Narrow-Linewidth Single-Frequency Ytterbium Laser Based on a New Composite Yb3+-Doped Fiber

Abstract

:1. Introduction

2. Materials and Methods

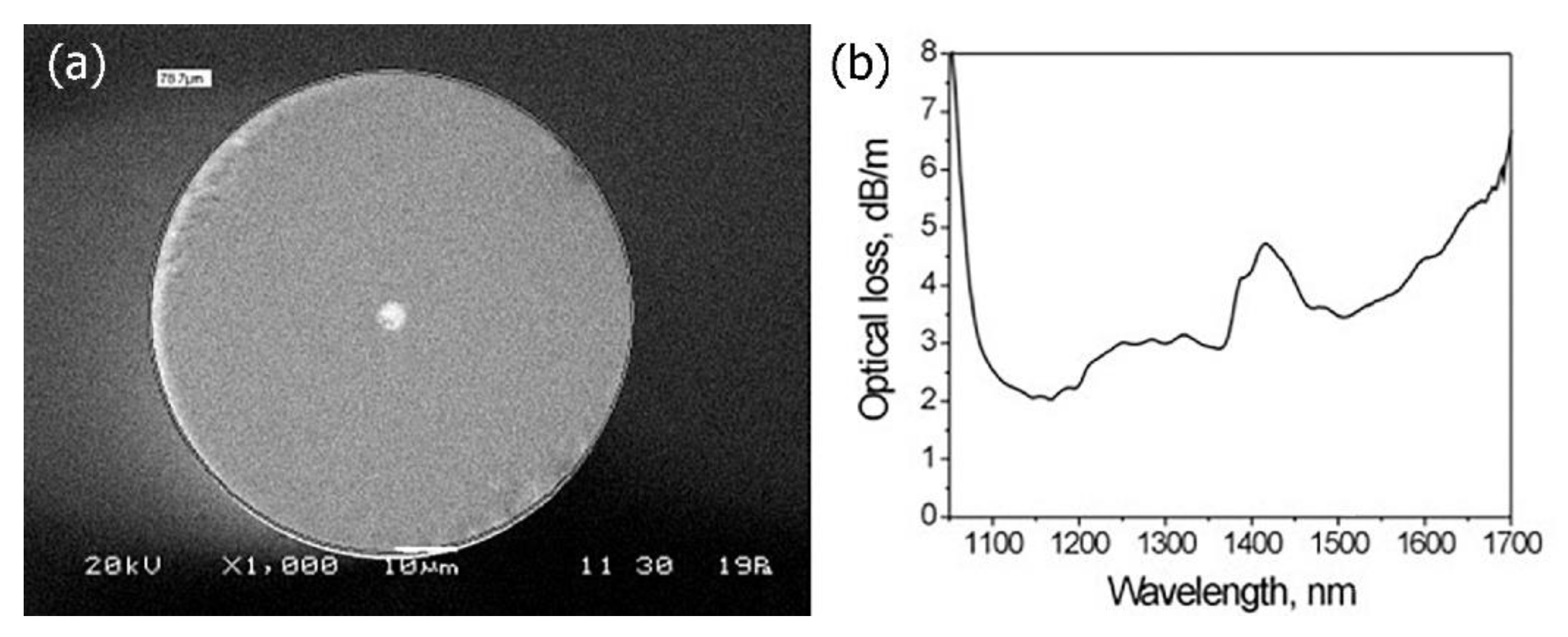

2.1. Composite Ytterbium-Doped Fiber

2.2. Experimental Setup

3. Results

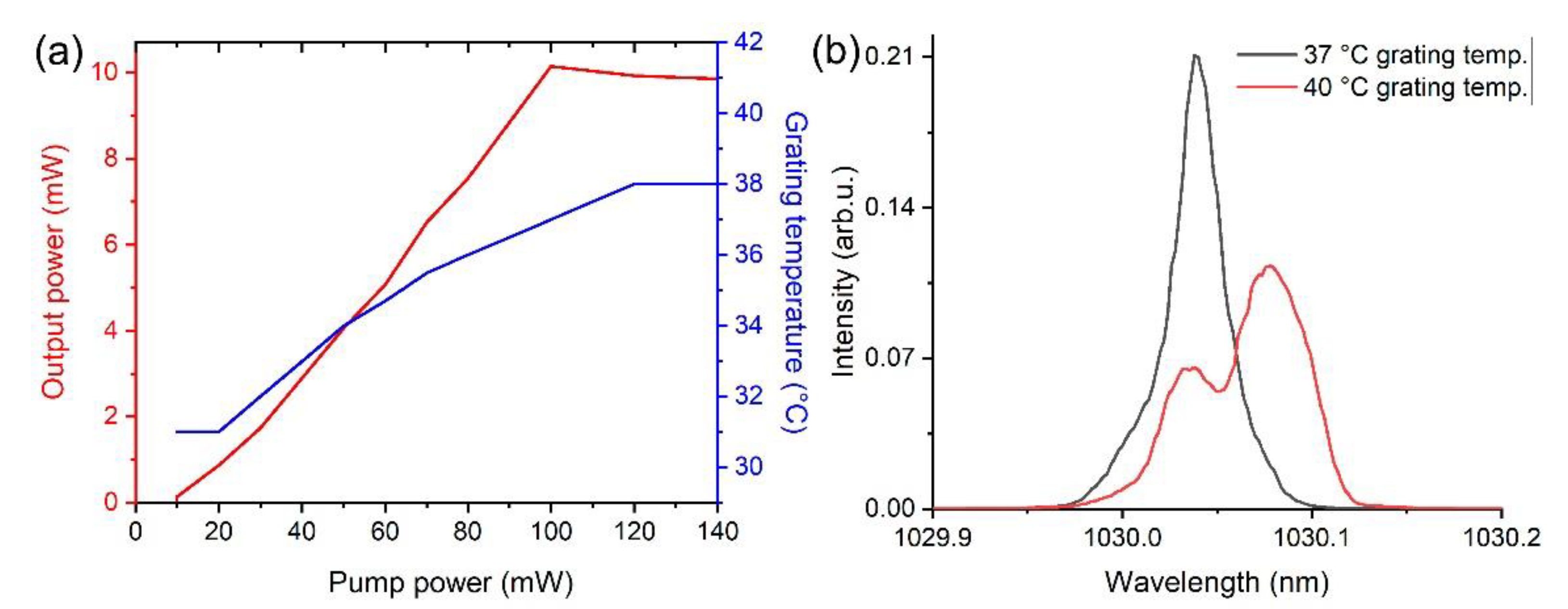

3.1. Optimization of the Active Fiber Length

3.2. Single-Frequency Regime

3.3. Laser Output Parameters

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bonfrate, G.; Vaninetti, F.; Negrisolo, F. Single-frequency MOPA Er/sup 3+/ DBR fiber laser for WDM digital telecommunication systems. IEEE Photonics Technol. Lett. 1998, 10, 1109–1111. [Google Scholar] [CrossRef]

- Abbott, B.P.; Abbott, R.; Adhikari, R.; Ajith, P.; Allen, B.; Allen, G.; Amin, R.S.; Anderson, S.B.; Anderson, W.G.; Arain, M.A.; et al. LIGO: The Laser Interferometer Gravitational-Wave Observatory. Rep. Prog. Phys. 2009, 72, 076901. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, X.; Leng, J.; Xiao, H.; Dong, X.; Zhu, J.; Du, W.; Zhou, P.; Xu, X.; Si, L.; et al. Coherent beam combination of 1.08 kW fiber amplifier array using single frequency dithering technique. Opt. Lett. 2011, 36, 951–953. [Google Scholar] [CrossRef]

- Vahala, K.J.; Dawson, J.W.; Park, N.; Sanders, S. Tunable single-frequency erbium fiber ring lasers. In Proceedings of the Conference on Lasers and Electro-Optics, Baltimore, ML, USA, 2–7 May 1993; p. CThR6. Available online: http://opg.optica.org/abstract.cfm?URI=CLEO-1993-CThR6 (accessed on 5 September 2022).

- Namkyoo, P.; Dawson, J.W.; Vahala, K.J.; Miller, C. All fiber, low threshold, widely tunable single-frequency, fiber ring laser with a tandem fiber Fabry–Perot filter. Appl. Phys. Lett. 1991, 59, 2369–2371. [Google Scholar] [CrossRef]

- Poozesh, R.; Madanipour, K.; Parvin, P. High SNR Watt-Level Single Frequency Yb-Doped Fiber Laser Based on a Saturable Absorber Filter in a Cladding-Pumped Ring Cavity. J. Lightwave Technol. 2018, 36, 4880–4886. [Google Scholar] [CrossRef]

- Sun, J.; Yuan, X.; Zhang, X.; Huang, D. Single-longitudinal-mode fiber ring laser using fiber grating-based Fabry–Perot filters and variable saturable absorbers. Opt. Commun. 2006, 267, 177–181. [Google Scholar] [CrossRef]

- Meng, Z.; Stewart, G.; Whitenett, G. Stable single-mode operation of a narrow-linewidth, linearly polarized, erbium-fiber ring laser using a saturable absorber. J. Lightwave Technol. 2006, 24, 2179–2183. [Google Scholar] [CrossRef]

- Honzatko, P.; Baravets, Y.; Myakalwar, A.K. Single-frequency fiber laser based on a fiber ring resonator filter tunable in a broad range from 1023 nm to 1107 nm. Opt. Lett. 2018, 43, 1339–1342. [Google Scholar] [CrossRef]

- Feng, S.; Mao, Q.; Tian, Y.; Ma, Y.; Li, W.; Wei, L. Widely Tunable Single Longitudinal Mode Fiber Laser with Cascaded Fiber-Ring Secondary Cavity. IEEE Photonics Technol. Lett. 2013, 25, 323–326. [Google Scholar] [CrossRef]

- Zhu, X.; Shi, W.; Zong, J.; Nguyen, D.; Norwood, R.A.; Chavez-Pirson, A.; Peyghambarian, N. 976 nm single-frequency distributed Bragg reflector fiber laser. Opt. Lett. 2012, 37, 4167–4169. [Google Scholar] [CrossRef]

- Kaneda, Y.; Spiegelberg, C.; Geng, J.; Hu, Y.; Luo, T.; Wang, J.; Jiang, S. 200-mW, narrow-linewidth 1064.2-nm Yb-doped fiber laser. In Proceedings of the Conference on Lasers and Electro-Optics/International Quantum Electronics Conference and Photonic Applications Systems Technologies, San Francisco, CA, USA, 16–21 May 2004; p. CThO3. Available online: http://opg.optica.org/abstract.cfm?URI=CLEO-2004-CThO3 (accessed on 5 September 2022).

- Xu, S.H.; Yang, Z.M.; Liu, T.; Zhang, W.N.; Feng, Z.M.; Zhang, Q.Y.; Jiang, Z.H. An efficient compact 300 mW narrow-linewidth single frequency fiber laser at 1.5 μm. Opt. Express 2010, 18, 1249–1254. [Google Scholar] [CrossRef]

- Xu, S.; Yang, Z.; Zhang, W.; Wei, X.; Qian, Q.; Chen, D.; Zhang, Q.; Shen, S.; Peng, M.; Qiu, J. 400 mW ultrashort cavity low-noise single-frequency Yb3+-doped phosphate fiber laser. Opt. Lett. 2011, 36, 3708–3710. [Google Scholar] [CrossRef]

- Hofmann, P.; Voigtländer, C.; Nolte, S.; Peyghambarian, N.; Schülzgen, A. 550-mW Output Power from a Narrow Linewidth All-Phosphate Fiber Laser. J. Lightwave Technol. 2013, 31, 756–760. [Google Scholar] [CrossRef]

- Bufetov, I.A.; Semenov, S.L.; Kosolapov, A.F.; Mel’kumov, M.A.; Dudin, V.V.; Galagan, B.I.; Denker, B.I.; Osiko, V.V.; Sverchkov, S.E.; Dianov, E.M. Ytterbium fibre laser with a heavily Yb3+-doped glass fibre core. Quantum Electron. 2006, 36, 189–191. [Google Scholar] [CrossRef]

- Karabulut, M.; Melnik, E.; Stefan, R.; Marasinghe, G.K.; Ray, C.S.; Kurkjian, C.R.; Day, D.E. Mechanical and structural properties of phosphate glasses. J. Non-Cryst. Solids 2001, 288, 8–17. [Google Scholar] [CrossRef]

- Egorova, O.N.; Semenov, S.L.; Velmiskin, V.V.; Yatsenko, Y.P.; Sverchkov, S.E.; Galagan, B.I.; Denker, B.I.; Dianov, E.M. Phosphate-core silica-clad Er/Yb-doped optical fiber and cladding pumped laser. Opt. Express 2014, 22, 7632–7637. [Google Scholar] [CrossRef]

- Egorova, O.N.; Semenov, S.L.; Medvedkov, O.I.; Astapovich, M.S.; Okhrimchuk, A.G.; Galagan, B.I.; Denker, B.I.; Sverchkov, S.E.; Dianov, E.M. High-beam quality, high-efficiency laser based on fiber with heavily Yb3+-doped phosphate core and silica cladding. Opt. Lett. 2015, 40, 3762–3765. [Google Scholar] [CrossRef]

- Rybaltovsky, A.A.; Egorova, O.N.; Zhuravlev, S.G.; Galagan, B.I.; Sverchkov, S.E.; Denker, B.I.; Semenov, S.L. Distributed Bragg reflector fiber laser directly written in a composite fiber manufactured by melting phosphate glass in a silica tube. Opt. Lett. 2019, 44, 3518–3521. [Google Scholar] [CrossRef]

- Barmenkov, Y.O.; Zalvidea, D.; Torres-Peiró, S.; Cruz, J.L.; Andrés, M.V. Effective length of short Fabry-Perot cavity formed by uniform fiber Bragg gratings. Opt. Express 2006, 14, 6394–6399. [Google Scholar] [CrossRef]

- Qiu, T.; Suzuki, S.; Schülzgen, A.; Li, L.; Polynkin, A.; Temyanko, V.; Moloney, J.V.; Peyghambarian, N. Generation of watt-level single-longitudinal-mode output from cladding-pumped short fiber lasers. Opt. Lett. 2005, 30, 2748–2750. [Google Scholar] [CrossRef]

- Mo, S.; Xu, S.; Huang, X.; Zhang, W.; Feng, Z.; Chen, D.; Yang, T.; Yang, Z. A 1014 nm linearly polarized low noise narrow-linewidth single-frequency fiber laser. Opt. Express 2013, 21, 12419–12423. [Google Scholar] [CrossRef]

- Xu, S.; Li, C.; Zhang, W.; Mo, S.; Yang, C.; Wei, X.; Feng, Z.; Qian, Q.; Shen, S.; Peng, M.; et al. Low noise single-frequency single-polarization ytterbium-doped phosphate fiber laser at 1083 nm. Opt. Lett. 2013, 38, 501–503. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koptev, M.Y.; Egorova, O.N.; Medvedkov, O.I.; Semjonov, S.L.; Galagan, B.I.; Sverchkov, S.E.; Denker, B.I.; Zapryalov, A.E.; Kim, A.V. Narrow-Linewidth Single-Frequency Ytterbium Laser Based on a New Composite Yb3+-Doped Fiber. Photonics 2022, 9, 760. https://doi.org/10.3390/photonics9100760

Koptev MY, Egorova ON, Medvedkov OI, Semjonov SL, Galagan BI, Sverchkov SE, Denker BI, Zapryalov AE, Kim AV. Narrow-Linewidth Single-Frequency Ytterbium Laser Based on a New Composite Yb3+-Doped Fiber. Photonics. 2022; 9(10):760. https://doi.org/10.3390/photonics9100760

Chicago/Turabian StyleKoptev, Maksim Yu., Olga N. Egorova, Oleg I. Medvedkov, Sergey L. Semjonov, Boris I. Galagan, Sergey E. Sverchkov, Boris I. Denker, Alexander E. Zapryalov, and Arkady V. Kim. 2022. "Narrow-Linewidth Single-Frequency Ytterbium Laser Based on a New Composite Yb3+-Doped Fiber" Photonics 9, no. 10: 760. https://doi.org/10.3390/photonics9100760

APA StyleKoptev, M. Y., Egorova, O. N., Medvedkov, O. I., Semjonov, S. L., Galagan, B. I., Sverchkov, S. E., Denker, B. I., Zapryalov, A. E., & Kim, A. V. (2022). Narrow-Linewidth Single-Frequency Ytterbium Laser Based on a New Composite Yb3+-Doped Fiber. Photonics, 9(10), 760. https://doi.org/10.3390/photonics9100760