Sunlight Communication System Built with Tunable 3D-Printed Optical Components

Abstract

:1. Introduction

2. Component Fabrication

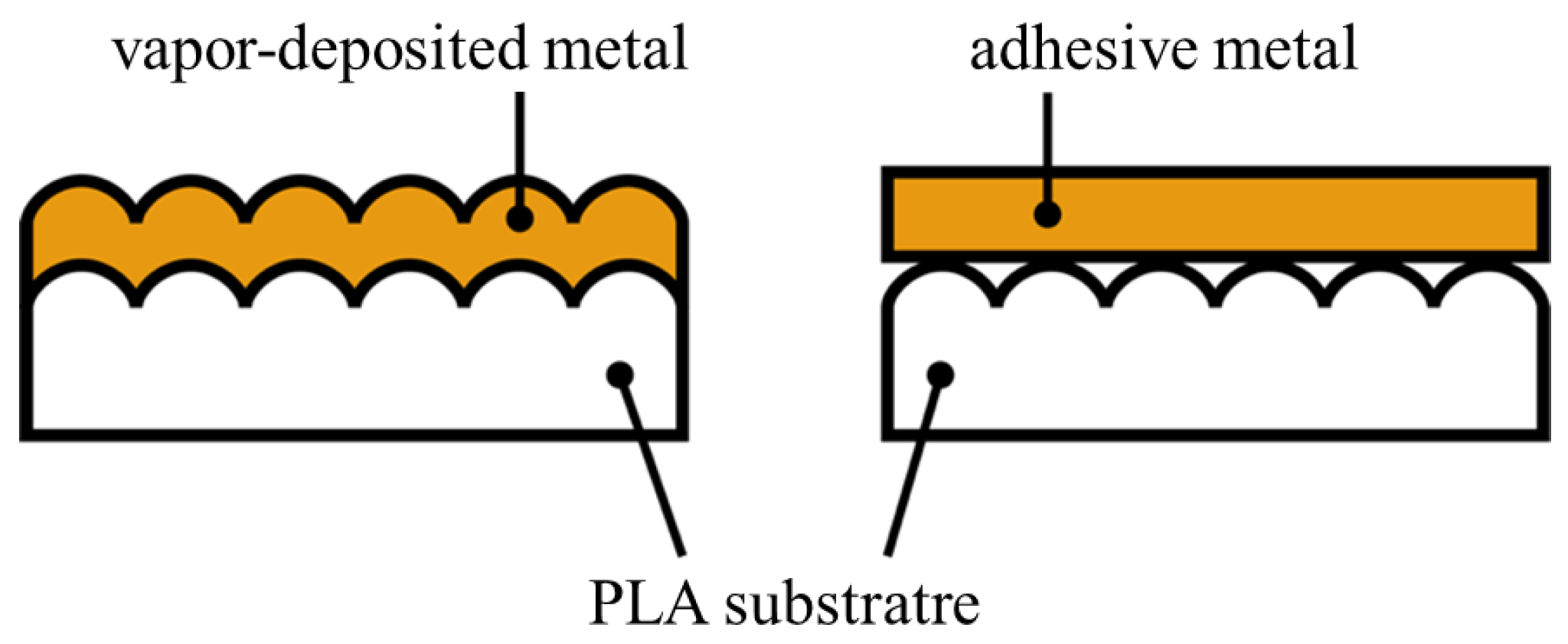

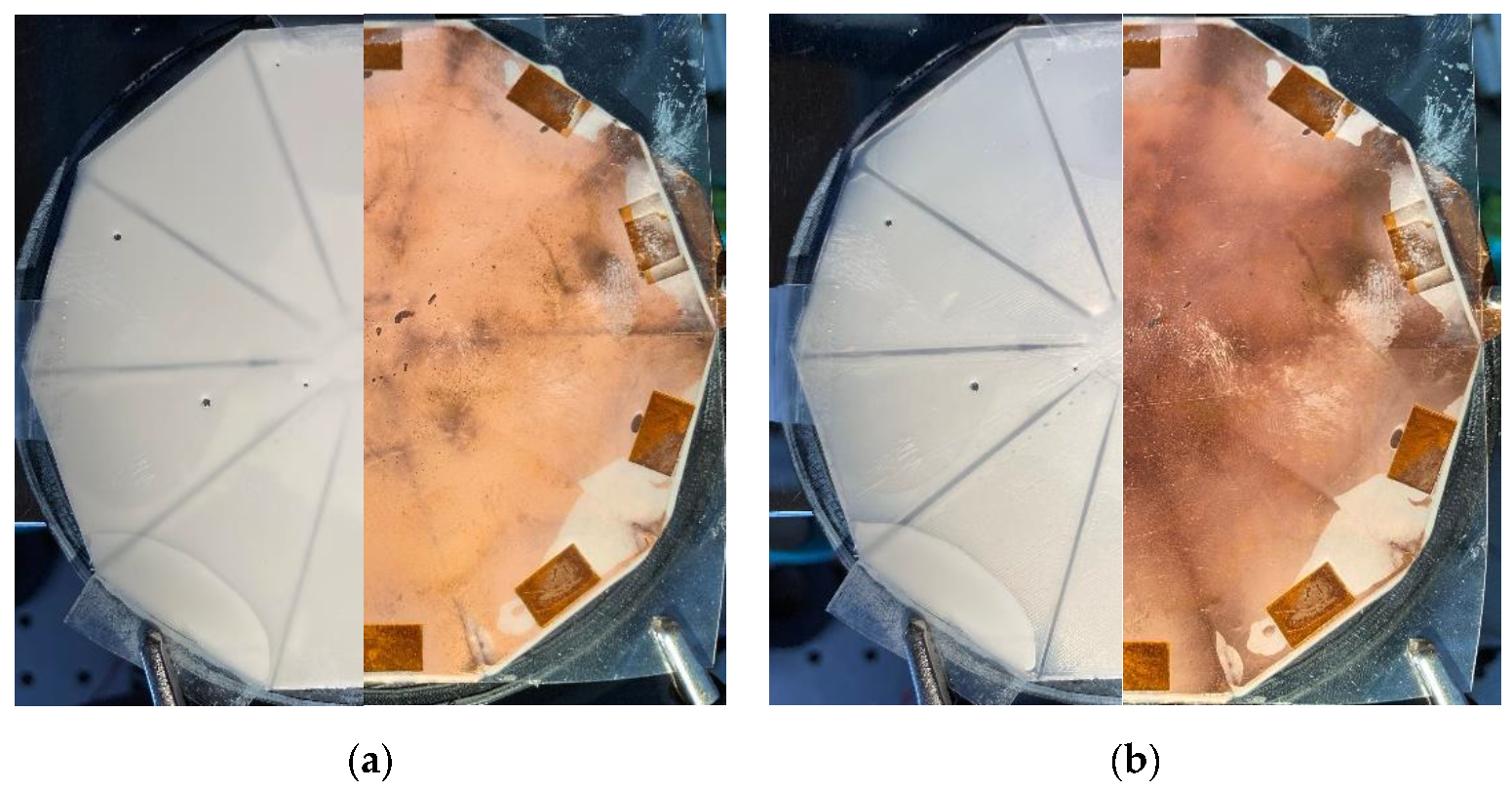

2.1. Parabolic Mirror (Strictly Speaking, Paraboloid-like Mirror)

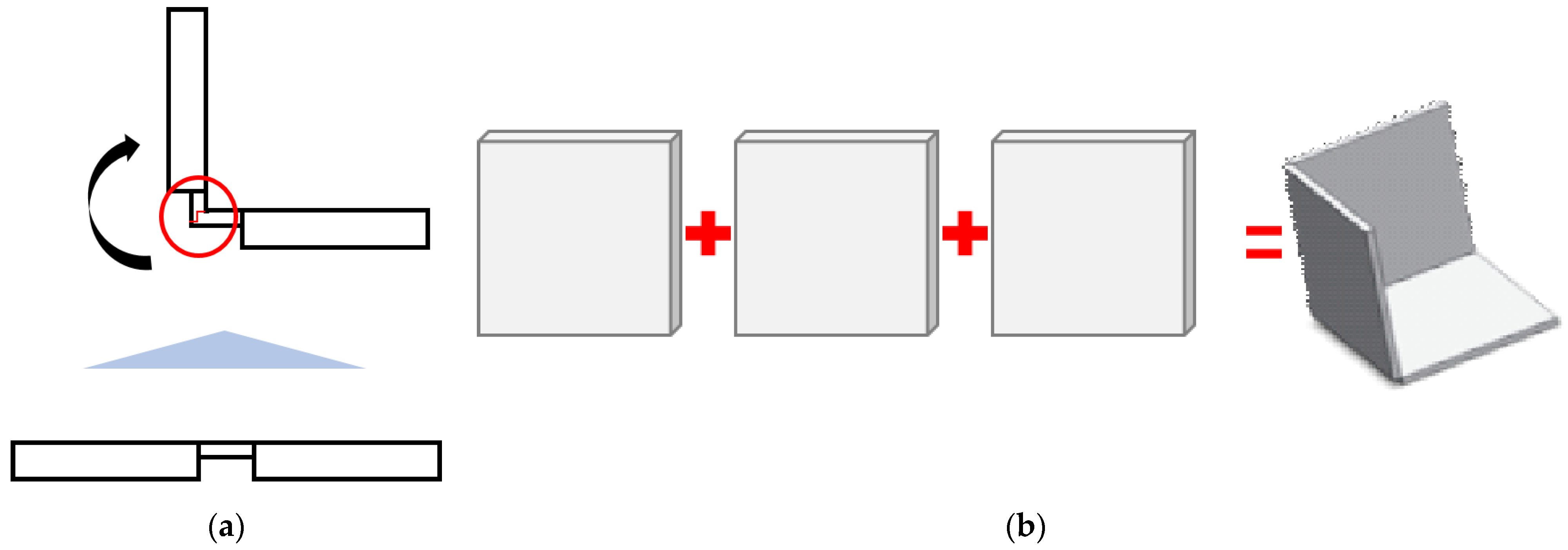

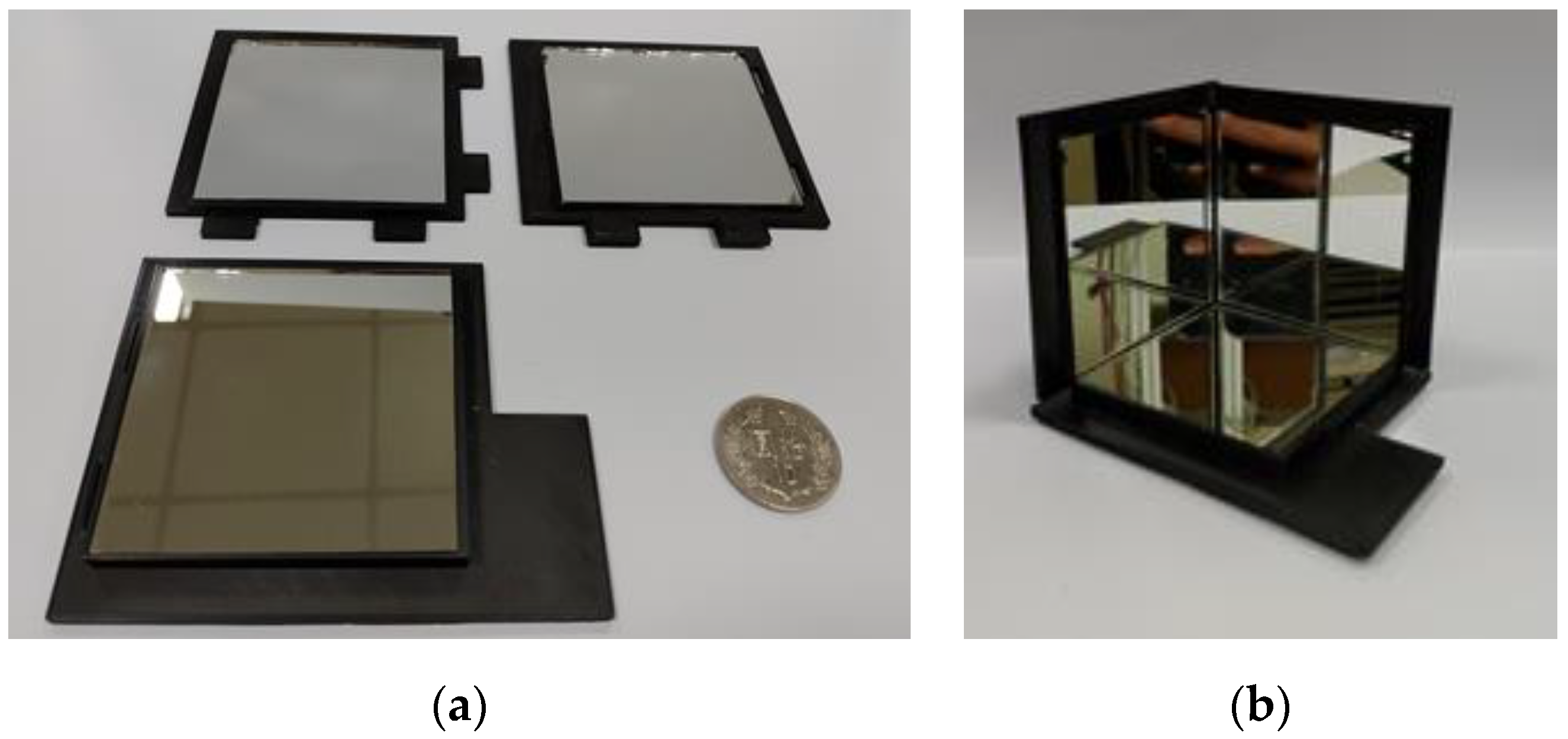

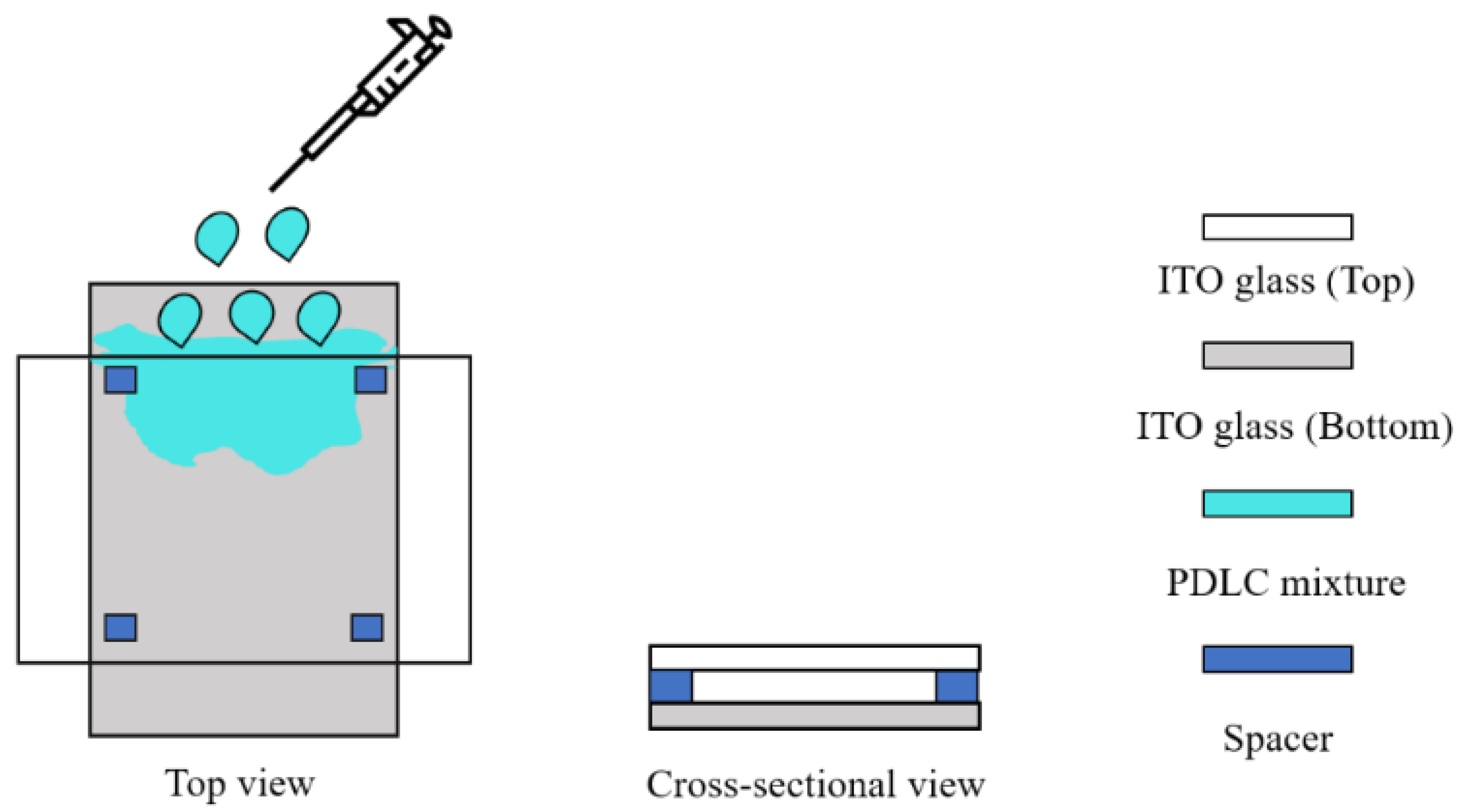

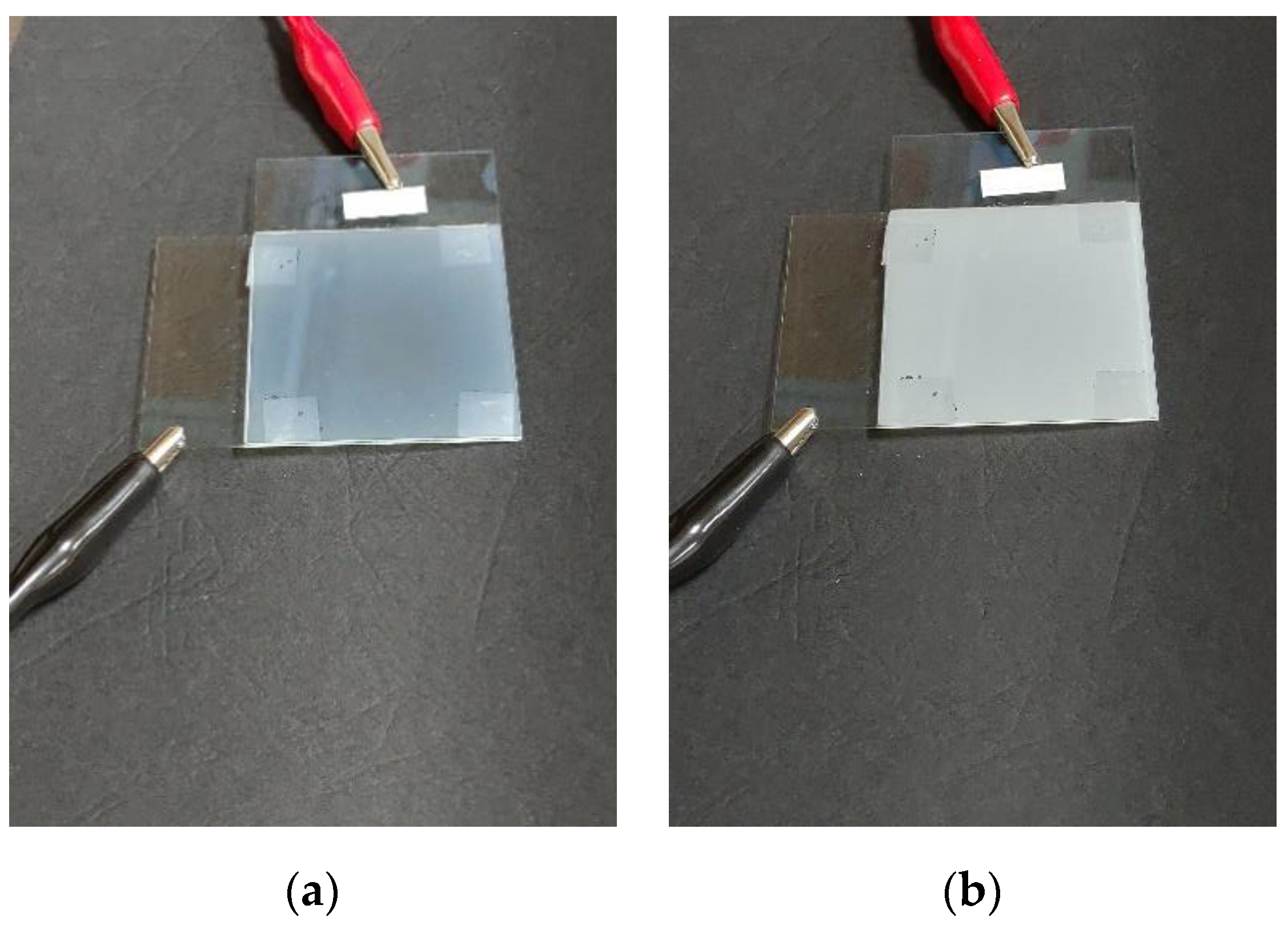

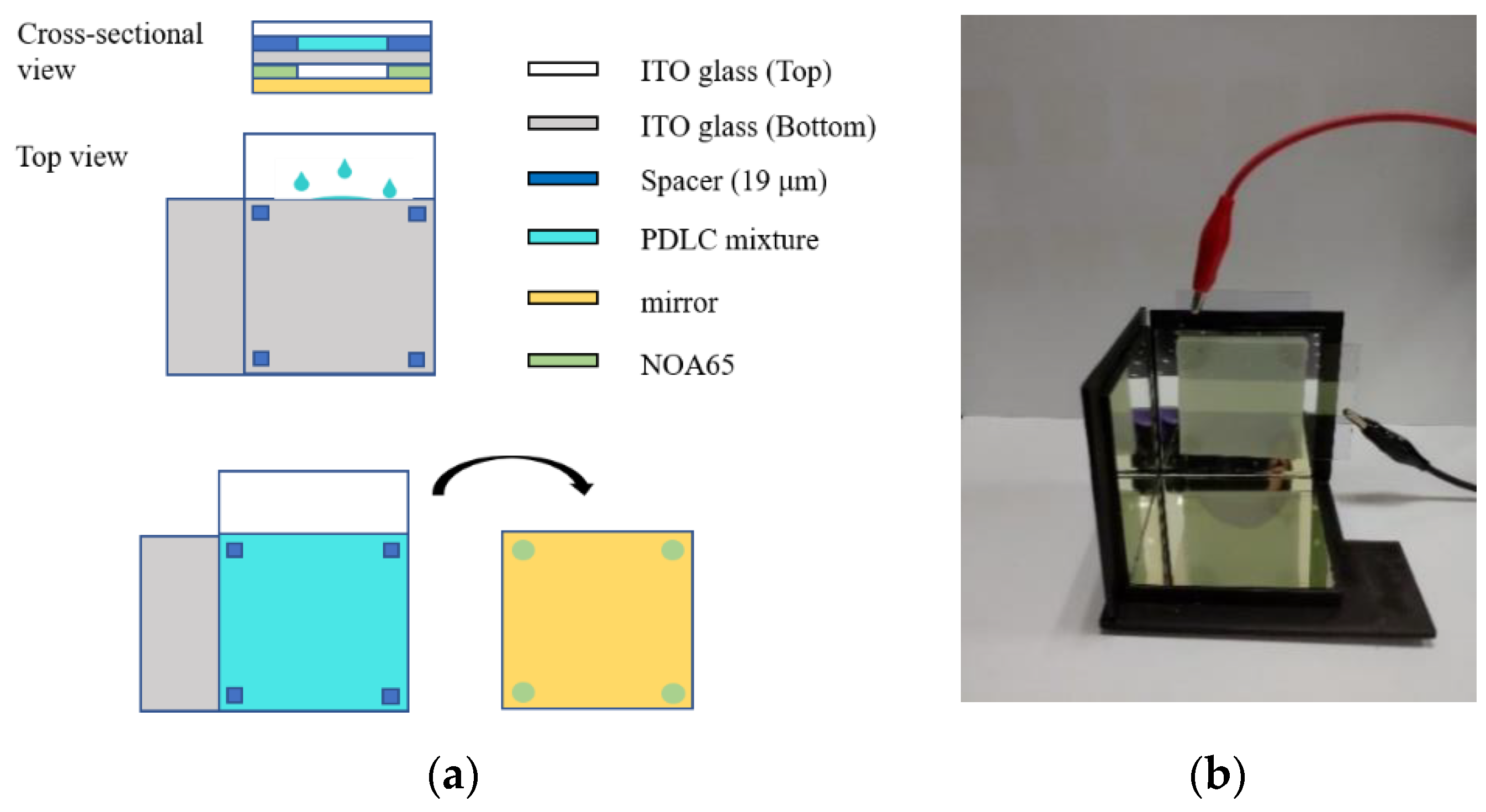

2.2. Corner Cube Retroreflector (CCR)

3. Results and Discussion

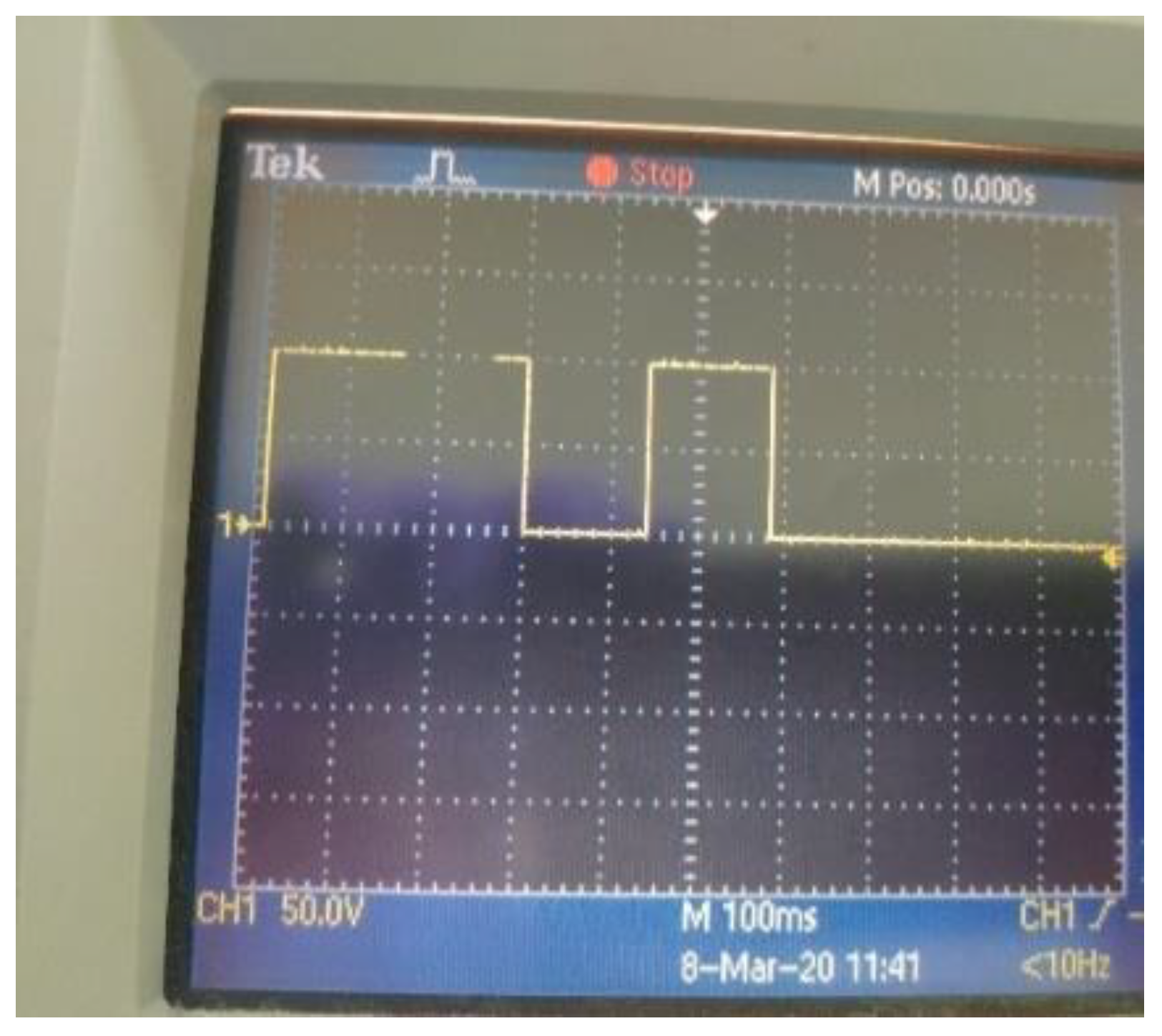

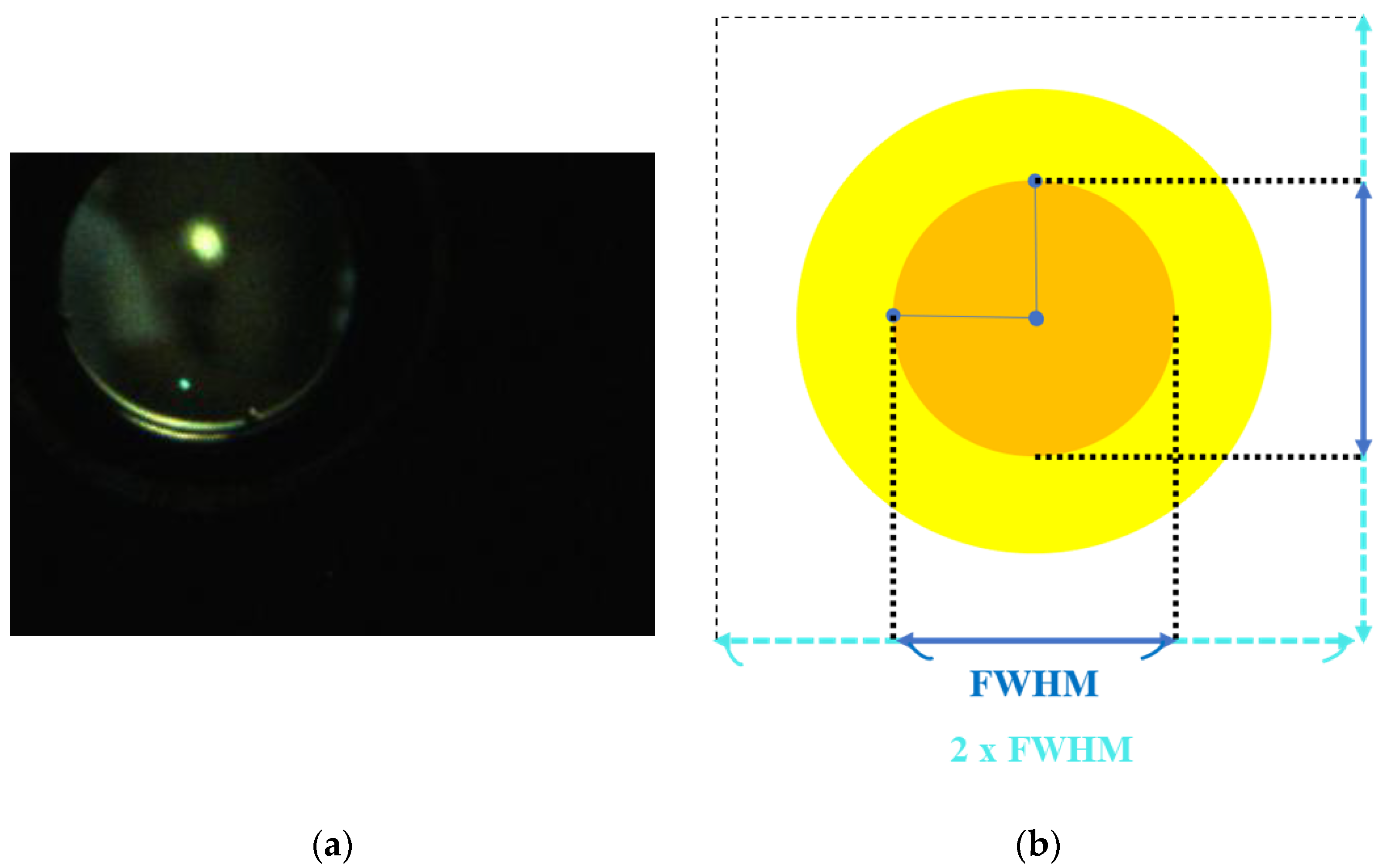

3.1. Device Characterization

3.1.1. Parabolic Mirror

3.1.2. Cube Corner Retroreflector (CCR)

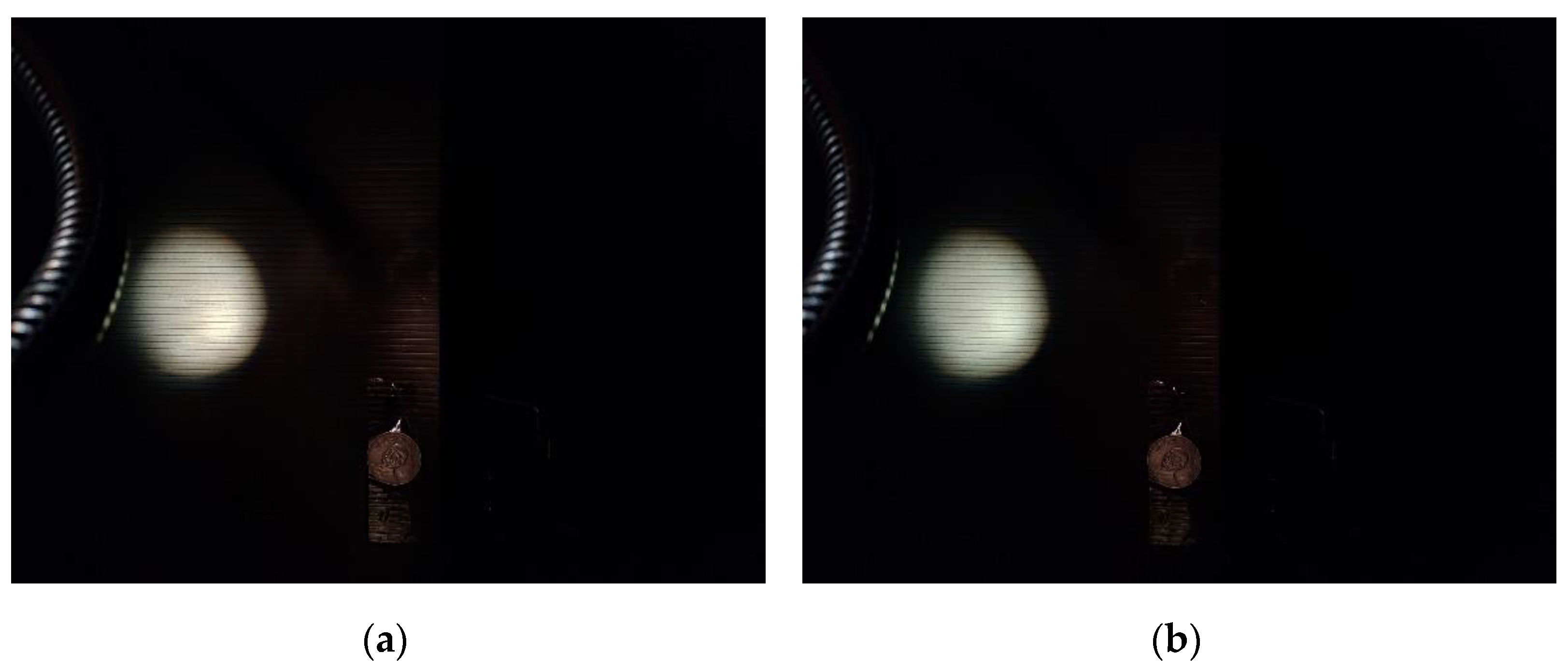

3.2. System Setup and Transmission Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, D.; Almeida, J. Highly efficient solar-pumped Nd:YAG laser. Opt. Express 2011, 19, 26399–26405. [Google Scholar] [CrossRef] [PubMed]

- Guan, Z.; Zhao, C.M.; Yang, S.H.; Wang, Y.; Ke, J.Y.; Zhang, H.Y. Demonstration of a free-space optical communication system using a solar-pumped laser as signal transmitter. Laser Phys. Lett. 2017, 14, 055804. [Google Scholar] [CrossRef]

- Gunawan, W.-H.; Liu, Y.; Chow, C.-W.; Chang, Y.-H.; Yeh, C.-H. High speed visible light communication using digital power domain multiplexing of orthogonal frequency division multiplexed (OFDM) signals. Photonics 2021, 8, 500. [Google Scholar] [CrossRef]

- Nie, Y.; Zhang, W.; Yang, Y.; Deng, X.; Liu, M.; Chen, C. Pairwise coded mCAP with chaotic dual-mode index modulation for secure bandlimited VLC systems. Photonics 2022, 9, 141. [Google Scholar] [CrossRef]

- Zhan, L.; Zhao, H.; Zhang, W.; Lin, J. An optimal scheme for the number of mirrors in vehicular visible light communication via mirror array-based intelligent reflecting surfaces. Photonics 2022, 9, 129. [Google Scholar] [CrossRef]

- Miao, P.; Yin, W.; Peng, H.; Yao, Y. Study of the performance of deep learning-based channel equalization for indoor visible light communication systems. Photonics 2021, 8, 453. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Yeh, C.-H.; Liaw, S.-K.; Chow, C.-W.; Hsu, W.-H.; Wang, B.-Y. Analysis and investigation of dual-polarized color LED based visible light communication system. Photonics 2021, 8, 210. [Google Scholar] [CrossRef]

- Kopp, G.; Lean, J.L. A new, lower value of total solar irradiance: Evidence and climate significance. Geophys. Res. Lett. 2011, 38, L01706. [Google Scholar] [CrossRef] [Green Version]

- Lai, K.Y.; Chen, W.T.; Wu, Y.H.; Chen, Y.F.; Tsai, J.C. 3D-printed and PDLC-tuned corner cube retro-reflector for sunlight communication. In Proceedings of the 2019 International Conference on Optical MEMS and Nanophotonics, Daejeon, Korea, 28 July–1 August 2019; pp. 164–165. [Google Scholar]

- EFUN Technology Co., LTD. Product: ITO. Available online: https://www.efun.com.tw/prod_intro/ito-%E9%80%8F%E6%98%8E%E5%B0%8E%E9%9B%BB%E8%86%9C (accessed on 18 January 2022).

- Chen, H.H.; Gu, J.H.; Lai, Y.X.; Lee, W.C.; Tsai, J.C. Digital Photography Using a High-Transmittance Electro-Optical Iris. IEEE Photonics J. 2019, 11, 1–8. [Google Scholar] [CrossRef]

| Aluminum-Coated Parabolic Mirror (Vapor-Deposited Aluminum) | Copper-Tape Parabolic Mirror (Attached Copper Tape) | |

|---|---|---|

| Actuation voltage | 175 V | 105 V |

| Contrast | 107.43% | 195.51% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.-K.; Chen, W.-T.; Wu, Y.-H.; Lai, K.-Y.; Tsai, J.-c. Sunlight Communication System Built with Tunable 3D-Printed Optical Components. Photonics 2022, 9, 188. https://doi.org/10.3390/photonics9030188

Shen C-K, Chen W-T, Wu Y-H, Lai K-Y, Tsai J-c. Sunlight Communication System Built with Tunable 3D-Printed Optical Components. Photonics. 2022; 9(3):188. https://doi.org/10.3390/photonics9030188

Chicago/Turabian StyleShen, Ching-Kai, Wei-Ting Chen, Yu-Hsin Wu, Kai-Ying Lai, and Jui-che Tsai. 2022. "Sunlight Communication System Built with Tunable 3D-Printed Optical Components" Photonics 9, no. 3: 188. https://doi.org/10.3390/photonics9030188

APA StyleShen, C.-K., Chen, W.-T., Wu, Y.-H., Lai, K.-Y., & Tsai, J.-c. (2022). Sunlight Communication System Built with Tunable 3D-Printed Optical Components. Photonics, 9(3), 188. https://doi.org/10.3390/photonics9030188