Simulation Study of Readily Manufactured High-Performance Polarization Gratings Based on Cured HSQ Materials

Abstract

1. Introduction

2. Structural Design

3. Analysis of Results

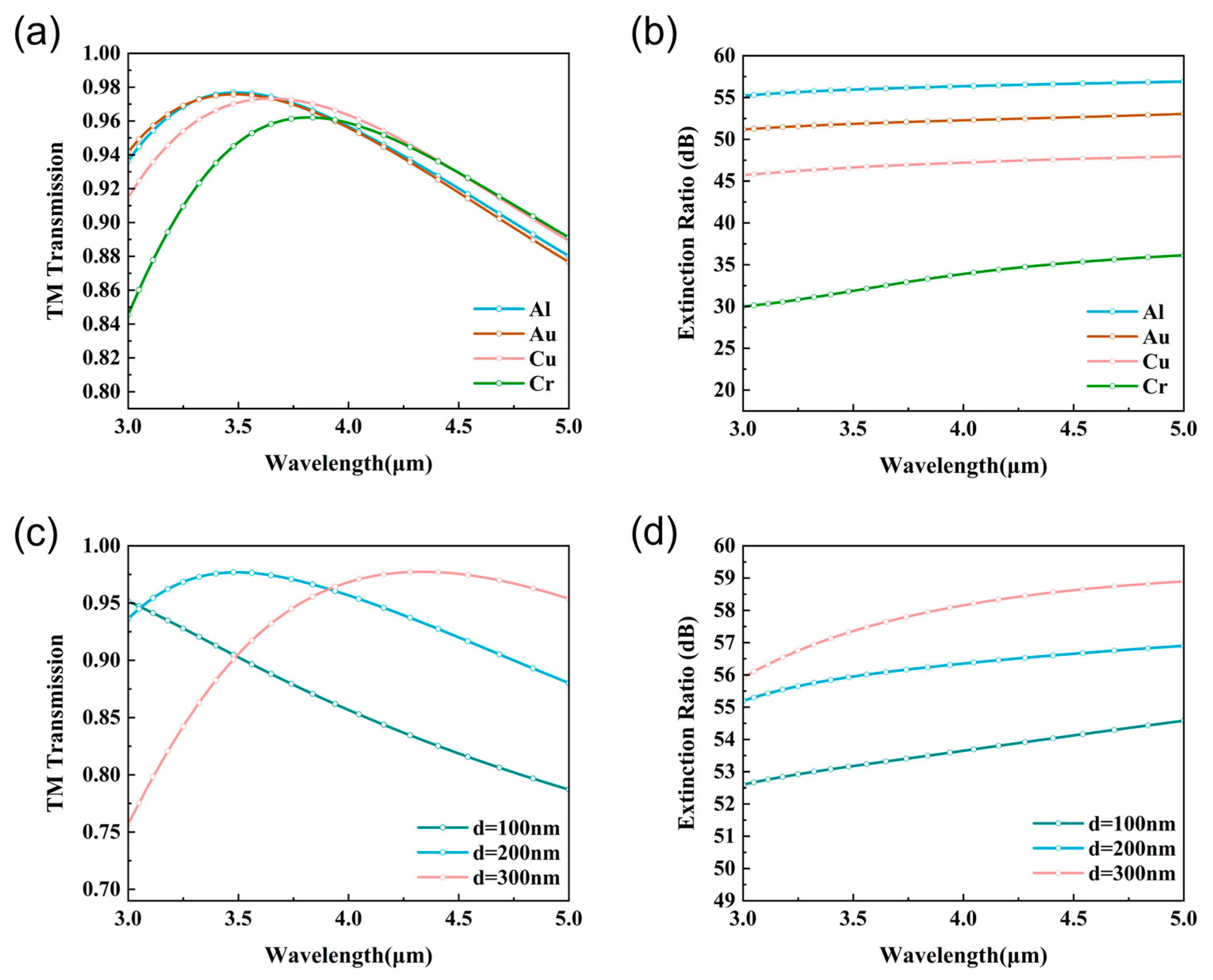

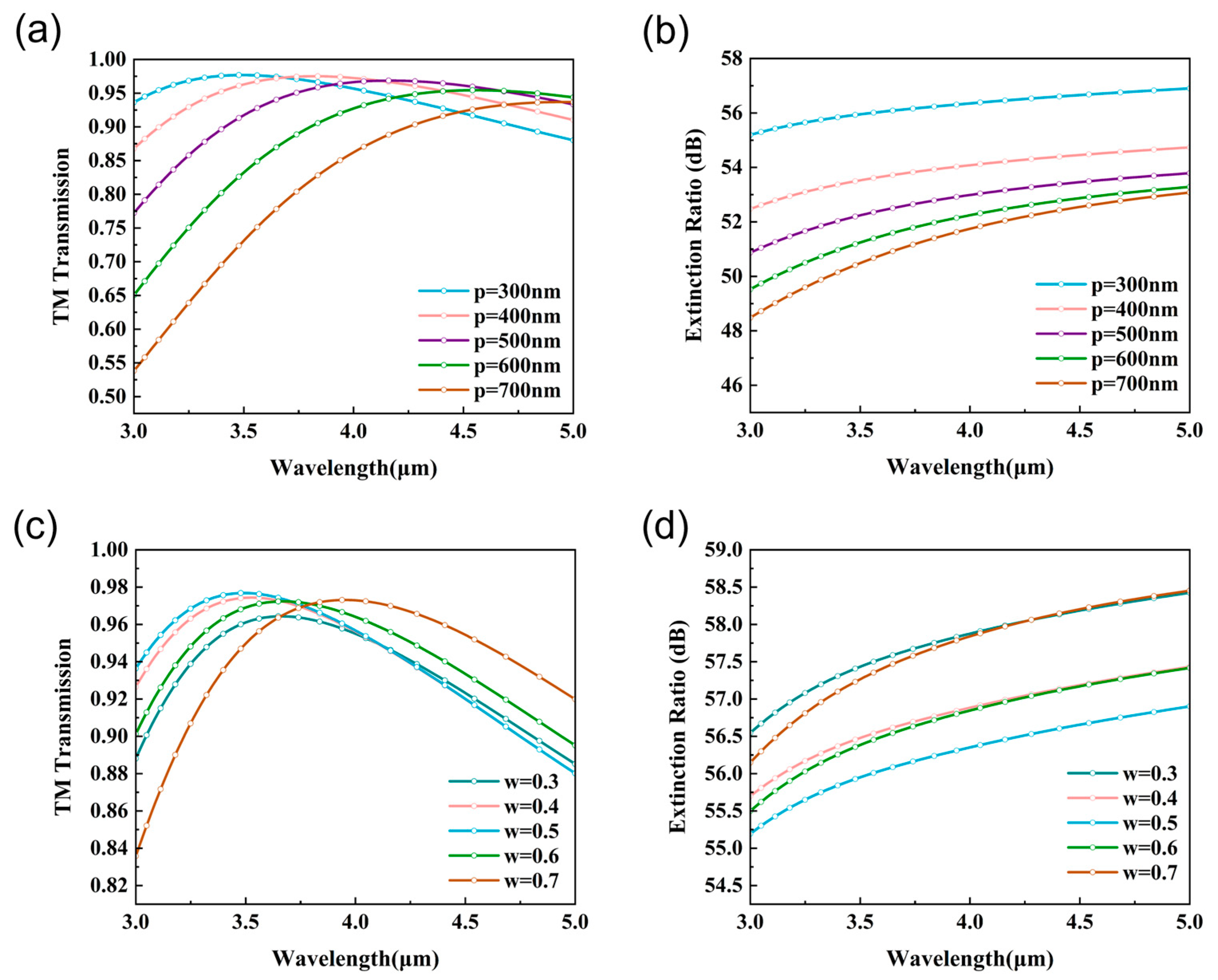

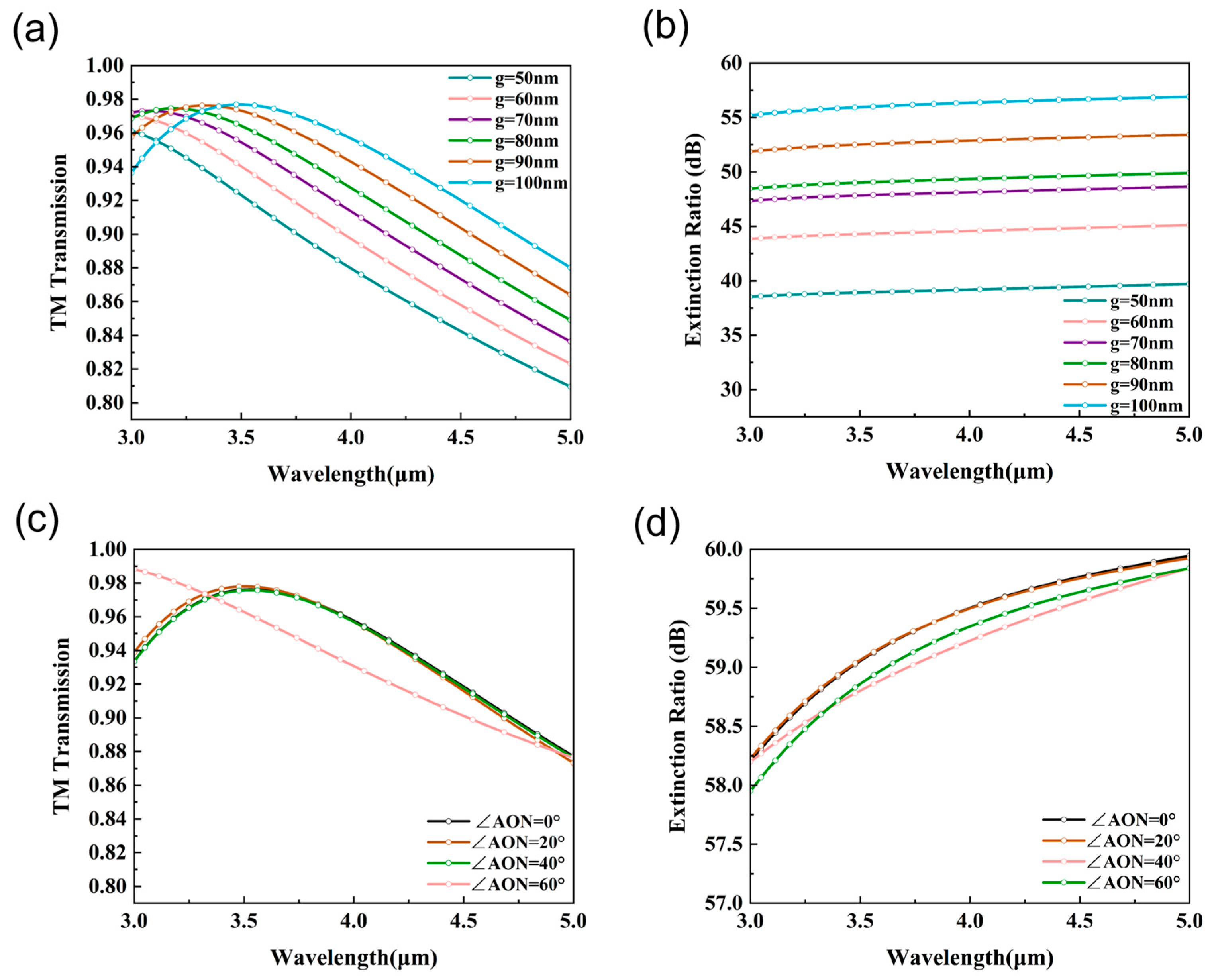

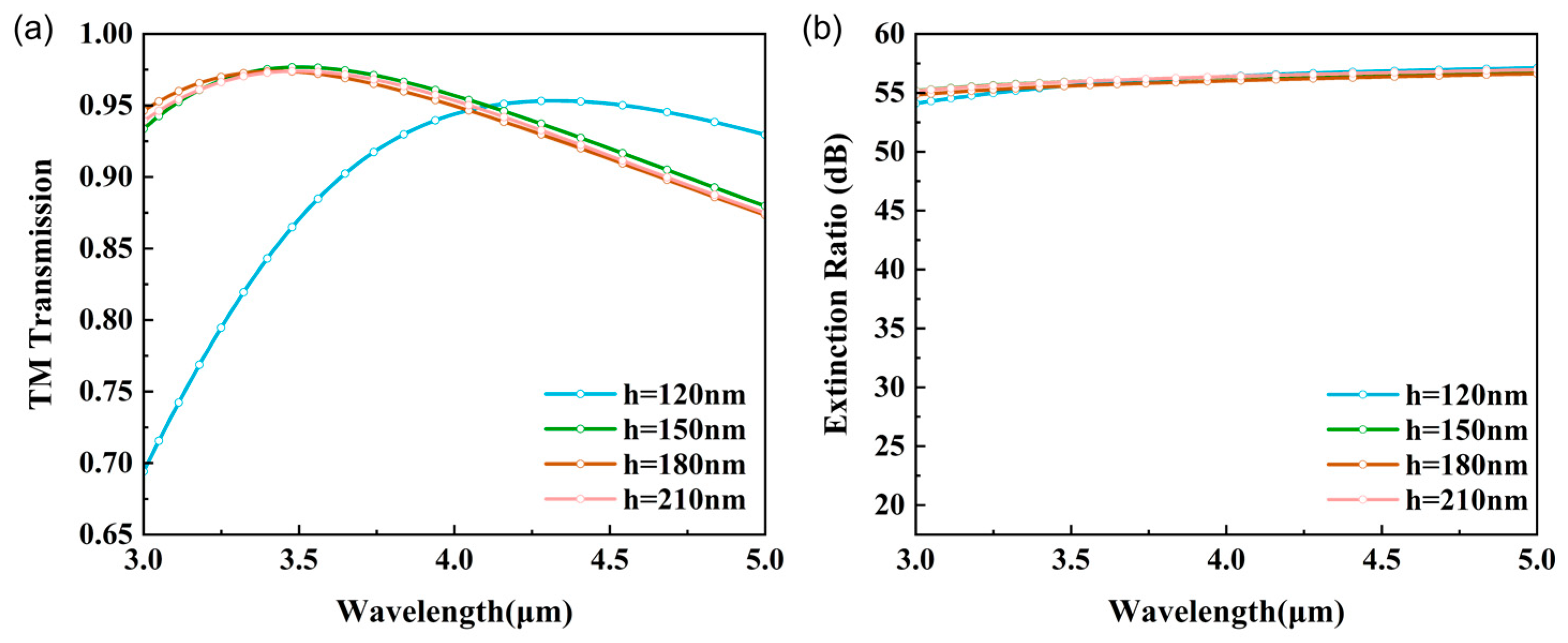

3.1. Structural Optimization

3.2. Analysis in Theory

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gaiarin, S.; Perego, A.M.; da Silva, E.P.; Da Ros, F.; Zibar, D. Dual-polarization nonlinear Fourier transform-based optical communication system. Optica 2018, 5, 263–270. [Google Scholar] [CrossRef]

- Dubreuil, M.; Delrot, P.; Leonard, I.; Alfalou, A.; Brosseau, C.; Dogariu, A. Exploring underwater target detection by imaging polarimetry and correlation techniques. Appl. Opt. 2013, 52, 997–1005. [Google Scholar] [CrossRef] [PubMed]

- Talmage, D.A.; Curran, P.J. Remote sensing using partially polarized light. Int. J. Remote Sens. 1986, 7, 47–64. [Google Scholar] [CrossRef]

- Qi, J.; Tatla, T.; Nissanka-Jayasuriya, E.; Yuan, A.Y.; Stoyanov, D.; Elson, D.S. Surgical polarimetric endoscopy for the detection of laryngeal cancer. Nat. Biomed. Eng. 2023, 7, 971–985. [Google Scholar] [CrossRef]

- He, C.; He, H.; Chang, J.; Chen, B.; Ma, H.; Booth, M.J. Polarisation optics for biomedical and clinical applications: A review. Light. Sci. Appl. 2021, 10, 194. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, Y.; Addamane, S.; Reno, J.L.; Williams, B.S. Tunable quantum-cascade VECSEL operating at 1.9 THz. Opt. Express 2021, 29, 34695–34706. [Google Scholar] [CrossRef]

- Li, L.; Han, W.; Pi, L.; Niu, P.; Han, J.; Wang, C.; Su, B.; Li, H.; Xiong, J.; Bando, Y.; et al. Emerging in-plane anisotropic two-dimensional materials. InfoMat 2019, 1, 54–73. [Google Scholar] [CrossRef]

- Wan, M.; Gu, G.; Qian, W.; Ren, K.; Chen, Q. Stokes-vector-based polarimetric imaging system for adaptive target/background contrast enhancement. Appl. Opt. 2016, 55, 5513–5519. [Google Scholar] [CrossRef]

- York, T.; Gruev, V. Characterization of a visible spectrum division-of-focal-plane polarimeter. Appl. Opt. 2012, 51, 5392–5400. [Google Scholar] [CrossRef]

- Park, H.; Crozier, K.B. Elliptical silicon nanowire photodetectors for polarization-resolved imaging. Opt. Express 2015, 23, 7209–7216. [Google Scholar] [CrossRef]

- Bavirisetti, D.P.; Dhuli, R. Two-scale image fusion of visible and infrared images using saliency detection. Infrared Phys. Technol. 2016, 76, 52–64. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, L.J. Transition from a spectrum filter to a polarizer in a metallic nano-slit array. Sci. Rep. 2014, 4, 3614. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Fan, F.; Zhao, C.; Kwok, H.-S.; Schadt, M. Low-driving-voltage, polarizer-free, scattering-controllable liquid crystal device based on randomly patterned photo-alignment. Opt. Lett. 2020, 45, 3697–3700. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Kim, A.D.; Shahili, M.; Curwen, C.A.; Addamane, S.; Reno, J.L.; Williams, B.S. THz time-domain characterization of amplifying quantum-cascade metasurface. Appl. Phys. Lett. 2021, 119, 181108. [Google Scholar] [CrossRef]

- Yamada, I.; Kintaka, K.; Nishii, J.; Akioka, S.; Yamagishi, Y.; Saito, M. Mid-infrared wire-grid polarizer with silicides. Opt. Lett. 2008, 33, 258–260. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zhao, M.; Dai, N.L.; Yang, G.; Long, H.; Li, Y.H.; Lu, P.X. Broadband polarizers using dual-layer metallic nanowire grids. IEEE Photonics Technol. Lett. 2008, 20, 697–699. [Google Scholar] [CrossRef]

- Zhang, G.; Cao, B.; Wang, C.; Han, Q.; Peng, C.; Wang, J.; Xu, K.; Yang, H.; Pessa, M. Polarized GaN-based light-emitting diode with an embedded metallic/dielectric subwavelength grating. Thin Solid Film. 2011, 520, 419–423. [Google Scholar] [CrossRef]

- Shen, S.; Yuan, Y.; Ruan, Z.; Tan, H. Optimizing the design of an embedded grating polarizer for infrared polarization light field imaging. Results Phys. 2018, 12, 21–31. [Google Scholar] [CrossRef]

- Sakamoto, M.; Nhan, H.T.; Noda, K.; Sasaki, T.; Tanaka, M.; Kawatsuki, N.; Ono, H. Polarization-probe polarization-imaging system in near-infrared regime using a polarization grating. Sci. Rep. 2022, 12, 15268. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, C.; Zhang, G.; Cao, B. Compound polarized wavelength filters with a single subwavelength structure. Opt. Commun. 2010, 284, 501–509. [Google Scholar] [CrossRef]

- Feng, B.; Chen, Y.; Sun, D.; Yang, Z.; Yang, B.; Li, X.; Li, T. Precision integration of grating-based polarizers onto focal plane arrays of near-infrared photovoltaic detectors for enhanced contrast polarimetric imaging. Int. J. Extrem. Manuf. 2021, 3, 035201. [Google Scholar] [CrossRef]

- Hobbs, R.G.; Putnam, W.P.; Fallahi, A.; Yang, Y.; Kärtner, F.X.; Berggren, K.K. Mapping Photoemission and Hot-Electron Emission from Plasmonic Nanoantennas. Nano Lett. 2017, 17, 6069–6076. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef]

- Grigorescu, A.; van der Krogt, M.; Hagen, C.; Kruit, P. 10 nm lines and spaces written in HSQ, using electron beam lithography. Microelectron. Eng. 2007, 84, 822–824. [Google Scholar] [CrossRef]

- Choi, S.; Yan, M.; Wang, L.; Adesida, I. Ultra-dense hydrogen silsesquioxane (HSQ) structures on thin silicon nitride membranes. Microelectron. Eng. 2009, 86, 521–523. [Google Scholar] [CrossRef]

- Saleem, M.R.; Stenberg, P.A.; Khan, M.B.; Khan, Z.M.; Honkanen, S.; Turunen, J. Hydrogen silsesquioxane resist stamp for replication of nanophotonic components in polymers. J. Micro/Nanolithography MEMS MOEMS 2012, 11, 013007. [Google Scholar] [CrossRef]

- Makita, M.; Karvinen, P.; Guzenko, V.A.; Kujala, N.; Vagovic, P.; David, C. Fabrication of diamond diffraction gratings for experiments with intense hard x-rays. Microelectron. Eng. 2017, 176, 75–78. [Google Scholar] [CrossRef]

- Zeng, P.; Feng, Z.; Zheng, M.; Gao, X.; Zhang, S.; Wang, Y.; Chen, Y.; Duan, H. Dimension and process effects on the mechanical stability of ultra-small HSQ nanopillars. J. Nanoparticle Res. 2021, 23, 255. [Google Scholar] [CrossRef]

- Chen, H.-T.; Zhou, J.; O’hara, J.F.; Chen, F.; Azad, A.K.; Taylor, A.J. Antireflection Coating Using Metamaterials and Identification of Its Mechanism. Phys. Rev. Lett. 2010, 105, 073901. [Google Scholar] [CrossRef]

- Cao, G.; Xu, H.-X.; Zhou, L.-M.; Deng, Y.; Zeng, Y.; Dong, S.; Zhang, Q.; Li, Y.; Yang, H.; Song, Q.; et al. Infrared metasurface-enabled compact polarization nanodevices. Mater. Today 2021, 50, 499–515. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Lezec, H.J.; Ghaemi, H.F.; Thio, T.; Wolff, P.A. Extraordinary optical transmission through sub-wavelength hole arrays. Nature 1998, 391, 667–669. [Google Scholar] [CrossRef]

- Lee, J.-K.; Kim, B.O.; Park, J.; Kim, J.B.; Kang, I.-S.; Sim, G.; Park, J.H.; Jang, H.-I. A bilayer Al nanowire-grid polarizer integrated with an IR-cut filter. Opt. Mater. 2019, 98, 109409. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, D.; Huang, Y.; Tao, C.; Hong, R.; Zhuang, S. Performance of a double-layer guided mode resonance filter with non-subwavelength grating period at oblique incidence. Opt. Laser Technol. 2015, 72, 42–47. [Google Scholar] [CrossRef]

- Deng, S.-R.; Lu, B.-R.; Dong, B.-Q.; Wan, J.; Shu, Z.; Xue, J.; Chen, Y.; Huq, E.; Liu, R.; Qu, X.-P. Effective polarization control of metallic planar chiral metamaterials with complementary rosette pattern fabricated by nanoimprint lithography. Microelectron. Eng. 2010, 87, 985–988. [Google Scholar] [CrossRef]

- Astilean, S.; Lalanne, P.; Palamaru, M. Light transmission through metallic channels much smaller than the wavelength. Opt. Commun. 2000, 175, 265–273. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.; Xie, F.; Zhang, X.; Zhou, X.; Yuan, Y.; Wang, L. Excitation of surface plasmon polariton modes with double-layer gratings of graphene. Nanomaterials 2022, 12, 1144. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, B.; Lu, B.; Chen, Y.; Li, W.; Zhang, W.; Li, T. A study of nano-structural effect on the polarization characteristics of metallic sub-wavelength grating polarizers in visible wavelengths. Microelectron. Eng. 2020, 227, 111327. [Google Scholar] [CrossRef]

- Jing, X.; Jin, Y. Transmittance analysis of diffraction phase grating. Appl. Opt. 2010, 50, C11–C18. [Google Scholar] [CrossRef]

- Zhiwen, W.; Wei, Y.; Jinliang, G. Polarization transmission mechanism analyzation of bi-layer nanowire polarizer. Opt. Commun. 2018, 424, 127–130. [Google Scholar] [CrossRef]

- Sun, J.; Liu, L.; Dong, G.; Zhou, J. An extremely broad band metamaterial absorber based on destructive interference. Opt. Express 2011, 19, 21155–21162. [Google Scholar] [CrossRef]

- Li, H.; Hao, R.; Chen, G.; Wang, W.; Sheng, P.; Xu, J.; Liu, J.; Li, Y.; Kong, J.; Zhao, J. Optimization of the inverted “T”-shaped double-layer subwavelength grating design integrated on an InSb detector. Opt. Commun. 2024, 573, 131016. [Google Scholar] [CrossRef]

- Kong, Y.; Liu, D.; Luo, H. Effect of magnetic polaritons on the polarization characteristics of metal–dielectric–metal infrared wire-grid polarizers. Opt. Commun. 2020, 474, 126111. [Google Scholar] [CrossRef]

| Element | Material | Pitch/nm | Duty Cycle | Material Thickness/nm | SiO2 Layer Thickness/nm |

|---|---|---|---|---|---|

| Results | Al | 300–400 | 0.3–0.6 | 90–100 | 200–300 |

| Structure Type | Methods | TM Transmission (%) | Extinction Ratio (dB) | Reference |

|---|---|---|---|---|

| Broadband polarizer | Simulation | 38–94 | 47–70 | [16] |

| An embedded grating polarizer | Simulation | 84 | >27.9 | [18] |

| Inverted ‘T’-shaped double-layer grating | Simulation | >75 | >53 | [41] |

| Metal–electrolyte–metal wire grids | Simulation | <89 | <42 | [42] |

| Readily manufactured bilayer polarization grating | Simulation | 88–97 | >55 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Xu, J.; Hao, R.; Chen, G.; Wang, W.; Sheng, P.; Li, H.; Wang, Y. Simulation Study of Readily Manufactured High-Performance Polarization Gratings Based on Cured HSQ Materials. Photonics 2025, 12, 287. https://doi.org/10.3390/photonics12030287

Liu J, Xu J, Hao R, Chen G, Wang W, Sheng P, Li H, Wang Y. Simulation Study of Readily Manufactured High-Performance Polarization Gratings Based on Cured HSQ Materials. Photonics. 2025; 12(3):287. https://doi.org/10.3390/photonics12030287

Chicago/Turabian StyleLiu, Jiatong, Jun Xu, Ruiting Hao, Gang Chen, Wen Wang, Pengcheng Sheng, Huizi Li, and Yunzhi Wang. 2025. "Simulation Study of Readily Manufactured High-Performance Polarization Gratings Based on Cured HSQ Materials" Photonics 12, no. 3: 287. https://doi.org/10.3390/photonics12030287

APA StyleLiu, J., Xu, J., Hao, R., Chen, G., Wang, W., Sheng, P., Li, H., & Wang, Y. (2025). Simulation Study of Readily Manufactured High-Performance Polarization Gratings Based on Cured HSQ Materials. Photonics, 12(3), 287. https://doi.org/10.3390/photonics12030287