Preparation of an Integrated Polarization Navigation Sensor via a Nanoimprint Photolithography Process

Abstract

1. Introduction

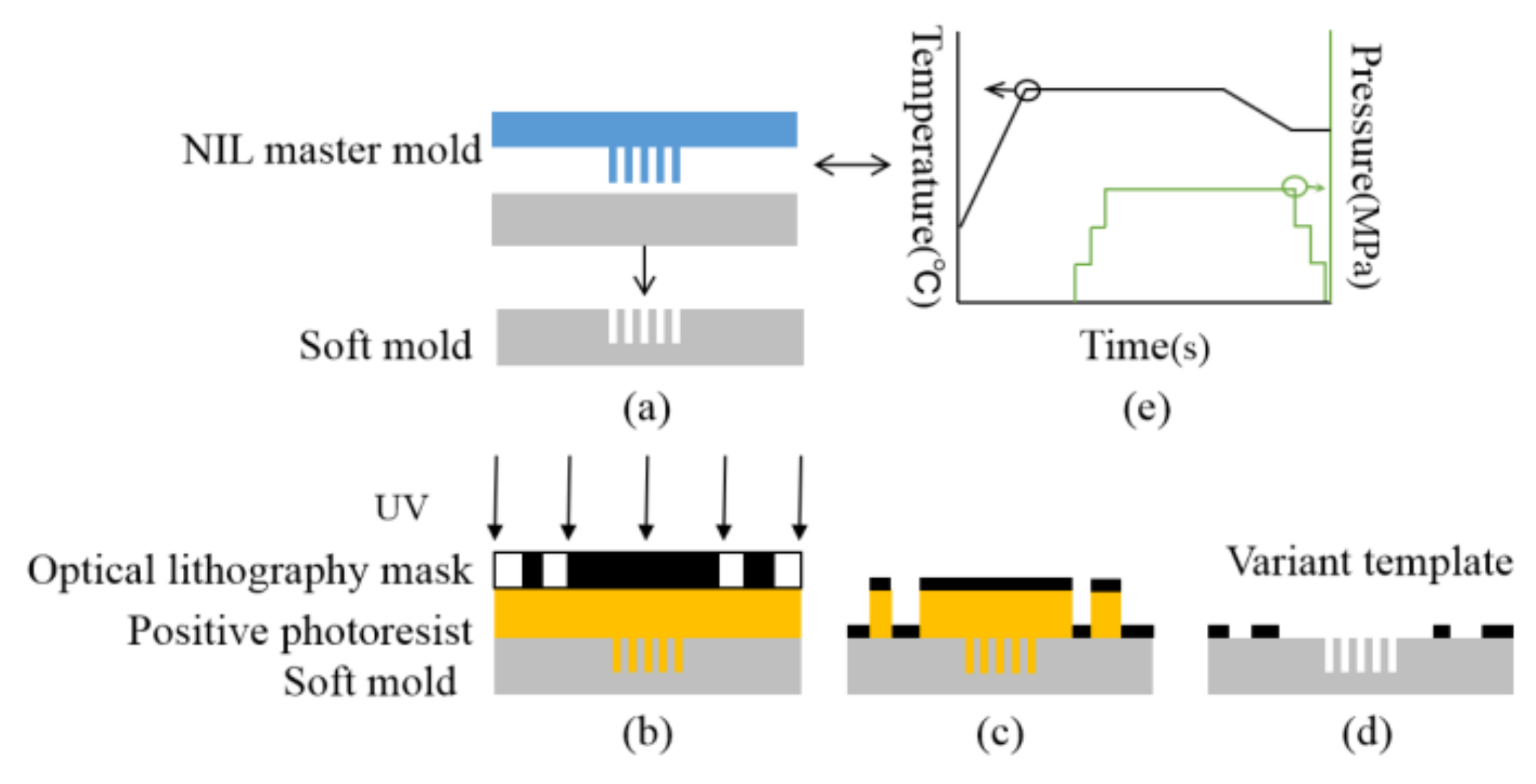

2. Nanoimprint Photolithography (NIPL) Process for Micro–Nano Cross-Scale Integration Process

2.1. Fabrication of the Variant Template

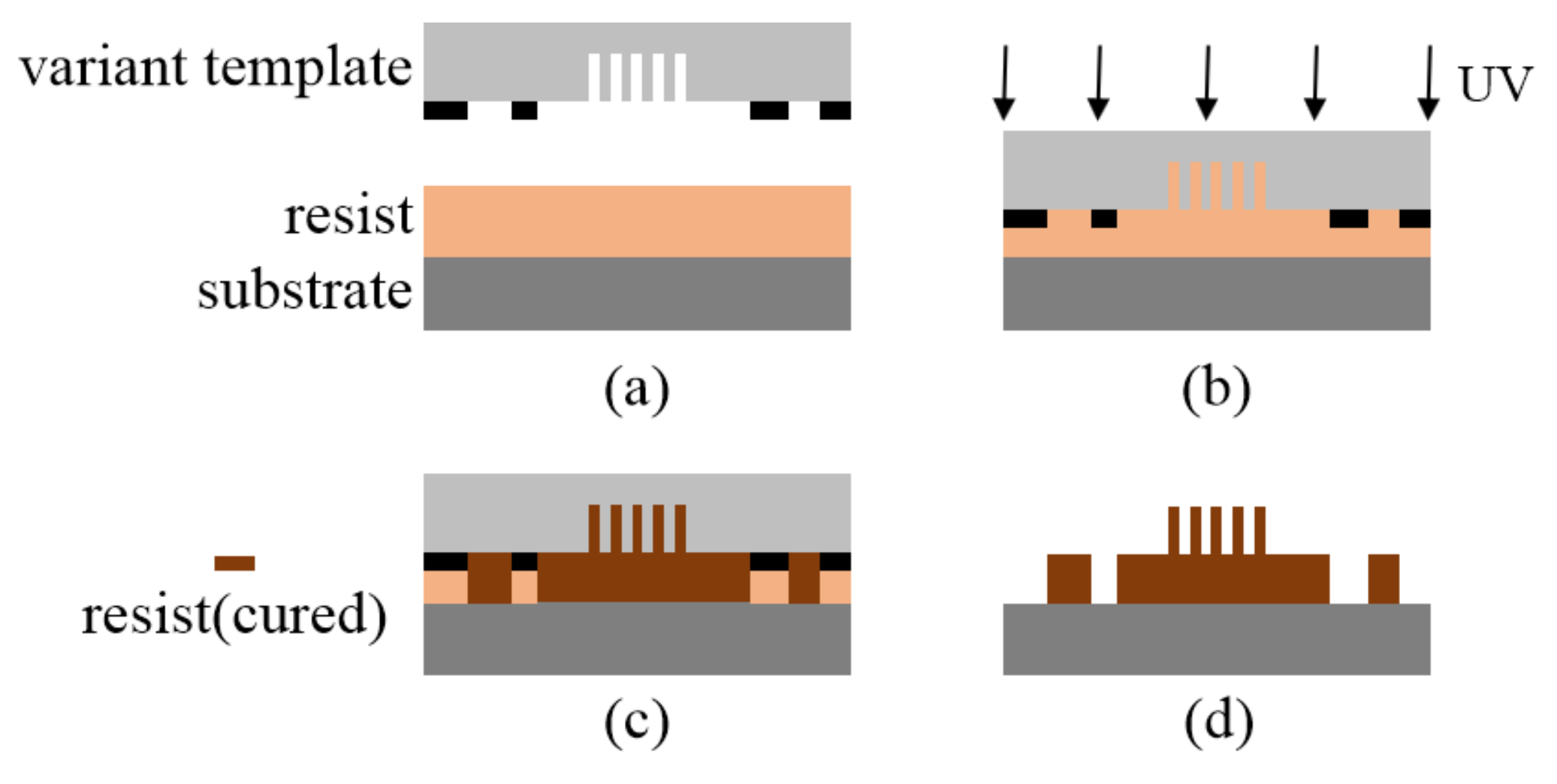

2.2. NIPL Process

3. Polarization Navigation Sensor with the Integration of Multidirectional Nanogratings and the Image Chip

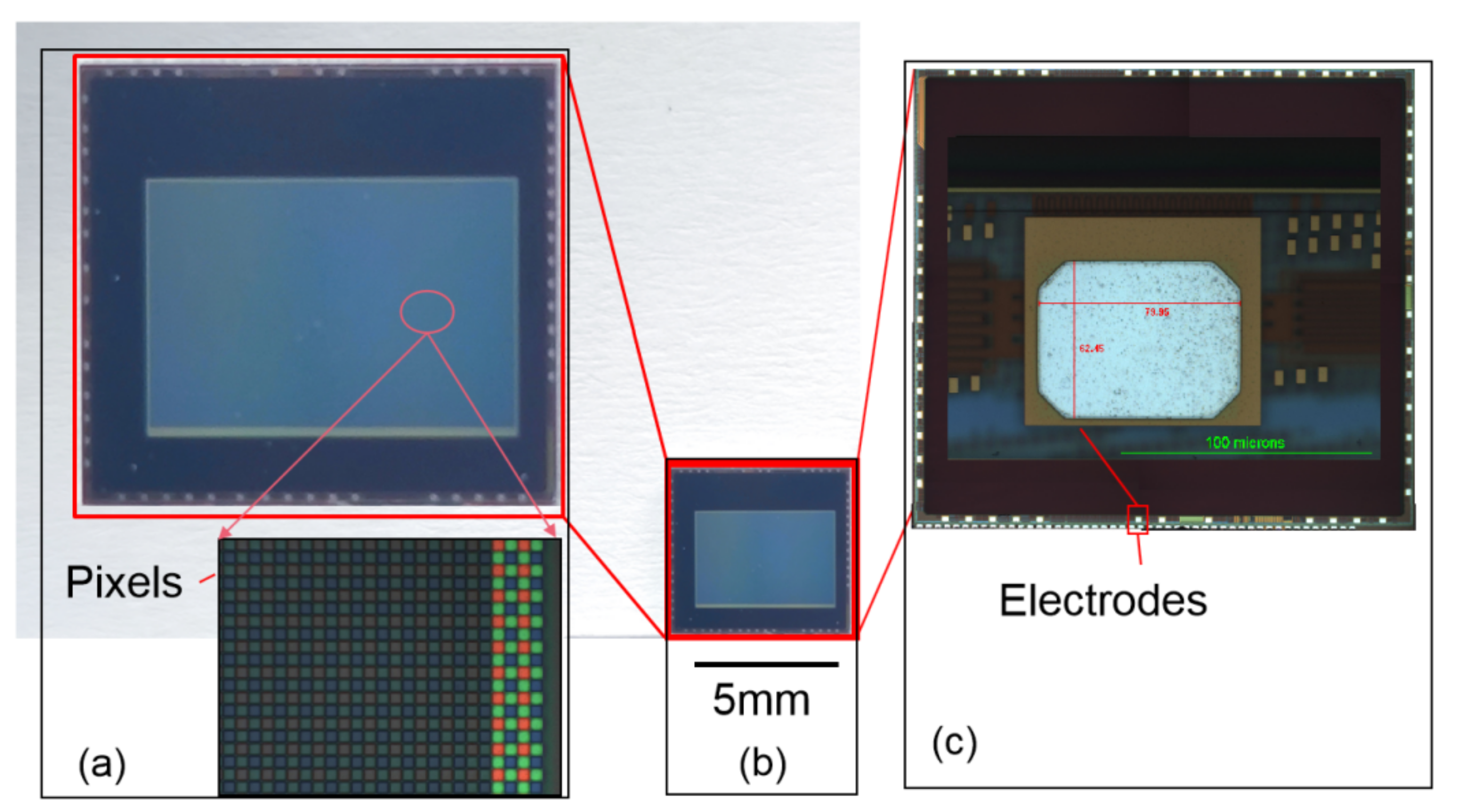

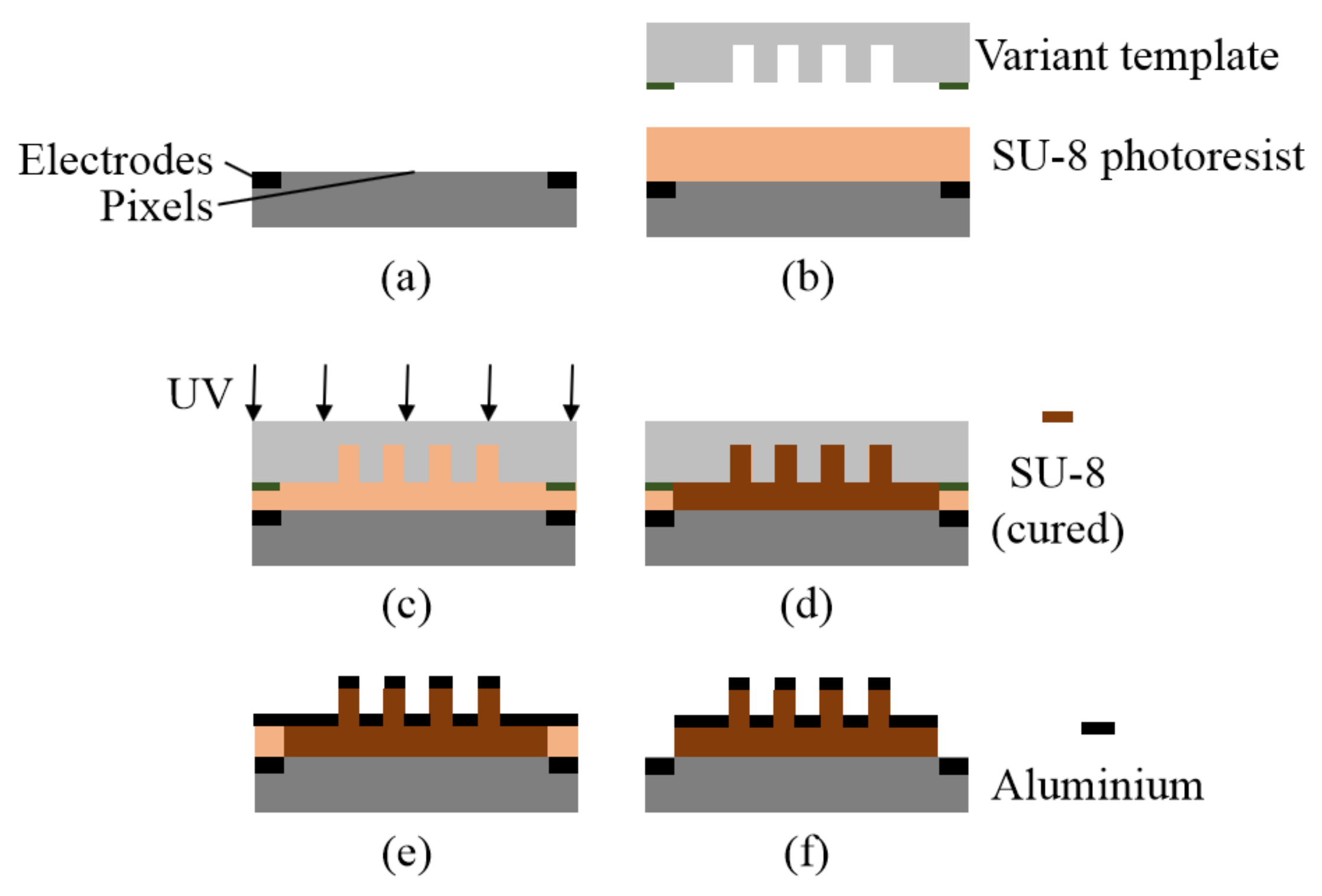

3.1. Integrated Fabrication of Multidirectional Nanogratings and the Image Chip

3.2. Hardware System of Integrated Polarization Sensor

3.3. Calculation of Polarization Angle of the Incident Light

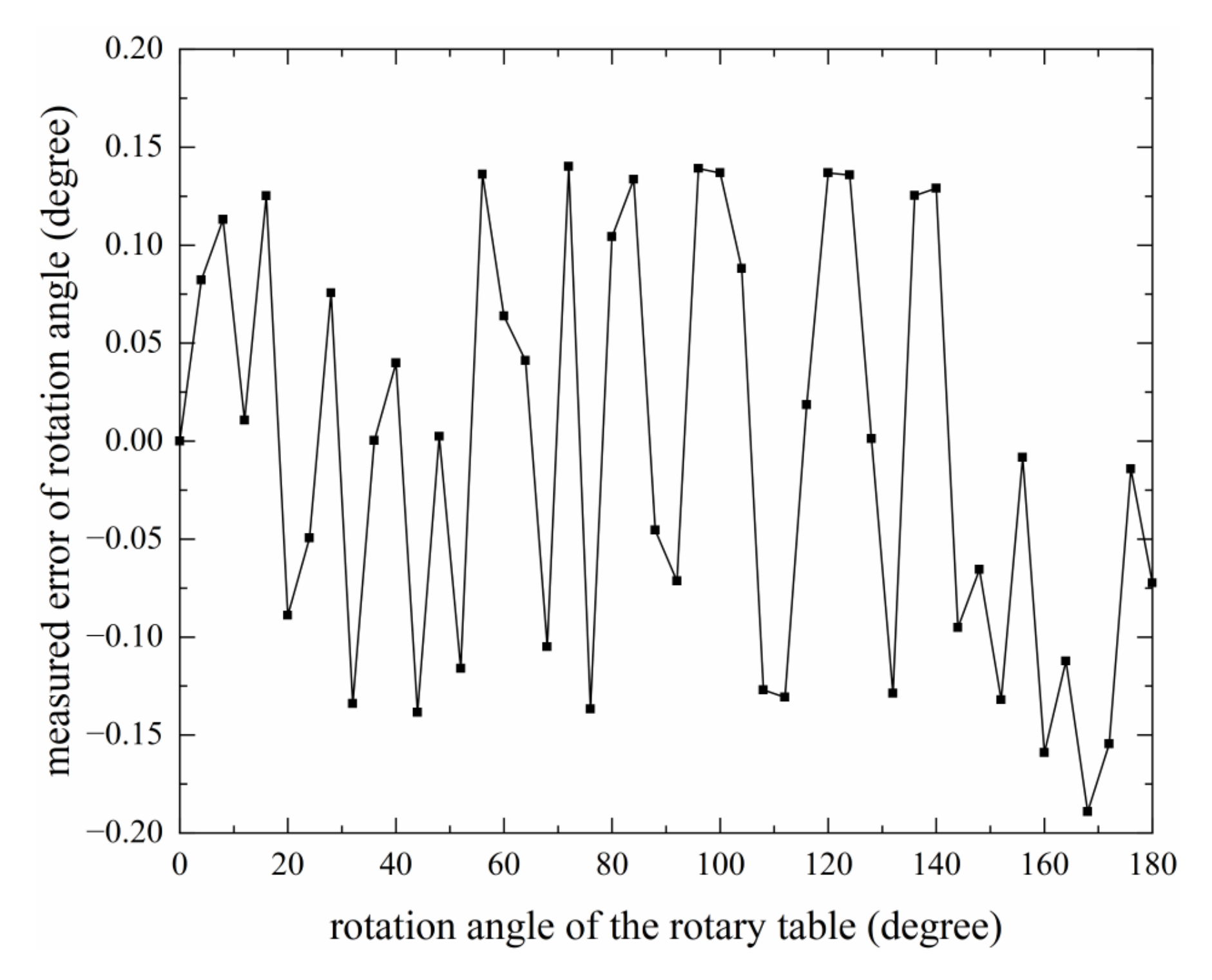

3.4. Performance Testing of the Integrated Polarization Sensor

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shakeri, R.; Al-Garadi, M.A.; Badawy, A.; Mohamed, A.; Khattab, T.; Al-Ali, A.K.; Harras, K.A.; Guizani, M. Design challenges of Multi-UAV systems in Cyber-Physical applications: A comprehensive survey and future directions. IEEE Commun. Surv. Tut. 2019, 21, 3340–3385. [Google Scholar] [CrossRef]

- Olikhov, I.; Golchenko, A. Electron-beam-pumped semiconductor laser emitters in glideslope aircraft landing system. Photonics 2013, 4, 76–93. [Google Scholar]

- Greif, S.; Borissov, I.; Yovel, Y.; Holland, R.A. A functional role of the sky’s polarization pattern for orientation in the greater mouse-eared bat. Nat. Commun. 2014, 5, 4488. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, G.; Wehner, R. The ants path integration system-a neural architecture. Biol. Cybern. 1995, 73, 483–497. [Google Scholar] [CrossRef]

- Wehner, R. Desert ant navigation: How miniature brains solve complex tasks. J. Comp. Physiol. A 2003, 189, 579–588. [Google Scholar] [CrossRef]

- Froy, O.; Gotter, A.L.; Casselman, A.L.; Reppert, S.M. Illuminating the circadian clock in monarch butterfly migration. Science 2003, 300, 1303–1305. [Google Scholar] [CrossRef]

- Powell, S.B.; Garnett, R.; Marshall, J.; Rizk, C.; Gruev, V. Bioinspired polarization vision enables underwater geolocalization. Sci. Adv. 2018, 4, eaao6841. [Google Scholar] [CrossRef]

- Lambrinos, D.; Maris, M.; Kobayashi, H.; Labhart, T.; Pfeifer, R.; Wehner, R. An autonomous agent navigating with a polarized light compass. Adapt. Behav. 1997, 6, 131–161. [Google Scholar] [CrossRef]

- Chu, J.K.; Wang, Z.W.; Guan, L.; Liu, Z.; Wang, Y.L.; Zhang, R. Integrated polarization dependent photodetector and its application for polarization navigation. IEEE Photonic. Technol. Lett. 2014, 26, 469–472. [Google Scholar]

- Liu, Z.; Zhang, R.; Wang, Z.W.; Guan, L.; Li, B.; Chu, J.K. Integrated polarization-dependent sensor for autonomous navigation. J. Micro Nanolith. Mem. 2015, 14, 015001. [Google Scholar] [CrossRef]

- Fan, C.; Hu, X.P.; Lian, J.X.; Zhang, L.L.; He, X.F. Design and calibration of a novel Camera-Based Bio-Inspired polarization navigation sensor. IEEE Sens. J. 2016, 16, 3640–3648. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, K.C.; Wang, X.C.; You, Z.; Huang, K.L. Real-time imaging orientation determination system to verify imaging polarization navigation algorithm. Sensors 2016, 16, 144. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

- Kim, J.; Bae, W.; Choung, H.; Lim, K.T.; Seonwoo, H.; Jeong, H.E.; Suh, K.; Jeon, N.L.; Choung, P.; Chung, J.H. Multiscale patterned transplantable stem cell patches for bone tissue regeneration. Biomaterials 2014, 35, 9058–9067. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Jiang, C.; Yin, H.; Chen, J.; Yuan, W. Superhydrophobic silicon surfaces with micro-nano hierarchical structures via deep reactive ion etching and galvanic etching. J. Colloid Interf. Sci. 2011, 364, 219–229. [Google Scholar] [CrossRef]

- Ruffato, G.; Capaldo, P.; Massari, M.; Mezzadrelli, A.; Romanato, F. Pancharatnam-Berry optical elements for spin and orbital angular momentum division demultiplexing. Photonics 2018, 5, 46. [Google Scholar] [CrossRef]

- Munshi, A.H.; Kephart, J.M.; Abbas, A.; Danielson, A.; Gelinas, G.; Beaudry, J.N.; Barth, K.L.; Walls, J.M.; Sampath, W.S. Effect of CdCl2 passivation treatment on microstructure and performance of CdSeTe/CdTe thin-film photovoltaic devices. Sol. Energ. Mat. Sol. C 2018, 186, 259–265. [Google Scholar] [CrossRef]

- Toyoda, H.; Kimino, K.; Kawano, A.; Takahara, J. Incandescent Light Bulbs Based on a Refractory Metasurface. Photonics 2019, 6, 105. [Google Scholar] [CrossRef]

- Hillmer, H.; Woidt, C.; Kobylinskiy, A.; Kraus, M.; Istock, A.; Iskhandar, M.S.Q.; Brunner, R.; Kusserow, T. Miniaturized interferometric sensors with spectral tunability for optical fiber Technology-A comparison of size requirements, performance, and new concepts. Photonics 2021, 8, 332. [Google Scholar] [CrossRef]

- Dundar, A.F.; Kolewe, K.W.; Homyak, B.; Kurtz, I.S.; Schiffman, J.D.; Watkins, J.J. Bioinspired photocatalytic Shark-Skin surfaces with antibacterial and antifouling activity via nanoimprint lithography. ACS Appl. Mater. Interfaces 2018, 10, 20055–20063. [Google Scholar] [CrossRef]

- Suresh, V.; Ding, L.; Chew, A.B.; Yap, F.L. Fabrication of Large-Area flexible SERS substrates by nanoimprint lithography. ACS Appl. Nano Mater. 2018, 1, 886–893. [Google Scholar] [CrossRef]

- Cheng, X.; Guo, L.J. A combined-nanoimprint-and-photolithography patterning technique. Microelectron. Eng. 2004, 71, 277–282. [Google Scholar] [CrossRef]

- Brokner-Christiansen, M.; Scholer, M.; Gersborg-Hansen, M.; Kristensen, A.; IEEE. Combined Nanoimprint and Photolithography of Integrated Polymer Optics. In Proceedings of the IEEE LEOS Summer Topical Meeting 2007, Portland, OR, USA, 23–25 July 2007. [Google Scholar]

- Christiansen, M.B.; Scholer, M.; Kristensen, A. Integration of active and passive polymer optics. Opt. Express 2007, 15, 3931–3939. [Google Scholar] [CrossRef]

- Lohse, M.; Heinrich, M.; Grutzner, S.; Haase, A.; Ramos, I.; Salado, C.; Thesen, M.W.; Grutzner, G. Versatile fabrication method for multiscale hierarchical structured polymer masters using a combination of photo- and nanoimprint lithography. Micro. Nano. Eng. 2021, 10, 100079. [Google Scholar] [CrossRef]

- Haisma, J.; Verheijen, M.; Vandenheuvel, K.; Vandenberg, J. Mold-assisted nanolithography: A process for reliable pattern replication. J. Vac. Sci. Technol. B 1996, 14, 4124–4128. [Google Scholar] [CrossRef]

- Nithi, A.; On-Uma, N.; Wutthinan, J.; Sitthisuntorn, S.; Charndet, H.; Amporn, P. Study of optimization condition for spin coating of the photoresist film on rectangular substrate by Taguchi design of an experiment. Songklanakarin J. Sci. Technol. 2009, 31, 331–335. [Google Scholar]

- Hun, L.; Kangsun, L.; Byungwook, A.; Jing, X.; Linfeng, X.; Kwang, W.O. A new fabrication process for uniform SU-8 thick photoresist structures by simultaneously removing edge bead and air bubbles. J. Micromech. Microeng. 2011, 21, 125006. [Google Scholar]

- Shaw, M.; Nawrocki, D.; Hurditch, R.; Johnson, D. Improving the process capability of SU-8. Microsyst. Technol. 2003, 10, 1–6. [Google Scholar] [CrossRef]

- Delgadillo, P.; Gronheid, R.; Thode, C.J.; Wu, H.P.; Cao, Y.; Neisser, M.; Somervell, M.; Nafus, K.; Nealey, P.F. Implementation of a chemo-epitaxy flow for directed self-assembly on 300-mm wafer processing equipment. J. Micro Nanolith. MEMS MOEMS 2012, 11, 31302. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, H.J.; Roh, J.H.; Choi, J.K.; Cha, K.R. Simple and Cost-Effective method for edge bead removal by using a taping method. J. Korean Phys. Soc. 2018, 73, 1473–1478. [Google Scholar] [CrossRef]

- Lin, C.H.; Lee, G.B.; Chang, B.W.; Chang, G.L. A new fabrication process for ultra-thick microfluidic microstructures utilizing SU-8 photoresist. J. Micromech. Microeng. 2002, 12, 590–597. [Google Scholar] [CrossRef]

- Pannek, M.; Dunkel, T.; Schubert, D.W. Effect of a bell-shaped cover in spin coating process on final film thickness. Mater. Res. Innov. 2001, 4, 340–343. [Google Scholar] [CrossRef]

- Torino, S.; Bhowmick, S.; Iodice, M.; Casalino, M.; Tufano, V.; Selvaggi, D.; Coppola, G.; Gioffrè, M. Edge beads removal in a photolithography process through a polymer mold. Songklanakarin J. Sci. Technol. 2021, 43, 485–491. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Chu, J.; Zhang, R.; Guan, C.; Fan, Y. Preparation of an Integrated Polarization Navigation Sensor via a Nanoimprint Photolithography Process. Photonics 2022, 9, 806. https://doi.org/10.3390/photonics9110806

Liu Z, Chu J, Zhang R, Guan C, Fan Y. Preparation of an Integrated Polarization Navigation Sensor via a Nanoimprint Photolithography Process. Photonics. 2022; 9(11):806. https://doi.org/10.3390/photonics9110806

Chicago/Turabian StyleLiu, Ze, Jinkui Chu, Ran Zhang, Chuanlong Guan, and Yuanyi Fan. 2022. "Preparation of an Integrated Polarization Navigation Sensor via a Nanoimprint Photolithography Process" Photonics 9, no. 11: 806. https://doi.org/10.3390/photonics9110806

APA StyleLiu, Z., Chu, J., Zhang, R., Guan, C., & Fan, Y. (2022). Preparation of an Integrated Polarization Navigation Sensor via a Nanoimprint Photolithography Process. Photonics, 9(11), 806. https://doi.org/10.3390/photonics9110806