Facile Preparation of Au–Ag Composite Nanostructure for High-Sensitive and Uniform Surface-Enhanced Raman Spectroscopy

Abstract

1. Introduction

2. Method

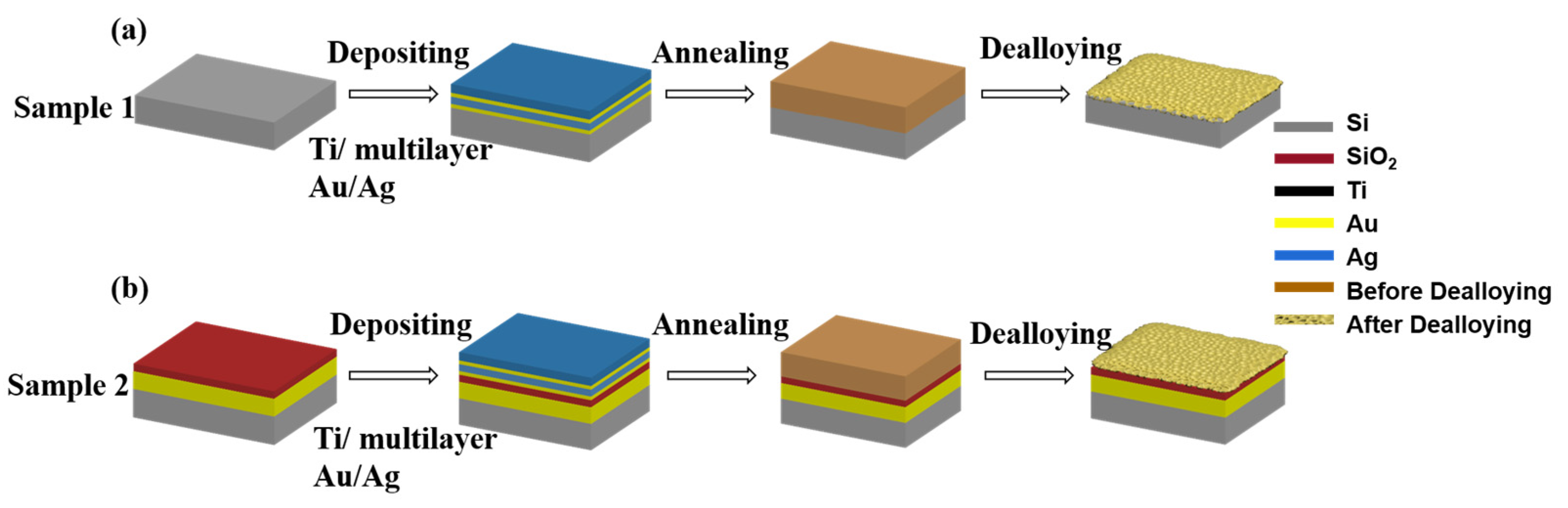

2.1. Sample Fabrication

2.2. Structural Characterization and SERS Measurements

2.3. Simulations

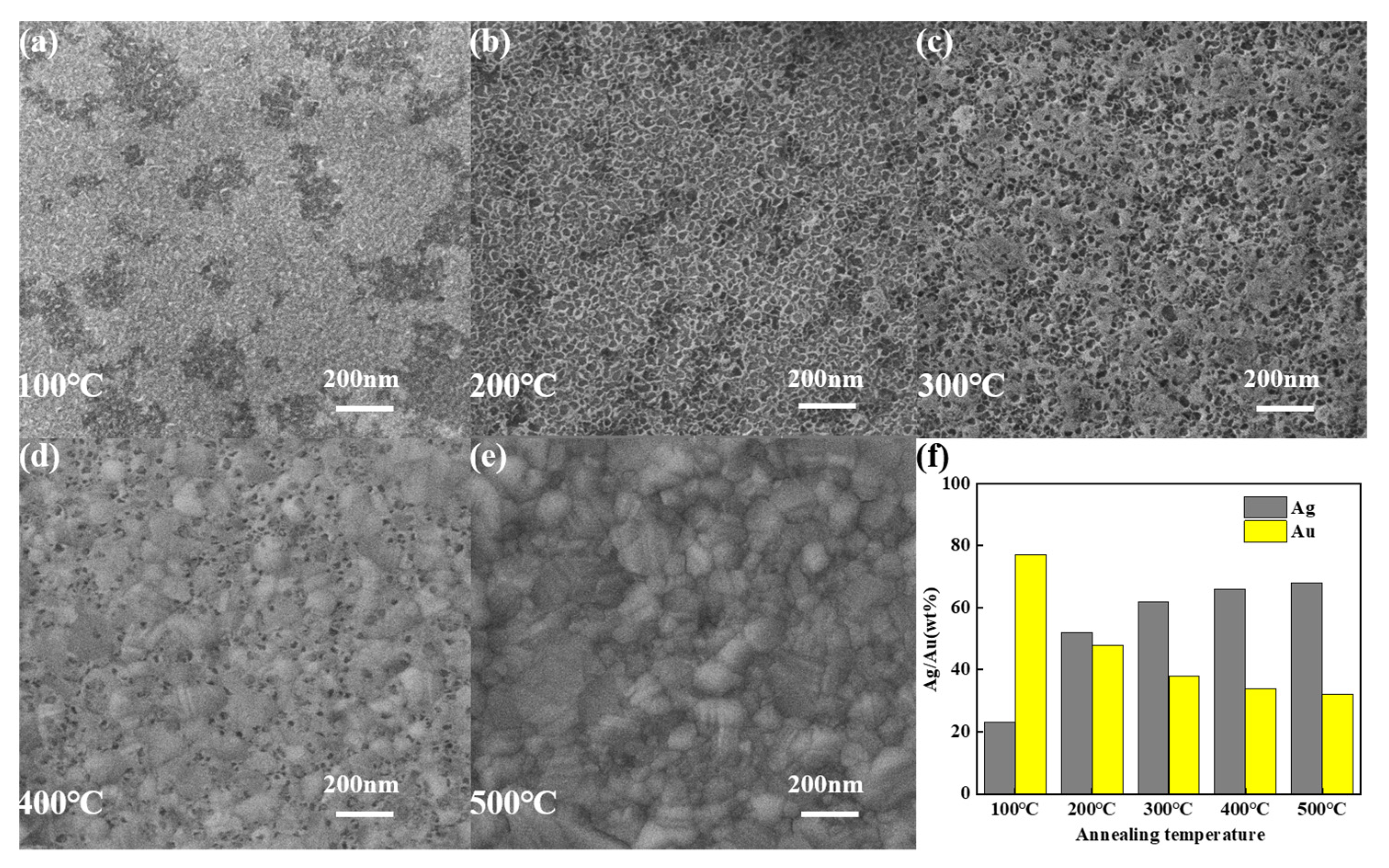

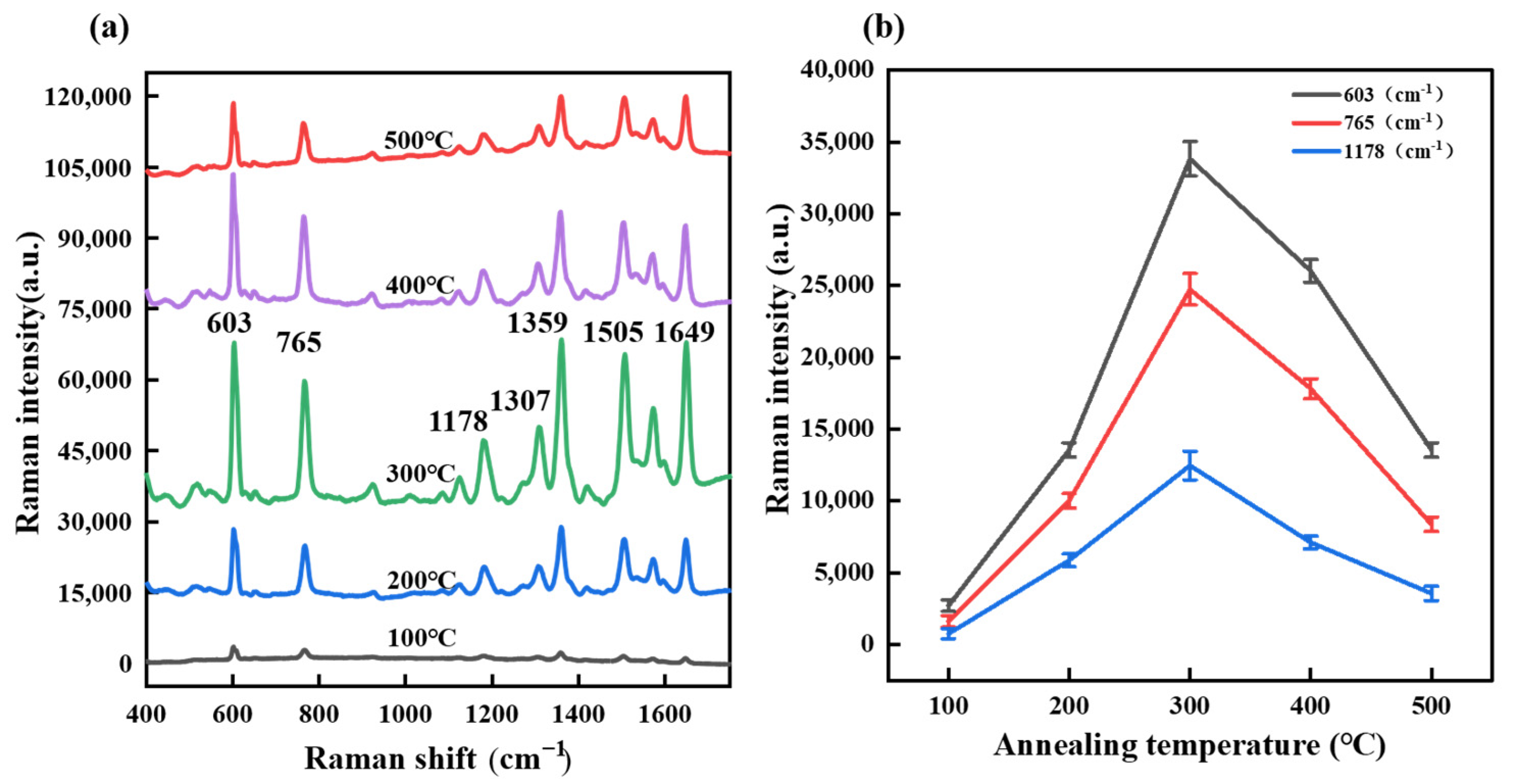

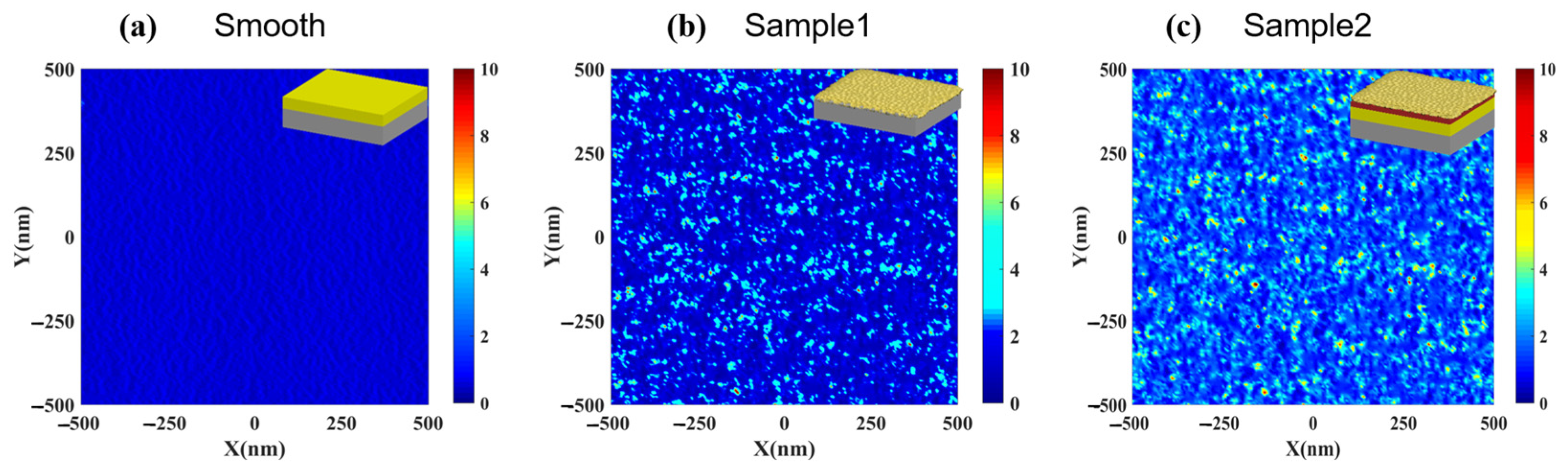

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baptista, P.; Pereira, E.; Eaton, P. Gold nanoparticles for the development of clinical diagnosis methods. Anal. Bioanal. Chem. 2008, 391, 943–950. [Google Scholar] [CrossRef] [PubMed]

- Lim, W.Q.; Gao, Z. Plasmonic nanoparticles in biomedicine. Nano Today 2016, 11, 168–188. [Google Scholar] [CrossRef]

- Zheng, T.; Li, G.G.; Li, F.Z.; Wu, R. Gold-Nanosponge-Based Multistimuli-Responsive Drug Vehicles for Targeted Chemo-Photothermal Therapy. Adv. Mater. 2016, 28, 8218–8226. [Google Scholar] [CrossRef] [PubMed]

- D’Acunto, M.; Cioni, P.; Gabellieri, E.; Presciuttini, G. Exploiting gold nanoparticles for diagnosis and cancer treatments. Nanotechnology 2021, 32, 192001. [Google Scholar] [CrossRef] [PubMed]

- Yaseen, T.; Pu, H.; Sun, D.W. Functionalization techniques for improving SERS substrates and their applications in food safety evaluation: A review of recent research trends. Trends Food Sci. Technol. 2018, 72, 162–174. [Google Scholar]

- Feng, J.; Hu, Y.; Grant, E.; Lu, X. Determination of thiabendazole in orange juice using an MISPE-SERS chemosensor. Food Chem. 2018, 239, 816–822. [Google Scholar] [CrossRef]

- Wang, P.; Pang, S.; Pearson, B.; Chujo, Y. Rapid concentration detection and differentiation of bacteria in skimmed milk using surface enhanced Raman scattering mapping on 4-mercaptophenylboronic acid functionalized silver dendrites. Anal. Bioanal. Chem. 2017, 409, 2229–2238. [Google Scholar] [CrossRef]

- Hu, Y.; Feng, S.; Gao, F.; Li-Chan, E.C. Detection of melamine in milk using molecularly imprinted polymers-surface enhanced Raman spectroscopy. Food Chem. 2015, 176, 123–129. [Google Scholar] [CrossRef]

- Yang, Y.; Creedon, N.; O’Riordan, A.; Lovera, P. Surface Enhanced Raman Spectroscopy: Applications in Agriculture and Food Safety. Photonics 2021, 8, 568. [Google Scholar] [CrossRef]

- Yue, S.; Ye, W.; Xu, Z. SERS monitoring of the Fenton degradation reaction based on microfluidic droplets and alginate microparticles. Analyst 2019, 144, 5882–5889. [Google Scholar] [CrossRef]

- Yu, J.; Yang, M.; Li, Z.; Liu, C.; Wei, Y.; Zhang, C. Hierarchical particle-in-quasicavity architecture for ultratrace in situ Raman sensing and its application in real-time monitoring of toxic pollutants. Anal. Chem. 2020, 92, 14754–14761. [Google Scholar] [CrossRef] [PubMed]

- Pal, P.; Bonyár, A.; Veres, M.; Himics, L. A generalized exponential relationship between the surface-enhanced Raman scattering (SERS) efficiency of gold/silver nanoisland arrangements and their non-dimensional interparticle distance/particle diameter ratio. Sens. Actuator A-Phys. 2020, 314, 112225. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Y.; Zhang, S.; Yang, W.; Chen, J. Ultrasensitive SERS detection of crystal violet and malachite green based on high surface roughness copper nanocorns prepared via solid-state ionics method. Sens. Actuator A-Phys. 2021, 331, 113042. [Google Scholar] [CrossRef]

- Campion, A.; Kambhampati, P. Surface-enhanced Raman scattering. Chem. Soc. Rev. 1998, 27, 241–250. [Google Scholar]

- Liu, Z.; Yang, Z.; Peng, B.; Cao, C.; Zhang, H.Y. Highly sensitive, uniform, and reproducible surface-enhanced Raman spec troscopy from hollow Au-Ag alloy nanourchins. Adv. Mater. 2014, 26, 2431–2439. [Google Scholar] [CrossRef]

- Ebrahimzadeh Esfahani, N.; Kováč, J.; Kováčová, S.; Feile, M. Plasmonic Properties of the Metal Nanoparticles (NPs) on a Metal Mirror Separated by an Ultrathin Oxide Layer. Photonics 2023, 10, 78. [Google Scholar] [CrossRef]

- Barbillon, G. Au Nanoparticles Coated ZnO Film for Chemical Sensing by PIERS Coupled to SERS. Photonics 2022, 9, 562. [Google Scholar] [CrossRef]

- Lee, H.; Lee, J.H.; Jin, S.M.; Suh, Y.D.; Nam, J.M. Single-molecule and single-particle-based correlation studies between localized surface plasmons of dimeric nanostructures with ~1 nm gap and surface-enhanced Raman scattering. Nano Lett. 2013, 13, 6113–6121. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, W.; Chu, Y.; Crozier, K.B. High directivity optical antenna substrates for surface enhanced Raman scattering. Adv. Mater. 2012, 24, 4376–4380. [Google Scholar] [CrossRef] [PubMed]

- Hatab, N.A.; Hsueh, C.H.; Gaddis, A.L.; Retterer, S.T. Free-standing optical gold bowtie nanoantenna with variable gap size for enhanced Raman spectroscopy. Nano Lett. 2010, 10, 4952–4955. [Google Scholar] [CrossRef]

- Shen, Y.; Cheng, X.; Li, G.; Zhu, Q.; Chi, Z.; Wang, J. Highly sensitive and uniform surface-enhanced Raman spectroscopy from grating-integrated plasmonic nanograss. Nanoscale Horiz. 2016, 1, 290–297. [Google Scholar] [CrossRef]

- Wei, X.; Fan, Q.; Liu, H.; Bai, Y.; Zhang, L.; Zheng, H. Holey Au-Ag alloy nanoplates with built-in hotspots for surface-enhanced Raman scattering. Nanoscale 2016, 8, 15689–15695. [Google Scholar] [CrossRef]

- Fu, Z.; Shen, Z.; Fan, Q.; Hao, S.; Wang, Y.; Liu, X. Preparation of multi-functional magnetic-plasmonic nanocomposite for adsorp tion and detection of thiram using SERS. J. Hazard. Mater. 2020, 392, 122356. [Google Scholar] [CrossRef]

- Xu, J.; Du, J.; Jing, C.; Zhang, Y.; Cui, J. Facile detection of polycyclic aromatic hydrocarbons by a surface-enhanced Raman scattering sensor based on the Au coffee ring effect. ACS Appl. Mater. Interfaces 2014, 6, 6891–6897. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.H.; Zhu, J.; Li, J.J.; Zhao, J.W. Small and sharp triangular silver nanoplates synthesized utilizing tiny triangular nuclei and their excellent SERS activity for selective detection of thiram residue in soil. ACS Appl. Mater. Interfaces 2017, 9, 17387–17398. [Google Scholar] [CrossRef]

- Thacker, V.V.; Herrmann, L.O.; Sigle, D.O.; Zhang, T. DNA origami based assembly of gold nanoparticle dimers for surface-enhanced Raman scattering. Nat. Commun. 2014, 5, 3448. [Google Scholar] [CrossRef] [PubMed]

- Niu, W.; Chua, Y.A.; Zhang, W.; Huang, H.; Lu, X. Highly Symmetric Gold Nanostars: Crystallographic Control and Surface-Enhanced Raman Scattering Property. J. Am. Chem. Soc. 2015, 137, 10460–10463. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Forbes, T.Z.; Haes, A.J. SERS detection of uranyl using functionalized gold nanostars promoted by nanoparticle shape and size. Analyst 2016, 141, 5137–5143. [Google Scholar] [CrossRef]

- Fang, X.G.; Zheng, C.X.; Yin, Z.; Wang, Z.M. Hierarchically ordered silicon metastructures from improved self-assembly-based nanosphere lithography. ACS Appl. Mater. Interfaces 2020, 12, 12345–12352. [Google Scholar] [CrossRef]

- Pisco, M.; Galeotti, F.; Grisci, G.; Quero, G. Self-assembled periodic patterns on the optical fiber tip by microsphere arrays. In Proceedings of the 24th International Conference on Optical Fibre Sensors, Curitiba, Brazil, 28 September–2 October 2015. [Google Scholar]

- Tang, H.; Meng, G.; Li, Z.; Zhu, C.; Huang, Z.; Wang, Z. Hexagonally arranged arrays of urchin-like Ag hemispheres decorated with Ag nanoparticles for surface-enhanced Raman scattering substrates. Nano Res. 2015, 8, 2261–2270. [Google Scholar] [CrossRef]

- Wu, G.; Cao, F.; Zhao, P.; Zhang, X.; Li, Z.; Yu, N. Novel periodic bilayer Au nanostructures for ultrasensitive surface-enhanced Raman spectroscopy. Adv. Mater. Interfaces 2018, 5, 1800820. [Google Scholar] [CrossRef]

- Koya, A.N.; Zhu, X.; Ohannesian, N.; Yanik, A.A. Nanoporous metals: From plasmonic properties to applications in enhanced spectroscopy and photocatalysis. ACS Nano 2021, 15, 6038–6060. [Google Scholar] [CrossRef]

- Liu, G.; Li, K.; Zhang, Y.; Du, J.; Ghafoor, S.; Lu, Y. A facile periodic porous Au nanoparticle array with high-density and built-in hotspots for SERS analysis. Appl. Surf. Sci. 2020, 527, 146807. [Google Scholar] [CrossRef]

- Mandal, M.; Ranjan Jana, N.; Kundu, S.; Kumar Ghosh, S. Synthesis of Aucore–Agshell type bimetallic nanoparticles for single molecule detection in solution by SERS method. J. Nanoparticle Res. 2004, 6, 53–61. [Google Scholar] [CrossRef]

- Gao, C.; Hu, Y.; Wang, M.; Chi, M.; Yin, Y. Fully alloyed Ag/Au nanospheres: Combining the plasmonic property of Ag with the stability of Au. J. Am. Chem. Soc. 2014, 136, 7474–7479. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Sun, Y.; Hang, L.; Li, H.; Liu, G.; Zhang, X. Periodic Porous Alloyed Au-Ag Nanosphere Arrays and Their Highly Sensitive SERS Performance with Good Reproducibility and High Density of Hotspots. ACS Appl. Mater. Interfaces 2018, 10, 9792–9801. [Google Scholar] [CrossRef]

- Liu, K.; Bai, Y.; Zhang, L.; Yang, Z.; Fan, Q.; Zheng, H. Porous Au–Ag Nanospheres with High-Density and Highly Accessible Hotspots for SERS Analysis. Nano Lett. 2016, 16, 3675–3681. [Google Scholar] [CrossRef]

- Li, K.; Liu, G.; Zhang, S.; Dai, Y.; Ghafoor, S.; Huang, W. A porous Au-Ag hybrid nanoparticle array with broadband absorption and high-density hotspots for stable SERS analysis. Nanoscale 2019, 11, 9587–9592. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids II; Academic Press: Boston, MA, USA, 1990; Volume 1, pp. 77–135. [Google Scholar]

- Sharma, B.; Frontiera, R.R.; Henry, A.-I. SERS: Materials, applications, and the future. Mater. Today 2012, 15, 16–25. [Google Scholar] [CrossRef]

- Yan, Y.; Radu, A.I.; Rao, W.; Wang, H. Mesoscopically Bi-continuous Ag−Au Hybrid Nanosponges with Tunable Plasmon Resonances as Bottom-Up Substrates for SurfaceEnhanced Raman Spectroscopy. Chem. Mater. 2016, 28, 7673–7682. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Yan, Z.; Zhang, W.; Wen, K.; Sun, B.; Hu, X.; Qin, Y. Facile Preparation of Au–Ag Composite Nanostructure for High-Sensitive and Uniform Surface-Enhanced Raman Spectroscopy. Photonics 2023, 10, 354. https://doi.org/10.3390/photonics10040354

Liu W, Yan Z, Zhang W, Wen K, Sun B, Hu X, Qin Y. Facile Preparation of Au–Ag Composite Nanostructure for High-Sensitive and Uniform Surface-Enhanced Raman Spectroscopy. Photonics. 2023; 10(4):354. https://doi.org/10.3390/photonics10040354

Chicago/Turabian StyleLiu, Wenjie, Zhonghua Yan, Weina Zhang, Kunhua Wen, Bo Sun, Xiaolong Hu, and Yuwen Qin. 2023. "Facile Preparation of Au–Ag Composite Nanostructure for High-Sensitive and Uniform Surface-Enhanced Raman Spectroscopy" Photonics 10, no. 4: 354. https://doi.org/10.3390/photonics10040354

APA StyleLiu, W., Yan, Z., Zhang, W., Wen, K., Sun, B., Hu, X., & Qin, Y. (2023). Facile Preparation of Au–Ag Composite Nanostructure for High-Sensitive and Uniform Surface-Enhanced Raman Spectroscopy. Photonics, 10(4), 354. https://doi.org/10.3390/photonics10040354