Multi-Parameter Synergistic Effects on Fine Coal Slurry Sedimentation in High-Gravity Fields: A CFD Study

Abstract

1. Introduction

2. Numerical Model

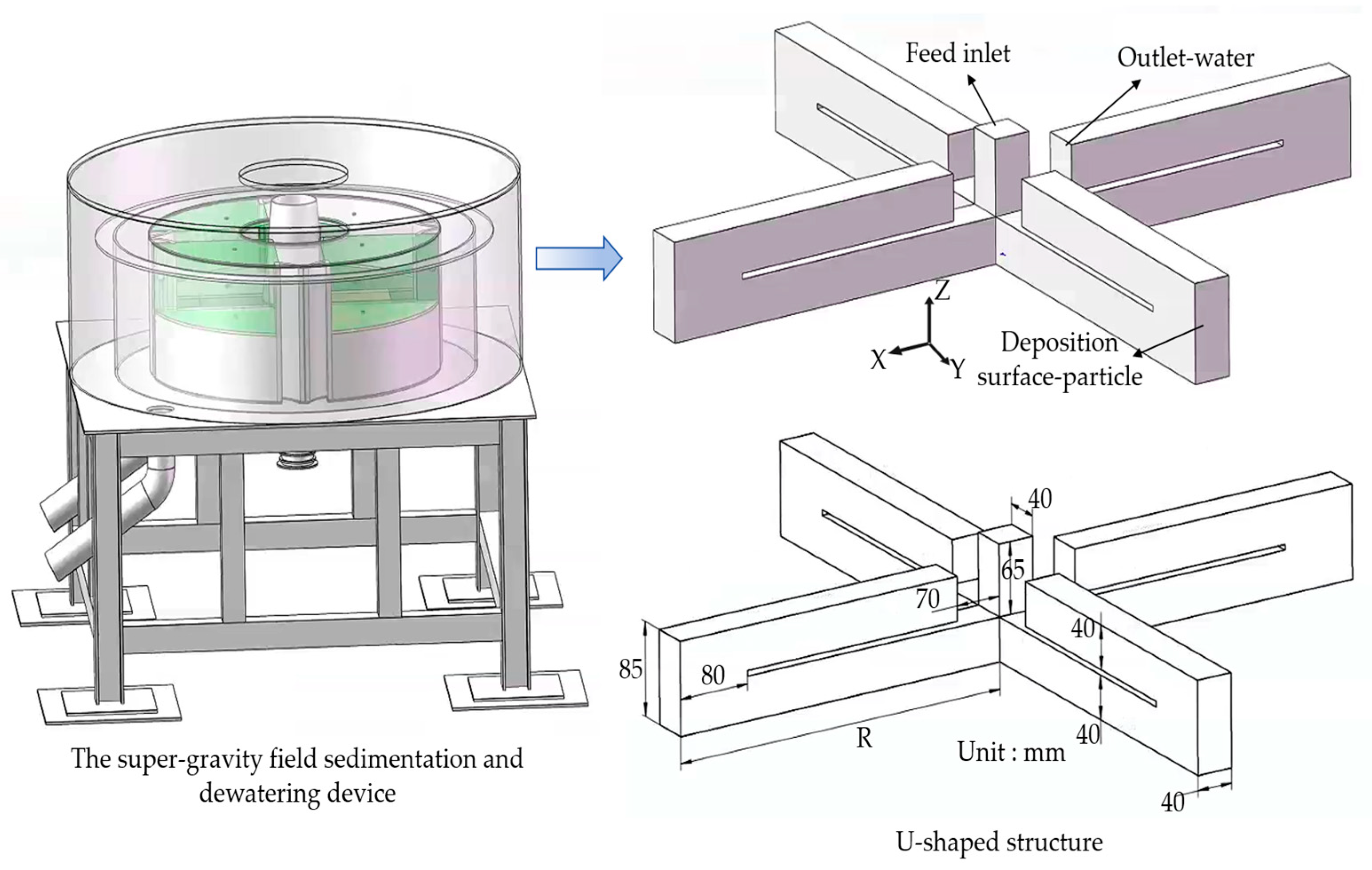

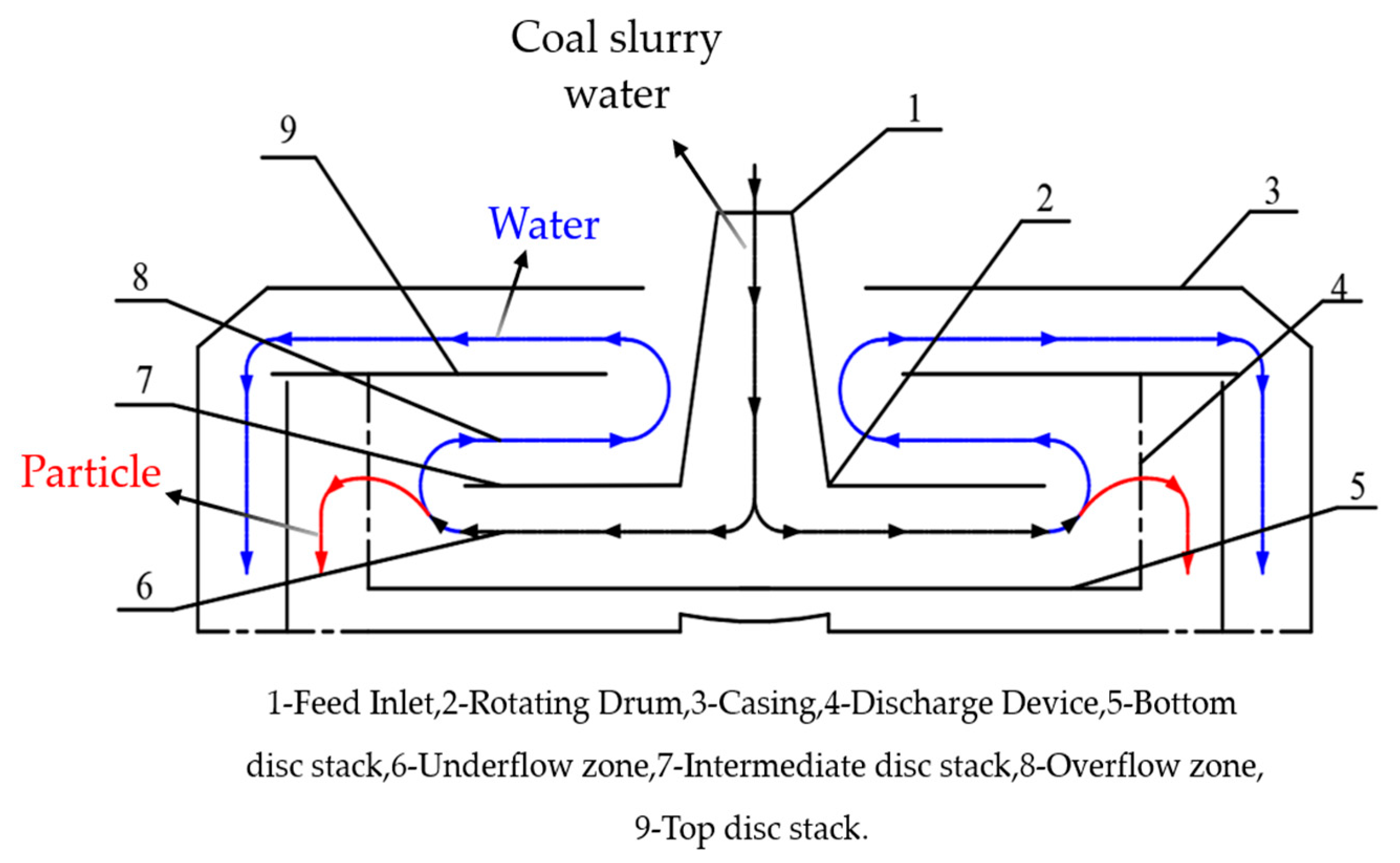

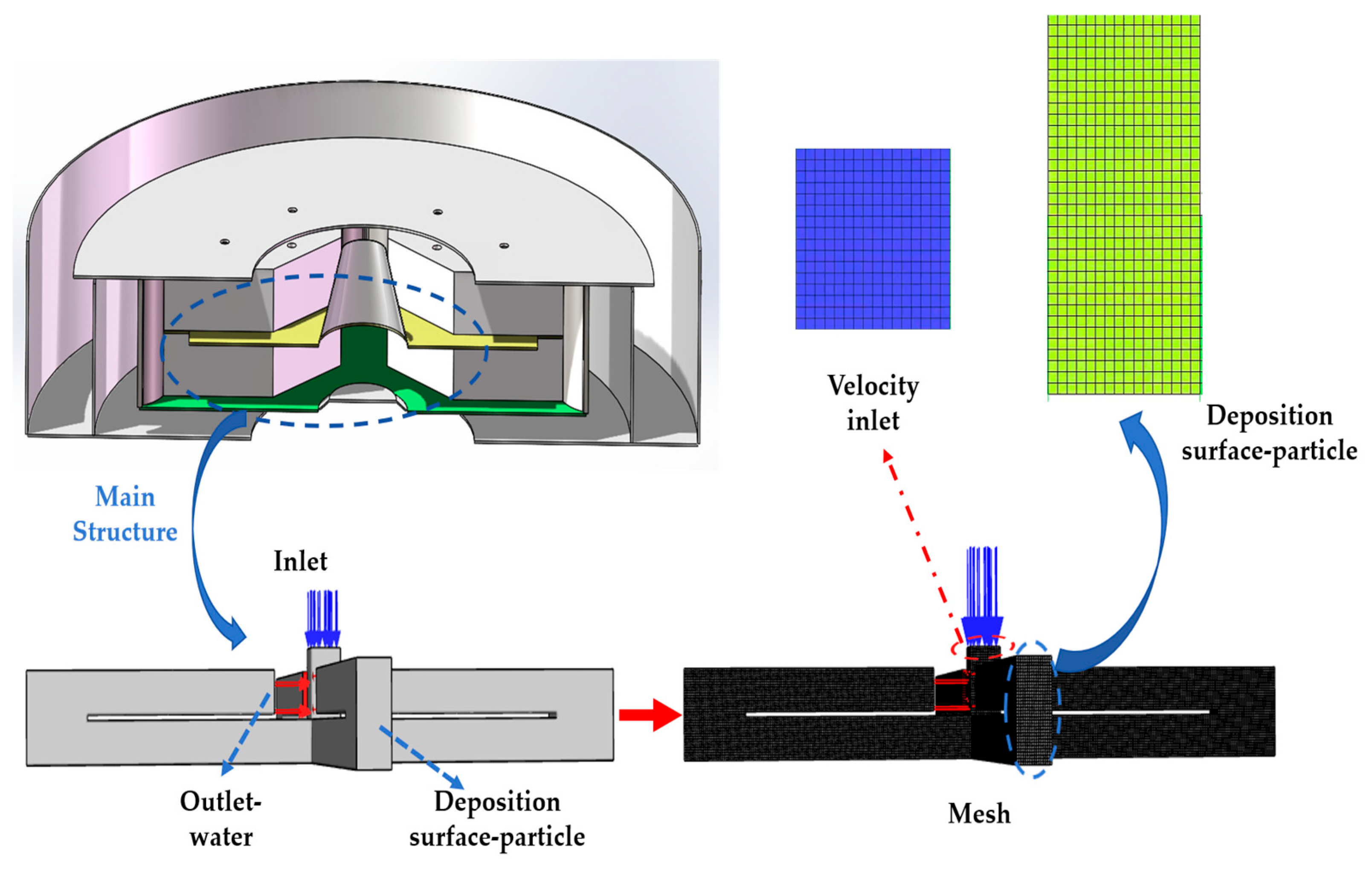

2.1. Geometry Model

2.2. Governing Equations

- (1)

- Solid–liquid two-phase continuity equation

- Liquid-phase continuity equation:

- Solid-phase continuity equation:where αl and αp are the volume fractions of the liquid and solid phases, ρl and ρp are their densities, and vl and vp are their velocity vectors.

- (2)

- Solid–liquid two-phase momentum conservation equation

- Liquid-phase momentum equation:

- Solid-phase momentum equation:where p is the common fluid pressure, Pp the solid pressure (closed via KTGF), τl and τp the shear stress tensors of liquid and solid phases, g the gravitational acceleration vector, and Mlp the interphase momentum exchange force satisfying Mlp = −Mpl. Here, ω denotes the angular velocity vector of the rotating frame and r the position vector from the rotation center to the computational point, providing an accurate description of particle-fluid motion [37,38].

- (3)

- Equations for turbulent kinetic energy and dissipation rate

- Equation for turbulent kinetic energy:where Pk denotes the turbulent kinetic energy production term, Gk the buoyancy-induced production, μ the molecular viscosity, μt the turbulent viscosity, σk the diffusion coefficient of turbulent kinetic energy, and ε the dissipation rate.

- Equation for turbulent dissipation rate:where σω denotes the diffusion coefficient of the turbulent dissipation rate, β1 and β2 are model constants, and ε/k is the production term of the dissipation rate, enabling accurate prediction in near-wall regions [39].

2.3. Numerical Methods

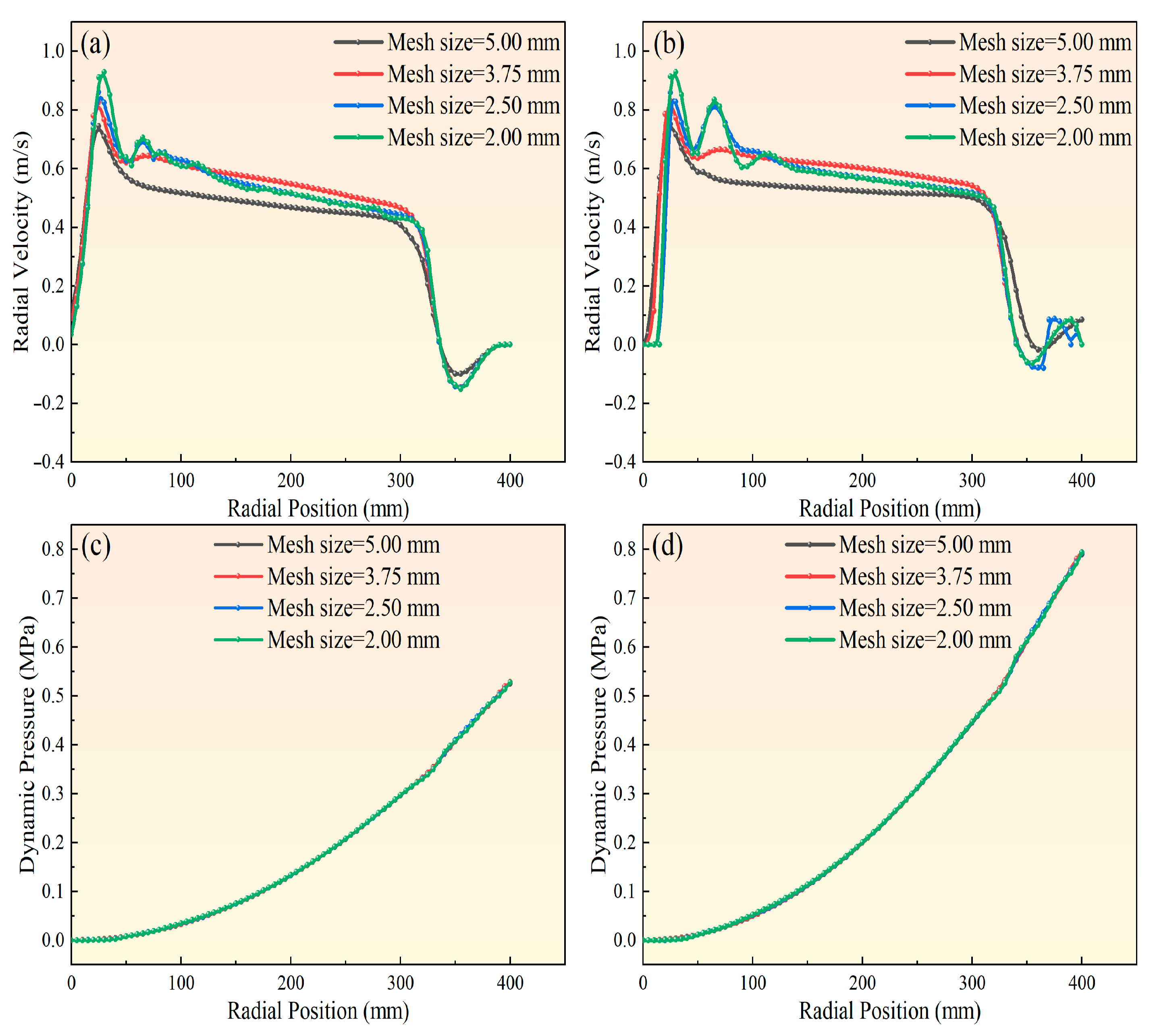

2.4. Mesh Generation and Independence Verification

3. Numerical Results and Discussion

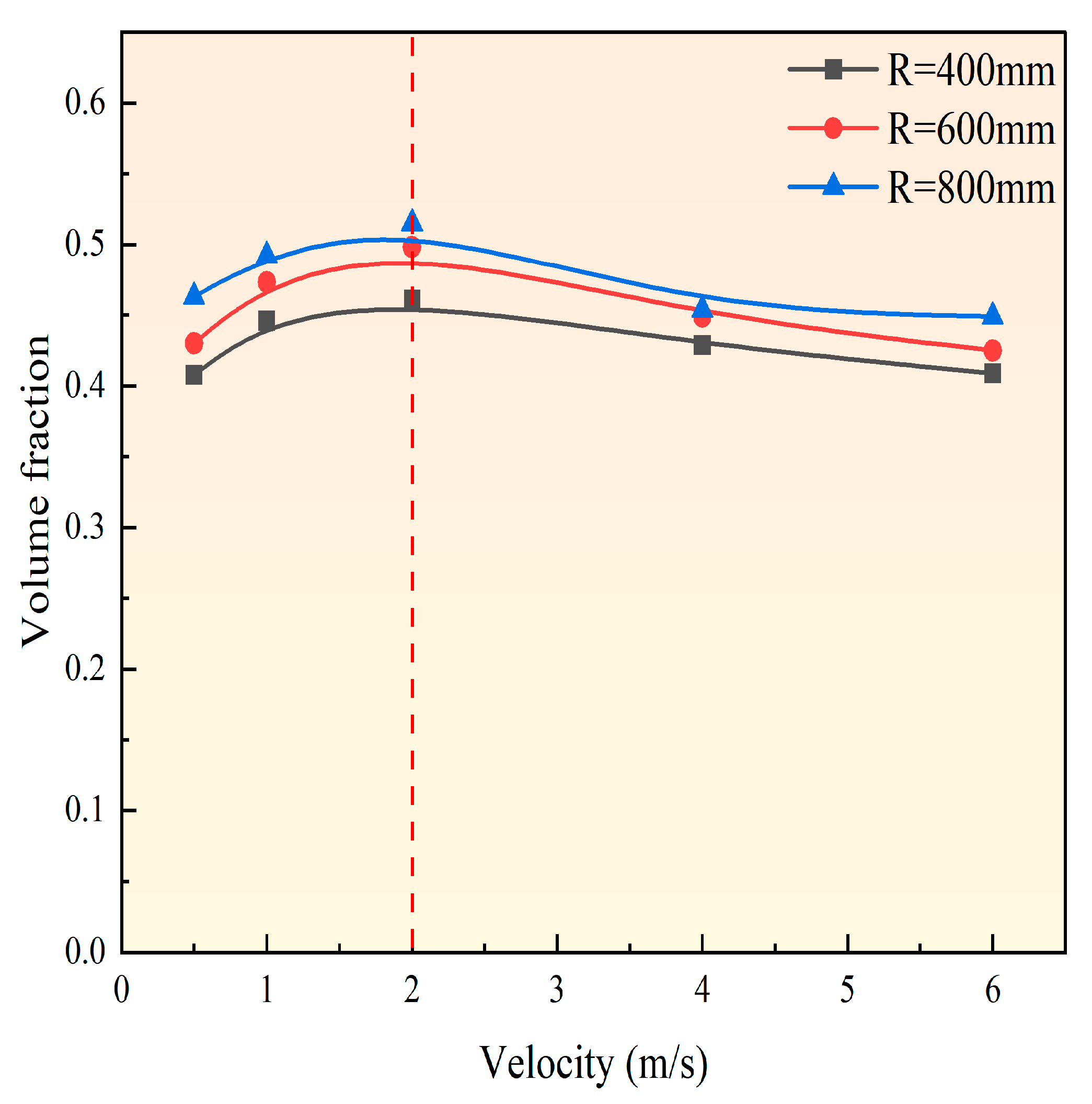

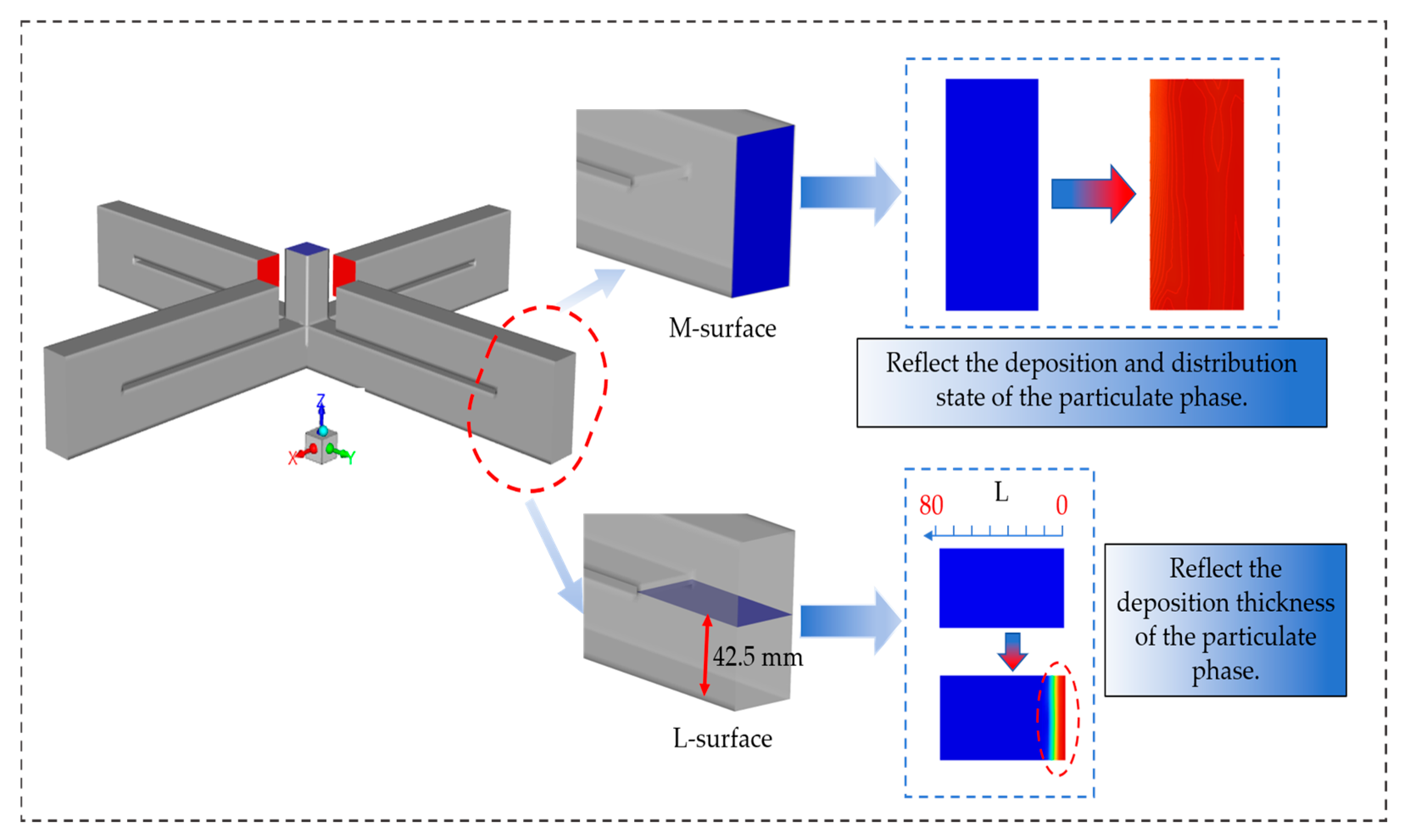

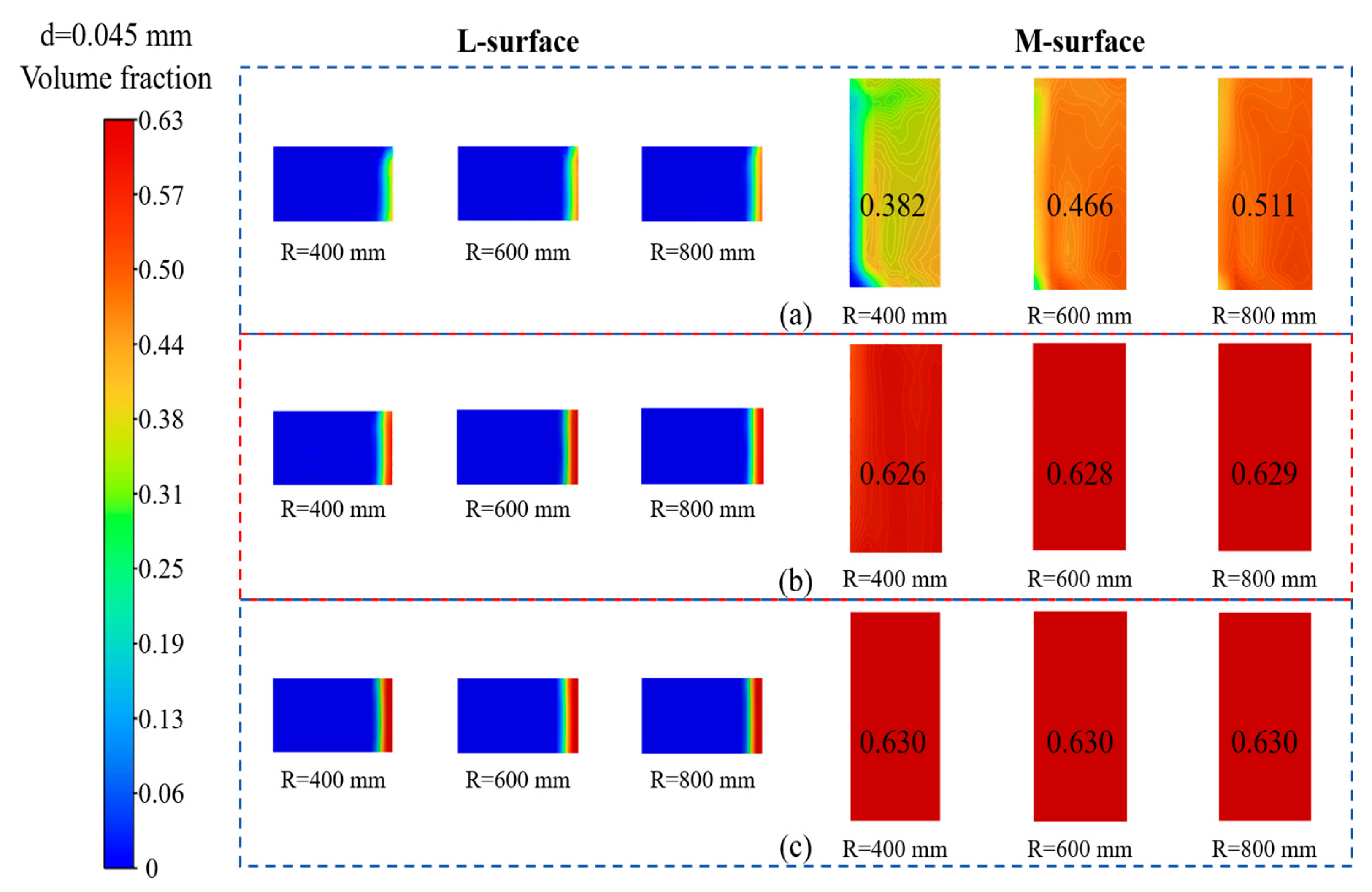

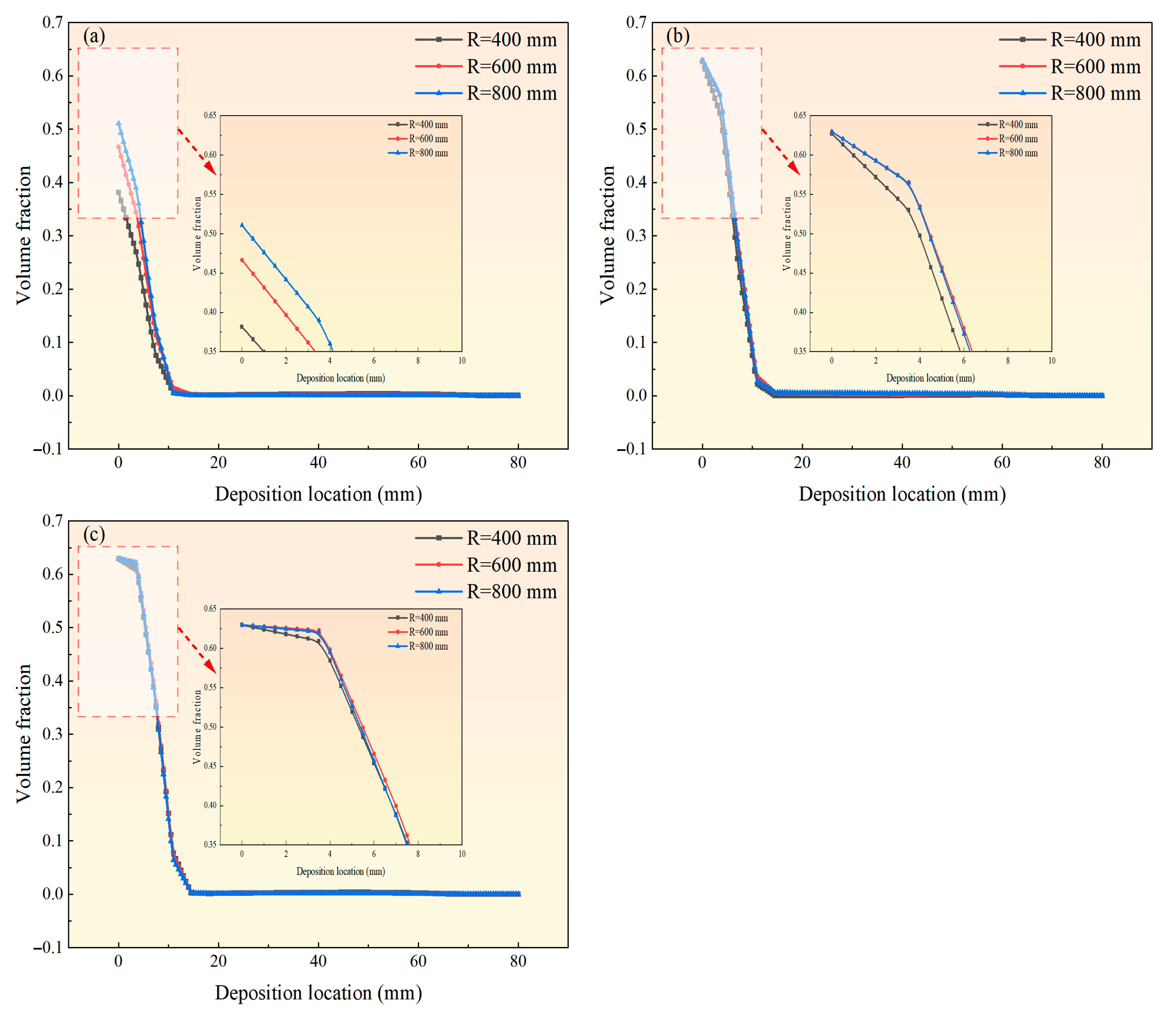

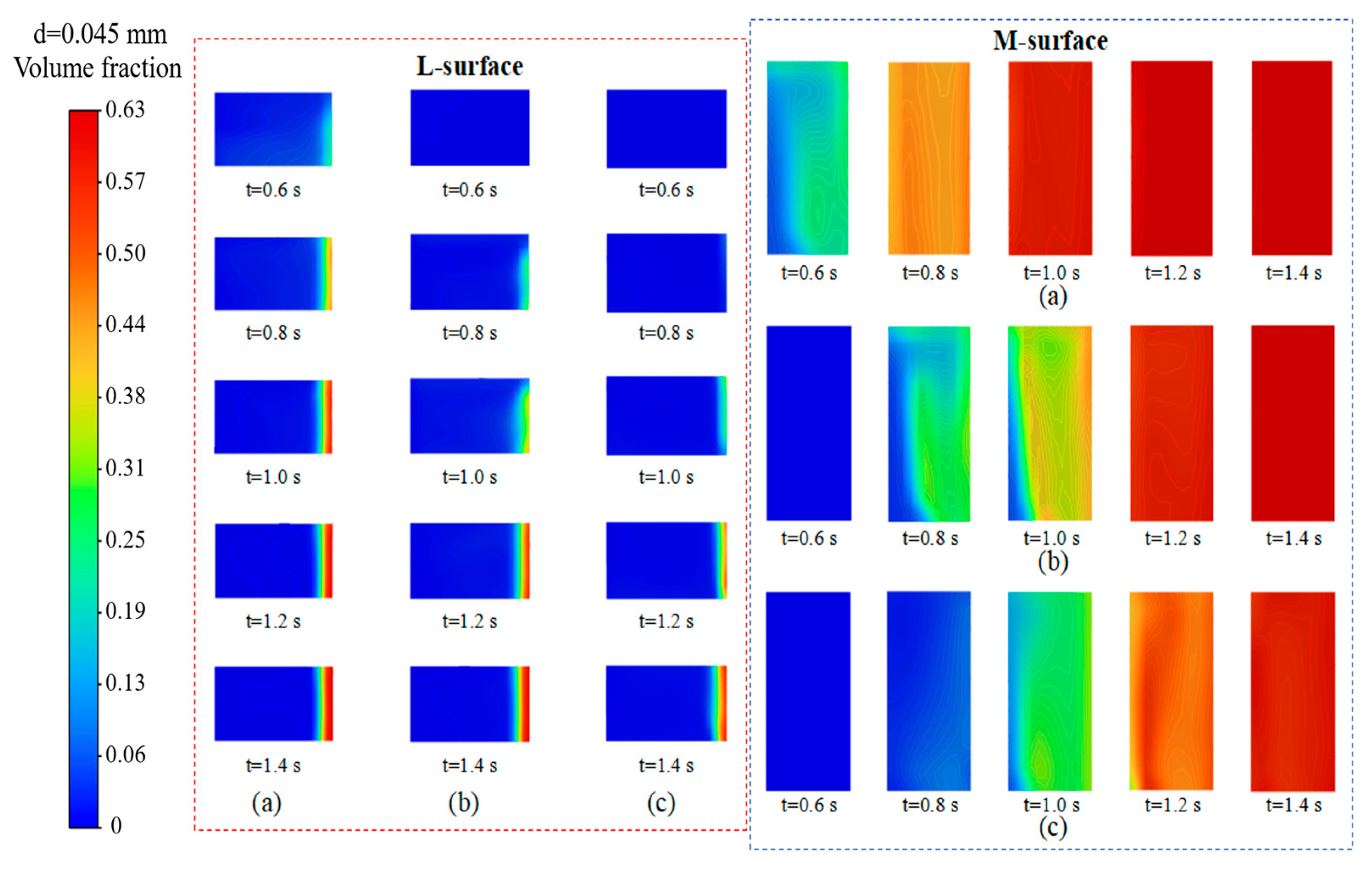

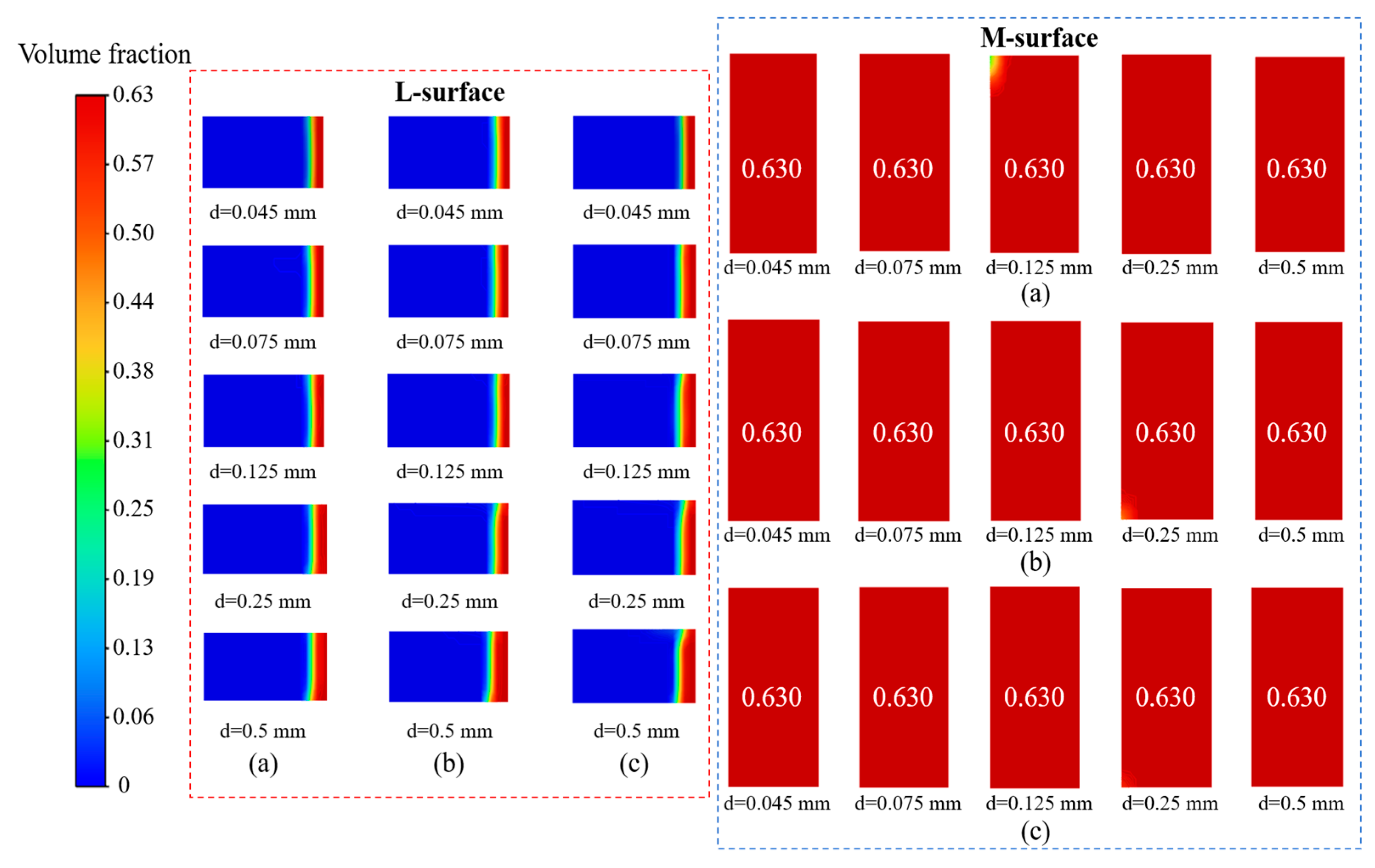

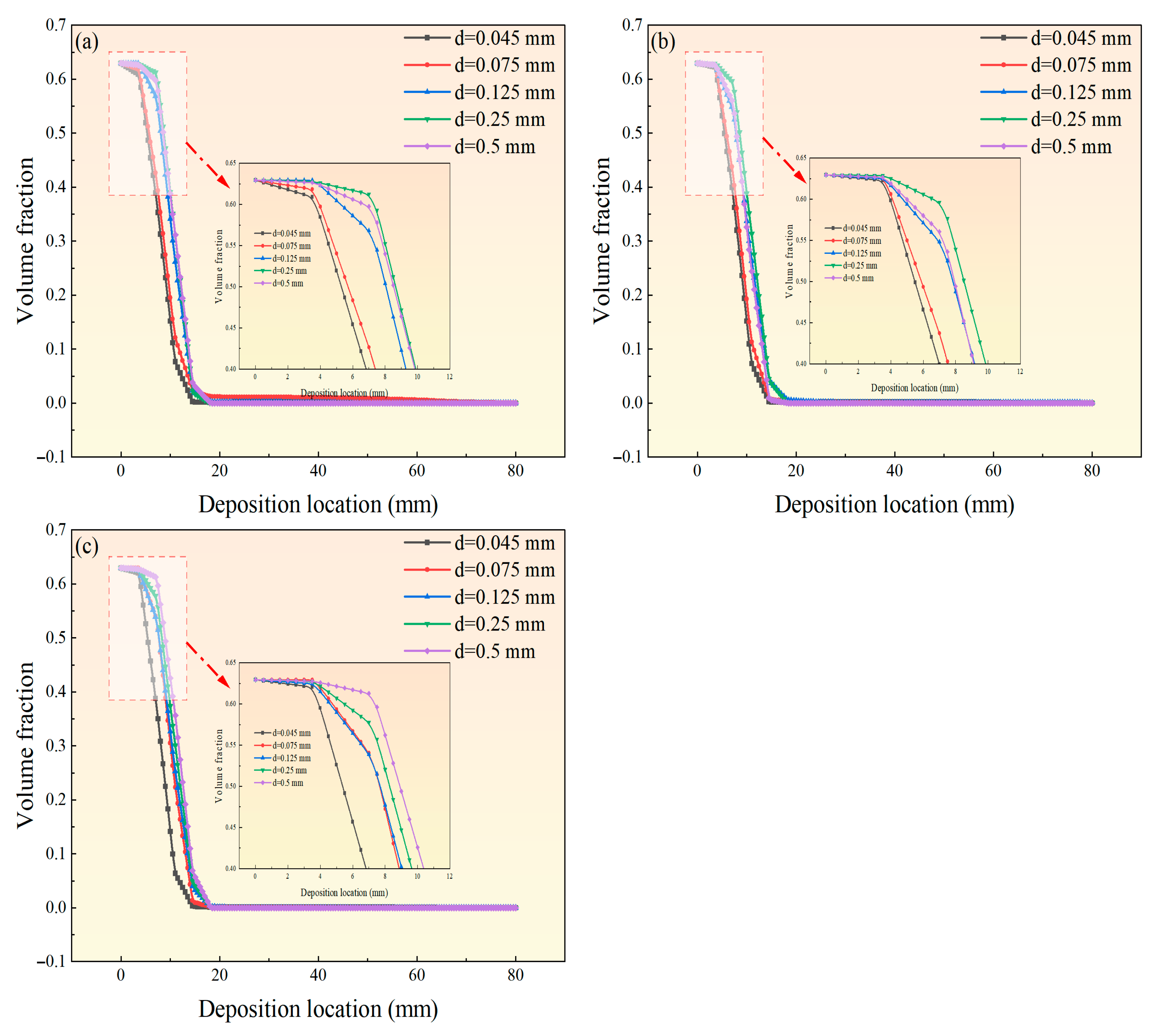

3.1. Distribution of Solid-Phase Deposition

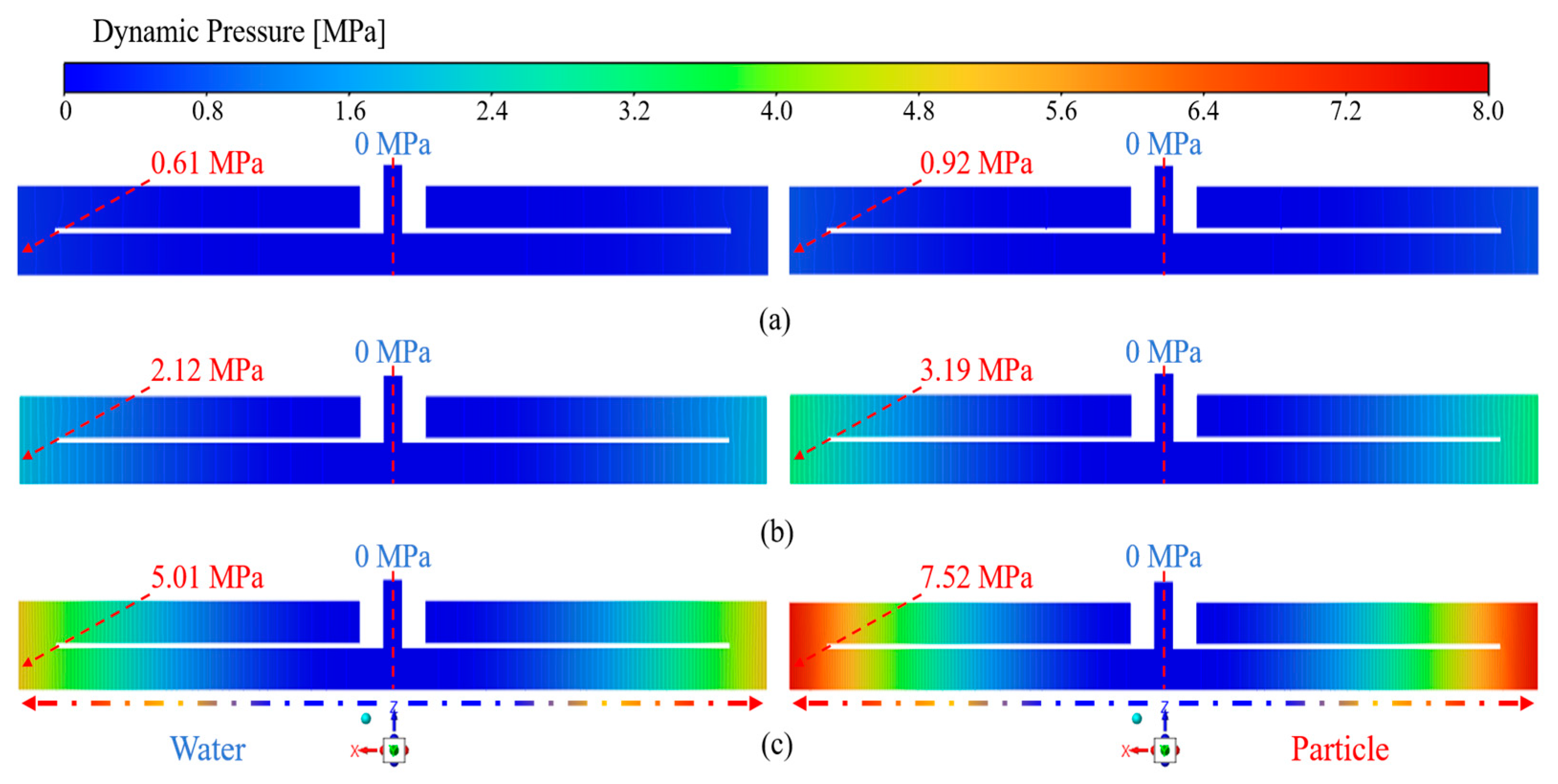

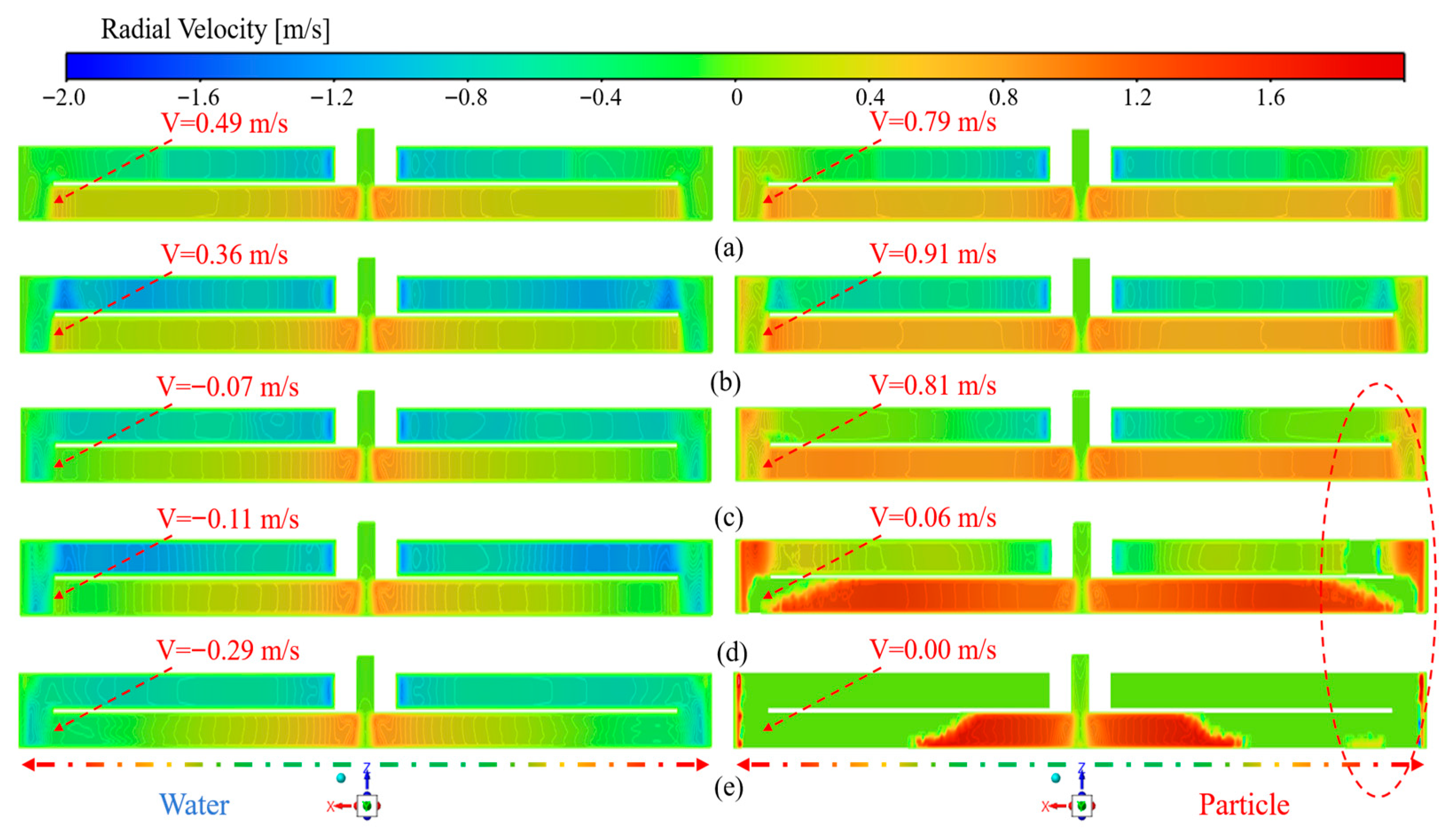

3.2. Analysis of Flow Field Characteristics

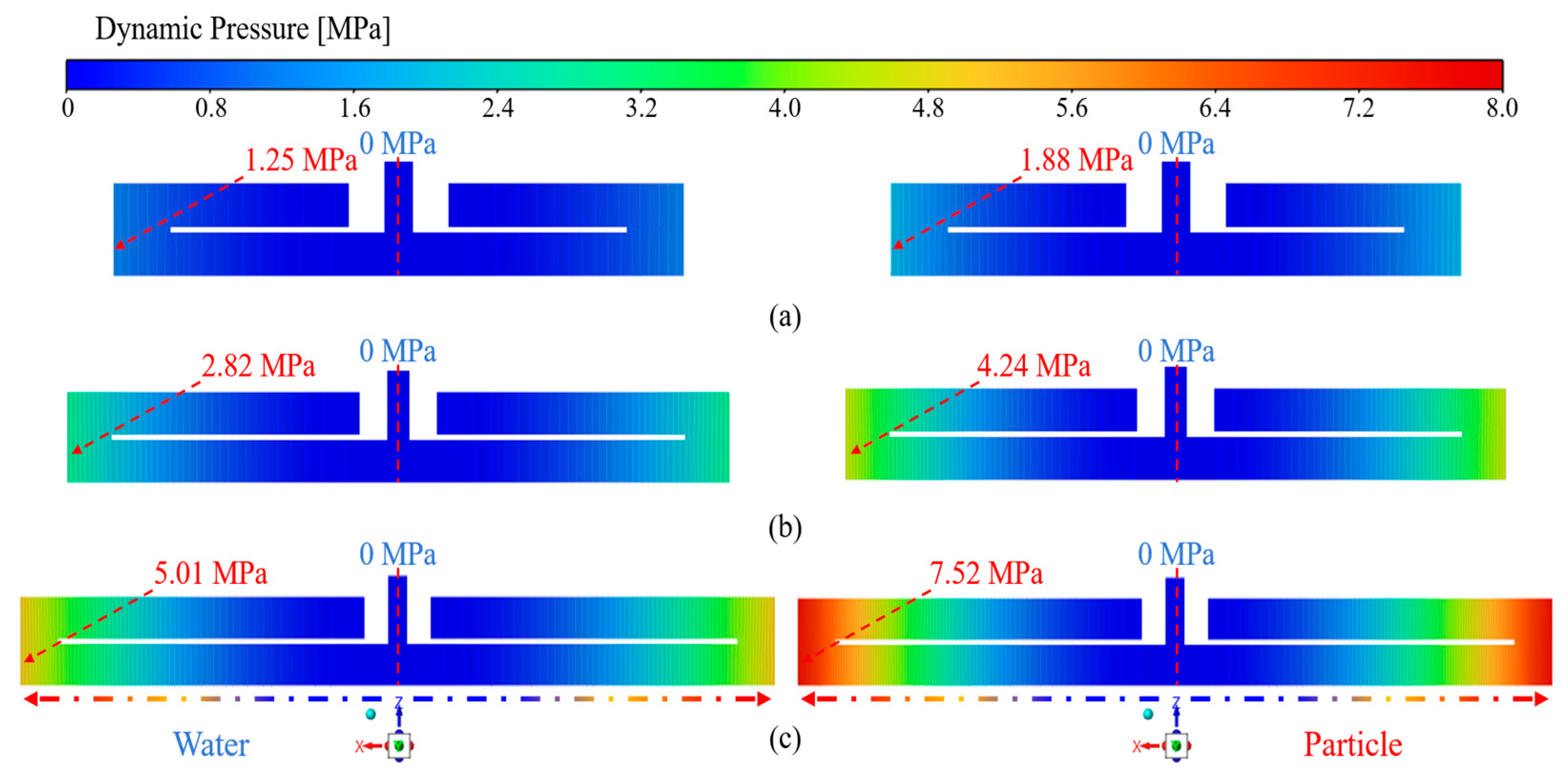

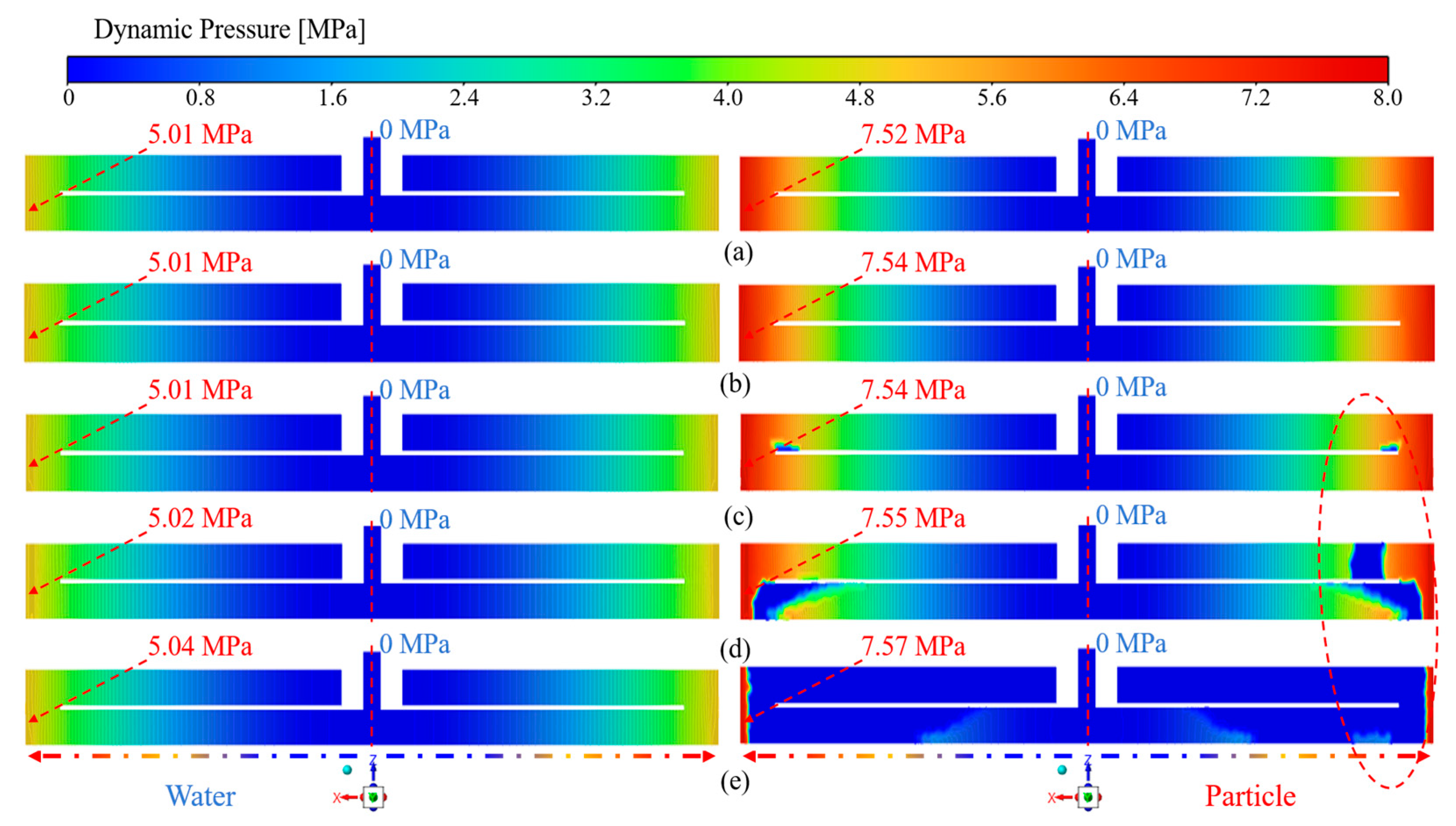

3.2.1. Pressure Distribution

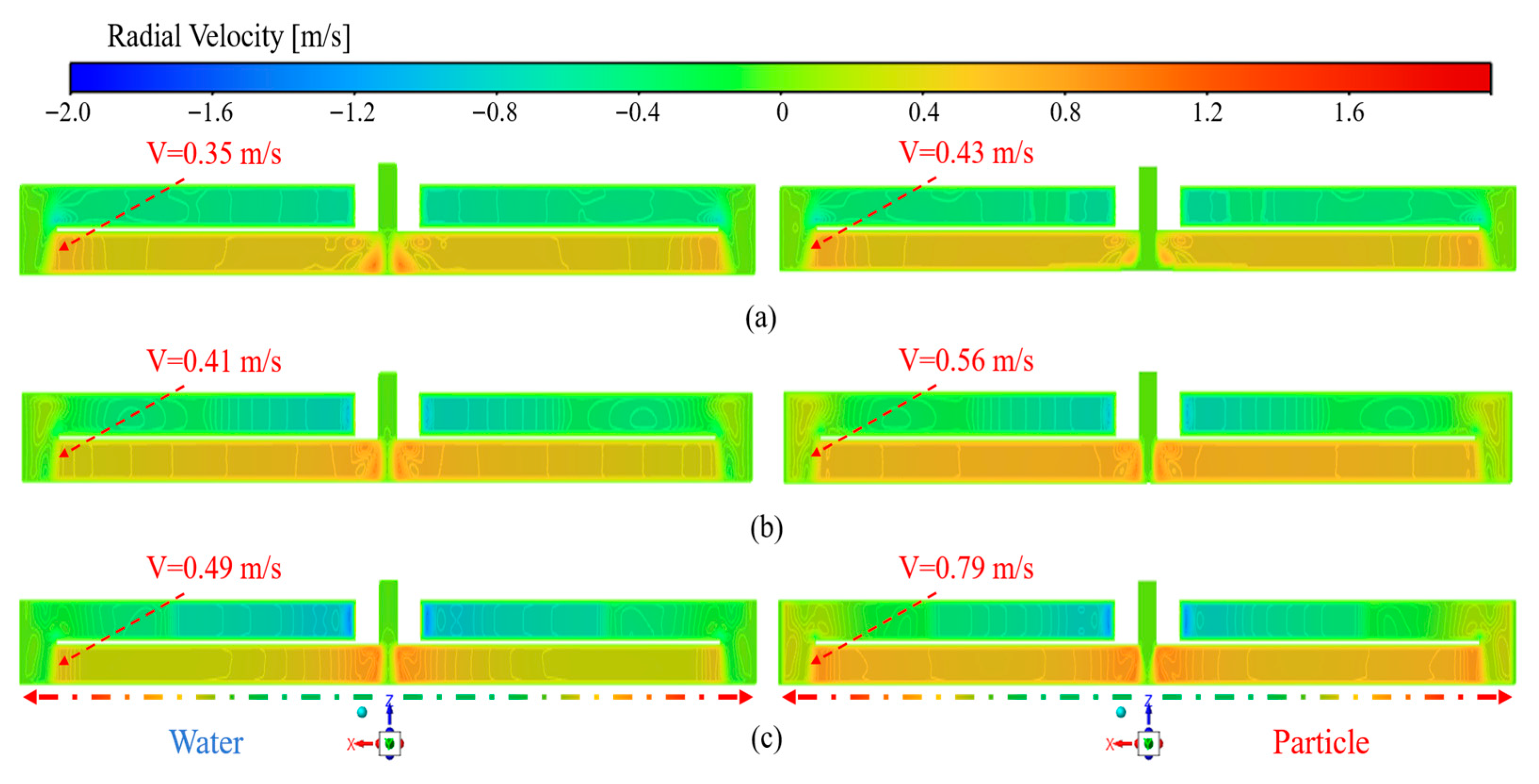

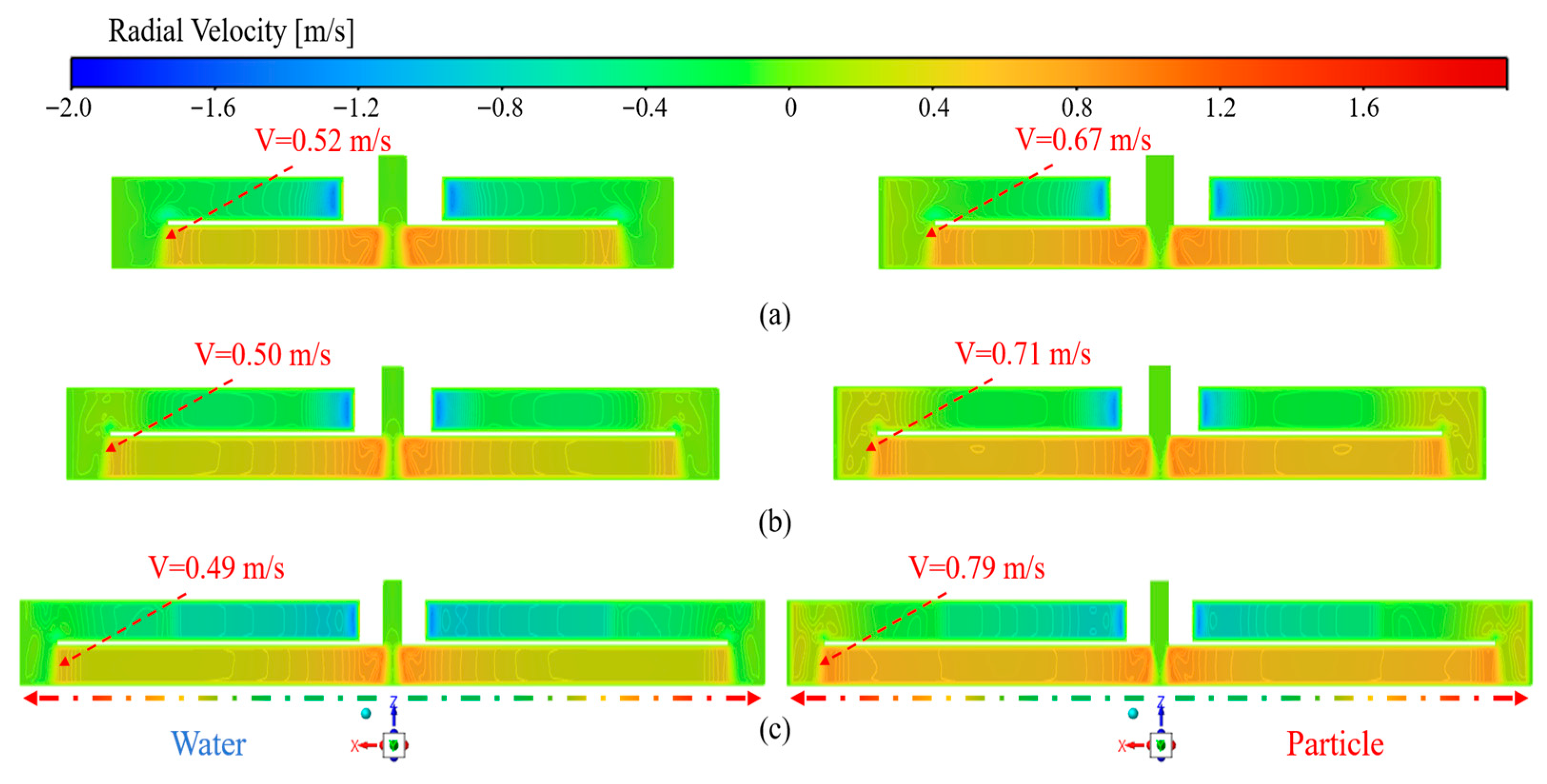

3.2.2. Velocity Distribution

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, S.; Pan, F.; Zhou, S.; Bu, X.; Alheshibri, M. Ultrasonic-assisted flocculation and sedimentation of coal slime water using the Taguchi method. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 10523–10536. [Google Scholar] [CrossRef]

- Liu, L.; Kong, C.; Zhao, H.; Lu, F. Elucidating the enhancement of kaolinite flotation by iron content through density functional theory: A study on sodium oleate adsorption efficiency. Int. J. Min. Sci. Technol. 2024, 34, 855–866. [Google Scholar] [CrossRef]

- Song, X.; Guo, Y.; Yang, X.; Zhang, P.; Wang, B. Influence of coal slime on migration behavior and ecological risk of heavy metals during hydrothermal carbonation of sewage sludge. J. Environ. Chem. Eng. 2024, 13, 115031. [Google Scholar] [CrossRef]

- Wei, Z.; Yang, M.; Zhang, Z. Interfacial mechanism of enhanced coal slime flotation using microemulsion collectors. Sep. Purif. Technol. 2025, 378, 134747. [Google Scholar] [CrossRef]

- Bai, C.; Park, H.; Wang, L. A Model–Based Parametric Study of Centrifugal Dewatering of Mineral Slurries. Minerals 2022, 12, 1288. [Google Scholar] [CrossRef]

- Xu, G.; Liu, L.; Geng, D.; Shao, H.; Wang, H.; Tao, D.; Liu, Z.; Bilal, M. Flocculation and filtration performance of coal slime water: Role of flocculant molecular weight and coagulants. Int. J. Coal Prep. Util. 2025, 2492718. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhao, B.; Tian, C.; Zhang, Y.; Sheng, Q.; Cheng, M.; Zhang, N.; Li, Z.; Liu, D. Plasma pretreatment to enhance the sedimentation of ultrafine kaolinite particles: Experiments and mechanisms. J. Water Process Eng. 2024, 59, 105012. [Google Scholar] [CrossRef]

- Qiao, P.; Liu, M.; Zhang, Z.; Feng, Y.; Chen, J. Separation performance and centrifugal characteristics of a cascade dewatering equipment. Sep. Purif. Technol. 2024, 360, 131075. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, J.; Lai, W.; Li, M.; Huo, B. Microstructure and mechanical behaviors of coal gangue—Coal slime water backfill cementitious materials. J. Mater. Res. Technol. 2022, 20, 3772–3783. [Google Scholar] [CrossRef]

- Zhao, Y.; Meng, L.; Shen, X. Study on ultrasonic-electrochemical treatment for difficult-to-settle slime water. Ultrason. Sonochemistry 2020, 64, 104978. [Google Scholar] [CrossRef]

- Lin, Z.; Sun, X.; Wang, Q.; Cao, J.; Wang, C.; Kuang, Y. Evaluation of the effect of hydraulic shear intensity on coal-slime water flocculation in a gradient fluidized bed. Powder Technol. 2020, 360, 392–397. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, J.; Li, M.; Zhou, N.; Zhang, Q.; Hao, Y. New insights into coal slime water in backfill materials: A fundamental study of pretreatment methods to enhance curing time. J. Clean. Prod. 2023, 389, 135924. [Google Scholar] [CrossRef]

- Shen, L.; Lai, W.; Zhang, J.; Sun, Z.; Li, M.; Zhou, N. Mechanical properties and micro characterization of coal slime water-based cementitious material-gangue filling: A novel method for co-treatment of mining waste. Constr. Build. Mater. 2023, 408, 133747. [Google Scholar] [CrossRef]

- Yan, X.; Wei, L.; Meng, Q.; Wang, J.; Yang, Q.; Zhai, S.; Lu, J. A study on the mechanism of calcium ion in promoting the sedimentation of illite particles. J. Water Process Eng. 2021, 42, 102153. [Google Scholar] [CrossRef]

- Zhang, X.; Min, F.; Liu, L. The complexation color development—Visible spectrophotometry method for rapid determination of Ca2+ concentration in mine wastewater and its mechanism. Microchem. J. 2024, 203, 110852. [Google Scholar] [CrossRef]

- Kong, C.; Liu, L.; Yang, X.; Lu, F. Study on the adsorption mechanism of ricinoleate and oleate on kaolinite and quartz surfaces. Miner. Eng. 2025, 232, 109544. [Google Scholar] [CrossRef]

- Massinaei, M.; Shabani, M.; Alidokht, M. Optimizing the tailings dewatering circuit in a coal preparation plant through industrial trials. J. Water Process Eng. 2025, 77, 108604. [Google Scholar] [CrossRef]

- Jiao, H.; Wu, Y.; Wang, H.; Chen, X.; Li, Z.; Wang, Y.; Zhang, B.; Liu, J. Micro-scale mechanism of sealed water seepage and thickening from tailings bed in rake shearing thickener. Miner. Eng. 2021, 173, 107043. [Google Scholar] [CrossRef]

- Liu, C.; Wang, H.; Xiao, B.; Nie, J.; Liu, M. Initial commissioning parameters research of full-tailings backfill system in metal mine: From laboratory tests to industrial operation. Constr. Build. Mater. 2025, 472, 140811. [Google Scholar] [CrossRef]

- Li, K.; Zhou, F.; Fu, S.; Zhang, Y.; Dai, C.; Yuan, H.; Yu, S. Study on the separation performance of a decanter centrifuge used for dewatering coal water slurry. Chem. Eng. Res. Des. 2023, 195, 711–720. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Shang, X.; Qi, H.; Liu, Y. Analysis of settling efficiency and structural optimization of settling tank. Chem. Eng. Res. Des. 2025, 218, 639–652. [Google Scholar] [CrossRef]

- Angle, C.W.; Gharib, S. Effects of sand and flocculation on dewaterability of kaolin slurries aimed at treating mature oil sands tailings. Chem. Eng. Res. Des. 2017, 125, 306–318. [Google Scholar] [CrossRef]

- Valuev, D.V.; Golik, V.I.; Israilov, R.Y. Optimal Settling Tank Treatment of Coal Mine Wastewater. Coke Chem. 2025, 67, 567–571. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, X.; Nicholson, T.; Peng, Y. The effect of saline water on the settling of coal slurry and coal froth. Powder Technol. 2019, 344, 161–168. [Google Scholar] [CrossRef]

- Wang, X.; Cui, B.; Wei, D.; Song, Z.; He, Y.; Bayly, A.E. CFD simulation of tailings slurry thickening in a gravity thickener. Powder Technol. 2021, 392, 639–649. [Google Scholar] [CrossRef]

- Akbari, M.; Salimi, H.; Zeynali, R.; Akbari, S. Enhancing an industrial feedwell design and operation using computational fluid dynamics. Comput. Part. Mech. 2023, 11, 757–769. [Google Scholar] [CrossRef]

- Qu, X.; Revankar, S.; Qi, X.; Guo, Q. Exploring on a three-fluid Eulerian-Eulerian-Eulerian approach for the prediction of liquid jet atomization. Appl. Therm. Eng. 2021, 195, 117160. [Google Scholar] [CrossRef]

- Dong, X. Comparative Analysis of Horizontal Vibrating Centrifuge and Vertical Scraper Centrifuge. J. Phys. Conf. Ser. 2022, 2403, 012019. [Google Scholar] [CrossRef]

- Mailler, R.; Ponce de léon, M.; Rocher, V.; Ginisty, P. Application of a laboratory screw decanter to evaluate sludge behaviour in mechanical thickening and dewatering: Preliminary results. J. Environ. Chem. Eng. 2021, 9, 106068. [Google Scholar] [CrossRef]

- Peichao, C.; Dong, Z.; Wenbin, L.; Murong, D. Structural optimization of mining decanter centrifuge based on response surface method and multi-objective genetic algorithm. Chem. Eng. Process. Process Intensif. 2025, 212, 110276. [Google Scholar] [CrossRef]

- Shen, S.; Zhou, F.; Fu, S.; Hu, Y.; Shen, Z.; Xu, M.; Li, K.; Zhang, S. Optimization and test study of centripetal pump in disc-stack centrifuge based on flow field analysis. J. Taiwan Inst. Chem. Eng. 2023, 153, 105200. [Google Scholar] [CrossRef]

- Zhang, X.; Tao, Y.; Ma, F. Application of Falcon centrifuge in the separation of siliceous phosphate ore. Part. Sci. Technol. 2022, 40, 958–971. [Google Scholar] [CrossRef]

- Ginisty, P.; Mailler, R.; Rocher, V. Sludge conditioning, thickening and dewatering optimization in a screw centrifuge decanter: Which means for which result? J. Environ. Manag. 2020, 280, 11745. [Google Scholar] [CrossRef]

- Zhan, M.; He, J.; Guo, B.; Liu, L.; Yu, A. Eulerian–Eulerian modeling of the formation and deposition of SiO2 in the outside vapor deposition process. Chem. Eng. J. 2022, 449, 137783. [Google Scholar] [CrossRef]

- Lv, X.-F.; Xu, K.-Y.; Liu, Y.; Wang, C.-S.; Peng, M.-G.; Du, H.; Cao, S.-C.; Ma, Q.-L.; Zhou, S.-d.; Song, S.-F. Numerical simulation analysis of stable flow of hydrate slurry in gas-liquid-solid multiphase flow. Ocean Eng. 2024, 300, 117336. [Google Scholar] [CrossRef]

- Vega-Garcia, D.; Cilliers, J.J.; Brito-Parada, P.R. CFD modelling of particle classification in mini-hydrocyclones. Sep. Purif. Technol. 2020, 251, 117253. [Google Scholar] [CrossRef]

- Natsuo, H.; Hitoshi, F.; Makoto, I.; Jung-Seock, K. Theoretical analysis of flow characteristics of multiphase mixtures in a vertical pipe. Int. J. Multiph. Flow 1998, 24, 539–561. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, H.; Mei, N.; Yan, Z. Estimation of solid concentration in solid–liquid two-phase flow in horizontal pipeline using inverse problem approach. Particuology 2021, 62, 1–13. [Google Scholar] [CrossRef]

- Shah, F.; Fall, I.; Zhang, D. Experimental and CFD evaluation of bubble diameter and turbulence model influence on nonlinear flow dynamics in vertical columns: A comparative study. Chaos Solitons Fractals 2025, 196, 116421. [Google Scholar] [CrossRef]

- Brazhenko, V.; Mochalin, I. Numerical simulation and experimental tests of the filter with a rotating cylindrical perforated filter element. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 2180–2191. [Google Scholar] [CrossRef]

- Brazhenko, V.; Qiu, Y.; Mochalin, I.; Zhu, G.; Cai, J.-C.; Wang, D. Study of hydraulic oil filtration process from solid admixtures using rotating perforated cylinder. J. Taiwan Inst. Chem. Eng. 2022, 141, 104578. [Google Scholar] [CrossRef]

- Hao, M.X.; Zhang, Y.H.; Huang, Y.; Wang, H.L.; Li, H.; Du, J.Q.; Lv, W.J.; Li, J.P.; Fu, P.B.; Wu, J.W. Effect of particle self-rotation on separation efficiency in mini-hydrocyclones. Powder Technol. 2022, 399, 117165. [Google Scholar] [CrossRef]

- Cheng, W.; Fan, H.; Cheng, W.; Shao, C. Investigation on wear induced by solid-liquid two-phase flow in a centrifugal pump based on EDEM-Fluent coupling method. Flow Meas. Instrum. 2024, 96, 102542. [Google Scholar] [CrossRef]

- Ren, Y.; Su, X.; Wang, H.; Chen, B.; Zhe, L.; Zhu, Z. Characterization of particle motion of a double-row hydraulic sluicing collector for deep-sea mining. Ocean Eng. 2024, 309, 118584. [Google Scholar] [CrossRef]

- Xu, C.; Tian, J.; Liu, Z.; Wang, R.; Wang, G. Three-dimensional Reverse Modeling and Hydraulic Analysis of the Intake Structure of Pumping Stations on Sediment-laden Rivers. Water Resour. Manag. 2022, 37, 537–555. [Google Scholar] [CrossRef]

- Talukdar, D.; Suzuki, Y. Numerical investigation of multiphase feature in a polydisperse gas-solid flow: Effect of particle size, volume fraction and shape. Int. Commun. Heat Mass Transf. 2024, 159, 108151. [Google Scholar] [CrossRef]

- Tu, Q.; Ma, Z.; Wang, H. Investigation of wet particle drying process in a fluidized bed dryer by CFD simulation and experimental measurement. Chem. Eng. J. 2022, 452, 139200. [Google Scholar] [CrossRef]

| Boundary Name | Boundary Type | Description |

|---|---|---|

| Inlet | Velocity–Inlet | V = Q/A |

| Outlet | Pressure–Outlet | Pressure–Outlet |

| Wall | Wall | Rotational |

| Wall-dj | Wall | Rotational |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Pan, H.; Ge, W.; Kong, C. Multi-Parameter Synergistic Effects on Fine Coal Slurry Sedimentation in High-Gravity Fields: A CFD Study. Separations 2025, 12, 320. https://doi.org/10.3390/separations12110320

Liu L, Pan H, Ge W, Kong C. Multi-Parameter Synergistic Effects on Fine Coal Slurry Sedimentation in High-Gravity Fields: A CFD Study. Separations. 2025; 12(11):320. https://doi.org/10.3390/separations12110320

Chicago/Turabian StyleLiu, Lingyun, Huikuan Pan, Wei Ge, and Chuilei Kong. 2025. "Multi-Parameter Synergistic Effects on Fine Coal Slurry Sedimentation in High-Gravity Fields: A CFD Study" Separations 12, no. 11: 320. https://doi.org/10.3390/separations12110320

APA StyleLiu, L., Pan, H., Ge, W., & Kong, C. (2025). Multi-Parameter Synergistic Effects on Fine Coal Slurry Sedimentation in High-Gravity Fields: A CFD Study. Separations, 12(11), 320. https://doi.org/10.3390/separations12110320