Abstract

Laser wireless power transfer (LWPT) offers a transformative approach to wireless energy transmission, addressing critical limitations in unmanned aerial vehicles (UAVs) such as battery energy limitation. However, challenges like beam divergence, non-uniform irradiation, and alignment instability limit its practical application. Here, we present a lightweight air-floating metalens platform to overcome these barriers. This innovative lens focuses laser beams near the photovoltaic receiver with an energy distribution uniformity across a single spot at the focal plane that is 50 times greater than that of a conventional Gaussian beam spot, achieving a multi-spot energy distribution uniformity of up to 99% theoretically. Experimentally, we achieved 75% uniformity using a metalens sample. Simultaneously, our system maintains superior beam quality within a dynamic range of 4 m and enhances charging efficiency by 1.5 times. Our research provides a robust technical solution to improve UAV endurance, enabling efficient, long-range wireless power transfer and opening broader technological implications.

1. Introduction

Laser wireless power transfer (LWPT) has emerged as a transformative technology for efficient and flexible wireless energy transmission, garnering significant attention due to its high power density, strong resistance to electromagnetic interference, and exceptional mobility [1]. With its broad applicability, LWPT is poised to play a pivotal role in diverse domains, ranging from aerospace applications like space-based solar power harvesting and deep-space exploration to the development of distributed laser charging networks [2,3,4,5,6,7]. For unmanned aerial vehicles (UAVs), in particular, LWPT addresses a critical bottleneck: battery energy limitation. This constraint severely restricts UAV performance in tasks requiring extended operation, such as long-duration monitoring, large-area surveying, and remote cargo transportation [8,9,10]. Existing battery technologies face a fundamental tradeoff—prolonged operation demands heavier batteries, which in turn hinder performance. By providing a continuous power supply, LWPT offers a pathway to significantly extend UAV mission durations, broadening their operational scope and effectiveness [11].

However, the deployment of LWPT for UAVs is not without significant challenges. The lightweight and aerodynamic requirements of UAVs demand highly compact, efficient power transfer systems that do not compromise flight dynamics. Precise beam alignment during flight, affected by UAV movement, wind, and atmospheric turbulence, poses a major obstacle. Furthermore, light diffraction and divergence during long-distance propagation necessitate large-aperture optical systems, which are impractical for compact aerial applications. A further challenge arises from non-uniform laser beam irradiation, which can cause localized thermal hotspots on photovoltaic cells, reducing efficiency and potentially damaging the system [12,13,14,15]. To address these challenges, power transfer systems must achieve uniform beam profiles, high alignment precision, and compact form factors—all while maintaining robustness under dynamic conditions [16].

Metalens—planar devices made of sub-wavelength structures capable of manipulating the phase [17,18,19,20,21], amplitude, and polarization of electromagnetic waves [22,23,24,25]—offer a promising solution to these challenges. Unlike traditional Fresnel lens arrays, a metalens can concurrently design the shape and energy distribution of the focal spots while effectively addressing issues of non-uniform light distribution and misalignment present in conventional methods [26,27,28]. In this study, we propose an air-floating metalens platform to enhance LWPT for UAVs. This lightweight floating lens mitigates light divergence by focusing beams near the photovoltaic receivers, enabling compact and efficient energy transmission. Furthermore, the lens achieves precise beam modulation, concentrating the laser into nine uniformly distributed square spots that align with photovoltaic cell geometry. This ensures uniform energy distribution, minimizes thermal effects, and improves energy conversion efficiency. The design is lightweight and portable. In simulations, the beam uniformity at each focus is approximately 50 times higher than that of traditional Gaussian beams, with energy distribution uniformity among the nine foci reaching 99%. During the experimental validation phase, an overall beam uniformity of 76% was also achieved. Furthermore, considering the position shifts of the drone due to atmospheric disturbances, simulation results verify that the beam quality remains excellent within a dynamic range of 4 m. Finally, experimental results validate that the charging efficiency with the floating lens prototype is 1.5 times higher. By addressing long-distance beam divergence, alignment issues, and uneven energy distribution, this innovative platform offers a transformative solution for UAV endurance, paving the way for efficient, long-range wireless power transfer in UAVs and beyond.

2. Transmission Efficiency Evaluation

In LWPT systems, beam uniformity plays a pivotal role in determining the conversion efficiency of photovoltaic cells. This section examines two aspects of beam intensity uniformity: the uniformity within a single focal spot and the overall uniformity across multiple focal spots. These are evaluated using two key metrics for quantitative analysis. Additionally, an enhancement factor, denoted as η, is introduced as a straightforward and reliable metric to estimate the improvement in transmission efficiency observed during the experiments.

2.1. Non-Uniformity of a Single Focal Spot

The uniformity within a single focal spot quantifies the consistency of the intensity distribution within the spot, directly influencing the energy conversion efficiency at the receiver. In simulations, grayscale values are employed to represent the intensity distribution across individual pixels. Accordingly, the non-uniformity, denoted as Δ, of a single focal spot’s light intensity is defined as the following:

where denotes the grayscale value of a single pixel within the beam spot, represents the average grayscale value of all pixels in the beam spot, and is the total number of pixels in the beam spot.

2.2. Overall Uniformity Estimation

The overall uniformity across multiple focal spots assesses the consistency of intensity and shape among the spots in a multi-focus configuration, which is crucial for enhancing the entire system’s performance. For this purpose, the illumination uniformity is introduced to evaluate the uniformity between spots as follows:

where denotes the highest irradiance among several regions, is the lowest irradiance, and is the average irradiance.

2.3. Enhancement Value

During the laboratory testing phase, to evaluate the impact of the flexible lightweight lens on photovoltaic cell efficiency, short-circuit currents ( and ) and open-circuit voltages ( and ) were recorded before and after introducing the flexible lightweight lens. The improvement in photovoltaic cell conversion efficiency can be quantified by calculating the enhancement value as follows:

3. Design of a Multi-Focus and Square Focal Spots Metalens (MFSM)

The design of a multi-focus and square-focal-spots metalens (MFSM) involves three key elements: multi-focus configuration, holographic design, and polarization-independent operation in 3D space. The process begins with constructing a metalens model that incorporates multiple focal points. The design and underlying physical mechanism of the multi-focus metalens are rooted in the principles of weighted phase distribution. The phase angle of the complex amplitude distribution is defined as follows:

where and are the amplitude and phase of each focus. The amplitude factor for each profile is set to adjust the weight of different focal points, ensuring consistent focusing efficiency across all focal points, thereby promoting parallel charging efficiency. is the total number of the desired focal points, and ranges from 1 to . is the propagation phase recovered using the Gerchberg–Saxton (GS) algorithm based on the target square intensity profile at the focal plane.

The phase functions of each focus can be defined as follows:

where is the location on the surface of the multi-focus metalenses, is the angular frequency of the incident light, is the speed of light, and is the location of the focus. A nine-focal-spots metalens was selected. The diameter of the metalens was = 10 cm, and the working distance of the lens was = 15 m. The coordinates of the focal spots were , , , , , , , and for = 1, 2, 3, 4, 5, 6, 7, 8, and 9, respectively. As shown in Figure 1b, the top panel depicts the optimized phase distribution of the multi-focal metalens.

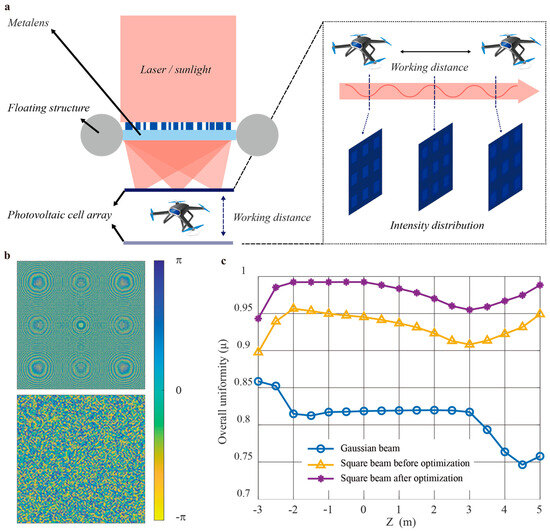

Figure 1.

(a) Schematic of the metalens designed to generate multiple focal spots. When light beams with arbitrary polarization states are incident, a 3 × 3 array of nine focal spots is formed on the focal plane. The uniformity across the focal spots reaches 99%, while the non-uniformity within each individual focal spot remains below 5; (b) Optimized phase profiles of the metalens used to generate nine focal spots and square-shaped focal spots, respectively; (c) Calculated uniformity of the nine focal spots as a function of the distance from the focal plane. The blue curve shows the trend for a metalens generating Gaussian focal spots. The yellow curve represents the uniformity trend for a metalens generating square focal spots prior to optimization, while the purple curve shows the improved trend after optimization.

The Gerchberg–Saxton (GS) algorithm, which reconstructs phase information from the measured intensities on two correlated planes (the source plane and the target plane), has been widely utilized in various applications [29,30]. In the design of the MFSM, the unknown propagation function for trapezoidal focal spots is retrieved based on the intensity distributions on the target plane.

Figure 1 presents a schematic of the MFSM, designed to achieve beam homogenization and shaping within a laser energy transfer system. We are considering a scenario where a drone is performing high-altitude operations, powered remotely by a high-power semiconductor laser transmitting energy to the drone’s photovoltaic cell array. This array is arranged in a 3 × 3 grid over an area of 10 cm × 10 cm, with each cell measuring 3 cm × 3 cm and separated by a 50 mm gap. This design can perfectly match the geometric structure of the photovoltaic array, ensuring optimal energy reception and conversion efficiency, as illustrated in Figure 1a. Figure 1b shows the optimized phase distribution for the square focal spots. Notably, the focusing phase of the lens integrates seamlessly with the GS algorithm, enabling precise control of the far-field projection at the focal plane. It is worth noting that the phase modulation of metalens can be achieved through two approaches: geometric phase and transmission phase. In this design, the transmission phase is preferred, as it allows for nearly complete energy utilization without the energy losses typically associated with polarization conversion. The data comparison in Figure 1c illustrates that the optimized metalens lens maintains uniform energy distribution across the nine focal spots it generates near the focal plane. The metalens lens we have designed is intended to float above the UAV, refocusing divergent laser beams to charge the UAV while it works within a distance range of 13 to 17 m. Even when the UAV experiences slight vibrations due to environmental factors, within a certain range, it can still receive a uniformly distributed laser beam, ensuring the stability and efficiency of charging. This capability underscores the robustness of our design in maintaining high-quality energy transfer under less-than-ideal conditions.

4. Simulation Results

In this section, we evaluate the performance of our proposed system in comparison to traditional Fresnel lenses. Beyond assessing performance at the focal plane, we also examine the consistency of the energy distribution across the focal spots at varying propagation distances—an essential factor for achieving stable and efficient energy transfer. Simulation results demonstrate that the MFSM not only simplifies the system structure and reduces the size and weight of the receiver but also significantly improves energy transfer efficiency and the quality of the focal spots.

4.1. Performance at the Focal Plane

Figure 2 shows the energy distribution of our proposed system compared with the Gaussian spots produced by traditional Fresnel lenses typically used for energy transmission. For the traditional Fresnel lenses shown in Figure 2a,c, the focused Gaussian beam spots exhibit an extremely high concentration of energy on the focal plane. Due to this highly concentrated energy distribution, photovoltaic cells must precisely control the receiving distance to ensure that the received spot pattern matches the requirements of the photovoltaic cell array. Moreover, secondary shaping of the spot is often required to improve its shape and achieve a more uniform energy distribution. However, this not only increases the complexity of the system but also significantly enlarges the size and weight of the receiver, thereby limiting the scope of application.

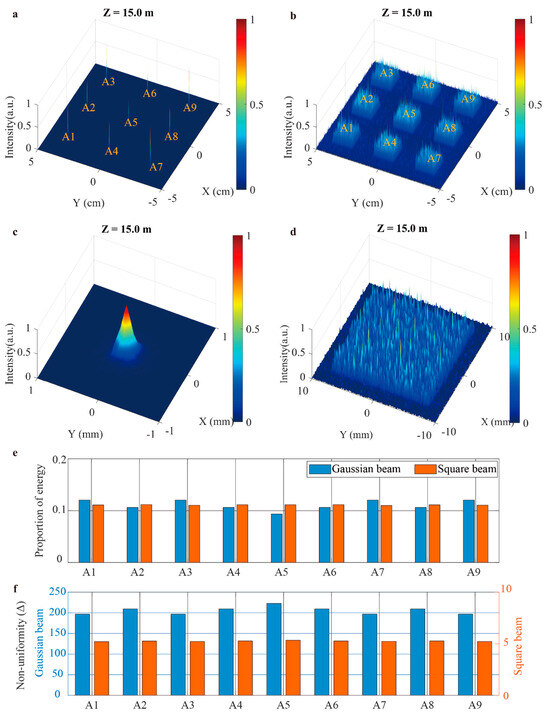

Figure 2.

Simulation results of Gaussian beam spots versus optimized metalens square beam spots at the focal plane (The maximum light intensity has been normalized to a unit value.). The focal spot is primarily divided into nine regions, denoted as A1, A2, A3, A4, A5, A6, A7, A8, and A9: (a) Energy distribution of nine Gaussian beam spots; (b) Energy distribution of nine square beam spots; (c) Energy distribution of a single Gaussian beam spot; (d) Energy distribution of a single square beam spot; (e) Comparison of energy proportions between Gaussian and square beam spots across nine sub-regions; (f) Comparison of non-uniformity across the nine sub-regions.

In contrast, our specially designed MFSM can directly generate the ideal spot at the focal plane. As shown in Figure 2b, this metalens produces a large 10 cm × 10 cm spot composed of nine smaller square spots. The 3D energy distribution of these spots is illustrated in Figure 2d. Each spot exhibits a more uniform energy distribution and matches the geometry of the photovoltaic cell array, eliminating the need for additional shaping devices. By calculating the intensity non-uniformity Δ (Figure 2f), it was found that the uniformity of individual square spots is approximately 50 times better than that of the Gaussian spots produced by the Fresnel lens. Analyzing the overall beam uniformity μ as defined by Equation (2), the μ value for square spots at the focal plane reached 99%, indicating an exceptionally uniform energy distribution within the spot. Moreover, the energy proportion of the nine square spots against the Gaussian spots in Figure 2e further demonstrates the effectiveness of the metalens in optimizing the quality of the spot.

4.2. Performance Across Different Propagation Distances

When utilizing the square spots generated by a metalens for airborne laser beam charging of drones, atmospheric disturbances and winds can cause slight movements in the drone’s position. This movement poses a challenge to maintaining the consistency of the beam’s energy distribution, especially over long-distance transmissions. Therefore, evaluating the consistency of the spot’s energy distribution across different propagation distances is crucial for ensuring a stable and efficient energy transfer.

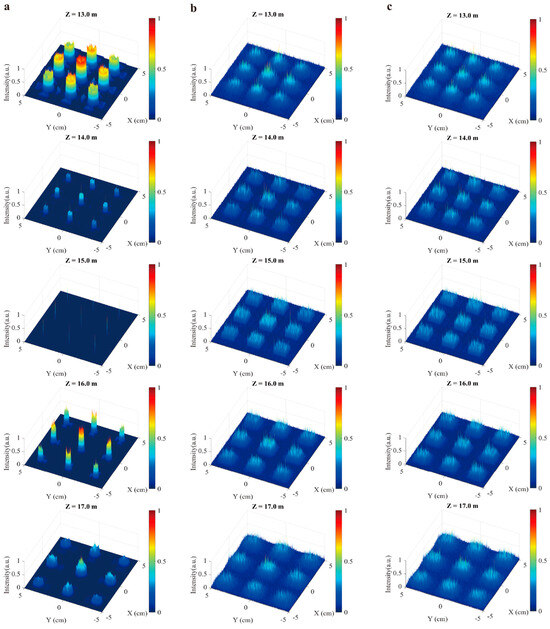

According to the simulation analysis results presented in Figure 3a–c, within the same propagation distance range of 13 to 17 m, traditional Gaussian beams exhibit a significant decrease in energy uniformity when the drone’s position shifts, as shown in Figure 3a. This is due to the inherent characteristics of Gaussian beams, where energy density is concentrated in the focal plane. As the propagation distance increases or the receiver position shifts, the working distance no longer aligns perfectly with the photovoltaic cell array, leading to reduced energy absorption efficiency. In contrast, the energy distribution of the nine square spots optimized by our MFSM system maintains high uniformity within the 13 to 17 m propagation range. As illustrated in Figure 3d,f, the overall energy uniformity of the spots exceeds 95%. This performance is attributed to the unique design of the metalens, which ensures good spot shape and uniform energy distribution over a wide distance range, even if there are slight positional changes in the drone, thereby not significantly impacting overall energy absorption efficiency. Figure 3e illustrates the variation in non-uniformity Δ for each spot at different transmission distances. The results show that the square spots generated by the metalens exhibit lower Δ, indicating that they can provide stable energy transmission over a broader charging range, which is highly advantageous for practical drone operations.

Figure 3.

Measurement of the dynamic range of energy distribution (The maximum light intensity has been normalized to a unit value.): (a) Energy distribution of Gaussian beam spots across various propagation distances; (b) Energy distribution of square beam spots across various propagation distances before optimization; (c) Energy distribution of optimized square beam spots across various propagation distances; (d) Comparison of energy proportions in the sub-regions of optimized square beam spots at different propagation distances; (e) Comparison of non-uniformity (Δ) within individual sub-regions of optimized square beam spots at different propagation distances; (f) Overall illumination uniformity (μ) of optimized square beam spots across various propagation distances.

5. Experiment Results

In this section, we present a ground test and an air-floating test to evaluate the feasibility of the proposed method. For the ground test, a metalens with a diameter of 2 mm and a focal length of 20 mm was fabricated to focus the laser into nine square spots. For the air-floating test, a flexible, lightweight lens made of polydimethylsiloxane (PDMS) was manufactured, featuring a 300 mm radius and a 500 mm focal length, and weighing only 90 g. Both components were assessed for their energy concentration characteristics. The results from both the ground and air-floating tests confirm the effectiveness and feasibility of the proposed approach.

5.1. Ground Test

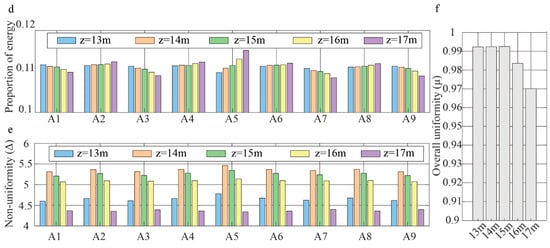

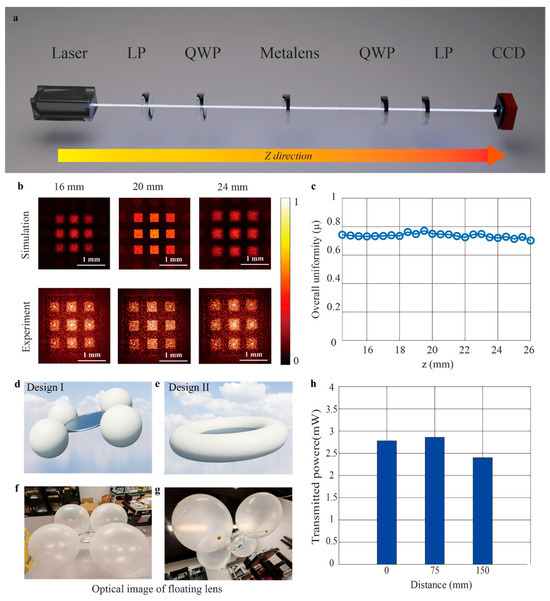

In this experiment, a metalens with a diameter of 2 mm and a focal length of 20 mm was fabricated to focus a laser into nine square spots. The metalens was realized by progressive scanning of the femtosecond laser [31]. Figure 4a illustrates the optical setup used to assess the energy concentration performance of the metalens on the ground. A 532 nm wavelength laser generated the beam, which was first passed through a linear polarizer (LP) and then a quarter-wave plate (QWP) to ensure that the beam’s polarization state was appropriate for illuminating the metalens. After transmission through the metalens, the beam passed through another QWP and LP to filter out the nonconverted part, compensating for polarization conversion inefficiencies caused by fabrication errors, before being imaged on a CCD to observe the energy intensity distribution across the nine spots. A camera recorded the light intensity distribution behind the metalens within the range of 14 mm to 26 mm, with a 0.5 mm step, and the uniformity for each distance was calculated. For clearer visualization, three images were selected: one taken exactly at the focal plane, and two taken 4 mm before and 4 mm after the focal plane, as shown in Figure 4b. We conducted a quantitative analysis based on specific measurements of energy distribution, which allows us to accurately compare performance differences under various conditions. The experimental results show that the light intensity distribution aligns well with the simulation design, though some stray light was observed due to fabrication errors. Analysis of these images revealed that the uniformity of the nine square spots remained approximately 75% across the tested range, as indicated in Figure 4c, ensuring uniform laser irradiation for photovoltaic cells within this distance interval. The optimized metalens lens maintains uniform energy distribution across the focal spots over a wide dynamic range, thereby mitigating the issue of non-uniform energy distribution due to positional shifts that is common with traditional Gaussian beams. Even when subjected to slight vibrations caused by environmental factors such as wind speed and air currents, the UAV can still receive a uniformly distributed laser beam within a certain range, ensuring the stability and efficiency of the charging process. This enhancement significantly improves the reliability and practicality of the LWPT system.

Figure 4.

Experimental verification of the metalens and floating structure: (a) Schematic diagram of the experimental setup for metalens testing; (b) Comparison between experimental and simulation results of square beam spots at various propagation distances; (c) Experimental results of the overall uniformity (μ) of the beam spots at different propagation distances; (d,e) 3D models of the floating structure; (f,g) Experimental verification images of the balloon-supported floating structure; (h) Laser-transmitted power at different positions of the flexible lens.

5.2. Air-Floating Test

To enhance the focusing and shaping of the beam at the reception end during drone flight, and thereby improve charging efficiency, we propose using helium balloons to elevate the flexible, lightweight lens. According to Archimedes’ principle, an object immersed in a stationary fluid experiences an upward buoyant force equal to the weight of the displaced fluid. Thus, the total buoyant force (Flift) provided by the helium balloons can be calculated as the following:

where represents the density of air, approximately 1.225 kg/m3, and represents the density of helium, around 0.1785 kg/m3, both values at sea level under standard atmospheric conditions (1 atm, 101,325 Pa), and a temperature of 0 °C (273.15 K); denotes the gravitational acceleration, roughly 9.8 m/s2; indicates the total volume of all the helium balloons; and is the total buoyant force provided by the helium balloons. Consequently, the required volume V of the helium can be calculated after correcting for density as follows:

where and represent the environmental pressure (Pa) and temperature (K), respectively, while and represent the standard pressure (101,325 Pa) and temperature (273.15 K), respectively.

The metalens lens we have designed is intended to float above the UAV, refocusing divergent laser beams to charge the UAV while it works within a distance range of 13 to 17 m. Based on this model, we have designed two floating structures to elevate the fabricated flexible lenses into the air, as shown in Figure 4d,e. In Figure 4d, we propose using four 21 inch helium balloons to lift a 100 g flexible lens, leveraging the buoyancy of the helium balloons to achieve the desired elevation angle for the lightweight lens. The experimental setup in Figure 4f demonstrates the feasibility of this approach, where four helium balloons are used to suspend a 100 g flexible lens. This experiment confirms the practicality and effectiveness of our design.

For the flight test of the flexible, lightweight lens, a laser with an intensity of 3.37 mW and a wavelength of 1064 nm was used to illuminate different positions on the lens surface, with the transmittance at each position measured. The results indicated that the transmittance remained approximately 80%, as shown in Figure 4h. Additionally, to evaluate the impact of the flexible lens on photovoltaic cell performance, we measured the short-circuit current and open-circuit voltage both before and after introducing the flexible lightweight lens. The experimental results showed that without the flexible lens, the short-circuit current was () and the open-circuit voltage was (). After introducing the flexible lightweight lens, the short-circuit current increased to (), and the open-circuit voltage rose to (). By substituting these experimental data into Formula (3), we calculated an enhancement in the conversion efficiency (η) of the silicon photovoltaic cell to be 154.1%.

6. Discussion

The results of this study provide a solid technical foundation for enhancing the endurance capabilities of unmanned aerial vehicles (UAVs). By optimizing the number, size, and shape of helium balloons, we have effectively supported flexible lenses while ensuring the system’s stability and reliability under various loading conditions. Notably, the design of the helium balloons in a ring structure, as shown in Figure 4e, has significantly improved control over the orientation of the lightweight flexible lens in flight.

This technology is particularly suitable for critical missions such as operations in high-risk airspace following disasters. For example, in scenarios where communication is interrupted and transportation is hindered, UAVs can penetrate deep into disaster-stricken areas for aerial surveying and photography, promptly acquiring information on the disaster situation [8,9,10]. LWPT technology enables real-time charging of UAVs in mid-air, extending their flight duration and coverage area. However, long-distance laser transmission faces challenges from complex environmental influences, leading to beam divergence and degradation of spot quality. This can potentially damage photovoltaic cells due to uneven energy distribution, necessitating the use of expensive, high-power, and high-quality lasers. To address these challenges, we have proposed an innovative solution: a floating multi-focus metalens lens for efficient airborne laser wireless charging. This design refocuses diverging laser beams and reshapes the focal spots. These improvements reduce the demands on the laser source while increasing the effective range of laser charging, significantly extending the operational range and duration of UAVs. Specifically, the metalens lens maintains spot quality and uniformity over a wide dynamic range, mitigating issues of energy divergence during long-distance transmission. By reducing the need for costly high-power lasers, the overall system cost is lowered, making remote UAV charging more economically viable. Uniform energy distribution also prevents potential damage to photovoltaic cells, enhancing system reliability and safety.

Moving forward, we will focus on advancing the manufacturing processes for flexible metalenses to develop high-quality, flexible components. Our efforts will also include optimizing the aerodynamic and structural design of the floating platform, integrating these optimized elements into a comprehensive system, and conducting field tests to validate their performance in real-world applications. Additionally, in our future research, we will investigate the effects of temperature [32,33] and humidity [34,35] on the metalenses and further optimize the lens design to enhance its performance under various environmental conditions. Yi-Cheng Chen analyzes the thermal–optical effects on a PMMA Fresnel lens in solar concentrators, using ray tracing and finite element analysis to assess how temperature changes impact refractive index and optical performance, offering key insights for performance optimization [32]. Thorsten Hornung effectively uses DTmaps to showcase the impact of Fresnel lens temperature and distance on optical efficiency, revealing key thermal behaviors in SOG Fresnel lenses and multi-junction solar cell systems. This provides valuable insights for optimizing solar concentrator design [33]. Yizhang Ai brilliantly highlights how ambient humidity affects the performance and laser damage resistance of dielectric films on SiO2 and K9 substrates [34]. D. A. Malevskii presents an innovative silica gel–based air-drying device for CPV modules that prevents condensation, reducing internal humidity to 25–55% and increasing dew point deficit by 10–25 °C under high ambient humidity [35]. These studies represent milestones by providing critical insights into the thermal and optical behaviors of lenses and CPV modules, laying a foundational framework that significantly aids future research and optimization efforts.

Building on these foundational studies, we will optimize lens design and manufacturing processes to enhance performance under various environmental conditions, ultimately providing a reliable technical solution for applications such as long-range UAV charging, which addresses key challenges in sustained aerial operations and energy replenishment.

7. Conclusions

This paper presents an innovative floating metalens platform designed to significantly enhance the efficiency of laser wireless power transmission (LWPT) for unmanned aerial vehicles (UAVs). The platform effectively shapes the beam at the receiver end, ensuring uniform energy distribution, which minimizes thermal effects on photovoltaic cells and boosts energy conversion efficiency. Through precise adjustment of the metalens parameters, simulations demonstrated a 50-fold increase in beam uniformity at each focus compared to traditional Gaussian spots, with the energy distribution uniformity among the nine foci reaching 99%. Even across a large dynamic range of 4 m, the platform maintained excellent beam quality, with uniformity remaining above 95%, showcasing its robust adaptability and reliability for practical applications. Initial ground tests using a 2 mm diameter, 20 mm focal length metalens successfully focused the beam into nine square spots, maintaining an overall beam uniformity of 76% within a specific dynamic range. Additionally, a flexible, lightweight lens prototype suspended by four helium balloons demonstrated a 1.5-times improvement in photovoltaic cell efficiency under this structure. Future research will focus on optimizing the manufacturing process for flexible lenses, aiming to produce high-performance metalenses suitable for long-distance charging of high-altitude UAVs. We also plan to explore aerodynamic characteristics and optimize the structural design of the floating metalens platform for further advancements. This work not only has significant potential in advancing LWPT but also presents a promising solution for the energy replenishment of high-altitude UAVs, opening new possibilities in the field.

Author Contributions

Z.M. and Y.X. contributed equally to this work. L.C., Z.M. and Y.X. conceived the design, and carried out the design and simulation. Y.F., S.W., Y.L., J.Z. and D.Z. conducted the experiment and simulation. M.P. and X.L. discussed the results and co-wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by West Light Project, CAS (xbzg-zdsys-202206) and National Natural Science Foundation of China (U24A6010).

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no competing financial interests.

References

- Jin, K.; Zhou, W. Wireless laser power transmission: A review of recent progress. IEEE Trans. Power Electron. 2018, 34, 3842–3859. [Google Scholar] [CrossRef]

- Mohammadnia, A.; Ziapour, B.M.; Ghaebi, H.; Khooban, M.H. Feasibility assessment of next-generation drones powering by laser-based wireless power transfer. Opt. Laser Technol. 2021, 143, 107283. [Google Scholar] [CrossRef]

- Kawashima, N.; Takeda, K.; Yabe, K. Application of the laser energy transmission technology to drive a small airplane. Chin. Opt. Lett. 2007, 5, S109–S110. [Google Scholar]

- Zhang, Q.; Shi, X.; Liu, Q.; Wu, J.; Xia, P.; Liao, Y. Adaptive distributed laser charging for efficient wireless power transfer. In Proceedings of the 2017 IEEE 86th Vehicular Technology Conference (VTC-Fall), Toronto, ON, Canada, 24–27 September 2017; pp. 1–5. [Google Scholar]

- Kawashima, N.; Takeda, K. Laser energy transmission for a wireless energy supply to robots. Robot. Constr. 2008, 10, 373–380. [Google Scholar]

- Qi, C.; Dechen, Z.; Dandi, Z. Design and experiment for realization of laser wireless power transmission for small unmanned aerial vehicles. In Proceedings of the Advances in Laser Technology and Applications, Beijing, China, 5–7 May 2015; Volume 9671, p. 96710N. [Google Scholar]

- Candiago, S.; Remondino, F.; De Giglio, M.; Dubbini, M.; Gattelli, M. Evaluating multispectral images and vegetation indices for precision farming applications from UAV images. Remote Sens. 2015, 7, 4026–4047. [Google Scholar] [CrossRef]

- Lu, Y.; Macias, D.; Dean, Z.S.; Kreger, N.R.; Wong, P.K. A UAV-mounted whole cell biosensor system for environmental monitoring applications. IEEE Trans. Nanobiosci. 2015, 14, 811–817. [Google Scholar] [CrossRef]

- Brooks, C.; Dobson, R.J.; Banach, D.M.; Dean, D.; Oommen, T.; Wolf, R.E.; Havens, T.C.; Ahlborn, T.M.; Hart, B. Evaluating the Use of Unmanned Aerial Vehicles for Transportation Purposes; Michigan Tech Research Institute Final Report; Michigan Department of Transportation—Office of Research and Best Practices: Lansing, MI, USA, 2014. [Google Scholar]

- Zhang, Q.; Fang, W.; Liu, Q.; Wu, J.; Xia, P.; Yang, L. Distributed laser charging: A wireless power transfer approach. IEEE Internet Things J. 2018, 5, 3853–3864. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, H.; Wang, J.; Gou, Y.; Li, J.; Zhou, S. Research on the output characteristics of laser wireless power transmission system with nonuniform laser irradiation. Opt. Eng. 2022, 61, 067106. [Google Scholar] [CrossRef]

- Li, G.; Zhang, H.; Wang, C.; Pan, Y.; Lu, J.; Zhou, D. Effect of 1070 nm laser intensity on parameters of In0.3Ga0.7As solar cell. Chin. Opt. Lett. 2019, 17, 31601. [Google Scholar]

- Wang, H.; Wang, J.; Yang, H.; Deng, G.; Yang, Q.; Niu, R.; Gou, Y. The effect of non-uniform irradiation on laser photovoltaics: Experiments and simulations. Photonics 2022, 9, 493. [Google Scholar] [CrossRef]

- Meng, X.; Liu, B.; Lopez, C.; Li, C. Multi-field coupling characteristics of photovoltaic cell under non-uniform laser beam irradiance. Sustain. Energy Technol. Assess. 2022, 52, 101963. [Google Scholar]

- Meng, X.; Hou, Y.; Liu, B.; Pu, Z.; Lopez, C.; Li, C. Improvements of PV receiver in laser wireless power transmission by non-imaging optics. Sol. Energy 2023, 255, 157–170. [Google Scholar]

- Chong, K.K.; Yew, T.K.; Wong, C.W.; Tan, M.H.; Tan, W.C.; Lim, B.H. Dense-array concentrator photovoltaic prototype using non-imaging dish concentrator and an array of cross compound parabolic concentrators. Appl. Energy 2017, 204, 898–911. [Google Scholar] [CrossRef]

- Zhang, Y.; Pu, M.; Jin, J.; Lu, X.; Guo, Y.; Cai, J.; Luo, X. Crosstalk-free achromatic full Stokes imaging polarimetry metasurface enabled by polarization-dependent phase optimization. Opto-Electron. Adv. 2022, 5, 220058. [Google Scholar] [CrossRef]

- Xie, X.; Pu, M.; Jin, J.; Xu, M.; Guo, Y.; Li, X.; Luo, X. Generalized Pancharatnam-Berry phase in rotationally symmetric meta-atoms. Phys. Rev. Lett. 2021, 126, 183902. [Google Scholar] [CrossRef]

- Luo, X. Subwavelength artificial structures: Opening a new era for engineering optics. Adv. Mater. 2019, 31, 1804680. [Google Scholar] [CrossRef]

- Liu, W.; Li, Z.; Ansari, M.A.; Cheng, H.; Tian, J.; Chen, X.; Chen, S. Design strategies and applications of dimensional optical field manipulation based on metasurfaces. Adv. Mater. 2023, 35, 2208884. [Google Scholar] [CrossRef]

- Xiao, Y.; Chen, L.; Pu, M.; Xu, M.; Zhang, Q.; Guo, Y.; Luo, X. Improved spatiotemporal resolution of anti-scattering super-resolution label-free microscopy via synthetic wave 3D metalens imaging. Opto-Electron. Sci. 2023, 2, 230037. [Google Scholar] [CrossRef]

- Arbabi, A.; Horie, Y.; Bagheri, M.; Faraon, A. Dielectric metasurfaces for complete control of phase and polarization with subwavelength spatial resolution and high transmission. Nat. Nanotechnol. 2015, 10, 937–943. [Google Scholar] [CrossRef]

- Liu, M.; Huo, P.; Zhu, W.; Zhang, C.; Zhang, S.; Song, M.; Xu, T. Broadband generation of perfect Poincaré beams via dielectric spin-multiplexed metasurface. Nat. Commun. 2021, 12, 2230. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, S.; Pu, M.; He, Q.; Jin, J.; Xu, M.; Zhang, Y.; Gao, P.; Luo, X. Spin-decoupled metasurface for simultaneous detection of spin and orbital angular momenta via momentum transformation. Light Sci. Appl. 2021, 10, 63. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Fan, X.; Wang, Y.; Liu, Y.; Wang, X.; Xu, K.; Deng, L.; Zeng, C.; Li, T.; Xia, J.; et al. Multi-foci metalens for spectra and polarization ellipticity recognition and reconstruction. Opto-Electron. Sci. 2023, 2, 220026. [Google Scholar] [CrossRef]

- Zhang, F.; Pu, M.; Li, X.; Ma, X.; Guo, Y.; Gao, P.; Yu, H.; Gu, M.; Luo, X. Extreme-angle silicon infrared optics enabled by streamlined surfaces. Adv. Mater. 2021, 33, 2008157. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Guo, Y.; Pu, M.; Chen, L.; Xu, M.; Liao, M.; Li, L.; Li, X.; Ma, X.; Luo, X. Meta-optics empowered vector visual cryptography for high security and rapid decryption. Nat. Commun. 2023, 14, 1946. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, J.; Leng, B.; Zhou, Y.; Cheng, J.; Yamaguchi, T.; Tanaka, T.; Chen, M. Edge enhanced depth perception with binocular meta-lens. Opto-Electron. Sci. 2024, 3, 230033. [Google Scholar] [CrossRef]

- Huang, G.; Wu, D.; Luo, J.; Lu, L.; Li, F.; Shen, Y.; Li, Z. Generalizing the Gerchberg–Saxton algorithm for retrieving complex optical transmission matrices. Photonics Res. 2020, 9, 34–42. [Google Scholar] [CrossRef]

- Zalevsky, Z.; Mendlovic, D.; Dorsch, R.G. Gerchberg–Saxton algorithm applied in the fractional Fourier or the Fresnel domain. Opt. Lett. 1996, 21, 842–844. [Google Scholar] [CrossRef]

- Wang, Q.; Fang, Y.; Meng, Y.; Hao, H.; Li, X.; Pu, M.; Luo, X. Vortex-field enhancement through high-threshold geometric metasurface. Opto-Electron. Adv. 2024, 7, 240112. [Google Scholar] [CrossRef]

- Chen, C.; Su, H. Integrated opto-mechanical analysis of a PMMA Fresnel lens for a concentrated photovoltaic system. Microsyst. Technol. 2013, 19, 1725–1729. [Google Scholar] [CrossRef]

- Hornung, T.; Kiefel, P.; Nitz, P. The distance temperature map as method to analyze the optical properties of Fresnel lenses and their interaction with multi-junction solar cells. AIP Conf. Proc. 2015, 1679, 070001. [Google Scholar]

- Ai, Y.; Wang, F.; Lv, Q.; Liu, H.; Chen, Y.; Zheng, T.; Ma, Z.; Deng, X. Influence of Ambient Humidity on the Performance of Complex Spectral Dielectric Films on SiO2/K9 Substrates. Crystals 2023, 13, 248. [Google Scholar] [CrossRef]

- Malevskii, D.A.; Malevskaya, A.V.; Pokrovskii, P.V.; Andreev, V.M. Dynamics of Air Humidity in a Concentrator Photovoltaic Module with a Drying Device. Tech. Phys. Lett. 2021, 47, 208–210. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).