Improved Differential Evolution Algorithm for Flexible Job Shop Scheduling Problems

Abstract

1. Introduction

2. Literature Review

2.1. Flexible Job Shop Scheduling Problems by Using Other Metaheuristic Methods

2.2. Flexible Job Shop Scheduling Problems by Using Differential Evolution Algorithm

2.3. Differential Evolution Algorithm for Solving Other Problems

3. Flexible Job Shop Scheduling Problem Pattern and Mathematical Model

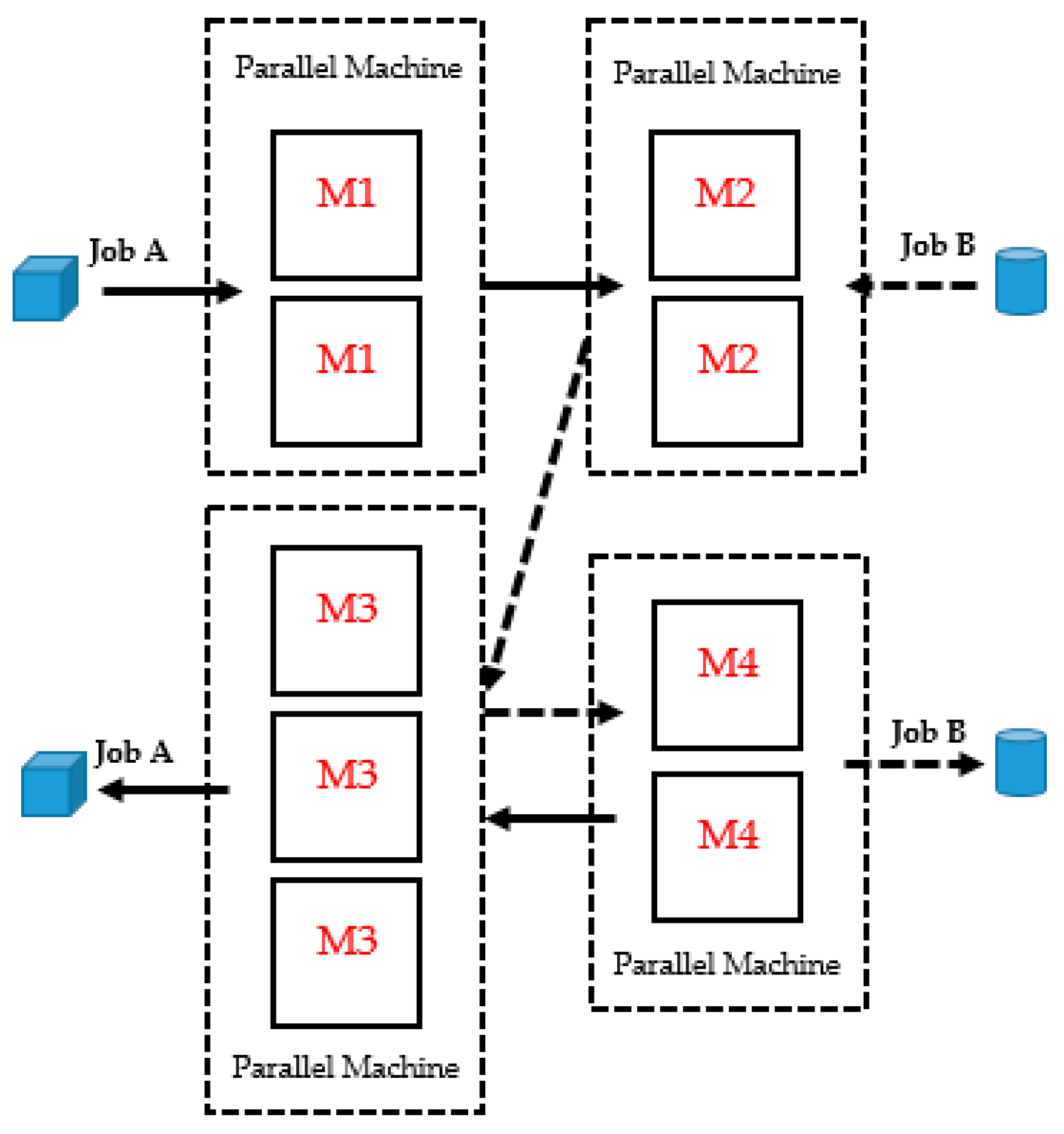

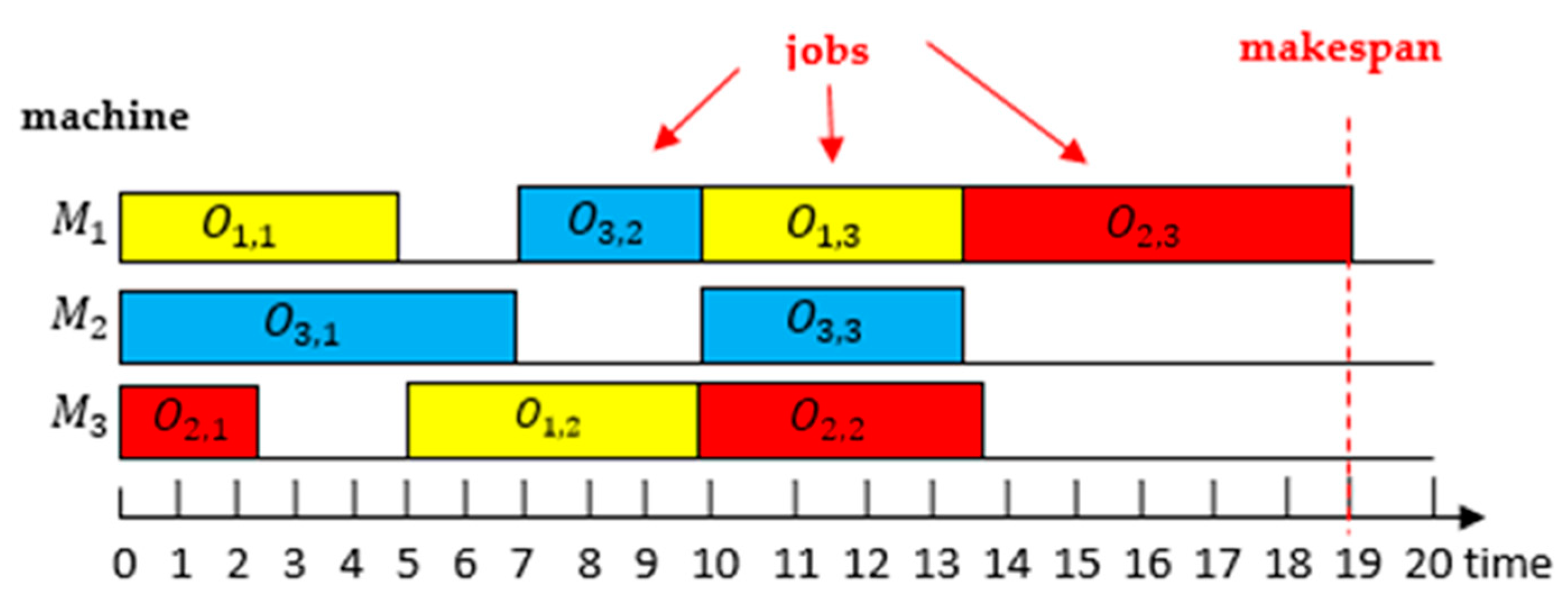

3.1. Flexible Job Shop Scheduling Problem (FJSP)

3.2. Mathematical Model of the Flexible Job Shop Scheduling Problem

3.2.1. Indices

3.2.2. Parameter

3.2.3. Decision Variables

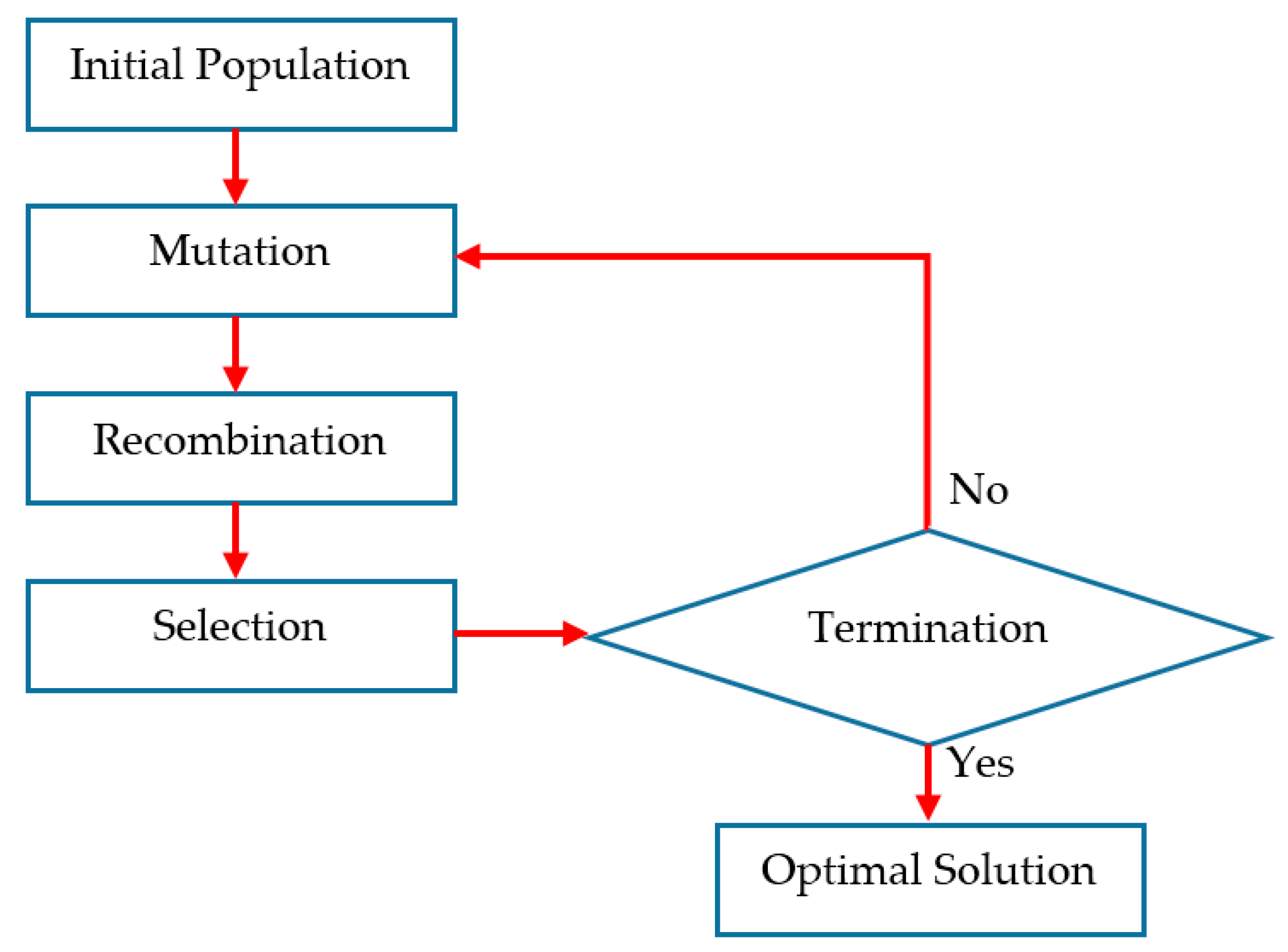

4. General Differential Evolution Algorithm

4.1. Procedure of FJSP by Using Differential Evolution Algorithm

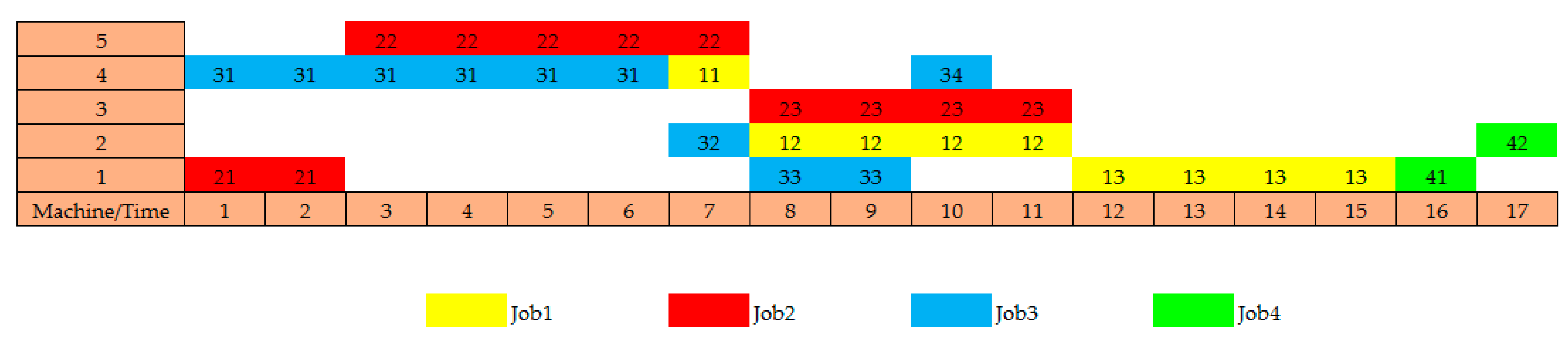

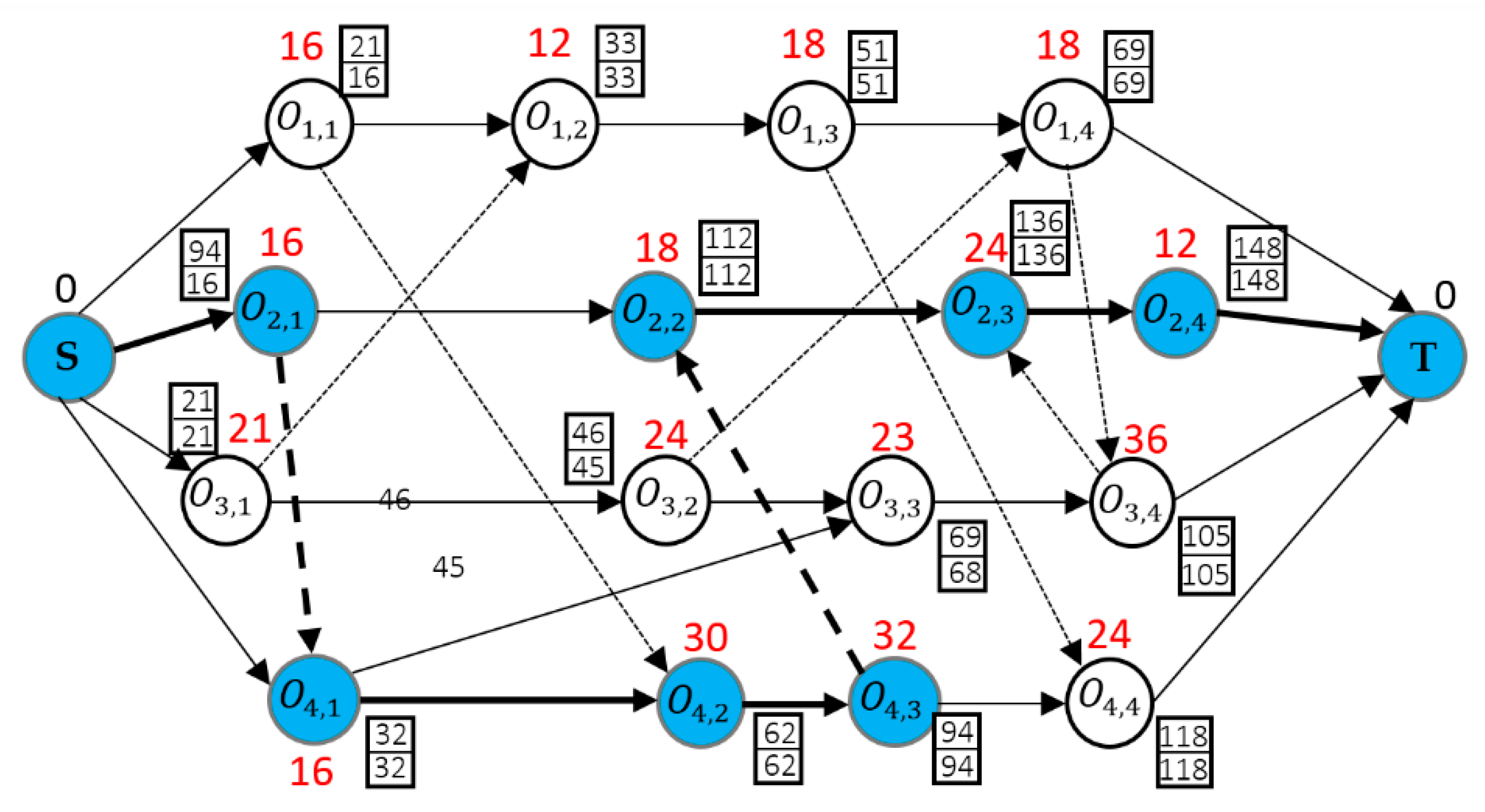

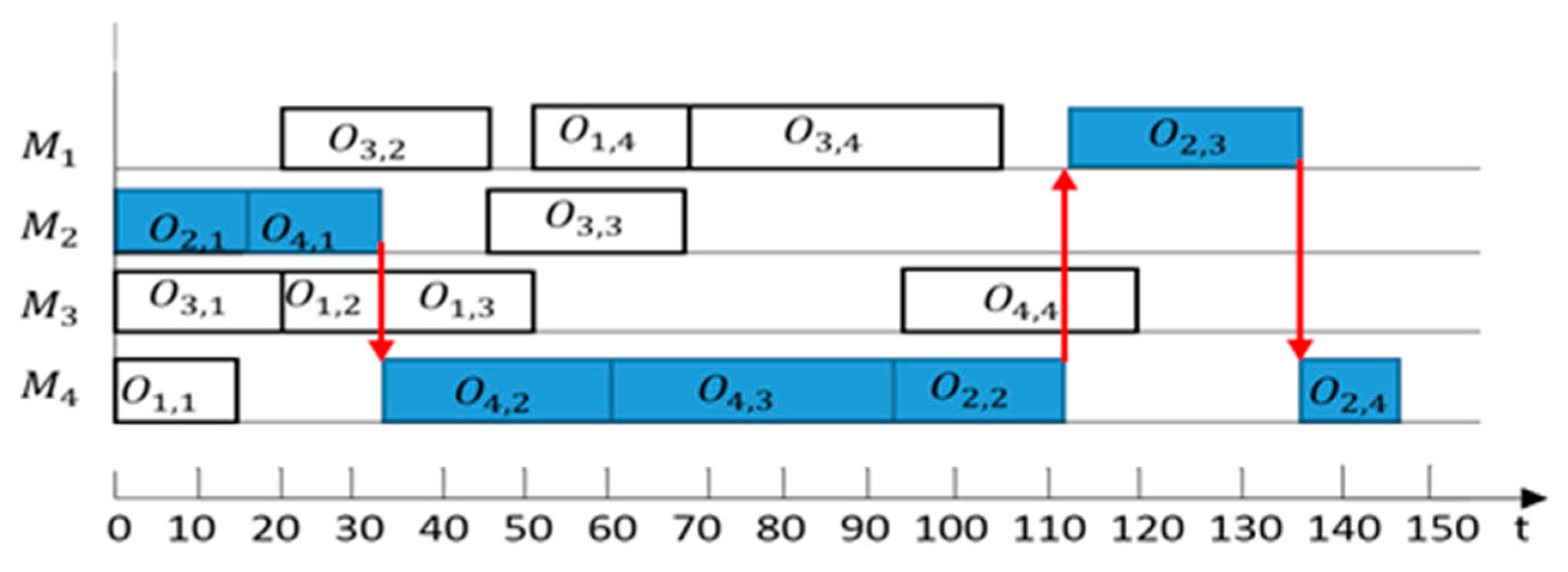

4.1.1. Calculation Using the General Differential Evolution Algorithm DE/rand/1 and Binomial Crossover

4.1.2. Procedure of FJSP by Using the Improved Differential Evolution Algorithm

| Algorithm 1. Pseudo-code of the improved DE for the FJSP |

| Setup the initial DE parameter Do while from first iteration to final iteration Do while from first DE to final DE Setup the initial parameters: job, operation, machine, processing time, operation sequence, machine assignment. Do while from first task to final task Find the start/following task where the fitness is the makespan of the data instances Input the scaling factor, crossover rate, NP, job assignment, machine assignment, and local search to data list Produce the four mutation equations: End do Select the best solution from all DEs in the iteration End do Show/select the best solution from all DEs in all iterations |

4.1.3. Procedure of FJSP by the Using Local Search with the Jump Search

5. Analysis of the Results from the Experiment on DE for Solving FJSP

5.1. Results of Solving the Flexible Job Shop Scheduling Problem with Sample Problems from Kacem et al.

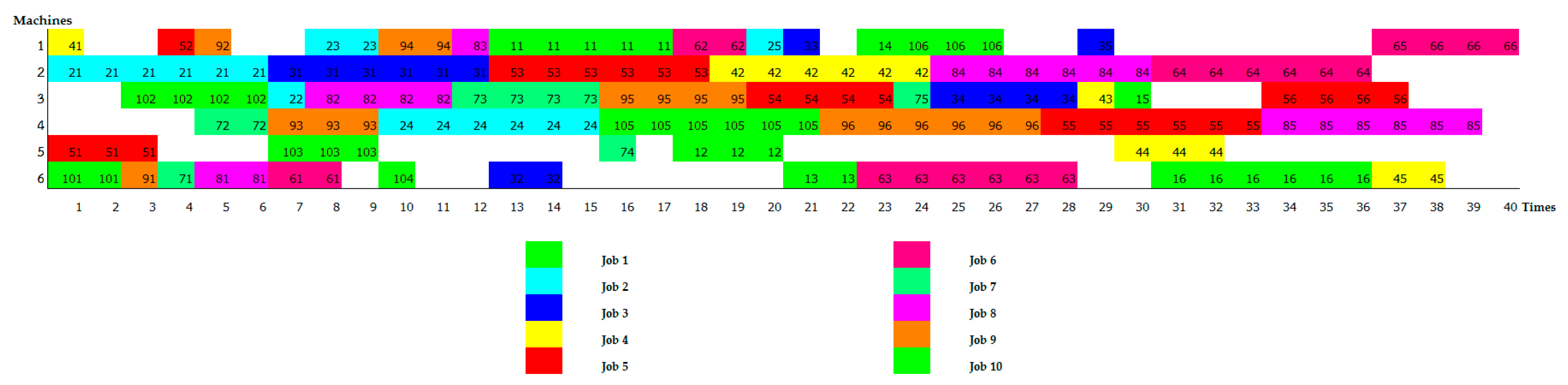

5.2. Results of Solving the Flexible Job Shop Scheduling Problem with Sample Problems of Brandimarte

5.3. Results of Solving the Flexible Job Shop Scheduling Problem with Sample Problems of Dauzere-Peres and Paulli

6. The Results of the Comparison of the DE Algorithm with Other Metaheuristic Methods

6.1. Results of Solving the Flexible Job Shop Scheduling Problem with Sample Problems of Brandimarte

6.2. Results of Solving the Flexible Job Shop Scheduling Problem with Sample Problems of Dauzere-Peres and Paulli

7. Conclusions and Suggestions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Karthikeyan, S.; Asokan, P.; Nickolas, S. A hybrid discrete firefly algorithm for multi-objective flexible job shop scheduling problem with limited resource constraints. Int. J. Adv. Manuf. Technol. 2014, 72, 1567–1579. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution—A simple and efficient heuristic for global optimization over continuous space. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Xia, W.; Wu, Z. An effective hybrid optimization approach for multi-objective flexible job-shop scheduling problems. Comput. Ind. Eng. 2005, 48, 409–425. [Google Scholar] [CrossRef]

- Kanate, P. Algorithm Development for Solving Flexible Job Shop Scheduling Problem. Ph.D. Thesis, Kasetsart University, Krung Thep Maha Nakhon, Thailand, 2011. [Google Scholar]

- Tang, J.; Zhang, G.; Lin, B.; Zhang, B. A Hybrid Algorithm for Flexible Job-shop Scheduling Problem. Procedia Eng. 2011, 15, 3678–3683. [Google Scholar] [CrossRef]

- Wannaporn, T.; Arit, T. Modified Genetic Algorithm for Flexible Job-Shop Scheduling Problems. Procedia Comput. Sci. 2012, 12, 122–128. [Google Scholar]

- Thanyapon, U.; Pupong, P.; Kwanniti, K. Solving an Advanced Planning and Scheduling Problem with Preventive Maintenance Time Window Constraints by Mixed Integer Programming Models. Thai J. Oper. Res. 2016, 4, 1–15. Available online: https://www.tci-thaijo.org/index.php/TJOR/article/view/60994 (accessed on 22 July 2019).

- Hamid, A.; Christoph, H.; Michael, D. Machine scheduling in production: A content analysis. Appl. Math. Model. 2017, 50, 279–299. [Google Scholar]

- Li, X.; Gao, L. An Effective Hybrid Genetic Algorithm and Tabu Search for Flexible Job Shop Scheduling Problem. Int. J. Prod. Econ. 2016, 174, 93–110. [Google Scholar] [CrossRef]

- Luan, F.; Cai, Z.; Wu, S.; Jiang, T.; Li, F.; Yang, J. Improved Whale Algorithm for Solving the Flexible Job Shop Scheduling Problem. Mathematics 2019, 7, 384. [Google Scholar] [CrossRef]

- Li, X.; Peng, Z.; Du, B.; Guo, J.; Xu, W.; Zhuang, K. Hybrid artificial bee colony algorithm with a rescheduling strategy for solving flexible job shop scheduling problems. Comput. Ind. Eng. 2017, 113, 10–26. [Google Scholar] [CrossRef]

- Wisittipanich, W. Minimizing Makespan in Flexible Job Shop Problems by Adapting the Differential Evolution. Thai J. Oper. Res. 2015, 3, 40–50. [Google Scholar]

- Yuan, Y.; Xu, H. Flexible job shop scheduling using hybrid differential evolution algorithms. Comput. Ind. Eng. 2013, 65, 246–260. [Google Scholar] [CrossRef]

- Bhaskara, P.; Padmanabhan, G.; Satheesh, K.B. Differential Evolution Algorithm for Flexible Job Shop Scheduling Problem. Int. J. Adv. Prod. Mech. Eng. 2015, 5, 71–79. [Google Scholar]

- Wang, L.; Pan, Q.K.; Tasgetiren, M.F. Minimizing the total flow time in a flow shop with blocking by using hybrid harmony search algorithms. Expert Syst. Appl. 2010, 37, 7929–7936. [Google Scholar] [CrossRef]

- Zhang, R.; Song, S.; Wu, C. A hybrid differential evolution algorithm for job shop scheduling problems with expected total tardiness criterion. Appl. Soft Comput. 2013, 13, 1448–1458. [Google Scholar] [CrossRef]

- Cao, E.; Lai, M. The open vehicle routing problem with fuzzy demands. Expert Syst. Appl. 2010, 37, 15. [Google Scholar] [CrossRef]

- Lai, M.; Cao, E. An improved differential evolution algorithm for vehicle routing problem with simultaneous pickups and deliveries and time windows. Eng. Appl. Artif. Intell. 2010, 23, 188–195. [Google Scholar]

- Xu, H.; Wen, J. Differential Evolution Algorithm for the Optimization of the Vehicle Routing Problem in Logistics. In Proceedings of the 2012 Eighth International Conference on Computational Intelligence and Security, Guangzhou, China, 17–18 November 2012; pp. 48–51. [Google Scholar]

- Cruz, I.L.; van Willigenburg, L.G.; van Straten, G. Efficient differential evolution algorithms for multimodal optimal control problems. Appl. Soft Comput. 2003, 3, 97–122. [Google Scholar] [CrossRef]

- Adeyemo, J.; Otieno, F. Differential evolution algorithm for solving multi-objective crop planning model. Agric. Water Manag. 2010, 97, 848–856. [Google Scholar] [CrossRef]

- Abou El Ela, A.A.; Abido, M.A.; Spea, S.R. Optimal power flow using differential Evolution algorithm. Electr. Power Syst. Res. 2010, 80, 878–885. [Google Scholar] [CrossRef]

- Kuila, P.; Jana, P.K. A novel differential evolution based clustering Algorithm for wireless sensor networks. Appl. Soft Comput. 2014, 25, 414–425. [Google Scholar] [CrossRef]

- Sharma, S.; Rangaiah, G.P. An improved multi-objective differential evolution with a termination criterion for optimizing chemical processes. Comput. Chem. Eng. 2013, 56, 155–173. [Google Scholar] [CrossRef]

- Pitakaso, R.; Parawech, P.; Jirasirierd, G. Comparisons of Different Mutation and Recombination Processes of the DEA for SALB-1. In Proceedings of the Institute of Industrial Engineers Asian Conference, Taipei, Taiwan, 18–20 July 2013; pp. 1571–1579. [Google Scholar]

- Kacem, I.; Hammadi, S.; Borne, P. Approach by localization and multiobjective evolutionary optimization for flexible job-shop scheduling problems. IEEE Trans. Syst. Man Cybern. 2002, 32, 1–13. [Google Scholar] [CrossRef]

- Kacem, I.; Hammadi, S.; Borne, P. Pareto-optimality approach for flexible job-shop scheduling problems: hybridization of evolutionary algorithms and fuzzy logic. Math. Comput. Simul. 2002, 60, 245–276. [Google Scholar] [CrossRef]

- Nguyen, S.; Kitchitvichynukul, V.; Wisittipanich, W. ET-Lib User’s Guide. Volume 2. Differential Evolution; Asian Institute of Technology: Khlong Luang, Thailand, 2013. [Google Scholar]

- Poontana, S.; Nuchsara, K.; Preecha, K.; Krit, C. U-Shaped Assembly Line Balancing by Using Differential Evolution Algorithm. Math. Comput. Appl. 2018, 23, 79. [Google Scholar]

- Brandimarte, P. Routing and Scheduling in a Flexible Job Shop by Tabu Search. Ann. Oper. Res. 1993, 41, 157–183. [Google Scholar] [CrossRef]

- Dauzere-Peres, S.; Paulli, J. An integrated approach for modeling and solving the general multiprocessor job-shop scheduling problem using tabu search. Ann. Oper. Res. 1997, 70, 281–306. [Google Scholar] [CrossRef]

- Chen, H.; Ihlow, J.; Lehmann, C. A genetic algorithm for flexible job-shop scheduling. In Proceedings of the IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; pp. 1120–1125. [Google Scholar]

- Girish, B.S.; Jawahar, N. A particle swarm optimization algorithm for flexible job shop scheduling problem. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Bangalore, India, 22–25 August 2009; pp. 298–303. [Google Scholar]

| Job | Operation | Machines | ||

|---|---|---|---|---|

| M1 | M2 | M3 | ||

| J1 | O1,1 | 5 | - | 3 |

| O1,2 | - | 5 | 10 | |

| O1,3 | 5 | 9 | - | |

| J2 | O2,1 | - | 10 | 7 |

| O2,2 | 20 | 6 | - | |

| O3,3 | 2 | - | 11 | |

| J3 | O3,1 | 2 | 5 | 4 |

| O3,3 | 2 | 5 | 10 | |

| 45. 35. 1 2 2 5 3 4 4 1 5 2 5 1 5 2 4 3 5 4 7 5 5 5 1 4 2 5 3 5 4 4 5 5 35. 1 2 2 5 3 4 4 7 5 8 5 1 5 2 6 3 9 4 8 5 5 5 1 4 2 5 3 4 4 54 5 5 45. 1 9 2 8 3 6 4 7 5 9 5 1 6 2 1 3 2 4 5 5 4 5 1 2 2 5 3 4 4 2 5 4 5 1 4 2 5 3 2 4 1 5 5 25. 1 1 2 5 3 2 4 4 5 12 5 1 5 2 1 3 2 4 1 5 2 |

| Jobs | Operations | Machines | ||||

|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M5 | ||

| J1 | O1,1 | 2 | 5 | 4 | 1 | 2 |

| O1,2 | 5 | 4 | 5 | 7 | 5 | |

| O1,3 | 4 | 5 | 5 | 4 | 5 | |

| J2 | O2,1 | 2 | 5 | 4 | 7 | 8 |

| O2,2 | 5 | 6 | 9 | 8 | 5 | |

| O2,3 | 4 | 5 | 4 | 54 | 5 | |

| J3 | O3,1 | 9 | 8 | 6 | 7 | 9 |

| O3,2 | 6 | 1 | 2 | 5 | 4 | |

| O3,3 | 2 | 5 | 4 | 2 | 4 | |

| O3,4 | 4 | 5 | 2 | 1 | 5 | |

| J4 | O4,1 | 1 | 5 | 2 | 4 | 12 |

| O4,2 | 5 | 1 | 2 | 1 | 2 | |

| NP | Dimensions, D | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 1 | 0.55 | 0.32 | 0.70 | 0.12 | 0.64 | 0.89 | 0.96 | 0.81 | 0.38 | 0.55 | 0.27 | 0.71 |

| 2 | 0.17 | 0.80 | 0.94 | 0.93 | 0.44 | 0.36 | 0.77 | 0.35 | 0.13 | 0.42 | 0.17 | 0.11 |

| 3 | 0.42 | 0.35 | 0.15 | 0.61 | 0.10 | 0.34 | 0.93 | 0.51 | 0.08 | 0.59 | 0.63 | 0.50 |

| 4 | 0.65 | 0.72 | 0.30 | 0.58 | 0.02 | 0.74 | 0.59 | 0.17 | 0.14 | 0.07 | 0.73 | 0.31 |

| 5 | 0.72 | 0.32 | 0.04 | 0.20 | 0.89 | 0.28 | 0.42 | 0.67 | 0.15 | 0.49 | 0.09 | 0.81 |

| Random Vector | r1 | r2 | r3 |

|---|---|---|---|

| 1 | 2 | 5 | 3 |

| 2 | 3 | 3 | 5 |

| 3 | 4 | 2 | 2 |

| 4 | 5 | 1 | 1 |

| 5 | 1 | 4 | 4 |

| Mutation | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.77 | 0.74 | 0.42 | 0.11 | 2.02 | 0.24 | −0.25 | 0.67 | 0.27 | 0.22 | −0.91 | 0.73 |

| 2 | 0.80 | 0.13 | 0.74 | 0.24 | 1.78 | 0.50 | −0.47 | 0.04 | 1.81 | 0.38 | −0.43 | 0.37 |

| 3 | 0.16 | 0.70 | 0.56 | 0.61 | 1.45 | 0.43 | −0.74 | 0.24 | 1.30 | −0.08 | 0.02 | 0.40 |

| 4 | 0.81 | 0.43 | 0.24 | −0.36 | 0.03 | 0.09 | 0.97 | 0.69 | −0.70 | 1.04 | 1.19 | 1.04 |

| 5 | 0.87 | 1.30 | 0.65 | 0.69 | 1.05 | 1.39 | 0.23 | −0.86 | 1.31 | 0.60 | 0.31 | 0.91 |

| Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.83 | 0.05 | 0.75 | 0.80 | 0.95 | 0.39 | 0.29 | 0.60 | 0.30 | 0.44 | 0.59 | 0.65 |

| 2 | 0.68 | 0.36 | 0.48 | 0.47 | 0.70 | 0.96 | 0.04 | 0.76 | 0.64 | 0.42 | 0.16 | 0.44 |

| 3 | 0.32 | 0.40 | 0.97 | 0.38 | 0.63 | 0.69 | 0.71 | 0.92 | 0.65 | 0.83 | 0.92 | 0.49 |

| 4 | 0.56 | 0.18 | 0.06 | 0.38 | 0.47 | 0.23 | 0.11 | 0.85 | 0.80 | 0.30 | 0.65 | 0.02 |

| 5 | 0.81 | 0.35 | 0.70 | 0.50 | 0.89 | 0.89 | 0.84 | 0.29 | 0.01 | 0.21 | 0.41 | 0.83 |

| Trial Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.55 | 0.74 | 0.42 | 0.12 | 0.64 | 0.24 | −0.25 | 0.67 | 0.27 | 0.22 | −0.91 | 0.73 |

| 2 | 0.80 | 0.13 | 0.74 | 0.24 | 1.78 | 0.50 | −0.47 | 0.04 | 1.81 | 0.38 | −0.43 | 0.37 |

| 3 | 0.16 | 0.70 | 0.56 | 0.61 | 1.45 | 0.43 | −0.74 | 0.24 | 1.30 | −0.08 | 0.02 | 0.40 |

| 4 | 0.65 | 0.72 | 0.30 | 0.58 | 0.02 | 0.74 | 0.59 | 0.17 | 0.14 | 0.07 | 0.73 | 0.31 |

| 5 | 0.72 | 0.32 | 0.04 | 0.20 | 0.89 | 0.28 | 0.42 | 0.67 | 0.15 | 0.49 | 0.09 | 0.81 |

| Vector | 11 | 7 | 4 | 10 | 6 | 9 | 3 | 1 | 5 | 8 | 12 | 2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | −0.91 | −0.25 | 0.12 | 0.22 | 0.24 | 0.27 | 0.42 | 0.55 | 0.64 | 0.67 | 0.73 | 0.74 |

| Oi,j | 1, 1 | 1, 2 | 1, 3 | 2, 1 | 2, 2 | 2, 3 | 3, 1 | 3, 2 | 3, 3 | 3, 4 | 4, 1 | 4, 2 |

| Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.55 | 0.74 | 0.42 | 0.12 | 0.64 | 0.24 | −0.25 | 0.67 | 0.27 | 0.22 | −0.91 | 0.73 |

| Oi,j | 3,2 | 4,2 | 3,1 | 1,3 | 3,3 | 2,2 | 1,2 | 3,4 | 2,3 | 2,1 | 1,1 | 4,1 |

| M | 2 | 2 | 4 | 1 | 1 | 5 | 2 | 4 | 3 | 1 | 4 | 1 |

| PT | 1 | 1 | 6 | 4 | 2 | 5 | 4 | 1 | 4 | 2 | 1 | 1 |

| Target Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Target |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.55 | 0.32 | 0.70 | 0.12 | 0.64 | 0.89 | 0.96 | 0.81 | 0.38 | 0.55 | 0.27 | 0.71 | 21 |

| 2 | 0.17 | 0.80 | 0.94 | 0.93 | 0.44 | 0.36 | 0.77 | 0.35 | 0.13 | 0.42 | 0.17 | 0.11 | 20 |

| 3 | 0.42 | 0.35 | 0.15 | 0.61 | 0.10 | 0.34 | 0.93 | 0.51 | 0.08 | 0.59 | 0.63 | 0.50 | 22 |

| 4 | 0.65 | 0.72 | 0.30 | 0.58 | 0.02 | 0.74 | 0.59 | 0.17 | 0.14 | 0.07 | 0.73 | 0.31 | 24 |

| 5 | 0.72 | 0.32 | 0.04 | 0.20 | 0.89 | 0.28 | 0.42 | 0.67 | 0.15 | 0.49 | 0.09 | 0.81 | 19 |

| Trial Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Target |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.55 | 0.74 | 0.42 | 0.12 | 0.64 | 0.24 | −0.25 | 0.67 | 0.27 | 0.22 | −0.91 | 0.73 | 18 |

| 2 | 0.80 | 0.13 | 0.74 | 0.24 | 1.78 | 0.50 | −0.47 | 0.04 | 1.81 | 0.38 | −0.43 | 0.37 | 25 |

| 3 | 0.16 | 0.70 | 0.56 | 0.61 | 1.45 | 0.43 | −0.74 | 0.24 | 1.30 | −0.08 | 0.02 | 0.40 | 16 |

| 4 | 0.65 | 0.72 | 0.30 | 0.58 | 0.02 | 0.74 | 0.59 | 0.17 | 0.14 | 0.07 | 0.73 | 0.31 | 17 |

| 5 | 0.72 | 0.32 | 0.04 | 0.20 | 0.89 | 0.28 | 0.42 | 0.67 | 0.15 | 0.49 | 0.09 | 0.81 | 26 |

| Vector | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Target |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.55 | 0.74 | 0.42 | 0.12 | 0.64 | 0.24 | −0.25 | 0.67 | 0.27 | 0.22 | −0.91 | 0.73 | 18 |

| 2 | 0.17 | 0.80 | 0.94 | 0.93 | 0.44 | 0.36 | 0.77 | 0.35 | 0.13 | 0.42 | 0.17 | 0.11 | 20 |

| 3 | 0.16 | 0.70 | 0.56 | 0.61 | 1.45 | 0.43 | −0.74 | 0.24 | 1.30 | −0.08 | 0.02 | 0.40 | 16 |

| 4 | 0.65 | 0.72 | 0.30 | 0.58 | 0.02 | 0.74 | 0.59 | 0.17 | 0.14 | 0.07 | 0.73 | 0.31 | 17 |

| 5 | 0.72 | 0.32 | 0.04 | 0.20 | 0.89 | 0.28 | 0.42 | 0.67 | 0.15 | 0.49 | 0.09 | 0.81 | 19 |

| Problem | BKS | Mutation Strategy | |||

|---|---|---|---|---|---|

| DE * | DE ** | DE *** | DE **** | ||

| K01 | 11 | 12 (9.09) | 12 (9.09) | 11 (0.00) | 11 (0.00) |

| K02 | 14 | 15 (7.14) | 15 (7.14) | 15 (7.14) | 15 (7.14) |

| K03 | 11 | 11 (0.00) | 11 (0.00) | 11 (0.00) | 11 (0.00) |

| K04 | 7 | 7 (0.00) | 7 (0.00) | 7 (0.00) | 7 (0.00) |

| K05 | 11 | 12 (9.09) | 12 (9.09) | 12 (9.09) | 12 (9.09) |

| MRE | 5.06 | 5.06 | 3.25 | 3.25 | |

| Problem | BKS | Mutation Strategy | |||

|---|---|---|---|---|---|

| DE * | DE ** | DE *** | DE **** | ||

| Mk1 | 40 | 43 (7.50) | 43 (7.50) | 40 (0.00) | 40 (0.00) |

| Mk2 | 27 | 28 (7.69) | 28 (7.69) | 28 (7.69) | 28 (7.69) |

| Mk3 | 204 | 204 (0.00) | 204 (0.00) | 204 (0.00) | 204 (0.00) |

| Mk4 | 60 | 71 (18.33) | 71 (18.33) | 71 (18.33) | 71 (18.33) |

| Mk5 | 174 | 178 (2.30) | 178 (2.30) | 179 (2.87) | 179 (2.87) |

| Mk6 | 59 | 73 (23.73) | 73 (23.73) | 73 (23.73) | 73 (23.73) |

| Mk7 | 143 | 149 (4.20) | 149 (4.20) | 148 (3.50) | 146 (2.10) |

| Mk8 | 523 | 528 (0.96) | 528 (0.96) | 528 (0.96) | 528 (0.96) |

| Mk9 | 307 | 324 (5.54) | 321 (4.56) | 323 (5.21) | 321 (4.56) |

| Mk10 | 212 | 234 (10.38) | 233 (9.90) | 236 (11.32) | 235 (10.85) |

| MRE | 8.06 | 7.92 | 7.36 | 7.11 | |

| Problem | BKS | Mutation Strategy | |||

|---|---|---|---|---|---|

| DE * | DE ** | DE *** | DE **** | ||

| 01a | 2530 | 2895 (14.42) | 2750 (8.70) | 2615 (3.36) | 2645 (4.55) |

| 04a | 2555 | 2859 (11.90) | 2770 (8.41) | 2650 (3.72) | 2610 (2.15) |

| 07a | 2396 | 2759 (15.15) | 2650 (10.60) | 2650 (10.60) | 2510 (4.76) |

| 09a | 2074 | 2281 (9.98) | 2269 (9.40) | 2210 (6.56) | 2150 (3.66) |

| 11a | 2078 | 2378 (14.44) | 2366 (13.86) | 2221 (6.88) | 2200 (5.87) |

| MRE | 13.18 | 10.19 | 6.22 | 4.20 | |

| Problem | n × m × k * | BKS ** | Chen et al. (GA) [32] | Girish and Jawahar (PSO) [33] | DE-FJSP |

|---|---|---|---|---|---|

| Cmax | Cmax | Cmax | Cmax | ||

| Mk01 | 10 × 6 × 55 | 40 | 40 (0.00) | 40 (0.00) | 40 (0.00) |

| Mk02 | 10 × 6 × 58 | 27 | 29 (6.89) | 27 (0.00) | 28 (7.69) |

| Mk03 | 15 × 8 × 150 | 204 | 204 (0.00) | 204 (0.00) | 204 (0.00) |

| Mk04 | 15 × 8 × 90 | 60 | 63 (4.76) | 62 (3.22) | 71 (18.33) |

| Mk05 | 15 × 4 × 106 | 174 | 181 (3.86) | 178 (2.24) | 179 (2.87) |

| Mk06 | 10 × 15 × 150 | 59 | 60 (1.66) | 78 (24.35) | 73 (23.73) |

| Mk07 | 20 × 5 × 100 | 143 | 148 (3.38) | 147 (2.72) | 146 (2.10) |

| Mk08 | 20 × 10 × 225 | 523 | 523 (0.00) | 523 (0.00) | 528 (0.96) |

| Mk09 | 20 × 10 × 240 | 307 | 308 (0.32) | 341 (9.97) | 321 (4.56) |

| Mk10 | 20 × 15 × 240 | 212 | 212 (0.00) | 252 (15.07) | 235 (10.85) |

| MRE | 2.08 | 7.75 | 7.11 | ||

| Problem | n × m × k * | BKS ** | Wisittipanich (1ST-DE) [12] | DE-FJSP |

|---|---|---|---|---|

| Cmax | Cmax | Cmax | ||

| 01a | 10 × 5 × 196 | 2530 | 2645 (4.55) | 2645 (4.55) |

| 04a | 10 × 5 × 196 | 2555 | 2616 (2.39) | 2610 (2.15) |

| 07a | 15 × 8 × 293 | 2396 | 2582 (7.76) | 2510 (4.76) |

| 09a | 15 × 8 × 293 | 2074 | 2153 (3.81) | 2150 (3.66) |

| 11a | 15 × 8 × 293 | 2078 | 2221 (6.88) | 2200 (5.87) |

| MRE | 5.08 | 4.20 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sriboonchandr, P.; Kriengkorakot, N.; Kriengkorakot, P. Improved Differential Evolution Algorithm for Flexible Job Shop Scheduling Problems. Math. Comput. Appl. 2019, 24, 80. https://doi.org/10.3390/mca24030080

Sriboonchandr P, Kriengkorakot N, Kriengkorakot P. Improved Differential Evolution Algorithm for Flexible Job Shop Scheduling Problems. Mathematical and Computational Applications. 2019; 24(3):80. https://doi.org/10.3390/mca24030080

Chicago/Turabian StyleSriboonchandr, Prasert, Nuchsara Kriengkorakot, and Preecha Kriengkorakot. 2019. "Improved Differential Evolution Algorithm for Flexible Job Shop Scheduling Problems" Mathematical and Computational Applications 24, no. 3: 80. https://doi.org/10.3390/mca24030080

APA StyleSriboonchandr, P., Kriengkorakot, N., & Kriengkorakot, P. (2019). Improved Differential Evolution Algorithm for Flexible Job Shop Scheduling Problems. Mathematical and Computational Applications, 24(3), 80. https://doi.org/10.3390/mca24030080