Flat Optical Frequency Comb Generation Based on Monolithic Integrated LNOI Intensity and Phase Modulator

Abstract

:1. Introduction

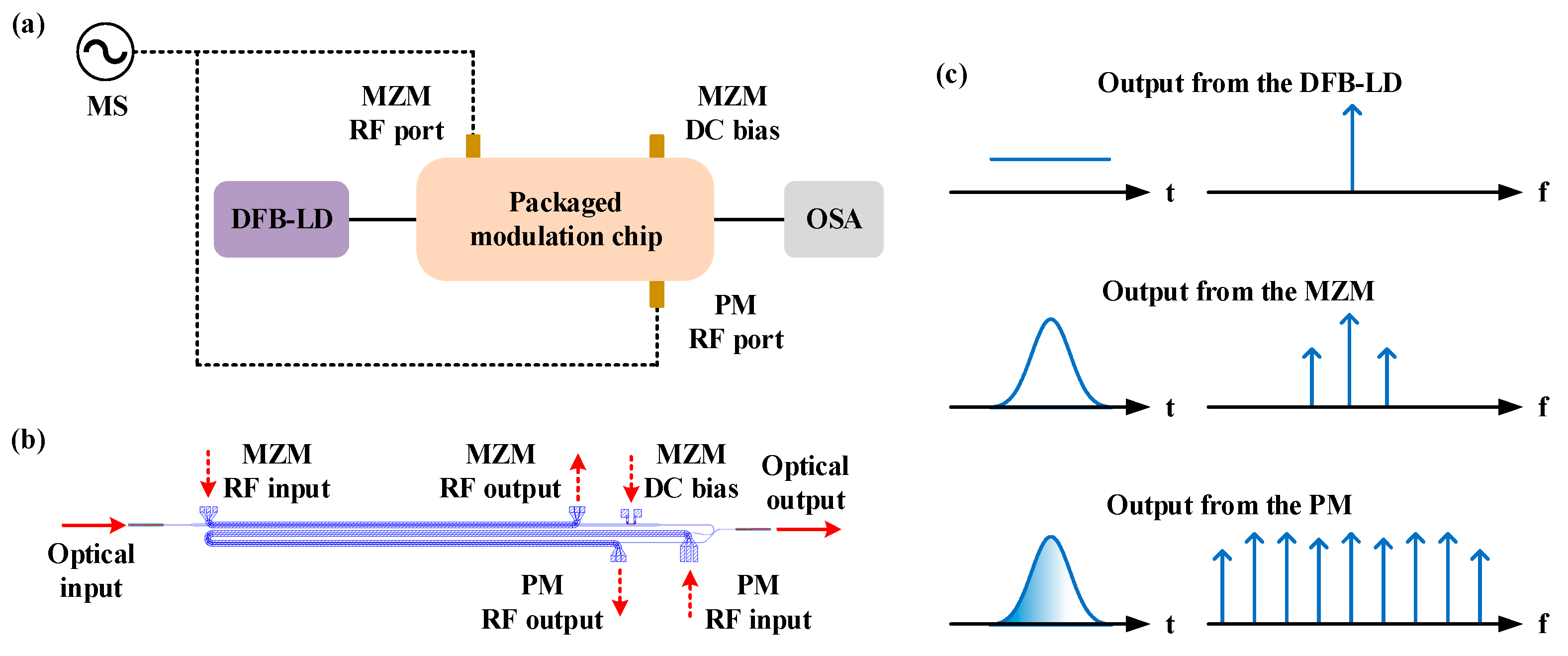

2. Operation Principle

3. Results and Discussion

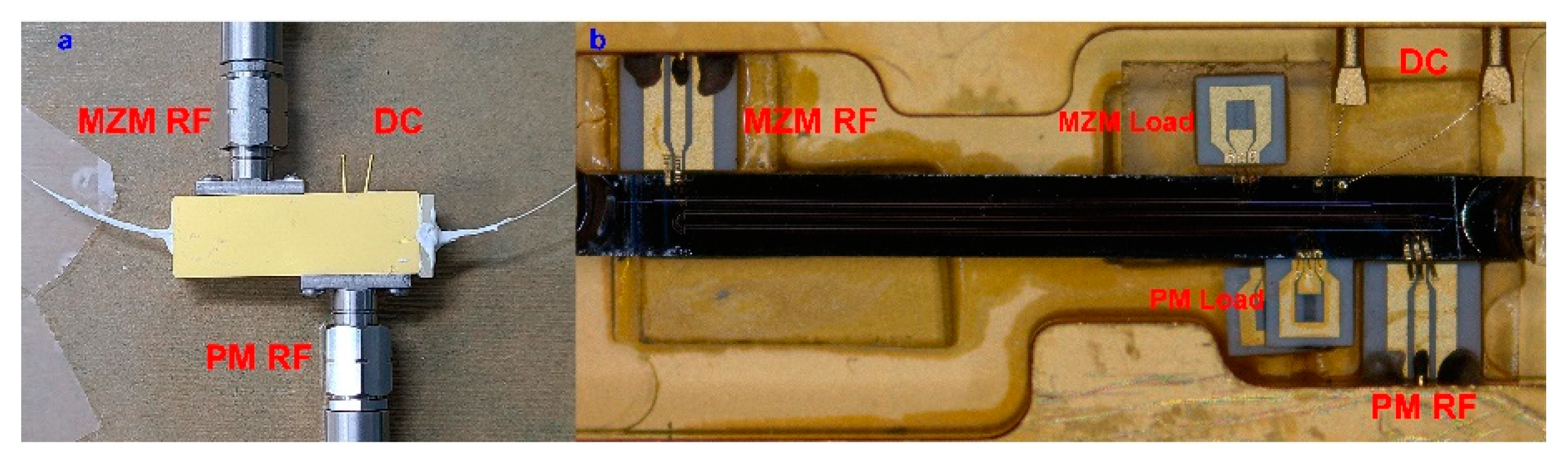

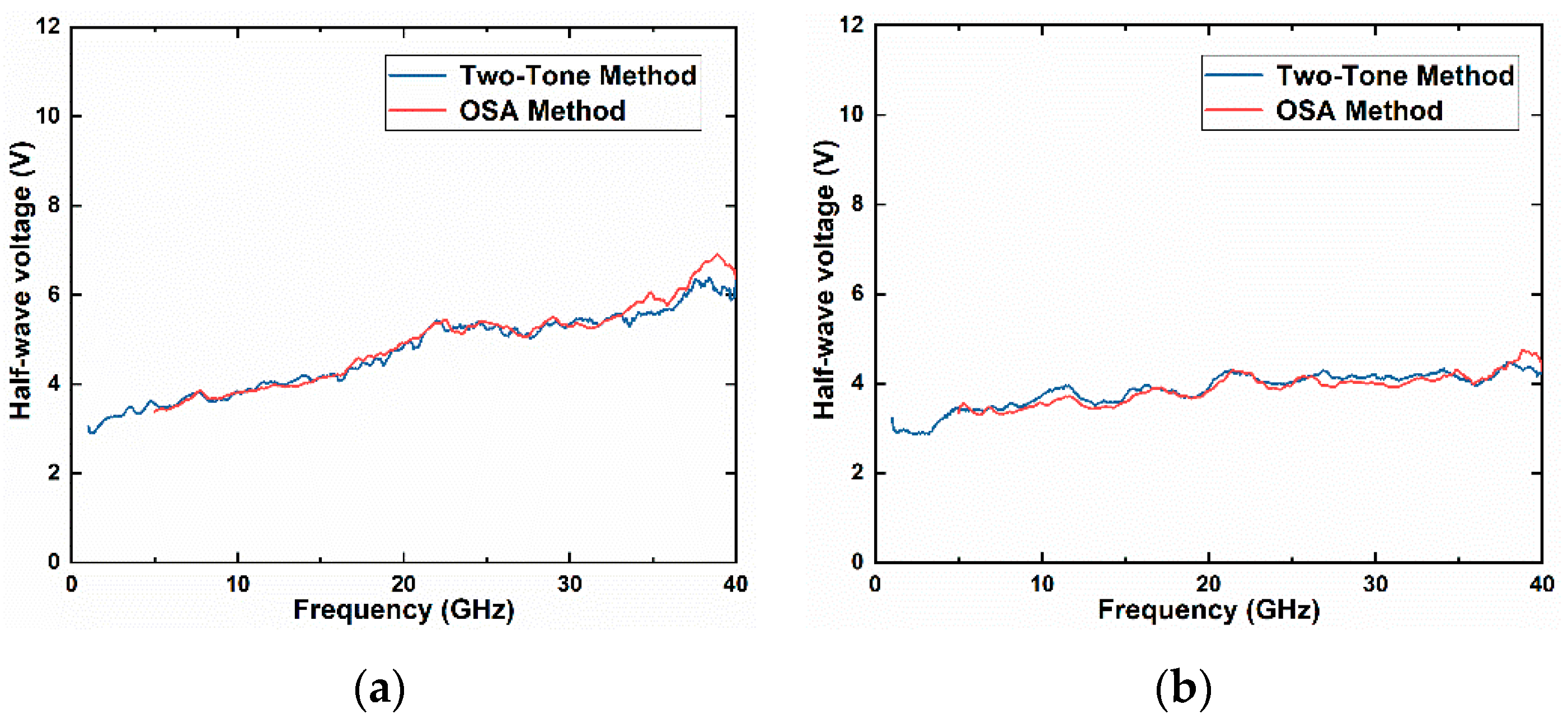

3.1. Device Characterization

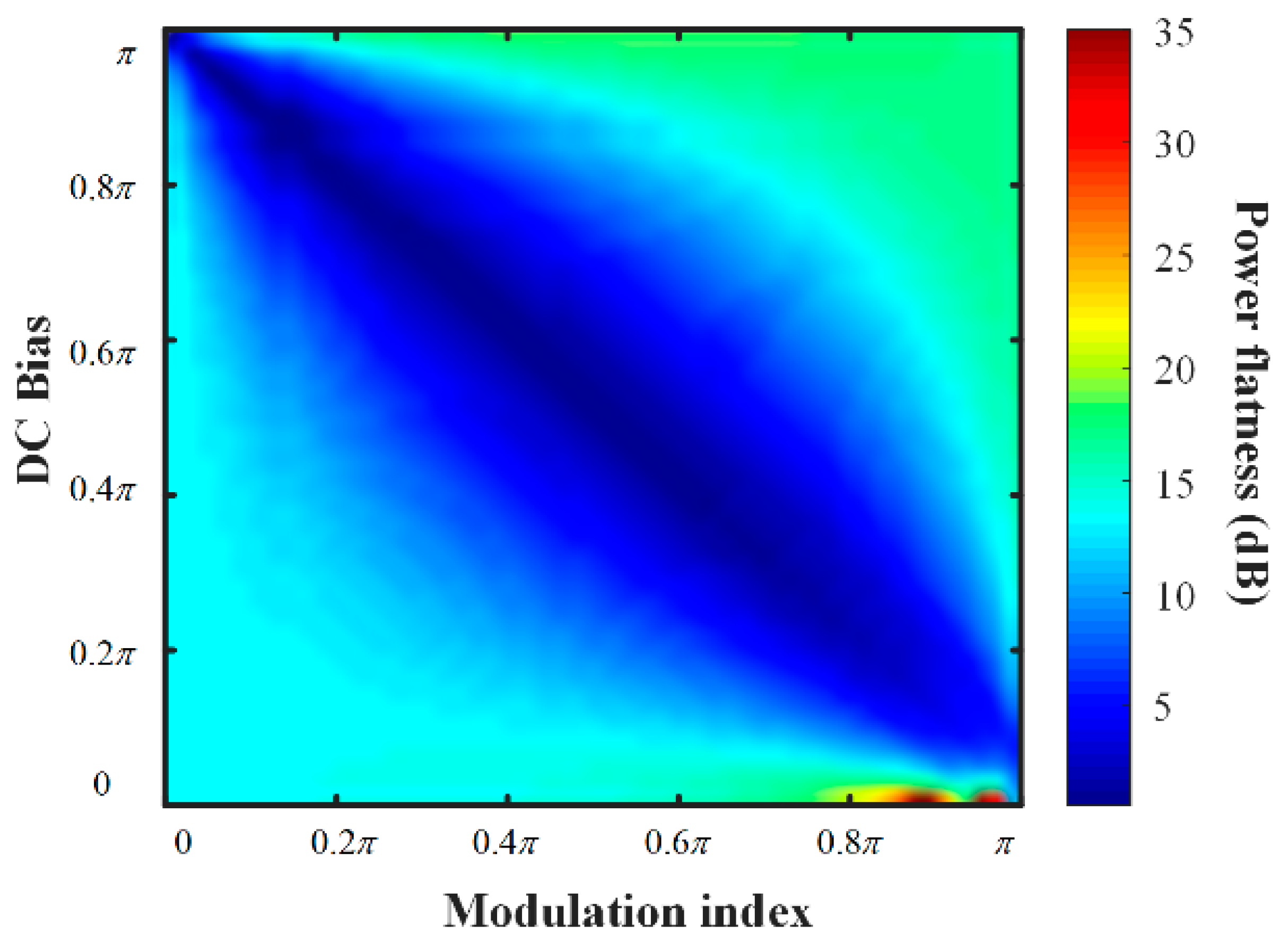

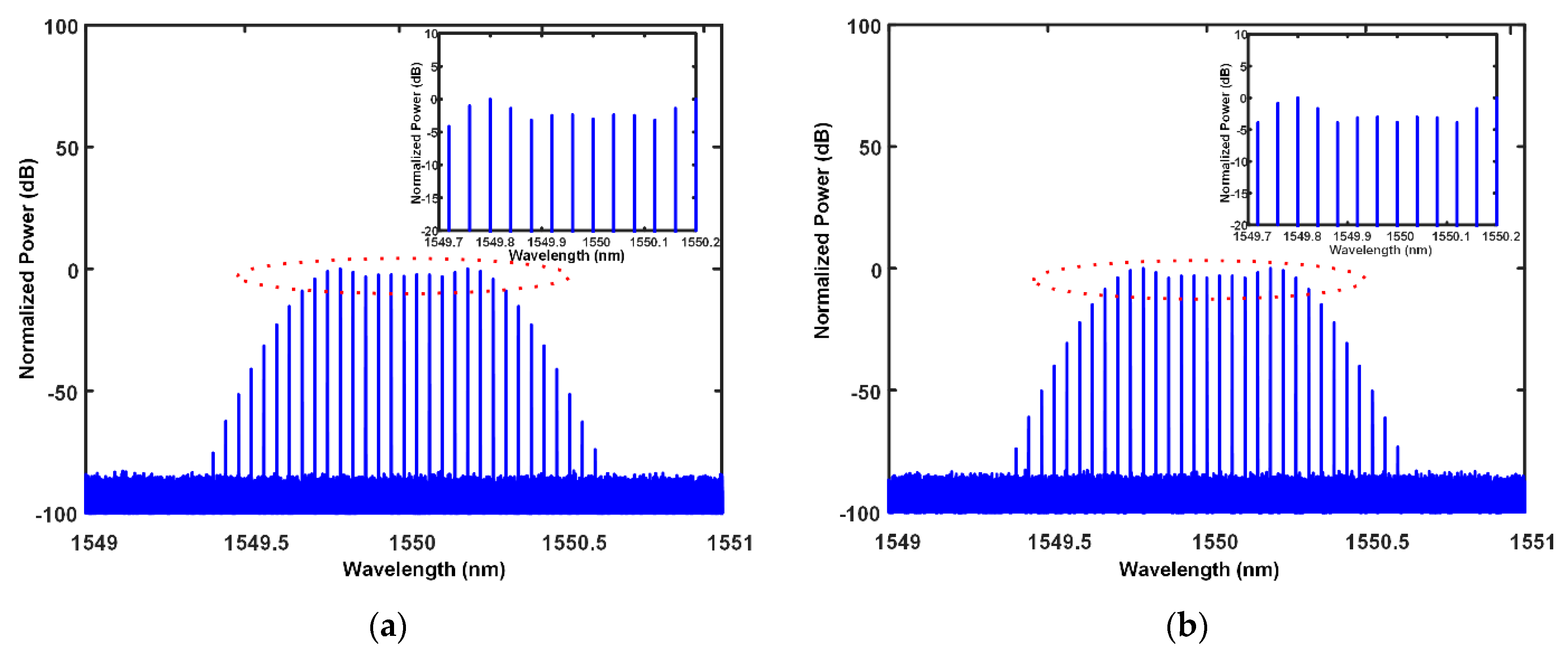

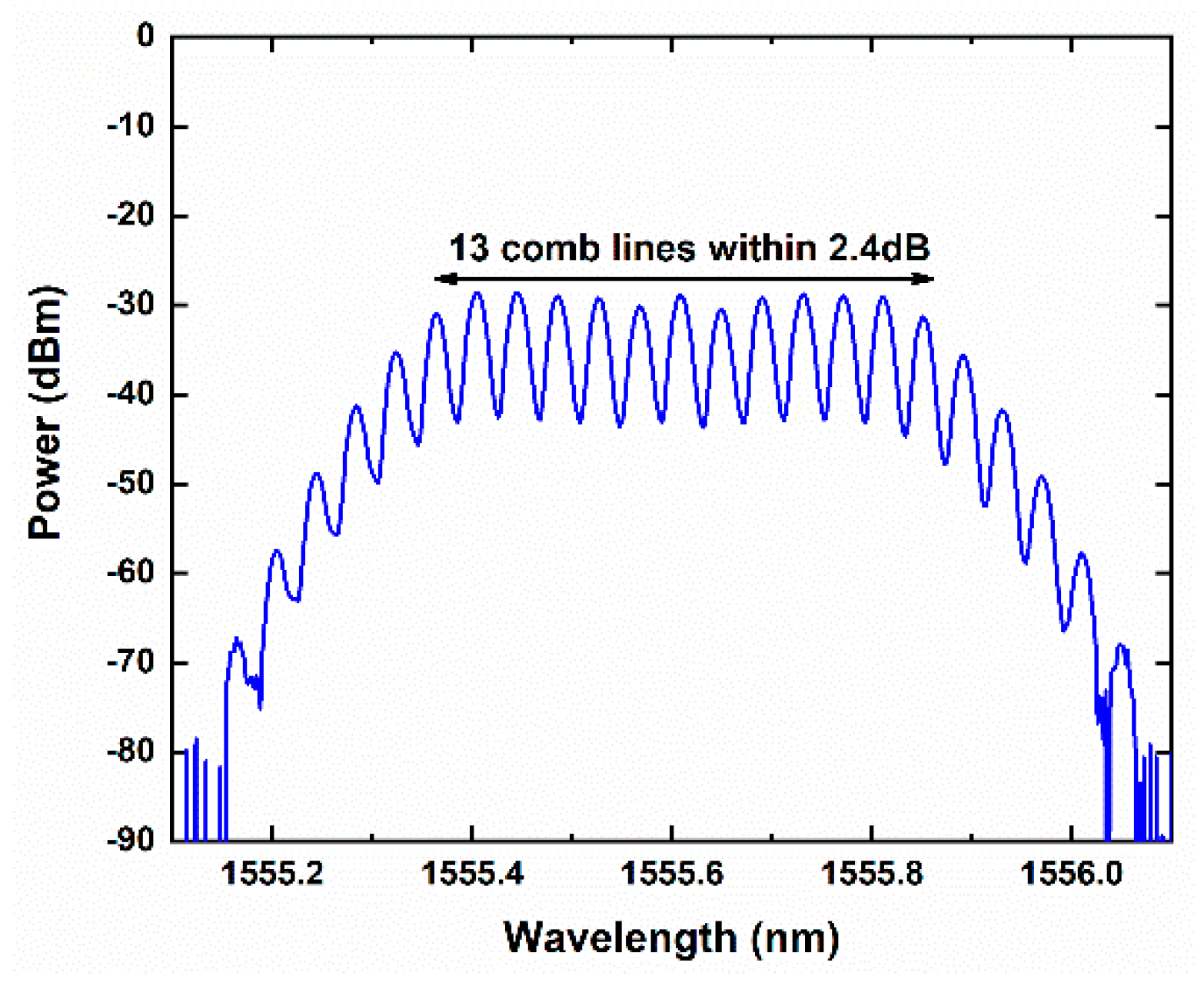

3.2. Simulation Results

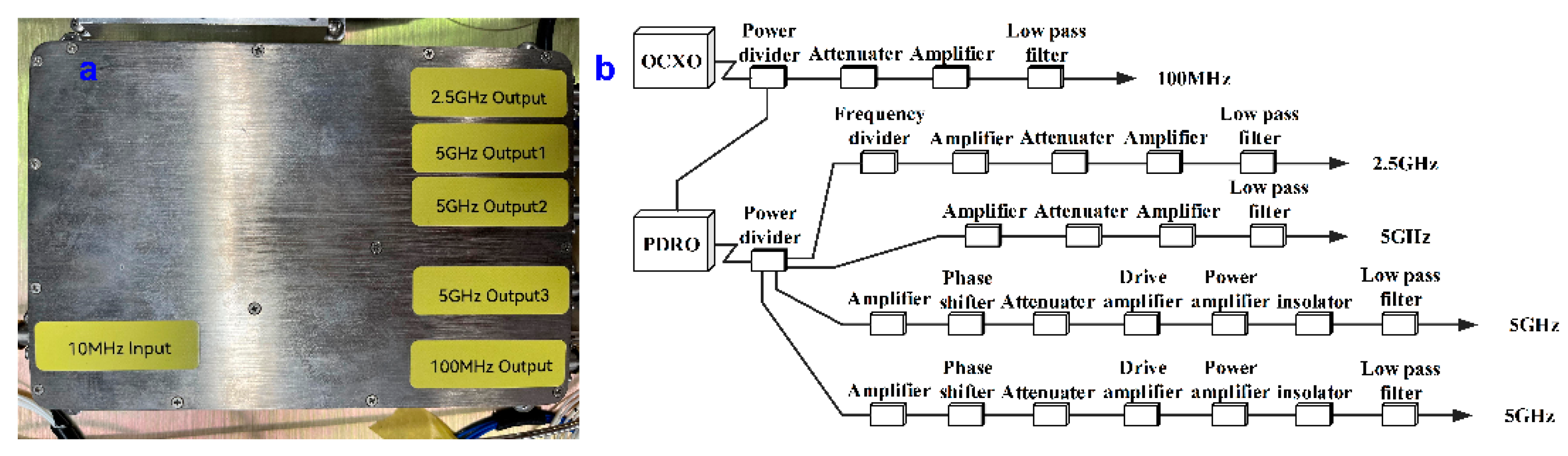

3.3. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schiller, S. Spectrometry with frequency combs. Opt. Lett. 2002, 27, 766–768. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parriaux, A.; Hammani, K.; Millot, G. Two-micron all-fibered dual-comb spectrometer based on electro-optic modulators and wavelength conversion. Commun. Phys. 2018, 1, 17. [Google Scholar] [CrossRef]

- Kang, J.; Feng, P.; Li, B.; Zhang, C.; Wei, X.; Lam, E.Y.; Tsia, K.K.; Wong, K.K.Y. Video-rate centimeter-range optical coherence tomography based on dual optical frequency combs by electro-optic modulators. Opt. Express 2018, 26, 24928–24939. [Google Scholar] [PubMed] [Green Version]

- Murphy, M.T.; Udem, T.H.; Holzwarth, R.; Sizmann, A.; Pasquini, L.; Araujo-Hauck, C.; Dekker, H.; D’Odorico, S.; Fischer, M.; Hänsch, T.W.; et al. High-precision wavelength calibration of astronomical spectrographs with laser frequency combs. Mon. Not. R. Astron. Soc. 2007, 380, 839–847. [Google Scholar] [CrossRef]

- Finot, C. 40-GHz photonic waveform generator by linear shaping of four spectral sidebands. Opt. Lett. 2015, 40, 1422–1425. [Google Scholar] [PubMed] [Green Version]

- Ma, Y.; Zhang, Z.; Zhang, S.; Yuan, J.; Zhang, Z.; Fu, D.; Wang, J.; Liu, Y. Self-calibrating microwave characterization of broadband Mach—Zehnder electro-optic modulator employing low-speed photonic down-conversion sampling and low-frequency detection. J. Light. Technol. 2019, 37, 2668–2674. [Google Scholar] [CrossRef]

- Kim, J.; Song, Y. Ultralow-noise mode-locked fiber lasers and frequency combs: Principles, status, and applications. Adv. Opt. Photon. 2016, 8, 465–540. [Google Scholar] [CrossRef]

- Kippenberg, T.; Gaeta, A.; Lipson, M.; Gorodetsky, M.L. Dissipative Kerr solitons in optical microresonators. Science 2018, 361, eaan8083. [Google Scholar] [CrossRef] [Green Version]

- Qu, K.; Zhao, S.; Li, X.; Zhu, Z.; Liang, D.; Liang, D. Ultra-Flat and broadband optical frequency comb generator via a single Mach—Zehnder modulator. IEEE Photon. Technol. Lett. 2017, 29, 255–258. [Google Scholar] [CrossRef]

- Sakamoto, T.; Kawanishi, T.; Tsuchiya, M. 10 GHz, 2.4 ps pulse generation using a single-stage dual-drive Mach-Zehnder modulator. Opt. Lett. 2008, 33, 890–892. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wu, K.; Zhou, L.; Lu, L.; Zhang, B.; Zhou, G.; Chen, J. Microwave pulse generation with a silicon dual-parallel modulator. J. Light. Technol. 2020, 38, 2134–2143. [Google Scholar] [CrossRef]

- Demirtzioglou, I.; Lacava, C.; Bottrill, K.; Thomson, D.; Reed, G.; Richardson, D.; Petropoulos, P. Frequency comb generation in a silicon ring resonator modulator. Opt. Express 2018, 26, 790–796. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.; Zhang, H.; Yao, M. Generation of flat optical-frequency comb using cascaded intensity and phase modulators. IEEE Photon. Technol. Lett. 2012, 24, 727–729. [Google Scholar] [CrossRef]

- Wu, R.; Supradeepa, V.R.; Long, C.M.; Leaird, D.E.; Weiner, A.M. Generation of very flat optical frequency combs from continuous-wave lasers using cascaded intensity and phase modulators driven by tailored radio frequency waveforms. Opt. Lett. 2010, 35, 3234–3236. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ma, M.; Sun, H.; Khalil, M.; Adams, R.; Yim, K.; Jin, X.; Chen, L.R. Optical Frequency comb generation using CMOS compatible cascaded Mach—Zehnder modulators. IEEE J. Quantum Electron. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Bontempi, F.; Andriolli, N.; Scotti, F.; Chiesa, M.; Contestabile, G. Comb line multiplication in an InP integrated photonic circuit based on cascaded modulators. IEEE J. Sel. Top. Quantum Electron. 2019, 25, 1–7. [Google Scholar] [CrossRef]

- Xu, M.; He, M.; Zhu, Y.; Yu, S.; Cai, X. Flat optical frequency comb generator based on integrated lithium niobate modulators. J. Light. Technol. 2021, 40, 339–345. [Google Scholar] [CrossRef]

- Hu, C.; Pan, A.; Li, T.; Wang, X.; Liu, Y.; Tao, S.; Zeng, C.; Xia, J. High-efficient coupler for thin-film lithium niobate waveguide devices. Opt. Express 2021, 29, 5397–5406. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Yan, L.; Willner, A. High-speed electrooptic modulator characterization using optical spectrum analysis. J. Light. Technol. 2003, 21, 2358–2367. [Google Scholar]

- Zhang, S.; Zhang, C.; Wang, H.; Zou, X.; Liu, Y.; Bowers, J.E. Calibration-free measurement of high-speed Mach—Zehnder modulator based on low-frequency detection. Opt. Lett. 2016, 41, 460–463. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, X.; Li, Z.; Lyu, W.; Lyu, Y.; Zeng, C.; Zhang, Z.; Zhang, S.; Zhang, Y.; Li, H.; et al. Flat Optical Frequency Comb Generation Based on Monolithic Integrated LNOI Intensity and Phase Modulator. Photonics 2022, 9, 495. https://doi.org/10.3390/photonics9070495

Zhang Y, Wang X, Li Z, Lyu W, Lyu Y, Zeng C, Zhang Z, Zhang S, Zhang Y, Li H, et al. Flat Optical Frequency Comb Generation Based on Monolithic Integrated LNOI Intensity and Phase Modulator. Photonics. 2022; 9(7):495. https://doi.org/10.3390/photonics9070495

Chicago/Turabian StyleZhang, Yujia, Xuanhao Wang, Zhengkai Li, Weiqiang Lyu, Yanjia Lyu, Cheng Zeng, Zhiyao Zhang, Shangjian Zhang, Yali Zhang, Heping Li, and et al. 2022. "Flat Optical Frequency Comb Generation Based on Monolithic Integrated LNOI Intensity and Phase Modulator" Photonics 9, no. 7: 495. https://doi.org/10.3390/photonics9070495

APA StyleZhang, Y., Wang, X., Li, Z., Lyu, W., Lyu, Y., Zeng, C., Zhang, Z., Zhang, S., Zhang, Y., Li, H., Xia, J., & Liu, Y. (2022). Flat Optical Frequency Comb Generation Based on Monolithic Integrated LNOI Intensity and Phase Modulator. Photonics, 9(7), 495. https://doi.org/10.3390/photonics9070495