A Study of Ultra-Thin Surface-Mounted MEMS Fibre-Optic Fabry–Pérot Pressure Sensors for the In Situ Monitoring of Hydrodynamic Pressure on the Hull of Large Amphibious Aircraft

Abstract

1. Introduction

2. The Principle of MEMS Fibre-Optic Fabry–Pérot Pressure Sensors

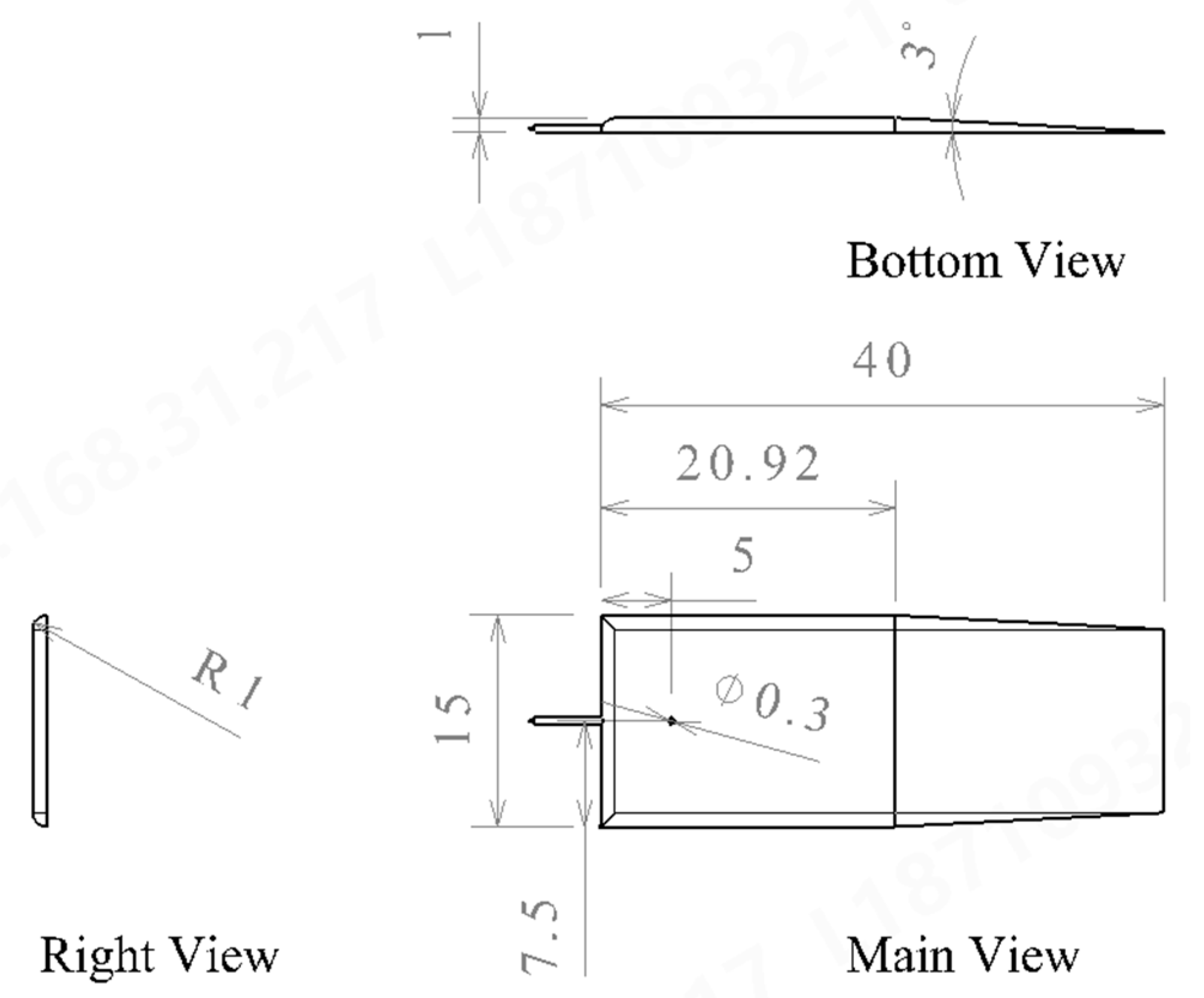

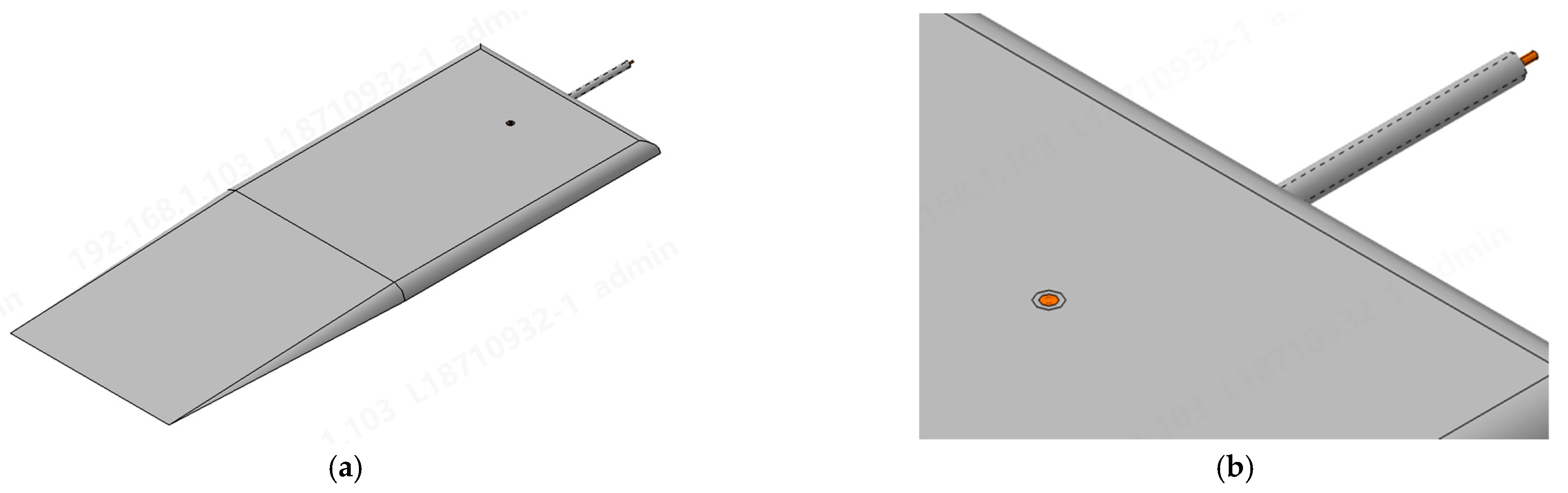

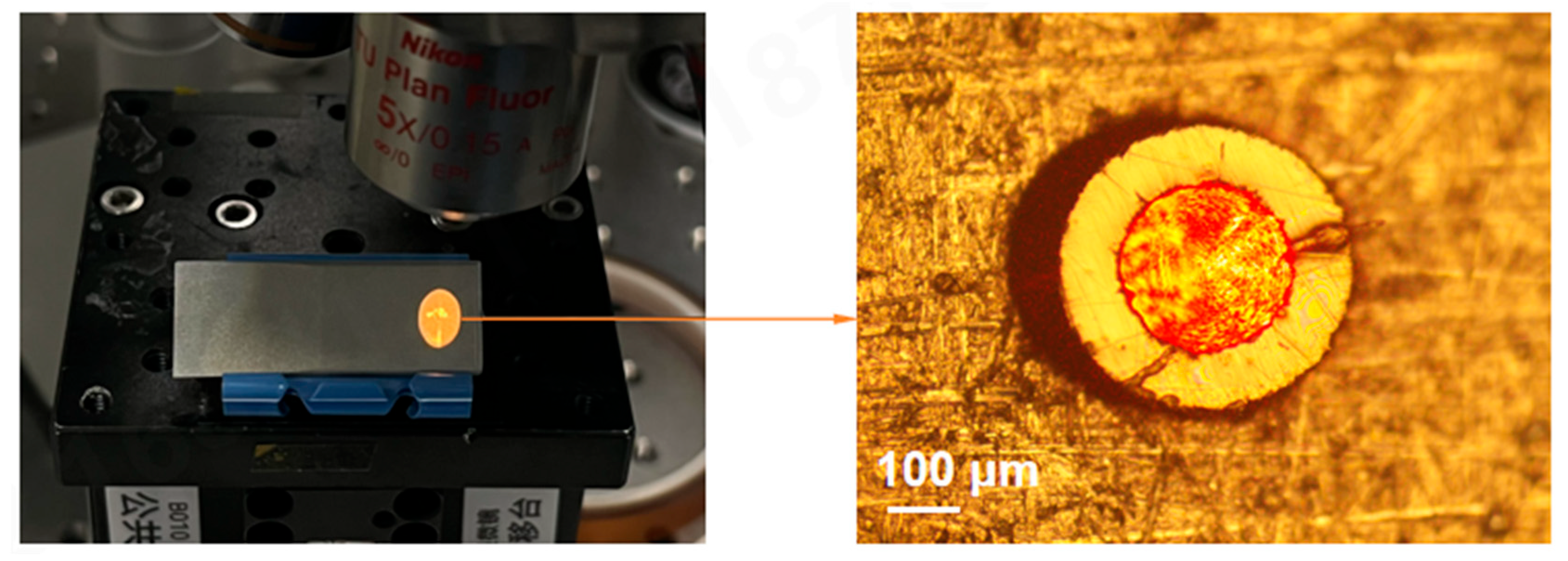

3. Design and Manufacture of the MEMS Pressure Sensor

4. Experiments

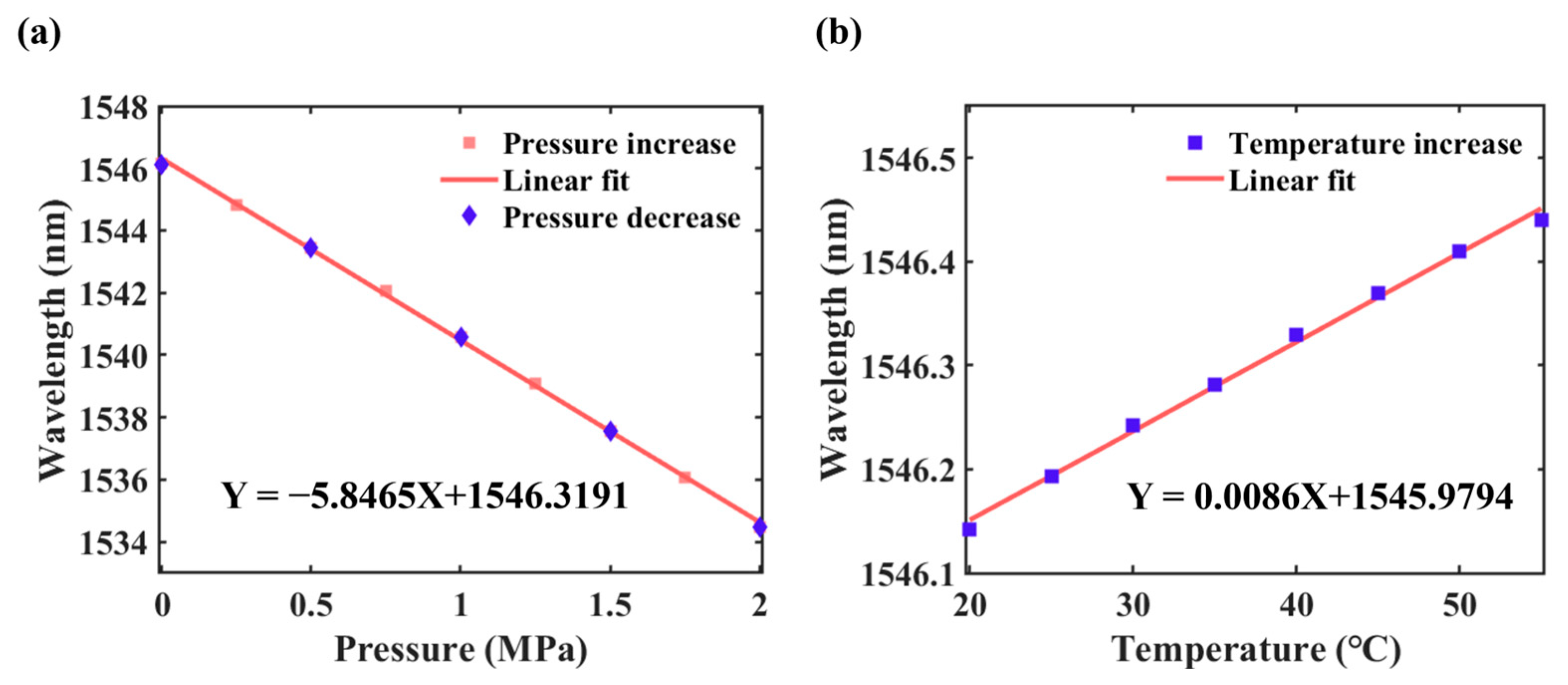

4.1. Calibration of the Optical Pressure Sensor

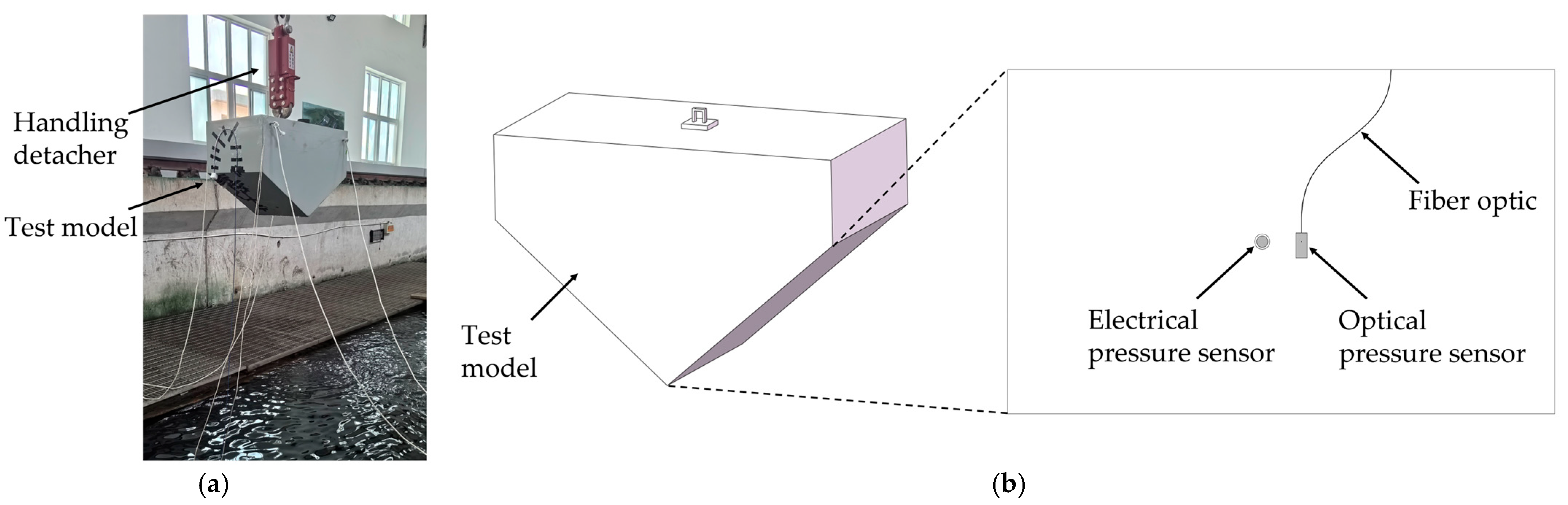

4.2. Water-Entry Test

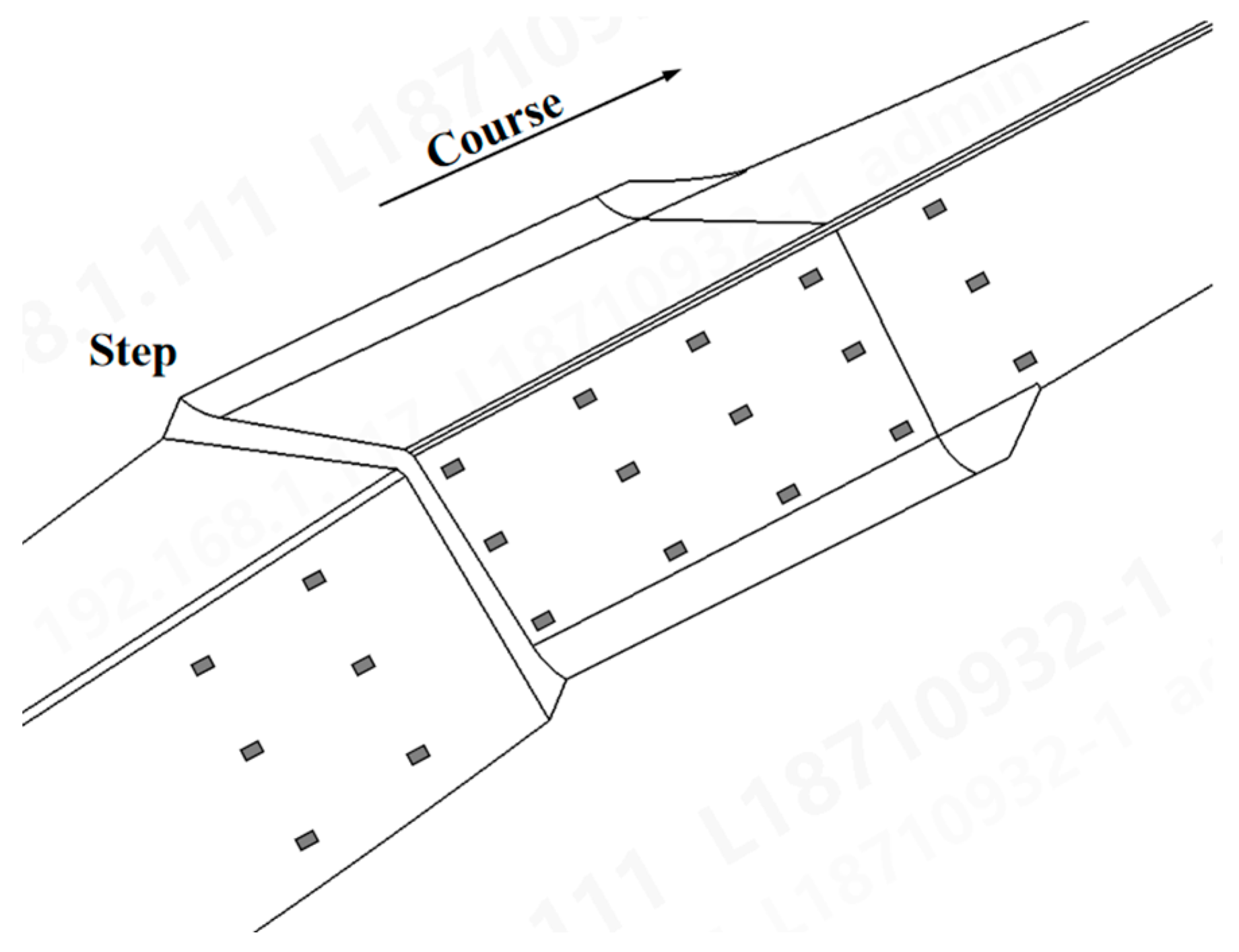

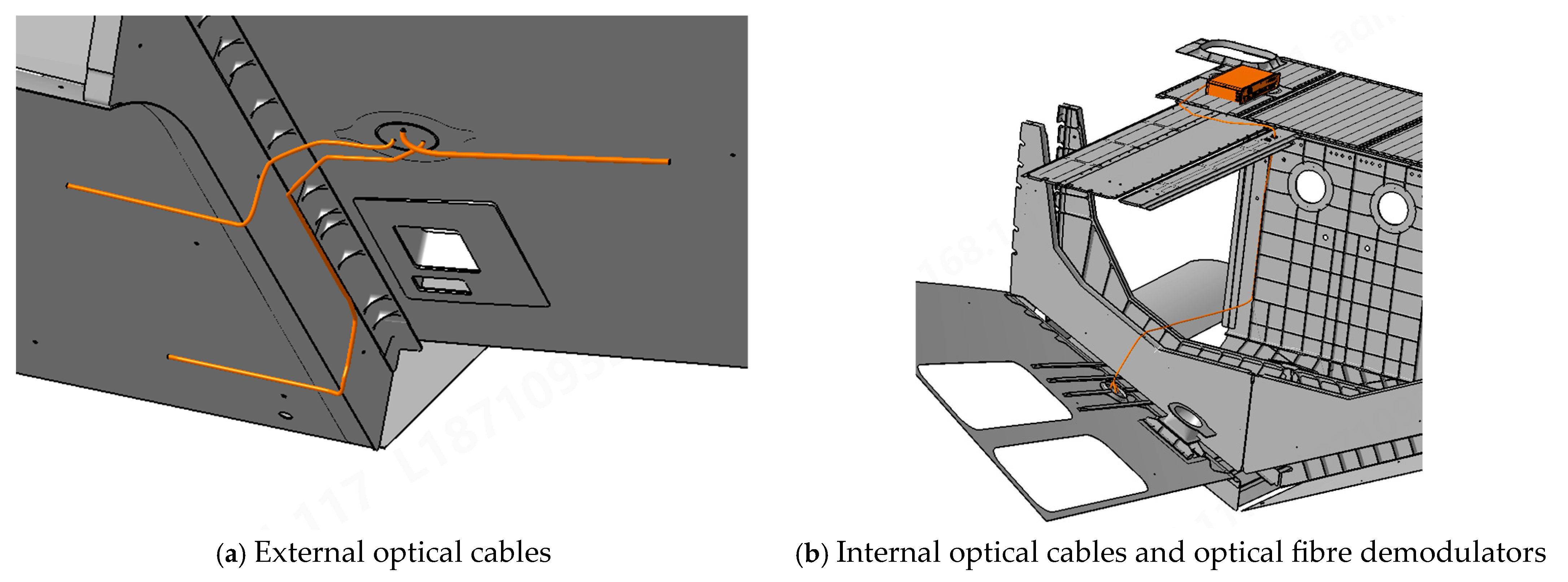

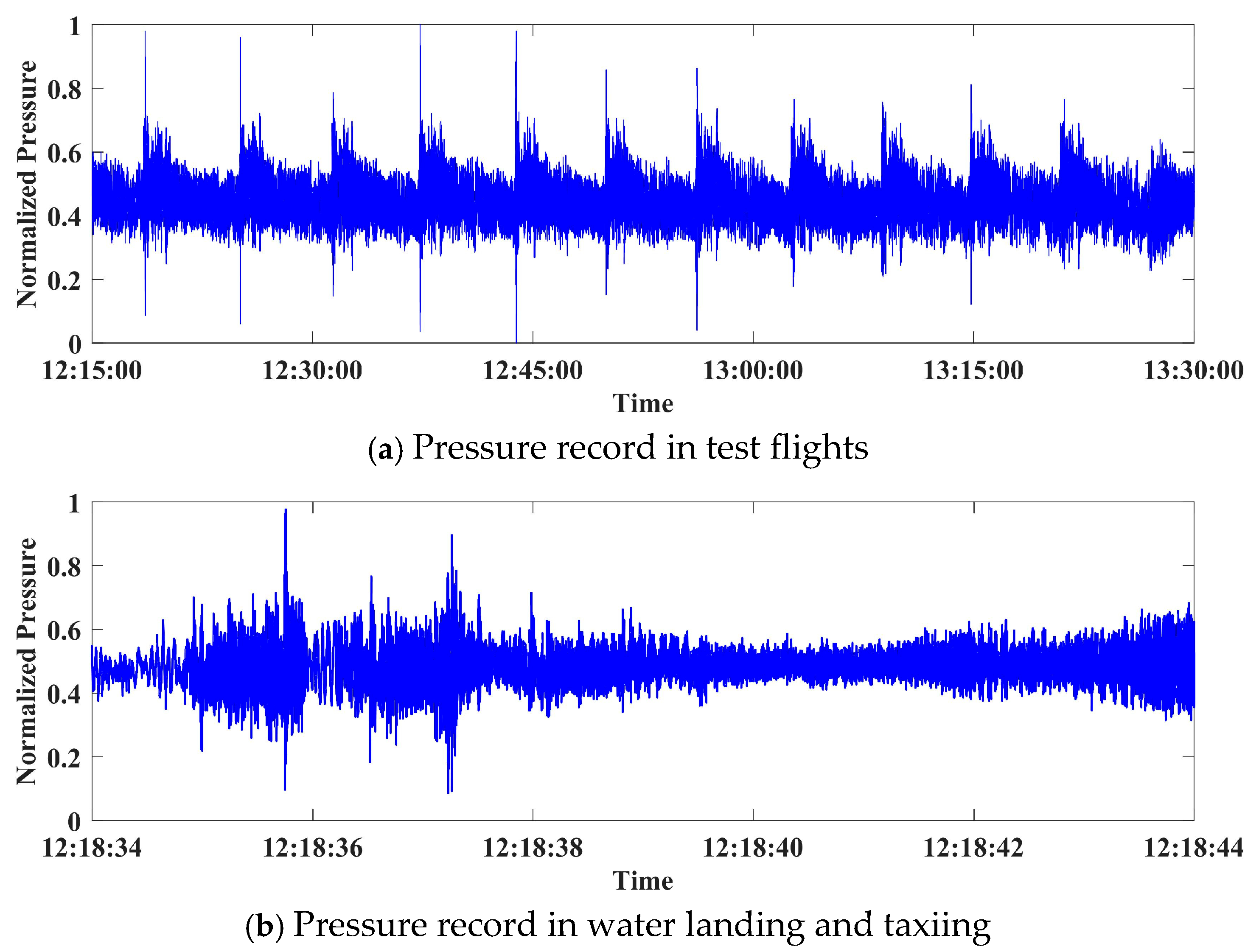

4.3. Flight Validation of the Water Landing for the MEMS Measuring System

5. Results

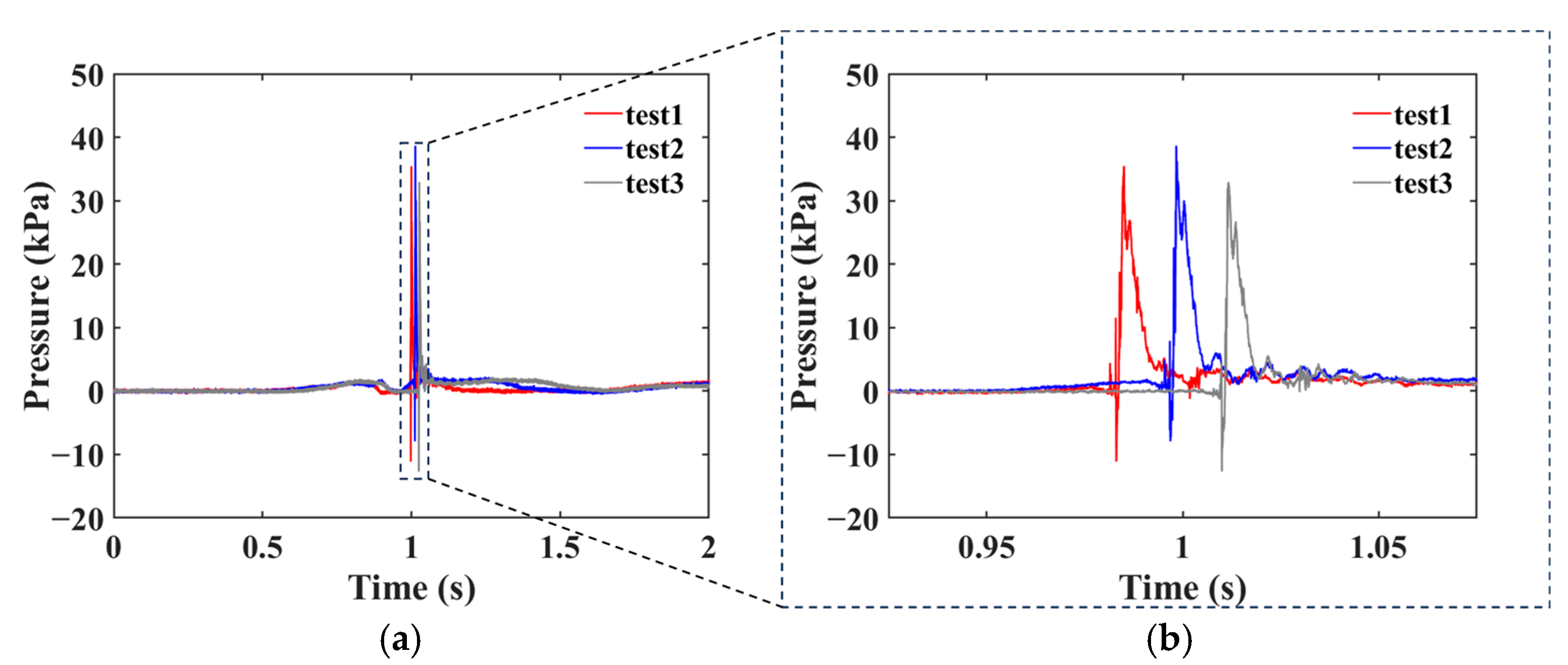

5.1. Water-Entry Test

5.2. Flight Validation of the Water Landing for the MEMS Measuring System

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qiu, L.; Song, W. Efficient Multiobjective Optimization of Amphibious Aircraft Fuselage Steps with Decoupled Hydrodynamic and Aerodynamic Analysis Models. J. Aerosp. Eng. 2016, 29, 04015071. [Google Scholar] [CrossRef]

- Qiu, L.; Song, W. Efficient Decoupled Hydrodynamic and Aerodynamic Analysis of Amphibious Aircraft Water Takeoff Process. J. Aircr. 2013, 50, 1369–1379. [Google Scholar] [CrossRef]

- Lyu, J.; Yang, R.; Huang, L. Structure Dynamic Response of Amphibious Aircraft Induced by Water-Taxiing. Int. J. Aerosp. Eng. 2021, 2021, 6104407. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, Y.; Dong, H.; Jin, T.; Zhang, C.; Zhu, Q. Test and numerical analysis for water entry of elastic cabin from amphibious aircraft. Aerosp. Sci. Technol. 2024, 150, 109168. [Google Scholar] [CrossRef]

- Seddon, C.M.; Moatamedi, M. Review of water entry with applications to aerospace structures. Int. J. Impact Eng. 2006, 32, 1045–1067. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, K.; Mao, L.; Sun, M.; Cao, J. Research on planing motion and stability of amphibious aircraft in waves based on cartesian grid finite difference method. Ocean. Eng. 2023, 272, 113848. [Google Scholar] [CrossRef]

- Ning, D.S.; Shi, Y.J.; Zhang, G.Y.; Wang, H.; Hu, H.; Zhang, Z.F. Numerical research on slamming characteristics of aircraft landing on water. J. Hydrodyn. 2023, 35, 171–184. [Google Scholar] [CrossRef]

- Liu, X.; Tan, L.; Zhang, X.; Li, L. Research of Slamming Load Characteristics during Trans-Media Aircraft Entry into Water. Drones 2024, 8, 89. [Google Scholar] [CrossRef]

- Huera-Huarte, F.J.; Jeon, D.; Gharib, M. Experimental investigation of water slamming loads on panels. Ocean. Eng. 2011, 38, 1347–1355. [Google Scholar] [CrossRef]

- Panciroli, R.; Biscarini, C.; Falcucci, G.; Jannelli, E.; Ubertini, S. Live monitoring of the distributed strain field in impulsive events through fiber Bragg gratings. J. Fluids Struct. 2016, 61, 60–75. [Google Scholar] [CrossRef]

- Faltinsen, O. Sea Loads on Ships and Offshore Structures; Cambridge University Press: Cambridge, UK, 1993; Volume 1. [Google Scholar]

- Faltinsen, O.M. Hydrodynamics of High-Speed Marine Vehicles; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Von Karman, T. The Impact on Seaplane Floats During Landing; Aerodynamical Institute of RWTH Aachen University: Aachen, Germany, 1929. [Google Scholar]

- Dobrovol’Skaya, Z. On some problems of similarity flow of fluid with a free surface. J. Fluid Mech. 1969, 36, 805–829. [Google Scholar] [CrossRef]

- Zhuo, Y.; Chen, L.; Su, S.; Li, S.; Chen, X. Research on the application of airbag loading technology in the strength test of amphibious aircraft. J. Phys. Conf. Ser. 2024, 2819, 012037. [Google Scholar] [CrossRef]

- Wagner, H. Über stoß-und gleitvorgänge an der oberfläche von flüssigkeiten. ZAMM J. Appl. Math. Mech. 1932, 12, 193–215. [Google Scholar] [CrossRef]

- Korobkin, A.; Gueret, R.; Malenica, Š. Hydroelastic coupling of beam finite element model with Wagner theory of water impact. J. Fluids Struct. 2006, 22, 493–504. [Google Scholar] [CrossRef]

- Singh, S.P.; Sen, D. A comparative study on 3D wave load and pressure computations for different level of modelling of nonlinearities. Mar. Struct. 2007, 20, 1–24. [Google Scholar] [CrossRef]

- Hirdaris, S.E.; Bai, W.; Dessi, D.; Ergin, A.; Gu, X.; Hermundstad, O.A.; Huijsmans, R.; Iijima, K.; Nielsen, U.D.; Parunov, J.; et al. Loads for use in the design of ships and offshore structures. Ocean. Eng. 2014, 78, 131–174. [Google Scholar] [CrossRef]

- Lakshmynarayanana, P.A.K.; Hirdaris, S. Comparison of nonlinear one- and two-way FFSI methods for the prediction of the symmetric response of a containership in waves. Ocean. Eng. 2020, 203, 107179. [Google Scholar] [CrossRef]

- Jiao, J.; Chen, Z.; Chen, C.; Ren, H. Time-domain hydroelastic analysis of nonlinear motions and loads on a large bow-flare ship advancing in high irregular seas. J. Mar. Sci. Technol. 2020, 25, 426–454. [Google Scholar] [CrossRef]

- Datta, R.; Guedes Soares, C. Analysis of the hydroelastic effect on a container vessel using coupled BEM–FEM method in the time domain. Ships Offshore Struct. 2020, 15, 393–402. [Google Scholar] [CrossRef]

- Zhang, G.; Feng, S.; Zhang, Z.; Chen, Y.; Sun, Z.; Zong, Z. Investigation of hydroelasticity in water entry of flexible wedges with flow detachment. Ocean. Eng. 2021, 222, 108580. [Google Scholar] [CrossRef]

- Jiao, J.; Huang, S.; Tezdogan, T.; Terziev, M.; Soares, C.G. Slamming and green water loads on a ship sailing in regular waves predicted by a coupled CFD–FEA approach. Ocean. Eng. 2021, 241, 110107. [Google Scholar] [CrossRef]

- Sun, J.Y.; Sun, S.L.; Zhang, Z.L.; Ren, H.L. Water entry of a seaplane section considering the wave effect. Phys. Fluids 2024, 36, 082115. [Google Scholar] [CrossRef]

- Xu, G.D.; Duan, W.Y.; Wu, G.X. Numerical simulation of oblique water entry of an asymmetrical wedge. Ocean. Eng. 2008, 35, 1597–1603. [Google Scholar] [CrossRef]

- Ma, S.; Mahfuz, H. Finite element simulation of composite ship structures with fluid structure interaction. Ocean. Eng. 2012, 52, 52–59. [Google Scholar] [CrossRef]

- Shadloo, M.S.; Oger, G.; Le Touzé, D. Smoothed particle hydrodynamics method for fluid flows, towards industrial applications: Motivations, current state, and challenges. Comput. Fluids 2016, 136, 11–34. [Google Scholar] [CrossRef]

- Krastev, V.K.; Facci, A.L.; Ubertini, S. Asymmetric water impact of a two dimensional wedge: A systematic numerical study with transition to ventilating flow conditions. Ocean. Eng. 2018, 147, 386–398. [Google Scholar] [CrossRef]

- Xie, H.; Ren, H.; Qu, S.; Tang, H. Numerical and experimental study on hydroelasticity in water-entry problem of a composite ship-hull structure. Compos. Struct. 2018, 201, 942–957. [Google Scholar] [CrossRef]

- Facci, A.L.; Panciroli, R.; Ubertini, S.; Porfiri, M. Assessment of PIV-based analysis of water entry problems through synthetic numerical datasets. J. Fluids Struct. 2015, 55, 484–500. [Google Scholar] [CrossRef]

- Facci, A.L.; Ubertini, S. Numerical Assessment of Similitude Parameters and Dimensional Analysis for Water Entry Problems. Math. Probl. Eng. 2015, 2015, 324961. [Google Scholar] [CrossRef]

- Duan, X.; Sun, W.; Chen, C.; Wei, M.; Yang, Y. Numerical investigation of the porpoising motion of a seaplane planing on water with high speeds. Aerosp. Sci. Technol. 2019, 84, 980–994. [Google Scholar] [CrossRef]

- Sun, H.; Kasdin, N.J.; Vanderbei, R. Identification and adaptive control of a high-contrast focal plane wavefront correction system. J. Astron. Telesc. Instrum. Syst. 2018, 4, 049006. [Google Scholar] [CrossRef]

- Shihua, J.M.; Liem, R.P.; Li, Y. An Improved Experimental Framework of Amphibious Marine Vehicle Hull Hydrodynamics. IEEE J. Ocean. Eng. 2023, 49, 80–91. [Google Scholar] [CrossRef]

- Zong, Z.; Sun, Y.; Jiang, Y.; Sun, T.; Yu, Y. Evolution of slamming load and flow field in water-entry process of trimaran ship section. Ocean. Eng. 2020, 205, 107319. [Google Scholar] [CrossRef]

- Yu, P.; Xie, H.; Liu, F.; Li, P.; Cheng-Lv, G. Numerical investigation on the water entry of a 2D seaplane section with heel angles. Ocean. Eng. 2022, 262, 112236. [Google Scholar] [CrossRef]

- Wang, S.; Soares, C.G. Stern slamming of a chemical tanker in irregular head waves. Ocean. Eng. 2016, 122, 322–332. [Google Scholar] [CrossRef]

- Wang, F.Z.; Animasaun, I.L.; Muhammad, T.; Okoya, S.S. Recent advancements in fluid dynamics: Drag reduction, lift generation, computational fluid dynamics, turbulence modelling, and multiphase flow. Arab. J. Sci. Eng. 2024, 49, 10237–10249. [Google Scholar] [CrossRef]

- Jiang, C.X.; Shuai, Z.J.; Zhang, X.Y.; Li, W.Y.; Li, F.C. Numerical study on the transient behavior of water-entry supercavitating flow around a cylindrical projectile influenced by turbulent drag-reducing additives. Appl. Therm. Eng. 2016, 104, 450–460. [Google Scholar] [CrossRef]

- Chen, J.; Li, L.; Fu, X.; Xiao, T.; Wu, B.; Tong, M. Scale effect on wave planing performance of amphibious aircraft at constant speed. Aerosp. Sci. Technol. 2024, 148, 109083. [Google Scholar] [CrossRef]

- Ghodoosipour, B.; Stolle, J.; Nistor, I.; Mohammadian, A.; Goseberg, N. Experimental study on extreme hydrodynamic loading on pipelines part 2: Induced force analysis. J. Mar. Sci. Eng. 2019, 7, 262. [Google Scholar] [CrossRef]

- Reed, S.; Holford, D. Guidance for aircraft operational loads measurement programmes. Mil. Aircr. Struct. Airworth. Advis. Group Pap. 2007, 109, 31. [Google Scholar]

- Huang, S.; Jiao, J.; Chen, C. Numerical prediction of ship motion and slamming load characteristics in cross wave. J. Mar. Sci. Technol. 2022, 27, 104–124. [Google Scholar] [CrossRef]

- Brewick, P.T.; Ibrahim, A.M.; Hutchinson, M.; Morgan, J. Using surrogate models and mechanics to predict pressure from strain data. Ocean. Eng. 2022, 261, 112064. [Google Scholar] [CrossRef]

- Chuang, W.-L. Experimental investigation on fluid kinematics and impact pressure of flat plate impacts on pure and aerated water. Ocean. Eng. 2022, 266, 112837. [Google Scholar] [CrossRef]

- Fukushima, H.; Wakahara, M.; Kanai, T. Hull Surface Pressure Measurement of the Affix-Type Multipoint Pressure Sensor Using Fiber Bragg Gratings. In Practical Design of Ships and Other Floating Structures, Proceedings of the 14th International Symposium, PRADS 2019, Yokohama, Japan, 22–26 September 2019; Springer: Berlin, Germany, 2021; Volume I. [Google Scholar]

- Hu, Q.; Wang, M.Z.; Wu, B.; Zhang, J.X.; Xiao, Z. The Application of Overset Grid in the Analysis of Impact Loads of Amphibious Aircraft during Landing on the Water. IOP Conf. Ser. Mater. Sci. Eng. 2020, 751, 012032. [Google Scholar] [CrossRef]

- Huang, M.; Wu, B.; Li, C. The water impact load study for seaplane during get-off and alighting process on rough water. J. Phys. Conf. Series. 2022, 2282, 012024. [Google Scholar] [CrossRef]

- Doll, U.; Migliorini, M.; Baikie, J.; Zachos, P.K.; Röhle, I.; Melnikov, S.; Steinbock, J.; Dues, M.; Kapulla, R.; MacManus, D.G.; et al. Non-intrusive flow diagnostics for unsteady inlet flow distortion measurements in novel aircraft architectures. Prog. Aerosp. Sci. 2022, 130, 100810. [Google Scholar] [CrossRef]

- Nila, A.; Vanlanduit, S.; Vepa, S.; Van Paepegem, W. A PIV-based method for estimating slamming loads during water entry of rigid bodies. Meas. Sci. Technol. 2013, 24, 045303. [Google Scholar] [CrossRef]

- CCAR-25-R4; Airworthiness Standards: Transport Category Airplanes. Civil Aviation Administration of China: Beijing, China, 2011. (In Chinese)

- Guo, Y.P.; Joshi, M.C.; Bent, P.H.; Yamamoto, K.J. Surface pressure fluctuations on aircraft flaps and their correlation with far-field noise. J. Fluid Mech. 2000, 415, 175–202. [Google Scholar] [CrossRef]

- Yuan, S.; Li, Y.; Bao, F.; Xu, H.; Yang, Y.; Yan, Q.; Zhong, S.; Yin, H.; Xu, J.; Huang, Z.; et al. Marine environmental monitoring with unmanned vehicle platforms: Present applications and future prospects. Sci. Total Environ. 2023, 858, 159741. [Google Scholar] [CrossRef]

- Abrate, S. Hull slamming. Appl. Mech. Rev. 2011, 64, 060803. [Google Scholar] [CrossRef]

- Song, Y.; Xia, L.; Wu, Y. The interrogation of quasi-distributed optical FBG sensing system through adopting a wavelength-tunable fiber chaotic laser. J. Light. Technol. 2019, 37, 2435–2442. [Google Scholar] [CrossRef]

- Zhang, Q.; Lei, J.; Chen, Y.; Wu, Y.; Chen, C.; Xiao, H. 3D printing of all-glass fiber-optic pressure sensor for high temperature applications. IEEE Sens. J. 2019, 19, 11242–11246. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Guo, G. A FBG inclinometer for simultaneous measurement of horizontal deformation and sudden deformation. IEEE Trans. Instrum. Meas. 2021, 70, 7503410. [Google Scholar]

- Wang, J.; Li, Z.; Fu, X.; Wang, H.; Jiang, D. Distributed temperature sensing system based on a densely spaced FBG array for small fire recognition. Measurement 2021, 179, 109406. [Google Scholar] [CrossRef]

- Xu, H.; Li, F.; Gao, Y.; Wang, W. Simultaneous measurement of tilt and acceleration based on FBG sensor. IEEE Sens. J. 2020, 20, 14857–14864. [Google Scholar] [CrossRef]

- Xu, H.; Wang, W.; Li, F.; Du, Y.; Tu, H.; Guo, C. Railway slope monitoring based on dual-parameter FBG sensor. Photonic Sens. 2025, 15, 250121. [Google Scholar] [CrossRef]

- Waskito, K.T.; Kashiwagi, M.; Iwashita, H.; Hinatsu, M. Prediction of nonlinear vertical bending moment using measured pressure distribution on ship hull. Appl. Ocean. Res. 2020, 101, 102261. [Google Scholar] [CrossRef]

- Xu, G.; He, B.; Li, H.; Gui, X.; Li, Z. FBG pressure sensor in pressure distribution monitoring of ship. Opt. Express 2022, 30, 21396–21409. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, D.; Xing, H.; Ding, H.; Luo, J.; Liu, H.; Kong, X.; Xu, F. Recent progress in MEMS fiber-optic Fabry–Perot pressure sensors. Sensors 2024, 24, 1079. [Google Scholar] [CrossRef]

- Kienitz, S.U.; Lohr, L.; Schmid, M.J.; Koch, A.W. Static and dynamic pressure measurement in flight test application with optical Fabry–Pérot sensors. IEEE Trans. Instrum. Meas. 2021, 70, 7004611. [Google Scholar] [CrossRef]

- Fadaei Rodi, R.; Kamali, H.A.; Pasandidehfard, M. Innovative optimization of parabolic cavitators: Improving hydrodynamic efficiency and supercavity qualitycavitatio. Phys. Fluids 2024, 36, 103356. [Google Scholar] [CrossRef]

| Range | Customizable, −100 kPa to 10 MPa |

| Dimensions | 0.3 mm (sensing element) |

| Sampling Frequency | Selectable, 10 kHz–30 kHz |

| Accuracy | 0.5% F.S. (customizable down to 0.1% F.S.) |

| Frequency Response | >2 MHz |

| Resolution | 0.1% F.S. |

| Operating Temperature | −10 °C to 100 °C |

| Overload Pressure | 2× F.S. |

| Encapsulation Material | 316 L stainless steel |

| Encapsulation Thickness | 1 mm |

| Connector Type | Angled physical contact (APC) |

| Test Number | Electrical Sensor Measurements (kPa) | Optical Sensor Measurements (kPa) | Pressure Deviation (kPa) |

|---|---|---|---|

| 1 | 35.43 | 36.44 | 1.01 |

| 2 | 36.70 | 38.27 | 1.57 |

| 3 | 34.77 | 32.93 | 1.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, T.; Chen, X.; Chen, Y.; Wu, B.; Xu, F.; Huang, L. A Study of Ultra-Thin Surface-Mounted MEMS Fibre-Optic Fabry–Pérot Pressure Sensors for the In Situ Monitoring of Hydrodynamic Pressure on the Hull of Large Amphibious Aircraft. Photonics 2025, 12, 627. https://doi.org/10.3390/photonics12070627

Feng T, Chen X, Chen Y, Wu B, Xu F, Huang L. A Study of Ultra-Thin Surface-Mounted MEMS Fibre-Optic Fabry–Pérot Pressure Sensors for the In Situ Monitoring of Hydrodynamic Pressure on the Hull of Large Amphibious Aircraft. Photonics. 2025; 12(7):627. https://doi.org/10.3390/photonics12070627

Chicago/Turabian StyleFeng, Tianyi, Xi Chen, Ye Chen, Bin Wu, Fei Xu, and Lingcai Huang. 2025. "A Study of Ultra-Thin Surface-Mounted MEMS Fibre-Optic Fabry–Pérot Pressure Sensors for the In Situ Monitoring of Hydrodynamic Pressure on the Hull of Large Amphibious Aircraft" Photonics 12, no. 7: 627. https://doi.org/10.3390/photonics12070627

APA StyleFeng, T., Chen, X., Chen, Y., Wu, B., Xu, F., & Huang, L. (2025). A Study of Ultra-Thin Surface-Mounted MEMS Fibre-Optic Fabry–Pérot Pressure Sensors for the In Situ Monitoring of Hydrodynamic Pressure on the Hull of Large Amphibious Aircraft. Photonics, 12(7), 627. https://doi.org/10.3390/photonics12070627