Related Standards and Certifications in the Architecture of Service-Oriented System in Welding Technology: A Systematic Review

Abstract

1. Introduction

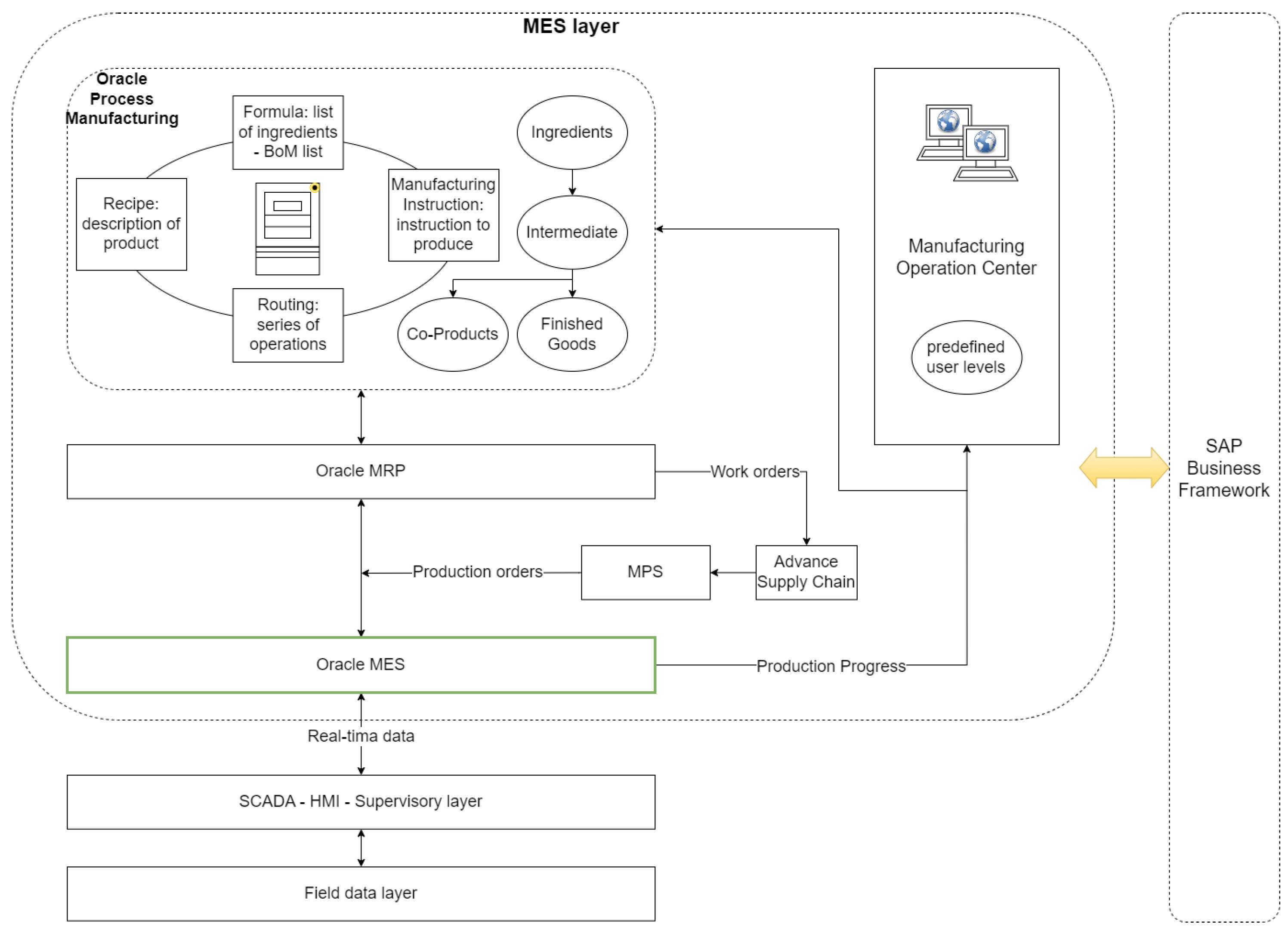

Software from Major Vendors

- Application layer: This layer contains the servers that are responsible for executing the intended business logic. This layer uses the proprietary SAP ABAP (Advanced Business Application Programming) programming language [26,27].In addition to ABAP, the SAP HANA environment supports the use of various programming languages, including SQLScript. The SAP Cloud Application Programming Model (SAP CAP) is a framework that integrates open source and SAP tools and technologies, consisting of tools, languages, libraries, and APIs [28]. The application layer consists of SAP ERP Enterprise Resource Planning, SAP CRM (Customer Relationship Management), and SAP SCM (Supply Chain Management), together forming the Business Suite applications. SAP HANA, an in-memory database, provides the single database as the underlying data architecture and serves the Business Suite [29].

- Database layer: The collection layer of database systems used to store relevant data. This is for example the case of SAP HANA [30]. In addition, SAP HANA (either cloud or on-premises solution) can connect to various data collections of different data types, for example, Apache Hadoop can be used for Big Data Analytic. Any relational database management system can be connected using standard SQL and database connect interfaces. The external input data can be in heterogeneous data type format, e.g., XLXSX, CSV, XML, etc. [28,29].

- Integration layer: an important layer for our study, as it provides the possibility to connect modules. An example is the SAP Cloud Platform Integration platform that consists of SAP Cloud Integration Suite, SAP Cloud Data Integration Suite, etc. [28]. As data analytics has become a core functional service of business information systems, also known as ERP systems, new roles have emerged, such as data curator, data architect, and data engineer, alongside the traditional database designer and data administrator.

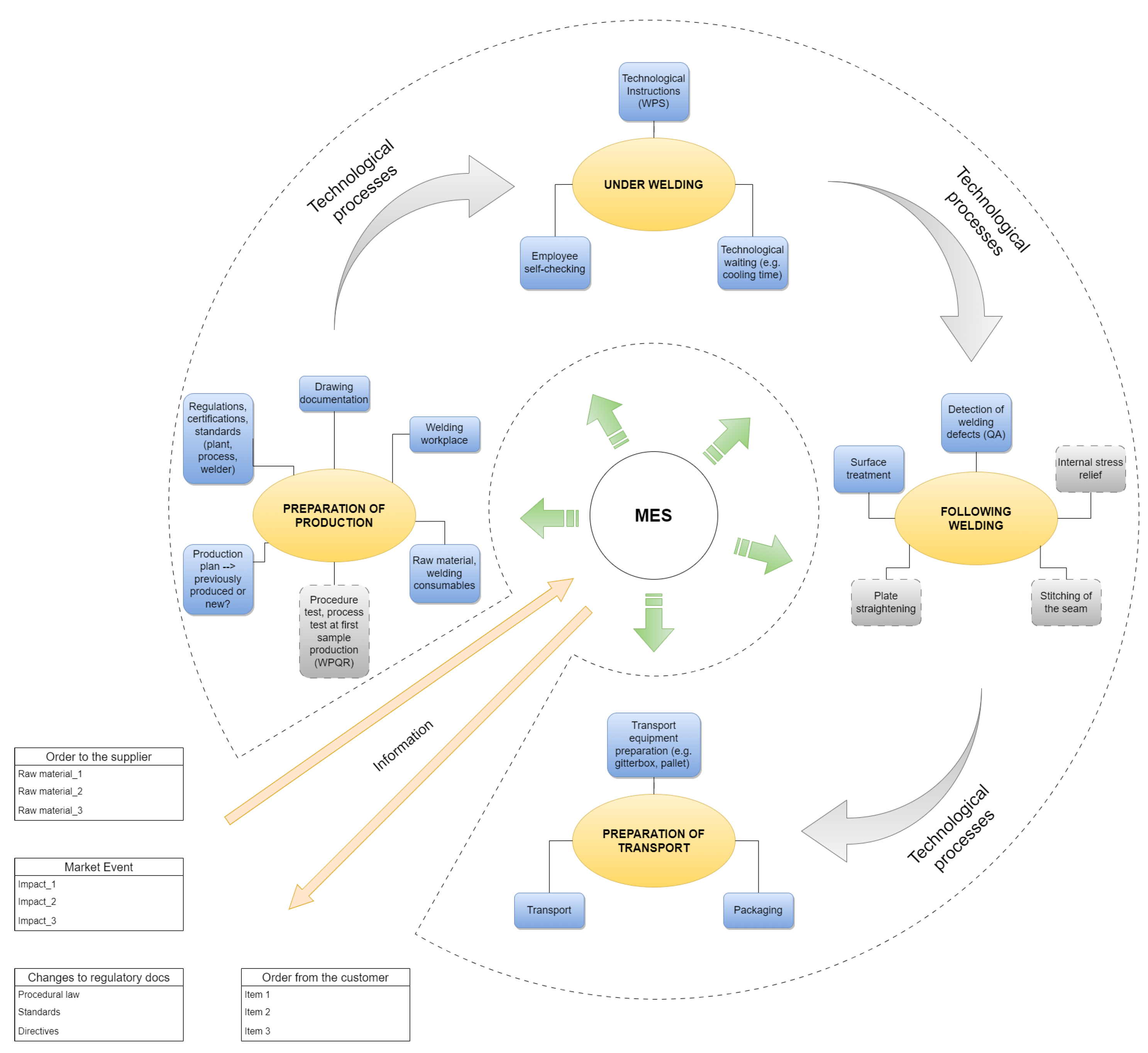

2. Welding Technology as an Information System

Welding Standards

3. Technical Components for the Designing of Architecture

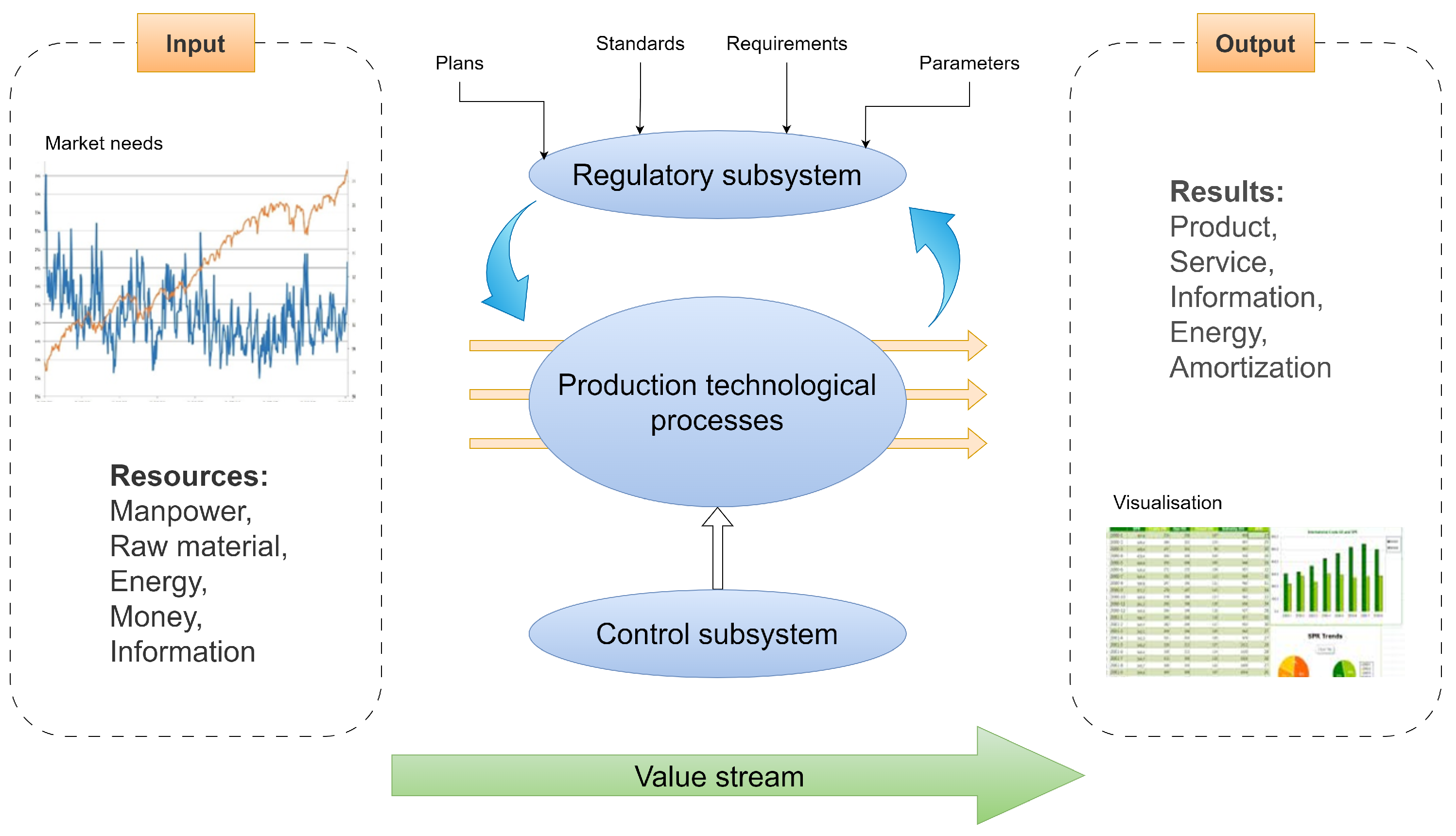

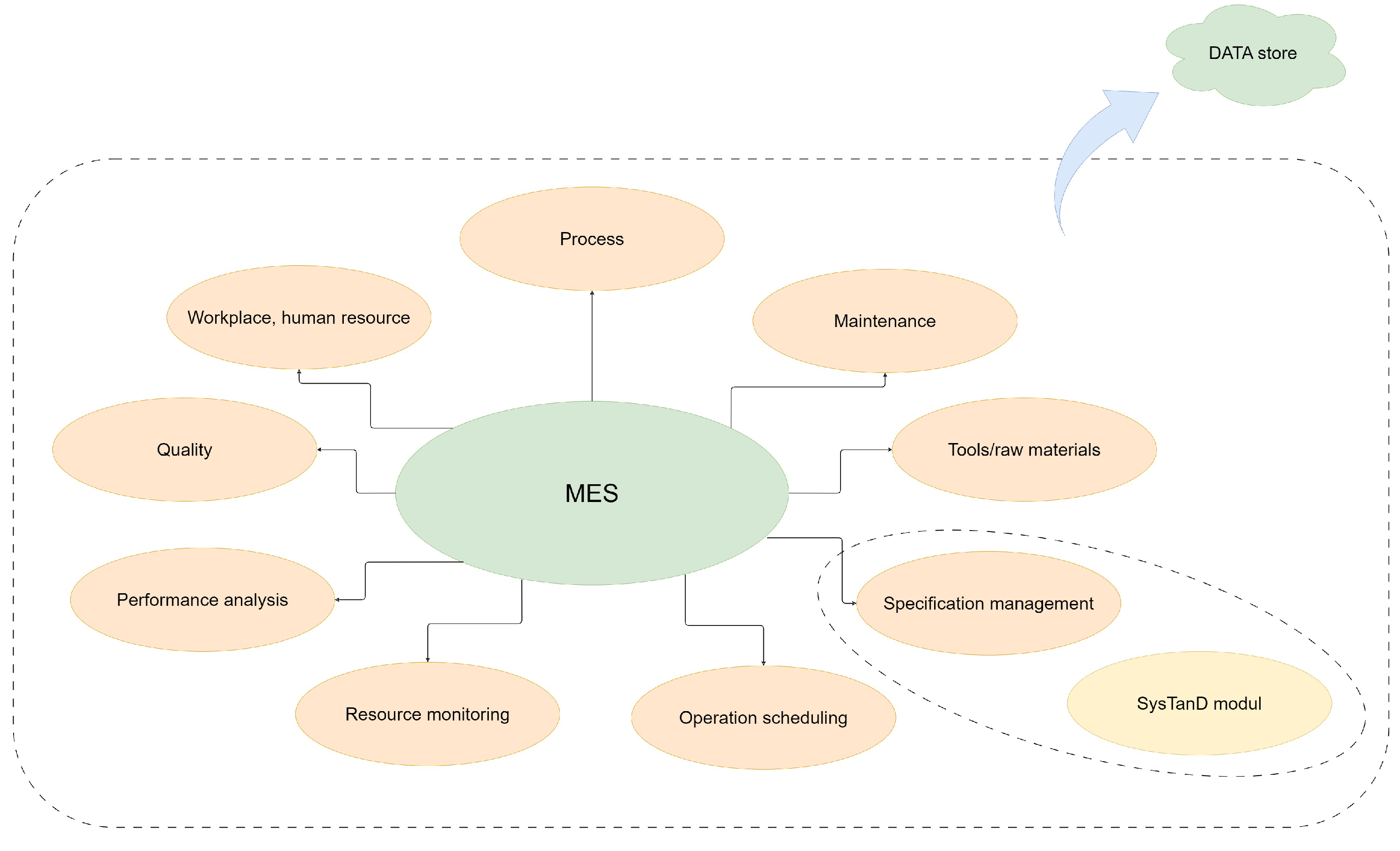

3.1. Operational Framework for Information Systems

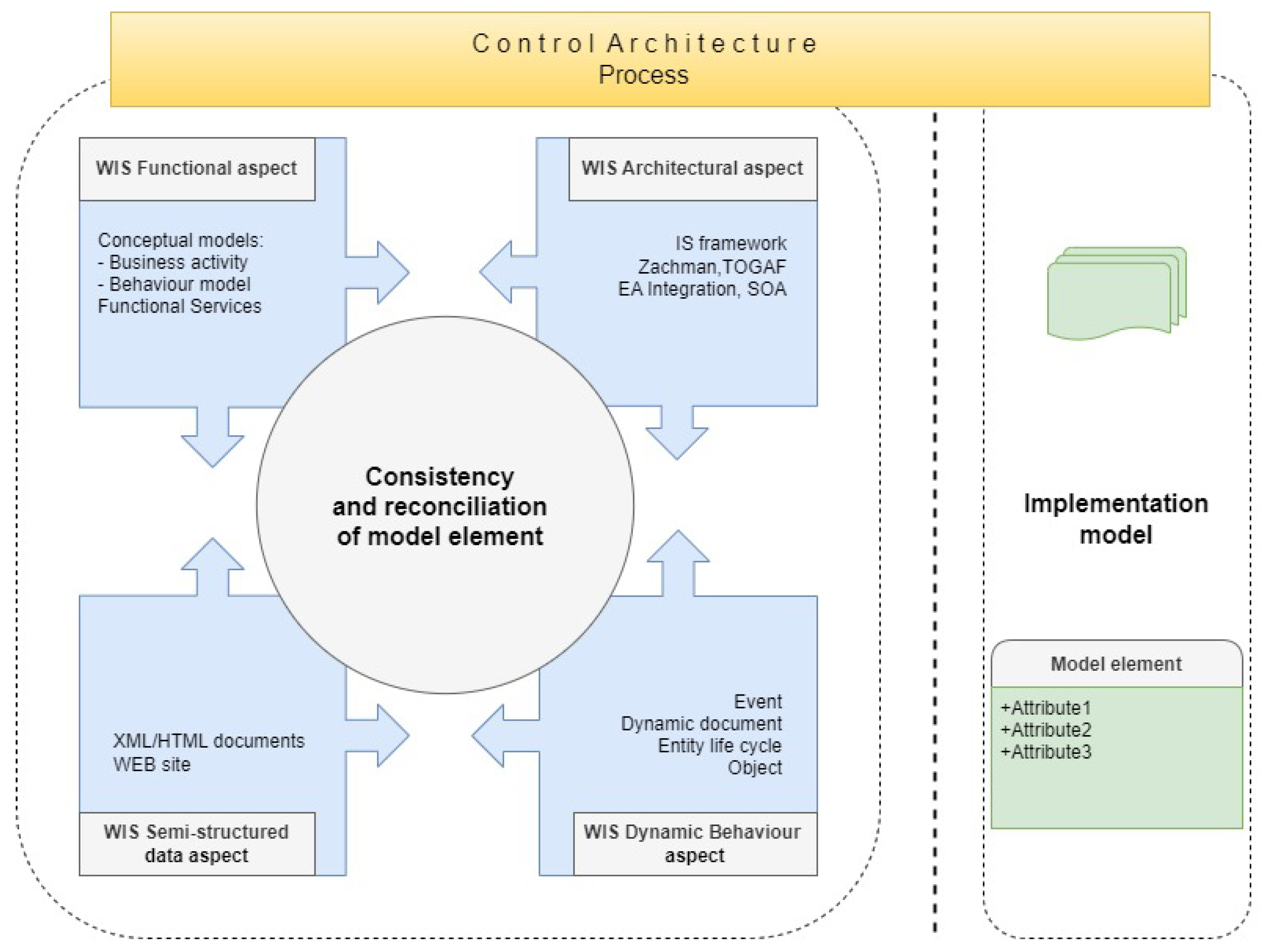

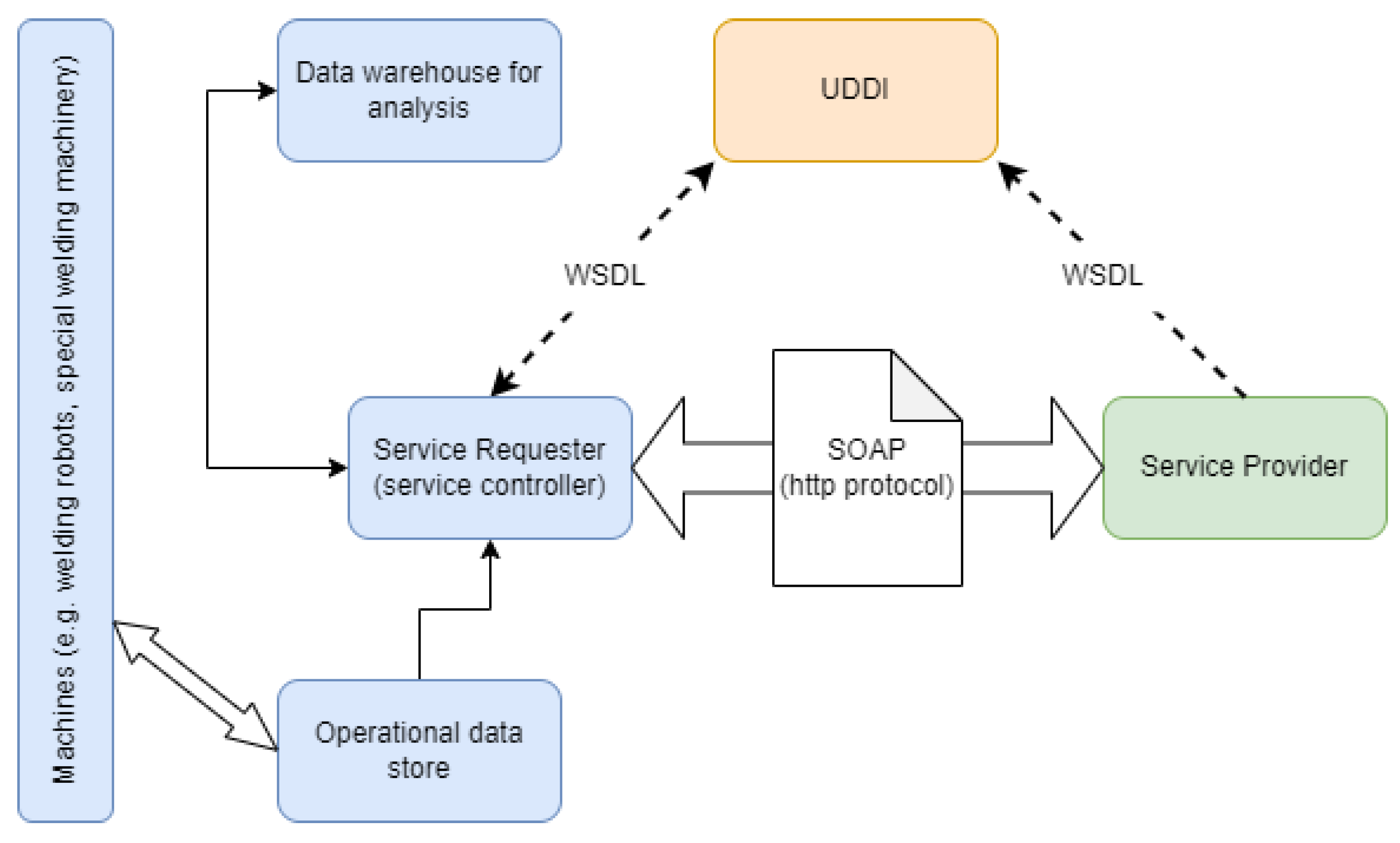

3.2. SOA (Service-Oriented Architecture)

3.3. Data Management

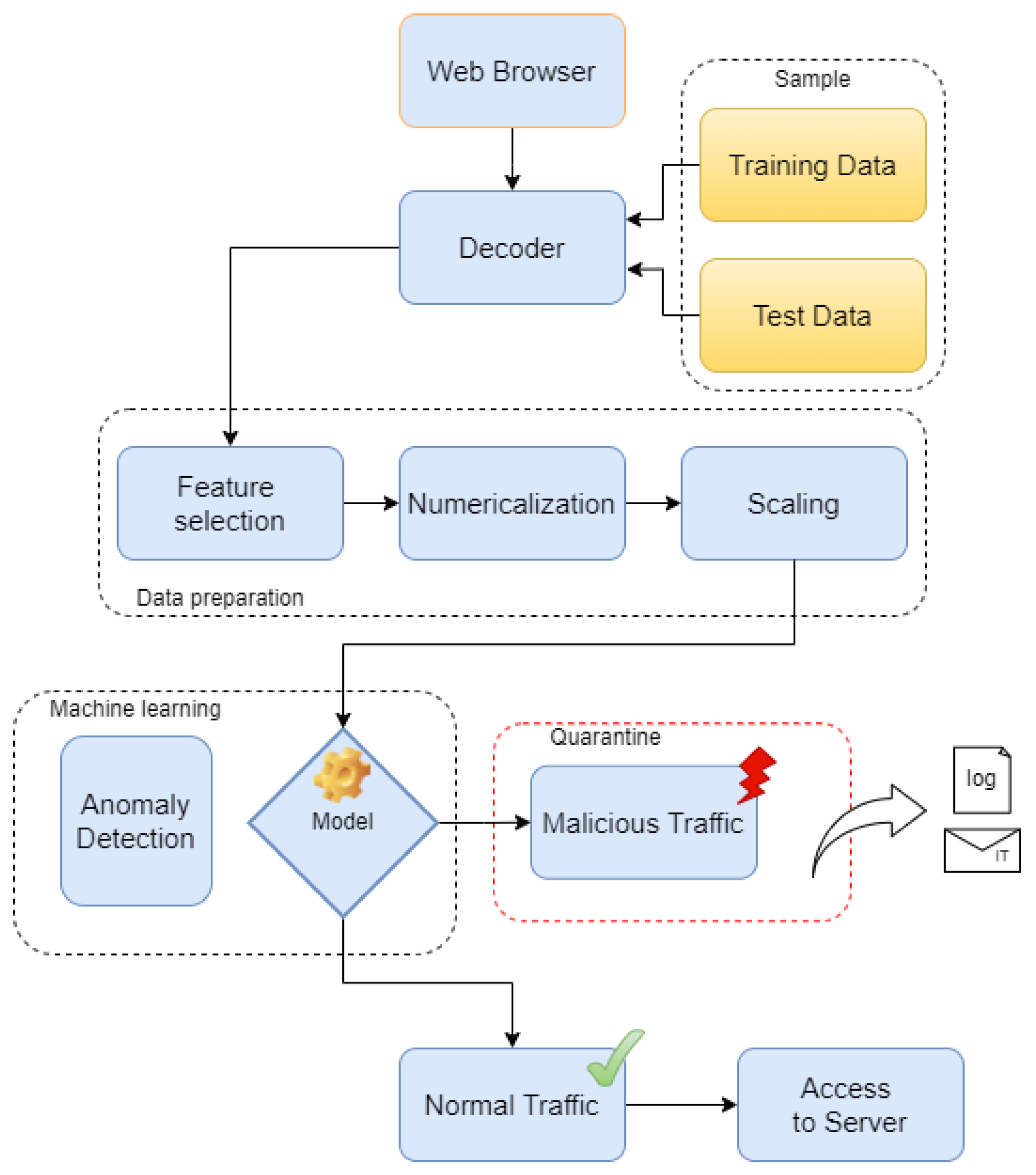

3.4. Interface, Platform Perspective, and Its Cybersecurity

4. Discussion

4.1. Applied Research Methodologies

4.2. UML Activity Diagrams and a Process

4.3. Technical Solutions for Software Integration

- It is ideal in cases where the goal is to design an enterprise architecture, or a part of it, that spans all business functions.

- The framework contains all the building blocks, roles, skills, and responsibilities necessary to make the system work. These are the artifacts, or ABBs (Architecture Building Blocks).

- It is based on the scenarios of a real organization, on which templates are built, which speed up the design process.

- Guidelines and technical solutions that may be encountered by the whole organization.

- It provides guidelines during the design of a highly complex architecture, showing what the gaps in the system are and what should be created in a chronological order of development activities.

- The reason for the enterprise continuum is that it uses a repository of objects, artifacts, that provide the same interpretation across designs.

- The TOGAF library contains reference architectures.

5. Conclusions

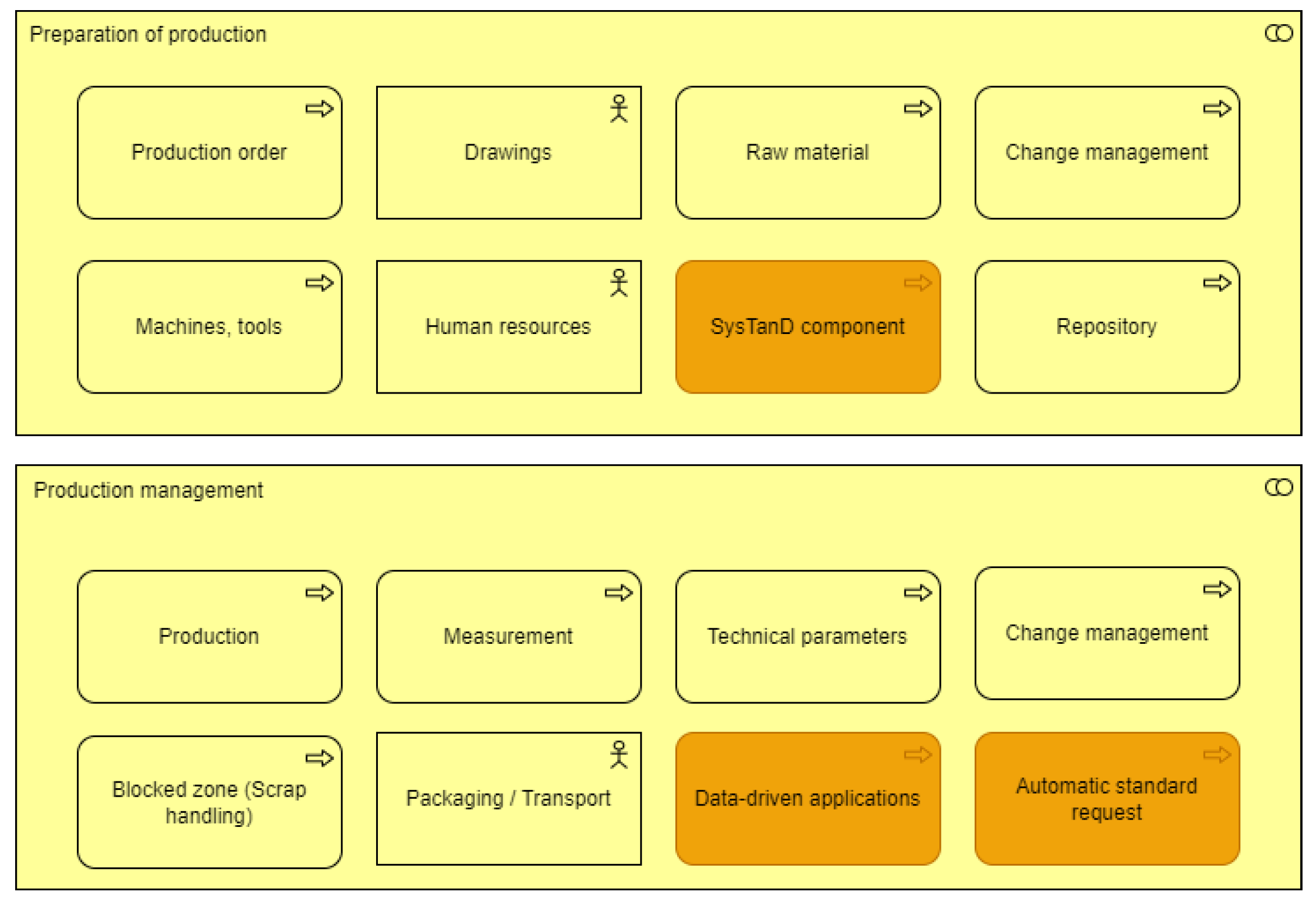

5.1. Example of a Design Concept

5.2. Ways Forward in the near Future

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Article specific | |

| IS | Information System |

| IT | Information Technology |

| IT/IS | Information Technology and Information System |

| ERP | Enterprise Resource-Planning System |

| WPQR | Welding Procedure Qualification Record |

| WPS | Welding Procedure Specification |

| KPIs | Key Performance Indicators |

| ITIL | Information Technology Infrastructure Library |

| TOGAF | The Open Group Architecture Framework |

| XML | eXtensible Markup Language |

| JSON | JavaScript Object Notation |

| DBMS | Database Management System |

| BPMN | Business Process modeling Notation standard version 2.0 |

| DOM | Document Object Model |

| PII | Personal Identifying Information |

References

- Vershinina, L. Intelligent technologies in the development of cyber-physical production systems. J. Phys. Conf. Ser. 2022, 2388, 012085. [Google Scholar] [CrossRef]

- Koren, I.; Rinker, F.; Meixner, K.; Matevska, J.; Walter, J. Challenges and Opportunities of DevOps in Cyber-Physical Production Systems Engineering. In Proceedings of the 2023 IEEE 6th International Conference on Industrial Cyber-Physical Systems (ICPS), Wuhan, China, 8–11 May 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Artamonova, I.; Adamtsevich, L.; Kharisov, I.; Morgunov, N. Increasing the construction production efficiency based on the use of cyber-physical systems and technologies. J. Law Sustain. Dev. 2023, 11, e280. [Google Scholar] [CrossRef]

- Temelkova, M. Model for the Organization of a Cyber-Physical Production System. In Proceedings of the Intelligent Sustainable Systems; Nagar, A.K., Singh Jat, D., Mishra, D.K., Joshi, A., Eds.; Springer: Singapore, 2023; pp. 703–718. [Google Scholar]

- Klarić, M. Smart digitalization and public services in the EU. EU Comp. Law Issues Chall. Ser. (ECLIC) 2023, 7, 151–174. [Google Scholar] [CrossRef]

- Sofrankova, B.; Kiselakova, D.; Širá, E.; Grzebyk, M. Analysis of relationships between innovative and digital performance of EU-27 countries. J. Manag. Bus. Res. Pract. 2022, 14, 1–14. [Google Scholar] [CrossRef]

- Krämer, L.; Rutinowski, J.; Endendyk, J.; Vaut, R.; Roidl, M. On Blockchain-based Token Usage in Cyber-Physical Production Systems. Logist. J. Proc. 2022, 2022, 1–11. [Google Scholar]

- Wally, B. Application Recommendation Provisioning for MES and ERP—Support for IEC 62264 and B2MML. 2021. Available online: https://www.researchgate.net/publication/357457963_Application_Recommendation_Provisioning_for_MES_and_ERP_-_Support_for_IEC_62264_and_B2MML (accessed on 9 February 2025).

- Apilioğulları, L. Digital transformation in project-based manufacturing: Developing the ISA-95 model for vertical integration. Int. J. Prod. Econ. 2022, 245, 108413. [Google Scholar] [CrossRef]

- Veilleux, R.F. Tool and Manufacturing Engineers Handbook, Vol. 5: Manufacturing Management, 4th ed.; Society of Manufacturing: Southfield, MI, USA, 1988. [Google Scholar]

- Molnar, B.; Szabo, G.; Benczur, A. Selection process of ERP systems. Bus. Syst. Res. Int. J. Soc. Adv. Innov. Res. Econ. 2013, 4, 36–48. [Google Scholar]

- Molnár, B.; Ori, D. Towards a hypergraph-based formalism for enterprise architecture representation to lead digital transformation. In Proceedings of the European Conference on Advances in Databases and Information Systems, Budapest, Hungary, 2–5 September 2018; Springer: Cham, Switzerland, 2018; pp. 364–376. [Google Scholar]

- Koleva, L.; Koleva, E.; Batchkova, I.; Mladenov, G. Integrated control system for electron beam processes. J. Phys. Conf. Ser. 2018, 992, 012014. [Google Scholar] [CrossRef]

- Åkerman, M. Implementing Shop Floor IT for Industry 4.0; Chalmers Tekniska Hogskola (Sweden): Gothenburg, Sweden, 2018. [Google Scholar]

- Czvetko, T.; Abonyi, J. Data sharing in Industry 4.0—AutomationML, B2MML and International Data Spaces-based solutions. J. Ind. Inf. Integr. 2023, 33, 100438. [Google Scholar] [CrossRef]

- Draugelates, U.; Schram, A. Metallographische Verfahren für die Güteprüfung von Schweißverbindungen / Metallographic Methods for Testing the Quality of Weld Joints. Pract. Metallogr. 1987, 24, 355–363. [Google Scholar] [CrossRef]

- Wyciślik-Sośnierz, J.; Matusiak, J.; Adamiec, J.; Lemanowicz, M.; Kusiorowski, R.; Gerle, A. Morphology of Welding Fume Derived from Stainless Steels Arc Welding. Arch. Foundry Eng. 2024, 2024, 103–108. [Google Scholar] [CrossRef]

- Erl, T.; Merson, P.; Stoffers, R. Service-Oriented Architecture: Analysis and Design for Services and Microservices, 2nd ed.; OCLC: ocn970612934; Prentice Hall: Boston, MA, USA, 2017. [Google Scholar]

- Alapati, S. Expert Oracle Database 11g Administration; Springer eBook Collection; Apress: Berkeley, CA, USA, 2009. [Google Scholar] [CrossRef]

- Zhao, D. Oracle transaction processing method in MES. In Proceedings of the 2011 IEEE Second International Conference on Mechanic Automation and Control Engineering, Inner Mongolia, China, 15–17 July 2011; pp. 501–503. [Google Scholar] [CrossRef]

- Zhao, D. Research on Improving Oracle Query Performance in MES. Appl. Mech. Mater. 2012, 201–202, 39–42. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, C. Research on Search Optimization Based on Oracle Database. J. Phys. Conf. Ser. 2020, 1648, 042047. [Google Scholar] [CrossRef]

- Musukutwa, S.C. Enterprise Architecture and SAP. In SAP Enterprise Architecture; Apress: Berkeley, CA, USA, 2022; pp. 93–118. [Google Scholar] [CrossRef]

- SAPHelpdesk; SAP GUI Technology: Walldorf, Germany, 2024.

- Guerrero, S. Custom Fiori Applications in SAP HANA Design, Develop, and Deploy Fiori Applications for the Enterprise; Apress: Berkeley, CA, USA, 2021. [Google Scholar] [CrossRef]

- Rogers, C. ABAP Objects: Designing A Programming Course For Information Systems Students Using Sap Software. ABAP Objects Des. Program. Course 2008, 9, 165–167. [Google Scholar]

- Zaidi, R. SAP ABAP Objects: A Practical Guide to the Basics and Beyond; Apress: Berkeley, CA, USA, 2019. [Google Scholar] [CrossRef]

- Figueiredo, M. SAP HANA Cloud in a Nutshell: Design, Develop, and Deploy Data Models Using SAP HANA Cloud; Apress: Berkeley, CA, USA, 2022. [Google Scholar] [CrossRef]

- Mankala, C. SAP HANA Cookbook; Packt Publishing: Birmingham, UK, 2013. [Google Scholar]

- Färber, F.; Cha, S.; Primsch, J.; Bornhövd, C.; Sigg, S.; Lehner, W. SAP HANA database: Data management for modern business applications. SIGMOD Record 2011, 40, 45–51. [Google Scholar] [CrossRef]

- Korhonen, J.J.; Halen, M. Enterprise Architecture for Digital Transformation. In Proceedings of the 2017 IEEE 19th Conference on Business Informatics (CBI), Thessaloniki, Greece, 24–27 July 2017. [Google Scholar] [CrossRef]

- Miler, D.; Hoic, M.; Birt, D.; Kostelac, M. A Comparison of Welded Structure Cost Calculation Methods. Trans. FAMENA 2022, 46, 85–96. [Google Scholar] [CrossRef]

- Norrish, J. An introduction to welding processes. In Advanced Welding Processes; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–15. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Ratnayake, R. Welding procedure qualification record (WPQR) for welds fabricated at proximity. Int. J. Adv. Manuf. Technol. 2022, 120, 4477–4491. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Sabatakakis, K. Data attributes in quality monitoring of manufacturing processes: The welding case. Appl. Sci. 2023, 13, 10580. [Google Scholar] [CrossRef]

- Liu, T.; Bao, J. A novel period-sensitive LSTM for laser welding quality prediction. IEEE Trans. Ind. Inform. 2024, 21, 830–838. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, P.; Liu, X. A multiple scale spaces empowered approach for welding radiographic image defect segmentation. Ndt E Int. 2023, 139, 102934. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, P.; Jinsong, B.; Chen, H. A state-of-the-art survey of welding radiographic image analysis: Challenges, technologies and applications. Measurement 2023, 214, 112821. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, P.; Bao, J. Deep learning-based welding image recognition: A comprehensive review. J. Manuf. Syst. 2023, 68, 601–625. [Google Scholar]

- Szőlősi, J.; Magyar, P.; Antal, J.; Szekeres, B.J.; Farkas, G.; Andó, M. Cyber-physical-based welding systems: Components and implementation strategies. IET Cyber-Phys. Syst. Theory Appl. 2024, 9, 293–312. [Google Scholar]

- Posch, G.; Bruckner, J.; Ennsbrunner, H. Industry 4.0 in Welding; Fronius International GmbH: Wels, Austria, 2017. [Google Scholar]

- Lundin, M. European (International) Standards for Fusion Welding. 2021. Available online: https://www.svets.se/download/18.1e24ab2e146d4b7d93c1862/1614553768310/Overview_fusion_welding_standards.pdf (accessed on 24 October 2022).

- WeldingStandard-6520; Welding Standard—ISO 6520-1:2007-Welding and Allied Processes—Classification of Geometric Imperfections in Metallic Materials—Part 1: Fusion Welding. International Organization for Standardization: Geneva, Switzerland, 2007.

- WeldingStandard-5817; Welding Standard—ISO 5817:2023-Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (beam Welding Excluded)—Quality levels for Imperfections. International Organization for Standardization: Geneva, Switzerland, 2023.

- Tong, J.; Zhao, B.; An, Y. A novel multi-objective service composition architecture for blockchain-based cloud manufacturing. J. Comput. Des. Eng. 2023, 10, 185–203. [Google Scholar] [CrossRef]

- Doumeingts, G.; Müller, J.; Morel, G.; Vallespir, B. Enterprise Interoperability: New Challenges and Approaches; Springer: London, UK, 2007. [Google Scholar] [CrossRef]

- Roach, T. CAPSICUM—A Semantic Framework for Strategically Aligned Business Architecture. Ph.D. Thesis, UNSW Sydney, Sydney, Australia, 2011. [Google Scholar]

- Evans, M.K.; Hague, L.R. Master Plan for Information Systems. Harv. Bus. Rev. 1962, 40, 92–103. [Google Scholar]

- Zachman, J. Business Systems Planning and Business Information Control Study: A comparison. IBM Syst. J. 1982, 21, 31–53. [Google Scholar]

- Zachman, J. A Framework for Information Systems Architecture. IBM Syst. J. 1987, 26, 321–5298. [Google Scholar]

- Sowa, J.F.; Zachman, J.A. Extending and formalizing the framework for information systems architecture. IBM Syst. J. 1992, 31, 590–616. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.M.; Afsarmanesh, H. On reference models for collaborative networked organizations. Int. J. Prod. Res. 2008, 46, 2453–2469. [Google Scholar] [CrossRef]

- Kotusev, S. The History of Enterprise Architecture: An Evidence-Based Review. J. Enterp. Archit. 2016, 12, 29–37. [Google Scholar]

- Molnár, B.; Benczúr, A. The application of directed hyper-graphs for analysis of models of information systems. Mathematics 2022, 10, 759. [Google Scholar] [CrossRef]

- Molnár, B.; Mattyasovszky-Philipp, D. An architectural approach to Cognitive Information System. In Proceedings of the 2019 10th IEEE International Conference on Cognitive Infocommunications (CogInfoCom), Naples, Italy, 23–25 October 2019; pp. 459–462. [Google Scholar] [CrossRef]

- Erl, T. SOA: Principles of Service Design, [repr.] ed.; The @Prentice Hall Service-Oriented Computing Series from Thomas Erl; Prentice Hall: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- McGovern, J.; Sims, O.; Jain, A.; Little, M. Enterprise Service Oriented Architectures: Concepts, Challenges, Recommendations; SpringerLink; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Arsanjani, A. Service-Oriented Modeling and Architecture. IBM Dev. Work. 2004, 1, 15. [Google Scholar]

- Pulier, E.; Taylor, H. Understanding Enterprise SOA; Manning Publications Co.: Shelter Island, NY, USA, 2006. [Google Scholar]

- Caplinskas, A.; Vasilecas, O.; Eder, J. Databases and Information Systems IV—Selected Papers from the Seventh International Conference DB&IS’2006; IOS Press: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Isakowitz, T.; Bieber, M.; Vitali, F. Web Information Systems. Commun. ACM 1998, 41, 78–80. [Google Scholar] [CrossRef]

- Schewe, K.D.; Thalheim, B. User Models: A Contribution to Pragmatics of Web Information Systems Design. In Proceedings of the Web Information Systems—WISE 2006; Aberer, K., Peng, Z., Rundensteiner, E.A., Zhang, Y., Li, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 512–523. [Google Scholar] [CrossRef]

- Molnár, B.; Benczúr, A.A.; Tarcsi, Á. Formal approach to a web information system based on story algebra. Eur. J. Appl. Econ. 2012, 9, 63–73. [Google Scholar]

- Jansen, J.M.; Plasmeijer, R.; Koopman, P.; Achten, P. Embedding a Web-Based Workflow Management System in a Functional Language experience paper. In Proceedings of the LDTA’10: Proceedings of the Tenth Workshop on Language Descriptions, Tools and Applications, Paphos, Cyprus, 28–29 March 2010. [Google Scholar] [CrossRef]

- Bernardi, M.; Cimitile, M.; Di Lucca, G.; Maggi, F. M3D: A tool for the model driven development of web applications. In Proceedings of the WIDM ’12: Proceedings of the Twelfth International Workshop on Web Information and Data Management, Maui, HI, USA, 2 November 2012; p. 1. [Google Scholar] [CrossRef]

- Kalin, M. Java Web Services-up and Running: A Quick, Practical, and Thorough Introduction: Covers JAX-WS 2.1., 1st ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2009. [Google Scholar]

- Abouzid, I.; Saidi, R. Proposal of BPMN extensions for modelling manufacturing processes. In Proceedings of the 2019 5th International Conference on Optimization and Applications (ICOA), Kenitra, Morocco, 25–26 April 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Weidlich, M.; Decker, G.; Großkopf, A.; Weske, M. BPEL to BPMN: The Myth of a Straight-Forward Mapping. In Proceedings of the On the Move to Meaningful Internet Systems: OTM 2008, Monterrey, Mexico, 9–14 November 2008; Meersman, R., Tari, Z., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 265–282. [Google Scholar]

- Viriyasitavat, W.; Xu, L.; Bi, Z.; Sapsomboon, A. Blockchain-based business process management (BPM) framework for service composition in industry 4.0. J. Intell. Manuf. 2020, 31, 1737–1748. [Google Scholar] [CrossRef]

- Stefansen, C.O.E. (I) A Declarative Framework for ERP Systems (II) Reactors: A Data-Driven Programming Model for Distributed Applications. Ph.D. Thesis, Department of Computer Science, University of Copenhagen, Copenhagen, Denmark, 2008. [Google Scholar]

- Peltokoski, M.; Eskelinen, H. Challenges of manufacturability and product data management in bending. Int. J. Adv. Manuf. Technol. 2018, 99, 2137–2148. [Google Scholar] [CrossRef]

- Serrano, M.A.; Marín, C.A.; Queralt, A.; Cordeiro, C.; Gonzalez, M.; Pinho, L.M.; Quiñones, E. An Elastic Software Architecture for Extreme-Scale Big Data Analytics. In Technologies and Applications for Big Data Value; Curry, E., Auer, S., Berre, A.J., Metzger, A., Perez, M.S., Zillner, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 89–110. [Google Scholar] [CrossRef]

- Liu, P.; Lu, J. Research on Enterprise Application Integration Platform Based on SOA Architecture. Int. J. Adv. Netw. Monit. Control. 2020, 5, 15–21. [Google Scholar] [CrossRef]

- Pulier, E.; Martinez, F.; Hill, D. System and Method for a Cloud Computing Abstraction Layer. U.S. Patent US8887228B2, 11 November 2014. [Google Scholar]

- Hanzelik, P.P.; Kummer, A.; Abonyi, J. Edge-Computing and Machine-Learning-Based Framework for Software Sensor Development. Sensors 2022, 22, 4268. [Google Scholar] [CrossRef]

- Al-Turjman, F. Edge Computing From Hype to Reality; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. X, 188. [Google Scholar] [CrossRef]

- Meyer, F. How Integration Appliances Simplify and Accelerate SOA Implementation. Available online: https://www.pmi.it/app/uploads/2018/02/000007-k52vOK.pdf (accessed on 9 February 2025).

- Josey, A. TOGAF® Version 9.1—A Pocket Guide; Van Haren Publishing: Hertogenbosch, The Netherlands, 2016. [Google Scholar]

- Dawadi, B.R.; Adhikari, B.; Srivastava, D.K. Deep Learning Technique-Enabled Web Application Firewall for the Detection of Web Attacks. Sensors 2023, 23, 2073. [Google Scholar] [CrossRef]

- Wieringa, R.J. Design Science Methodology for Information Systems and Software Engineering; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Hevner, A.; Chatterjee, S. Design Research in Information Systems. In Design Research in Information Systems; Springer: Boston, MA, USA, 2010; pp. 9–22. [Google Scholar] [CrossRef]

- Russell, N.; van der Aalst, W.M.P.; ter Hofstede, A.H.M. Workflow Patterns: The Definitive Guide; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Runeson, P. (Ed.) Case Study Research in Software Engineering; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Runeson, P.; Höst, M. Höst, M.: Guidelines for Conducting and Reporting Case Study Research in Software Engineering. Empir. Softw. Eng. 2009, 14, 131–164. [Google Scholar] [CrossRef]

- Runeson, P.; Höst, M.; Rainer, A.; Björn, R. Design of the Case Study. In Case Study Research in Software Engineering; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; Chapter 3; pp. 23–45. [Google Scholar] [CrossRef]

- Bellahsene, Z.; Woo, C.; Hunt, E.; Franch, X.; Coletta, R. Proceedings of the Forum at the CAiSE’08 Conference, Montpellier, France, 18–20 June 2008. p. 1. Available online: https://ceur-ws.org/Vol-344/CAiSEForum08.pdf (accessed on 9 February 2025).

- Seiger, R.; Kühn, R.; Korzetz, M.; Assmann, U. HoloFlows: Modelling of processes for the Internet of Things in mixed reality. Softw. Syst. Model. 2021, 20, 1465–1489. [Google Scholar] [CrossRef]

- ForcamEniscoGmbH. Forcam Enisco: The Factory of the Future—Efficient, Reliable, Profitable. 2025. Available online: https://forcam-enisco.net/en/ (accessed on 10 January 2025).

- Magyar, P.; Hegedűs-Kuti, J.; Szőlősi, J.; Farkas, G. Real-time data visualization of welding robot data and preparation for future of digital twin system. Sci. Rep. 2024, 14, 10229. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Sampatakakis, K. A CPS platform oriented for Quality Assessment in welding. MATEC Web Conf. 2020, 318, 01030. [Google Scholar] [CrossRef]

- Cimini, C.; Romero, D.; Pinto, R.; Cavalieri, S. Task Classification Framework and Job-Task Analysis Method for Understanding the Impact of Smart and Digital Technologies on the Operators 4.0 Job Profiles. Sustainability 2023, 15, 3899. [Google Scholar] [CrossRef]

- Molnár, B.; Béleczki, A.; Benczúr, A. Information systems modelling based on graph-theoretic background. J. Inf. Telecommun. 2018, 2, 68–90. [Google Scholar] [CrossRef]

- Ahmed, F.; Jannat, N.E.; Zamanzad Gavidel, S.; Rickli, J.; Kim, K.Y. A Conceptual Framework for Cyber-physical System in Connected RSW Weldability Certification. Procedia Manuf. 2019, 38, 431–438. [Google Scholar] [CrossRef]

| Main Components | Sub Components | Area of Welding |

|---|---|---|

| Enterprise framework (CIS—complex information system) | MES | Resource management; workflow management; documentation; change management; cooperation with a standard module for autonomous recognition and application of relevant standard recommendations; example: digitized welding technical specification from customer ordering data (drawings). |

| Digital storage for welding knowledge and best practice | Document handling subsystem | Recommendation for quality-based technology areas; recommendation modul for the application of directives, standards and certifications; example: data lake technology with SOA with implemented web applications. |

| Data | Welding parameters | Technological parameters for the production of workpiece; data storage, feedback, optimization; example: parameter optimization with ANN (Artificial Neural Network) predictor. |

| Transfer of data and communication | Use of modern data transmission tools, interfaces, cloud-based systems, human–machine interactions; example: intelligent interface technology and IO-link to transfer bus. | |

| Technology procedures | Automatization | Application of automated technical equipment: robotic environment, microchip power sources; example: intelligent control units in robotcells. |

| Virtuality and simulation | The result of the welding process is an inherently destructible joint; by creating a simulation environment, the safety and quality of the process can be improved; example: CAW (Computer-Aided Welding), CAR-W (Computer-Aided Robotic Welding)—design manufacturing process and VR (Virtual Reality) technology | |

| Sensor-based measurement system | Recognizing the correct position of the torch is essential for the good seams; the use of advanced image processing systems is necessary; example: sensor technology for welding torch position to recognize | |

| Cybersecurity | Security levels | The network of the CPS used is open to facilitate the fastest possible access, and the machines themselves use computer software systems that require the use of a common operating system; example: use of special hardware keys and intelligent software and access levels |

| Aspects/Perspectives | What | How | Where | Who | When | Why | Model View |

|---|---|---|---|---|---|---|---|

| Contextual | Fact, business data/for analysis with cognitive resonance | Business Service with the synergy of the cognitive resonance | Chain of Business Process Workflow | Business entity, function | Chain of Business Process, Workflow | Business goal | Scope |

| Conceptual | Underlying Conceptual data model/Data Lake structured and unstructured data | Service with added value originated by the cognitive resonance | Service composition with cognitive business intelligence | Actor, Role | Business Process Model | Business Objective | Enterprise Model |

| Logical | Notion hierarchy of CIS, Logical Model for structured, semi-structured and unstructured data of CIS | Cognitive Service Component | Hierarchy of Components of CIS | Actors, building blocks of Service | BPEL, BPMN, Orchestration | Business Rule | System Model |

| Physical | Object hierarchy, Data model | Cognitive Service Component | Hierarchy of Cognitive Service Component | Component, Object | Choreography | Rule Design | Technical Model |

| Detail | Data in DBMS | Cognitive Service Component | Hierarchy of Cognitive Service Component | Component, Object | Choreography, Security architecture | Rule specification | Components |

| Functioning Enterprise | Data | Function | Network | Organization | Schedule | Strategy | Service |

| Information system: PC + Nvidia Jetson TX2 model training and compression experiment | |||

| Platform Service Category | Subcategory | Required | Supporting Technology |

| Data Interchange Services | Audio Processing | yes | Librosa (resampling, splitting, MFCC conversion) |

| Electronic Data Interchange | yes | Google Drive | |

| Data Management Services | Data Dictionary/Repository | yes | Numpy (encode dataset into binary format, .npy files) |

| Joblib (sklearn model persistence), PyTorch (pickle-based model serialization, .pt files), ONNX | |||

| Location and Directory Services | Filtering | yes | Imbalanced-learn (undersampling of majority class) |

| Network Services | Data Communications | yes | http, ftp |

| Distributed Data | yes | Google Drive | |

| System and Network Management Services | Software Installation | yes | pip (Python package manager system) |

| Nvidia SDK Manager | |||

| Operating System Services | Command Interpreter and Utility | yes | psutil (memory queries) |

| time | |||

| Software Engineering Services | Programming Language | yes | Python |

| Computer-Aided Software Engineering (CASE) Environment and Tools | yes | Geany (IDE) | |

| Software library | yes | PyTorch, Scikit-learn, TensorRT, Neural Network Distiller |

| Research Activities | |||||

|---|---|---|---|---|---|

|

Design Science Research

(Information Technology /Information Systems/ Informatics) |

Natural Science/

Behavior Science | ||||

|

Activities

/Artifacts |

Build

(How It Was Created, Elaborated, Used, Utilized, Realized, Implemented) |

Evaluate

(The Component Whether Achieved the Goals, Fits the Purpose, Worked Properly). |

Theorize

(Generalize Experiences, Experiment, Conclude Discerned Facts) | Justify (Underpin, Buttress, Support Your Ideas and Experiment) | |

| Research Outputs | Constructs | ||||

| Model | |||||

| Method | |||||

| Instantiation | |||||

| Case Study Design | ||

|---|---|---|

| Case Study Design and Preparation for Data Collection | 1. | What is the object of study? |

| 2. | Is a clear purpose/objective/research question/hypothesis/proposition defined upfront? | |

| 3. | Is the theoretical basis—relation to existing literature and other cases—defined? | |

| 4. | Are the authors’ intentions with the research made clear? | |

| 5. | Is the case adequately defined (size, domain, process, etc.)? | |

| 6. | Is a cause-effect relation under study? If yes, is the cause distinguished from other factors? | |

| 7. | Will data be collected from multiple sources? Using multiple methods? | |

| 8. | Is there a rationale behind the selection of roles, artefacts, viewpoints, etc.? | |

| 9. | Are the case study settings relevant to validly address for the research question? | |

| 10. | Is the integrity of individuals/organizations taken into account? | |

| Preparation for Data Collection | ||

| 11. | Is a protocol for data collection and analysis derived (what, why, how)? | |

| 12. | Are multiple data sources and collection methods planned? | |

| 13. | For quantitative data, are the measurements well defined? | |

| 14. | Are the planned methods and measurements sufficient to fulfil the objective of the study? | |

| 15. | Is the study design approved by a review board and has informed consent obtained from individuals and organizations? | |

| Case Study Design | ||

| Collecting Evidence and Analysis of Collected Data | 16. | Are data collected according to the protocol? |

| 17. | Is the observed phenomenon correctly implemented (e.g., to what extent is a design method under study actually used)? | |

| 18. | Are data recorded to enable further analysis? | |

| 19. | Are sensitive results identified (for individuals, organization, or project)? | |

| 20. | Are the data collection procedures well traceable? | |

| 21. | Do the collected data provide the ability to address the research question? | |

| Analysis of Collected Data | ||

| 22. | Is the analysis methodology defined, including roles and review procedures? | |

| 23. | Is a chain of evidence shown with traceable inferences from data to research questions and existing theory? | |

| 24. | Are alternative perspectives and explanations used in the analysis? | |

| 25. | Is a cause-effect relation under study? If yes, is the cause distinguished from other factors? | |

| Reporting | Reporting | |

| 28. | Are the case and its context adequately reported? | |

| 29. | Are the research questions and corresponding answers reported? | |

| 30. | Are related theory, hypotheses, and propositions clearly reported? | |

| 31. | Are the data collection procedures presented, with relevant motivation? | |

| 32. | Are sufficient raw data presented? | |

| 33. | Are the analysis procedures clearly reported. | |

| 34. | Are threats to validity analyses reported? | |

| 35. | Are ethical issues reported openly (personal intentions, integrity issues) | |

| 36. | Does the report contain conclusions, implications for practice and future research? | |

| 37. | Does the report give a realistic and credible impression? | |

| 38. | Is the report suitable for its audience, easy to read and well structured? |

| No. | Milestones of Main Activities/Details |

|---|---|

| 1. | MES components and business function definition |

| 1.1 | Definition of machine environment involving 1st CNC machine |

| 1.2 | Creating business workflows |

| 1.2.1 | Definition of services: DCU-DACQ modules, Rule-engine for intelligent integration capability |

| 1.2.2 | Definition of machine workstation master data: equipment workplace, machine state, downtime reasons, physical signals, number of items ordered, |

| 1.3 | Workflow management involving 2nd CNC machine and welding robot cell |

| 1.4 | B2B relationship definition in MES |

| 1.5 | Create a system connection between ERP-MES |

| 2. | Designation of pilot standards |

| 2.1 | Definition of workpieces and sample drawing for customer expectations |

| 2.1.1 | Technologization of the chosen workpiece (process, manufacturing environment, raw material, welding consumables, shielding gas, WPQR process test) |

| 2.1.2 | Selection of related standards and directives |

| 2.2 | Definition of standard object classes for pilot standards |

| 3. | SQL database development |

| 3.1 | Defining the database structure |

| 3.1.1 | Database implementation |

| 3.1.2 | SQL-MES software integration |

| 3.2 | Database upload—data migration |

| 4. | 1st Testing Phase (pilot standards implementing) |

| 4.1 | Summary of software run experiences |

| 4.1.1 | Collection of functional gaps |

| 4.1.2 | Identification of improvement steps |

| 5. | 2nd Testing Phase (main standards and directives—project extension) |

| 5.1 | Summary of software run experiences |

| 5.1.1 | Collection of functional gaps |

| 5.1.2 | Identification of improvement steps |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molnár, B.; Szőlősi, J.; Gludovátz, A.; Andó, M. Related Standards and Certifications in the Architecture of Service-Oriented System in Welding Technology: A Systematic Review. Math. Comput. Appl. 2025, 30, 38. https://doi.org/10.3390/mca30020038

Molnár B, Szőlősi J, Gludovátz A, Andó M. Related Standards and Certifications in the Architecture of Service-Oriented System in Welding Technology: A Systematic Review. Mathematical and Computational Applications. 2025; 30(2):38. https://doi.org/10.3390/mca30020038

Chicago/Turabian StyleMolnár, Bálint, József Szőlősi, Attila Gludovátz, and Mátyás Andó. 2025. "Related Standards and Certifications in the Architecture of Service-Oriented System in Welding Technology: A Systematic Review" Mathematical and Computational Applications 30, no. 2: 38. https://doi.org/10.3390/mca30020038

APA StyleMolnár, B., Szőlősi, J., Gludovátz, A., & Andó, M. (2025). Related Standards and Certifications in the Architecture of Service-Oriented System in Welding Technology: A Systematic Review. Mathematical and Computational Applications, 30(2), 38. https://doi.org/10.3390/mca30020038