An Ultra-Compact Design of Plasmonic Memristor with Low Loss and High Extinction Efficiency Based on Enhanced Interaction between Filament and Concentrated Plasmon

Abstract

1. Introduction

2. Experimental and Methods

3. Results and Discussions

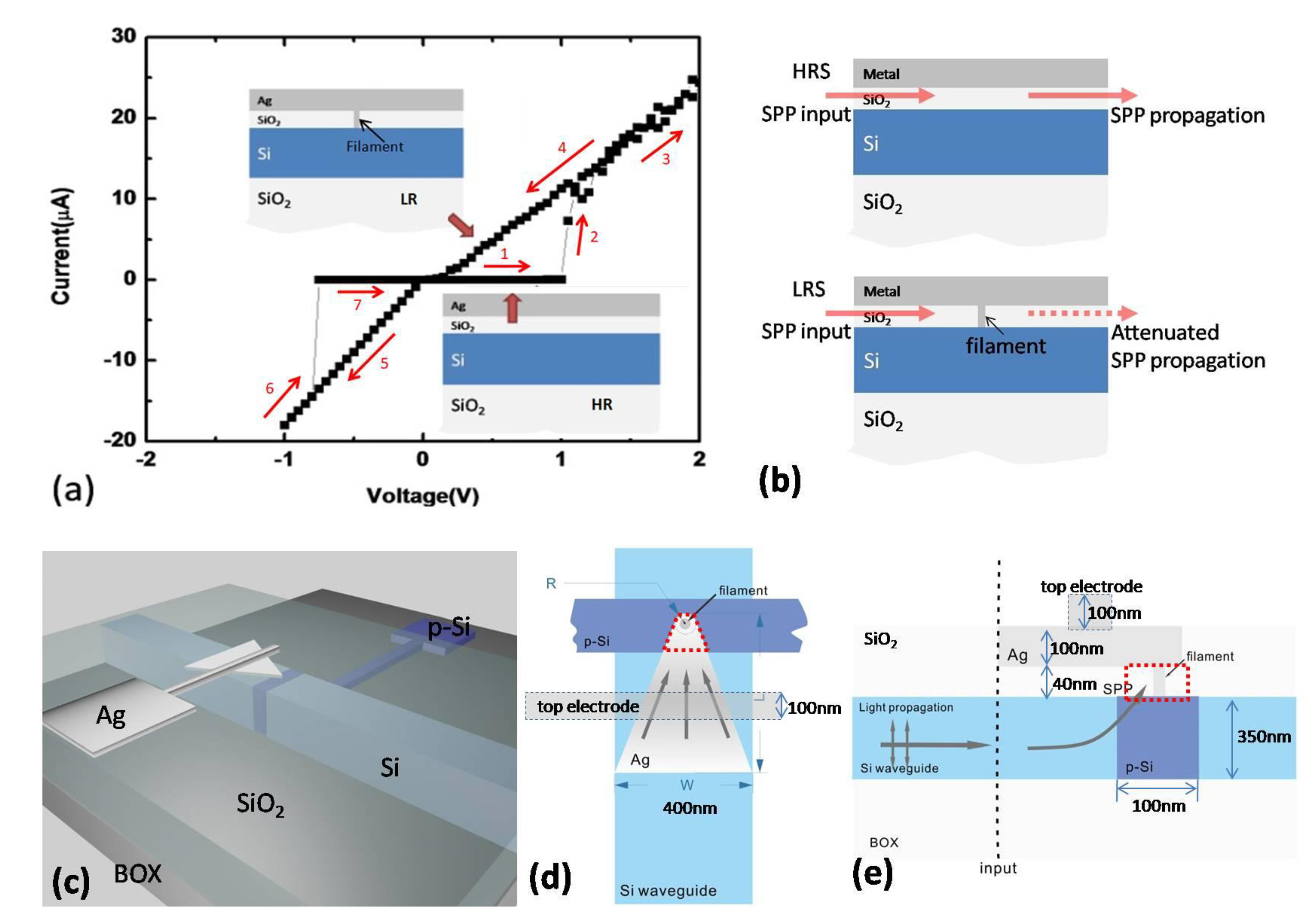

3.1. The Device Working Principle

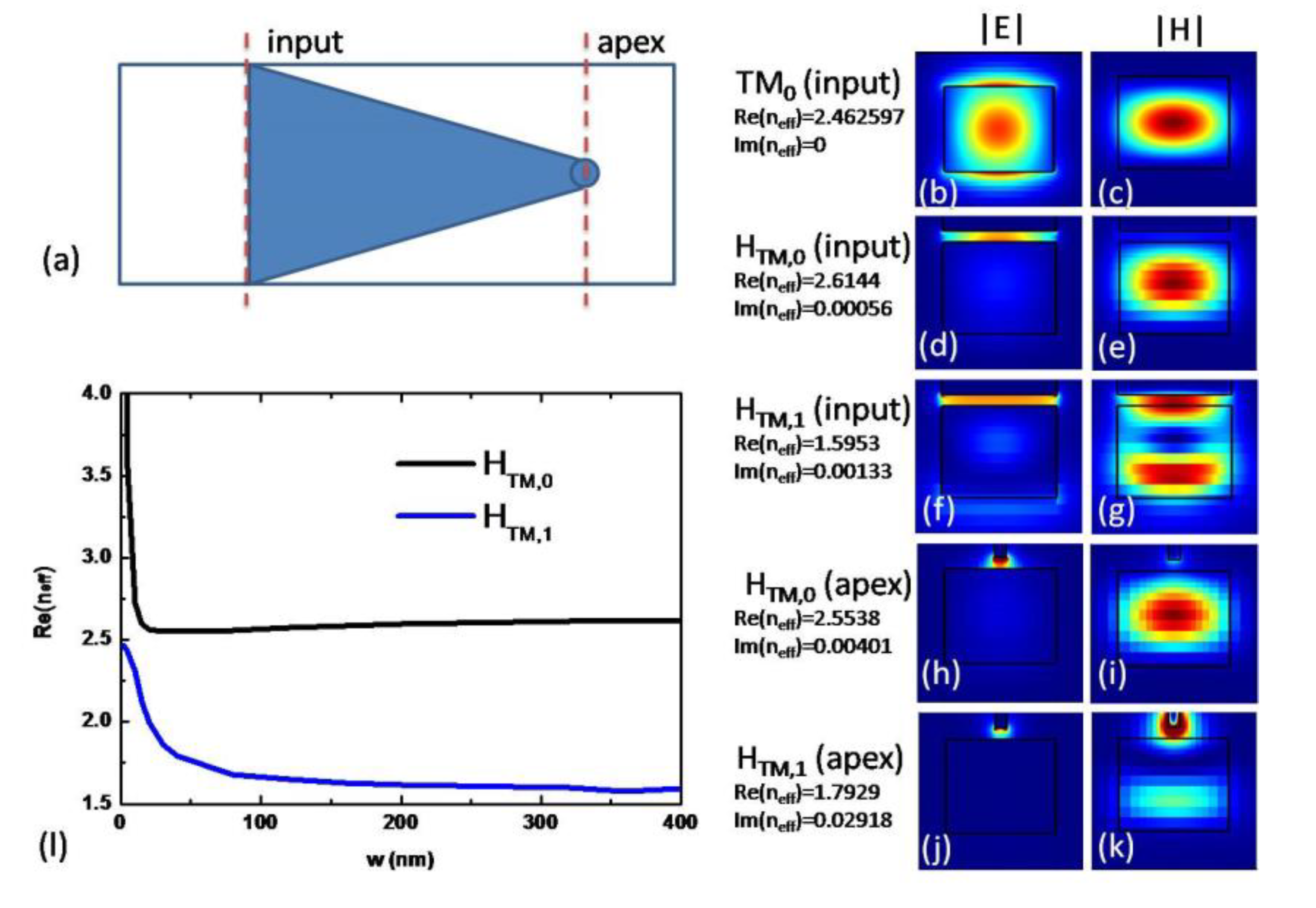

3.2. Mode Analysis of the Plasmonic Memristor

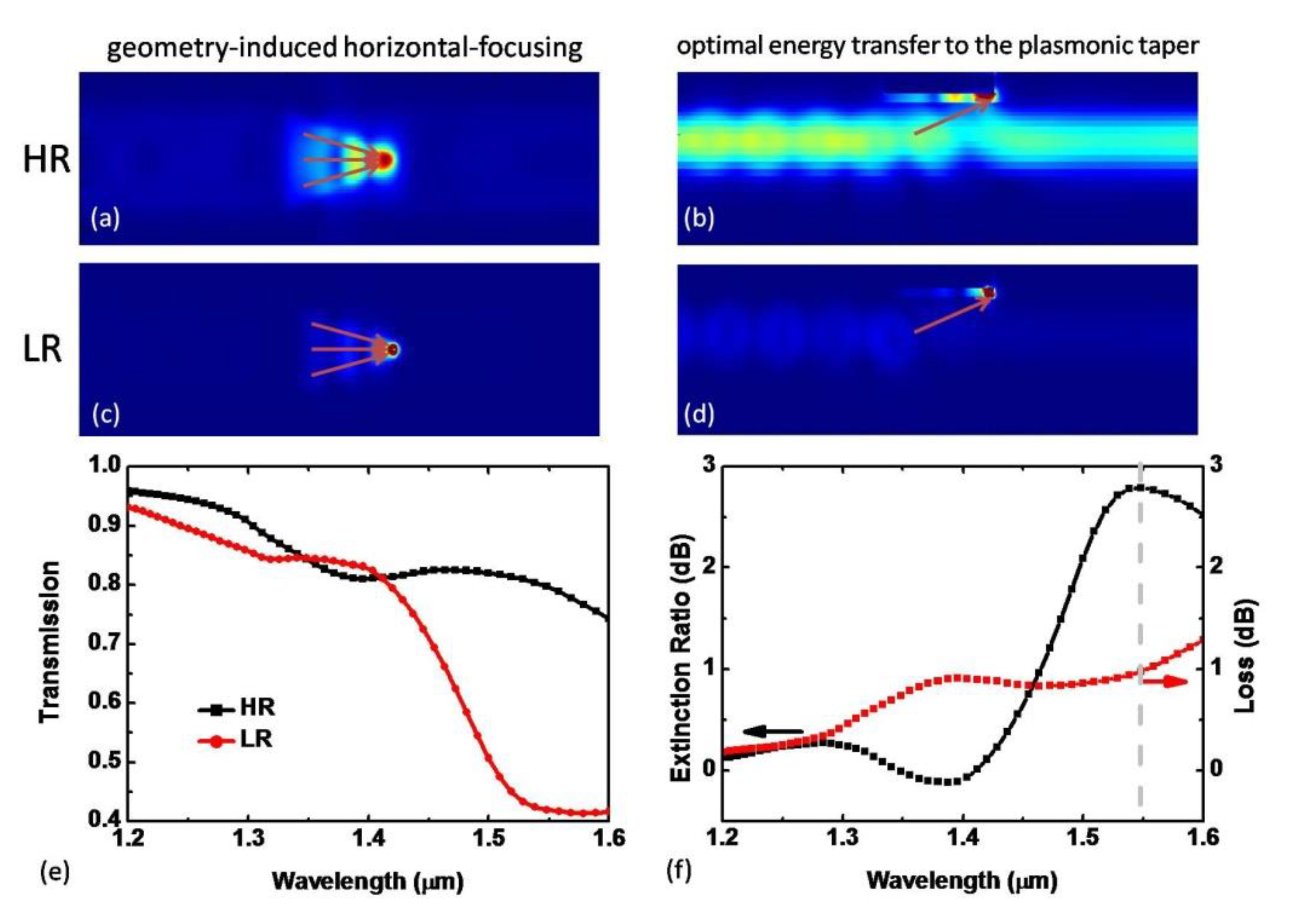

3.3. The Properties of the Plasmonic Memristor with Specified Size

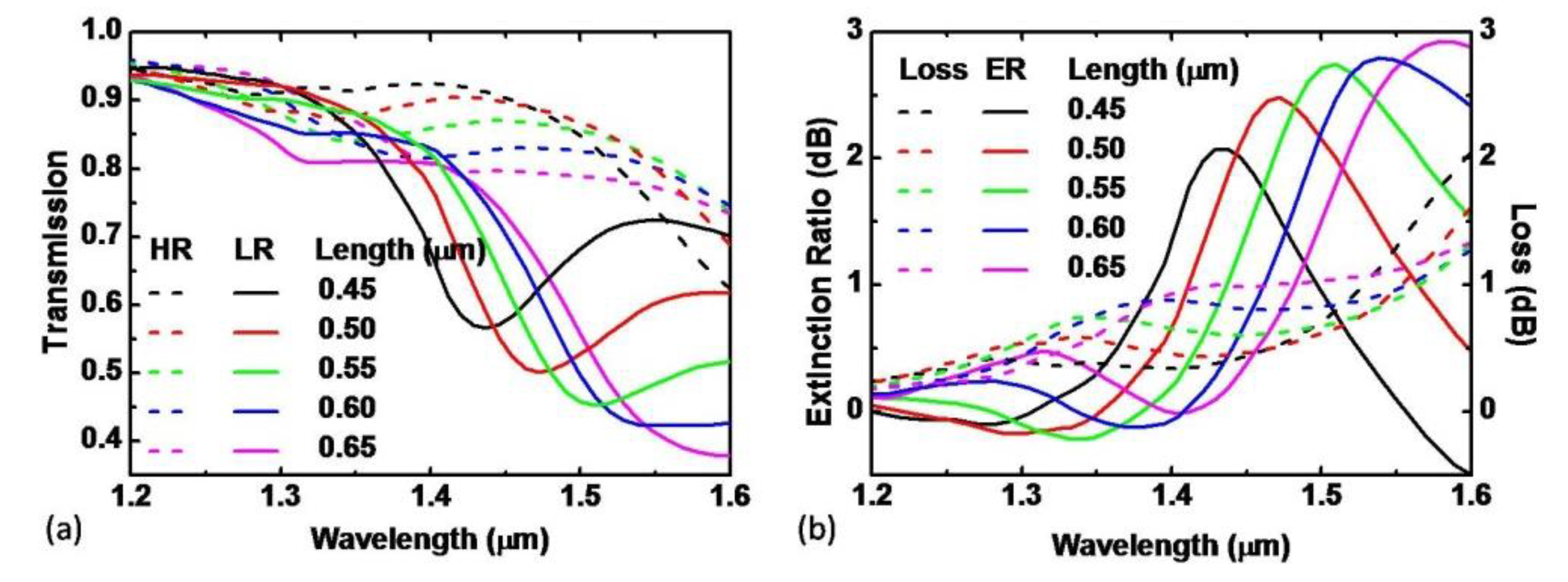

3.4. Taper Length Dependence of the Properties of the Plasmonic Memristor

3.5. Filament Dependence of the Properties of the Plasmonic Memristor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soref, R. The Past, Present, and Future of Silicon Photonics. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 1678–1687. [Google Scholar] [CrossRef]

- Melikyan, A.; Koehnle, K.; Lauermann, M.; Palmer, R.; Koeber, S.; Muehlbrandt, S.; Schindler, P.; Elder, D.; Wolf, S.; Heni, W.; et al. Plasmonic-organic hybrid (POH) modulators for OOK and BPSK signaling at 40 Gbit/s. Opt. Express. 2015, 23, 9938–9946. [Google Scholar] [CrossRef] [PubMed]

- Melikyan, A.; Alloatti, L.; Muslija, A.; Hillerkuss, D.; Schindler, P.C.; Li, J.; Palmer, R.; Korn, D.; Muehlbrandt, S.; Van Thourhout, D.; et al. High-speed plasmonic phase modulators. Nat. Photon. 2014, 8, 229–233. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef]

- Tian, Y.; Jiang, L.; Deng, Y.; Deng, S.; Zhang, G.; Zhang, X. Bi-nanorod/Si-nanodot hybrid structure: Surface dewetting induced growth and its tunable surface plasmon resonance. Opt. Mater. Express 2015, 5, 2655–2666. [Google Scholar] [CrossRef]

- Yang, J.; Perrin, M.; Lalanne, P. Analytical Formalism for the Interaction of Two-Level Quantum Systems with Metal Nanoresonators. Phys. Rev. X 2015, 5, 021008. [Google Scholar] [CrossRef]

- Pile, D.F.; Ogawa, T.; Gramotnev, D.K.; Matsuzaki, Y.; Vernon, K.C.; Yamaguchi, K.; Okamoto, T.; Haraguchi, M.; Fukui, M. Two-dimensionally localized modes of a nanoscale gap plasmon waveguide. Appl. Phys. Lett. 2005, 87, 261114. [Google Scholar] [CrossRef]

- Nikolajsen, T.; Leosson, K.; Bozhevolnyi, S.I. Surface plasmon polariton based modulators and switches operating at telecom wavelengths. Appl. Phys. Lett. 2004, 85, 5833–5835. [Google Scholar] [CrossRef]

- Heeres, R.W.; Dorenbos, S.N.; Koene, B.; Solomon, G.S.; Kouwenhoven, L.P.; Zwiller, V. On-chip single plasmon detection. Nano Lett. 2009, 10, 661–664. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Emboras, A.; Goykhman, I.; Desiatov, B.; Mazurski, N.; Stern, L.; Shappir, J.; Levy, U. Nanoscale Plasmonic Memristor with Optical Readout Functionality. Nano Lett. 2013, 13, 6151–6155. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, S. The missing memristor found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Mehonic, A.; Cueff, S.; Wojdak, M.; Hudziak, S.; Jambois, O.; Labbé, C.; Garrido, B.; Rizk, R.; Kenyon, A. Resistive switching in silicon suboxide films. J. Appl. Phys. 2012, 111, 074507. [Google Scholar] [CrossRef]

- Tian, Y.; Guo, C.; Guo, S.; Yu, T.; Liu, Q. Bivariate-continuous-tunable interface memristor based on Bi2S3 nested nano-networks. Nano Res. 2014, 7, 953–962. [Google Scholar] [CrossRef]

- Hoessbacher, C.; Fedoryshyn, Y.; Emboras, A.; Melikyan, A.; Kohl, M.; Hillerkuss, D.; Hafner, C.; Leuthold, J. The plasmonic memristor: A latching optical switch. Optica 2014, 1, 198. [Google Scholar] [CrossRef]

- Di Martino, G.; Tappertzhofen, S.; Hofmann, S.; Baumberg, J. Nanoscale Plasmon-Enhanced Spectroscopy in Memristive Switches. Small 2016, 12, 1334–1341. [Google Scholar] [CrossRef]

- Koch, U.; Hoessbacher, C.; Emboras, A.; Leuthold, J. Optical memristive switches. J. Electroceramics 2017, 39, 239–250. [Google Scholar] [CrossRef]

- Borghetti, J.; Snider, G.S.; Kuekes, P.J.; Yang, J.J.; Stewart, D.R.; Williams, R.S. Memristive’switches enable ‘stateful’ logic operations via material implication. Nature 2010, 464, 873–876. [Google Scholar] [CrossRef]

- Kvatinsky, S.; Kolodny, A.; Weiser, U.C.; Friedman, E.G. Memristor-based IMPLY logic design procedure. In Proceedings of the 2011 IEEE 29th International Conference on Computer Design (ICCD), Amherst, MA, USA, 9–12 October 2011; pp. 142–147. [Google Scholar]

- Parra, J.; Olivares, I.; Brimont, A.; Sanchis, P. Non-volatile epsilon-near-zero readout memory. Opt. Lett. 2019, 44, 3932–3935. [Google Scholar] [CrossRef]

- Singh, L.; Jain, S.; Kumar, M. Electrically writable silicon nanophotonic resistive memory with inherent stochasticity. Opt. Lett. 2019, 44, 4020–4023. [Google Scholar] [CrossRef]

- Ríos, C.; Youngblood, N.; Cheng, Z.; Le Gallo, M.; Pernice, W.H.P.; Wright, C.D.; Sebastian, A.; Bhaskaran, H. In-memory computing on a photonic platform. Sci. Adv. 2019, 5, eaau5759. [Google Scholar] [CrossRef]

- Xue, W.; Ci, W.; Xu, X.-H.; Liu, G. Optoelectronic memristor for neuromorphic computing. Chin. Phys. B 2020, 29, 048401. [Google Scholar] [CrossRef]

- Portner, K.; Schmuck, M.; Lehmann, P.; Weilenmann, C.; Haffner, C.; Ma, P.; Leuthold, J.; Luisier, M.; Emboras, A. Analog Nanoscale Electro-Optical Synapses for Neuromorphic Computing Applications. ACS Nano 2021, 15, 14776–14785. [Google Scholar] [CrossRef] [PubMed]

- Waser, R.; Dittmann, R.; Staikov, G.; Szot, K. Redox-based resistive switching memories–nanoionics mechanisms, prospects, and challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef]

- Tian, Y.; Pan, L.; Guo, C.F.; Liu, Q. Atomic origin of the traps in memristive interface. Nano Res. 2016, 10, 1924–1931. [Google Scholar] [CrossRef]

- Sawa, A. Resistive switching in transition metal oxides. Mater. Today 2008, 11, 28–36. [Google Scholar] [CrossRef]

- Flammer, P.D.; Banks, J.M.; Furtak, T.E.; Durfee, C.G.; Hollingsworth, R.E.; Collins, R.T. Hybrid plas-mon/dielectric waveguide for integrated silicon-on-insulator optical elements. Opt. Express 2010, 18, 21013–21023. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Chamanzar, M.; Adibi, A. Compact on-chip plasmonic light concentration based on a hybrid pho-tonic-plasmonic structure. Opt. Expres. 2013, 21, 1898–1910. [Google Scholar] [CrossRef]

- Dong, P.; Liao, S.; Liang, H.; Shafiiha, R.; Feng, D.; Li, G.; Zheng, X.; Krishnamoorthy, A.V.; Asghari, M. Submilliwatt, ultrafast and broadband electro-optic silicon switches. Opt. Express 2010, 18, 25225–25231. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Shu, Z.; Zhang, S.; Zeng, P.; Liang, H.; Zheng, M.; Duan, H. Sub-10 nm fabrication: Methods and applications. Int. J. Extreme Manuf. 2021, 3, 032002. [Google Scholar] [CrossRef]

- Stockman, M.I. Nanofocusing of Optical Energy in Tapered Plasmonic Waveguides. Phys. Rev. Lett. 2004, 93, 137404. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, K.; Yu, Z.; Fan, J.A. Electrochemically Programmable Plasmonic Antennas. ACS Nano 2016, 10, 6716–6724. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Son, J.Y. The effect of size on the resistive switching characteristics of NiO nanodots. J. Phys. Chem. Solids 2016, 99, 134–137. [Google Scholar] [CrossRef]

- Ma, Y.; Yeoh, P.P.; Shen, L.; Goodwill, J.M.; Bain, J.A.; Skowronski, M. Evolution of the conductive filament with cycling in TaOx-based resistive switching devices. J. Appl. Phys. 2020, 128, 194501. [Google Scholar] [CrossRef]

- Emboras, A.; Niegemann, J.; Ma, P.; Haffner, C.; Pedersen, A.; Luisier, M.; Schimmel, T.; Leuthold, J. Atomic Scale Plasmonic Switch. Nano Lett. 2016, 16, 709–714. [Google Scholar] [CrossRef]

- Matsuzaki, Y.; Okamoto, T.; Haraguchi, M.; Fukui, M.; Nakagaki, M. Characteristics of gap plasmon wave-guide with stub structures. Opt. Express. 2008, 16, 16314–16325. [Google Scholar] [CrossRef]

- Singh, L.; Srivastav, S.; Kaushik, V.; Rajput, S.; Mishra, R.D.; Kumar, M. Light Assisted Electro-Metallization in Resistive Switch with Optical Accessibility. J. Light. Technol. 2021. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, J.; Guo, C.F.; Zhang, B.; Liu, Q. Photoconductive probing of the trap distribution in switchable interfaces. Nanoscale 2016, 8, 915–920. [Google Scholar] [CrossRef]

- Pan, F.; Chen, C.; Wang, Z.-S.; Yang, Y.-C.; Yang, J.; Zeng, F. Nonvolatile resistive switching memo-ries-characteristics, mechanisms and challenges. Prog. Nat. Sci. Mater. Int. 2010, 20, 1–15. [Google Scholar] [CrossRef]

- Wu, W.; Shan, B.; Feng, K.; Nan, H. Resistive switching behavior of Sb2S3 thin film prepared by chemical bath deposition. Mater. Sci. Semicond. Process. 2016, 44, 18–22. [Google Scholar] [CrossRef]

- Nardi, F.; Ielmini, D.; Cagli, C.; Spiga, S.; Fanciulli, M.; Goux, L.; Wouters, D. Control of filament size and reduction of reset current below 10μA in NiO resistance switching memories. Solid State Electron. 2011, 58, 42–47. [Google Scholar] [CrossRef]

| Refs | Device Length (μm) | Loss (dB) | extinction Ratio (dB) | Extinction Efficiency (dB/μm) |

|---|---|---|---|---|

| [10] | 3 | 4.2 | 0.09 | 0.03 |

| [14] | 5 (10) | 18 (23) | 6 (12) | 1.2 |

| [25] | 2.2 | 25 | 9.2 | 4.2 |

| [32] *,# | 5 | 0.2 | 10 | 2 |

| [33] | 5000 | / | 10 | 0.002 |

| [34] | 1000 | / | 16 | 0.016 |

| This work * | 0.61 | 1 | 2.8 | 4.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Zhang, S.; Tan, W. An Ultra-Compact Design of Plasmonic Memristor with Low Loss and High Extinction Efficiency Based on Enhanced Interaction between Filament and Concentrated Plasmon. Photonics 2021, 8, 437. https://doi.org/10.3390/photonics8100437

Tian Y, Zhang S, Tan W. An Ultra-Compact Design of Plasmonic Memristor with Low Loss and High Extinction Efficiency Based on Enhanced Interaction between Filament and Concentrated Plasmon. Photonics. 2021; 8(10):437. https://doi.org/10.3390/photonics8100437

Chicago/Turabian StyleTian, Ye, Saiwen Zhang, and Weishi Tan. 2021. "An Ultra-Compact Design of Plasmonic Memristor with Low Loss and High Extinction Efficiency Based on Enhanced Interaction between Filament and Concentrated Plasmon" Photonics 8, no. 10: 437. https://doi.org/10.3390/photonics8100437

APA StyleTian, Y., Zhang, S., & Tan, W. (2021). An Ultra-Compact Design of Plasmonic Memristor with Low Loss and High Extinction Efficiency Based on Enhanced Interaction between Filament and Concentrated Plasmon. Photonics, 8(10), 437. https://doi.org/10.3390/photonics8100437