High Performance Dual-Core D-Shaped PCF Refractive Index Sensor Coated with Gold Grating

Abstract

1. Introduction

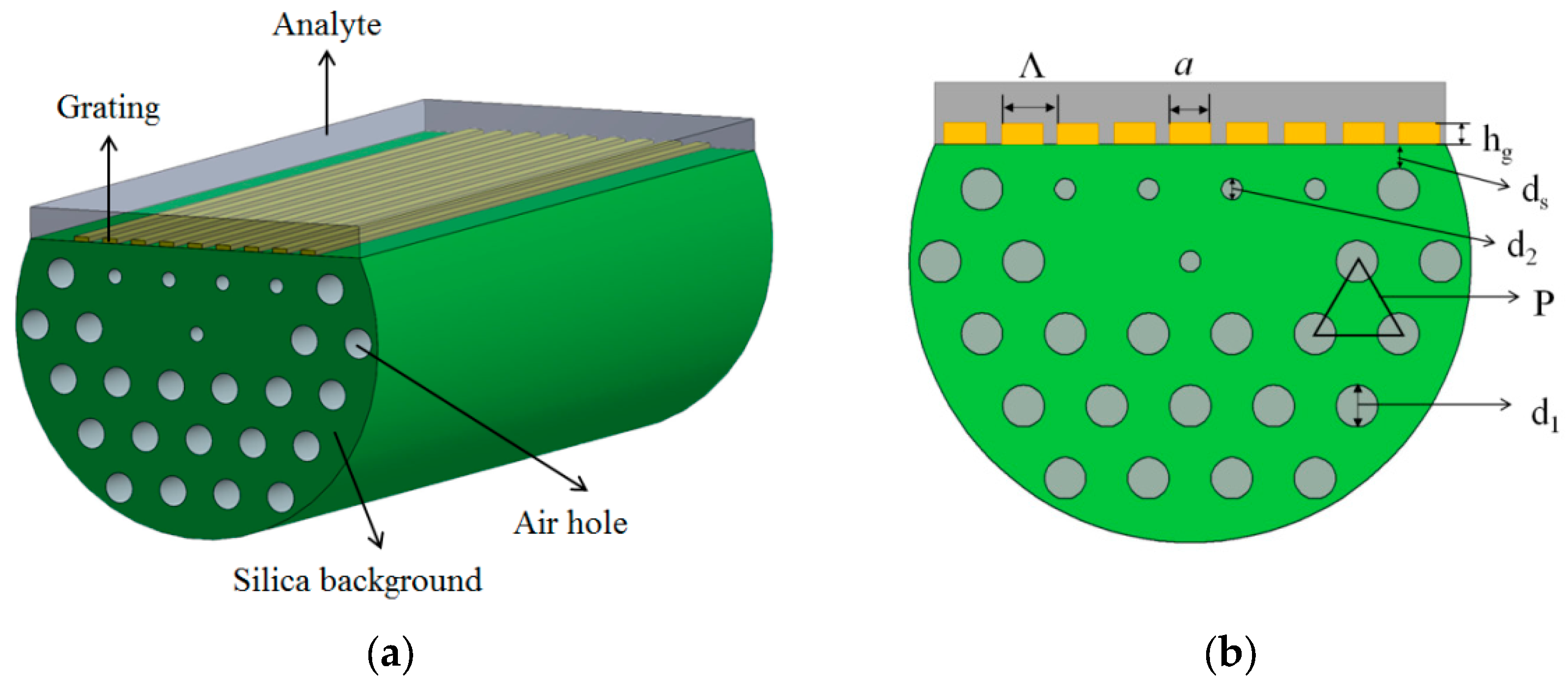

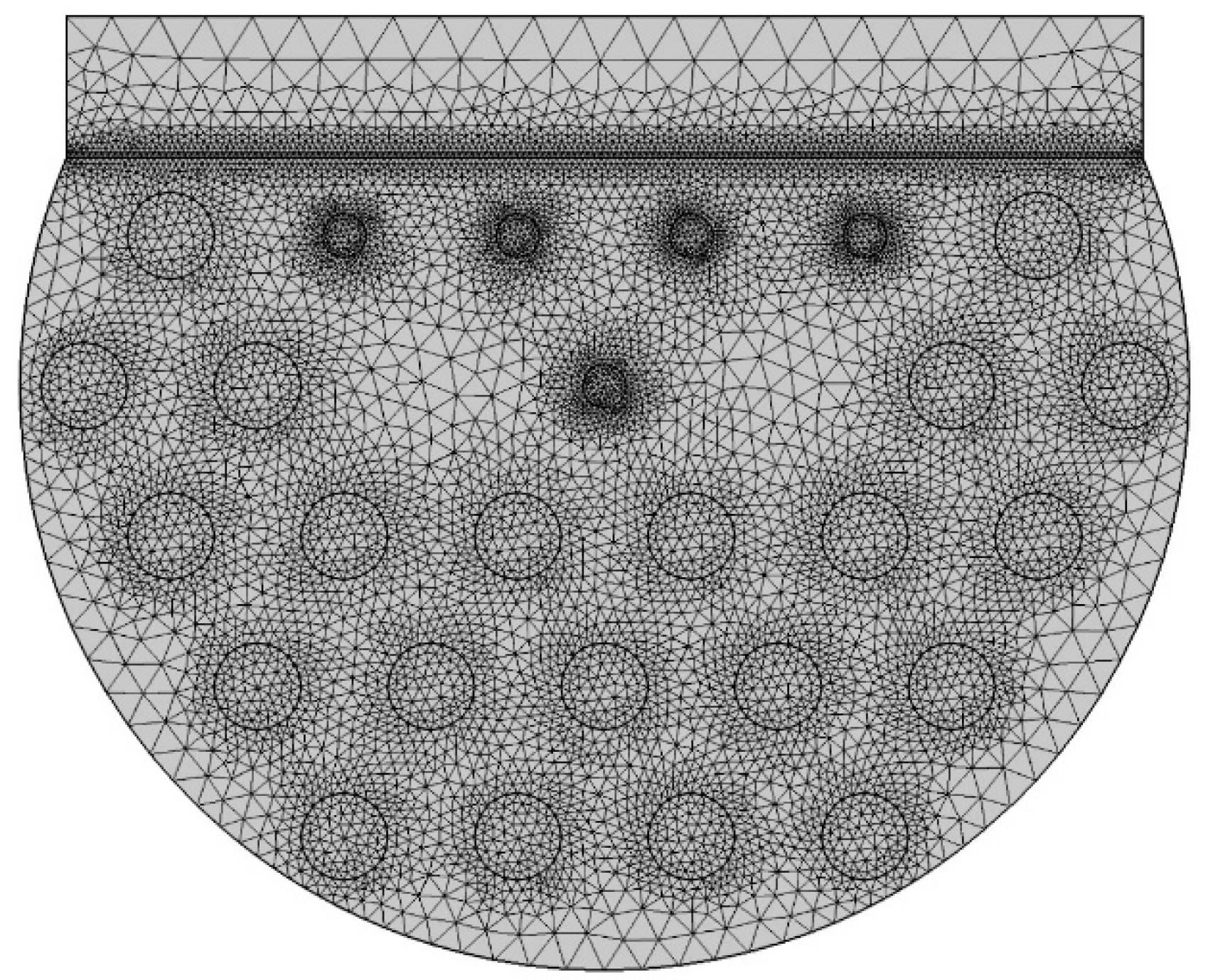

2. Design and Theoretical Method

3. Results and Discussions

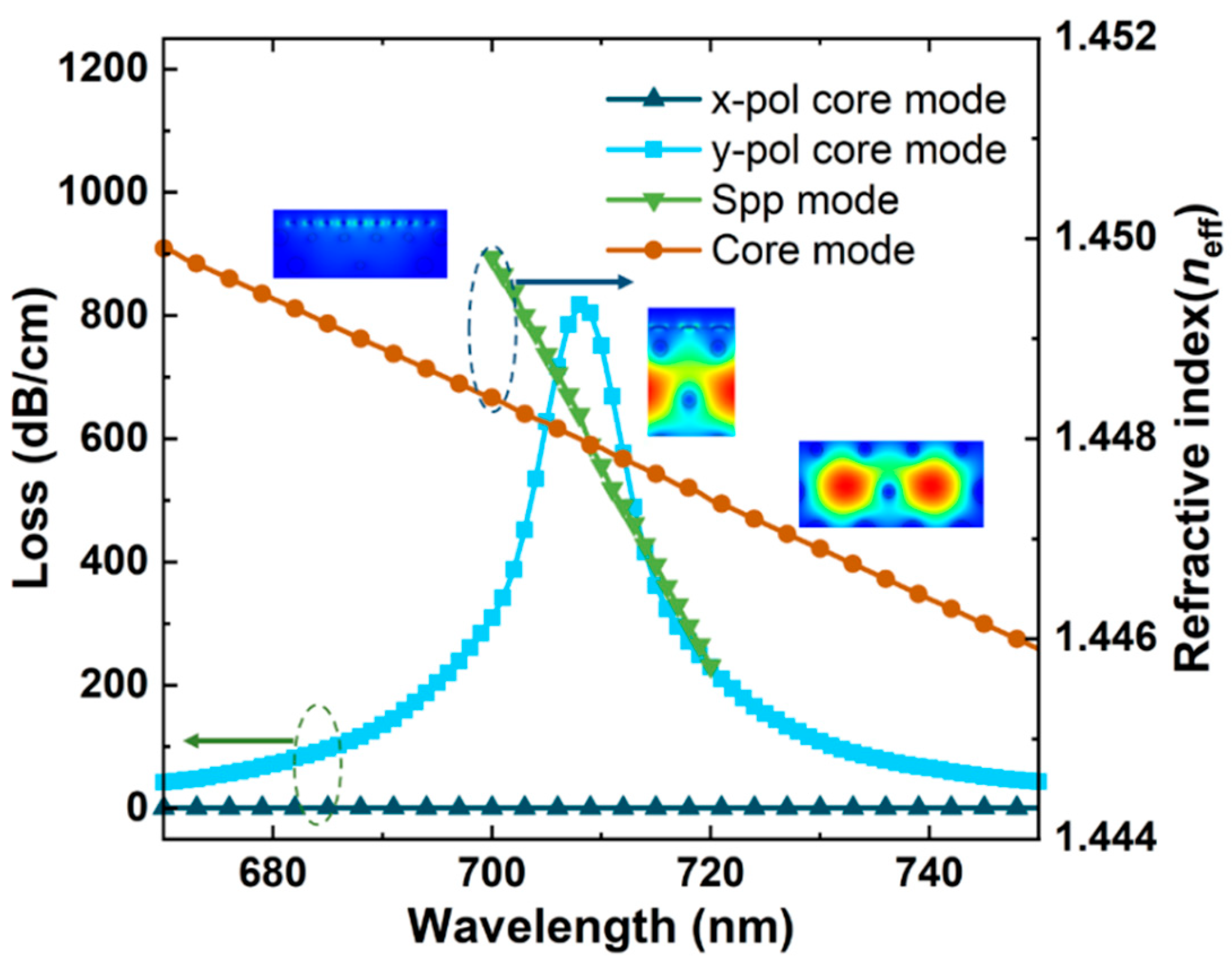

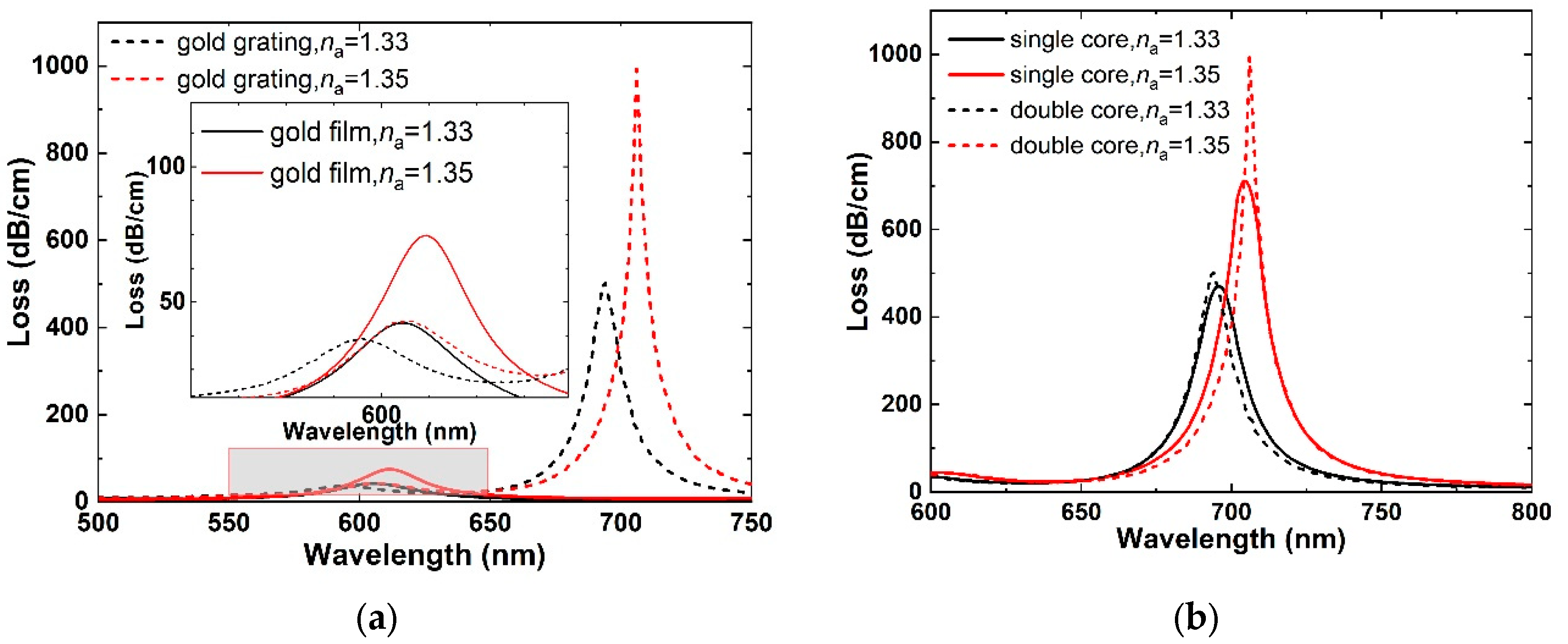

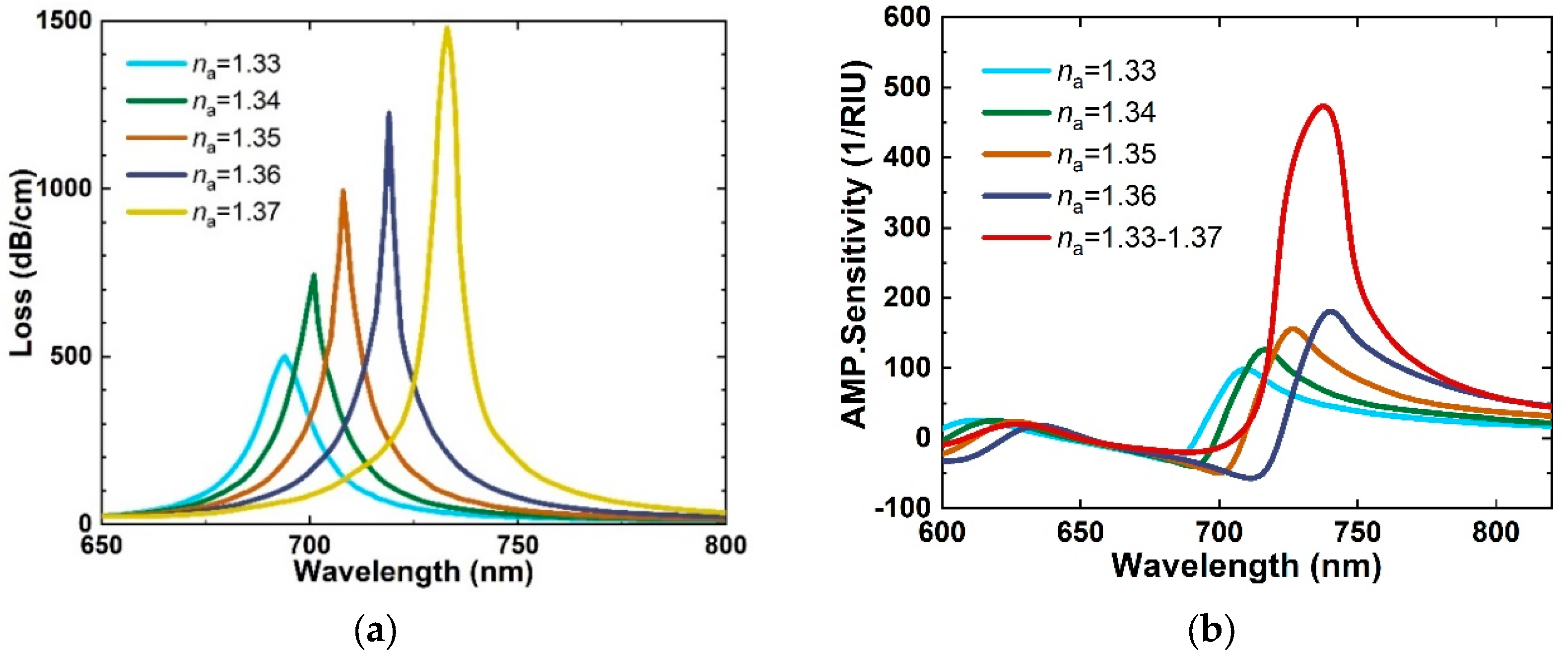

3.1. Sensitivity

3.2. Two-Feature (2F) Resolution

3.3. Investigation of the Proposed Sensor

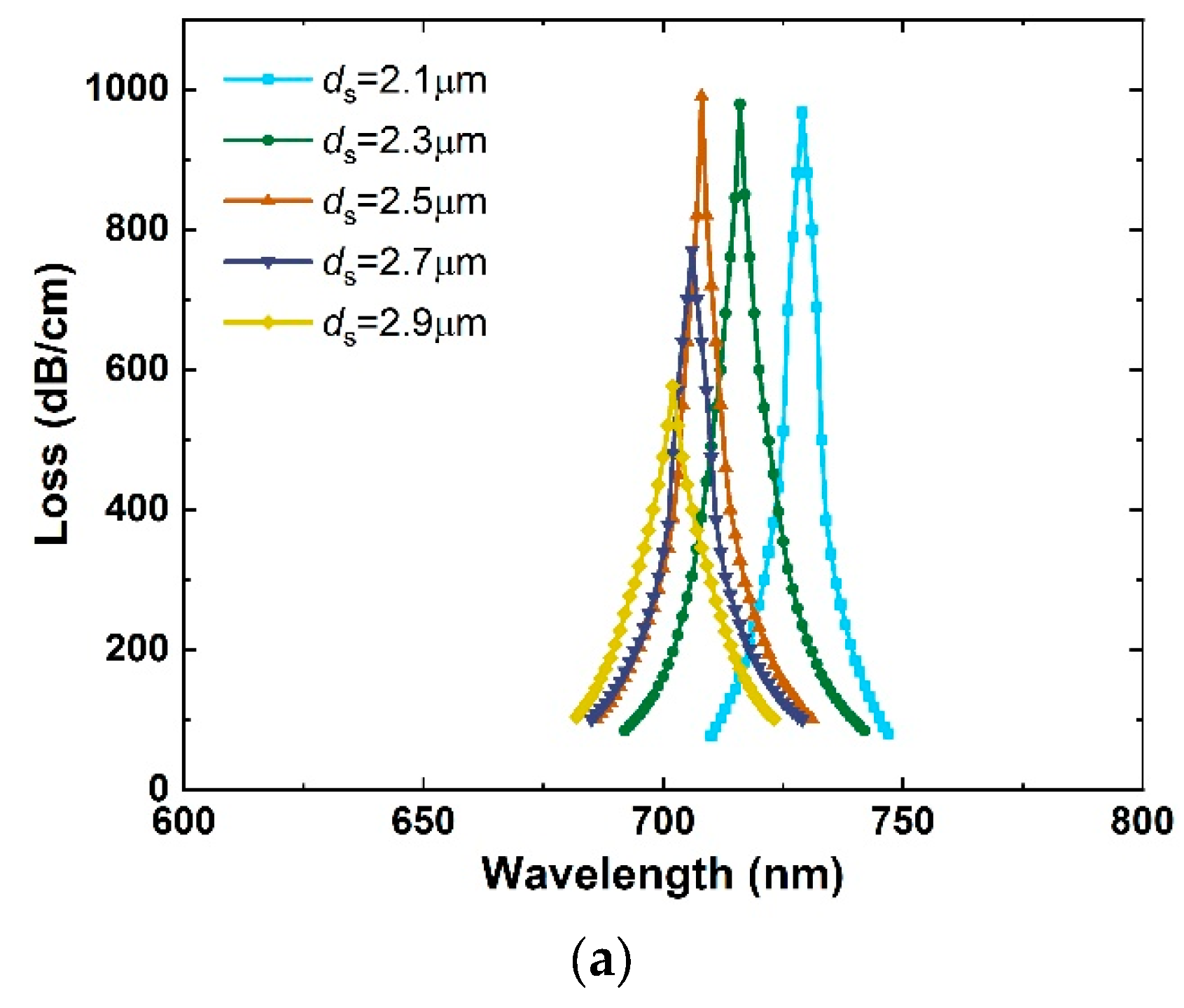

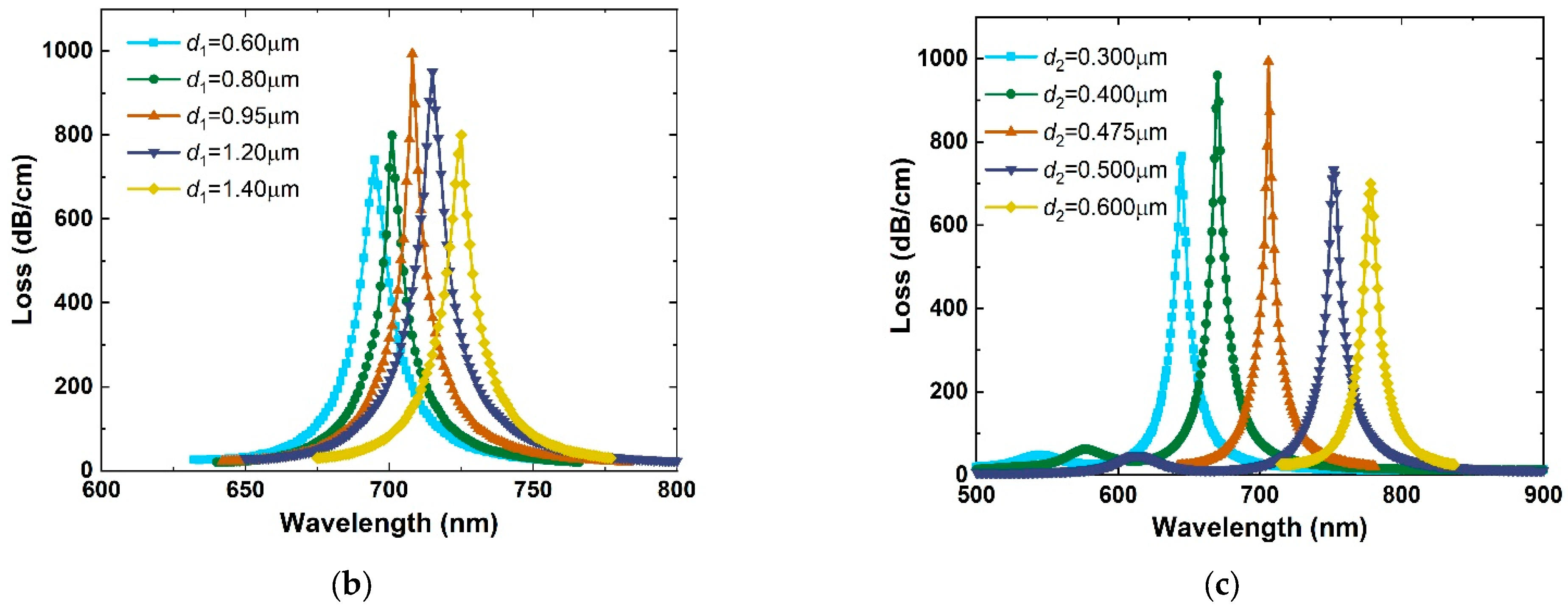

3.3.1. Effects of PCF Structural Parameters

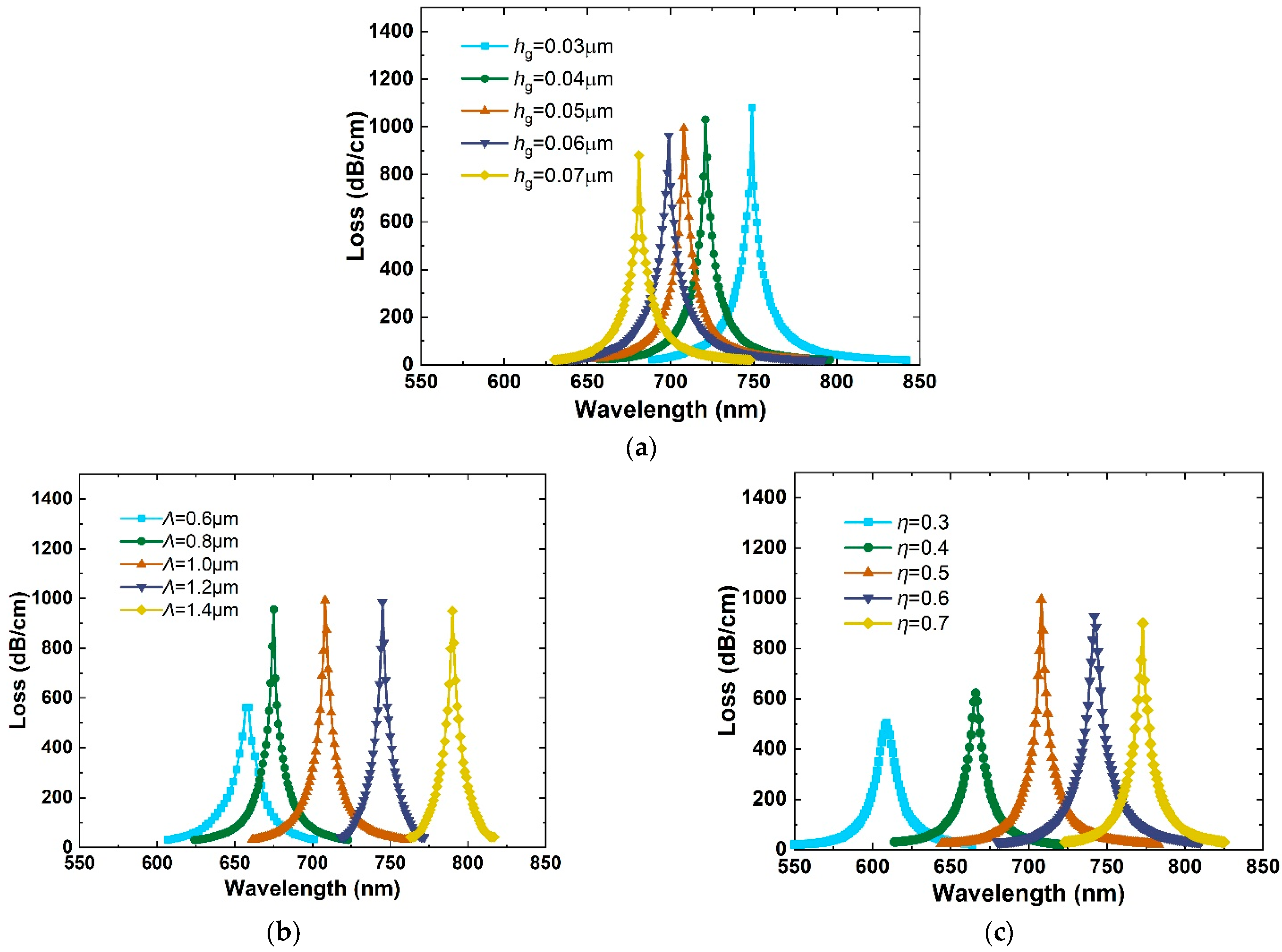

3.3.2. Effects of Gold Grating Structural Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Islam, M.R.; Khan, M.M.I.; Siraz, S.; Mehjabin, F.; Rahman, M.; Islam, M.; Anzum, M.S.; Chowdhury, J.A.; Noor, F. Design and analysis of a QC-SPR-PCF sensor for multipurpose sensing with supremely high FOM. Appl. Nanosci. 2022, 12, 29–45. [Google Scholar] [CrossRef]

- El-Saeed, A.H.; Khalil, A.E.; Hameed, M.F.O.; Azab, M.Y.; Obayya, S.S.A. Highly sensitive SPR PCF biosensors based on Ag/TiN and Ag/ZrN configurations. Opt. Quantum Electron. 2019, 51, 56. [Google Scholar] [CrossRef]

- Kaur, V.; Singh, S. Design of titanium nitride coated PCF-SPR sensor for liquid sensing applications. Opt. Fiber Technol. 2019, 48, 159–164. [Google Scholar] [CrossRef]

- Mittal, S.; Sharma, T.; Tiwari, M. Surface plasmon resonance based photonic crystal fiber biosensors: A review. Mater. Today Proc. 2021, 43, 3071–3074. [Google Scholar] [CrossRef]

- Paul, A.K.; Sarkar, A.K.; Khaleque, A. Dual-core photonic crystal fiber plasmonic refractive index sensor: A numerical analysis. Photonic Sens. 2019, 9, 151–161. [Google Scholar] [CrossRef]

- Li, J.; Chen, G.; Meng, F. A fiber-optic formic acid gas sensor based on molybdenum disulfide nanosheets and chitosan works at room temperature. Opt. Laser Technol. 2022, 150, 107975. [Google Scholar] [CrossRef]

- Wang, D.; Yi, Z.; Ma, G.; Dai, B.; Yang, J.; Zhang, J.; Yu, Y.; Liu, C.; Wu, X.; Bian, Q. Two-channel photonic crystal fiber based on surface plasmon resonance for magnetic field and temperature dual-parameter sensing. Phys. Chem. Chem. Phys. 2022, 24, 21233–21241. [Google Scholar] [CrossRef]

- Zhu, W.; Yi, Y.; Yi, Z.; Bian, L.; Yang, H.; Zhang, J.; Yu, Y.; Liu, C.; Li, G.; Wu, X. High confidence plasmonic sensor based on photonic crystal fibers with a U-shaped detection channel. Phys. Chem. Chem. Phys. 2023, 25, 8583–8591. [Google Scholar] [CrossRef]

- Nielsen, M.D.; Mortensen, N.A. Photonic crystal fiber design based on the V-parameter. Opt. Express 2003, 11, 2762–2768. [Google Scholar] [CrossRef]

- Uniyal, A.; Srivastava, G.; Pal, A.; Taya, S.; Muduli, A. Recent Advances in Optical Biosensors for Sensing Applications: A Review. Plasmonics 2023, 18, 735–750. [Google Scholar] [CrossRef]

- Karki, B.; Jha, A.; Pal, A.; Srivastava, V. Sensitivity enhancement of refractive index-based surface plasmon resonance sensor for glucose detection. Opt. Quantum Electron. 2022, 54, 595. [Google Scholar] [CrossRef]

- Rifat, A.A.; Ahmed, R.; Yetisen, A.K.; Butt, H.; Sabouri, A.; Mahdiraji, G.A.; Yun, S.H.; Adikan, F.M. Photonic crystal fiber based plasmonic sensors. Sens. Actuators B Chem. 2017, 243, 311–325. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, R.-J.; Xia, F.; Peng, Y. Current status of optical fiber biosensor based on surface plasmon resonance. Biosens. Bioelectron. 2019, 142, 111505. [Google Scholar] [CrossRef] [PubMed]

- Yesudasu, V.; Pradhan, H.S.; Pandya, R.J. Recent progress in surface plasmon resonance based sensors: A comprehensive review. Heliyon 2021, 7, e06321. [Google Scholar] [CrossRef] [PubMed]

- Popescu, V.; Sharma, A.K.; Marques, C. Resonant interaction between a core mode and two complementary supermodes in a honeycomb PCF reflector-based SPR sensor. Optik 2021, 227, 166121. [Google Scholar] [CrossRef]

- Chaudhary, V.S.; Kumar, D.; Kumar, S. Gold-immobilized photonic crystal fiber-based SPR biosensor for detection of malaria disease in human body. IEEE Sens. J. 2021, 21, 17800–17807. [Google Scholar] [CrossRef]

- Wang, J.; Pei, L.; Wu, L.; Wang, J.; Ruan, Z.; Zheng, J. A polarization-independent SPR sensor based on photonic crystal fiber for low RI detection. Plasmonics 2020, 15, 327–333. [Google Scholar] [CrossRef]

- Chaudhary, V.S.; Kumar, D.; Kumar, S. SPR-assisted photonic crystal fiber-based dual-wavelength single polarizing filter with improved performance. IEEE Trans. Plasma Sci. 2021, 49, 3803–3810. [Google Scholar] [CrossRef]

- Guo, Z.; Fan, Z.; Kong, X.; Meng, Z. Photonic crystal fiber based wide-range of refractive index sensor with phase matching between core mode and metal defect mode. Opt. Commun. 2020, 461, 125233. [Google Scholar] [CrossRef]

- Yang, H.; Wang, G.; Lu, Y.; Yao, J. Highly sensitive refractive index sensor based on SPR with silver and titanium dioxide coating. Opt. Quantum Electron. 2021, 53, 341. [Google Scholar] [CrossRef]

- Ying, Y.; Si, G.-Y.; Luan, F.-J.; Xu, K.; Qi, Y.-W.; Li, H.-N. Recent research progress of optical fiber sensors based on D-shaped structure. Opt. Laser Technol. 2017, 90, 149–157. [Google Scholar] [CrossRef]

- Sakib, M.N.; Hossain, M.B.; Al-tabatabaie, K.F.; Mehedi, I.M.; Hasan, M.T.; Hossain, M.A.; Amiri, I.S. High performance dual core D-shape PCF-SPR sensor modeling employing gold coat. Results Phys. 2019, 15, 102788. [Google Scholar] [CrossRef]

- Jabin, M.A.; Ahmed, K.; Rana, M.J.; Paul, B.K.; Luo, Y.; Vigneswaran, D. Titanium-coated dual-core D-shaped SPR-based PCF for hemoglobin sensing. Plasmonics 2019, 14, 1601–1610. [Google Scholar] [CrossRef]

- Singh, S.; Prajapati, Y.K. Highly sensitive dual-core symmetrical side-polished modified D-shaped SPR based PCF refractive index sensor with deeply etched micro openings. Optik 2021, 235, 166657. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Han, Y.; Liu, Y.; Gao, J. D-shaped photonic crystal fiber plasmonic refractive index sensor based on gold grating. Appl. Opt. 2018, 57, 5268–5272. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Wei, C.; Yang, H.; Zhao, B.; Yuan, L.; Li, J. D-Shaped Photonic Crystal Fiber Plasmonic Sensor Based on Silver-Titanium Dioxide Composite Micro-grating. Plasmonics 2021, 16, 2049–2059. [Google Scholar] [CrossRef]

- Wang, Q.; Jing, J.Y.; Wang, X.Z.; Niu, L.Y.; Zhao, W.M. A D-shaped fiber long-range surface plasmon resonance sensor with high Q-factor and temperature self-compensation. IEEE Trans. Instrum. Meas. 2019, 69, 2218–2224. [Google Scholar] [CrossRef]

- Dong, Y.; Wu, B.; Wang, M.; Xiao, H.; Xiao, S.; Sun, C.; Li, H.; Jian, S. Magnetic field and temperature sensor based on D-shaped fiber modal interferometer and magnetic fluid. Opt. Laser Technol. 2018, 107, 169–173. [Google Scholar] [CrossRef]

- Li, J.; Liu, B.; Liu, J.; Shi, J.-L.; He, X.-D.; Yuan, J.; Wu, Q. Low-cost wearable device based D-shaped single mode fiber curvature sensor for vital signs monitoring. Sens. Actuators A Phys. 2022, 337, 113429. [Google Scholar] [CrossRef]

- Lin, K.; Lu, Y.; Chen, J.; Zheng, R.; Wang, P.; Ming, H. Surface plasmon resonance hydrogen sensor based on metallic grating with high sensitivity. Opt. Express 2008, 16, 18599–18604. [Google Scholar] [CrossRef]

- Pathak, A.K.; Singh, V.K. SPR based optical fiber refractive index sensor using silver nanowire assisted CSMFC. IEEE Photonics Technol. Lett. 2020, 32, 465–468. [Google Scholar] [CrossRef]

- Zhu, L.; Zhao, N.; Lin, Q.; Zhao, L.; Jiang, Z. Optical fiber SPR magnetic field sensor based on photonic crystal fiber with the magnetic fluid as cladding. Meas. Sci. Technol. 2021, 32, 075106. [Google Scholar] [CrossRef]

- D’Amico, A.; Di Natale, C. A contribution on some basic definitions of sensors properties. IEEE Sens. J. 2001, 1, 183–190. [Google Scholar] [CrossRef]

- Huang, Q.; Zeng, D.; Li, H.; Xie, C. Room temperature formaldehyde sensors with enhanced performance, fast response and recovery based on zinc oxide quantum dots/graphene nanocomposites. Nanoscale 2012, 4, 5651–5658. [Google Scholar] [CrossRef]

- Divya, J.; Selvendran, S.; Raja, A.S.; Sivasubramanian, A. Graphene-Au-Coated Plasmonic Sensor Based on D-Shaped Bezier Polygonal Hollow Core Photonic Crystal Fiber. Braz. J. Phys. 2021, 51, 1314–1323. [Google Scholar] [CrossRef]

- An, G.; Li, S.; Yan, X.; Zhang, X.; Yuan, Z.; Zhang, Y. High-sensitivity and tunable refractive index sensor based on dual-core photonic crystal fiber. J. Opt. Soc. Am. B 2016, 33, 1330–1334. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, Q.; Li, X.; Zhou, H.; Hong, X.; Geng, Y. Experimental realization of D-shaped photonic crystal fiber SPR sensor. J. Phys. D Appl. Phys. 2016, 50, 025101. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Li, S.; Liu, Q.; Wu, J.; Guo, Y. Surface plasmon resonance sensor based on D-shaped photonic crystal fiber with two micro-openings. J. Phys. D Appl. Phys. 2018, 51, 305104. [Google Scholar] [CrossRef]

- Falah, A.A.S.; Wong, W.R.; Adikan, F.R.M. Single-mode eccentric-core D-shaped photonic crystal fiber surface plasmon resonance sensor. Opt. Laser Technol. 2022, 145, 107474. [Google Scholar] [CrossRef]

- Gangwar, R.K.; Amorim, V.A.; Marques, P.V.S. High performance titanium oxide coated D-shaped optical fiber plasmonic sensor. IEEE Sens. J. 2019, 19, 9244–9248. [Google Scholar] [CrossRef]

- Khanikar, T.; Singh, V.K. Gold grating assisted SPR based D-shaped single mode fiber for detection of liquid refractive index. Opt. Quantum Electron. 2019, 51, 296. [Google Scholar] [CrossRef]

- An, G.; Li, S.; Cheng, T.; Yan, X.; Zhang, X.; Zhou, X.; Yuan, Z. Ultra-stable D-shaped optical fiber refractive index sensor with graphene-gold deposited platform. Plasmonics 2019, 14, 155–163. [Google Scholar] [CrossRef]

| RI of Analyte (RIU) | 1.33 | 1.34 | 1.35 | 1.36 | 1.37 |

|---|---|---|---|---|---|

| Wavelength (nm) | 694.11 | 701.47 | 708.26 | 719.35 | 733.89 |

| Loss (dB/cm) | 502.07 | 743.33 | 993.25 | 1225.22 | 1480.66 |

| Sensing Type | Detection Range | Linearity | Resolution (RIU) | Ref |

|---|---|---|---|---|

| All-glass endless single-mode PCF | 1.33–1.37 | 0.9544 | 6.53 × 10−5 | [37] |

| D-shaped PCF with two micro-openings | 1.33–1.37 | 0.9712 | 8.51 × 10−6 | [38] |

| Single-mode eccentric-core D-shaped PCF | 1.33–1.37 | 0.9308 | 4.72 × 10−6 | [39] |

| D-shaped PCF with a gold layer covered by a TiO2 layer | 1.36–1.41 | 0.9355 | 3.33 × 10−6 | [40] |

| Gold grating assisted D-shaped fiber | 1.34–1.38 | 0.9890 | 1.31 × 10−5 | [41] |

| D-shaped PCF with graphene-gold deposited platform | 1.33–1.39 | 0.9574 | 2.28 × 10−5 | [42] |

| Dual-core D-shaped PCF coated with gold grating | 1.33–1.34 | 2.075 × 10−6 | Present work | |

| 1.34–1.35 | 0.9742 | 1.998 × 10−6 | ||

| 1.34–1.36 | 2.157 × 10−6 | |||

| 1.36–1.37 | 1.956 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, Y.; Xia, Y.; Cheng, S.; Shan, D.; Gao, Z.; Si, G.; Tian, X. High Performance Dual-Core D-Shaped PCF Refractive Index Sensor Coated with Gold Grating. Photonics 2023, 10, 473. https://doi.org/10.3390/photonics10040473

Ying Y, Xia Y, Cheng S, Shan D, Gao Z, Si G, Tian X. High Performance Dual-Core D-Shaped PCF Refractive Index Sensor Coated with Gold Grating. Photonics. 2023; 10(4):473. https://doi.org/10.3390/photonics10040473

Chicago/Turabian StyleYing, Yu, You Xia, Siyu Cheng, Dan Shan, Zhijun Gao, Guangyuan Si, and Xiaoxi Tian. 2023. "High Performance Dual-Core D-Shaped PCF Refractive Index Sensor Coated with Gold Grating" Photonics 10, no. 4: 473. https://doi.org/10.3390/photonics10040473

APA StyleYing, Y., Xia, Y., Cheng, S., Shan, D., Gao, Z., Si, G., & Tian, X. (2023). High Performance Dual-Core D-Shaped PCF Refractive Index Sensor Coated with Gold Grating. Photonics, 10(4), 473. https://doi.org/10.3390/photonics10040473