3.1. Devices Emitting above 3 μm

An increase in the operating wavelength of the type-I QW GaSb-based laser into a spectral region above 3 μm is expected to be accompanied by a fundamental enhancement of the Auger recombination and free carrier absorption rates, as well as material-specific reduction of the hole confinement barriers [

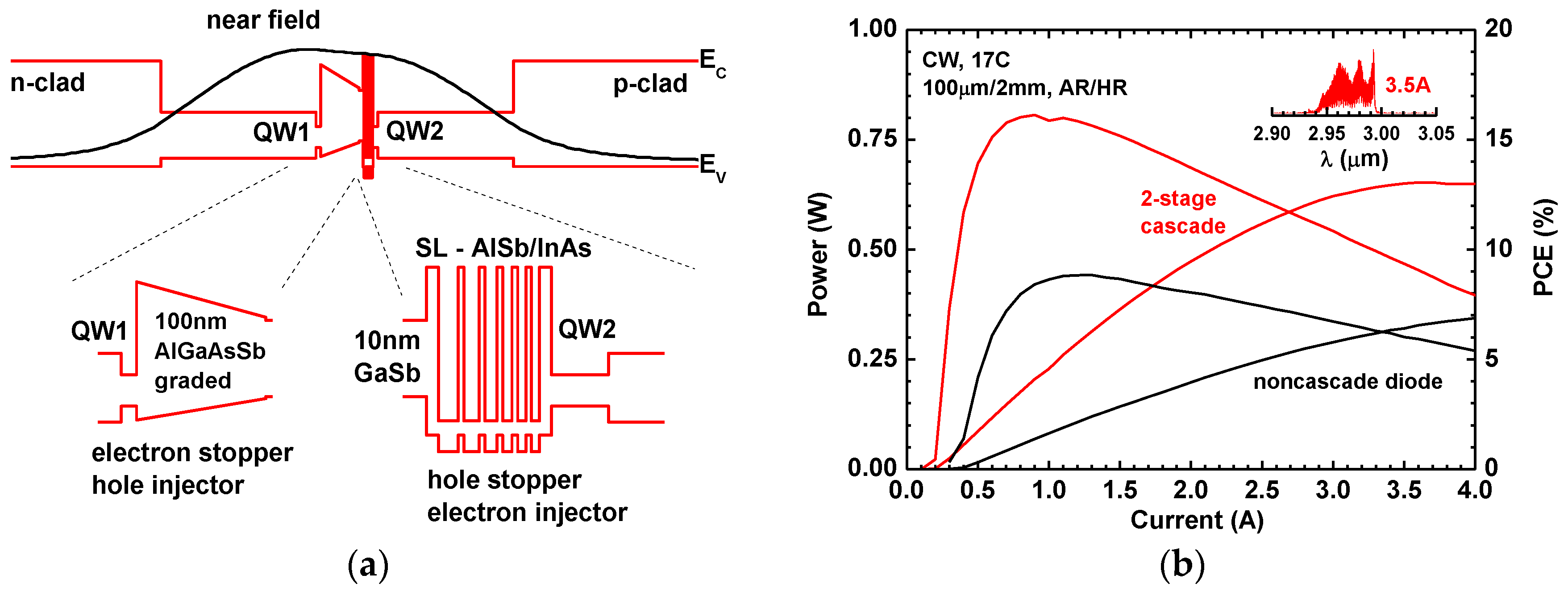

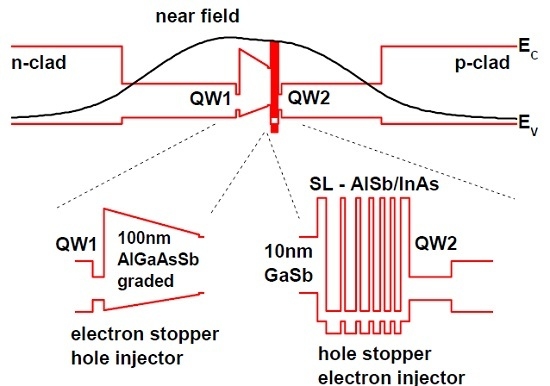

17]. The attempt to utilize the same two-stage laser heterostructure, as was used for λ ~ 3 μm emitters (

Figure 1) but with the QW indium composition increased to ~55%, yielded 3.15–3.2-μm lasers with a twofold improvement of slope efficiency compared to reference diodes. However, there was no improvement in terms of threshold current density and maximum CW output power [

16]. Modal gain measurements revealed that the two-stage cascade lasers where λ > 3 μm suffer from gain saturation. The experiment showed [

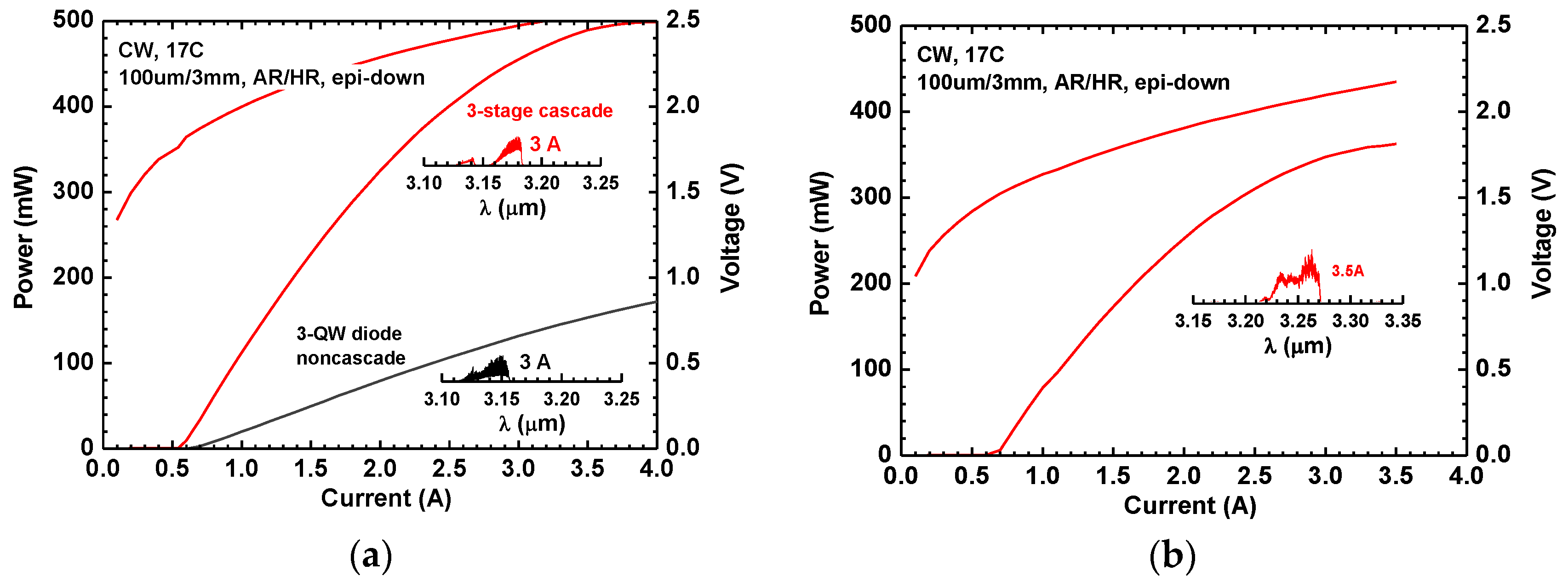

15] that the increase in the number of cascades from two to three led to a critical enhancement of the differential gain and reduction in the threshold current density of λ > 3-μm lasers. Light p-doping of the AlGaAsSb graded section did not introduce extra optical loss but aided hole transport, as required for the realization of the efficient multi-stage cascade pumping scheme. Corresponding coated three-stage devices with an ~100-μm-wide aperture and a 3-mm-long cavity demonstrated CW output power of 500 mW near 3.18 μm at 17 °C—a more than twofold increase compared to previous state-of-the-art diode lasers emitting ~200 mW (

Figure 2a). The device threshold current density was about 200 A/cm

2. These parameters were achieved using lasers soldered epi-down with indium directly onto gold-plated copper blocks. Coated 3-mm-long devices demonstrated parameters T

0 and T

1 of ~45 K and ~80 K, respectively, as measured in a low-duty cycle regime (200 ns/100 kHz) in a temperature range from 15 to 60 °C.

In order to extend the operating wavelength of the three-stage cascade lasers into a technologically important spectral region of the methane absorption, we further increased the indium composition of active QWs to about 58%. The laser heterostructure was similar to three-stage designs used for the development of 3.15–3.2-μm emitters except for the AlGaInAsSb layer between n-cladding and QW1, being replaced with lightly tellurium-doped GaSb. The hole confinement in QW1 was achieved by adding an InAs/AlSb superlattice insert between GaSb and QW1. The devices demonstrated an internal optical loss of 6–7-cm

−1 as determined by the Hakki–Paoli gain measurements and record low (for lasers operating in this spectral region) threshold current densities of ~250 A/cm

2.

Figure 2b shows light-current-voltage characteristics measured in a CW regime for 100-μm-wide, 3-mm-long, coated three-stage cascade lasers. A more than threefold improvement of output power compared to previously reported non-cascade diodes [

18] was demonstrated with the three-stage modified cascade design, leading to a record 360-mW output power level near 3.25 μm. The voltage drop across the laser heterostructure was about 2.2 V at the current of 3.5 A, corresponding to the maximum CW output power level. Peak power conversion efficiency was near 7%.

It should be noted that cascade pumping scheme allows for easy integration of the active regions with a slightly different gain spectrum into laser heterostructure, helping to achieve a wide net optical gain spectrum. Since each of the QWs is separated by an injector region, they do not compete for pumping current and can be separately designed to contribute to laser optical gain in different regions of spectra. This flexibility in gain shaping related to the cascade pumping scheme can yield efficient external cavity lasers with a wide tuning range, offering critical benefits to various tunable laser spectroscopy applications.

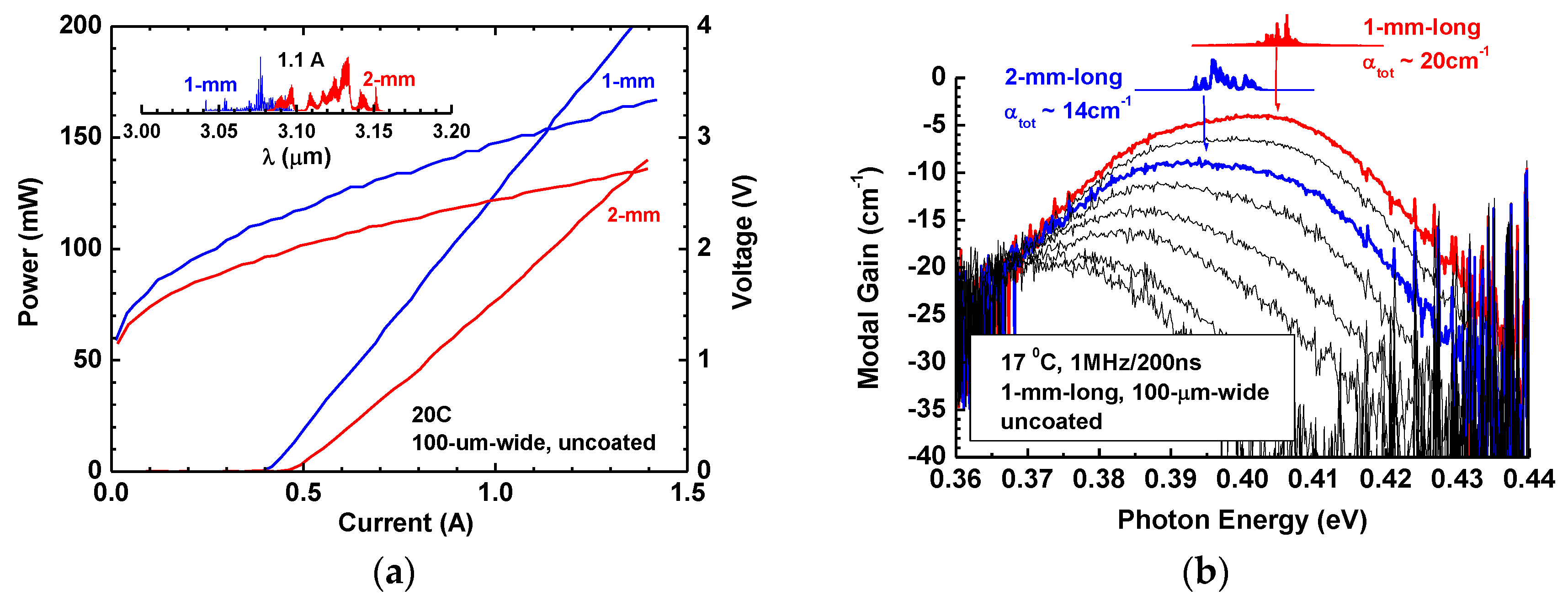

Figure 3 plots light-current-voltage characteristics and modal optical gain measured for three stage cascade lasers containing three slightly different QWs, yielding wide optical gain peak. In the example of

Figure 3b, the gain spectra peak near 0.39 eV after transparency, and then it shifts to ~0.41 eV with pumping current. This leads to device operation at very different wavelengths for different net cavity loss levels. Inserts to

Figure 3a,b show the emission spectra of 1-mm- and 2-mm-long lasers made of this wafer. Since 2-mm-long devices have about 6 cm

−1 lower total loss compared to 1-mm-long lasers, the lower pumping current yields gain peak at longer wavelengths. At a certain pumping level, the gain spectrum has a wide flat region, implying a virtually unchanged threshold current for lasers with a corresponding emission wavelength if selected by an external cavity element such as diffraction grating.

The utilization of the benefits of cascade diode laser technology in the field of tunable laser spectroscopy (TLS) requires the development of a robust method for the fabrication of efficient devices with a diffraction limited beam. One classic approach to produce single-spatial-mode diode lasers is based on etching the narrow-ridge to confine mode in a lateral direction. Our studies of the shallow ridge waveguide two-stage cascade diode lasers demonstrated that the utilization of the ridge geometry that was nearly optimal for non-cascade multiple-QW diode lasers [

19] led to excessive lateral current spreading penalty [

10]. Efficient device operation in a spectral region above 3 μm requires more than two cascades, and an increase in the number of cascades increases the tendency to lateral current spreading. Deep etching through the interband gain section confines the current well but often signifies the role of the parasitic surface recombination current and can increase internal losses in narrow-ridge designs or promote multimode operation when wider ridges are used. One possible solution is based on a separate lateral confinement structure in which a wide deep ridge confines the current, while a narrow shallow ridge forms a modal field. It was demonstrated that this approach can dramatically improve performance parameters of the interband cascade, laterally coupled distributed-feedback lasers [

20]. It should be noted that in case of tunnel-junction vertical cavity surface-emitting lasers based on GaSb, the lateral current spreading promoted by a GaSb/GaSb pn junction was utilized to guide the current into the aperture defined by a heavily doped GaSb/InAs tunnel junction (see, for instance, [

21]).

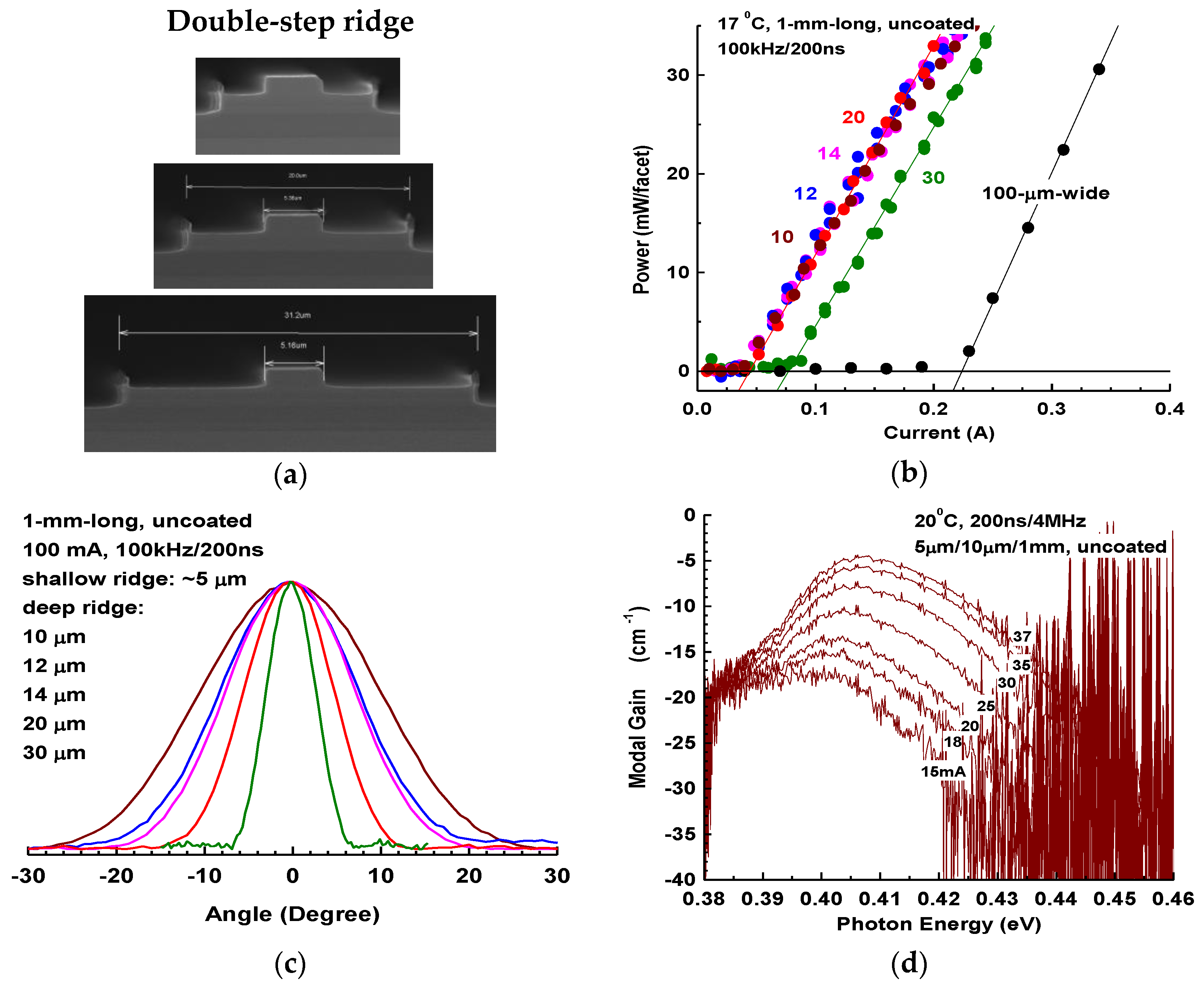

We studied the effect of the width of the deep-etched and etching depth of the shallow ridges on threshold current and fundamental mode stability in a three-stage cascade type-I QW double-step ridge lasers.

Figure 4a shows the example of a cross-sectional scanning electron microscope (SEM) image of the double-step ridge waveguide structure with a shallow ridge width of ~5 μm and a deep-etched section of variable width. In our experiments, the width of the deep-etched ridge varied from ~10 to ~30 μm. A strong tendency to lateral current spreading was confirmed by a dependence of the threshold current on the width of the deep-etched section in devices with a fixed geometry of the shallow-etched ridge. The threshold current nearly perfectly scales with the deep-etched width reduction from 100 to 20 μm. A further reduction in the deep-etched section width does not reduce the threshold current, presumably due to an increased role of the recombination current and scattering loss at the etched ridge sidewalls. It should be noted that the experiment shows, and modeling confirms, that the wide deep-etched section does affect the fundamental mode shape, and the lateral far-field divergence angle decreases with an increasing wide-ridge section width (

Figure 4c).

The far-field pattern corresponding to the single-step shallow ridge is only approached for a wide deep ridge width above ~30 μm (

Figure 4c) when lateral current spreading substantially increases the device threshold (

Figure 4b). Devices with 10-μm-wide deep-etched ridges generated beams with slow axis far-field divergence angle above 20 degrees at full width at half maximum due to a strong lateral confinement of the modal field.

Figure 4d plots modal gain spectra measured at different currents below the threshold for lasers with a 10-μm-wide deep-ridge section. The internal loss of about 9–10 cm

−1 can be estimated from the long-wavelength part of the gain spectra—only about 2–3 cm

−1 above the values measured for 100-μm-wide single-step deep-etched reference lasers. Thus, the strong lateral confinement of the laser mode reinforced by deep etching does not generate excessive optical loss. This observation is also reflected in rather similar efficiencies of 100-μm-wide broad-stripe and narrow-ridge lasers (

Figure 4b). The injection efficiencies of wide- and narrow-ridge devices are estimated to be ~180%. It should be noted that the etching depth of the narrow shallow ridge is a critical parameter for stable single-spatial-mode operation at high current/power and insufficient etching does not introduce enough loss to prevent excitation of the higher-order modes that are supported in double-step waveguide structures with a wide deep-ridge section. The CW performance of the optimized λ > 3-μm ridge devices and their operation as tunable external cavity lasers will be reported elsewhere.

3.2. Devices Emitting near 2 μm

To develop a cascade heterostructure compatible with an operating wavelength near 2 μm, the carrier injectors had to be redesigned compared to those used in 3-μm lasers (

Figure 1a). The fundamental absorption edge of the first InAs QWs of an electron injector that defines a minimum wavelength for an efficient laser operation should be adjusted. The injector design used in lasers described in previous sections was expected to introduce a strong absorption loss in a spectral region below ~2.3 μm. Indeed, the devices with QWs emitting near 2 μm and utilizing an AlGaAsSb layer compositionally graded from 50 to 5% of aluminum and AlSb/InAs electron injector with a 4.2-nm-wide first InAs QW (the design utilized in lasers discussed in previous sections of this paper) were hardly able to start lasing at room temperature. In order to move the injector absorption edge below 2 μm, the AlSb/InAs electron injector (

Figure 1a, insert) was redesigned, and the first InAs QW thickness decreased to 3 nm (the rest of the chirped superlattice was modified appropriately). The devices based on the new injector design but using an unchanged AlGaAsSb compositionally graded layer demonstrated a reduced threshold and increased efficiency and became comparable to reference double-QW diode lasers at room temperature. A further strong improvement of the laser performance was achieved when initial composition of the AlGaAsSb graded layer was increased to 80% aluminum, and its doping level was set to nominal 10

17 cm

−3. The addition of the 30-nm-thick Al

0.8Ga

0.2As

0.07Sb

0.93 constant composition layer just before the 100-nm graded layer led to a further slight increase in device efficiency [

16].

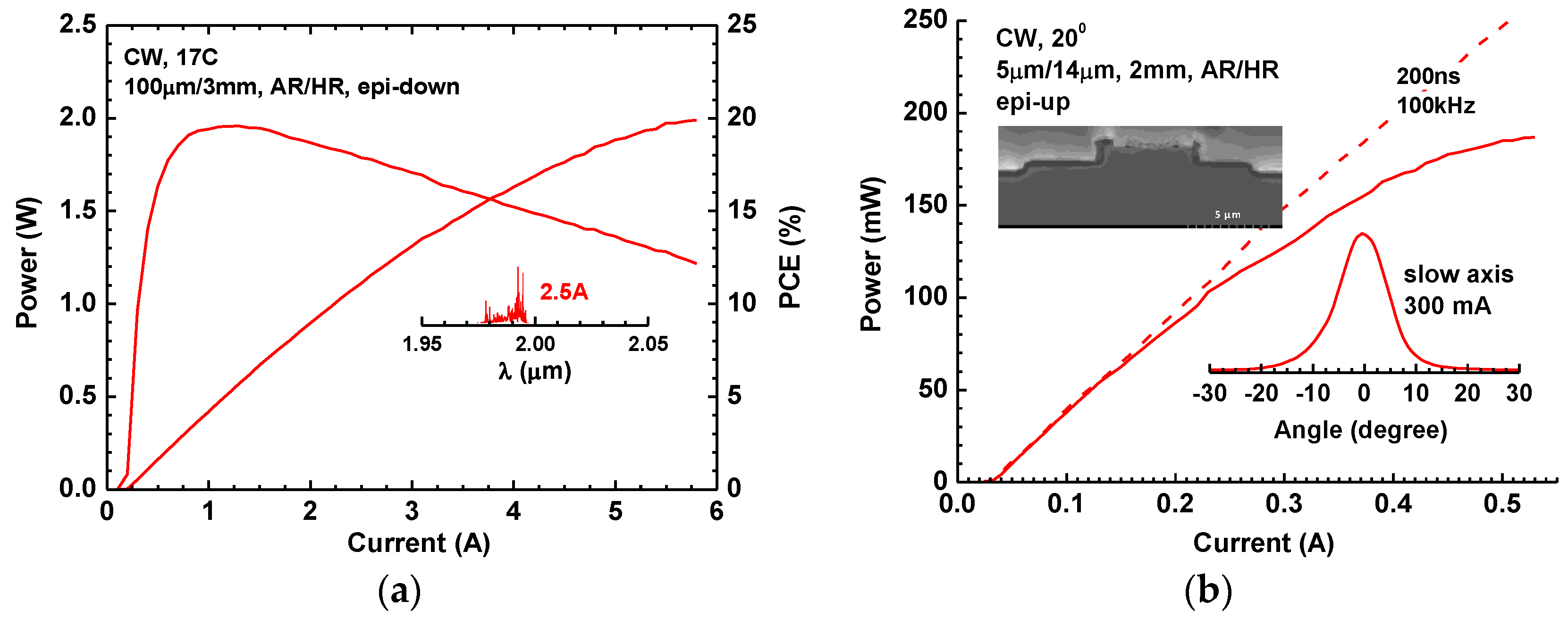

Figure 5a shows light-current-power conversion characteristics of 100-μm-wide, 3-mm-long, coated lasers generating a record ~2 W of CW output power from a 100-μm-wide aperture, as reported in [

16] and repeated here for consistency. Devices demonstrated threshold current densities of ~80 A/cm

2, an injection efficiency of ~180%, and a peak power conversion efficiency of ~20%. Double-step ridge waveguide lasers (similar to

Figure 4a) with a shallow narrow ridge of the width (~5 μm) and a ~14-μm-wide deep-etched section were fabricated.

Figure 5b plots pulsed (200 ns/100 kHz) and CW light-current characteristics of AR/HR coated 2-mm-long lasers mounted epi-side-up. Inserts show the SEM image of the as-cleaved facet of the processed laser and slow axis far-field pattern measured at 300 mA. Thanks to a large value of the slope efficiency of the cascade lasers and strong thermal stability, an output power in excess of 150 mW was achieved without the need for epi-down mounting. The estimated thermal resistance of the epi-up mounted lasers is about 40 K/W, as determined from a comparison of the spectral shift with temperature and deposited electrical power. The lasers mounted epi-down demonstrated a thermal resistance of about 25 K/W. Clearly, devices mounted epi-down were able to generate higher power levels, and their performance will be reported elsewhere. In this work, we would like to stress that for many applications, the power of the order of 100 mW in the nearly diffraction-limited beam is ample, and epi-up mounting promotes reliability and an ease of optical alignment. The parameters T

0 and T

1 measured in a low-duty cycle regime in a temperature range from 20 to 60 °C for narrow-ridge devices were about 65–75 K and 300 K, respectively. The higher values were observed for longer coated lasers. It should be noted that, if the CW regime is used to determine the parameter T

0, the artificially increased values above 80 K can be obtained.