Design and Fabrication of Highly Selective Polarizers Using Metallic–Dielectric Gratings

Abstract

1. Introduction

2. Theoretical Design and Assessment

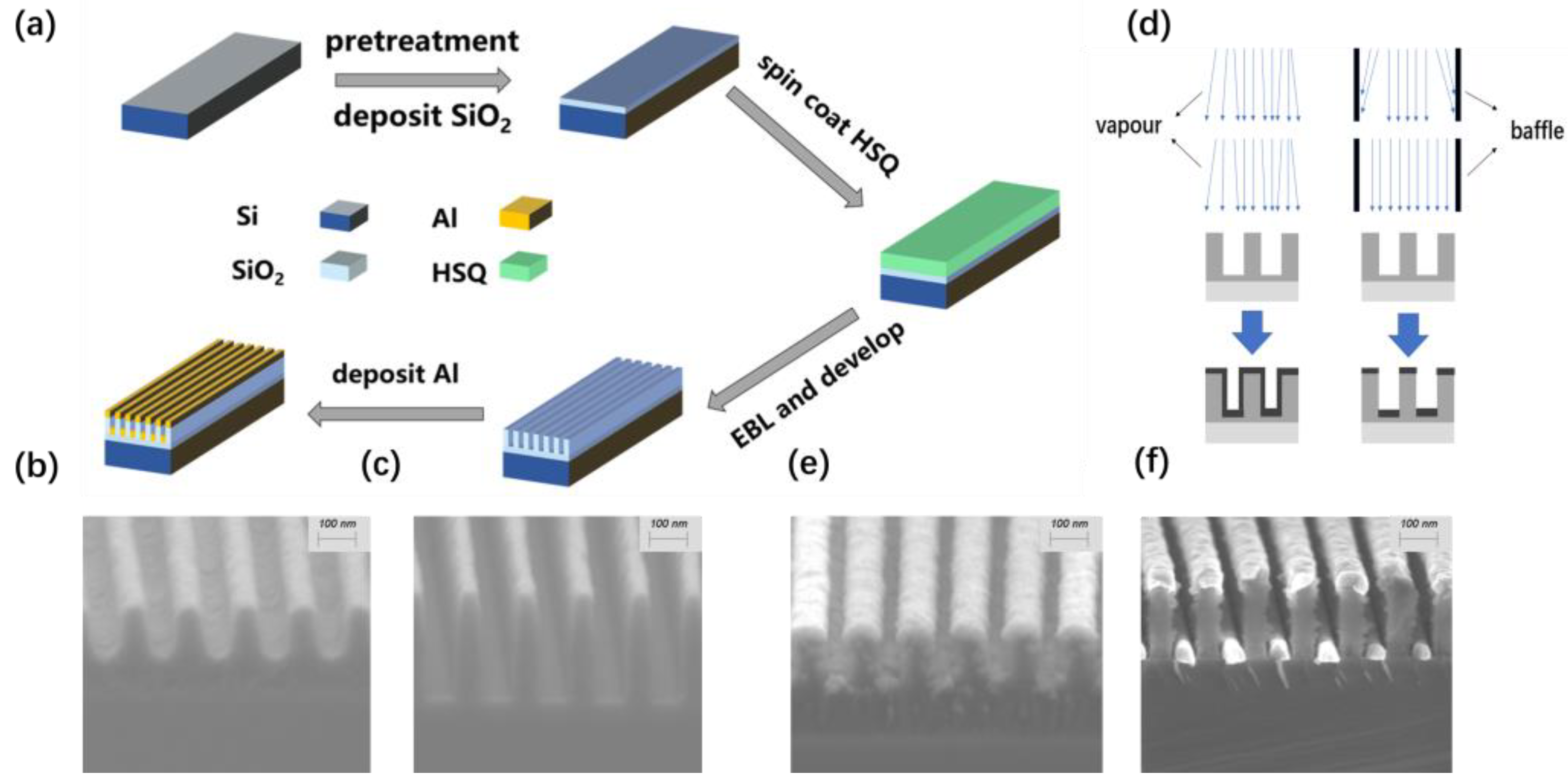

3. Fabrication Process and Results

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andreou, A.G.; Kalayjian, Z.K. Polarization imaging: Principles and integrated polarimeters. IEEE Sens. J. 2002, 2, 566–576. [Google Scholar] [CrossRef]

- Magnusson, R.; Wang, S.S. Transmission bandpass guided-mode resonance filters. Appl. Opt. 1995, 34, 8106–8109. [Google Scholar] [CrossRef] [PubMed]

- Lopez, A.G.; Craighead, I.I.G. Wave-plate polarizing beam splitter based on a form-birefringent multilayer grating. Opt. Lett. 1998, 23, 1627–1629. [Google Scholar] [CrossRef] [PubMed]

- Gruev, V.; Perkins, R.; York, T. CCD polarization imaging sensor with aluminum nanowire optical filters. Opt. Express 2010, 18, 19087–19094. [Google Scholar] [CrossRef]

- Tokuda, T.; Sato, S.; Yamada, H.; Sasagawa, K.; Ohta, J. Polarisation-analysing CMOS photosensor with monolithically embedded wire grid polariser. Electron. Lett. 2009, 45, 228–229. [Google Scholar] [CrossRef]

- Mateus, C.F.R.; Huang, M.C.Y.; Deng, Y.F.; Neureuther, A.R.; Chang-Hasnain, C.J. Ultrabroadband mirror using low-index cladded subwavelength grating. IEEE Photonics Technol. Lett. 2004, 16, 518–520. [Google Scholar] [CrossRef]

- Tyo, J.S.; Goldstein, D.L.; Chenault, D.B.; Shaw, J.A. Review of passive imaging polarimetry for remote sensing applications. Appl. Opt. 2006, 45, 5453–5469. [Google Scholar] [CrossRef]

- He, C.; He, H.; Chang, J.; Chen, B.; Ma, H.; Booth, M.J. Polarisation optics for biomedical and clinical applications: A review. Light Sci. Appl. 2021, 10, 194. [Google Scholar] [CrossRef]

- Brasselet, S. Fluorescence polarization modulation super-resolution imaging provides refined dynamics orientation processes in biological samples. Light Sci. Appl. 2022, 11, 322. [Google Scholar] [CrossRef]

- Yue, F.; Zhang, C.; Zang, X.-F.; Wen, D.; Gerardot, B.D.; Zhang, S.; Chen, X. High-resolution grayscale image hidden in a laser beam. Light Sci. Appl. 2018, 7, 17129. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Dong, F.L.; Cheng, T.; Qiu, K.; Zhang, Q.C.; Chu, W.G.; Wu, X.P. Nano-fabricated pixelated micropolarizer array for visible imaging polarimetry. Rev. Sci. Instrum. 2014, 85, 105002. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.W.; Lee, K.D.; Kim, J.S.; Kim, S.H.; Park, J.D.; Lee, S.H.; Yoon, P.W. Fabrication of a 50 nm half-pitch wire grid polarizer using nanoimprint lithography. Nanotechnology 2005, 16, 1874–1877. [Google Scholar] [CrossRef]

- Kanamori, Y.; Shimono, M.; Hane, K. Fabrication of transmission color filters using silicon subwavelength gratings on quartz substrates. IEEE Photonics Technol. Lett. 2006, 18, 2126–2128. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Feng, B.; Lu, B.R.; Chen, Y.F.; Li, W.H.; Zhang, W.; Li, T. A study of nano-structural effect on the polarization characteristics of metallic sub-wavelength grating polarizers in visible wavelengths. Microelectron. Eng. 2020, 227, 111327. [Google Scholar] [CrossRef]

- Shiraishi, K.; Oyama, S.; Tsai, C.S. A polarizer using thin metallic-film subwavelength grating for infrared to terahertz region. J. Light. Technol. 2011, 29, 670–676. [Google Scholar] [CrossRef]

- Kim, W.; Kim, M.; Kim, T.Y.; Choi, H.; Jin, M.J.; Lee, K.T.; Lee, M.; Hwangbo, C.K. Nanogap engineering for enhanced transmission of wire grid polarizers in mid-wavelength infrared region. Sci. Rep. 2019, 9, 4201. [Google Scholar] [CrossRef]

- Bomzon, Z.; Biener, G.; Kleiner, V.; Hasman, E. Radially and azimuthally polarized beams generated by space-variant dielectric subwavelength gratings. Opt. Lett. 2002, 27, 285–287. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, B.; Lu, B.; Chen, Y.; Li, W.; Zhang, W.; Li, T. Optimization study of metallic sub-wavelength gratings as the polarizer in infrared wavelengths. Appl. Opt. 2020, 59, 1253–1258. [Google Scholar] [CrossRef]

- Mateus, C.F.R.; Huang, M.C.Y.; Chen, L.; Chang-Hasnain, C.J.; Suzuki, Y. Broad-band mirror (1.12–1.62 µm) using a subwavelength grating. IEEE Photonics Technol. Lett. 2004, 16, 1676–1678. [Google Scholar] [CrossRef]

- Magdenko, L.; Gaucher, F.; Aassime, A.; Vanwolleghem, M.; Lecoeur, P.; Dagens, B. Sputtered metal lift-off for grating fabrication on InP based optical devices. Microelectron. Eng. 2009, 86, 2251–2254. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Shu, Z.W.; Zhang, S.; Zeng, P.; Liang, H.K.; Zheng, M.J.; Duan, H.G. Sub-10 nm fabrication: Methods and applications. Int. J. Extrem. Manuf. 2021, 3, 032002. [Google Scholar] [CrossRef]

- Guillaumee, M.; Dunbar, L.A.; Santschi, C.; Grenet, E.; Eckert, R.; Martin, O.J.F.; Stanley, R.P. Polarization sensitive silicon photodiodes using nanostructured metallic grids. Appl. Phys. Lett. 2009, 94, 193503. [Google Scholar] [CrossRef]

- Ahn, S.H.; Kim, J.S.; Guo, L.J. Bilayer metal wire-grid polarizer fabricated by roll-to-roll nanoimprint lithography on flexible plastic substrate. J. Vac. Sci. Technol. B 2007, 25, 2388–2391. [Google Scholar] [CrossRef]

- Shin, Y.J.; Shin, M.J.; Guo, L.J.; Shin, J.S. Fabrication of contact lens containing high-performance wire grid polarizer. Polym. Int. 2017, 66, 1269–1274. [Google Scholar] [CrossRef]

- Franklin, D.; Modak, S.; Vázquez-Guardado, A.; Safaei, A.; Chanda, D. Covert infrared image encoding through imprinted plasmonic cavities. Light Sci. Appl. 2018, 7, 93. [Google Scholar] [CrossRef]

- Fischl, D.S.; Hess, D.W. Molybdenum etching with chlorine atoms and molecular chlorine plasmas. J. Vac. Sci. Technol. B 1988, 6, 1577–1580. [Google Scholar] [CrossRef]

- Yatsui, T.; Tsuboi, T.; Yamaguchi, M.; Nobusada, K.; Tojo, S.; Stehlin, F.; Soppera, O.; Bloch, D. Optically controlled magnetic-field etching on the nano-scale. Light Sci. Appl. 2016, 5, e16054. [Google Scholar] [CrossRef]

- Lee, J.K.; Kim, B.O.; Park, J.; Kim, J.B.; Kang, I.S.; Sim, G.; Park, J.H.; Jang, H.I. A bilayer Al nanowire-grid polarizer integrated with an IR-cut filter. Opt. Mater. 2019, 98, 6. [Google Scholar] [CrossRef]

- Chai, Y.; Li, F.; Wang, J.; Karvinen, P.; Kuittinen, M.; Kang, G. Enhanced sensing performance from trapezoidal metallic gratings fabricated by laser interference lithography. Opt. Lett. 2022, 47, 1009–1012. [Google Scholar] [CrossRef]

- Ye, Z.C.; Zheng, J.; Sun, S.; Guo, L.D.; Shieh, H.P.D. Compact transreflective color filters and polarizers by bilayer metallic nanowire gratings on flexible substrates. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 4800205. [Google Scholar] [CrossRef]

- Ye, Z.C.; Peng, Y.; Zhai, T.R.; Zhou, Y.; Liu, D.H. Surface plasmon-mediated transmission in double-layer metallic grating polarizers. J. Opt. Soc. Am. B-Opt. Phys. 2011, 28, 502–507. [Google Scholar] [CrossRef]

- Lee, B.J.; Wang, L.P.; Zhang, Z.M. Coherent thermal emission by excitation of magnetic polaritons between periodic strips and a metallic film. Opt. Express 2008, 16, 11328–11336. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.J.; Luo, J.; Song, M.W.; Yu, H.L. Polarization filtering and phase controlling metasurfaces based on a metal-insulator-metal grating. Plasmonics 2017, 12, 1797–1803. [Google Scholar] [CrossRef]

- An, C.; Chu, J.K.; Zhang, R. Optimization of Bilayer Sub-Wavelength Metallic Grating Based on Genetic Algorithm. Laser Optoelectron. Prog. 2019, 56, 7. [Google Scholar] [CrossRef]

- Wu., F.; Bu, Y.; Liu, Z.-F.; Wang, S.-Q.; Li, S.-K.; Wang, X.-Z. Design and analysis of bilayer metallic grating polarizer in deep ultraviolet band. Acta Phys. Sin. 2021, 70, 044203. [Google Scholar] [CrossRef]

- Yeh, P. New optical-model for wire grid polarizers. Opt. Commun. 1978, 26, 289–292. [Google Scholar] [CrossRef]

- Brundrett, D.L.; Glytsis, E.N.; Gaylord, T.K. Homogeneous layer models for high-spatial-frequency dielectric surface-relief gratings—Conical diffraction and antireflection designs. Appl. Opt. 1994, 33, 2695–2706. [Google Scholar] [CrossRef]

- Kikuta, H.; Ohira, Y.; Kubo, H.; Iwata, K. Effective medium theory of two-dimensional subwavelength gratings in the non-quasi-static limit. J. Opt. Soc. Am. A-Opt. Image Sci. Vis. 1998, 15, 1577–1585. [Google Scholar] [CrossRef]

- Wang, Z.W.; Yuan, W.; Gong, J.L. Polarization transmission mechanism analyzation of bi-layer nanowire polarizer. Opt. Commun. 2018, 424, 127–130. [Google Scholar] [CrossRef]

- Chen, Y.F.; Yang, H.F.; Cui, Z. Effects of developing conditions on the contrast and sensitivity of hydrogen silsesquioxane. Microelectron. Eng. 2006, 83, 1119–1123. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Ning, Y.; Liu, L.; Dong, S.; Chen, Y.; Wang, Z.; Cheng, X. Design and Fabrication of Highly Selective Polarizers Using Metallic–Dielectric Gratings. Photonics 2023, 10, 52. https://doi.org/10.3390/photonics10010052

Zhu J, Ning Y, Liu L, Dong S, Chen Y, Wang Z, Cheng X. Design and Fabrication of Highly Selective Polarizers Using Metallic–Dielectric Gratings. Photonics. 2023; 10(1):52. https://doi.org/10.3390/photonics10010052

Chicago/Turabian StyleZhu, Jingyuan, Yi Ning, Liang Liu, Siyu Dong, Yifang Chen, Zhanshan Wang, and Xinbin Cheng. 2023. "Design and Fabrication of Highly Selective Polarizers Using Metallic–Dielectric Gratings" Photonics 10, no. 1: 52. https://doi.org/10.3390/photonics10010052

APA StyleZhu, J., Ning, Y., Liu, L., Dong, S., Chen, Y., Wang, Z., & Cheng, X. (2023). Design and Fabrication of Highly Selective Polarizers Using Metallic–Dielectric Gratings. Photonics, 10(1), 52. https://doi.org/10.3390/photonics10010052