Finite Element Method-Based Modeling of a Novel Square Photonic Crystal Fiber Surface Plasmon Resonance Sensor with a Au–TiO2 Interface and the Relevance of Artificial Intelligence Techniques in Sensor Optimization

Abstract

1. Introduction

- The periodic arrangement of air holes allows for fine-tuning of the effective refractive index (RI), making PCFs ideal for controlling light propagation in sensing applications [5].

- The ability of PCF to guide light in the core while exposing it to the surrounding medium maximizes the light–matter interaction (LMI), making PCFs particularly sensitive to small changes in the RI, which is crucial for detecting biomolecular interactions, pollutants, or other trace elements [6].

- The optimization of light confinement in the core and the ability to work in both single-mode and multi-mode configurations result in minimal transmission losses, enhancing the sensitivity of sensors based on PCFs [7].

2. Artificial Intelligence Algorithms for Enhancing PCF SPR Sensor Design and Performance

2.1. Bayesian Regularization Artificial Neural Networks (BRANNs) in PCF SPR Sensors

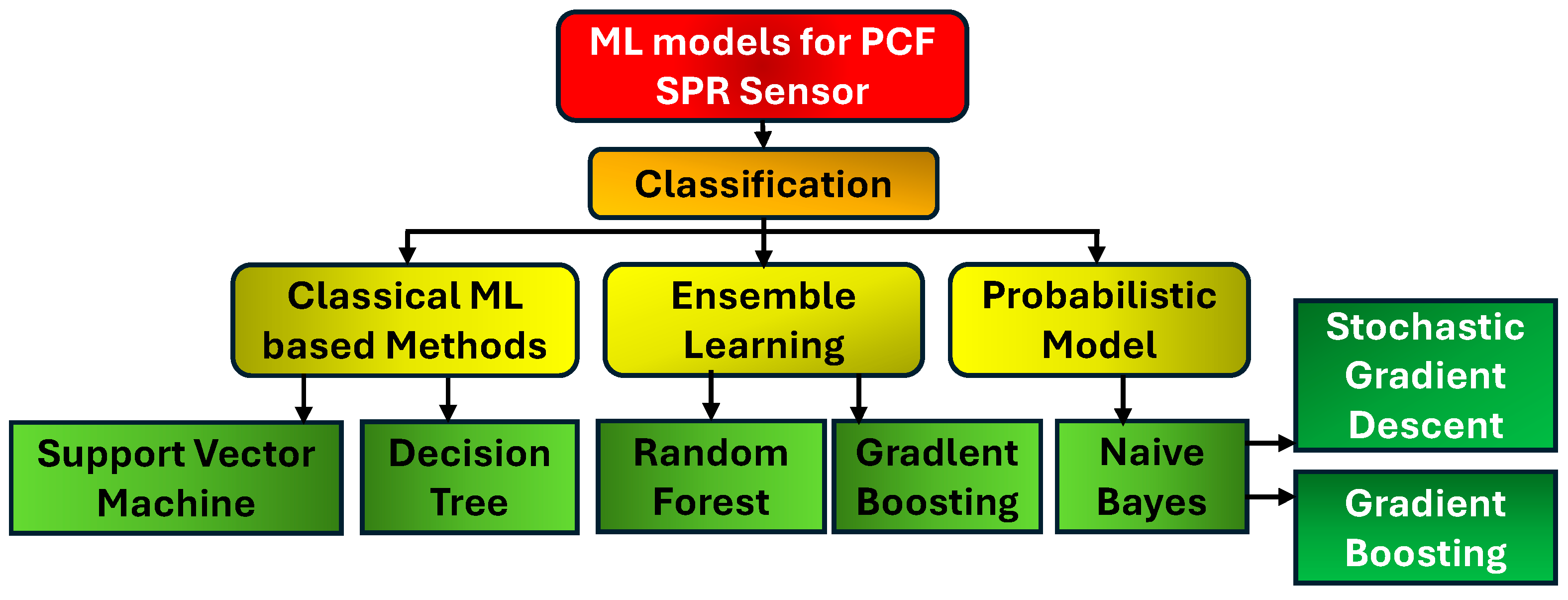

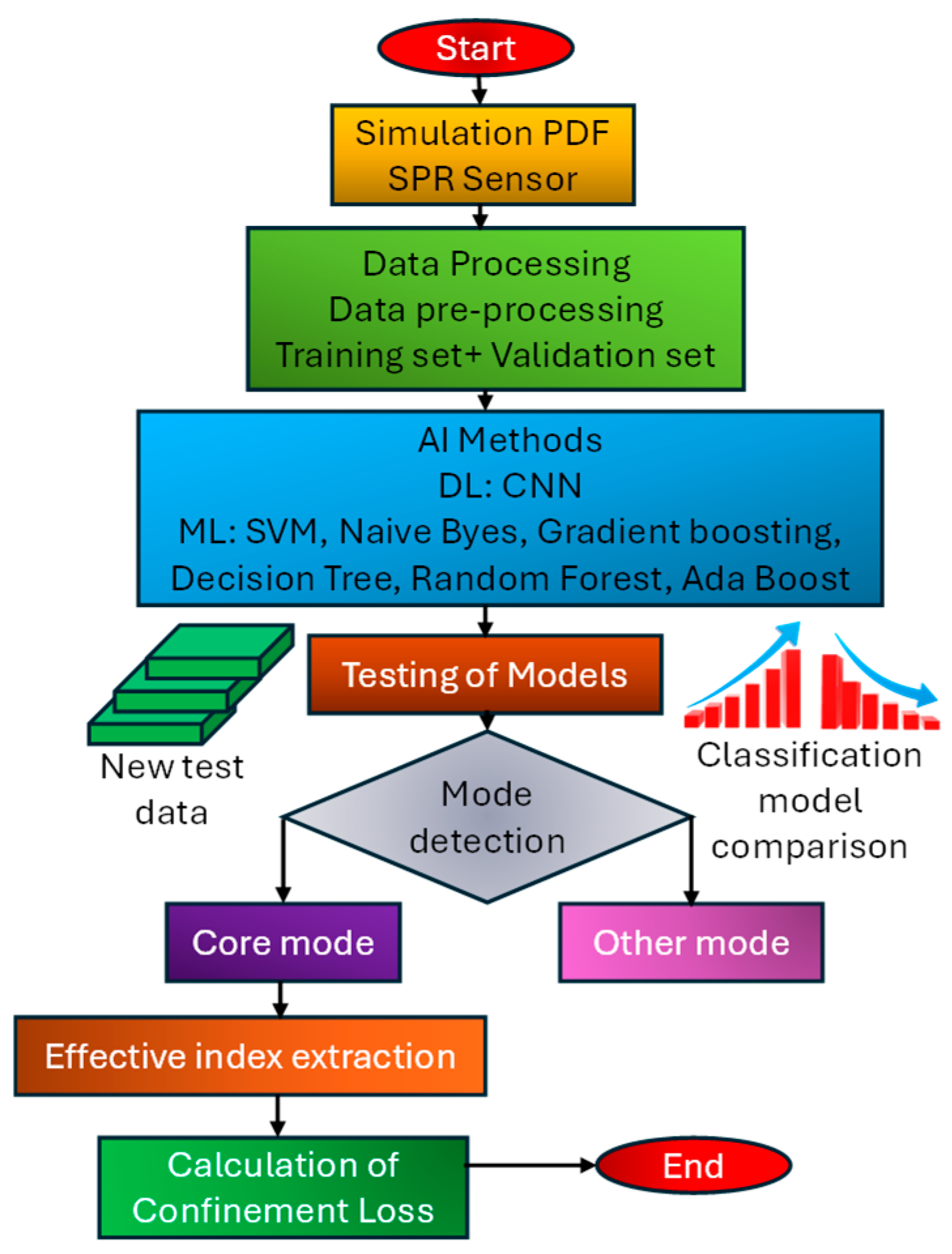

2.2. Machine Learning Models for PCF SPR Sensors

2.3. Deep Learning Models for PCF SPR Sensors

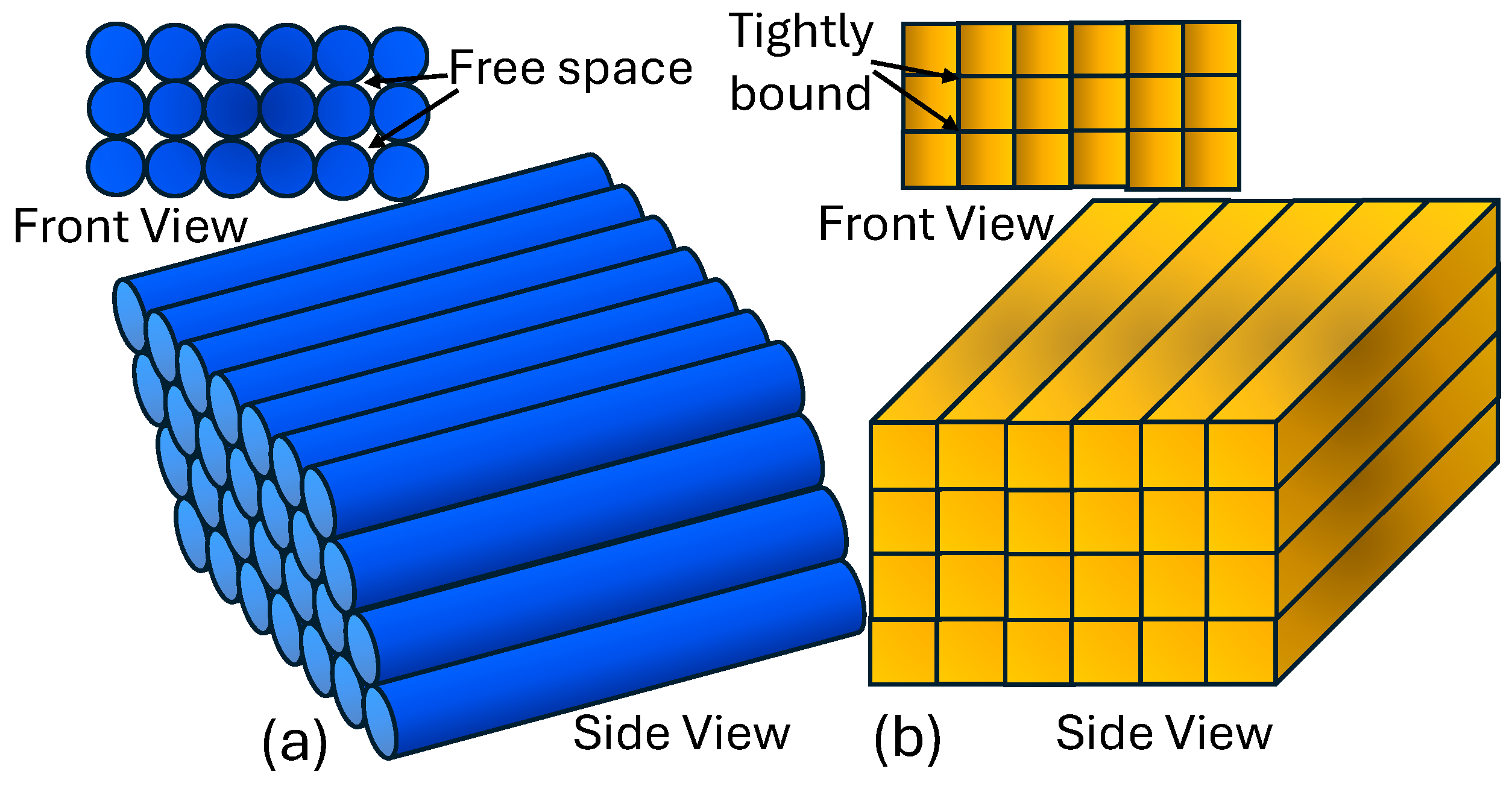

3. Geometrical Modeling of the Proposed Sensor

- TiO2 enhances the plasmonic coupling efficiency between the core mode and the surface plasmon mode supported by the Au layer [65].

- The combination results in a stronger and more confined surface plasmon field, yielding higher sensitivity and sharper resonance dips [65].

- TiO2 also helps reduce metal loss and provides a stable interface, thus enhancing the resolution and durability of the sensor [65].

- AI, particularly ML algorithms such as SVMs, random forests, and ANNs, can predict the key optical properties of materials, e.g., permittivity, RI, and plasmonic resonance frequency, based on structural and compositional features [66].

- AI can be integrated with density functional theory (DFT) and finite element method (FEM) simulations to conduct high-throughput screening of large material libraries. This helps identify candidates with optimal optical properties and minimal losses for plasmonic applications [67].

- DRL algorithms can be used to guide experimental parameter tuning, e.g., the thickness of metal/dielectric layers, nanostructure dimensions, etc., to achieve desired plasmonic responses with fewer experimental iterations [70].

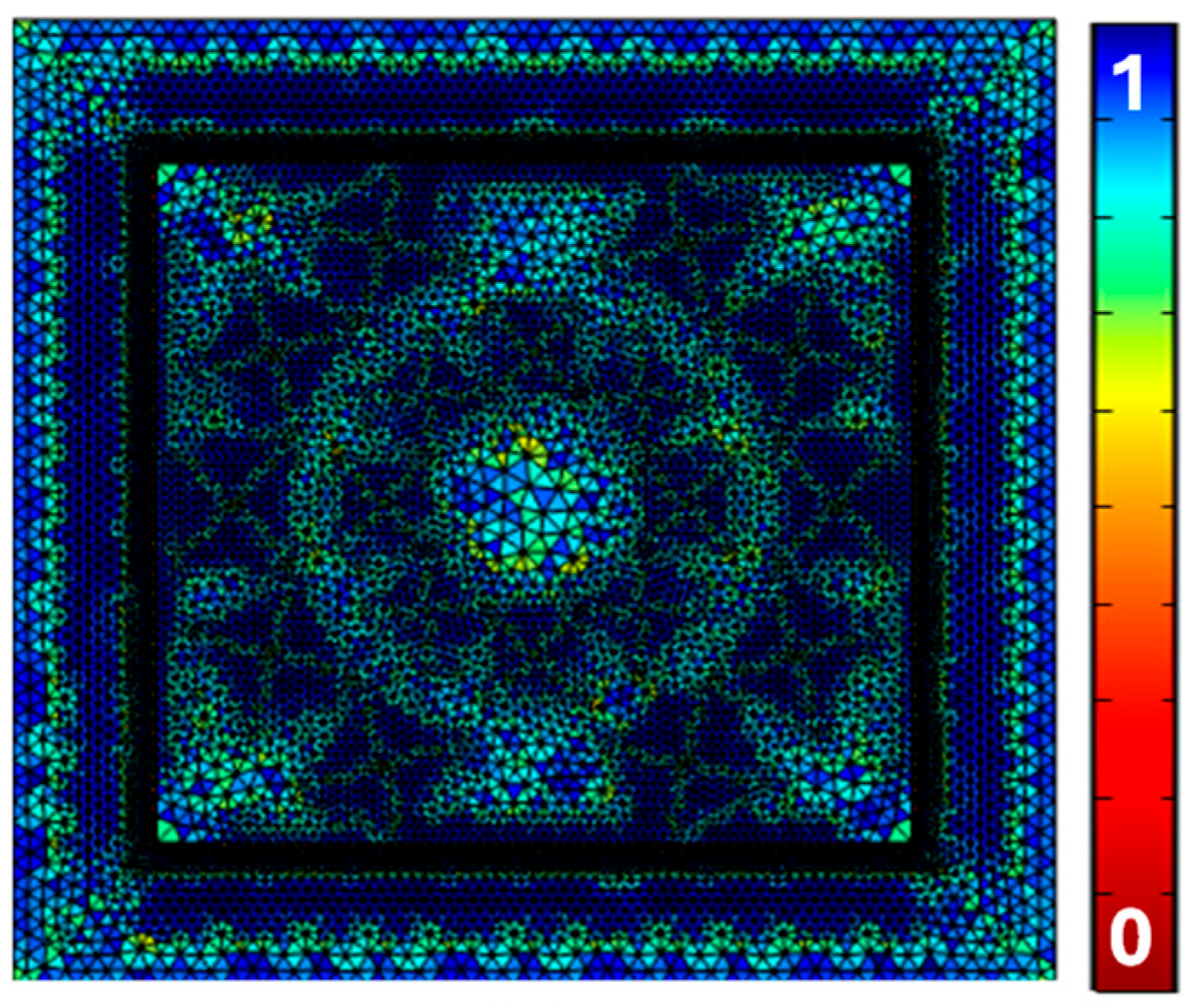

4. Numerical Analysis of the Performance Parameters of the Proposed Sensor

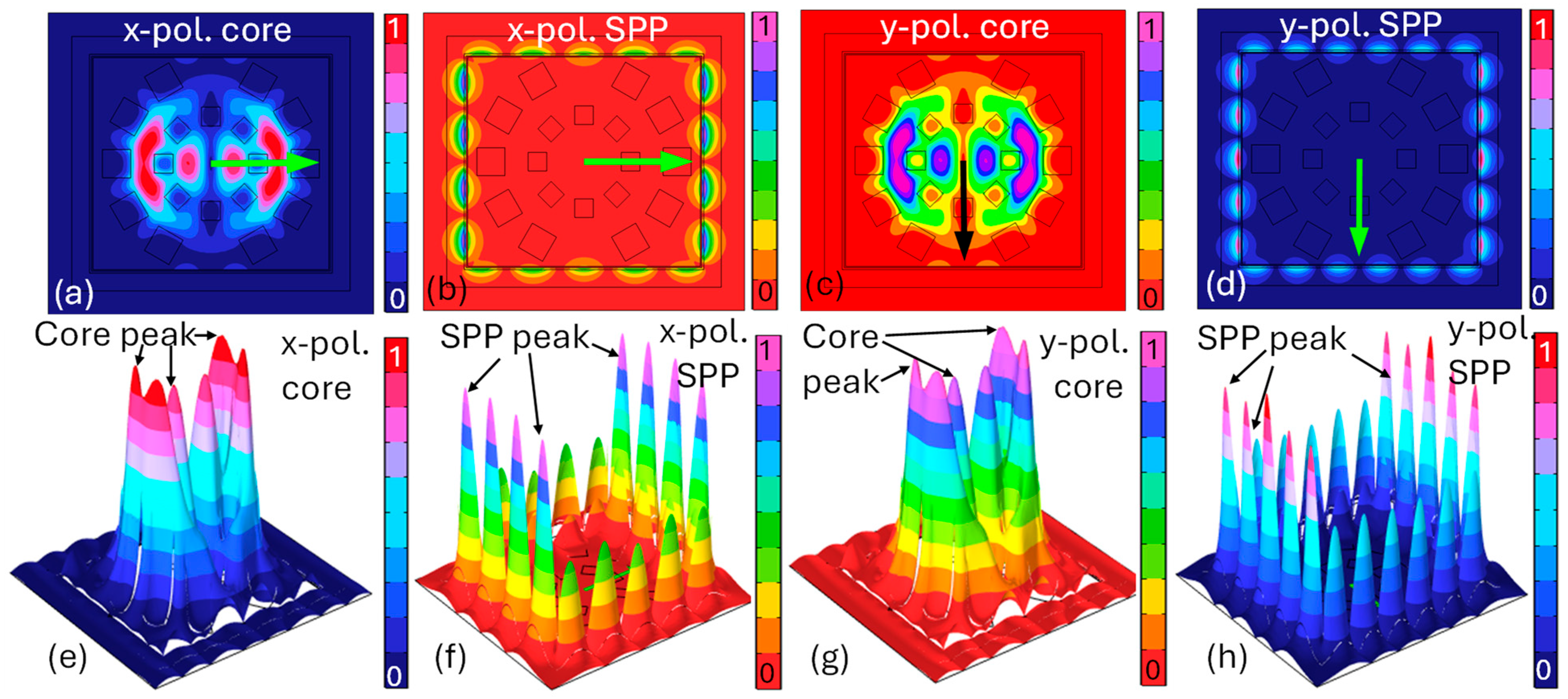

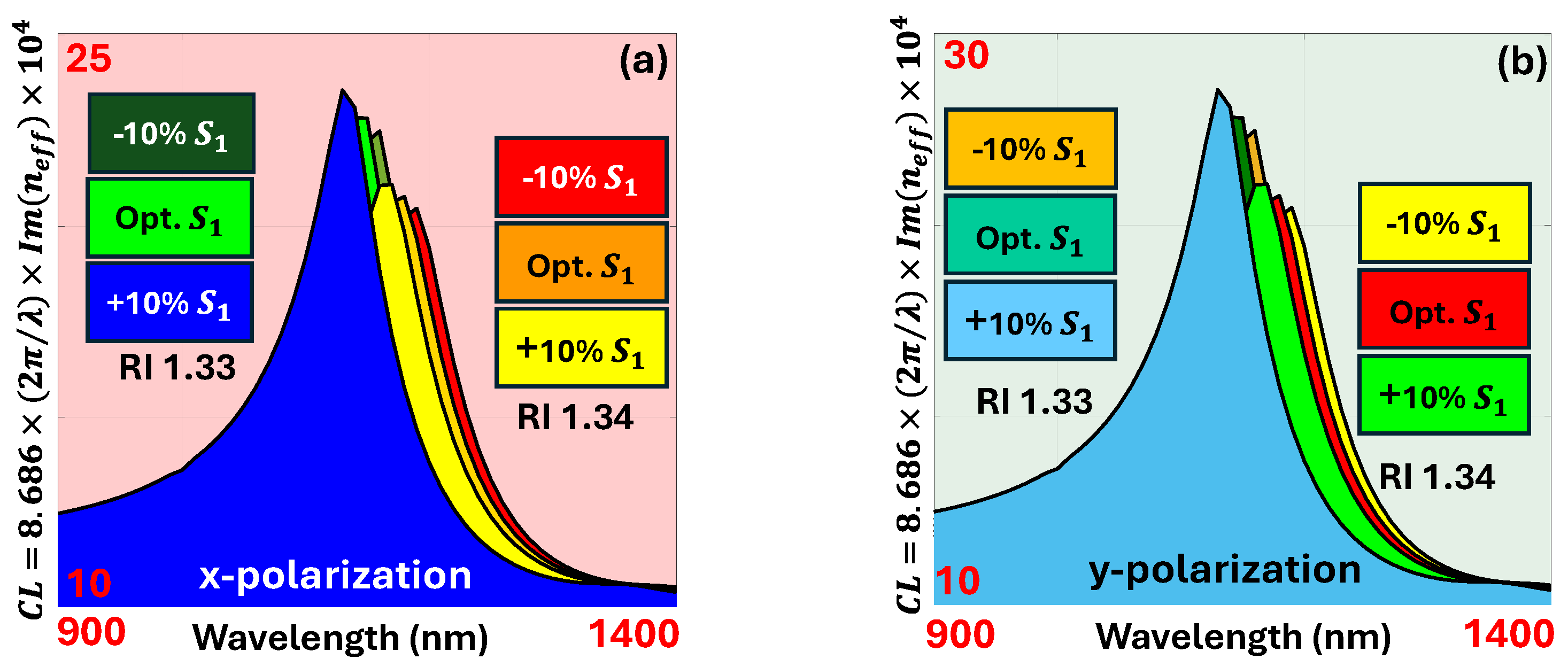

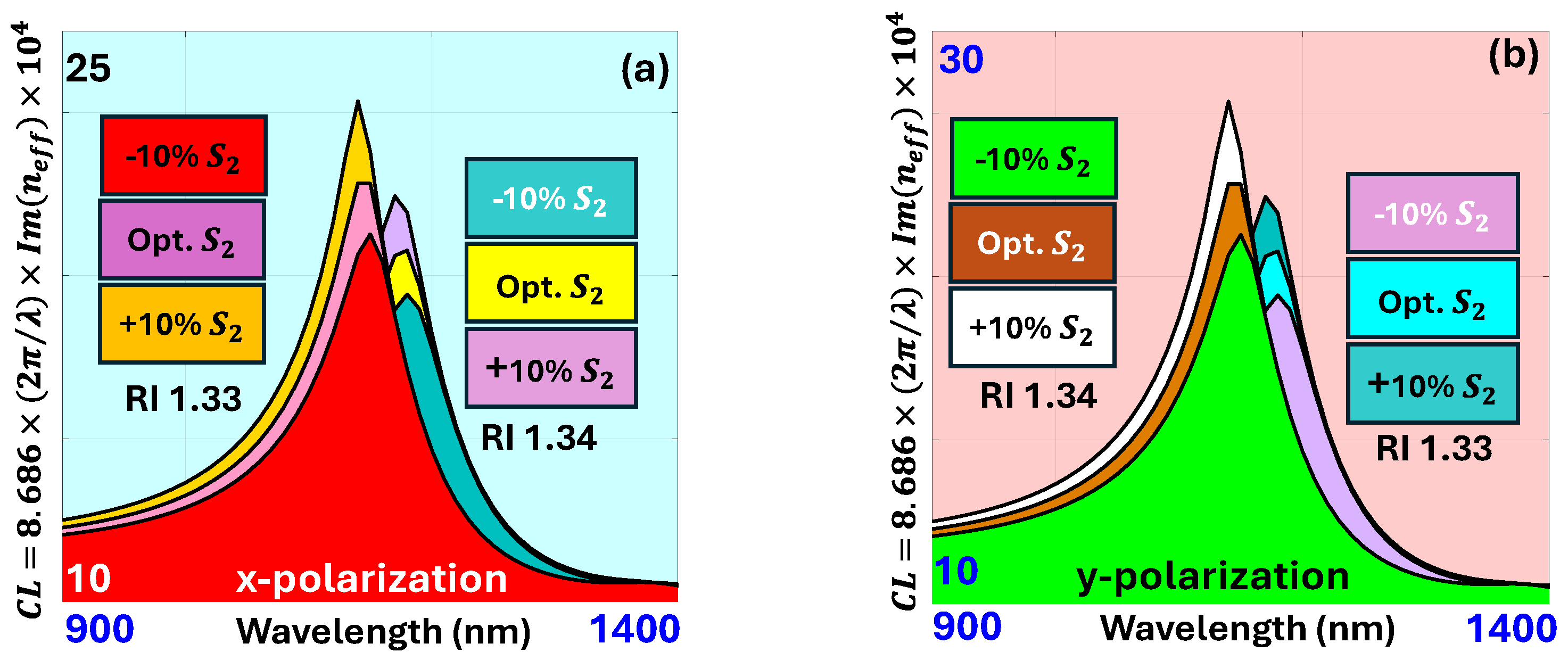

4.1. Calculation of CL for the Sensor Model

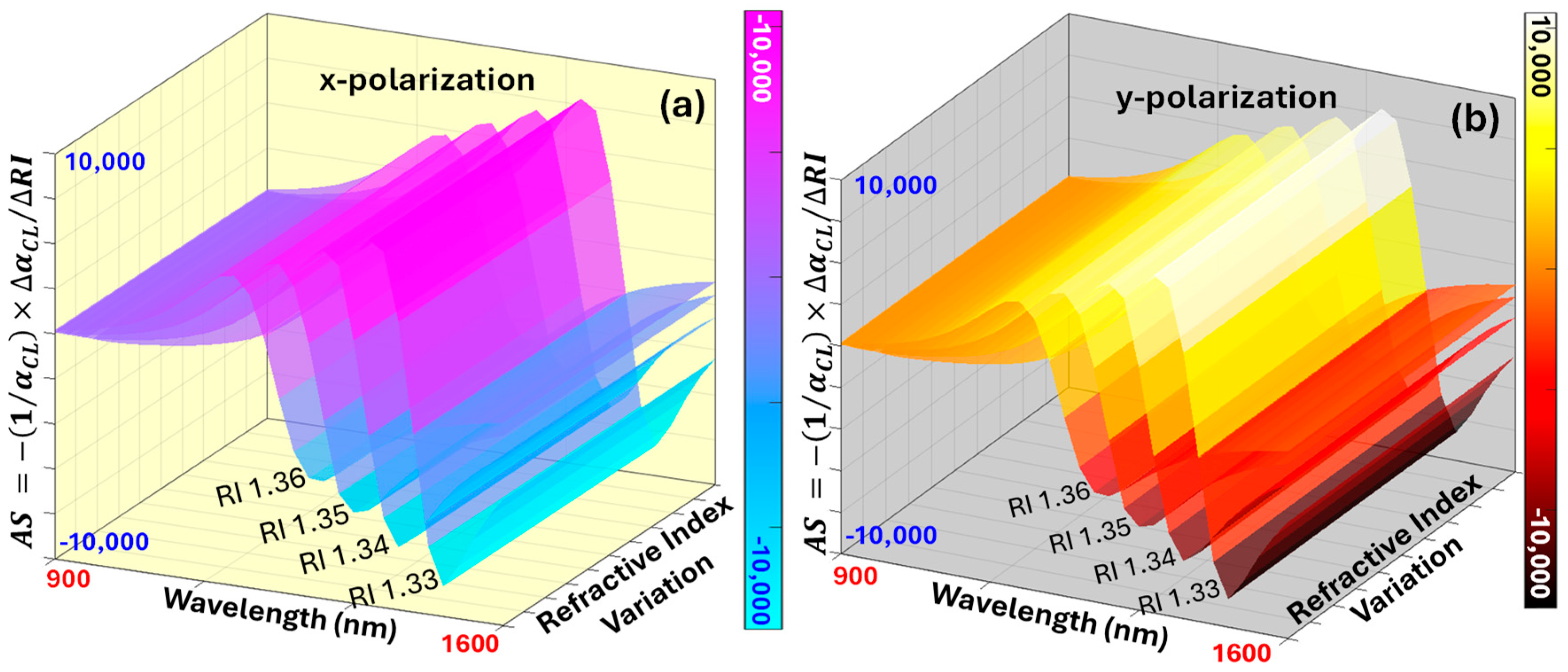

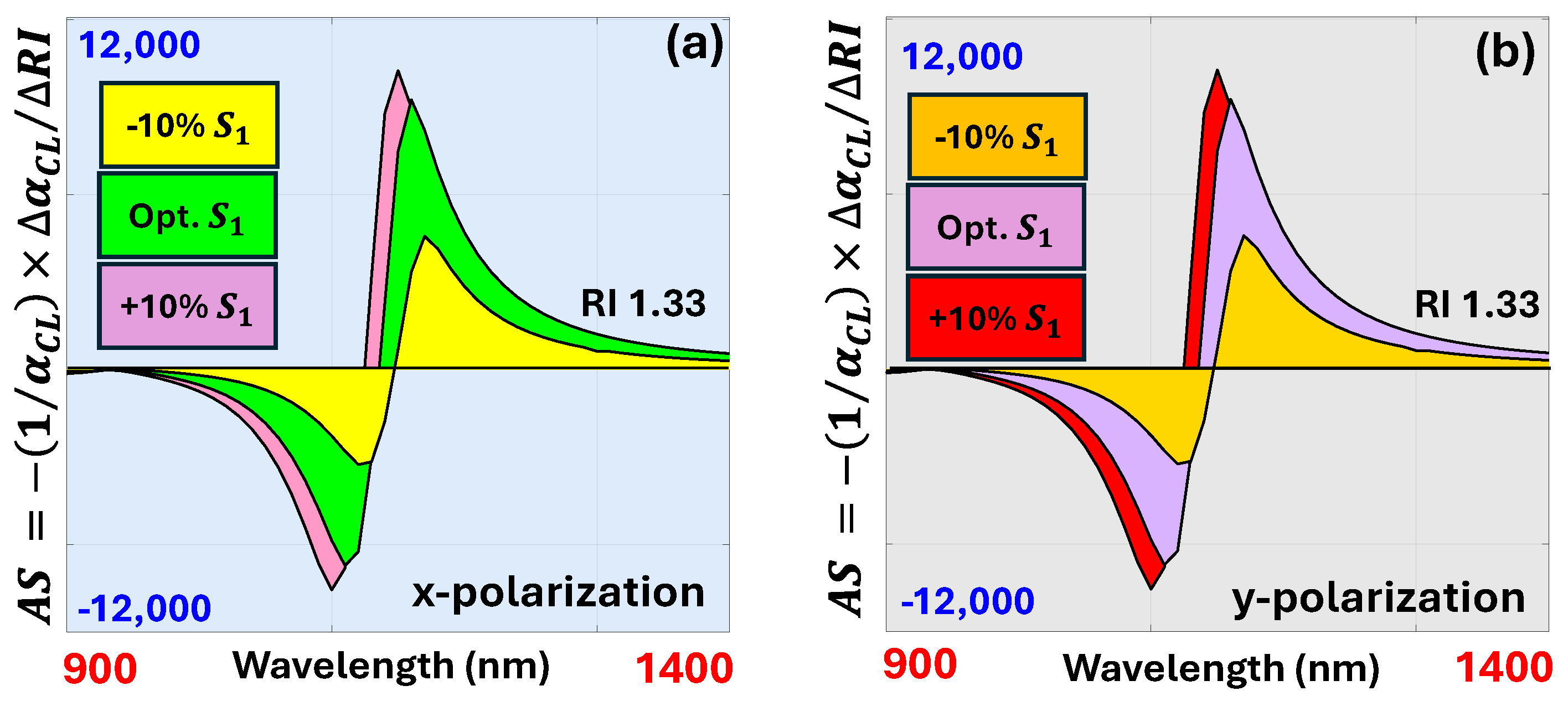

4.2. Calculation of AS for the Sensor Model

4.3. Calculation of WS for the Sensor Model

4.4. Calculation of SR for the Sensor Model

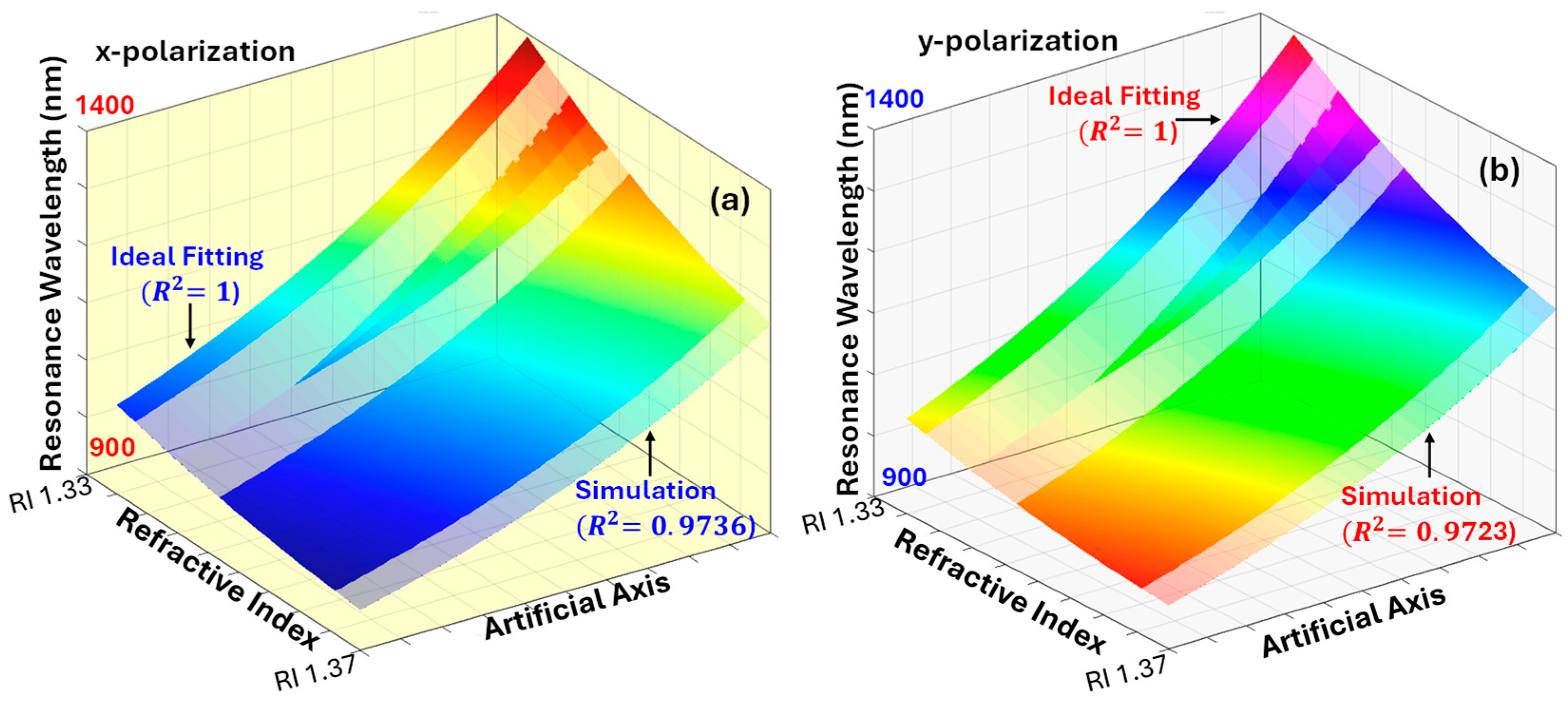

4.5. Linear Fitting Between the Resonance Wavelength and Refractive Index of the Sensor Parameters

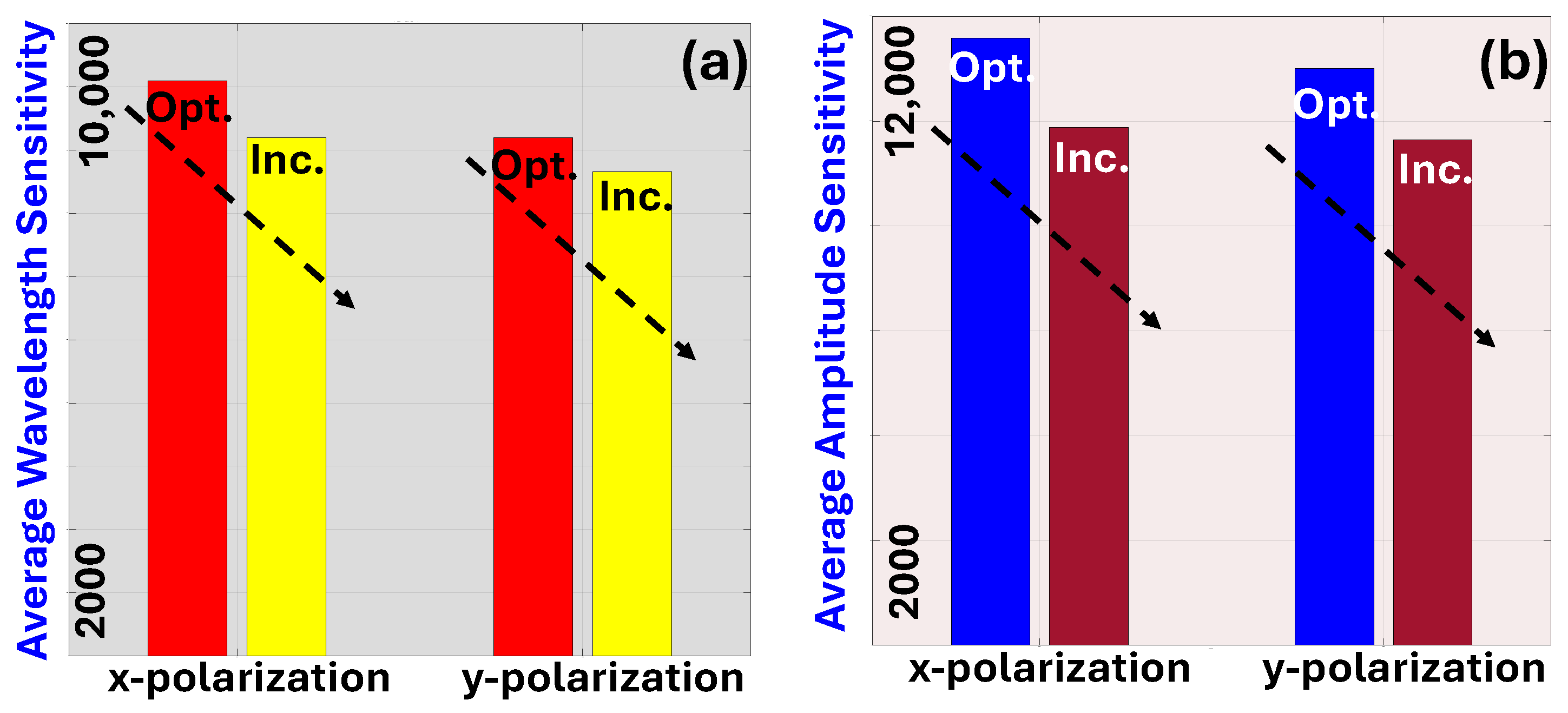

4.6. Analysis of the Sensor Parameters by Increasing the Thickness of Plasmonic Coating Beyond the Optimum Thickness

4.7. Fabrication Tolerance Assessment for the Proposed Sensor

5. Discussion and Potential Use of AI in the Future

5.1. Complexity and Large Dataset Generation in PCF SPR Sensors

5.2. Simulation and Design Optimization

5.3. Data Interpretation and Feature Extraction

5.4. Material and Plasmonic Coating Selection

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fei, Y.; Luo, B.; An, M.; Hu, T.; Lin, W.; Jia, H. A Highly Efficient D-Shaped Dual-Core PCF-SPR Sensor Coated with ITO Film for Refractive Index Detection. Plasmonics 2025, 20, 1379–1393. [Google Scholar] [CrossRef]

- Zhang, Z.; Yin, Z.; Li, S. A SPR Sensor With Wide RI Measuring Range and Narrow FWHM Based on PCF-Silver Film Structure. J. Light. Technol. 2024, 42, 7398–7404. [Google Scholar] [CrossRef]

- Shakya, A.K.; Ramola, A.; Singh, S.; Vidyarthi, A. Optimized Design of Plasmonic Biosensor for Cancer Detection: Core Configuration and Nobel Material Coating Innovation. Plasmonics 2025, 20, 1789–1810. [Google Scholar] [CrossRef]

- Saad, N.M.; Rabaie, E.-S.M.E.; Khalaf, A.A.M. Highly universal sensitive star core photonic crystal fiber (S-PCF)-based sensor for both chemical and biomedical applications. J. Opt. 2024, 1–26. [Google Scholar] [CrossRef]

- Ji, Y.; Du, Y.; Dai, J.; Zou, H.; Zhang, R.; Zhou, D. Dual-Core Photonic Crystal Fiber Polarization Beam Splitter Based on a Nematic Liquid Crystal with an Ultra-Short Length and Ultra-Wide Bandwidth. Electronics 2024, 13, 2343. [Google Scholar] [CrossRef]

- Ferdous, A.I.; Hosen, M.S.; Khandakar, K.; Kundu, D.; Bani, M.M.; Noor, S.A.T.K.S. Pioneering terahertz blood analysis: Hollow-core PCF with optimized sensitivity and low loss. PLoS ONE 2025, 20, e0319860. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Liu, M.; Qi, Y.; Luan, N.; Bai, Z.; Ding, J. Tunable Single and Multi-Wavelength Er-Doped Mode-Locked Fiber Laser Based on GIMF-PCF-GIMF. IEEE Photonics Technol. Lett. 2023, 35, 1043–1046. [Google Scholar] [CrossRef]

- Fallahi, V.; Kordrostami, Z.; Hosseini, M. Sensitivity and quality factor improvement of photonic crystal sensors by geometrical optimization of waveguides and micro-ring resonators combination. Sci. Rep. 2024, 14, 2001. [Google Scholar] [CrossRef]

- Theodosiou, A. Recent Advances in Fiber Bragg Grating Sensing. Sensors 2024, 24, 532. [Google Scholar] [CrossRef]

- Shakya, A.K.; Cheng, F.; Carmon, T. Ultracoherent emission by orthogonal lasers. In SPIE 13012 Integrated Photonics Platforms III; SPIE: Strasbourg, France, 2024. [Google Scholar]

- Sun, A.; Wu, Z.; Fang, D.; Zhang, J.; Wang, W. Multimode Interference-Based Fiber-Optic Ultrasonic Sensor for Non-Contact Displacement Measurement. IEEE Sens. J. 2016, 16, 5632–5635. [Google Scholar] [CrossRef]

- Capelli, D.; Scognamiglio, V.; Montanari, R. Surface plasmon resonance technology: Recent advances, applications and experimental cases. TrAC Trends Anal. Chem. 2023, 163, 117079. [Google Scholar] [CrossRef]

- Falah, A.A.S.; Wong, W.R.; Adikan, F.R.M. Single-mode eccentric-core D-shaped photonic crystal fiber surface plasmon resonance sensor. Opt. Laser Technol. 2022, 145, 107474. [Google Scholar] [CrossRef]

- Mittal, S.; Saharia, A.; Ismail, Y.; Petruccione, F.; Bourdine, A.V.; Morozov, O.G. Design and Performance Analysis of a Novel Hoop-Cut SPR-PCF Sensor for High Sensitivity and Broad Range Sensing Applications. IEEE Sens. J. 2024, 24, 2697–2704. [Google Scholar] [CrossRef]

- Zakaria, R.; Zainuddin, N.A.M.; Raya, S.A.; Alwi, S.A.K.; Anwar, T.; Sarlan, A.; Ahmed, K.; Amiri, I.S. Sensitivity Comparison of Refractive Index Transducer Optical Fiber Based on Surface Plasmon Resonance Using Ag, Cu, and Bimetallic Ag–Cu Layer. Micromachines 2020, 11, 77. [Google Scholar] [CrossRef]

- Alhawari, A.R.; Almawgani, A.H.; Taya, S.A.; Daher, M.G.; Prajapati, Y.K.; Gumaih, H.S. Highly sensitive protein sensor based on surface plasmon resonance nanostructure employing titanium dioxide and graphene layers. Diam. Relat. Mater. 2025, 151, 111867. [Google Scholar] [CrossRef]

- Jaffray, W.; Saha, S.; Shalaev, V.M.; Boltasseva, A.; Ferrera, M. Transparent conducting oxides: From all-dielectric plasmonics to a new paradigm in integrated photonics. Adv. Opt. Photonics 2022, 14, 148–208. [Google Scholar] [CrossRef]

- Ramola, A.; Shakya, A.K.; Bergman, A. ComprehensivAnalysis of Advancement in Optical Biosensing Techniques for Early Detection of Cancerous Cells. Biosensors 2025, 15, 292. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, X.; Zhang, H.; Bai, X.; Ai, R.; Shao, L.; Wang, J. Gold Nanorods: The Most Versatile Plasmonic Nanoparticles. Chem. Rev. 2021, 121, 13342–13453. [Google Scholar] [CrossRef]

- Montes-García, V.; Squillaci, M.A.; Diez-Castellnou, M.; Ong, Q.K.; Stellacci, F.; Samorì, P. Chemical sensing with Au and Ag nanoparticles. Chem. Soc. Rev. 2021, 50, 1269–1304. [Google Scholar] [CrossRef]

- Paul, A.K.; Mollah, M.A.; Hassan, M.Z.; Gomez-Cardona, N.; Reyes-Vera, E. Graphene-Coated Highly Sensitive Photonic Crystal Fiber Surface Plasmon Resonance Sensor for Aqueous Solution: Design and Numerical Analysis. Photonics 2021, 8, 155. [Google Scholar] [CrossRef]

- Mahmood, K.; Munir, R.; Kang, H.W.; Sung, H.J. An atmospheric pressure-based electrospraying route to fabricate the multi-applications bilayer (AZO/ITO) TCO films. RSC Adv. 2013, 3, 25741–25751. [Google Scholar] [CrossRef]

- Lou, J.; Yang, Y.; Qu, Q.; Li, S. Research on application of secondary drawing technology in the preparation of various solid-core and hollow-core photonic crystal fibers. Opt. Laser Technol. 2024, 174, 110678. [Google Scholar] [CrossRef]

- Islam, M.S.; Ferdous, A.I.; Noor, K.S.; Bani, M.M. Designing hollow-core PCF sensors for high-performance terahertz detection of NaCN and KCN. Heliyon 2024, 10, e37681. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Nan, P.; Lim, K.-S.; Liu, X.; Dang, W.; Li, Z. Double F-P Interference Optical Fiber High Temperature Gas Pressure Sensor Based on Suspended Core Fiber. IEEE Sens. J. 2021, 21, 26805–26813. [Google Scholar] [CrossRef]

- Singer, A.M.; Hameed, M.F.O.; Heikal, A.M.; El-Mikati, H.A.; Obayya, S.S.A. Highly birefringent slotted core photonic crystal fiber for terahertz waveguiding. Opt. Quantum Electron. 2021, 53, 1–15. [Google Scholar] [CrossRef]

- Chen, N.; Yue, W.; Xu, Y.; Guo, W.; Xiao, Y.; Ren, Z.; Ding, X.; Li, M.; Xu, Y.; Wu, T.; et al. Design and simulation of a compact polarization beam splitter based on dual-core photonic crystal fiber with elliptical gold layer. Sci. Rep. 2024, 14, 18017. [Google Scholar] [CrossRef]

- Singh, S.; Chaudhary, B.; Upadhyay, A.; Taya, S.A. Bottom side partially etched D-shaped PCF biosensor for early diagnosis of cancer cells. Eur. Phys. J. Plus 2023, 138, 511. [Google Scholar] [CrossRef]

- Zhang, J.; Tong, Z.; Zhang, W.; Zhao, Y.; Li, J. Research on simultaneous temperature and relative humidity measurement based on tapered PCF Mach-Zehnder interferometer. Opt. Fiber Technol. 2021, 61, 102408. [Google Scholar] [CrossRef]

- Shakya, A.K.; Singh, S. Design of novel Penta core PCF SPR RI sensor based on fusion of IMD and EMD techniques for analysis of water and transformer oil. Measurement 2022, 188, 110513. [Google Scholar] [CrossRef]

- Hasan, M.S.; Kalam, M.A.E.; Faisal, M. PCF Based Four-Channel SPR Biosensor with Wide Sensing Range. IEEE Trans. NanoBiosci. 2023, 23, 233–241. [Google Scholar] [CrossRef]

- Gamal, Y.; Younis, B.M.; Abd-Elkader, A.E.-S.; Furniss, D.; Farries, M.; Phang, S.; Benson, T.M.; Seddon, A.B.; Hameed, M.F.O.; Obayya, S.S.A. Mid-infrared water pollutant sensor based on SPR-PCF. Opt. Quant. Electron. 2023, 55, 966. [Google Scholar] [CrossRef]

- Hossain, M.S.; Sen, S. Design and Performance Improvement of Optical Chemical Sensor Based Photonic Crystal Fiber (PCF) in the Terahertz (THz) Wave Propagation. Silicon 2020, 13, 3879–3887. [Google Scholar] [CrossRef]

- Kaziz, S.; Echouchene, F.; Gazzah, M.H. Optimizing PCF-SPR sensor design through Taguchi approach, machine learning, and genetic algorithms. Sci. Rep. 2024, 14, 7837. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Yang, K.; Jiang, T.; Zhang, J.; Letaief, K.B. Communication-Efficient Edge AI: Algorithms and Systems. IEEE Commun. Surv. Tutor. 2020, 22, 2167–2191. [Google Scholar] [CrossRef]

- Dogan, Y.; Katirci, R.; Erdogan, I. Machine learning-based optimization for D-shaped PCF SPR refractive index sensor. Opt. Commun. 2025, 575, 131304. [Google Scholar] [CrossRef]

- Guedri-Knani, L.; Kaziz, S.; Dridi, C. Performance Prediction of a Highly Sensitive Optimized PCF-SPR Biosensor for Cancer Cell Detection Using MLP-Based ANN Model. IEEE Sens. J. 2025, 25, 17136–17143. [Google Scholar] [CrossRef]

- Goswami, M.; Khare, P.; Shakya, S. AI Algorithm for Mode Classification of PCF-SPR Sensor Design. Plasmonics 2024, 19, 363–377. [Google Scholar] [CrossRef]

- Truong, T.T.; Airao, J.; Hojati, F.; Ilvig, C.F.; Azarhoushang, B.; Karras, P.; Aghababaei, R. Data-driven prediction of tool wear using Bayesian regularized artificial neural networks. Measurement 2024, 238, 115303. [Google Scholar] [CrossRef]

- Shaik, N.B.; Mantrala, K.M.; Bakthavatchalam, B.; Gillani, Q.F.; Rehman, M.F. Corrosion Behavior of LENS Deposited CoCrMo Alloy Using Bayesian Regularization-Based Artificial Neural Network (BRANN). J. Bio-Tribo-Corros. 2024, 7, 116. [Google Scholar] [CrossRef]

- Ghiassi, M.; Saidane, H. A dynamic architecture for artificial neural networks. Neurocomputing 2005, 63, 397–413. [Google Scholar] [CrossRef]

- Abioduna, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed]

- Shakya, A.K.; Ramola, A.; Vidyarthi, A. Modeling of texture quantification and image classification for change prediction due to COVID lockdown using Skysat and Planetscope imagery. Model. Earth Syst. Environ. 2022, 8, 2767–2792. [Google Scholar] [CrossRef] [PubMed]

- Shakya, A.K.; Ramola, A.; Singh, S.; Vidyarthi, A. Optimum supervised classification algorithm identification by investigating PlanetScope and Skysat multispectral satellite data of Covid lockdown. Geosyst. Geoenviron. 2023, 2, 100163. [Google Scholar] [CrossRef]

- Lucas, T.J.; Figueiredo, I.S.D.; Tojeiro, C.A.C.; Almeida, A.M.G.D.; Scherer, R.; Brega, J.R.F. A Comprehensive Survey on Ensemble Learning-Based Intrusion Detection Approaches in Computer Networks. IEEE Access 2023, 11, 122638–122676. [Google Scholar] [CrossRef]

- Samuel, D.; Khan, S.; Balos, C.J.; Abuelhaj, Z.; Dutoi, A.D.; Kari, C.; Mueller, D.; Pallipuram, V.K. A2Cloud-RF: A random forest based statistical framework to guide resource selection for high-performance scientific computing on the cloud. Concurr. Comput. Pract. Exp. 2020, 32, e5942. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Sung, E. AdaBoost with SVM-based component classifiers. Eng. Appl. Artif. Intell. 2008, 21, 785–795. [Google Scholar] [CrossRef]

- Bentéjac, C.; Csörgő, A.; Martínez-Muñoz, G. A comparative analysis of gradient boosting algorithms. Artif. Intell. Rev. 2021, 54, 1937–1967. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, H.; Cai, Z. A Novel Bayes Model: Hidden Naive Bayes. IEEE Trans. Knowl. Data Eng. 2009, 21, 1361–1371. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, Y.; Zhang, H. Recent Advances in Stochastic Gradient Descent in Deep Learning. Mathematics 2023, 11, 682. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A Survey of Convolutional Neural Networks: Analysis, Applications, and Prospects. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 6999–7019. [Google Scholar] [CrossRef]

- Kattenborn, T.; Leitloff, J.; Schiefer, F.; Hinz, S. Review on Convolutional Neural Networks (CNN) in vegetation remote sensing. ISPRS J. Photogramm. Remote Sens. 2021, 173, 24–49. [Google Scholar] [CrossRef]

- Svozil, D.; Kvasnicka, V.; Pospichal, J. Introduction to multi-layer feed-forward neural networks. Chemom. Intell. Lab. Syst. 1997, 39, 43–62. [Google Scholar] [CrossRef]

- Vakalopoulou, M.; Christodoulidis, S.; Burgos, N.; Colliot, O.; Lepetit, V. Deep Learning: Basics and Convolutional Neural Networks (CNNs). In Machine Learning for Brain Disorders; Springer: New York, NY, USA, 2023; pp. 77–115. [Google Scholar]

- Kim, H.; Arigi, A.M.; Kim, J. Development of a diagnostic algorithm for abnormal situations using long short-term memory and variational autoencoder. Ann. Nucl. Energy 2021, 153, 108077. [Google Scholar] [CrossRef]

- Hamghalam, M.; Simpson, A.L. Medical image synthesis via conditional GANs: Application to segmenting brain tumours. Comput. Biol. Med. 2024, 170, 107982. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, S.; Liang, X.; Zhao, D.; Huang, J.; Xu, X.; Dai, B.; Miao, Q. Deep reinforcement learning: A survey. IEEE Trans. Neural Netw. Learn. Syst. 2022, 35, 5064–5078. [Google Scholar] [CrossRef]

- Ashrafian, M.; Olyaee, S.; Seifouri, M. Highly sensitive cancer detection using an open D-channel PCF-based SPR biosensor. Sci. Rep. 2025, 15, 10168. [Google Scholar] [CrossRef]

- Kadi, M.; Smaali, A.; Outemzabet, R. Analysis of optical and related properties of tin oxide thin films determined by Drude-Lorentz model. Surf. Coat. Technol. 2012, 211, 45–49. [Google Scholar] [CrossRef]

- Emon, W.; Chaki, A.; Mondal, T.P.; Nayan, M.F.; Mahmud, R.R. Photonic crystal fiber-based SPR biosensor coated with Ag-TiO2 and Au-TiO2 for the detection of skin cancer: A comparison. Opt. Quant. Electron. 2024, 56, 1332. [Google Scholar] [CrossRef]

- Danlard, I.; Akowuah, E.K. Assaying with PCF-based SPR refractive index biosensors: From recent configurations to outstanding detection limits. Opt. Fiber Technol. 2020, 54, 102083. [Google Scholar] [CrossRef]

- Homola, J. Surface Plasmon Resonance Sensors for Detection of Chemical and Biological Species. Chem. Rev. 2008, 108, 462–493. [Google Scholar] [CrossRef]

- Shakya, A.K.; Singh, S. Design of refractive index sensing based on optimum combination of plasmonic materials gold with indium tin oxide/titanium dioxide. J. Nanophotonics 2022, 16, 026010. [Google Scholar] [CrossRef]

- Shakya, A.K.; Singh, S. Design and analysis of dual polarized Au and TiO2-coated photonic crystal fiber surface plasmon resonance refractive index sensor: An extraneous sensing approach. J. Nanophotonics 2021, 15, 016009. [Google Scholar] [CrossRef]

- Tamm, A.; Acik, I.O.; Arroval, T.; Kasikov, A.; Seemen, H.; Marandi, M.; Krunks, M. Plasmon resonance effect caused by gold nanoparticles formed on titanium oxide films. Thin Solid Film. 2016, 616, 449–455. [Google Scholar] [CrossRef]

- Kumar, A.; Verma, P.; Jindal, P. Machine learning approach to surface plasmon resonance sensor based on MXene coated PCF for malaria disease detection in RBCs. Optik 2023, 274, 170549. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Y.; Dong, J. Ultra-wide measurement range D-shaped photonic crystal fiber sensor based on surface plasmon resonance. Eur. Phys. J. D 2024, 78, 111. [Google Scholar] [CrossRef]

- Islam, N.; Hasan, M.M.S.; Shibly, I.H.; Rashid, M.B.; Yousuf, M.A.; Haider, F.; Aoni, R.A.; Ahmed, R. Plasmonic sensor using generative adversarial networks integration. Opt. Express 2024, 32, 34184–34198. [Google Scholar] [CrossRef]

- Ahammed, M.T.; Hossain, M.F. Inverse Design of a PCF-Based SPR Sensor Using Machine Learning. In Proceedings of the IEEE International Conference on Computing, Applications and Systems (COMPAS), Cox’s Bazar, Bangladesh, 25–26 September 2024. [Google Scholar]

- Kaium, S.M.A.; Mollah, M.A. Optical properties estimation of photonic crystal fiber using Gaussian process regression. Opt. Contin. 2024, 3, 1369–1388. [Google Scholar] [CrossRef]

- Islam, M.R.; Jamil, M.A.; Zaman, M.S.-U.; Ahsan, S.A.H.; Pulak, M.K.; Mehjabin, F. Design and analysis of birefringent SPR based PCF biosensor with ultra-high sensitivity and low loss. Optik 2020, 221, 165311. [Google Scholar] [CrossRef]

- Li, W.; Chen, Y.; Xu, J.; Jiang, M.; Zou, H. A D-Shaped SPR-Based PCF Sensor with an Extremely High-Amplitude Sensitivity for Measuring the Refractive Index. Micromachines 2022, 14, 1295. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Fang, D. Research on D-Shape Open-Loop PCF Temperature Refractive Index Sensor Based on SPR Effect. IEEE Photonics J. 2022, 14, 5727605. [Google Scholar] [CrossRef]

- Hoque, A.M.T.; Al-Tabatabaie, K.F.; Ali, M.E.; Butt, A.M.; Mitu, S.S.I.; Qureshi, K.K. U-Grooved Selectively Coated and Highly Sensitive PCF-SPR Sensor for Broad Range Analyte RI Detection. IEEE Access 2023, 11, 74486–74499. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.K.; Sarkar, S.; Mukherjee, S.; Das, N.R. Optimization and characterization of a PCF-based SPR sensor for enhanced sensitivity and reliability in diverse chemical and biological applications. J. Opt. Soc. Am. B 2025, 42, 97–104. [Google Scholar] [CrossRef]

- Islam, N.; Masum, M.M.U.; Arif, M.F.H.; Asaduzzaman, S.; Roy, M.; Yousuf, M.A. Enhanced Sensitivity of Open Channel SPR-Based PCF Sensor Employing Plasmonic Materials for Analyte Sensing. Plasmonics 2022, 17, 2075–2087. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y. A PCF-SPR sensor for dual-polarization and wide refractive index detection range. Opt. Commun. 2024, 569, 130810. [Google Scholar] [CrossRef]

- Islam, M.R.; Khan, M.M.I.; Naser, A.M.A.; Mehjabin, F.; Jaba, F.Z.; Chowdhury, J.A.; Anzum, F.; Islam, M. Design of a quad channel SPR-based PCF sensor for analyte, strain, temperature, and magnetic field strength sensing. Opt. Quant. Electron. 2022, 54, 563. [Google Scholar] [CrossRef]

- Mim, M.A.; Khatun, M.R.; Hossain, M.M.; Rahman, W. Advanced PCF-SPR biosensor design and performance optimization using machine learning techniques. Optik 2025, 333, 172391. [Google Scholar] [CrossRef]

- Panagiotopoulou, O. Finite element analysis (FEA): Applying an engineering method to functional morphology in anthropology and human biology. Ann. Hum. Biol. 2009, 36, 609–623. [Google Scholar] [CrossRef]

- Zeng, W.; Liu, G.R. Smoothed Finite Element Methods (S-FEM): An Overview and Recent Developments. Arch. Comput. Methods Eng. 2018, 25, 397–435. [Google Scholar] [CrossRef]

- Teixeira, F.L.; Sarris, C.; Zhang, Y.; Na, D.-Y.; Berenger, J.-P.; Su, Y.; Okoniewski, M.; Chew, W.C.; Backman, V.; Simpson, J.J. Finite-difference time-domain methods. Nat. Rev. Methods Primers 2023, 3, 75. [Google Scholar] [CrossRef]

- Feng, J.; Phillips, R.V.; Malenica, I.; Bishara, A.; Hubbard, A.E.; Celi, L.A.; Pirracchio, R. Clinical artificial intelligence quality improvement: Towards continual monitoring and updating of AI algorithms in healthcare. npj Digit. Med. 2022, 5, 66. [Google Scholar] [CrossRef]

- Plumb, A.P.; Rowe, R.C.; York, P.; Brown, M. Optimisation of the predictive ability of artificial neural network (ANN) models: A comparison of three ANN programs and four classes of training algorithm. Eur. J. Pharm. Sci. 2005, 25, 395–405. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.; Man, K.; Kwong, S.; He, Q. Genetic algorithms and their applications. IEEE Signal Process. Mag. 1996, 13, 22–37. [Google Scholar] [CrossRef]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Arulkumaran, K.; Deisenroth, M.P.; Brundage, M.; Bharath, A.A. Deep reinforcement learning: A brief survey. IEEE Signal Process. Mag. 2017, 34, 26–38. [Google Scholar]

- Elish, M.C.; Boyd, D. Situating methods in the magic of Big Data and AI. Commun. Monogr. 2017, 85, 57–80. [Google Scholar] [CrossRef]

- Chiroma, H.; Abdullahi, U.A.; Abdulhamid, S.M.; Alarood, A.A.; Gabralla, L.A.; Rana, N. Progress on Artificial Neural Networks for Big Data Analytics: A Survey. IEEE Access 2018, 7, 70535–70551. [Google Scholar] [CrossRef]

- Dobrzański, L.; Staszuk, M.; Honysz, R. Application of artificial intelligence methods in PVD and CVD coatings properties modelling. Arch. Mater. Sci. Eng. 2012, 58, 152–157. [Google Scholar]

| Ref | Sensor Shape | Methodology | RI | Pol. | WS (nm/RIU) | AS (RIU−1) | SR (RIU) | Order/R2 |

|---|---|---|---|---|---|---|---|---|

| [76] | Circular | EMD | 1.33–1.40 | y-pol. | 6000 | 573.83 | 10−5 | NA |

| [77] | Circular | H-shaped EMD | 1.29–1.35 | x-pol. | 7800 | NA | NA | NA |

| 1.37–1.41 | y-pol. | 11,700 | ||||||

| [78] | Circular | EMD | 1.33–1.43 | x-pol. and y-pol. | 10,000 | 4646.1 | 10−6 | II/0.999 |

| [79] | Circular | EMD | 1.31–1.40 | y-pol. | 9000 | 1241.93 | 10−5 | I/0.86–0.99 |

| Proposed Sensor | Square | EMD | 1.33–1.37 | x-pol. | 15,800 | 11,584 | 10−6 | I/0.9736 |

| y-pol. | 14,300 | 11,007 | 10−6 | I/I0.9723 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramola, A.; Shakya, A.K.; Bergman, A. Finite Element Method-Based Modeling of a Novel Square Photonic Crystal Fiber Surface Plasmon Resonance Sensor with a Au–TiO2 Interface and the Relevance of Artificial Intelligence Techniques in Sensor Optimization. Photonics 2025, 12, 565. https://doi.org/10.3390/photonics12060565

Ramola A, Shakya AK, Bergman A. Finite Element Method-Based Modeling of a Novel Square Photonic Crystal Fiber Surface Plasmon Resonance Sensor with a Au–TiO2 Interface and the Relevance of Artificial Intelligence Techniques in Sensor Optimization. Photonics. 2025; 12(6):565. https://doi.org/10.3390/photonics12060565

Chicago/Turabian StyleRamola, Ayushman, Amit Kumar Shakya, and Arik Bergman. 2025. "Finite Element Method-Based Modeling of a Novel Square Photonic Crystal Fiber Surface Plasmon Resonance Sensor with a Au–TiO2 Interface and the Relevance of Artificial Intelligence Techniques in Sensor Optimization" Photonics 12, no. 6: 565. https://doi.org/10.3390/photonics12060565

APA StyleRamola, A., Shakya, A. K., & Bergman, A. (2025). Finite Element Method-Based Modeling of a Novel Square Photonic Crystal Fiber Surface Plasmon Resonance Sensor with a Au–TiO2 Interface and the Relevance of Artificial Intelligence Techniques in Sensor Optimization. Photonics, 12(6), 565. https://doi.org/10.3390/photonics12060565