Temperature-Insensitive Cryogenic Packaging for Thin-Film Lithium Niobate Photonic Chips

Abstract

1. Introduction

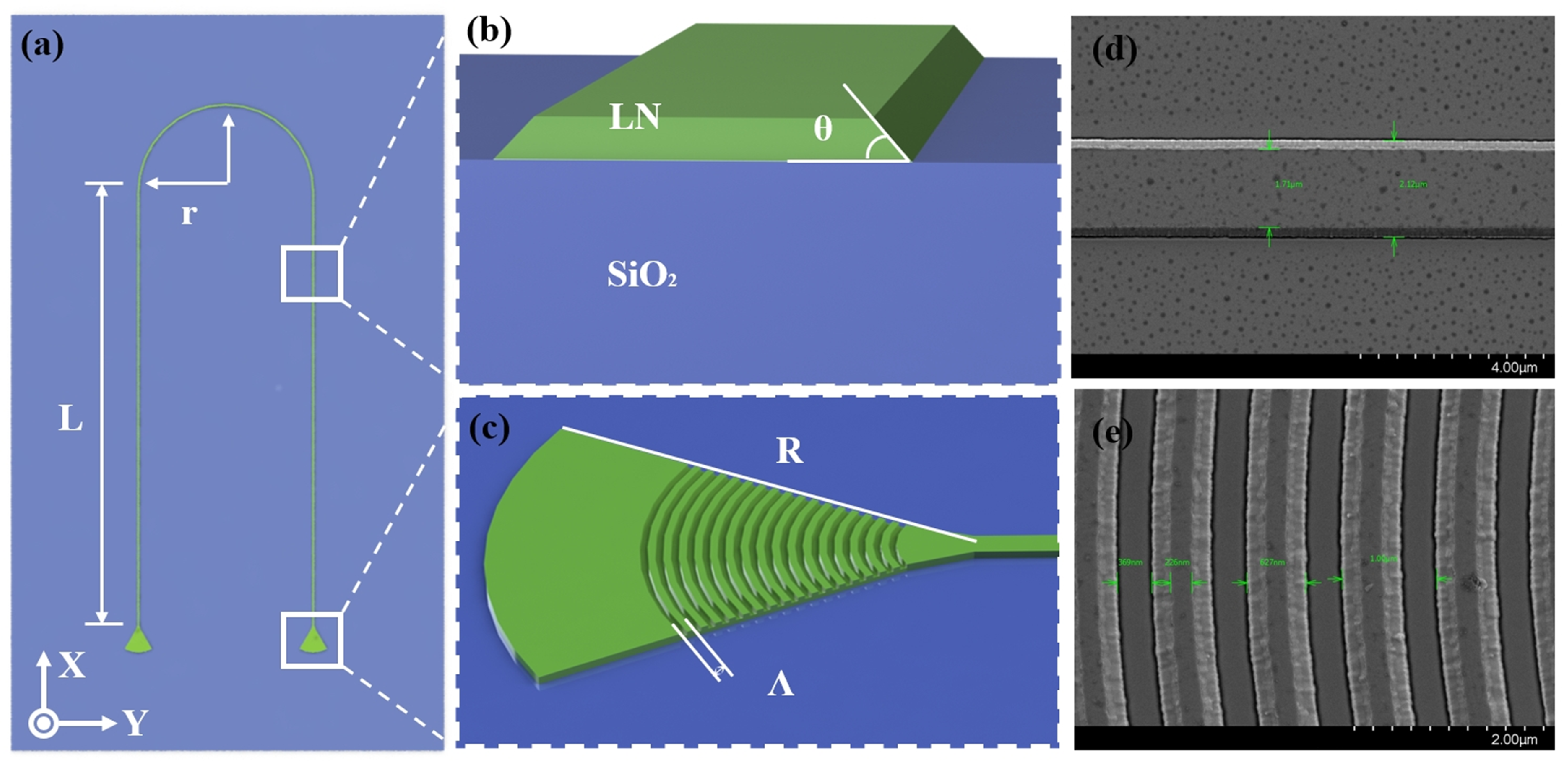

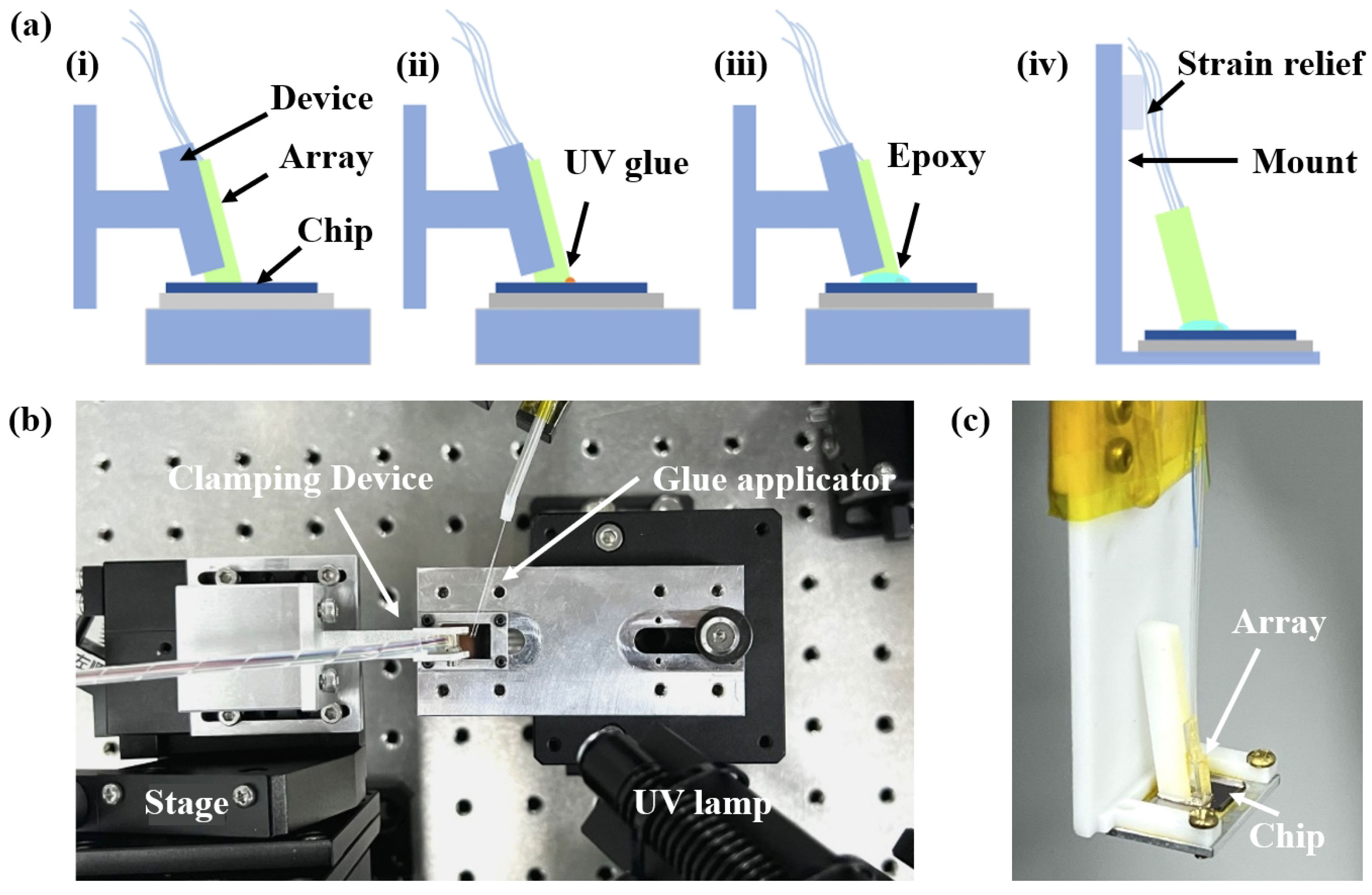

2. Fabrication and Packaging

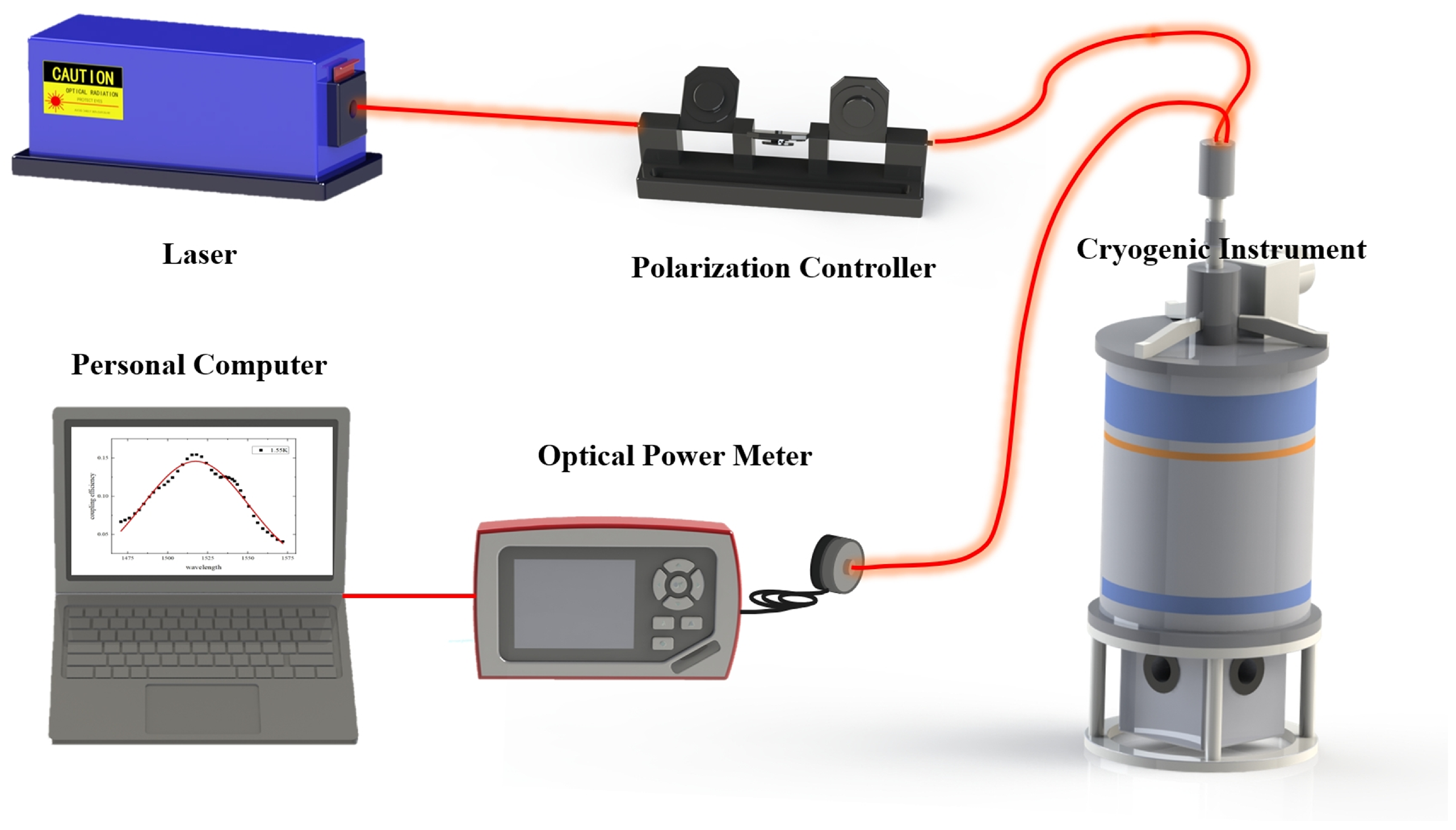

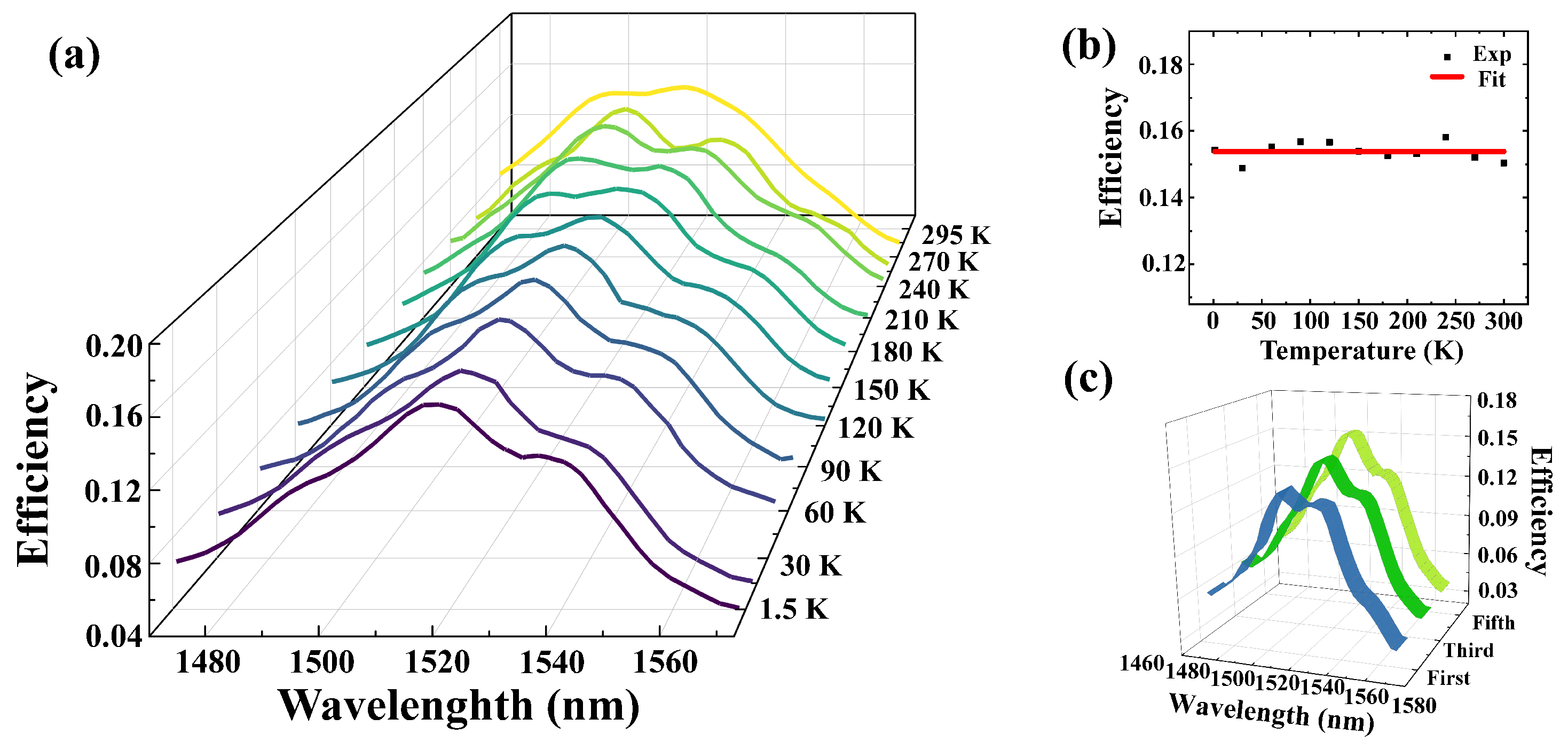

3. Experimental Results

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, D.; Shao, L.; Yu, M.; Cheng, R.; Desiatov, B.; Xin, C.; Hu, Y.; Holzgrafe, J.; Ghosh, S.; Shams-Ansari, A.; et al. Integrated photonics on thin-film lithium niobate. Adv. Opt. Photonics 2021, 13, 242–352. [Google Scholar] [CrossRef]

- Saravi, S.; Pertsch, T.; Setzpfandt, F. Lithium niobate on insulator: An emerging platform for integrated quantum photonics. Adv. Opt. Mater. 2021, 9, 2100789. [Google Scholar] [CrossRef]

- Smit, M.; Williams, K.; Van Der Tol, J. Past, present, and future of inp-based photonic integration. APL Photonics 2019, 4, 050901. [Google Scholar] [CrossRef]

- Wang, J.; Sciarrino, F.; Laing, A.; Thompson, M.G. Integrated photonic quantum technologies. Nat. Photonics 2020, 14, 273–284. [Google Scholar] [CrossRef]

- Ramakrishnan, R.K.; Ravichandran, A.B.; Mishra, A.; Kaushalram, A.; Hegde, G.; Talabattula, S.; Rohde, P.P. Integrated photonic platforms for quantum technology: A review. ISSS J. Micro Smart Syst. 2023, 12, 83–104. [Google Scholar] [CrossRef]

- Moody, G.; Chang, L.; Steiner, T.J.; Bowers, J.E. Chip-scale nonlinear photonics for quantum light generation. AVS Quantum Sci. 2020, 2, 041702. [Google Scholar] [CrossRef]

- Wu, R.; Wang, M.; Xu, J.; Qi, J.; Chu, W.; Fang, Z.; Zhang, J.; Zhou, J.; Qiao, L.; Chai, Z.; et al. Long low-loss-litium niobate on insulator waveguides with sub-nanometer surface roughness. Nanomaterials 2018, 8, 910. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, M.; Chen, X.; Bertrand, M.; Shams-Ansari, A.; Chandrasekhar, S.; Winzer, P.; Lončar, M. Integrated lithium niobate electro-optic modulators operating at cmos-compatible voltages. Nature 2018, 562, 101–104. [Google Scholar] [CrossRef]

- Zhang, M.; Buscaino, B.; Wang, C.; Shams-Ansari, A.; Reimer, C.; Zhu, R.; Kahn, J.M.; Lončar, M. Broadband electro-optic frequency comb generation in a lithium niobate microring resonator. Nature 2019, 568, 373–377. [Google Scholar] [CrossRef]

- Fang, X.-X.; Du, H.-Y.; Zhang, X.; Wang, L.; Chen, F.; Lu, H. High-efficiency on-chip quantum photon source in modal phase-matched lithium niobate nanowaveguide. Laser Photonics Rev. 2025, 19, 2400782. [Google Scholar] [CrossRef]

- Wang, X.; Jiao, X.; Wang, B.; Liu, Y.; Xie, X.-P.; Zheng, M.-Y.; Zhang, Q.; Pan, J.-W. Quantum frequency conversion and single-photon detection with lithium niobate nanophotonic chips. npj Quantum Inf. 2023, 9, 38. [Google Scholar] [CrossRef]

- Feng, H.; Ge, T.; Guo, X.; Wang, B.; Zhang, Y.; Chen, Z.; Zhu, S.; Zhang, K.; Sun, W.; Huang, C.; et al. Integrated lithium niobate microwave photonic processing engine. Nature 2024, 627, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Youssefi, A.; Shomroni, I.; Joshi, Y.J.; Bernier, N.R.; Lukashchuk, A.; Uhrich, P.; Qiu, L.; Kippenberg, T.J. A cryogenic electro-optic interconnect for superconducting devices. Nat. Electron. 2021, 4, 326–332. [Google Scholar] [CrossRef]

- Shen, M.; Xie, J.; Xu, Y.; Wang, S.; Cheng, R.; Fu, W.; Zhou, Y.; Tang, H.X. Photonic link from single-flux-quantum circuits to room temperature. Nat. Photonics 2024, 18, 371–378. [Google Scholar] [CrossRef]

- Lomonte, E.; Wolff, M.A.; Beutel, F.; Ferrari, S.; Schuck, C.; Pernice, W.H.; Lenzini, F. Single-photon detection and cryogenic reconfigurability in lithium niobate nanophotonic circuits. Nat. Commun. 2021, 12, 6847. [Google Scholar] [CrossRef]

- Mobassem, S.; Lambert, N.J.; Rueda, A.; Fink, J.M.; Leuchs, G.; Schwefel, H.G. Thermal noise in electro-optic devices at cryogenic temperatures. Quantum Sci. Technol. 2021, 6, 045005. [Google Scholar] [CrossRef]

- Riedinger, R.; Wallucks, A.; Marinković, I.; Löschnauer, C.; Aspelmeyer, M.; Hong, S.; Gröblacher, S. Remote quantum entanglement between two micromechanical oscillators. Nature 2018, 556, 473–477. [Google Scholar] [CrossRef]

- Zhao, M.; Fang, K. Observation of photon-phonon correlations via dissipative filtering. Phys. Rev. Appl. 2022, 18, 034043. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, X.; Feng, L.; Li, H.; Sun, W.; Song, X.; Ding, Y.; Guo, G.; Wang, C.; Ren, X. Efficient cryogenic nonlinear conversion processes in periodically-poled thin-film lithium niobate waveguides. Laser Photonics Rev. 2025, 19, 2401491. [Google Scholar] [CrossRef]

- Sund, P.I.; Lomonte, E.; Paesani, S.; Wang, Y.; Carolan, J.; Bart, N.; Wieck, A.D.; Ludwig, A.; Midolo, L.; Pernice, W.H.; et al. High-speed thin-film lithium niobate quantum processor driven by a solid-state quantum emitter. Sci. Adv. 2023, 9, eadg7268. [Google Scholar] [CrossRef]

- Cohen, J.D.; Meenehan, S.M.; MacCabe, G.S.; Gröblacher, S.; Safavi-Naeini, A.H.; Marsili, F.; Shaw, M.D.; Painter, O. Phonon counting and intensity interferometry of a nanomechanical resonator. Nature 2015, 520, 522–525. [Google Scholar] [CrossRef] [PubMed]

- McKenna, T.P.; Patel, R.N.; Witmer, J.D.; Laer, R.V.; Valery, J.A.; Safavi-Naeini, A.H. Cryogenic packaging of an optomechanical crystal. Opt. Express 2019, 27, 28782–28791. [Google Scholar] [CrossRef] [PubMed]

- Wasserman, W.; Harrison, R.; Harris, G.; Sawadsky, A.; Sfendla, Y.; Bowen, W.; Baker, C. Cryogenic and hermetically sealed packaging of photonic chips for optomechanics. Opt. Express 2022, 30, 30822–30831. [Google Scholar] [CrossRef]

- Vermeulen, D.; Poulton, C.V. Optical interfaces for silicon photonic circuits. Proc. IEEE 2018, 106, 2270–2280. [Google Scholar] [CrossRef]

- Carroll, L.; Lee, J.-S.; Scarcella, C.; Gradkowski, K.; Duperron, M.; Lu, H.; Zhao, Y.; Eason, C.; Morrissey, P.; Rensing, M.; et al. Photonic packaging: Transforming silicon photonic integrated circuits into photonic devices. Appl. Sci. 2016, 6, 426. [Google Scholar] [CrossRef]

- Zeng, B.; De-Eknamkul, C.; Assumpcao, D.; Renaud, D.; Wang, Z.; Riedel, D.; Ha, J.; Robens, C.; Levonian, D.; Lukin, M.; et al. Cryogenic packaging of nanophotonic devices with a low coupling loss < 1 db. Appl. Phys. Lett. 2023, 123, 161106. [Google Scholar]

- Lin, B.; Witt, D.; Young, J.F.; Chrostowski, L. Cryogenic optical packaging using photonic wire bonds. APL Photonics 2023, 8, 126109. [Google Scholar] [CrossRef]

- Chen, G.; Chen, K.; Yu, Z.; Liu, L. Low-loss and broadband polarization-diversity edge coupler on a thin-film lithium niobate platform. Opt. Lett. 2023, 48, 4145–4148. [Google Scholar] [CrossRef]

- Chen, B.; Ruan, Z.; Wang, M.; Gong, S.; Liu, L. High-performance and fabrication-tolerant edge coupler on thin film lithium niobate based on a three-dimensional inverse taper. APL Photonics 2024, 9, 116111. [Google Scholar] [CrossRef]

- Chen, S.; Ourari, S.; Raha, M.; Phenicie, C.M.; Uysal, M.T.; Thompson, J.D. Hybrid microwave-optical scanning probe for addressing solid-state spins in nanophotonic cavities. Opt. Express 2021, 29, 4902–4911. [Google Scholar] [CrossRef]

- Chen, B.; Ruan, Z.; Fan, X.; Wang, Z.; Liu, J.; Li, C.; Chen, K.; Liu, L. Low-loss fiber grating coupler on thin film lithium niobate platform. APL Photonics 2022, 7, 076103. [Google Scholar] [CrossRef]

- Lomonte, E.; Lenzini, F.; Pernice, W.H. Efficient self-imaging grating couplers on a lithium-niobate-on-insulator platform at near-visible and telecom wavelengths. Opt. Express 2021, 29, 20205–20216. [Google Scholar] [CrossRef] [PubMed]

- You, M.; Lin, Z.; Li, X.; Liu, J. Chip-scale silicon ring resonators for cryogenic temperature sensing. J. Light. Technol. 2020, 38, 5768–5773. [Google Scholar] [CrossRef]

- Witt, D.; Chrostowski, L.; Young, J. Packaged cryogenic photon pair source using an effective packaging methodology for cryogenic integrated optics. arXiv 2024, arXiv:2401.02068. [Google Scholar]

- Ranno, L.; Gupta, P.; Gradkowski, K.; Bernson, R.; Weninger, D.; Serna, S.; Agarwal, A.M.; Kimerling, L.C.; Hu, J.; Brien, P.O. Integrated photonics packaging: Challenges and opportunities. ACS Photonics 2022, 9, 3467–3485. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, J.-H.; Xiao, X.; Sun, W.-M.; Zhang, X.-J.; Chu, T.; Yu, J.-Z.; Yu, Y.-D. High efficiency grating coupler for coupling between single-mode fiber and soi waveguides. Chin. Phys. Lett. 2013, 30, 014207. [Google Scholar] [CrossRef]

- Mehta, K.K.; Zhang, C.; Malinowski, M.; Nguyen, T.-L.; Stadler, M.; Home, J.P. Integrated optical multi-ion quantum logic. Nature 2020, 586, 533–537. [Google Scholar] [CrossRef]

- Starling, D.J.; Shtyrkova, K.; Christen, I.; Murphy, R.; Li, L.; Chen, K.C.; Kharas, D.; Zhang, X.; Cummings, J.; Nowak, W.J.; et al. Fully packaged multichannel cryogenic quantum memory module. Phys. Rev. Appl. 2023, 19, 064028. [Google Scholar] [CrossRef]

- Snyder, B.; O’Brien, P. Packaging process for grating-coupled silicon photonic waveguides using angle-polished fibers. IEEE Trans. Components Packag. Manuf. Technol. 2013, 3, 954–959. [Google Scholar] [CrossRef]

- Li, C.; Chee, K.S.; Tao, J.; Zhang, H.; Yu, M.; Lo, G.Q. Silicon photonics packaging with lateral fiber coupling to apodized grating coupler embedded circuit. Opt. Express 2014, 22, 24235–24240. [Google Scholar] [CrossRef]

- Zimmermann, L.; Preve, G.B.; Tekin, T.; Rosin, T.; Landles, K. Packaging and assembly for integrated photonics—A review of the epixpack photonics packaging platform. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 645–651. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Shen, M.; Xie, J.; Tang, H.X. Controlling single rare earth ion emission in an electro-optical nanocavity. Nat. Commun. 2023, 14, 1718. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Zhang, R.; Hao, Z.; Jia, D.; Gao, F.; Bo, F.; Zhang, G.; Xu, J. High-efficiency chirped grating couplers on lithium niobate on insulator. Opt. Lett. 2020, 45, 6651–6654. [Google Scholar] [CrossRef]

- Krasnokutska, I.; Chapman, R.J.; Tambasco, J.-L.J.; Peruzzo, A. High coupling efficiency grating couplers on lithium niobate on insulator. Opt. Express 2019, 27, 17681–17685. [Google Scholar] [CrossRef]

- Scarcella, C.; Gradkowski, K.; Carroll, L.; Lee, J.-S.; Duperron, M.; Fowler, D.; O’Brien, P. Pluggable single-mode fiber-array-to-pic coupling using micro-lenses. IEEE Photonics Technol. Lett. 2017, 29, 1943–1946. [Google Scholar] [CrossRef]

- Chen, B.; Ruan, Z.; Chen, K.; Liu, L. One-dimensional grating coupler on lithium-niobate-on-insulator for high-efficiency and polarization-independent coupling. Opt. Lett. 2023, 48, 1434–1437. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, F.; Peucheret, C.; Ou, H.; Miyamoto, Y.; Morioka, T. On-chip grating coupler array on the soi platform for fan-in/fan-out of mcfs with low insertion loss and crosstalk. Opt. Express 2015, 3, 3292–3298. [Google Scholar] [CrossRef]

- Luo, H.; Chen, L.; Yu, S.; Cai, X. Efficient four-way vertical coupler array for chip-scale space-division-multiplexing applications. Opt. Lett. 2021, 46, 4324–4327. [Google Scholar] [CrossRef]

- Dutta, S.; Zhao, Y.; Saha, U.; Farfurnik, D.; Goldschmidt, E.A.; Waks, E. An atomic frequency comb memory in rare-earth-doped thin-film lithium niobate. ACS Photonics 2023, 10, 1104–1109. [Google Scholar] [CrossRef]

| Platform | Reference | Scalability | Method | Temperature/Efficiency | CEL-Cryo |

|---|---|---|---|---|---|

| Si | [22] | Single fiber | UV Glue | 7 mK/∼20% | ∼8% |

| [33] | Fiber array | UV Glue | 180 K/∼0.3% | ∼20% | |

| [34] | Fiber array | Epoxy | 5 K/∼38% | ∼4% | |

| TFLN | [14] | Single fiber | UV Glue | 4 K/∼25% | – |

| [42] | Single fiber | UV Glue | 1 K/∼10% | – | |

| This work | Fiber array | UV Glue + Epoxy | 1.5 K/∼15.7% | ∼0.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Ma, Y.; Wang, X.; Zhao, Z.; Li, Y.; Yang, T. Temperature-Insensitive Cryogenic Packaging for Thin-Film Lithium Niobate Photonic Chips. Photonics 2025, 12, 545. https://doi.org/10.3390/photonics12060545

Wang Y, Ma Y, Wang X, Zhao Z, Li Y, Yang T. Temperature-Insensitive Cryogenic Packaging for Thin-Film Lithium Niobate Photonic Chips. Photonics. 2025; 12(6):545. https://doi.org/10.3390/photonics12060545

Chicago/Turabian StyleWang, Yongteng, Yuxin Ma, Xiaojie Wang, Ziwei Zhao, Yongmin Li, and Tianshu Yang. 2025. "Temperature-Insensitive Cryogenic Packaging for Thin-Film Lithium Niobate Photonic Chips" Photonics 12, no. 6: 545. https://doi.org/10.3390/photonics12060545

APA StyleWang, Y., Ma, Y., Wang, X., Zhao, Z., Li, Y., & Yang, T. (2025). Temperature-Insensitive Cryogenic Packaging for Thin-Film Lithium Niobate Photonic Chips. Photonics, 12(6), 545. https://doi.org/10.3390/photonics12060545