Research on Support Structure of Rectangular Cryogenic Infrared Lens with Large Aperture

Abstract

:1. Introduction

2. Scheme on Support Structure

2.1. Difficulties in Support Structure Design

- To prevent obstruction of the lens aperture, support points must be positioned at the periphery of the lens. However, in double convex lenses, the pronounced thickness gradient toward the edges results in increased stress at the edges [19].

- The asymmetry of circular lenses complicates the selection of optimal support locations.

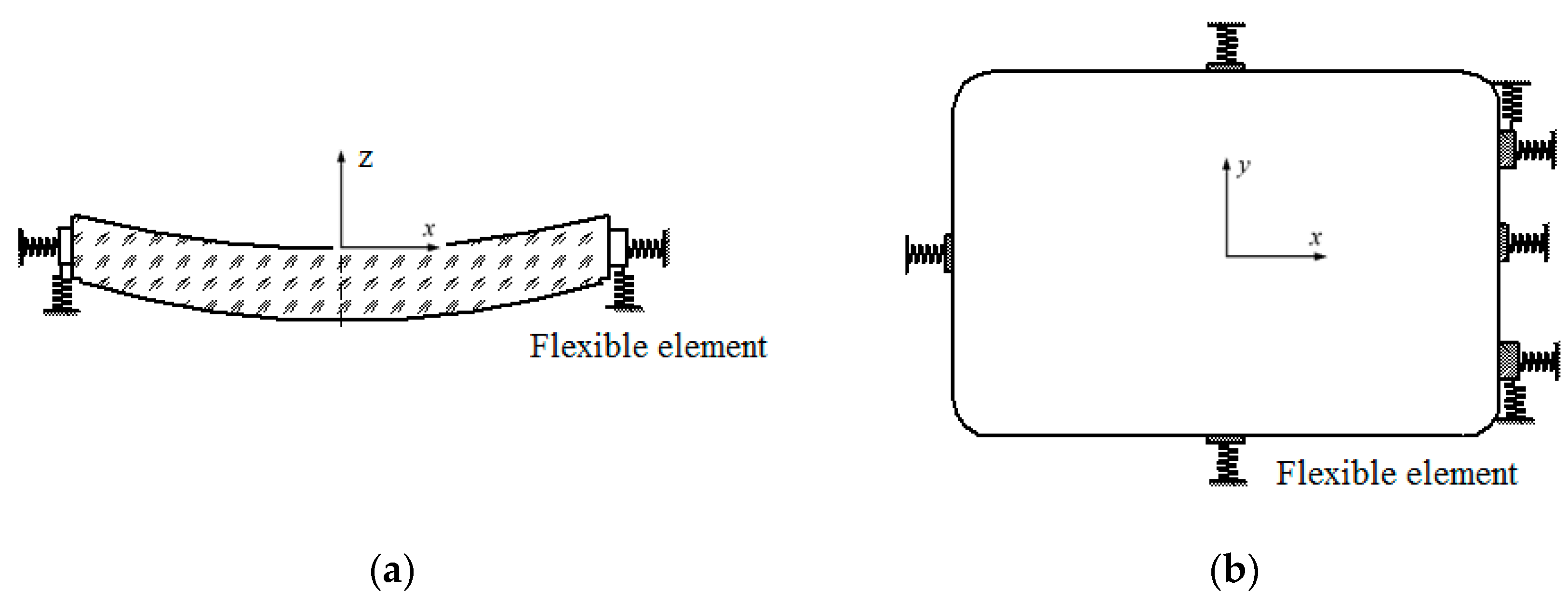

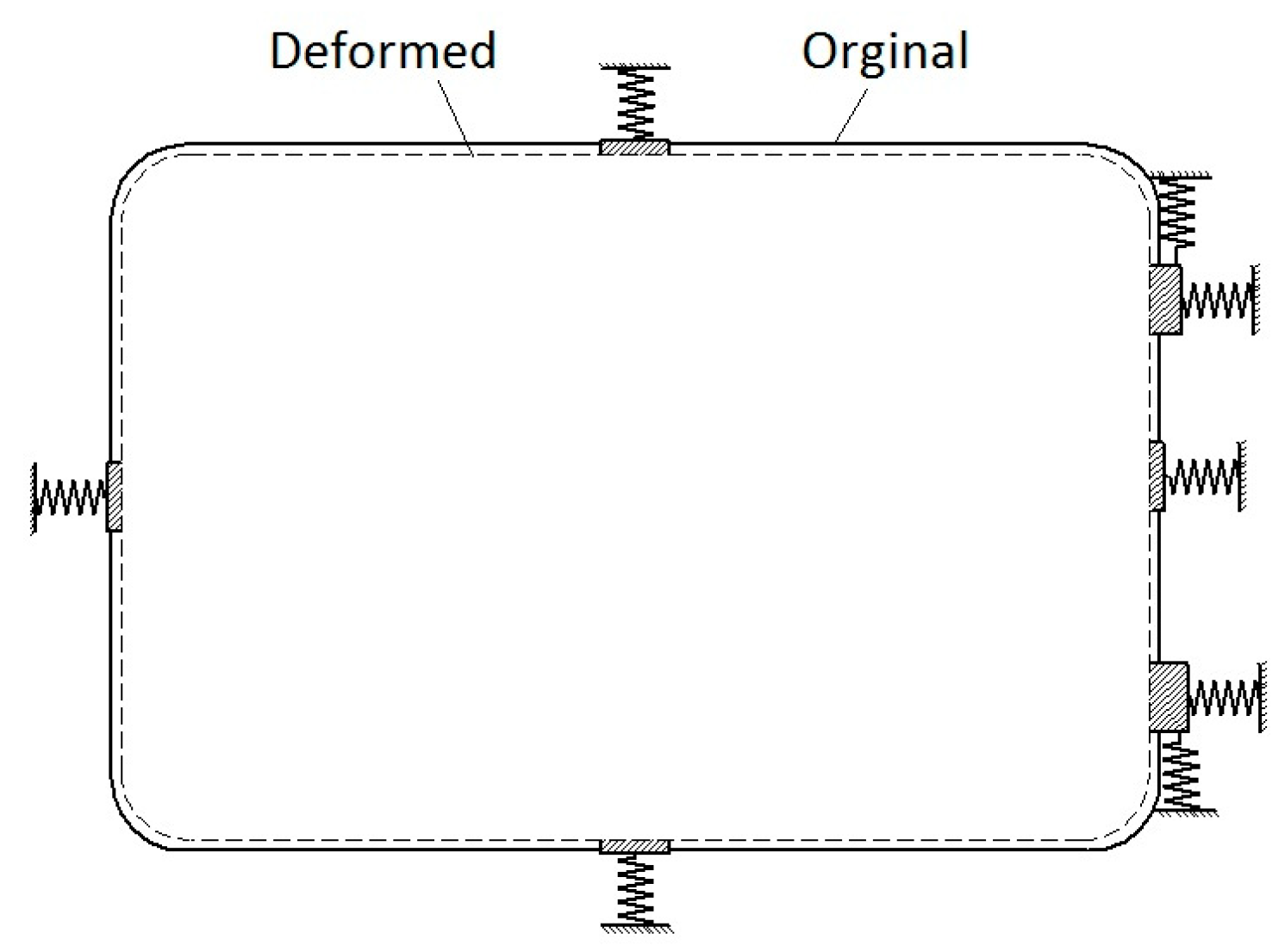

2.2. General Structure Design

- As depicted in Figure 3, the radial flexibility of the individual flexures allows the support structure to accommodate inconsistent thermal deformations between the frame and the lens, effectively reducing thermal stress and maintaining the radial position of the lens.

3. Mechanical Model of the Flexible Support Structure

3.1. Flexible Structure in Cantilever Form

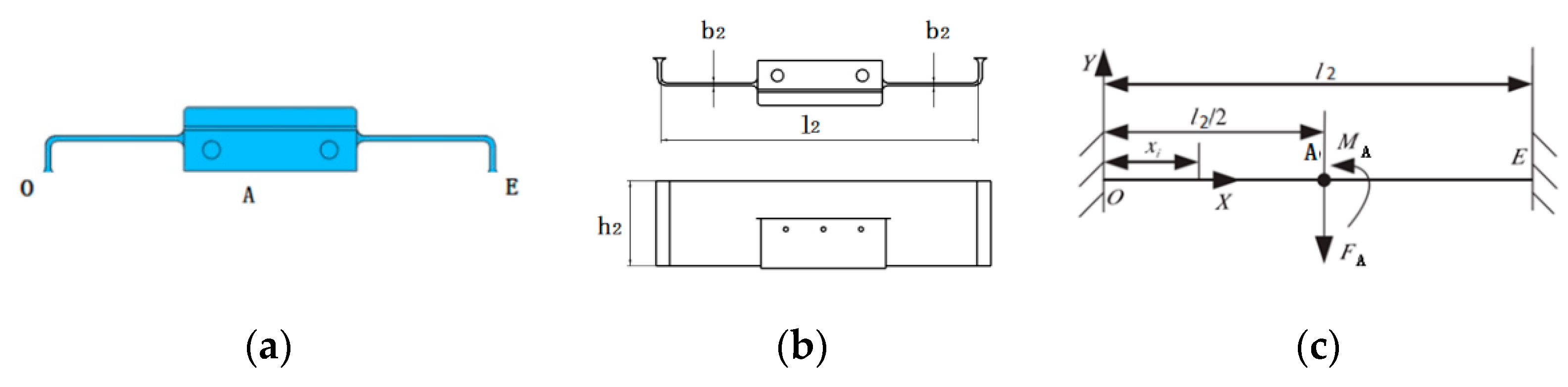

3.2. Flexible Structure with Fixed Beams at Both Ends

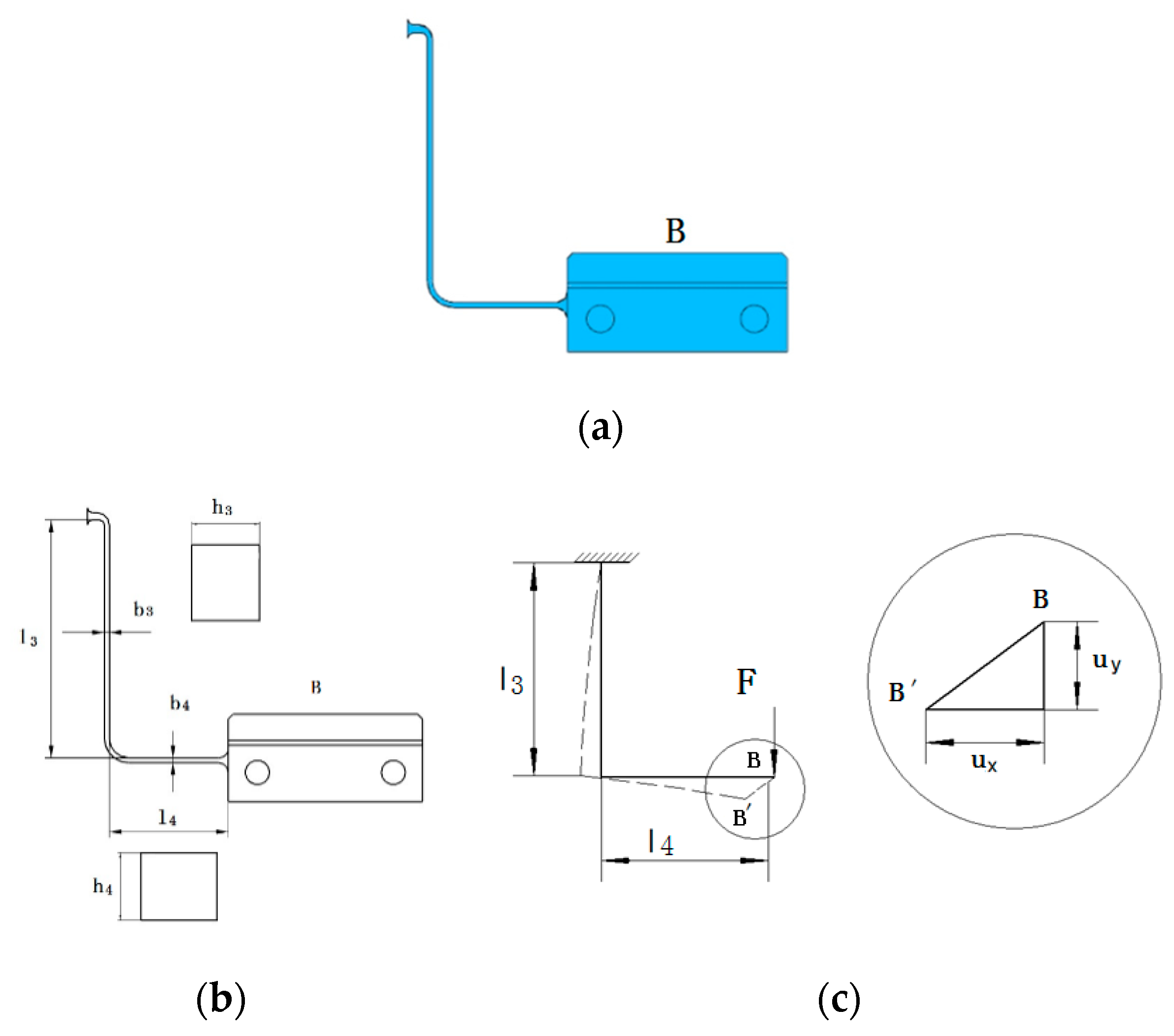

3.3. Flexible Structures with Cantilever Steel Frame

3.4. Model of the Whole Support Structure

3.5. Optimization Design of Support Structure

4. Simulation Analysis of Lens Sub-Assemblies

4.1. Modal Analysis

4.2. Surface Shape and Rigid Body Displacement Analysis

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, C.; Wang, J.; Xue, L.; Zhao, L. Next Generation of Astronomical Telescope and Survey Mission (I). Infrared Laser Eng. 2016, 45, 204–208. [Google Scholar]

- Huang, C.; Wang, J.; Xue, L.; Zhao, L. Next Generation of Astronomical Telescope and Survey Mission (II). Infrared Laser Eng. 2016, 45, 170–175. [Google Scholar]

- Pan, C.; Cang, L.; Luo, M.; Tao, L.; Chen, S.; Chen, B.; Bai, Z.; Cui, H.; Xu, C.; Zhao, J. Development Status and Application of Space Infrared Camera Optical Technology. Infrared Technol. 2022, 44, 1186–1193. [Google Scholar]

- Fu, L.; Xu, S.; Jiao, T.; Du, K. Development Status and Trend of Space Optical Loading. In Proceedings of the 2015 Infrared and Remote Sensing Technology and Application Symposium and Interdisciplinary Forum, Barcelona, Spain, 19–24 April 2015; pp. 1–10. [Google Scholar]

- Global Security. SBIRS GEO—Geostationary Earth Orbit [EB/OL]. Available online: http://www.globalsecurity.org/space/systems/sbirs-geo.html (accessed on 25 October 2022).

- Zhang, J. Lockheed Martin Aerospace Development Research in 2020; Aerospace China: Jingjiang, China, 2021; Volume 1, pp. 20–30. [Google Scholar]

- Kvamme, E.T.; Trevias, D.; Simonson, R. A Low Stress Cryogenic Mount for Space-borne Lithium Fluoride Optics. SPIE 2005, 5877, 276–286. [Google Scholar]

- Chen, G.; Shi, G.; Wu, F.; Wang, J.; Pei, L.; Shi, G. Analysis of thermal optical properties for a thermal infrared lens. Laser Infrared 2017, 47, 1299–1304. (In Chinese) [Google Scholar]

- Wang, Z.; Liang, J.; Zhao, M.; Chen, H.; Wang, J.; Wei, L. Lens mount for cryogenic refractive optics cooled by mechanical cryo-cooler. Infrared Laser Eng. 2019, 48, 0218006. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Liu, J.; Zhang, L.; Liu, X. Analysis and suppression of external stray light in spatial infrared detection system. Laser Infrared 2015, 45, 185–188. [Google Scholar]

- Yu, X. Simulation Analysis of Spurious Radiation Transmission Characteristics of Infrared Detection System and Its Environment; Harbin Institute of Technology: Harbin, China, 2015. [Google Scholar]

- Gao, Y.; Zhang, B. Design and analysis for the flexible support structure of high precision lens assembly. Optik 2018, 175, 228–236. [Google Scholar] [CrossRef]

- Gao, Y.; Li, F.; Shen, Z.; Ding, L.; Hu, B.; Xu, S. Simulation method and its test verification of cryogenic infrared lens design. Infrared Laser Eng. 2021, 50, 20200397. [Google Scholar]

- Kvamme, E.T.; Jacoby, M.; Osborne, L. Opto-mechanical Test Results for the Near Infra-red Camera on the James Webb Space Telescope. In Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter; SPIE: Bellingham, WA, USA, 2008; Volume 7010, pp. 310–321. [Google Scholar]

- Ge, H.; Xiao, Z.; Wang, Y. Research on Cryogenic Lens Support Structures Based on a Bi-material System for Thermal Deformation Compensation. Spacecr. Recovery Remote Sens. 2022, 43, 69–75. (In Chinese) [Google Scholar]

- Zhao, L.; Peng, H.; Yu, X. Lens Support Structure of Multi-points Equal Supporting with Wholly Radical Freedom. Opto-Electron. Eng. 2015, 42, 43–48. (In Chinese) [Google Scholar]

- Zhang, L.; Zhang, X.; Zhang, F. Structural Optimization Design of Large Tolerance and Multi-flexibility Lens Sub-assembly. J. Jilin Univ. (Eng. Technol. Ed.) 2021, 51, 478–485. (In Chinese) [Google Scholar]

- Wang, X.; Cao, Y.; Wang, F.; Chu, H.; Li, Y. Optimization Design of Large-aperture Lens Mixed Flexible Support Structure. Infrared Laser Eng. 2022, 51, 1–7. [Google Scholar]

- Cao, Y.Y.; Wang, J.L.; Chu, H.L.; Li, H.W.; Chen, T.; Ming, M.; Jiang, F. Design and Analysis of Bi-flexible Mounting Structure for Large Optical Lens. Opt. Precis. Eng. 2021, 29, 1868–1879. [Google Scholar] [CrossRef]

- Wittrick, W.H. The properties of crossed flexure pivots, and the influence of the point at which the strips cross. Aeronaut. Q. 2016, 2, 272–292. [Google Scholar] [CrossRef]

- Chen, X.; Li, Z.; Jin, G. Dimensionless design model for biaxial Cart wheel flexure hinges. Mech. Based Des. Struct. Mach. 2018, 46, 401–409. [Google Scholar]

- Cao, Y.Y.; Wang, Z.C.; Zhou, C.; Fan, L.; Han, X.D.; Zhang, Y.Z. General modeling and optimal design of flexure sup-porting structure for optical components. Opt. Precis. Eng. 2016, 24, 2792–2803. (In Chinese) [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Z.C.; Zhou, C. Modeling and optimal design of circular-arch flexible structure with radial freedom considering geometry and material selection simultaneously. Precis. Eng. 2017, 48, 83–97. [Google Scholar] [CrossRef]

- Wang, C.; Hu, Z.; Chen, Y.; Xu, M.; Chen, L. Structural design optimization of space gravitational wave telescope primary mirror system. Infrared Laser Eng. 2020, 49, 20190469. (In Chinese) [Google Scholar] [CrossRef]

- Qu, H.; Wei, J.; Dong, D.; Hu, H.; Guan, Y. Lightweight structural design of rectangular space mirror assembly. Infrared Laser Eng. 2021, 50, 20200404. (In Chinese) [Google Scholar]

- Karim, T.; Lee, J.H.; Eisenstein, D.J.; Burtin, E.; Moustakas, J.; Raichoor, A.; Yèche, C. Validation of emission-line galaxies target selection algorithms for the dark energy spectroscopic instrument using the MMT binospec. Mon. Not. R. Astron. Soc. 2020, 497, 4587–4601. [Google Scholar] [CrossRef]

- Cao, D.; Gao, Y. Error Analysis of Precise Non-guiding Displacement Platform. Opt. Precis. Eng. 2012, 20, 313–321. [Google Scholar]

- Ma, L.; Cao, D.; Liu, C. Design and Analysis on Multi-points Flexible Support Structure of Large-aperture Lens. Opto-Electron. Eng. 2015, 42, 88–93. [Google Scholar]

- Wang, Z.; Zhang, J.; Wang, J.; He, X.; Fu, L.; Tian, F.; Liu, X.; Zhao, Y. A Back Propagation neural network based optimizing model of space-based large mirror structure. Optik 2019, 179, 780–786. [Google Scholar] [CrossRef]

- Wang, H.; Guo, J.; Shao, M.; Sun, J.; Tian, F.; Yang, X. Optimization design of an ultralight large-aperture space mirror. Appl. Opt. 2021, 60, 10878–10883. [Google Scholar] [CrossRef]

- Ke, S. Satellite Environment Engineering and Simulation Experiment (2); China Aatronautic Publishing House: Beijing, China, 2005; pp. 23–31. (In Chinese) [Google Scholar]

- Song, J.; Xing, H.; Pei, J.; Yang, T.; Mu, S. Measurement and error analysis of encircled energy of cryogenic lens. Infrared Laser Eng. 2019, 48, 0717007. (In Chinese) [Google Scholar] [CrossRef]

| Face | Tran_x (μm) | Tran_y (μm) | Rotation_x (″) | Rotation_y (″) | RMS (nm) |

|---|---|---|---|---|---|

| Face1 | 30 | 30 | 20 | 20 | 18.08 |

| Face2 | 30 | 30 | 20 | 20 | 18.08 |

| Supports Position | ln/mm | hn/mm | bn/mm |

|---|---|---|---|

| A (n = 2) | 40.0 | 34.0 | 2.0 |

| D,E (n = 1) | 35.0 | 30.0 | 1.0 |

| B,C (n = 3) | 35.0 | 34.0 | 2.0 |

| B,C (n = 4) | 28.0 | 34.0 | 2.0 |

| M (n = 1) | 40.0 | 30.0 | 1.0 |

| Materials | Density ρ (g/cm3) | Elastic Modulus E (GPa) | Poisson’s Ratio | Thermal Expansion Coefficient α (10−6/°C) |

|---|---|---|---|---|

| Si | 2.33 | 13.1 | 0.26 | 4.15 |

| TC4 | 4.44 | 10.9 | 0.34 | 9.1 |

| Order | Frequency/Hz | Mode Shapes |

|---|---|---|

| 1 | 143.37 | Move along Z-axis |

| 2 | 189.69 | Move along Y-axis |

| 3 | 200.42 | Move along X-axis |

| Load Case | Face | Tran_x (μm) | Tran_y (μm) | Rotation_x (″) | Rotation_y (″) | Rotation_z (″) | PV (nm) | RMS (nm) |

|---|---|---|---|---|---|---|---|---|

| Grav_Y | Face1 | 0.57 | 6.5 | 1.52 | −1.08 | 0.23 | 29.34 | 7.08 |

| Face2 | 0.57 | 6.4 | 1.52 | −1.07 | 0.39 | 30.52 | 8.41 | |

| Grav_X | Face1 | 7.01 | −0.028 | −1.12 | 1.05 | −0.001 | 32.46 | 7.72 |

| Face2 | 7.02 | −0.28 | −1.11 | 1.06 | 0.29 | 36.56 | 8.62 | |

| Grav_Z | Face1 | 0.76 | −0.43 | −0.07 | 0.27 | −0.11 | 40.03 | 9.60 |

| Face2 | 0.57 | −0.35 | 0.1 | −0.07 | 0.23 | 40.95 | 9.64 |

| Load Case | Face | Tran_x (μm) | Tran_y (μm) | Rotation_x (″) | Rotation_y (″) | Rotation_z (″) | PV (nm) | RMS (nm) |

|---|---|---|---|---|---|---|---|---|

| 200k | Face1 | 0.3 | 2.6 | −1.31 | 0.62 | 0.77 | 12.47 | 2.41 |

| Face2 | −0.1 | 1.7 | −2.11 | 1.05 | 1.41 | 12.96 | 2.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, M.; Guo, J.; Qi, H.; Pang, X.; Li, Y. Research on Support Structure of Rectangular Cryogenic Infrared Lens with Large Aperture. Photonics 2024, 11, 1084. https://doi.org/10.3390/photonics11111084

Shao M, Guo J, Qi H, Pang X, Li Y. Research on Support Structure of Rectangular Cryogenic Infrared Lens with Large Aperture. Photonics. 2024; 11(11):1084. https://doi.org/10.3390/photonics11111084

Chicago/Turabian StyleShao, Mingdong, Jiang Guo, Hongyu Qi, Xinyuan Pang, and Yibo Li. 2024. "Research on Support Structure of Rectangular Cryogenic Infrared Lens with Large Aperture" Photonics 11, no. 11: 1084. https://doi.org/10.3390/photonics11111084

APA StyleShao, M., Guo, J., Qi, H., Pang, X., & Li, Y. (2024). Research on Support Structure of Rectangular Cryogenic Infrared Lens with Large Aperture. Photonics, 11(11), 1084. https://doi.org/10.3390/photonics11111084