Research on Pt-Based Film Negative Photoconductivity Photothermal Detector Under Different Wavelength Laser Irradiation

Abstract

1. Introduction

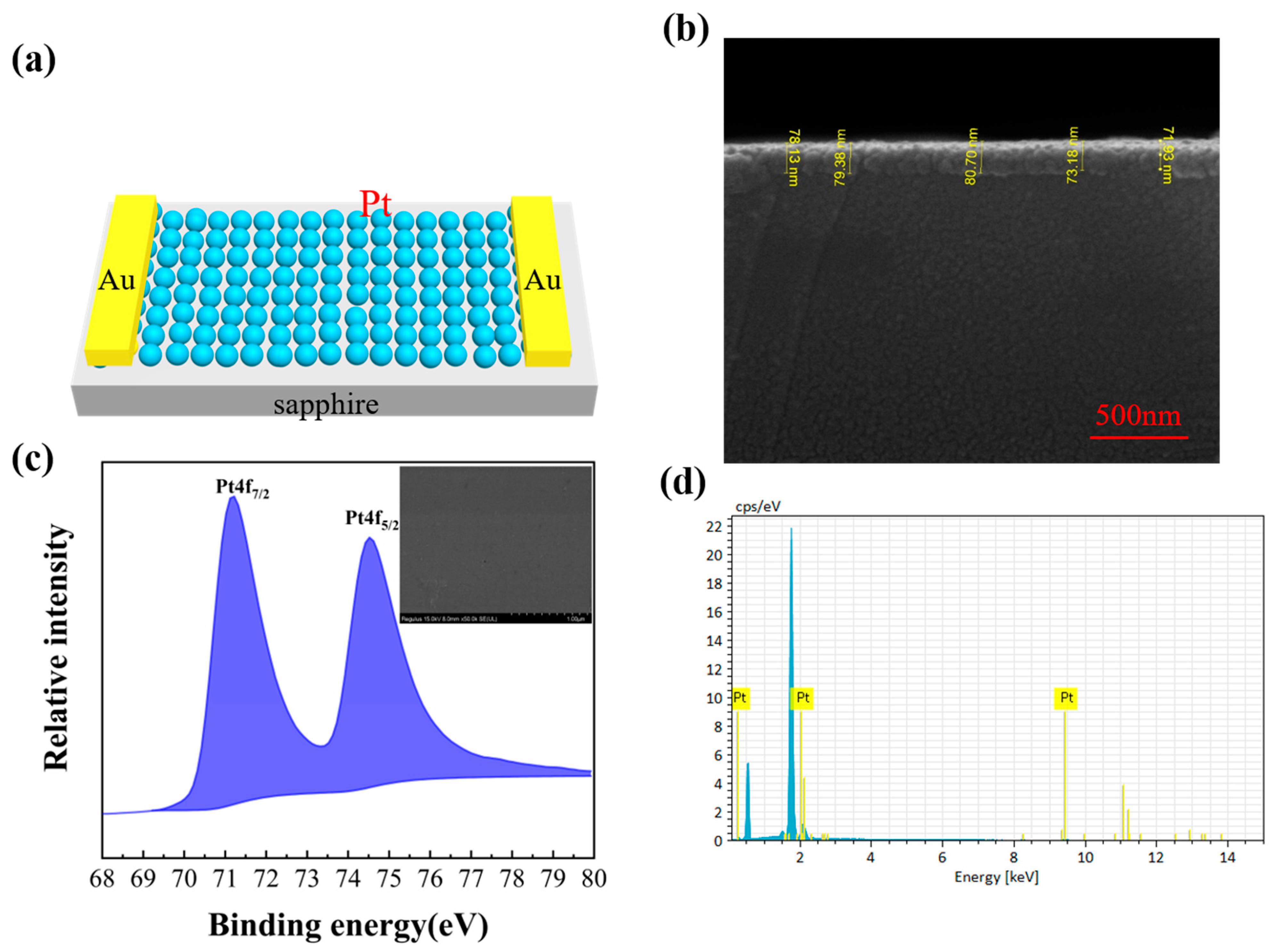

2. Experimental Section

2.1. Device Preparation

2.2. Material Characterization and Device Measurement

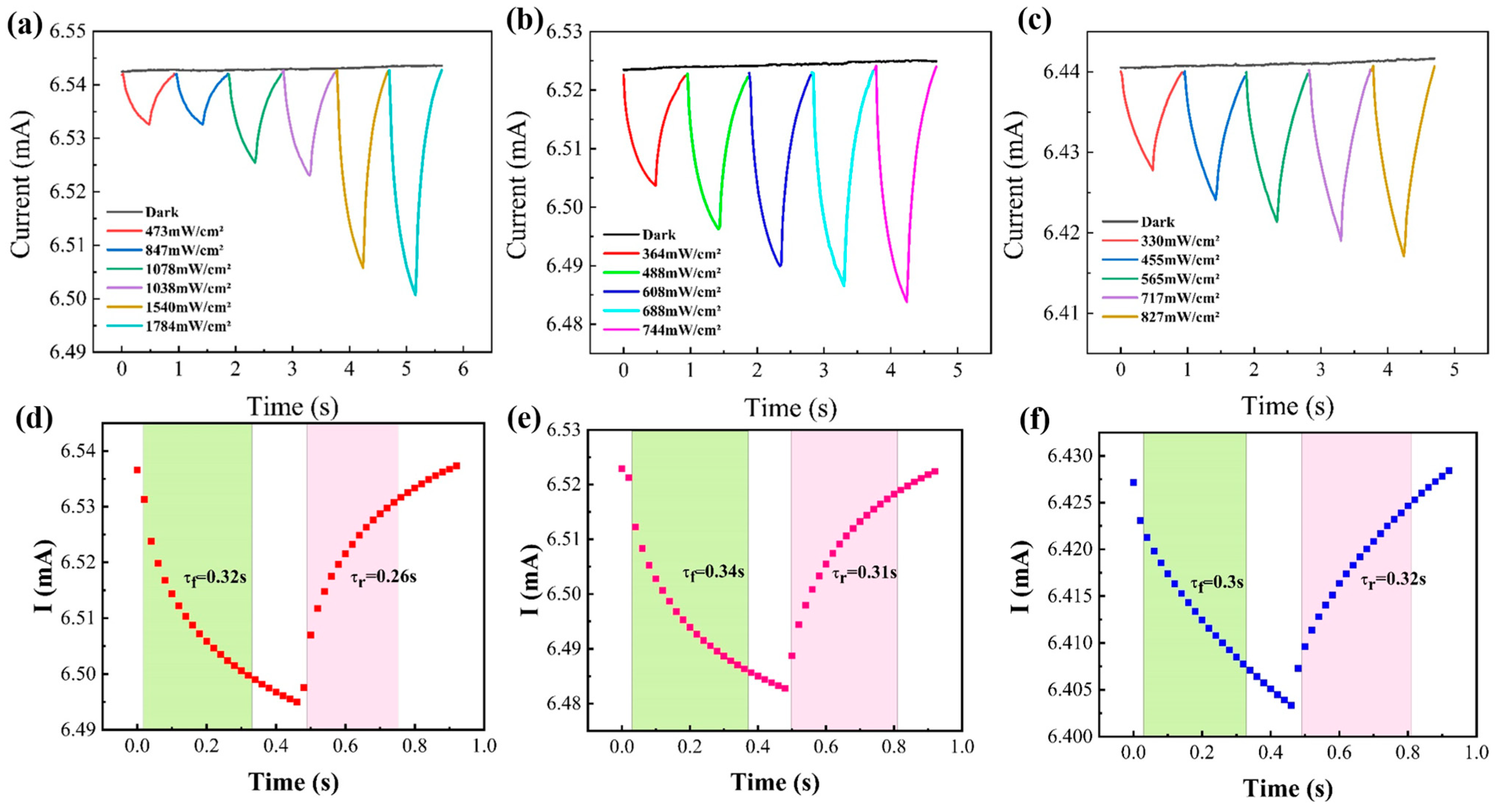

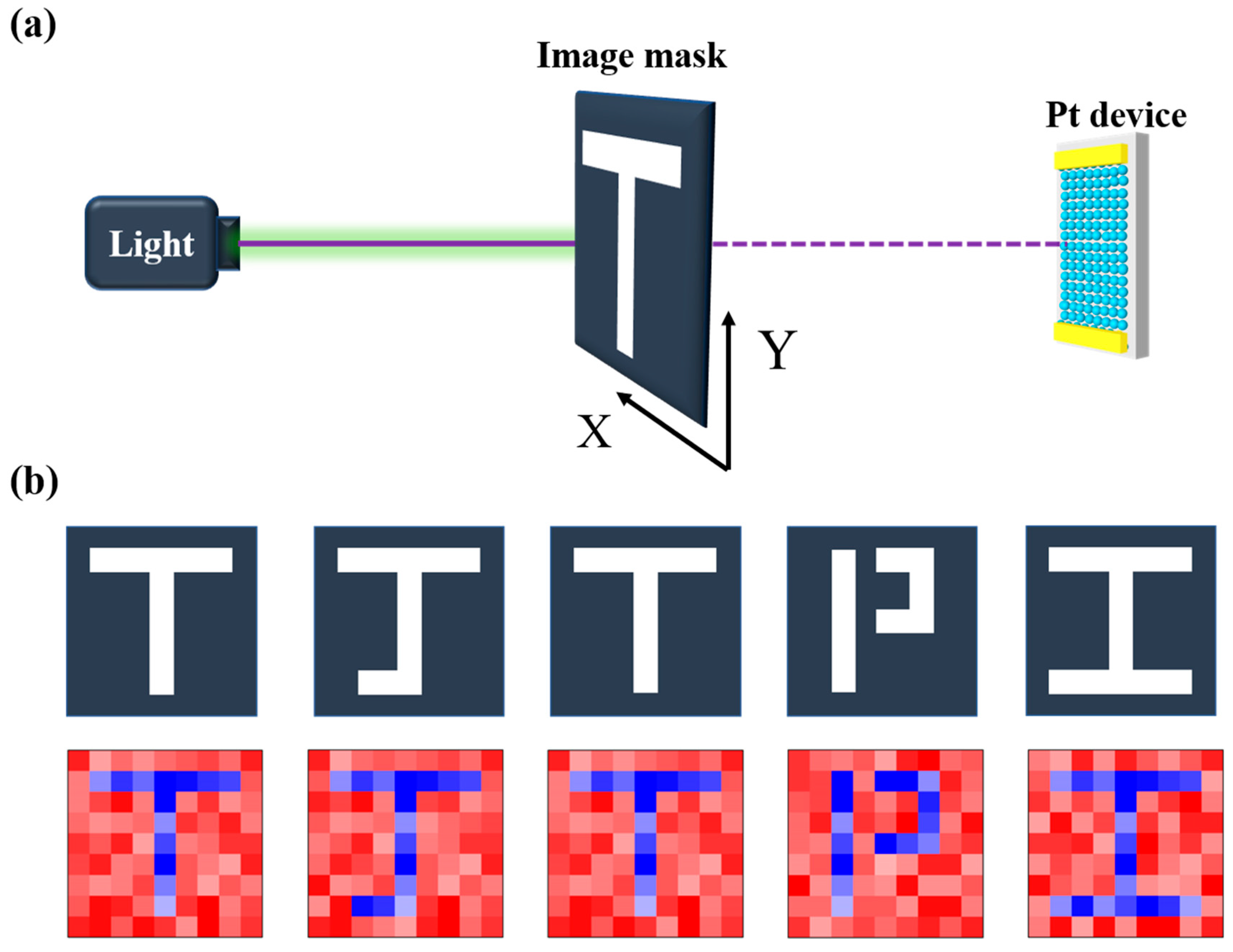

3. Discussion and Results

4. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coufal, H. Photothermal spectroscopy using a pyroelectric thin-film detector. Appl. Phys. Lett. 1984, 44, 59–61. [Google Scholar] [CrossRef]

- Lu, X.; Sun, L.; Jiang, P.; Bao, X. Progress of Photodetectors Based on the Photothermoelectric Effect. Adv. Mater. 2019, 31, 1902044. [Google Scholar] [CrossRef] [PubMed]

- Miao, J.; Song, B.; Li, Q.; Cai, L.; Zhang, S.; Hu, W.; Dong, L.; Wang, C. Photothermal Effect Induced Negative Photoconductivity and High Responsivity in Flexible Black Phosphorus Transistors. ACS Nano 2017, 11, 6048–6056. [Google Scholar] [CrossRef]

- Wang, X.; Cui, Y.; Li, T.; Lei, M.; Li, J.; Wei, Z. Recent Advances in the Functional 2D Photonic and Optoelectronic Devices. Adv. Opt. Mater. 2019, 7, 1801274. [Google Scholar] [CrossRef]

- Li, C.; Ma, Y.; Xiao, Y.; Shen, L.; Ding, L. Advances in perovskite photodetectors. InfoMat 2020, 2, 1247–1256. [Google Scholar] [CrossRef]

- Lei, Y.; Gu, L.; Yang, X.; Lin, Y.; Zheng, Z. Ductile-Metal Ag as Buffer Layer for Flexible Self-Powered Ag2S Photodetectors. Adv. Mater. Interfaces 2021, 8, 2002255. [Google Scholar] [CrossRef]

- Cui, X.; Ruan, Q.; Zhuo, X.; Xia, X.; Hu, J.; Fu, R.; Li, Y.; Wang, J.; Xu, H. Photothermal Nanomaterials: A Powerful Light-to-Heat Converter. Chem. Rev. 2023, 123, 6891–6952. [Google Scholar] [CrossRef]

- Chekcheyev, S. A Temperature-Stable Metal Detector. IEEE Trans. Instrum. Meas. 2009, 58, 1907–1910. [Google Scholar] [CrossRef]

- Zhu, H.; Yi, F.; Cubukcu, E. Nanoantenna Absorbers for Thermal Detectors. IEEE Photonics Technol. Lett. 2012, 24, 1194–1196. [Google Scholar] [CrossRef]

- Xu, B.; An, Y.; Zhu, J.; He, Y. Flexible photosensors based on photothermal conversion. Green Chem. Eng. 2024, 6, 6–20. [Google Scholar] [CrossRef]

- Xiang, H.; Hu, Z.; Xin, C.; Chen, Z.; Yuan, X.; Aigouy, L. Photothermal-Induced Electrical Behavior of Micron-Sized Platinum Structures and Their Efficient Photodetection. Energy Technol. 2022, 10, 2200757. [Google Scholar] [CrossRef]

- Losi, A.; Braslavsky, S.E. The time-resolved thermodynamics of the chromophore–protein interactions in biological photosensors as derived from photothermal measurements. Phys. Chem. Chem. Phys. 2003, 5, 2739–2750. [Google Scholar] [CrossRef]

- Singh, S.C.; Peng, Y.; Rutledge, J.; Guo, C. Photothermal and Joule-Heating-Induced Negative-Photoconductivity-Based Ultraresponsive and Near-Zero-Biased Copper Selenide Photodetectors. ACS Appl. Electron. Mater. 2019, 1, 1169–1178. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Wang, D.; He, W.; Liu, D.; Cao, J.; Zhang, X.; Liu, S.; Zhang, B.; Pan, J.; Zeng, Z.; et al. Photothermal synergistic high-sensitivity self-driven vertical asymmetric Te/Bi2Te3/In2O3 heterojunction near-infrared imaging photodetector. Chem. Eng. J. 2024, 486, 150183. [Google Scholar] [CrossRef]

- Jaque, D.; Martínez Maestro, L.; del Rosal, B.; Haro-Gonzalez, P.; Benayas, A.; Plaza, J.L.; Martín Rodríguez, E.; García Solé, J. Nanoparticles for photothermal therapies. Nanoscale 2014, 6, 9494–9530. [Google Scholar] [CrossRef]

- Watanabe, K.; Menzel, D.; Nilius, N.; Freund, H.-J. Photochemistry on Metal Nanoparticles. Chem. Rev. 2006, 106, 4301–4320. [Google Scholar] [CrossRef]

- Zijlstra, P.; Chon, J.W.M.; Gu, M. Five-dimensional optical recording mediated by surface plasmons in gold nanorods. Nature 2009, 459, 410–413. [Google Scholar] [CrossRef]

- Dyer, G.C.; Aizin, G.R.; Reno, J.L.; Shaner, E.A.; Allen, S.J. Novel Tunable Millimeter-Wave Grating-Gated Plasmonic Detectors. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 85–91. [Google Scholar] [CrossRef]

- Zhang, S.; He, X.; Ding, Y.; Shi, Z.; Wu, B. Supply and demand of platinum group metals and strategies for sustainable management. Renew. Sustain. Energy Rev. 2024, 204, 114821. [Google Scholar] [CrossRef]

- Chen, A.; Holt-Hindle, P. Platinum-Based Nanostructured Materials: Synthesis, Properties, and Applications. Chem. Rev. 2010, 110, 3767–3804. [Google Scholar] [CrossRef]

- Tian, C.; Jiang, D.; Pei, J.; Sun, L.; Liu, R.; Guo, Z.; Hou, J.; Zhao, J.; Liang, Q.; Gao, S.; et al. Performance enhancement of MgZnO-based visible-blind photodetectors by Pt nanoparticles. J. Alloys Compd. 2016, 667, 65–68. [Google Scholar] [CrossRef]

- Pei, J.; Jiang, D.; Zhao, M.; Duan, Q.; Liu, R.; Sun, L.; Guo, Z.; Hou, J.; Qin, J.; Li, B.; et al. Controlled enhancement range of the responsivity in ZnO ultraviolet photodetectors by Pt nanoparticles. Appl. Surf. Sci. 2016, 389, 1056–1061. [Google Scholar] [CrossRef]

- Zeng, W.; Chen, N.; Zhang, L.; Liu, C.; Liu, P.; Xie, F.; Zhou, Y.; Xie, W. Construction of Schottky contact by modification with Pt particles to enhance the performance of ultra-long V2O5 nanobelt photodetectors. J. Colloid Interface Sci. 2022, 607, 1919–1927. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Yan, F. Flexible Photodetectors Based on Novel Functional Materials. Small 2017, 13, 1701822. [Google Scholar] [CrossRef]

- Zeng, L.-H.; Wu, D.; Lin, S.-H.; Xie, C.; Yuan, H.-Y.; Lu, W.; Lau, S.P.; Chai, Y.; Luo, L.-B.; Li, Z.-J.; et al. Controlled Synthesis of 2D Palladium Diselenide for Sensitive Photodetector Applications. Adv. Funct. Mater. 2019, 29, 1806878. [Google Scholar] [CrossRef]

- Jacobs-Gedrim, R.B.; Shanmugam, M.; Jain, N.; Durcan, C.A.; Murphy, M.T.; Murray, T.M.; Matyi, R.J.; Moore, R.L., II; Yu, B. Extraordinary Photoresponse in Two-Dimensional In2Se3 Nanosheets. ACS Nano 2014, 8, 514–521. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, H.; Fujii, M.; Ago, H.; Takahashi, K.; Ikuta, T.; Abe, H.; Shimizu, T. Thermal and electrical conductivity of a suspended platinum nanofilm. Appl. Phys. Lett. 2005, 86, 171912. [Google Scholar] [CrossRef]

- Yang, C.-M.; Chen, T.-C.; Verma, D.; Li, L.-J.; Liu, B.; Chang, W.-H.; Lai, C.-S. Bidirectional All-Optical Synapses Based on a 2D Bi2O2Se/Graphene Hybrid Structure for Multifunctional Optoelectronics. Adv. Funct. Mater. 2020, 30, 2001598. [Google Scholar] [CrossRef]

- Zhou, X.; Su, F.; Tian, Y.; Johnson, R.H.; Meldrum, D.R. Platinum (II) porphyrin-containing thermoresponsive poly(N-isopropylacrylamide) copolymer as fluorescence dual oxygen and temperature sensor. Sens. Actuators B Chem. 2011, 159, 135–141. [Google Scholar] [CrossRef]

- Zuo, Y.; Gao, Y.; Qin, S.; Wang, Z.; Zhou, D.; Li, Z.; Yu, Y.; Shao, M.; Zhang, X. Broadband multi-wavelength optical sensing based on photothermal effect of 2D MXene films. Nanophotonics 2020, 9, 123–131. [Google Scholar] [CrossRef]

- Yang, H.; Tan, C.; Deng, C.; Zhang, R.; Zheng, X.; Zhang, X.; Hu, Y.; Guo, X.; Wang, G.; Jiang, T.; et al. Bolometric Effect in Bi2O2Se Photodetectors. Small 2019, 15, 1904482. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Liu, Y.; Dong, S.; Xu, H.; Wu, Y.; Hao, L.; Cao, B.; Li, M.; Wang, Z.; Han, Z.; et al. Photothermoelectric SnTe Photodetector with Broad Spectral Response and High On/Off Ratio. ACS Appl. Mater. Interfaces 2020, 12, 49830–49839. [Google Scholar] [CrossRef] [PubMed]

- Gabor, N.M.; Song, J.C.W.; Ma, Q.; Nair, N.L.; Taychatanapat, T.; Watanabe, K.; Taniguchi, T.; Levitov, L.S.; Jarillo-Herrero, P. Hot Carrier–Assisted Intrinsic Photoresponse in Graphene. Science 2011, 334, 648–652. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Liu, X.; Afshinmanesh, F.; Li, W.; Xu, G.; Sun, J.; Lian, B.; Curto, A.G.; Ye, G.; Hikita, Y.; et al. Polarization-sensitive broadband photodetector using a black phosphorus vertical p–n junction. Nat. Nanotechnol. 2015, 10, 707–713. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Du, L.; Yuan, Q.; Sun, Y.; Fu, Z.; Zhang, H.; Song, X.; Dong, S.; Yao, J. Research on Pt-Based Film Negative Photoconductivity Photothermal Detector Under Different Wavelength Laser Irradiation. Photonics 2025, 12, 6. https://doi.org/10.3390/photonics12010006

Sun W, Du L, Yuan Q, Sun Y, Fu Z, Zhang H, Song X, Dong S, Yao J. Research on Pt-Based Film Negative Photoconductivity Photothermal Detector Under Different Wavelength Laser Irradiation. Photonics. 2025; 12(1):6. https://doi.org/10.3390/photonics12010006

Chicago/Turabian StyleSun, Wenbao, Langlang Du, Qinlang Yuan, Yueyu Sun, Zhendong Fu, Haiting Zhang, Xiaoxian Song, Shanshan Dong, and Jianquan Yao. 2025. "Research on Pt-Based Film Negative Photoconductivity Photothermal Detector Under Different Wavelength Laser Irradiation" Photonics 12, no. 1: 6. https://doi.org/10.3390/photonics12010006

APA StyleSun, W., Du, L., Yuan, Q., Sun, Y., Fu, Z., Zhang, H., Song, X., Dong, S., & Yao, J. (2025). Research on Pt-Based Film Negative Photoconductivity Photothermal Detector Under Different Wavelength Laser Irradiation. Photonics, 12(1), 6. https://doi.org/10.3390/photonics12010006