Abstract

This study examines the impact of Pineapple Leaf Fiber (PALF) loading on the properties of High-Density Polyethylene (HDPE)/PALF composites successfully produced through a melt extrusion process. The melt-extruded HDPE/PALF composites were characterized by their thermal and mechanical properties and their morphologies. Subsequently, adding 5% maleic anhydride (MA) to the HDPE/PALF composite formulation led to significant improvements in the mechanical strength properties. Moreover, adding 10 wt.% PALF and 5% MA to the composites improves the crystallinity (10.38%) and Young’s modulus (17.30%) properties and affects the thermal stability. The optimal formulation is achieved with 10 wt.% PALF filler incorporated into the HDPE composite. This study highlights the promising potential of HDPE/PALF composites for plastic product applications.

1. Introduction

In recent years, biomaterial sources have become readily available in a variety of forms, easily recyclable in the environment, globally dispersed, locally accessible, renewable, and biodegradable [1,2]. Natural fibers are widely available as sources of biomaterials worldwide, including flax, kenaf, jute, sisal, hemp, and pineapple [3,4]. They have drawn a lot of attention as potential reinforcing elements for plastic composites in a variety of industries, including packaging and automobiles [5]. In comparison to conventional reinforcing materials such as glass, aramid, and carbon fiber, these biomaterial sources have the following benefits: low cost, high toughness, low density, specific strength properties, decreased tool wear, decreased irritation to the skin and breathing system, thermal properties, and most importantly, biodegradability [6,7].

Similarly, Idicula et al. suggested that fibers’ high tensile strength is a result of inherent characteristics such as their high cellulose content and low microfibrillar angle. In other words, plant fibers with a higher cellulose content have higher tensile strength and Young’s modulus. On the other hand, when cellulose microfibrils grow in a spiral orientation toward the fiber axis, the orientation of the microfibrils determines the stiffness of the fibers along with their good ductility [8]. Investigating the incorporation of renewable and natural resources into these recycled products is also important. Natural fibers and agricultural waste compose biomass, providing an efficient alternative to producing sustainable composite materials.

The tropical fruits in the world are citrus, bananas, and pineapple [9]. Pineapple originated in Brazil and has since spread to other tropical regions of the world [10]. The primary producers are Costa Rica in Central America and Brazil in South America, Africa (Nigeria and South Africa), and Asia (Thailand, Indonesia, Philippines, India, and China). It is mostly grown in tropical and coastal areas, mostly for its fruits [11]. It generates around 384,673 metric tons of waste material annually. Pineapple leaf fiber production is abundant for commercial use, renewable yearly, and easily obtainable [12]. PALF has a higher crystallinity and cellulose concentration (70–82%) with good reinforcing material compared to jute fiber [13]. Its fiber bundle strength is higher, and its filaments are properly separated. It is also 2.5 times more extensible. Pineapple Leaf Fiber (PALF), an undervalued byproduct from pineapple cultivation, has gained attention for its renewable, cost-effective, and biodegradable properties. Despite being a waste material, PALF offers potential as a reinforcement agent in composite materials, particularly in replacing pure resin to improve mechanical properties. PALF has diverse applications in textiles, cosmetics, medicine, and biopolymer coatings, and further research could unlock its potential in other products [14,15].

For the past decades, plastic items have expanded due to increased demand for various industrial applications and their versatility and low production cost. It can be molded into different, even complex shapes, making it ideal for producing multiple products, from packaging to automotive parts [16,17]. High-density polyethylene (HDPE) is one of the dominant conventional plastics produced from ethylene monomer and is being used in our everyday lives for a variety of products, including toys, bags, bottles, drums, packing containers, and home appliances. Predominantly, HDPE is a low-cost thermoplastic with a linear structure compared to others, with a low branching degree [18]. Using abundant and cheap renewable precursors, such as natural fibers, in melt extrusion to modify the properties of HDPE is one of the most efficient ways to reduce costs and increase attributes suitable for certain end products, among others. Excellent properties including lightweight, high strength, and biodegradability are also exhibited by these fillers [19].

Natural fibers have been used to reinforce polymers in several studies that have been published in the literature. Ma X et al. [20] Examined the impact of the fiber content on the tensile characteristics of micro winceyette fiber-reinforced maize starch composites and discovered that an increase in the fiber content from 0% to 20% wt. about tripled the composite’s tensile strength. However, as the amount of fiber increased, the elongation at break dropped. Lee et al. [21] revealed that that both the Young’s modulus and tensile strength decreased because the fiber content of polypropylene reinforced with kenaf 30%, and jute fiber (40%) increased to a maximum. In their study, Rozman et al. [22] examined the use of coconut fiber as reinforcement in polypropylene (PP) composites. They found that the addition of the fiber (40%) decreased the composite’s tensile and impact strengths. This response was ascribed to both the irregularity in the fiber size and the incompatibility between the fiber and the PP matrix. Nonetheless, it was discovered that raising the fiber quantity improved the composites flexural modulus (22%) and tensile strength (28%) [23]. When the fiber concentration was 5%, the tensile strength of the fiber-reinforced 1-pentene/PP polymer composites rose from 20 to 30 MPa, according to Khoathane et al., who examined the effects of bleached hemp fiber contents on the tensile strength of the composites [24]. However, at 20% fiber content, the tensile strength decreased to 23 MPa and then grew once again, reaching the same value as at 30% fiber content. Furthermore, Eze IO et al. [25] observed that when the fiber content of HDPE reinforced with PALF contents was examined, the tensile strength and modulus, flexural strength, and hardness of PALF/HDPE composites usually increased with the filler content; conversely, the elongation at break of PALF/HDPE composites decreased with the filler content, and PALP can be used as a reinforcing filler in polymer composites. Using the extrusion molding technique produced HDPE/PALP composites of slightly (0.91%) better mechanical properties than those made using the injection molding technique [26]. Aji IS et al. [27] investigated the impact of 40% PALF/Kenaf fiber loading on the properties of HDPE composites. With an increase in the amount of Pineapple Leaf Fiber in the composite, the strength and modulus values improved, and the higher aspect ratio of kenaf helped in the matrix’s dispersion inside the composite. Kenaf increased the impact strength and decreased water absorption, while the fiber from pineapple leaves improved the composite’s tensile and flexural properties. It was evident that the modulus was influenced by the percentage of cellulose in natural fibers. Moreover, Aji IS et al. [28] produced samples at a fiber ratio of 1:1 kenaf/PALF and fiber lengths of 0.25, 0.5, 0.75, and 2 mm and used fiber loadings ranging from 10% to 70% in their investigation. The impact strength exhibited better qualities with 0.75 and 2 mm fiber lengths, while around a 0.25 mm fiber length showed the best tensile and flexural abilities with a linear increase in values up to 60% fiber loading. Furthermore, at a fiber loading of 60% and fiber length of 0.25 mm, a tensile strength of 32.24 MPa was found, with a flexural strength of 34.01 MPa and modulus of 4114.11 MPa. The observed trend of an increase in the mechanical properties of the composites with an increase in the filler content may be attributed to two main factors: the better dispersion of filler in the polymer, and the filler–matrix interaction.

In addition, there have been four studies on PALF utilization for reinforcement in some materials such as HDPE. Recently, a few research studies on polymer composites of HDPE/PALF mainly studied the composite morphology and mechanical properties; however, they did not provide an adequate indication of the final polymer composite. In this study, we have studied the effects of PALF and its content on the morphological, mechanical, and thermal properties of composites based on HDPE with MA. Maleic anhydride as well as additional compatibilizing agents can be added to the formulation as a means of enhancing the compatibility between HDPE and natural fillers [29]. The compatibilizer effect of the MA level is one of the elements that affects the interfacial adhesion and stress transfer between the filler and the matrix. According to these studies, the MA ratio and filler aspect ratio affect the characteristics of filler-reinforced composites [30]. Thus, it was essential to assess the combined impact of the created coupling agent and PALF concentration on the polymer composite attributes to improve the sustainability of HDPE/PALF composites.

2. Materials and Methods

2.1. Materials

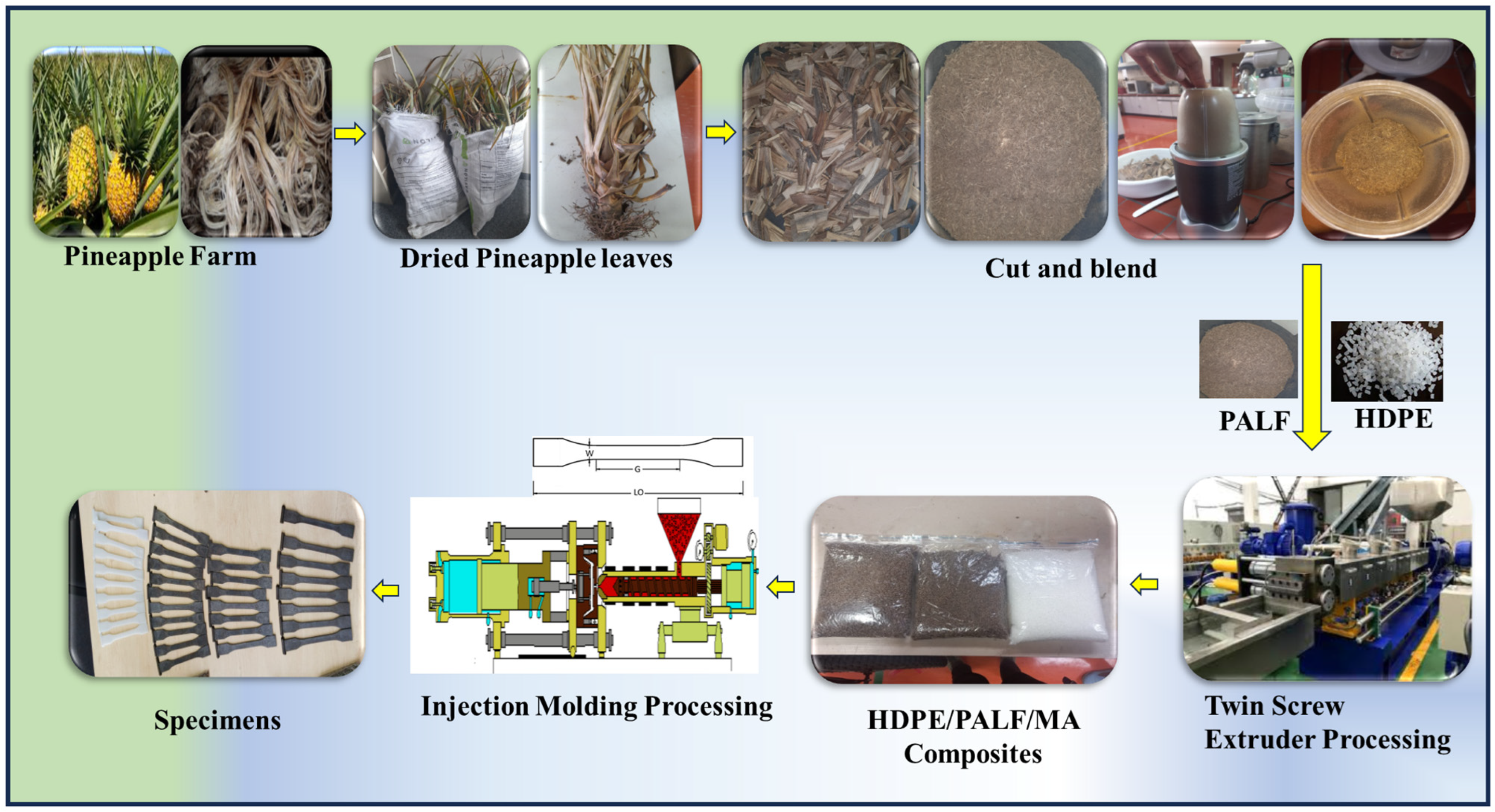

HDPE, PALF, and MA were used in this study. The HDPE used in this study was obtained from Safripol, Sasolburg, South Africa. It has a density of 0.97 g/cm3 and MFR (Melt Flow Rate) of 9.0 g/10 min at 165 °C and 6.97 g/10 min at 190 °C. MA was purchased from Sigma-Aldrich United States. Pineapple leaves from nearby pineapple farms in Eastern Cape, South Africa, were collected, chopped, and sun-dried for thirty days before being oven-dried for sixteen hours at 60 °C. Subsequently, a manual blender mixer was used to grind the chopped dry pineapple leaves into filler. The HDPE (C1) composites of the PALF with MA were prepared by thoroughly mixing HDPE95/PALF5 (C2), HDPE90/PALF10 (C3), HDPE90/PALF5/MA5 (C4), and HDPE85/PALF10/MA5 (C5) wt.% PALF filler contents.

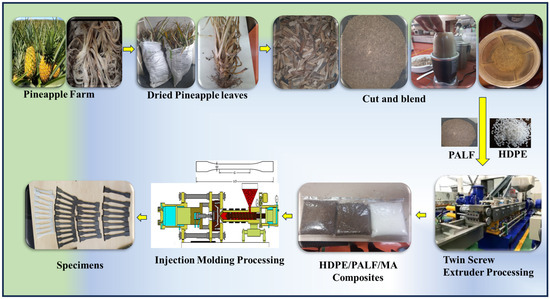

2.2. Compounding and Injection Molding

The HDPE composites of the PALF were prepared by melt compounding HDPE with PALF filler contents as shown in Table 1. The formulated blend compositions were each processed using an injection molding machine. The process was repeated with the incorporation of MA (5%) in the C4 and C5 formulations. The composition of the produced composites samples is shown in Table 1. All the composite samples were prepared by extrusion using a Nanjing Giant SHJ-20 twin-screw extruder from Nanjing Giant Machinery Co., Ltd., Qilin town, JiangNing District, NanJing, China. The extruder has a screw diameter of 20 mm and an L/D (length/diameter) ratio of 40:1. The PALF was subjected to pre-drying in an air oven at 60 °C for 24 h and thoroughly mixed with HDPE pellets and MA in a Jones-LMCB high-speed mixer from Jones industrial mixers South Africa. Processing occurred at a screw speed of 190 rpm and a feeding rate of 3 kg/h. The extrudate, in the form of strings, was cooled in a water bath and pelletized using a 10 rpm pelletizing speed. The extruder temperature profile across the different zones was set as follows: Zone 1 (140 °C), Zone 2 (150 °C), Zone 3 (170 °C), Zone 4 (170 °C), Zone 5 (175 °C), Zone 6 (175 °C), and the die (180 °C), to limit the degradation of the low thermally stable HDPE. The pellets were pre-dried in an oven at 60 °C for 24 h to remove all the moisture. All composites were then injection molded according to ASTM D3641-21 [31]. The samples were injection molded into Type I dog bone test specimens with a cross-sectional area of 4 × 10 × 100 mm, using a TMC-30H injection molding machine, with a 30-ton clamping force from TMC Technology Corp, Taoyuan, Taiwan. The processing temperature was set as follows: Zone 1 (160 °C), Zone 2 (180 °C), Zone 3 (190 °C), and Nozzle (200 °C). The schematic representation of the preparation of HDPE/PALF composites is shown in Scheme 1. The HDPE and HDPE composites were processed into 60 μm thick films by compression molding of 4–5 g between Teflon-covered aluminum sheets under pressure at 150 °C for 5 min [32].

Table 1.

Composition of the produced composite samples.

Scheme 1.

Schematic representation of HDPE/PALF composites.

2.3. Composite Characterization

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

A Fourier transform infrared (FTIR) spectrometer (Bruker) was used for recording the test materials’ spectra, which were obtained in the 500–4000 cm−1 range with a resolution of 32 cm−1.

2.3.2. Scanning Electron Microscopy (SEM)

Thin specimens (ca. 50 nm), prepared by cryocutting with the above ultramicrotome at T = –120 °C, were subjected to scanning electron microscopy SEM (CHRTEM Helios D9660, Nelson Mandela University, Gqeberha, South Africa) operating at 3 kV investigations without any staining. The samples were coated in gold and freeze-fractured in liquid nitrogen before examination.

2.4. Thermal Analysis

2.4.1. Thermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA 5500, TA instruments, New Castle, DE, USA) was used to analyze the samples for thermal stability. A prepared sample weighing about 10 mg was put on a platinum plate, and the samples were scanned from room temperature to 600 °C, at a heating rate of 10 °C/min, in a nitrogen atmosphere.

2.4.2. Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimeter (DSC) analyses were performed in a Perkin Elmer model 2500, with a continuous nitrogen flow rate of 30 mL/min. The temperature of the test samples (8 mg) was raised to 200 °C at a rate of 10 °C per minute. The melt–crystallization behavior of the HDPE/PALF composites was studied. The samples were then heated from 20 °C to 200 °C and held for 1 min and then cooled to 10 °C at the same rate.

2.5. Tensile Analysis

Tensile testing of the injection-molded specimens was conducted using a Tinius Toisen 10 ST Lloyd testing machine fitted with a 10 kN load cell following the ASTM D638 standard to assess the tensile properties [33]. Each sample had a cross-sectional area of 4 mm × 10 mm, with a gauge length of 100 mm. The experiment maintained a constant crosshead speed of 50 mm/min. To obtain the average value, five repeats of each sample were tested.

2.6. Rheological Analysis

The rheological behavior was analyzed using an Anton Paar Modular Compact Rheometer in dynamic oscillatory shear mode. Samples were prepared into disks of 25 mm diameter and 2 mm thickness by a Carver hot press at 160 °C. Measurements were conducted under a dynamic oscillatory shear gap distance of 1 mm adjusted by squeezing. When the temperature of the specimen was attained, the normal force was monitored and kept at ~0.03 N to avoid any normal stress caused by the squeezing of a specimen. A frequency sweep was performed within the linear viscoelastic regime of the sample at 0.1% strain and a range of 1–100 Hz. All the tests were performed in a nitrogen atmosphere to avoid any thermal degradation of the polymer during the measurements.

3. Results and Discussion

3.1. FTIR and SEM Analysis

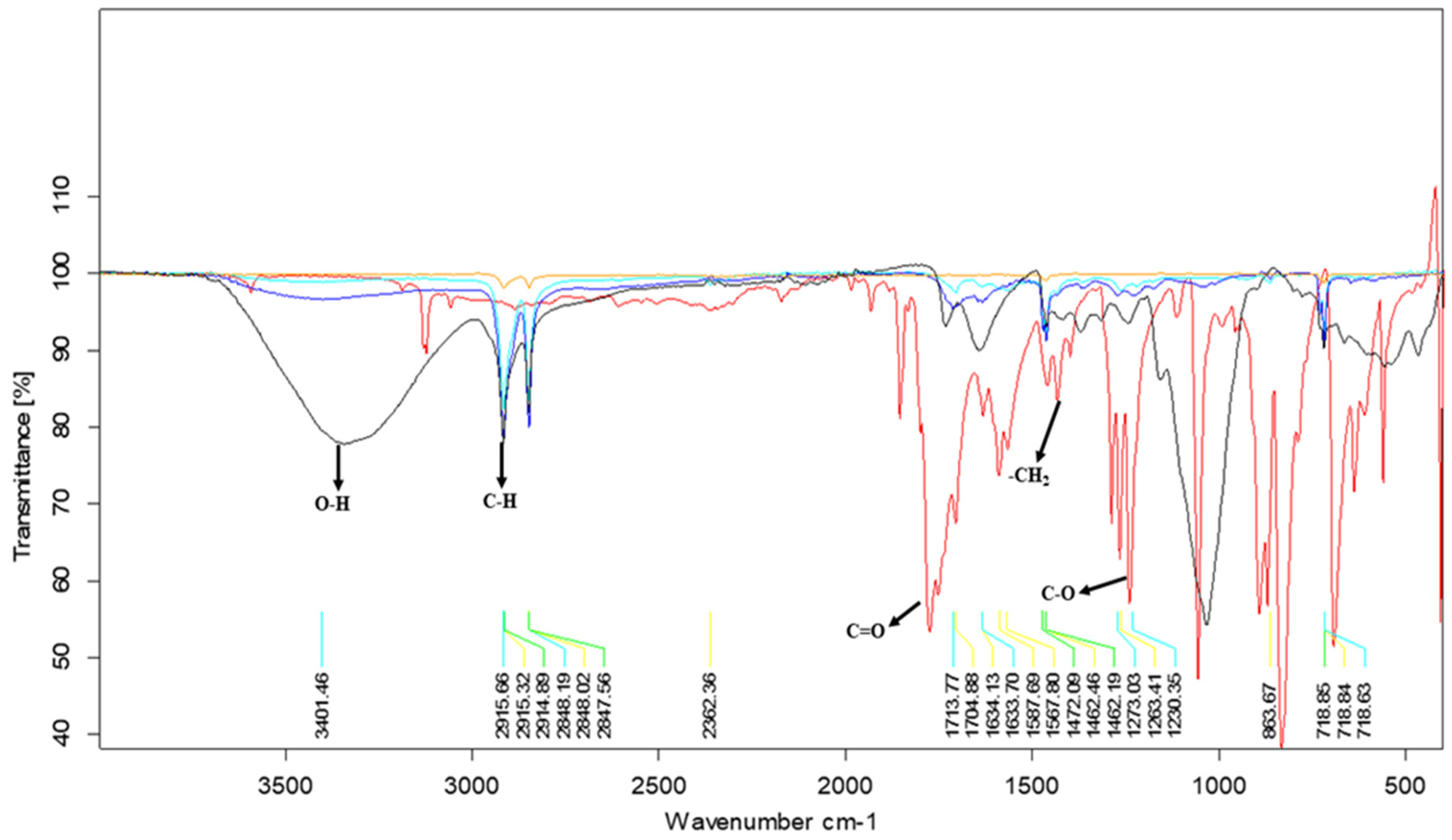

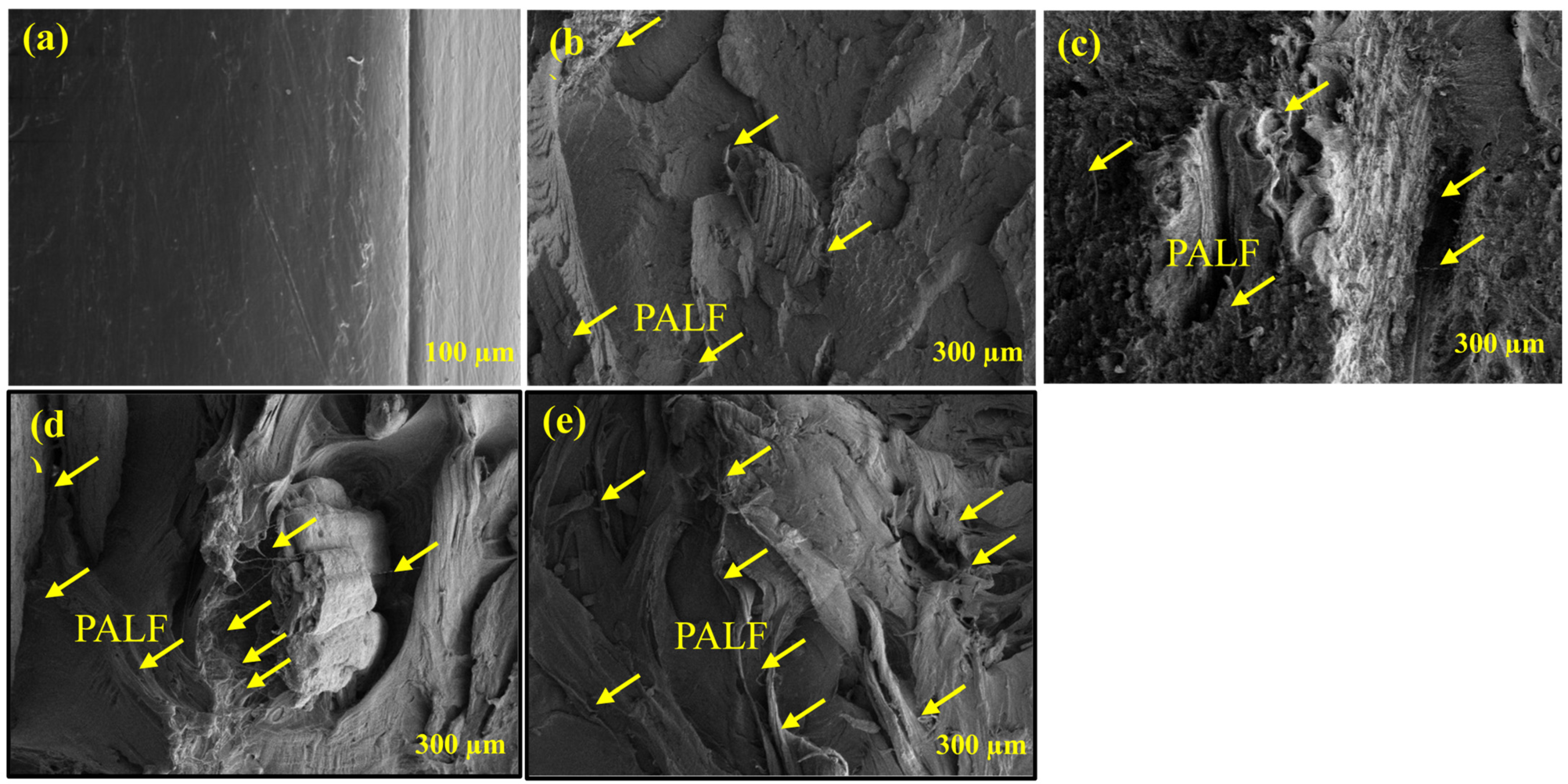

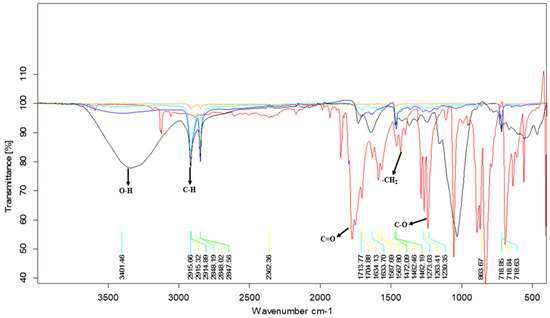

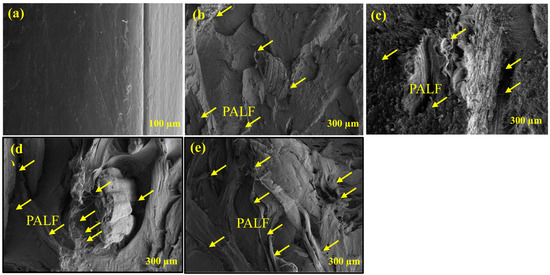

FTIR spectra are used to examine many functional groups found in natural fibers, including ketone groups, vinyl and carbonyl groups, hydroxyl groups, and more [34,35]. It is useful for determining how the chemical composition of natural fibers changes before and after the polymer composite. The characteristic hydroxyl group is common to all natural fibers, typically appearing with an intensity between 3336–3442 cm−1 [36]. The PALF filler FTIR spectra in Figure 1 depict the presence of the characteristic O–H group, which is apparent between the intensity range of 3323–3401 cm−1. The PALF exhibits common peaks owing to C=O and C–H stretching at 1713 and 2915 cm−1, respectively. The FTIR spectrum of the HDPE shows that the absorbance bands are located at 2914 cm−1, 2847 cm −1, 1472 cm−1, 1462 cm−1, and 718 cm−1 [37,38] shown in Figure 1. In the FTIR spectrum of maleic anhydride, the plot exhibited well-defined peaks at 1780 cm−1. Asymmetric and symmetric ring stretching of the (=C−O−C=) groups, unique to the cyclic ethers, were also clearly spotted at 1263 cm−1 and 1051 cm−1, respectively. From the opposite side of the monomeric structure, a relatively broad peak, noticed at around 718 cm−1, was identified as the stretching of the olefinic bond (C=C) [39]. The spectra of HDPE and PALF with MA samples, in contrast, clearly display different characteristic bands, indicating that the polymer structure was altered during reactive processing. The FTIR spectrum illustrates the direct relationship between MA on the HDPE backbone and the PALF filler content. Finally, the FTIR results of the HDPE/PALF/MA showed a broadened intensity of the hydroxyl group peak and a reduction in the carbonyl group peak at wave numbers of 3401 and 1713 cm−1, respectively. On the other hand, the composites showed a sharpened intensity of the alkane peak with an increase at a wave number of 2914–2847 cm-1. Figure 2 displays the cross-sectional SEM images of the neat HDPE and HDPE composites. In Figure 2a, the SEM images of the neat HDPE display a smooth and homogeneous structure. Moreover, the SEM images (Figure 2b,c) illustrate that the 5 and 10 wt.% added PALF was poorly dispersed within the HDPE composites, with noticeable interactions of PALF in the HDPE composites. The hydroxyl groups in the cellulose structure are responsible for this poor dispersion because they inhibit the interaction between the hydroxyl groups of cellulose and the HDPE composites by forming hydrogen bonds both within and between molecules [40]. Thereafter, Figure 2d,e illustrates that the MA modified the 5 and 10 wt.% PALF so that it was uniformly dispersed and well aligned in the HDPE composites. Covalent bonds developed between the cellulose hydroxy groups and maleic anhydride. As a result, the interface phases between the two matrices were improved by the presence of MA.

Figure 1.

FTIR spectra of Black—PALF, Mustard—100% HDPE, Blue—85:10:5 HDPE:PALF:MA, Turquoise—90:5:5 HDPE:PALF:MA, Red—Maleic Anhydride (MA).

Figure 2.

SEM images of HDPE and HDPE composites. (a) HDPE, (b) HDPE/PALF5%, (c) HDPE/PALF10%, (d) HDPE/PALF5%/MA5%, and (e) HDPE/PALF10%/MA5%.

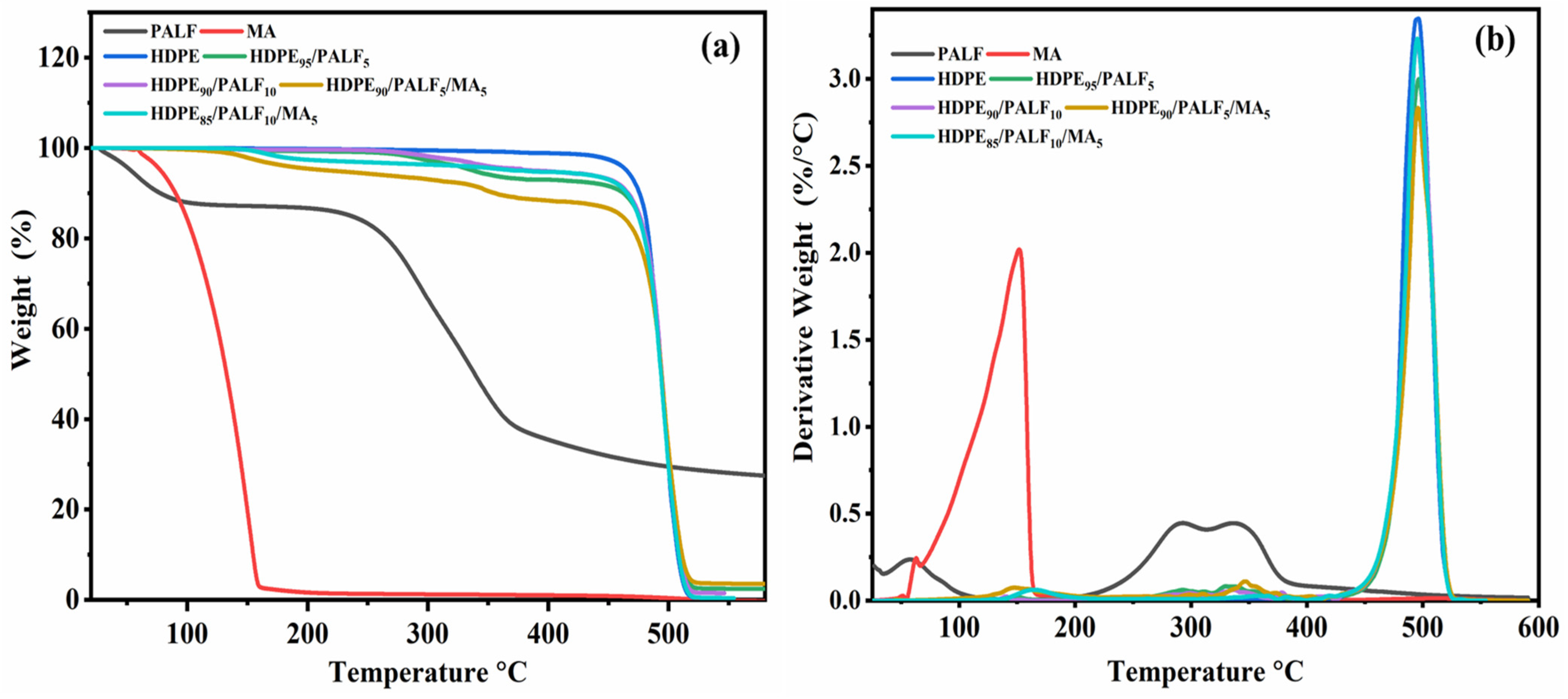

3.2. Thermal Stability Analysis

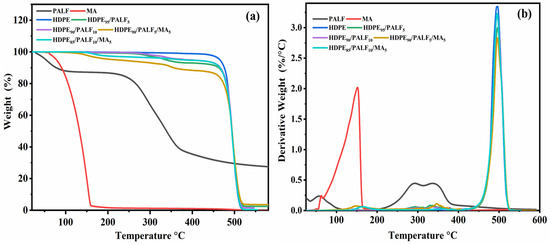

Using TGA, the thermal stability of the neat HDPE mix of MA reinforced with different weight percentages of PALF was investigated. The composite’s weight loss as a function of temperature is shown in Figure 3a,b. The derivative thermogravimetry curves show the magnitude and location of the decomposition temperature peaks. The thermal characteristics (Tonset and Tmax = Maximum) are shown in Table 2. The pineapple leaves led to a small weight loss found in the region of 35–100 °C due to the removal of water molecules absorbed into the fiber. Hemicellulose, pectin, and lignin have low degradation temperatures, so the pineapple leaves exhibited a weight loss at 200 °C. The DTG curve showed a maximum peak at 336.60 °C, which can be due to the degradation of cellulose. The second degradation temperature is at about 292.06 °C, which is due to the cellulose–hemicellulose depolymerization. The third degradation temperature is above 375 °C because of the deterioration of lignin and carbon residues [41]. The onset and maximum degradation temperatures of maleic anhydride are about 60.62 and 150.49 °C, respectively [42]. Additionally, the onset and maximum degradation temperatures of HDPE are about 140.70 and 495.75 °C, respectively [43]. It is important to remember that HDPE has a higher thermal stability than MA and PALF. Mixing HDPE and PALF with and without the presence of MA was found to exhibit three stages in the thermal degradation process that correspond to the excellent bond interaction temperatures. While the C4 blend decreased the thermal stability at 147.51, 346.87, and 496.27 °C, respectively, the increase in PALF to 10% in the C5 blend increased the thermal stability in the three thermal degradation phases to 164.79, 366.38, and 496.47 °C. The improved bonding between HDPE and PALF explains this. Therefore, good matrix bonding of HDPE/PALF is created when the hydroxyl groups of the cellulose react with the functional groups of the coupling agent. This bonding then forms the polymer matrix [44]. The individual molecules of the MA coupling agent are intended to build a continuous bond with cellulose. Van der Waals forces allow the lengthy hydrophobic polymer chain of polymerized MA to bind to HDPE. As a result, there is substantial contact at the HDPE/PALF matrix interface [45]. The first stage was a slight weight loss that occurred at temperatures ranging from 60 °C to 90 °C, attributed to the evaporation of moisture on the surface of the PALF and HDPE composites. This is because water forms strong chemical bonds but is physically weak [46]. The second stage showed a deterioration that started at 140 °C and continued to 370 °C. The weight loss of C2, C3, C4, and C5 was around 6%, 4%, 3%, and 4.1%, respectively, and was attributed to the thermal degradation of lignin and dehydrocellulose. Ultimately, 90% of the weight disappeared during the third stage, which was the primary peak, and had a maximum degradation temperature of 495 °C [47]. This weight loss was consistent with dehydrocellulose heat breakdown.

Figure 3.

(a) Thermogravimetry analysis and (b) DTG analysis.

Table 2.

Thermal properties of the composite samples.

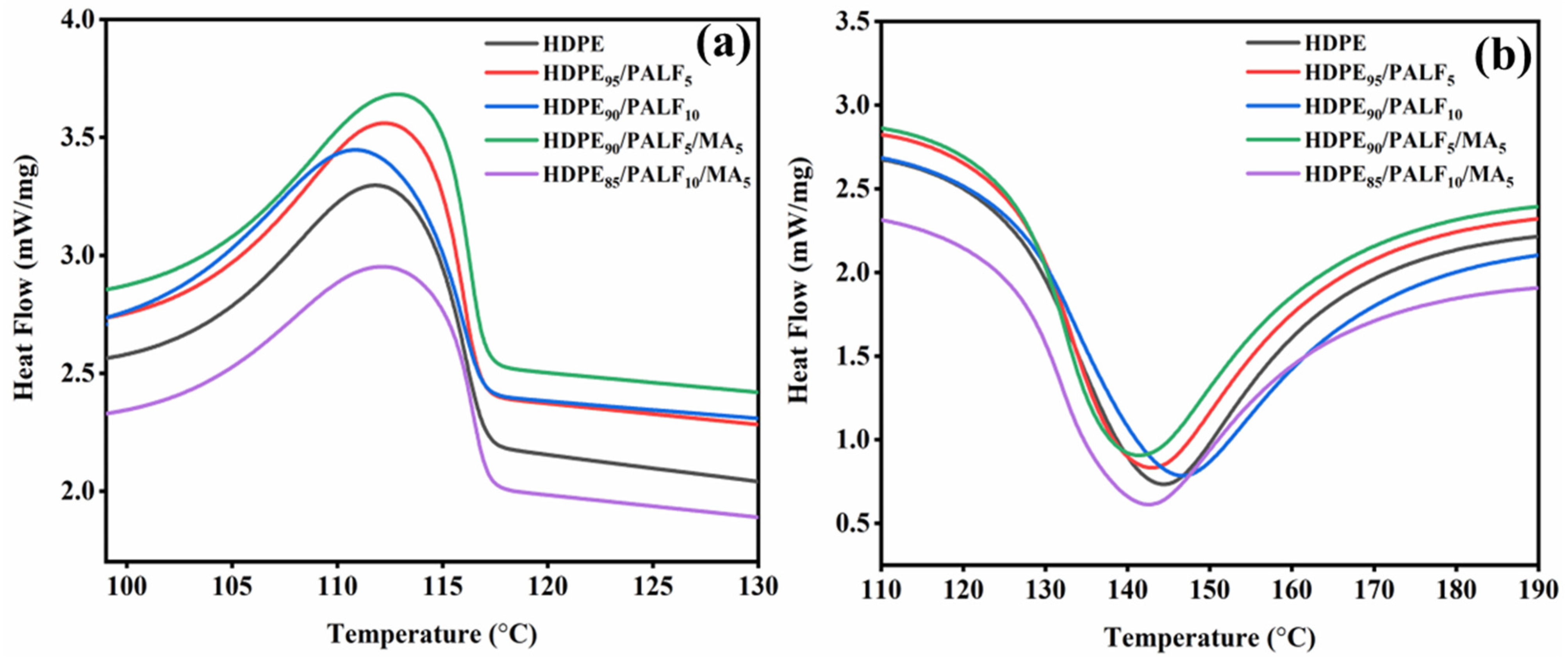

3.3. DSC Analysis

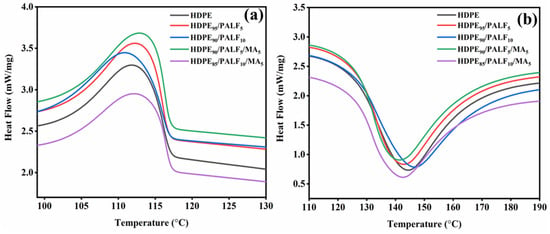

Table 3 lists the thermal characteristics of HDPE and its PALF composites, including the crystallinity Xc (%), melting temperature Tm, and cold crystallization temperature Tcc. Note that all characteristics are acquired during the DSC scan’s second heating run. The degree of crystallinity was calculated using the formula X = ΔHm/ΔH0m × 100, where ΔH0m is the 293 J/g melting enthalpy of a pure crystalline matrix and ΔHm is the observed melting enthalpy [48,49]. The Tcc, Tm, and Xc (%) values of the HDPE are 111.87, 144.81 °C, and 10.10%. As can be observed, there were no appreciable differences in the melting and crystallization temperatures of the composites. However, compared to other composites, the Tm (%) of the HDPE containing 10% PALF was greater. Up to 10% loading, the results indicate increased crystallinity for the HDPE and PALF. According to the determined Xc values of 10.10, 10.61, 11.64, 10.23, and 10.38, HDPE composites containing 10% PALF had the maximum crystallinity. A potential reason for the 10% PALF addition’s higher Tcc in the HDPE composites is that PALF could foster good interactions with polymers, increasing the kinetics of crystallization. This could be explained by interactions such as hydrogen bonding, which help the polymer chains align and arrange during crystallization [50,51]. The observations are shown in Figure 4a,b. The nucleation was delayed in the HDPE with 5% PALF in comparison to the other composites. Conversely, in the 10% PALF and HDPE composites, faster nucleation with a greater nuclei density was observed. This provides evidence that the necessary PALF dispersed in the HDPE matrix acted as a nucleating agent to cause the HDPE to crystallize. The 10% PALF was able to aggregate, which helped to speed up the nucleation process. A lower degree of crystallinity, melting temperature, and cold crystallization temperature result in a lower arrangement of the polymer chains of the composite, according to the MA coupling agent samples with PALF loadings of 5 and 10 weight percent.

Table 3.

Thermal characteristics of composites obtained from DSC analysis.

Figure 4.

(a,b) DSC cooling and second heating scans of neat HDPE and PALF composites.

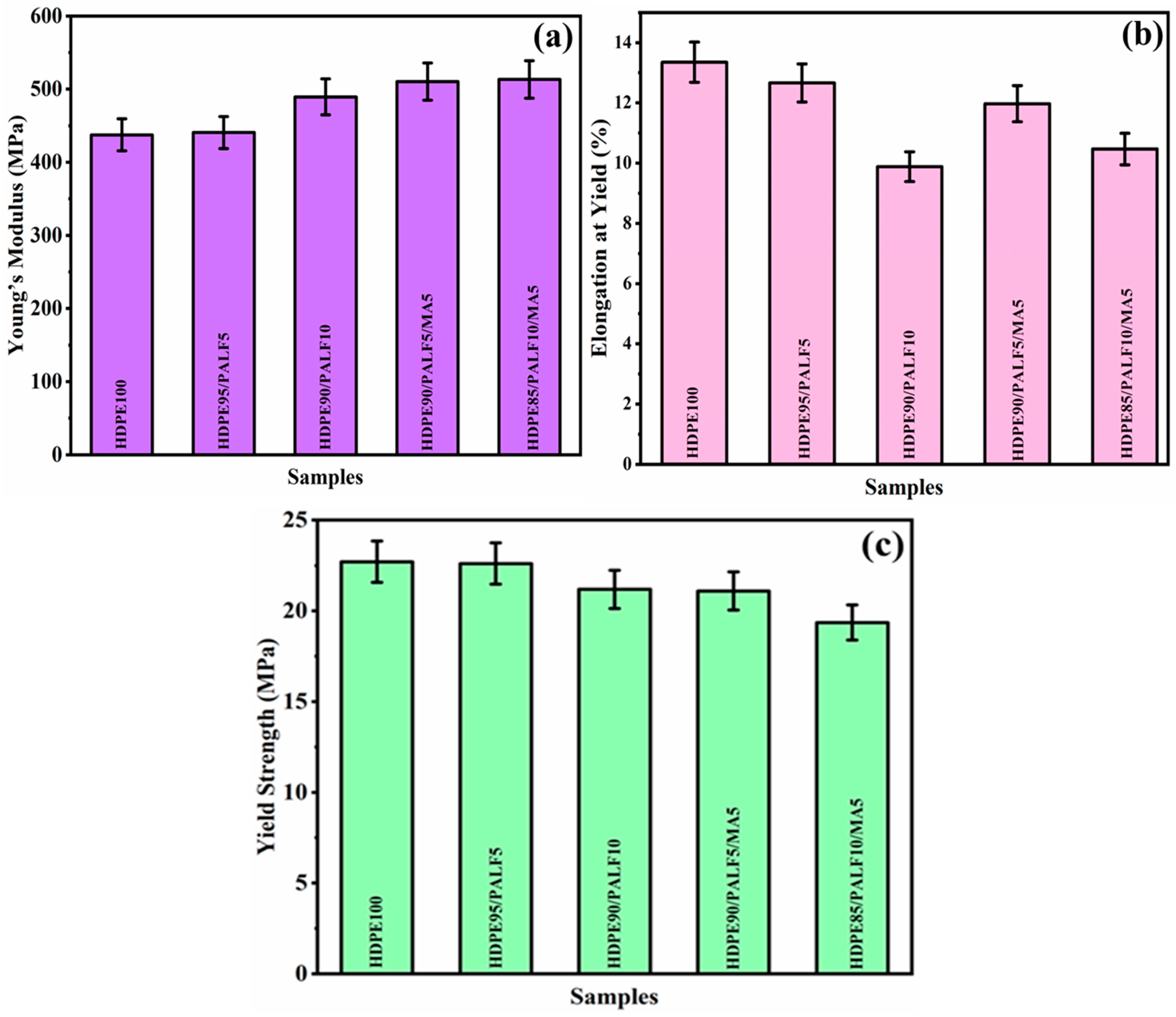

3.4. Tensile Properties

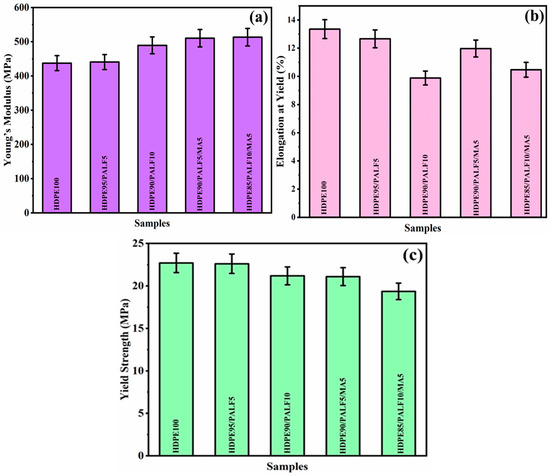

Figure 5 shows the tensile characteristics of the developed composites. The tensile characteristics are summarized in Table 4. The neat HDPE demonstrated elongation at yield and yield strength, together with a decreased Young’s modulus as shown in Figure 5.

Figure 5.

Tensile properties of the produced samples. (a) Young’s modulus, (b) elongation at yield, and (c) yield strength.

Table 4.

Tensile properties of the produced samples.

However, the yield strength and elongation at yield decreased when 5 and 10 wt.% PALF was added to the HDPE composites as shown in Figure 5a,b. Figure 5c shows that the tensile modulus of the HDPE composites was observed to increase with the increase in PALF content. This increase in modulus is to be expected when rigid fillers are incorporated into softer polymer matrices since at a high filler content, the composites will be able to withstand greater load. Furthermore, the addition of 5 wt.% MA in HDPE/PALF composites is displayed in Figure 5. The Young’s modulus increased, but the yield strength and elongation at yield decreased. The increased interfacial adhesion between HDPE and PALF with MA is the cause of this phenomenon. Similar behavior between the PP and the jute fiber has also been described by A.K. Rana to help understand the stiffness and strength of thermoplastics reinforced with fibers [52]. Several elements play a significant role in this. These include the microstructure, adhesion, fiber distribution, breakage and agglomeration, and weight fraction of the fibers. Maleic anhydride-grafted polyolefins are used to improve adhesion and dispersion [53]. This indicates that the interfacial adhesion was enhanced by the coupling agent MA added to the HDPE and PALF mixture. It suggests that when the maleic anhydride was added to the backbone of the hydrogen bond with the hydroxyl-terminated HDPE and PALF, the intermolecular force between the precursors increased [54,55]. Furthermore, using PALF as reinforcement worked well, as indicated by the composites’ increased moduli. Similar to reports from other researchers, compatibilizers, also known as MA coupling agents, are commonly used to reinforce composites that contain fillers [56]. The surface energy of cellulose fibers is raised to a level very near to the surface energy of the matrix following treatment with MA, according to observations by Mohanty et al., and better wettability and increased interfacial adhesion between the fiber and matrix are the outcomes, which raise the stiffness of the composites [57]. This research suggests that the yield strength and elongation at yield are reduced with increasing PALP/HDPE composite modulus. The weakening of the bond between the polymer and PALF filler as the filler concentration increases is the root cause of the composites’ decreased yield strength and elongation at yield (Figure 5c). The modulus increases as the concentration of PALF increases, indicating that sufficient stress transfer occurs across the polymer–filler interface. It is notable that at the highest filler content, the reinforcing impact of PALF in the HDPE and MA blend was predominant.

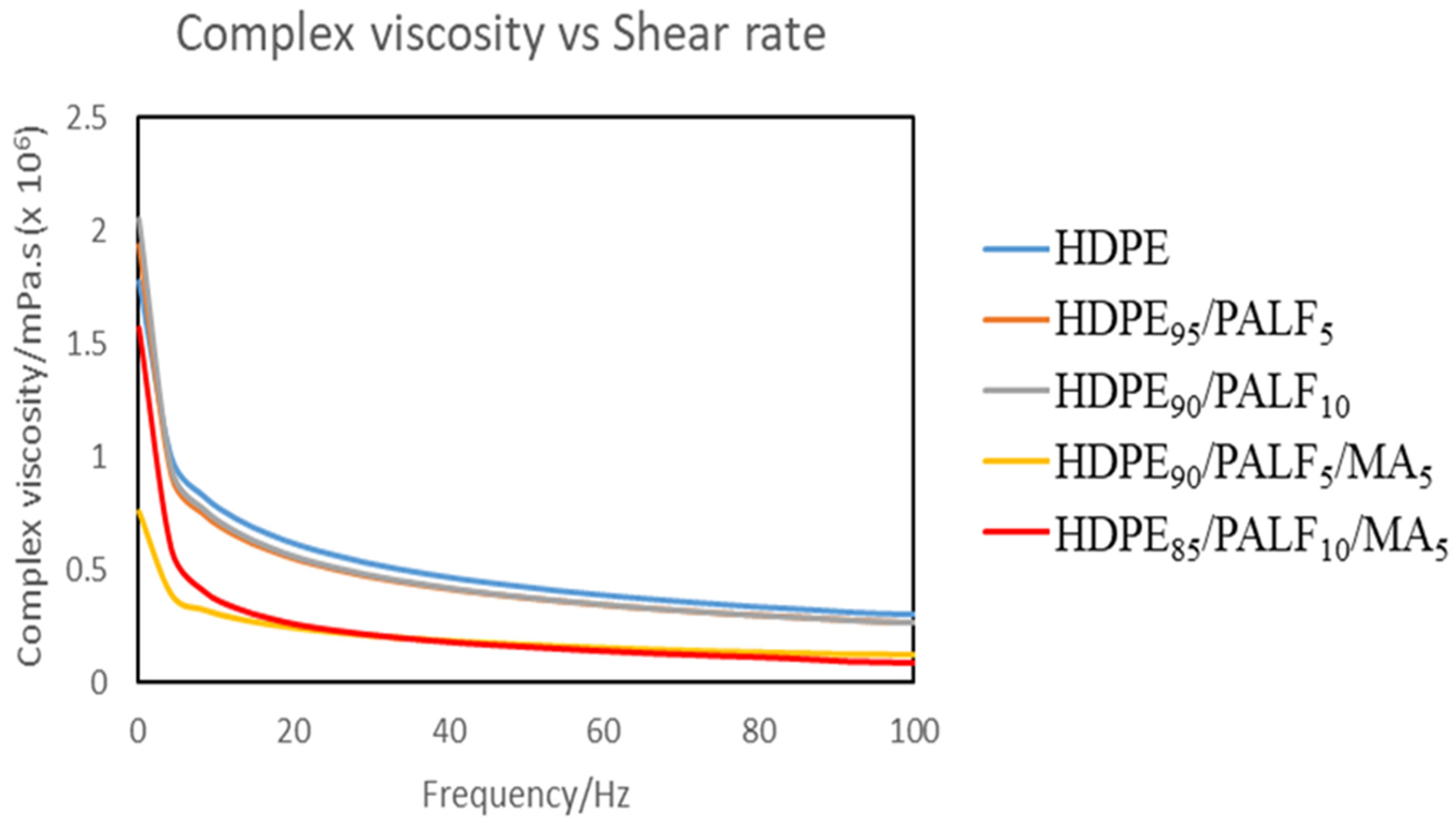

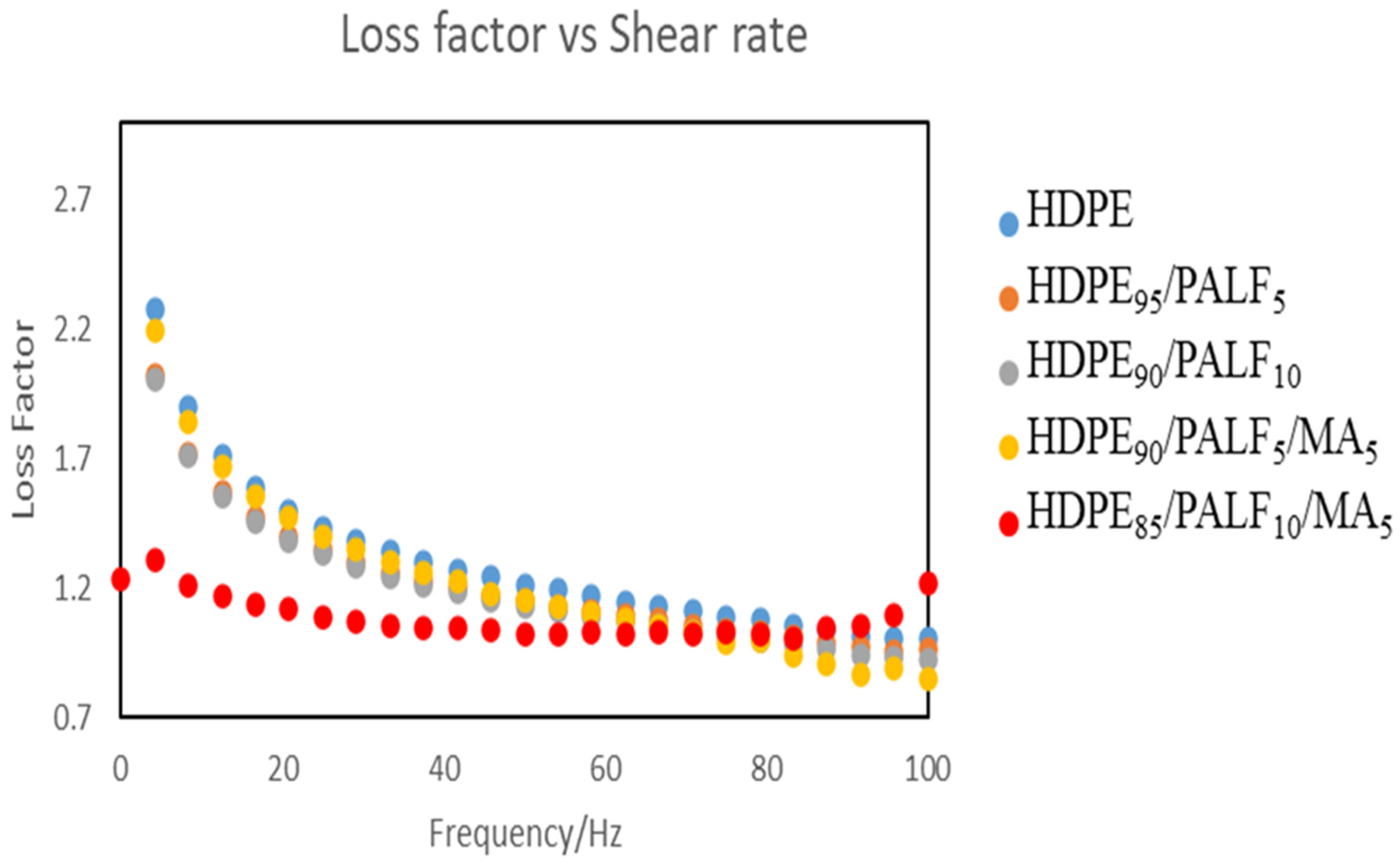

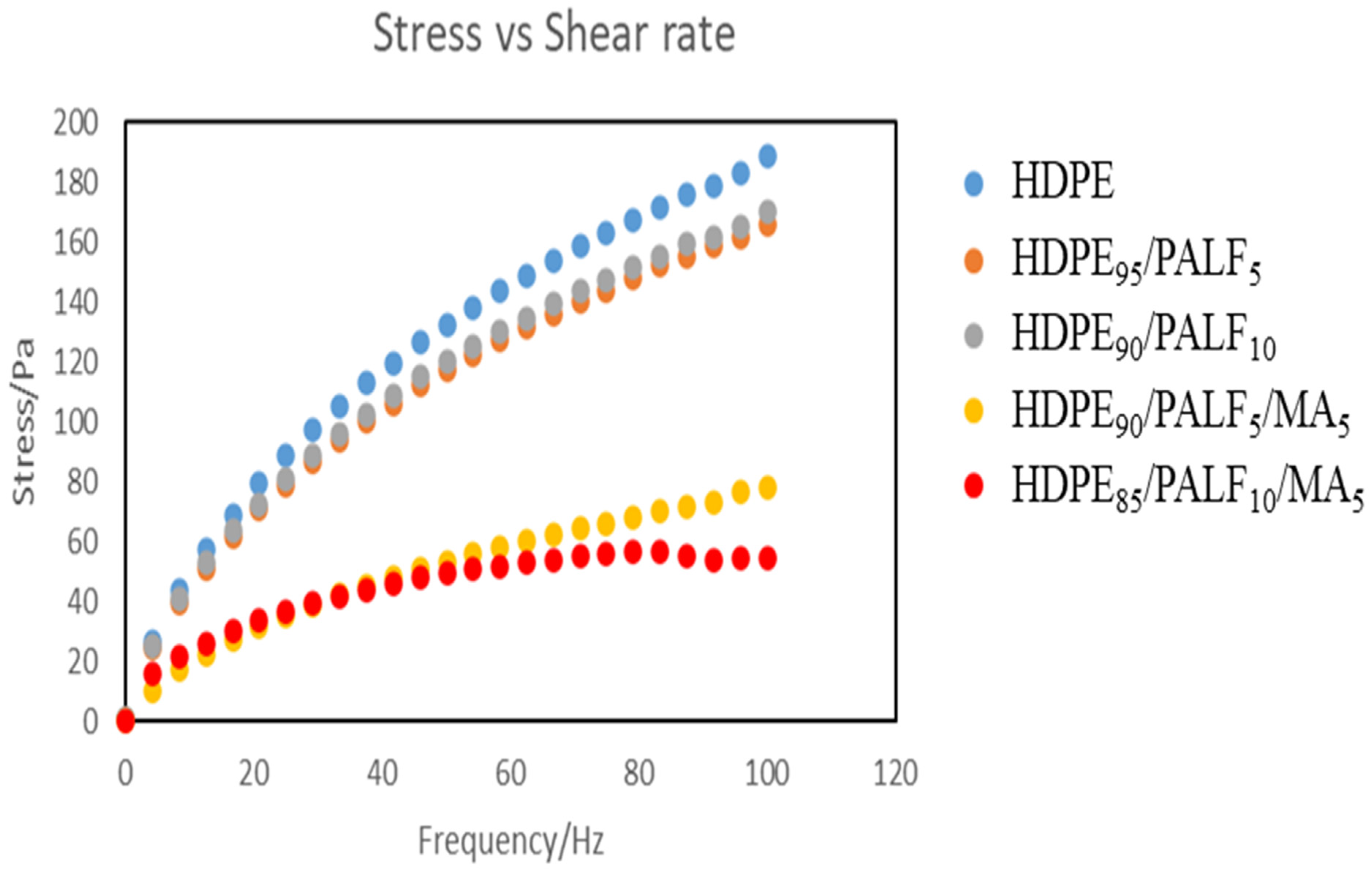

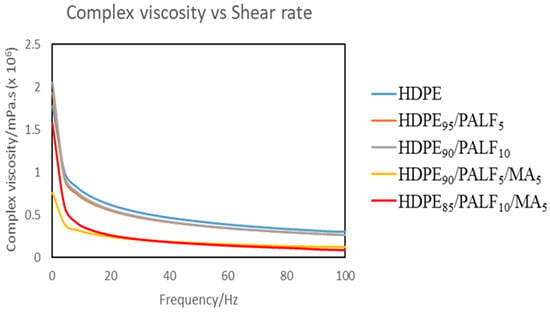

3.5. Rheological Properties of Changes in Complex Viscosity, Dynamic Moduli, Loss Factor, and Shear Stress of Melt Composites

The rheological behavior of all the samples exhibited shear thinning behavior as the shear rate was increased. Shear thinning behavior has been shown to be a result of the inability of polymer chains to reform bonds at high shear rates [58]. According to Figure 6, all composite samples showed complex viscosity that is lower than the matrix viscosity. This implies a disruption of the matrix intermolecular forces due to the addition of fiber and MA. It seems that the presence of 5% and 10% PALF is not enough to result in significant opposition to polymer flow but, on the contrary, disrupts polymer–polymer interactions, thereby lowering the matrix viscosity. The incorporation of MA further lowered the composite viscosity. MA has been shown to exhibit a plasticizing effect in composites, with some literature reporting a reinforcing effect that raises the viscosity of the composite melt [59]. Nonetheless, lowering of the composite melt viscosity facilitates the wetting of fibers. The MA drastically lowered the viscosity of both the 5 and 10% PALF composites equally. A low viscosity is good for processing and ensures good dispersion of the fiber in the matrix. Because of the decreased free volume and constrained mobility of the HDPE chains, the addition of PALF/MA lowered the melt viscosity. The maximum viscosity was observed in the 5 and 10% PALF, which is suggestive of a stronger inhibition of HDPE chain mobility [60]. However, the fiber content of the composites was too low to show any significant differences in viscosities in the absence of MA (5% vs. 10% PALF) and in the presence of MA (5% vs. 10% PALF/MA). We can associate such a result with the presence of a highly dispersed MA phase in the HDPE matrix as compared to PALF, as seen in the SEM images.

Figure 6.

Changes in the complex viscosity of HDPE/PALF composites.

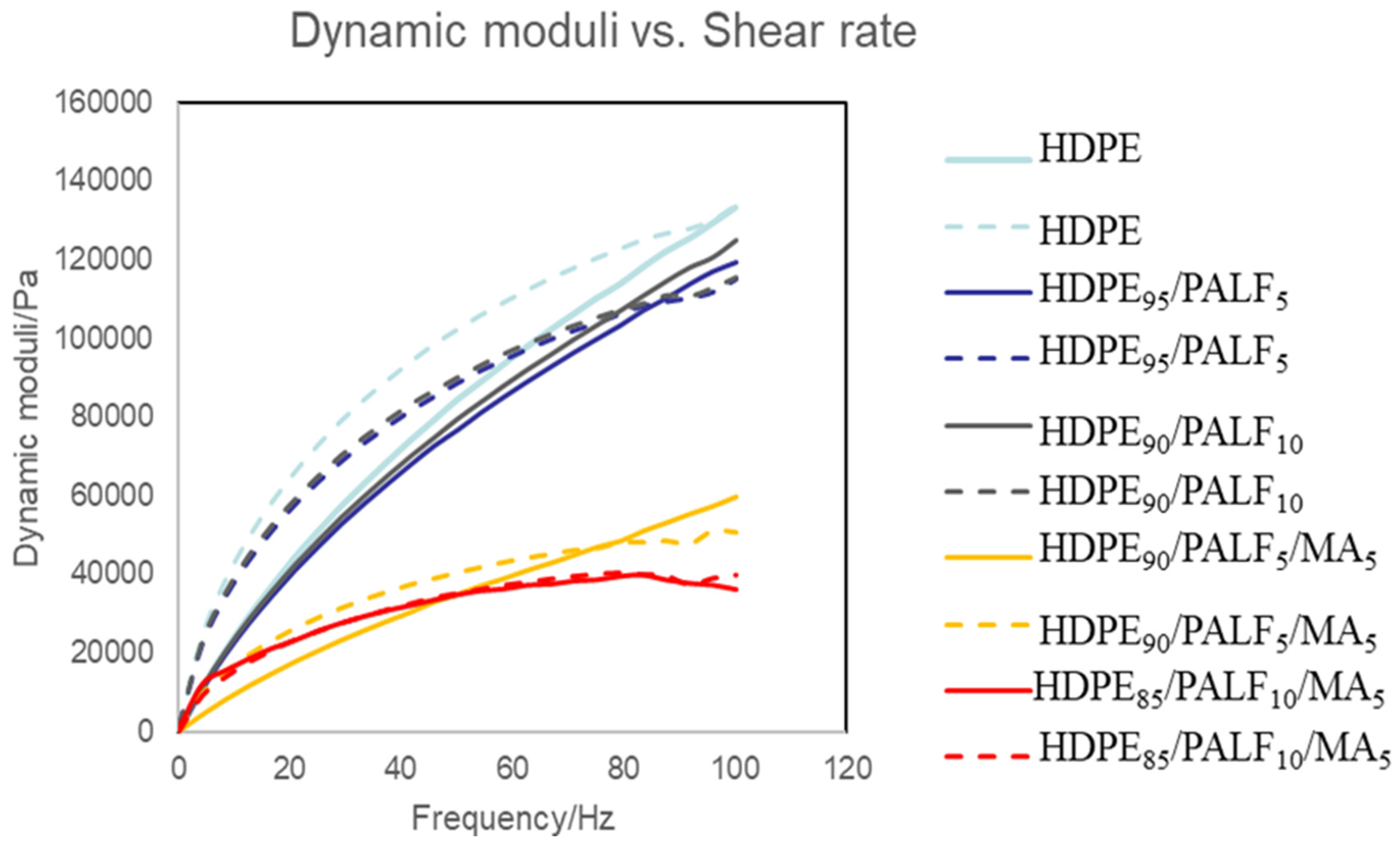

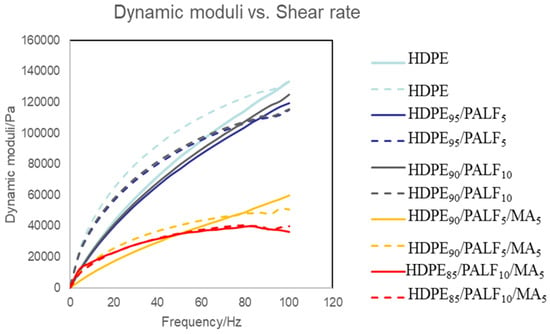

Changes in the dynamic moduli (i.e., storage, G′, and loss, G″, moduli) show how energy is dissipated as shear stress is applied to the material sample at an increasing rate. The storage modulus shows the elastic response and depicts the solid behavior of the sample, while the loss modulus shows energy losses through the viscous or liquid behavior of the samples as the shear rate is increased. Thus, as the shear rate is increased, the elastic response tends to increase faster than the viscous response as the polymer now has less time to re-arrange and re-form bonds [61]. Stronger polymer–polymer or polymer–filler interactions are manifested in rapid increases in the storage moduli over the viscous moduli. Considering this, the changes in the dynamic moduli as shown in Figure 7 corroborate observations of the changes in the complex viscosity. It seems like the matrix interactions are stronger than the polymer–filler interactions, both in the presence and absence of the MA. This may imply inadequate interactions between the filler and the matrix. Due to the low filler content (5 and 10% PALF), the chances of polymer–filler interactions are lower than polymer–polymer interactions; thus, the effect of polymer–filler interactions will tend to be minimal in comparison. This is shown by the relatively high dynamic moduli of the 10% PALF compared to the 5% PALF, for both the MA-treated and untreated samples. An increase in the PALF content from 5 to 10% results in increased polymer–filler interactions and hence an increased dynamic modulus. The addition of MA significantly lowered the dynamic moduli of the melt composites compared to the neat HDPE. From this, it can be deduced that the addition of 5% MA does not favor strong polymer–filler interactions, which could mean that the filler and the matrix may separate during extrusion, resulting in poor PALF dispersion in the extruded filaments. However, in the absence of MA, both the 5% and 10% PALF show interactions similar to that of HDPE, implying good polymer–filler interaction.

Figure 7.

Changes in the storage (G′) and loss (G″) moduli of composite melts.

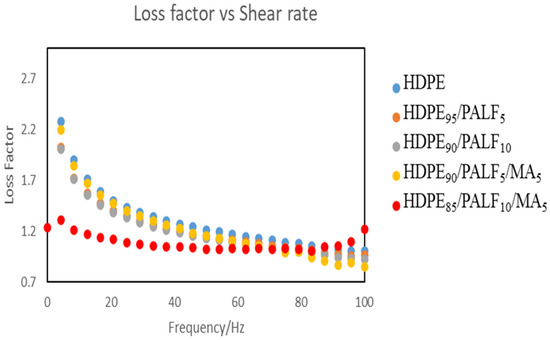

The loss factor shows the ratio of the viscous to storage modulus; thus, it is a good indicator of changes in the liquid sample behavior relative to solid behavior as the shear rate is increased (G″/G′). A loss factor greater than one indicates liquid behavior of the melt composite, and the higher the loss factor is, the more the liquid behavior of the composite, as shown in Figure 8. This was the case for all the samples, with HDPE showing the highest liquid behavior, while the rest of the samples followed the order: C5 > C3 = C2 > C4. One would expect the 10% PALF/MA to exhibit more viscous behavior than the 10% PALF due to the plasticizing effect of the MA; however, the opposite was observed. The low viscosity may enhance the good wettability and mixing of the fiber with the matrix or result in the separation of the relatively more mobile (liquid) matrix phase from the filler. If the latter happens, poor dispersion of the filler in the matrix results, leading to fiber agglomeration.

Figure 8.

Changes in the loss factor of composite melts.

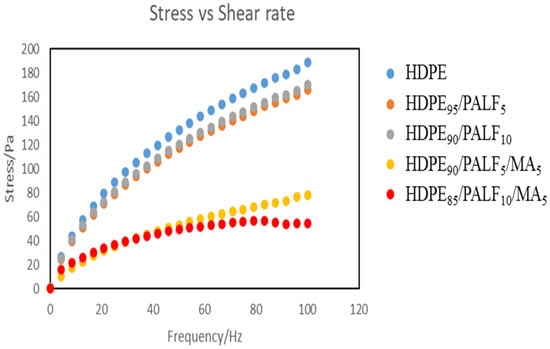

The amount of stress applied before composite flow clearly shows the degree of resistive forces present within the composite and HDPE structure. In contrast to most reports [62,63], the addition of 5 and 10% PALF lowered the stress resistance as shown in Figure 9. The neat HDPE samples showed greater resistance to flow than in the presence of PALF and MA. This suggests stronger polymer–polymer than polymer–filler forces. The low resistance to flow may be beneficial on the throughput rate and processing efficiency but has to be weighed against the desired mechanical properties of the resultant composites. The addition of MA drastically lowered the stress resistance. This indicates that the amount of MA used may have been a lot compared to fiber loading.

Figure 9.

Changes in the shear stress of composite melts.

4. Conclusions

In this study, the HDPE/PALF blend was successfully reinforced with 5% MA via the melt extrusion process to evaluate the morphology and the mechanical and thermal properties. The intermolecular interactions of the HDPE/PALF composites were investigated, and the presence of a functional group was confirmed by FTIR spectroscopy. The SEM images indicated that increasing the filler content in the HDPE/PALF blend resulted in the agglomeration of the PALF. The thermal stability of the HDPE/PALF composites was affected by the presence of the coupling agent. Better interfacial adhesion between HDPE and 10 wt.% PALF as the result of the MA coupling agent leads to better thermal stability. The crystallinity of the HDPE/PALF composites compared to neat HDPE (10.10%) increases with the addition of 10% PALF (11.64%). The mechanical properties of the HDPE/PALF composites were affected by the PALF loading and the presence of the coupling agent (MA). Neat HDPE exhibited an average Young’s modulus (MPa) of 437.50 MPa. The presence of MA as a coupling agent in the composites influenced the tensile strength. The Young’s modulus increased by 17% from the neat HDPE to C5, which contained 10 wt.% PALF, indicating the beneficial effect of the coupling agent on enhancing the Young’s modulus value and promoting compatibilization. The results show that the degree of MA influenced the modulus and suggested improved interfacial adhesion between the filler and the matrix. Conversely, the maximum elongation at yield and yield strength of neat HDPE were 21.64% and 14.75%. This study anticipated a decrease in the elongation at yield and yield strength with the addition of PALF loading and the presence of the coupling agent. The results showed a slight decrease in the elongation at yield and yield strength in the presence of the coupling agent, indicating improved interfacial adhesion and a potential stiffening effect on the composites. The rheological behaviors of the HDPE/PALF composites are slightly affected by the addition of 10% PALF. The rheological tests resulted in unexpected results. This is very beneficial for the processing of such composites as their melt viscosity practically does not drastically change with either the type or amount of PALF. To figure out the possible mechanisms behind this finding, further investigations are required. The improved properties of the HDPE/PALF composites open possibilities for lightweight and high-performance applications, such as bicycle, motorcycle, and automotive components, offering weight reduction without compromising mechanical integrity. This research contributes to developing sustainable solutions by effectively utilizing plastics and reducing the environmental impact.

Author Contributions

M.S.: Methodology; writing—original draft; writing—review and editing. M.V.K.: Conceptualization; investigation; methodology; writing—review and editing; S.J.S.: Review and editing. S.M.: Supervision; writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support from the Postdoctoral Research Fellowship Funds Department of Chemistry at Nelson Mandela University, South Africa. The Author supported by Nelson Mandela University, Chemistry Department Research Funding Acknowledgement to Dr Zikhona Tywabi-Ngeva and Eastern Cape farmers for supplying with Pineapple leafs.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mahmood, H.; Moniruzzaman, M.; Yusup, S.; Welton, T. Ionic liquids assisted processing of renewable resources for the fabrication of biodegradable composite materials. Green Chem. 2017, 19, 2051–2075. [Google Scholar] [CrossRef]

- Kumar, A.; Mishra, R.K.; Verma, K.; Aldosari, S.M.; Maity, C.K.; Verma, S.; Patel, R.; Thakur, V.K. A comprehensive review of various biopolymer composites and their applications: From biocompatibility to self-healing. Mater. Today Energy 2023, 23, 100431. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A comprehensive review on natural fibers: Technological and socio-economical aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers–A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing technologies of carbon/glass fiber-reinforced polymer composites and their properties: A review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- Alhijazi, M.; Zeeshan, Q.; Qin, Z.; Safaei, B.; Asmael, M. Finite element analysis of natural fibers composites: A review. Nanotechnol. Rev. 2020, 9, 853–875. [Google Scholar] [CrossRef]

- Prasad, V.; Alliyankal Vijayakumar, A.; Jose, T.; George, S.C. A comprehensive review of sustainability in natural-fiber-reinforced polymers. Sustainability 2024, 16, 1223. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Joseph, K.; Thomas, S. Dynamic mechanical analysis of randomly oriented intimately mixed short banana/sisal hybrid fibre reinforced polyester composites. Compos. Sci. Technol. 2005, 65, 1077–1087. [Google Scholar] [CrossRef]

- Treenate, P.; Limphitakphong, N.; Chavalparit, O. A complete life cycle assessment of high-density polyethylene plastic bottle. IOP Conf. Ser. Mater. Sci. Eng. 2017, 222, 012010. [Google Scholar] [CrossRef]

- Ali, M.M.; Hashim, N.; Bejo, S.K.; Jahari, M.; Shahabudin, N.A. Innovative non-destructive technologies for quality monitoring of pineapples: Recent advances and applications. Trends Food Sci. Technol. 2023, 133, 176–188. [Google Scholar]

- Omuse, E.R.; Tonnang, H.E.; Yusuf, A.A.; Machekano, H.; Egonyu, J.P.; Kimathi, E.; Mohamed, S.F.; Kassie, M.; Subramanian, S.; Onditi, J.; et al. The global atlas of edible insects: Analysis of diversity and commonality contributing to food systems and sustainability. Sci. Rep. 2024, 14, 5045. [Google Scholar] [CrossRef]

- Akbar, A.; Gnanamoorthy, R. Characterization of Treated and Untreated Pineapple Leaf Fiber for Engineering Applications. Mater. Circ. Econ. 2024, 6, 18. [Google Scholar] [CrossRef]

- Baigh, T.A.; Nanzeeba, F. Integration and Mechanical Characterization of PALF and Jute Fibre in Epoxy Polymer to Fabricate Structural Hybrid Biocomposites. Ph.D. Thesis, Department of Mechanical and Production Engineering (MPE), Islamic University of Technology (IUT), Gazipur, Bangladesh, 2023. [Google Scholar]

- Suthenthiraveerappa, V.; Gopalan, V.; Pragasam, V.; Sampath, A.; Chinnaiyan, P.; Kalidas, V.K.; Pitchumani, S.V.; Kulendran, B.; Gopal, R. Tensile properties of basalt/jute fiber reinforced epoxy composite. Cogent Eng. 2024, 11, 2348083. [Google Scholar] [CrossRef]

- Akter, M.; Uddin, M.H.; Anik, H.R. Plant fiber-reinforced polymer composites: A review on modification, fabrication, properties, and applications. Polym. Bull. 2024, 81, 1–85. [Google Scholar] [CrossRef]

- Gilani, I.E.; Sayadi, S.; Zouari, N.; Al-Ghouti, M.A. Plastic waste impact and biotechnology: Exploring polymer degradation, microbial role, and sustainable development implications. Bioresour. Technol. 2023, 24, 101606. [Google Scholar] [CrossRef]

- Balasubramanian, V.K.; Chellapandi, R.; Balakrishnan, M.; Murugan, K.; Kennedy, J.P.; Murugan, S.; Khumalo, M.V.; Sarangi, P.K.; Chou, J.Y.; Muthuramalingam, J.B. Biosynthesis of bioplastic polyhydroxybutyrate (PHB) from microbes isolated from paddy/sugarcane fields and fabrication of biodegradable thin film. Process Saf. Environ. Prot. 2024, 187, 1178–1188. [Google Scholar] [CrossRef]

- Kokkılıç, O.; Mohammadi-Jam, S.; Chu, P.; Marion, C.; Yang, Y.; Waters, K.E. Separation of plastic wastes using froth flotation–an overview. Adv. Colloid Interface Sci. 2022, 308, 102769. [Google Scholar] [CrossRef]

- Shuvescha, D.; Parvin, R.; Rafiquzzaman, M.D. Fibre orientation effect on mechanical properties of coconut leaf midrib reinforced polymer composite. Eur. J. Adv. Eng. Technol. 2017, 4, 914–919. [Google Scholar]

- Ma, X.; Yu, J.; Kennedy, J.F. Studies on the properties of natural fibers-reinforced thermoplastic starch composites. Carbohydr. Polym. 2005, 62, 19–24. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, H.J.; Yu, W.R. Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties. Fibers Polym. 2009, 10, 83–90. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tay, G.S.; Kumar, R.N.; Abubakar, A.; Ismail, H.; Ishak, Z.M. Polypropylene hybrid composites: A preliminary study on the use of glass and coconut fiber as reinforcements in polypropylene composites. Polym.-Plast. Technol. Eng. 1999, 38, 997–1011. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Mano, J.F.; Reis, R.L. Hybrid cork–polymer composites containing sisal fibre: Morphology, effect of the fibre treatment on the mechanical properties and tensile failure prediction. Compos. Struct. 2013, 105, 153–162. [Google Scholar] [CrossRef]

- Khoathane, M.C.; Vorster, O.C.; Sadiku, E.R. Hemp fiber-reinforced 1-pentene/polypropylene copolymer: The effect of fiber loading on the mechanical and thermal characteristics of the composites. J. Reinf. Plast. Compos. 2008, 27, 1533–1544. [Google Scholar] [CrossRef]

- Eze, I.O.; Igwe, I.O.; Ogbobe, O.; Anyanwu, E.E.; Nwachukwu, I. Mechanical properties of pineapple leaf powder filled high density polyethylene. Int. J. Eng. Technol. 2016, 9, 13–19. [Google Scholar] [CrossRef]

- Igwe, I.E. Comparison of Some Mechanical Properties of Injection and Extrusion Moulded Pineapple Leaf Powder Filled High Density Polyethylene. Eur. J. Adv. Eng. Technol. 2018, 5, 236–243. [Google Scholar]

- Aji, I.S.; Zainudin, E.S.; Abdan, K.; Sapuan, S.M.; Khairul, M.D. Mechanical properties and water absorption behavior of hybridized kenaf/pineapple leaf fibre-reinforced high-density polyethylene composite. J. Compos. Mater. 2013, 47, 979–990. [Google Scholar] [CrossRef]

- Aji, I.S.; Zainudin, E.S.; Khalina, A.; Sapuan, S.M.; Khairul, M.D. Thermal property determination of hybridized kenaf/PALF reinforced HDPE composite by thermogravimetric analysis. J. Therm. Anal. Calorim. 2012, 109, 893–900. [Google Scholar] [CrossRef]

- Salleh, F.M.; Hassan, A.; Yahya, R.; Lafia-Araga, R.A.; Azzahari, A.D.; Nazir, M.N. Improvement in the mechanical performance and interfacial behavior of kenaf fiber reinforced high density polyethylene composites by the addition of maleic anhydride grafted high density polyethylene. J. Polym. Res. 2014, 21, 439. [Google Scholar] [CrossRef]

- Naik, J.B.; Mishra, S. The compatibilizing effect of maleic anhydride on swelling properties of plant-fiber-reinforced polystyrene composites. Polym.-Plast. Technol. Eng. 2006, 45, 923–927. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Aguado, R.J.; Morcillo-Martín, R.; Méndez, J.A.; Vilaseca, F.; Tarres, Q.; Mutje, P. Behavior of the Flexural Strength of Hemp/Polypropylene Composites: Evaluation of the Intrinsic Flexural Strength of Untreated Hemp Strands. Polymers 2023, 15, 371. [Google Scholar] [CrossRef]

- Letwaba, J.; Makwakwa, D.; Muniyasamy, S.; Motloung, M.; Moropeng, L. Melt extruded polylactic acid (PLA)/algae bio-composites: Effect of grafting level and filler loading on thermal and mechanical properties. J. Appl. Polym. Sci. 2023, 140, 54669. [Google Scholar] [CrossRef]

- Pastrnak, A.; Henriquez, A.; La Saponara, V. Parametric study for tensile properties of molded high—density polyethylene for applications in additive manufacturing and sustainable designs. J. Appl. Polym. Sci. 2020, 137, 49283. [Google Scholar] [CrossRef]

- Jayamani, E.; Loong, T.G.; Bakri, M.K. Comparative study of Fourier transform infrared spectroscopy (FTIR) analysis of natural fibres treated with chemical, physical and biological methods. Polym. Bull. 2020, 77, 1605–1629. [Google Scholar] [CrossRef]

- Dalmis, R. Description of a new cellulosic natural fiber extracted from Helianthus tuberosus L. as a composite reinforcement material. Physiol. Plant. 2023, 175, e13960. [Google Scholar] [CrossRef]

- Amirulhakim, H.; Juwono, A.L.; Roseno, S. Isolation and characterization of cellulose nanofiber from subang pineapple leaf fiber waste produced using ultrafine grinding method. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1098, 062067. [Google Scholar] [CrossRef]

- Charles, J. Qualitative analysis of high-density polyethylene using FTIR spectroscopy. Asian J. Chem. 2009, 21, 4477. [Google Scholar]

- Shivasharana, C.T.; Kesti, S.S. Physical and chemical characterization of low-density polyethylene and high density polyethylene. J. Adv. Sci. Res. 2019, 10, 30–34. [Google Scholar]

- Zemzem, M.; Vinches, L.; HallE, S. Morphological investigation of maleic anhydride-grafted nitrile/nanoclay nanocomposites. Mater. Res. Express 2022, 9, 085302. [Google Scholar] [CrossRef]

- Sukwijit, C.; Seubsai, A.; Charoenchaitrakool, M.; Sudsakorn, K.; Niamnuy, C.; Roddecha, S.; Prapainainar, P. Production of PLA/cellulose derived from pineapple leaves as bio-degradable mulch film. Int. J. Biol. Macromol. 2024, 270, 132299. [Google Scholar] [CrossRef]

- Ravindran, L.; Sreekala, M.S.; Thomas, S. Novel processing parameters for the extraction of cellulose nanofibres (CNF) from environmentally benign pineapple leaf fibres (PALF): Structure-property relationships. Int. J. Biol. Macromol. 2019, 131, 858–870. [Google Scholar] [CrossRef]

- Chang, Y.L.; Sharma, S.U.; Shiu, J.P.; Lee, J.T. Xylitol-Maleic Anhydride as Small-Molecule Binders for Silicon Anodes in Lithium-Ion Batteries. J. Electrochem. Soc. 2021, 168, 100533. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.K. Pyrolysis kinetics of waste high-density polyethylene using thermogravimetric analysis. Int. J. ChemTech Res. 2014, 6, 131–137. [Google Scholar]

- Pollanen, M.; Suvanto, M.; Pakkanen, T.T. Cellulose reinforced high density polyethylene composites—Morphology, mechanical and thermal expansion properties. Compos. Sci. Technol. 2013, 76, 21–28. [Google Scholar] [CrossRef]

- George, J.; Bhagawan, S.S.; Thomas, S. Effects of environment on the properties of low-density polyethylene composites reinforced with pineapple-leaf fibre. Compos. Sci. Technol. 1998, 58, 1471–1485. [Google Scholar] [CrossRef]

- Sucinda, E.F.; Majid, M.A.; Ridzuan, M.J.; Cheng, E.M.; Alshahrani, H.A.; Mamat, N. Development and characterisation of packaging film from Napier cellulose nanowhisker reinforced polylactic acid (PLA) bionanocomposites. Int. J. Biol. Macromol. 2021, 187, 43–53. [Google Scholar] [CrossRef]

- Scheirs, J.; Camino, G.; Tumiatti, W. Overview of water evolution during the thermal degradation of cellulose. Eur. Polym. J. 2001, 37, 933–942. [Google Scholar] [CrossRef]

- Samiotaki, C.; Tarani, E.; Karavasili, D.; Zamboulis, A.; Chrissafis, K.; Bikiaris, D.N. Structural Characteristics and Improved Thermal Stability of HDPE/Calcium Pimelate Nanocomposites. Macromol 2024, 4, 42–57. [Google Scholar] [CrossRef]

- Aji, I.S.; Zainudin, E.S.; Sapuan, S.M.; Khalina, A.; Khairul, M.D. Study of hybridized kenaf/palf-reinforced HDPE composites by dynamic mechanical analysis. Polym.-Plast. Technol. Eng. 2012, 51, 146–153. [Google Scholar] [CrossRef]

- Rahman, H.; Rana, S.; Das, A.; Alagirusamy, R. Physically processed waste pineapple leaf fibre for high performance composite with polypropylene. Cellulose 2024, 31, 2881–2901. [Google Scholar] [CrossRef]

- Savini, G.; Orefice, R.L. Comparative study of HDPE composites reinforced with microtalc and nanotalcs: High performance filler for improving ductility at low concentration levels. J. Mater. Res. Technol. 2020, 9, 16387–16398. [Google Scholar] [CrossRef]

- Rana, A.K.; Mandal, A.; Mitra, B.C.; Jacobson, R.; Rowell, R.; Banerjee, A.N. Short jute fiber-reinforced polypropylene composites: Effect of compatibilizer. J. Appl. Polym. Sci. 1998, 69, 329–338. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled newspaper fibers as reinforcing fillers in thermoplastics: Part I-Analysis of tensile and impact properties in polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Vepoes, I. Characterization filled polyester composites. Compos. Sci. Technol. 2003, 63, 1241–1272. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, S.; Jacob, M.; Thomas, S. Oil palm fibre reinforced phenol formaldehyde composites: Influence of fibre surface modifications on the mechanical performance. Appl. Compos. Mater. 2000, 7, 295–329. [Google Scholar] [CrossRef]

- Sayeed, M.A.; Sayem, A.S.; Haider, J.; Akter, S.; Habib, M.M.; Rahman, H.; Shahinur, S. Assessing mechanical properties of jute, kenaf, and pineapple leaf fiber-reinforced polypropylene composites: Experiment and modelling. Polymers 2023, 15, 830. [Google Scholar] [CrossRef]

- Venkatesh, R. Significance of TiO2 on the Mechanical Behavior of High-Density Polyethylene Nanocomposite Made with Pineapple Fiber. J. Inst. Eng. (India) Ser. D 2024, 13, 1–5. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K. TK Brown M aleated Coupling A gent s for Natural Fiber composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 359–362. [Google Scholar] [CrossRef]

- Mohanty, S. Surface treatments of fibres and their effects. J. Reinf. Plast. Compos. 2004, 23, 625–645. [Google Scholar] [CrossRef]

- Hwang, S.; Han, Y.; Gardner, D.J. Morphological characteristics of spray dried cellulose nanofibers produced using various wood pulp feedstocks and their effects on polypropylene composite properties. Compos. Part B Eng. 2024, 268, 111093. [Google Scholar] [CrossRef]

- Danyadi, L.; Moczo, J.; Pukanszky, B. Effect of various surface modifications of wood flour on the properties of PP/wood composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 199–206. [Google Scholar] [CrossRef]

- Agbakoba, V.C.; Hlangothi, P.; Andrew, J.; John, M.J. Preparation of cellulose nanocrystal (CNCs) reinforced polylactic acid (PLA) bionanocomposites filaments using biobased additives for 3D printing applications. Nanoscale Adv. 2023, 5, 4447–4463. [Google Scholar] [CrossRef]

- Sofiah, A.G.; Pasupuleti, J.; Samykano, M.; Kadirgama, K.; Koh, S.P.; Tiong, S.K.; Pandey, A.K.; Yaw, C.T.; Natarajan, S.K. Harnessing nature’s ingenuity: A comprehensive exploration of nanocellulose from production to cutting-edge applications in engineering and sciences. Polymers 2023, 15, 3044. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).