Univ. Ser. Mech. Eng. 2023. online first. [Google Scholar] [CrossRef]

- Bobinger, M.; Keddis, S.; Hinterleuthner, S.; Becherer, M.; Kluge, F.; Schwesinger, N.; Salmerón, J.F.; Lugli, P.; Rivadeneyra, A. Light and Pressure Sensors Based on PVDF with Sprayed and Transparent Electrodes for Self-Powered Wireless Sensor Nodes. IEEE Sens. J. 2019, 19, 1114–1126. [Google Scholar] [CrossRef]

- Ayham, N.G.; Zuheir Fadhel, E.; Hashem Abbud, L. Investigation of the mechanical properties of nanocomposites with multi-wall carbon nanotube reinforcement and carbon fiber/epoxy. Rep. Mech. Eng. 2023, 4, 153–160. [Google Scholar] [CrossRef]

- Chen, S.; Song, L.; Tao, Z.; Shao, X.; Huang, Y.; Cui, Q.; Guo, X. Neutral-pH PEDOT:PSS as over-coating layer for stable silver nanowire flexible transparent conductive films. Org. Electron. 2014, 15, 3654–3659. [Google Scholar] [CrossRef]

- Cho, S.; Kang, S.; Pandya, A.; Shanker, R.; Khan, Z.; Lee, Y.; Park, J.; Craig, S.L.; Ko, H. Large-Area Cross-Aligned Silver Nanowire Electrodes for Flexible, Transparent, and Force-Sensitive Mechanochromic Touch Screens. ACS Nano 2017, 11, 4346–4357. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.H.; Lee, K.Y.; Kim, S.W. Ultra-bendable and durable Graphene–Urethane composite/silver nanowire film for flexible transparent electrodes and electromagnetic-interference shielding. Compos. Part B Eng. 2019, 177, 107406. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, C.S.; Jo, S. Spray Deposition of Ag Nanowire–Graphene Oxide Hybrid Electrodes for Flexible Polymer–Dispersed Liquid Crystal Displays. Materials 2018, 11, 2231. [Google Scholar] [CrossRef] [PubMed]

- Fang, F.; Huang, G.-W.; Xiao, H.-M.; Li, Y.-Q.; Hu, N.; Fu, S.-Y. Largely enhanced electrical conductivity of layer-structured silver nanowire/polyimide composite films by polyaniline. Compos. Sci. Technol. 2018, 156, 144–150. [Google Scholar] [CrossRef]

- Hwang, B.; Lund, A.; Tian, Y.; Darabi, S.; Müller, C. Machine-Washable Conductive Silk Yarns with a Composite Coating of Ag Nanowires and PEDOT:PSS. ACS Appl. Mater. Interfaces 2020, 12, 27537–27544. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Qaiser, N.; Hwang, B. Electro-Mechanical Response of Stretchable PDMS Composites with a Hybrid Filler System. Facta Univ. Ser. Mech. Eng. 2023, 21, 51–61. [Google Scholar] [CrossRef]

- Ghosh, D.S.; Chen, T.L.; Mkhitaryan, V.; Pruneri, V. Ultrathin Transparent Conductive Polyimide Foil Embedding Silver Nanowires. ACS Appl. Mater. Interfaces 2014, 6, 20943–20948. [Google Scholar] [CrossRef]

- Leroy, J.-E.; Popov, V.L. Stress tensor in the linear viscoelastic incompressible half-space beneath axisymmetric bodies in normal contact. Rep. Mech. Eng. 2023, 4, 310–316. [Google Scholar] [CrossRef]

- Ha, H.; Müller, S.; Baumann, R.-P.; Hwang, B. PeakForce Quantitative Nanomechanical Mapping for Surface Energy Characterization on the Nanoscale: A Mini-Review. Facta Univ. Ser. Mech. Eng. 2023. online first. [Google Scholar] [CrossRef]

- Gao, D.; Zhao, P.; Liu, J.; Zhou, Y.; Lyu, B.; Ma, J.; Shao, L. Polyaniline/silver nanowire cotton fiber: A flexible electrode material for supercapacitor. Adv. Powder Technol. 2021, 32, 3954–3963. [Google Scholar] [CrossRef]

- Ha, H.; Amicucci, C.; Matteini, P.; Hwang, B. Mini review of synthesis strategies of silver nanowires and their applications. Colloid Interface Sci. Commun. 2022, 50, 100663. [Google Scholar] [CrossRef]

- Bzinkowski, D.; Ryba, T.; Siemiatkowski, Z.; Rucki, M. Real-time monitoring of the rubber belt tension in an industrial conveyor. Rep. Mech. Eng. 2022, 3, 1–10. [Google Scholar] [CrossRef]

- Ha, H.; Qaiser, N.; Yun, T.G.; Cheong, J.Y.; Lim, S.; Hwang, B. Sensing Mechanism and Application of Mechanical Strain Sensor: A Mini-Review. Facta Univ. Ser. Mech. Eng. 2023, 21, 751–772. [Google Scholar] [CrossRef]

- Seo, Y.; Hwang, B. Mulberry-paper-based composites for flexible electronics and energy storage devices. Cellulose 2019, 26, 8867–8875. [Google Scholar] [CrossRef]

- Shah, K.W.; Xiong, T. Multifunctional Metallic Nanowires in Advanced Building Applications. Materials 2019, 12, 1731. [Google Scholar] [CrossRef]

- Nam, V.B.; Lee, D. Copper Nanowires and Their Applications for Flexible, Transparent Conducting Films: A Review. Nanomaterials 2016, 6, 47. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, H.; Chen, Y.; Zheng, M.; Zhao, Y.; Kong, X.; Wang, Y.; Zhang, X.; Kong, X.; Wang, P.; et al. Highly Conductive, Air-Stable Silver Nanowire@Iongel Composite Films toward Flexible Transparent Electrodes. Adv. Mater. 2016, 28, 7167–7172. [Google Scholar] [CrossRef]

- Lian, L.; Dong, D.; Feng, D.; He, G. Low roughness silver nanowire flexible transparent electrode by low temperature solution-processing for organic light emitting diodes. Org. Electron. 2017, 49, 9–18. [Google Scholar] [CrossRef]

- Luo, M.; Liu, Y.; Huang, W.; Qiao, W.; Zhou, Y.; Ye, Y.; Chen, L.-S. Towards Flexible Transparent Electrodes Based on Carbon and Metallic Materials. Micromachines 2017, 8, 12. [Google Scholar] [CrossRef]

- Morales-Masis, M.; De Wolf, S.; Woods-Robinson, R.; Ager, J.W.; Ballif, C. Transparent Electrodes for Efficient Optoelectronics. Adv. Electron. Mater. 2017, 3, 1600529. [Google Scholar] [CrossRef]

- Hwang, B.; Yun, T.G. Stretchable and patchable composite electrode with trimethylolpropane formal acrylate-based polymer. Compos. Part B Eng. 2019, 163, 185–192. [Google Scholar] [CrossRef]

- Xie, H.; Yang, X.; Du, D.; Zhao, Y.; Wang, Y. Flexible Transparent Conductive Film Based on Random Networks of Silver Nanowires. Micromachines 2018, 9, 295. [Google Scholar] [CrossRef]

- He, X.; Shen, G.; Xu, R.; Yang, W.; Zhang, C.; Liu, Z.; Chen, B.; Liu, J.; Song, M. Hexagonal and Square Patterned Silver Nanowires/PEDOT:PSS Composite Grids by Screen Printing for Uniformly Transparent Heaters. Polymers 2019, 11, 468. [Google Scholar] [CrossRef]

- Khadtare, S.; Ko, E.J.; Kim, Y.H.; Lee, H.S.; Moon, D.K. A flexible piezoelectric nanogenerator using conducting polymer and silver nanowire hybrid electrodes for its application in real-time muscular monitoring system. Sens. Actuators A Phys. 2019, 299, 111575. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, X.; Li, D.; Yu, H.; Li, X.; Guo, F. Solvent Welding-Based Methods Gently and Effectively Enhance the Conductivity of a Silver Nanowire Network. Nanomaterials 2023, 13, 2865. [Google Scholar] [CrossRef]

- Sohn, H.; Park, C.; Oh, J.-M.; Kang, S.W.; Kim, M.-J. Silver Nanowire Networks: Mechano-Electric Properties and Applications. Materials 2019, 12, 2526. [Google Scholar] [CrossRef]

- Gorji, M.; Mazinani, S.; Faramarzi, A.-R.; Ghadimi, S.; Kalaee, M.; Sadeghianmaryan, A.; Wilson, L.D. Coating Cellulosic Material with Ag Nanowires to Fabricate Wearable IR-Reflective Device for Personal Thermal Management: The Role of Coating Method and Loading Level. Molecules 2021, 26, 3570. [Google Scholar] [CrossRef]

- Kim, J.-H.; Ma, J.; Jo, S.; Lee, S.; Kim, C.S. Enhancement of Antibacterial Performance of Silver Nanowire Transparent Film by Post-Heat Treatment. Nanomaterials 2020, 10, 938. [Google Scholar] [CrossRef]

- Jin, I.S.; Lee, H.D.; Hong, S.I.; Lee, W.; Jung, J.W. Facile Post Treatment of Ag Nanowire/Polymer Composites for Flexible Transparent Electrodes and Thin Film Heaters. Polymers 2021, 13, 586. [Google Scholar] [CrossRef]

- Kumar, A.; Shaikh, M.O.; Chuang, C.-H. Silver Nanowire Synthesis and Strategies for Fabricating Transparent Conducting Electrodes. Nanomaterials 2021, 11, 693. [Google Scholar] [CrossRef]

- Choi, J.H.; Shin, M.G.; Jung, Y.; Kim, D.H.; Ko, J.S. Fabrication and Performance Evaluation of Highly Sensitive Flexible Strain Sensors with Aligned Silver Nanowires. Micromachines 2020, 11, 156. [Google Scholar] [CrossRef]

- Zeng, F.; Zheng, Y.; Wei, Y.; Li, H.; Wang, Q.; Shi, J.; Wang, Y.; Hong, X. Multifunctional Silver Nanowire Fabric Reinforced by Hot Pressing for Electromagnetic Interference Shielding, Electric Heating, and Sensing. Polymers 2023, 15, 4258. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, S. Cantilever Type Acceleration Sensors Made by Roll-to-Roll Slot-Die Coating. Sensors 2020, 20, 3748. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Shan, J.; Li, Z.; Guo, X.; Zhao, X.; Yang, H. Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating. Materials 2022, 15, 2634. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, G.; Kim, H.-K. Study of Brush-Painted Ag Nanowire Network on Flexible Invar Metal Substrate for Curved Thin Film Heater. Metals 2019, 9, 1073. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, Z.; Wang, Y.; Li, J. Syntheses of Silver Nanowires Ink and Printable Flexible Transparent Conductive Film: A Review. Coatings 2020, 10, 865. [Google Scholar] [CrossRef]

- Jeong, H.; Lee, J.H.; Song, J.-Y.; Ghani, F.; Lee, D. Continuous Patterning of Silver Nanowire-Polyvinylpyrrolidone Composite Transparent Conductive Film by a Roll-to-Roll Selective Calendering Process. Nanomaterials 2023, 13, 32. [Google Scholar] [CrossRef]

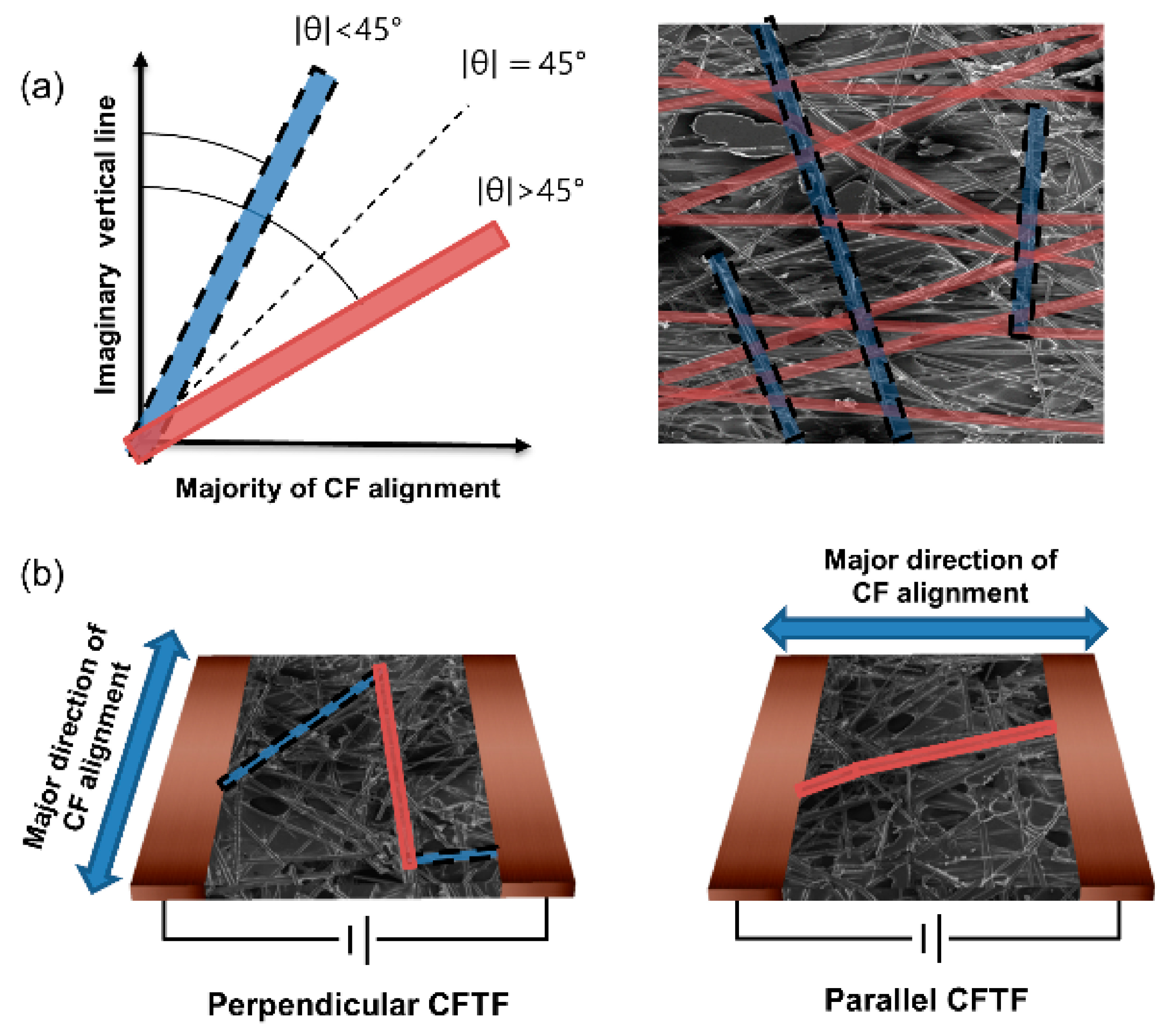

- Lim, S.-H.; Kim, H.-K. Thermal Profiles of Carbon Fiber Based Anisotropic Thin-Films: An Emerging Heat Management Solution for High-Current Flow Electrocatalysis and Electrochemical Applications. Catalysts 2020, 10, 1172. [Google Scholar] [CrossRef]

- Xu, H.; Liu, P.; Huang, B.; Jiang, X.; Gao, Q.; Liu, L. Preparation of Double-Layer Crossed Silver Nanowire Film and Its Application to OLED. Coatings 2022, 12, 26. [Google Scholar] [CrossRef]

- Camic, B.T.; Jeong, H.I.; Aslan, M.H.; Kosemen, A.; Kim, S.; Choi, H.; Basarir, F.; Lee, B.R. Preparation of Transparent Conductive Electrode via Layer-By-Layer Deposition of Silver Nanowires and Its Application in Organic Photovoltaic Device. Nanomaterials 2020, 10, 46. [Google Scholar] [CrossRef]

- Heo, S.W. Ultra-Flexible Organic Photovoltaics with Nanograting Patterns Based on CYTOP/Ag Nanowires Substrate. Nanomaterials 2020, 10, 2185. [Google Scholar] [CrossRef]

- Li, X.; Zhou, J.; Yan, D.; Peng, Y.; Wang, Y.; Zhou, Q.; Wang, K. Effects of Concentration and Spin Speed on the Optical and Electrical Properties of Silver Nanowire Transparent Electrodes. Materials 2021, 14, 2219. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, X.; Xu, J.; Xu, R.; Yang, H.; Kan, C. Comparative Study on Preparation Methods for Transparent Conductive Films Based on Silver Nanowires. Molecules 2022, 27, 8907. [Google Scholar] [CrossRef]

- Lee, G.; Kim, H.; Lee, S.B.; Kim, D.; Lee, E.; Lee, S.K.; Lee, S.G. Tailored Uniaxial Alignment of Nanowires Based on Off-Center Spin-Coating for Flexible and Transparent Field-Effect Transistors. Nanomaterials 2022, 12, 1116. [Google Scholar] [CrossRef]

- Wang, J.; Yu, J.; Bai, D.; Li, Z.; Liu, H.; Li, Y.; Chen, S.; Cheng, J.; Li, L. Biodegradable, Flexible, and Transparent Conducting Silver Nanowires/Polylactide Film with High Performance for Optoelectronic Devices. Polymers 2020, 12, 604. [Google Scholar] [CrossRef]

- Yang, X.; Du, D.; Wang, Y.; Zhao, Y. Silver Nanowires Inks for Flexible Circuit on Photographic Paper Substrate. Micromachines 2019, 10, 22. [Google Scholar] [CrossRef]

- Kong, J.; Wang, Y.; Wu, Y.; Zhang, L.; Gong, M.; Lin, X.; Wang, D. Toward High-Energy-Density Aqueous Lithium-Ion Batteries Using Silver Nanowires as Current Collectors. Molecules 2022, 27, 8207. [Google Scholar] [CrossRef]

- Yoon, H.; Matteini, P.; Hwang, B. Effect of the Blade-Coating Conditions on the Electrical and Optical Properties of Transparent Ag Nanowire Electrodes. Micromachines 2023, 14, 114. [Google Scholar] [CrossRef]

- Du, D.; Yang, X.; Yang, Y.; Zhao, Y.; Wang, Y. Silver Nanowire Ink for Flexible Circuit on Textiles. Micromachines 2019, 10, 42. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Lu, J.; Luo, Z.; Xie, H.; Zhang, X.; Lin, K.; Wang, Y. Inkjet-Printed Silver Nanowire Ink for Flexible Transparent Conductive Film Applications. Nanomaterials 2022, 12, 842. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Wang, K.; Lin, K.; Xie, H.; Zhang, X.; Li, J. Novel Insights into Inkjet Printed Silver Nanowires Flexible Transparent Conductive Films. Int. J. Mol. Sci. 2021, 22, 7719. [Google Scholar] [CrossRef]

- Ke, S.-H.; Xue, Q.-W.; Pang, C.-Y.; Guo, P.-W.; Yao, W.-J.; Zhu, H.-P.; Wu, W. Printing the Ultra-Long Ag Nanowires Inks onto the Flexible Textile Substrate for Stretchable Electronics. Nanomaterials 2019, 9, 686. [Google Scholar] [CrossRef]

- Wu, X.; Wang, S.; Luo, Z.; Lu, J.; Lin, K.; Xie, H.; Wang, Y.; Li, J.-Z. Inkjet Printing of Flexible Transparent Conductive Films with Silver Nanowires Ink. Nanomaterials 2021, 11, 1571. [Google Scholar] [CrossRef]

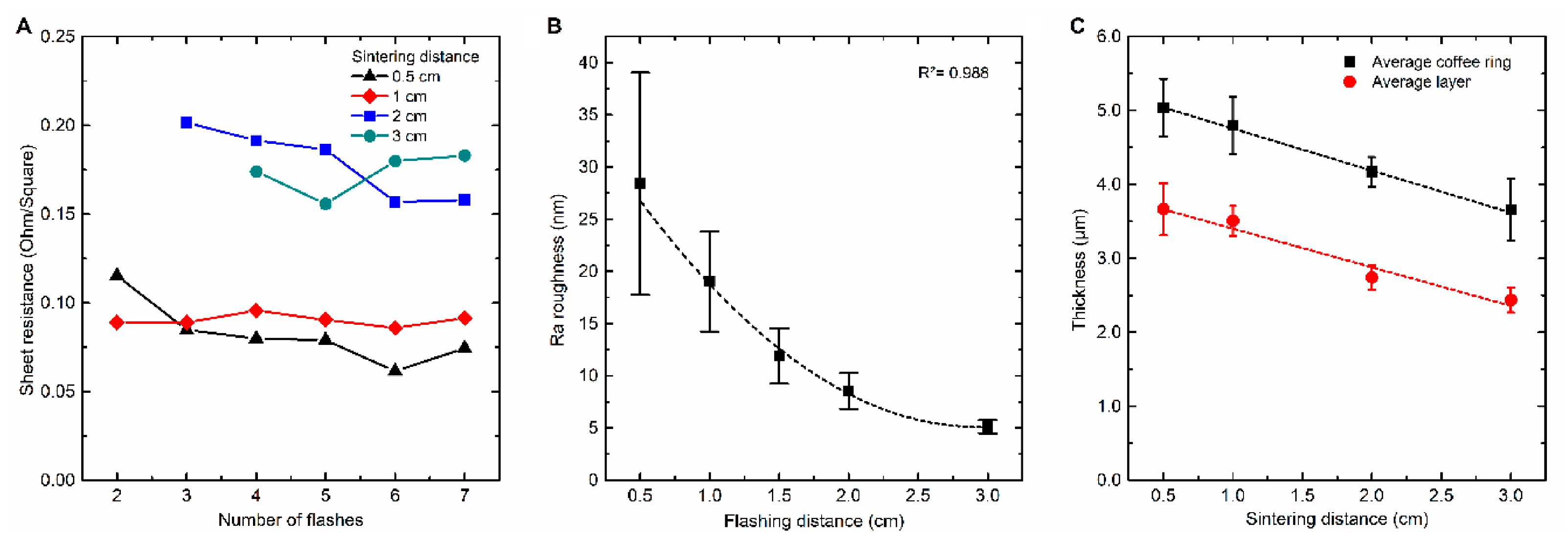

- Reenaers, D.; Marchal, W.; Biesmans, I.; Nivelle, P.; D’Haen, J.; Deferme, W. Layer Morphology and Ink Compatibility of Silver Nanoparticle Inkjet Inks for Near-Infrared Sintering. Nanomaterials 2020, 10, 892. [Google Scholar] [CrossRef]

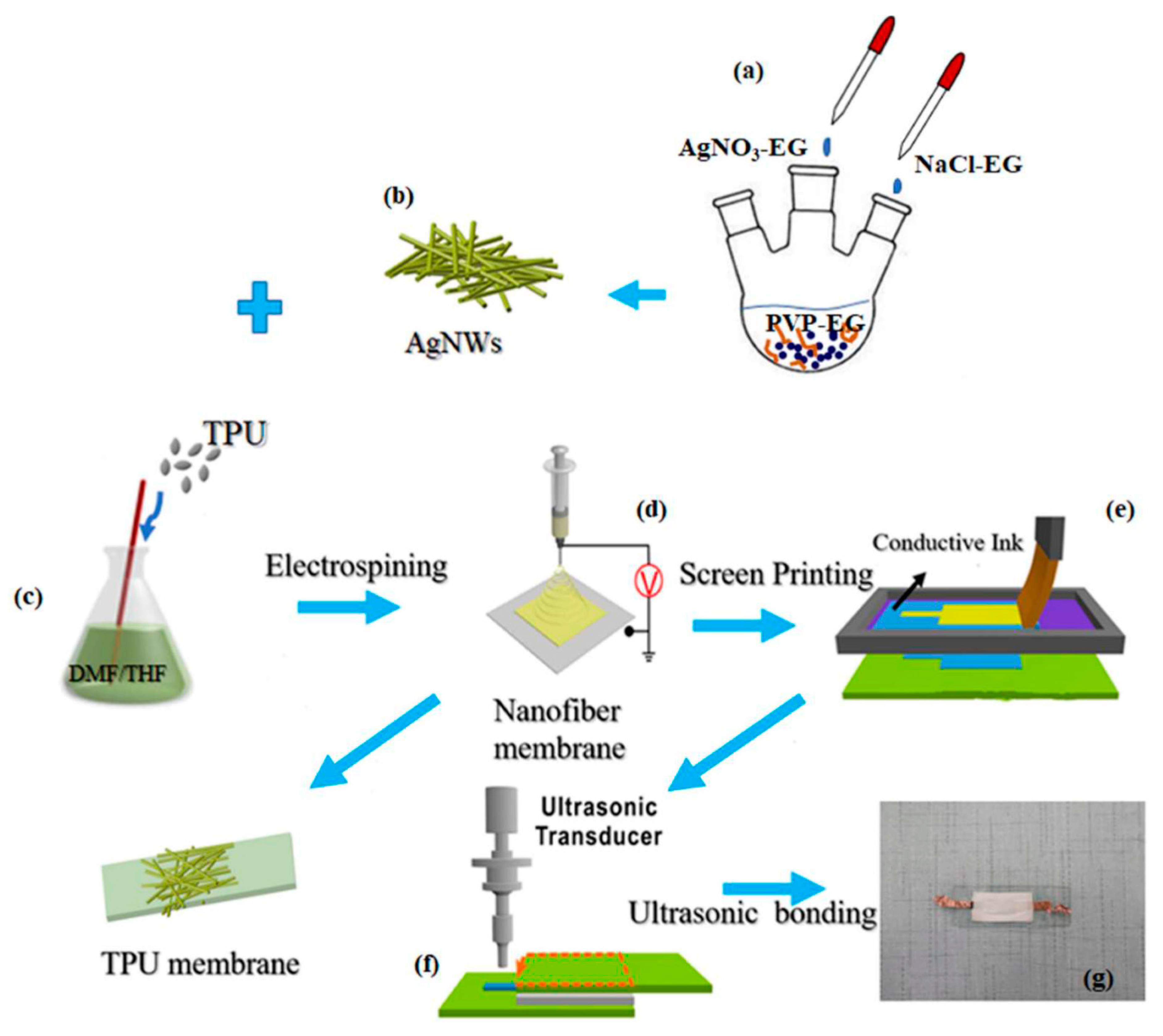

- Wang, J.; Lou, Y.; Wang, B.; Sun, Q.; Zhou, M.; Li, X. Highly Sensitive, Breathable, and Flexible Pressure Sensor Based on Electrospun Membrane with Assistance of AgNW/TPU as Composite Dielectric Layer. Sensors 2020, 20, 2459. [Google Scholar] [CrossRef]

- Li, B.; Xu, C.; Zheng, J.; Xu, C. Sensitivity of Pressure Sensors Enhanced by Doping Silver Nanowires. Sensors 2014, 14, 9889–9899. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Z.; Zheng, Y.; Zhang, Q.; He, B.; Yang, J.; Qi, M.; Wei, L. Flexible Tactile Sensor Based on Patterned Ag-Nanofiber Electrodes through Electrospinning. Sensors 2021, 21, 2413. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Y.; Wang, J.; Xu, Y.; Zhang, G.; Leng, C. Preparation and Antibiosis Investigation of Kaolinite Nanotubes and Silver Nanowires Co-Doped Electrospinning-Silk Fibroin/Gelatin Porous Fiber Films. Metals 2023, 13, 745. [Google Scholar] [CrossRef]

- Wang, X.; Sun, F.; Yin, G.; Wang, Y.; Liu, B.; Dong, M. Tactile-Sensing Based on Flexible PVDF Nanofibers via Electrospinning: A Review. Sensors 2018, 18, 330. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Kim, J.-H.; Yeo, W.-H. Advanced Nanomaterials, Printing Processes, and Applications for Flexible Hybrid Electronics. Materials 2020, 13, 3587. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, W.; Li, Y.; Yi, Z.; Zhou, G. Fabrication of Screen Printing-Based AgNWs Flexible Transparent Conductive Film with High Stability. Micromachines 2020, 11, 1027. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef]

- Giasafaki, D.; Mitzithra, C.; Belessi, V.; Filippakopoulou, T.; Koutsioukis, A.; Georgakilas, V.; Charalambopoulou, G.; Steriotis, T. Graphene-Based Composites with Silver Nanowires for Electronic Applications. Nanomaterials 2022, 12, 3443. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Jalabert, T.; Pusty, M.; Defoor, V.; Mescot, X.; Montanino, M.; Sico, G.; Loffredo, F.; Villani, F.; Nenna, G.; et al. Size and Semiconducting Effects on the Piezoelectric Performances of ZnO Nanowires Grown onto Gravure-Printed Seed Layers on Flexible Substrates. Nanoenergy Adv. 2022, 2, 197–209. [Google Scholar] [CrossRef]

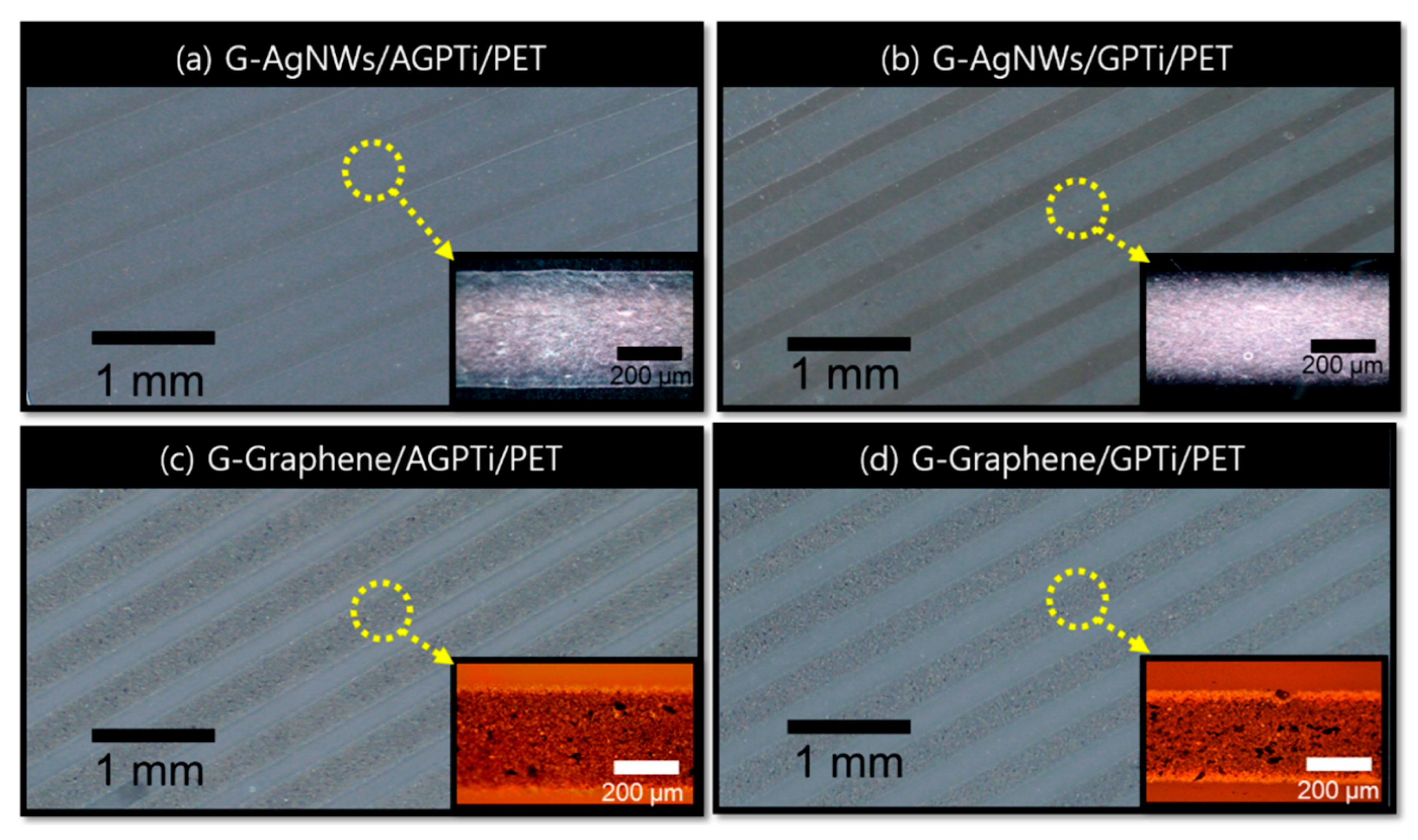

- Li, X.; Kim, N.; Youn, S.; An, T.K.; Kim, J.; Lim, S.; Kim, S.H. Sol–Gel-Processed Organic–Inorganic Hybrid for Flexible Conductive Substrates Based on Gravure-Printed Silver Nanowires and Graphene. Polymers 2019, 11, 158. [Google Scholar] [CrossRef]

- Huang, C.-H.; Wang, Y.-Y.; Lu, T.-H.; Li, Y.-C. Flexible Transparent Electrode of Hybrid Ag-Nanowire/Reduced-Graphene-Oxide Thin Film on PET Substrate Prepared Using H2/Ar Low-Damage Plasma. Polymers 2017, 9, 28. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Weng, W.-C.; Yeh, Y.-C. Continuous Wave Laser Nanowelding Process of Ag Nanowires on Flexible Polymer Substrates. Nanomaterials 2021, 11, 2511. [Google Scholar] [CrossRef] [PubMed]

- Zacharatos, F.; Karvounis, P.; Theodorakos, I.; Hatziapostolou, A.; Zergioti, I. Single Step Laser Transfer and Laser Curing of Ag NanoWires: A Digital Process for the Fabrication of Flexible and Transparent Microelectrodes. Materials 2018, 11, 1036. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.; Wen, L.; Tak, H.; Kim, H.; Kim, G.; Hong, J.; Chang, W.; Kim, D.; Yeom, G. Radio Frequency Induction Welding of Silver Nanowire Networks for Transparent Heat Films. Materials 2021, 14, 4448. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Li, X.; Xu, Y.; Wu, L.; Yu, A.; Lai, G.; Wei, Q.; Chi, H.; Jiang, N.; Fu, L.; et al. Intertwined Carbon Nanotubes and Ag Nanowires Constructed by Simple Solution Blending as Sensitive and Stable Chloramphenicol Sensors. Sensors 2021, 21, 1220. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.; Hernandez, Y.; Feng, X.; Müllen, K. Graphene as Transparent Electrode Material for Organic Electronics. Adv. Mater. 2011, 23, 2779–2795. [Google Scholar] [CrossRef] [PubMed]

- Tokuno, T.; Nogi, M.; Karakawa, M.; Jiu, J.; Nge, T.T.; Aso, Y.; Suganuma, K. Fabrication of silver nanowire transparent electrodes at room temperature. Nano Res. 2011, 4, 1215–1222. [Google Scholar] [CrossRef]

- Hu, W.; Niu, X.; Zhao, R.; Pei, Q. Elastomeric transparent capacitive sensors based on an interpenetrating composite of silver nanowires and polyurethane. Appl. Phys. Lett. 2013, 102, 083303. [Google Scholar] [CrossRef]

- Kim, A.; Won, Y.; Woo, K.; Kim, C.-H.; Moon, J. Highly Transparent Low Resistance ZnO/Ag Nanowire/ZnO Composite Electrode for Thin Film Solar Cells. ACS Nano 2013, 7, 1081–1091. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Lee, H.; Ahn, Y.; Jeong, Y.; Lee, D.-Y.; Lee, Y. Highly stable and flexible silver nanowire–graphene hybrid transparent conducting electrodes for emerging optoelectronic devices. Nanoscale 2013, 5, 7750–7755. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, H.; Qaiser, N.; Hwang, B. Introductory Overview of Layer Formation Techniques of Ag Nanowires on Flexible Polymeric Substrates. Inorganics 2024, 12, 65. https://doi.org/10.3390/inorganics12030065

Ha H, Qaiser N, Hwang B. Introductory Overview of Layer Formation Techniques of Ag Nanowires on Flexible Polymeric Substrates. Inorganics. 2024; 12(3):65. https://doi.org/10.3390/inorganics12030065

Chicago/Turabian StyleHa, Heebo, Nadeem Qaiser, and Byungil Hwang. 2024. "Introductory Overview of Layer Formation Techniques of Ag Nanowires on Flexible Polymeric Substrates" Inorganics 12, no. 3: 65. https://doi.org/10.3390/inorganics12030065

APA StyleHa, H., Qaiser, N., & Hwang, B. (2024). Introductory Overview of Layer Formation Techniques of Ag Nanowires on Flexible Polymeric Substrates. Inorganics, 12(3), 65. https://doi.org/10.3390/inorganics12030065